Assembling type vacuum foam wall body and preparation method thereof

A prefabricated, vacuum technology, used in ceramic products, other household appliances, insulation improvement and other directions, can solve the problems of large thickness, easy to mildew, easy to fall off, etc., to achieve long life, increase indoor use space, and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A prefabricated vacuum foam wall and its preparation method related to the present invention will be explained and illustrated in detail below in conjunction with the accompanying drawings.

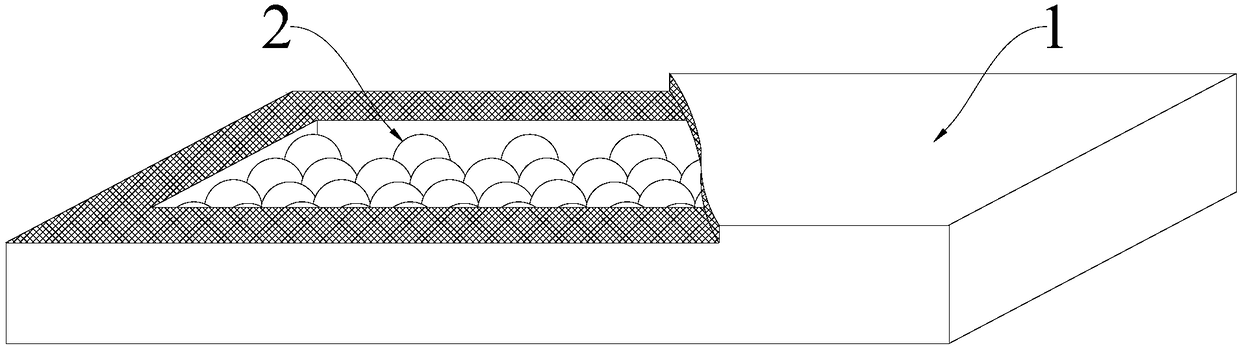

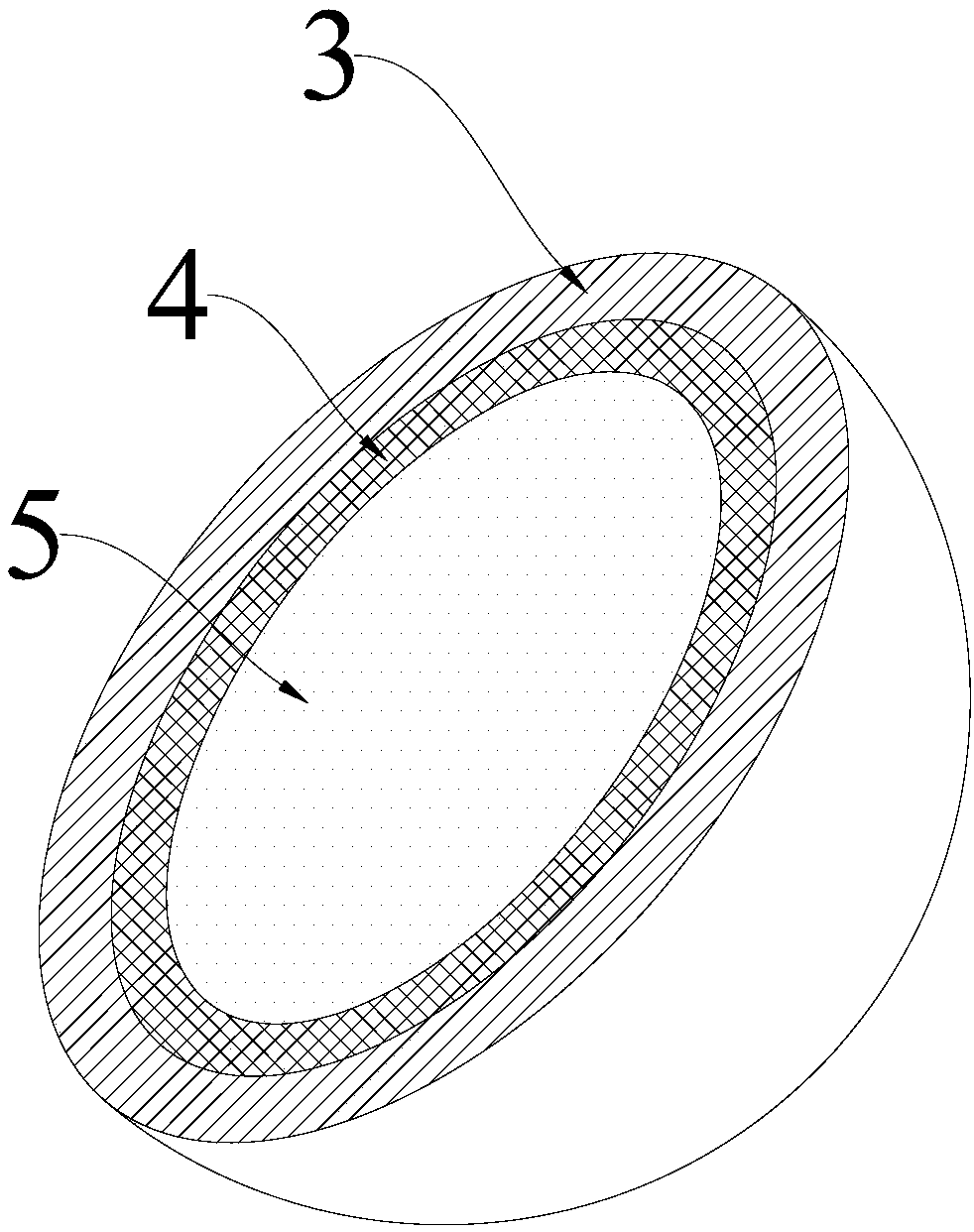

[0032] Such as figure 1 , 2 As shown, this embodiment discloses a prefabricated vacuum foam wall, the prefabricated vacuum foam wall includes a wall surface layer 1 and a vacuum ball 2, the wall surface layer 1 encloses a first cavity, and the vacuum ball 2 is arranged on In the first cavity, a plurality of vacuum balls 2 are arranged in the most densely packed manner, the above-mentioned first cavity is filled with foam filler, and the foam filler is distributed between the vacuum ball 2 and the wall surface layer 1 In the gap between and in the gap between adjacent vacuum balls 2 (vacuum balls and vacuum balls), more specifically, as figure 2 As shown, the vacuum ball 2 includes an outer protective layer 3, a vacuum diaphragm 4 and a foam 5, and the outer protective layer 3, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com