Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

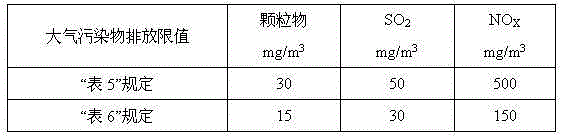

47results about How to "Desulfurization achieved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

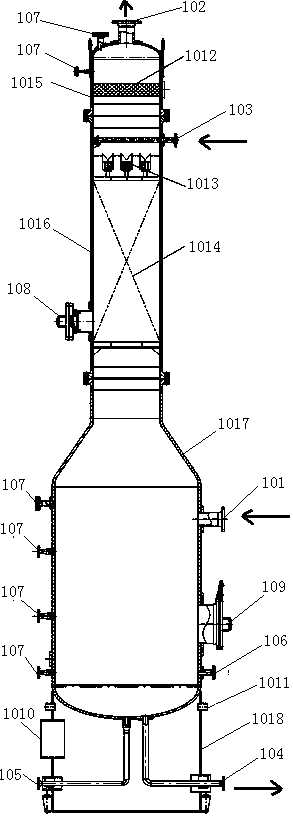

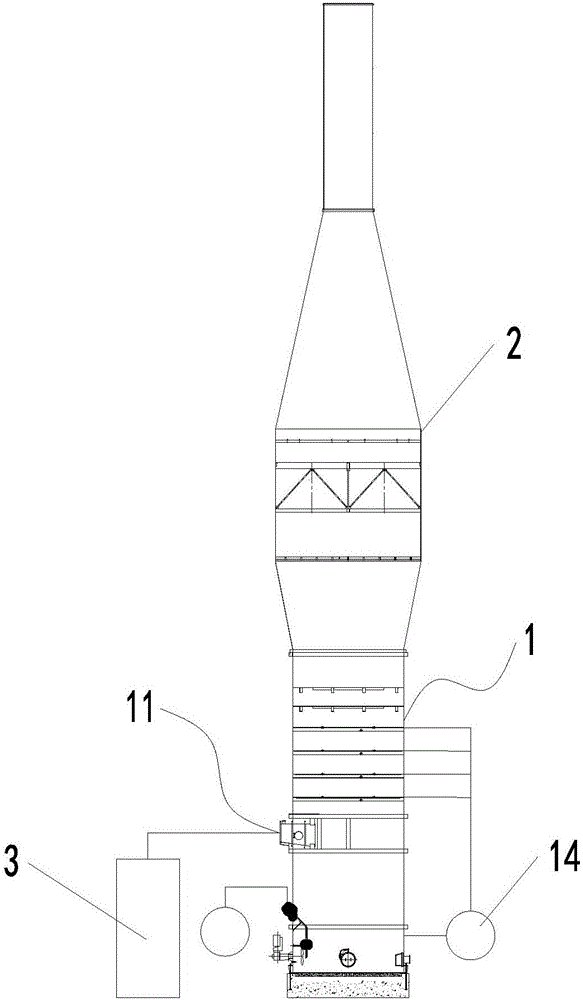

