Lightweight external hanging prefabricated wallboard and production method thereof

A prefabricated wall panel, lightweight technology, applied in building components, buildings, building structures, etc., can solve problems such as the decline in thermal insulation performance of thermal insulation boards, the decline in thermal insulation performance of openings, and the impact on building thermal insulation performance, and achieve good sound insulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

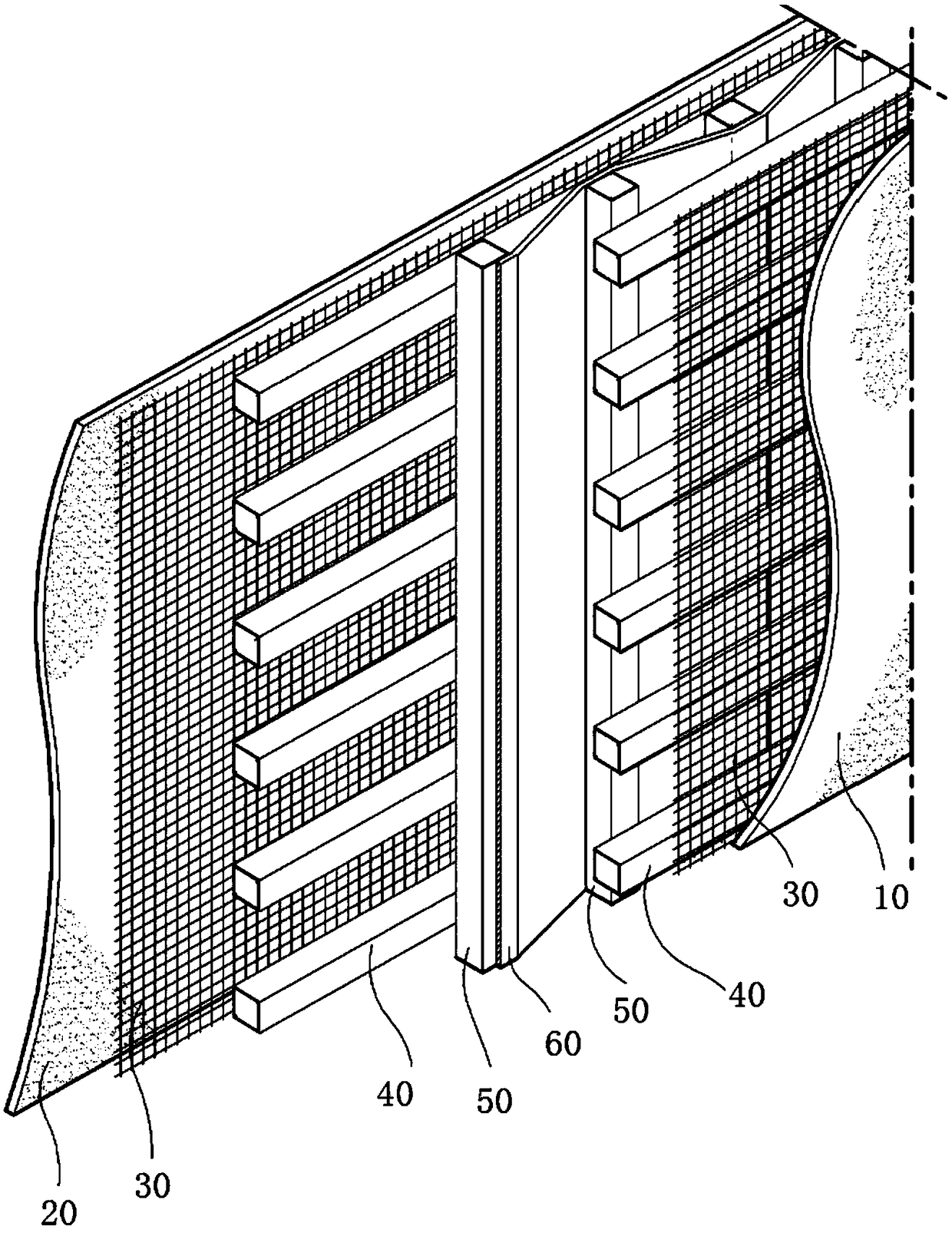

[0026] Such as figure 1 As shown, a kind of lightweight external hanging prefabricated wallboard comprises a core skeleton, an inner wallboard 20 and an outer wallboard 10, the core skeleton includes two outer skeleton layers and an inner skeleton layer arranged between the two outer skeleton layers, and the outer The framework layer includes a plurality of horizontal lightweight frameworks 40 placed at a certain distance, the horizontal lightweight frameworks 40 are parallel to each other and the distances between adjacent horizontal lightweight frameworks 40 are the same. The inner frame layer includes a plurality of vertical lightweight frames 50 placed at intervals, and the multiple vertical lightweight frames 50 are parallel to each other and the distance between adjacent vertical lightweight frames 50 is the same.

[0027] The horizontal lightweight frame 40 and the vertical lightweight frame 50 are fixedly connected at the vertical intersection of the two. The fixed con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com