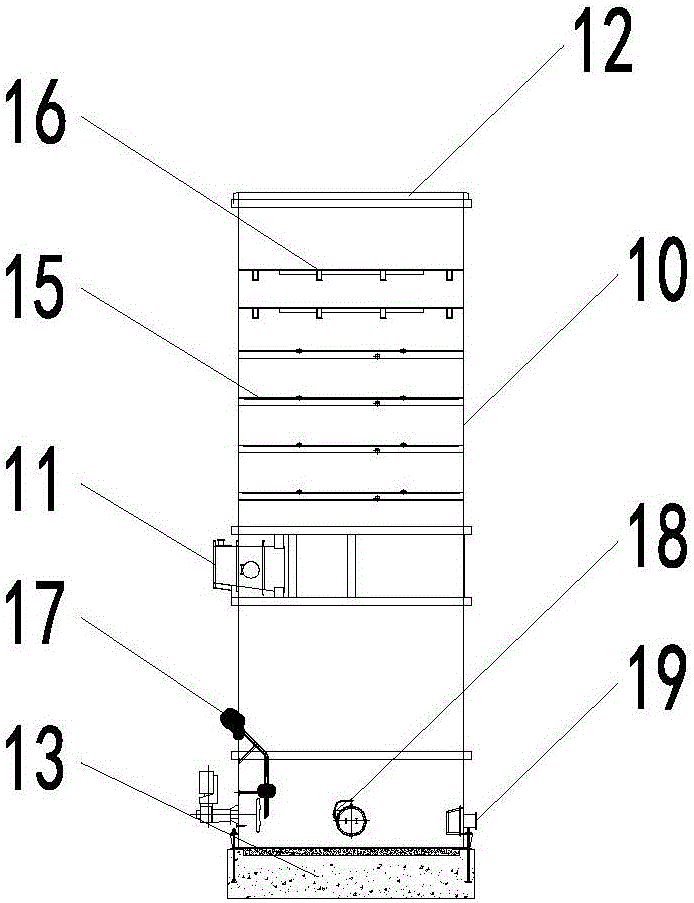

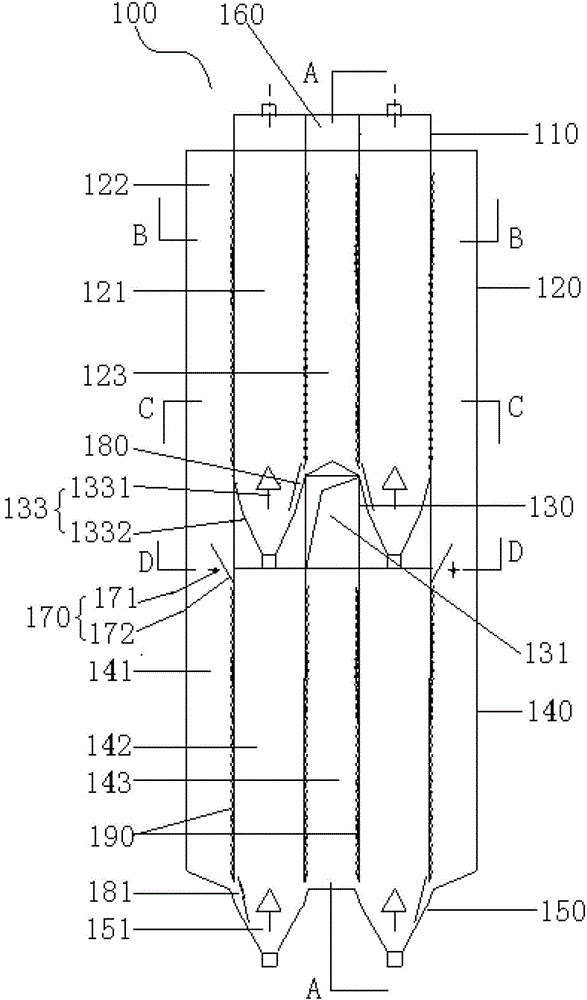

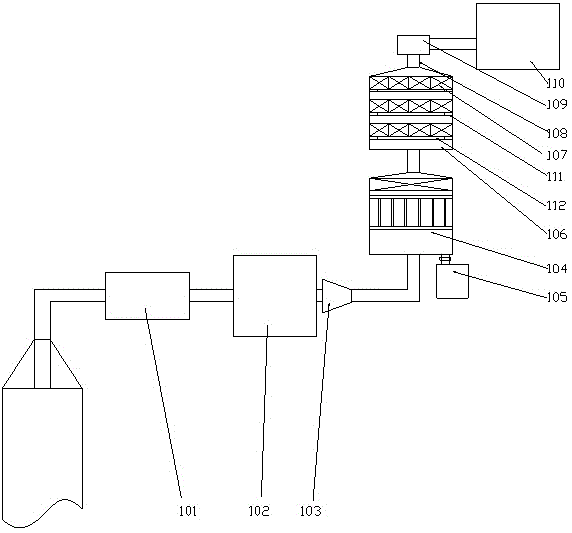

Cross-flow type two-stage moving bed active coke waste gas integrated purification tower

ActiveCN103349892AImprove the utilization rate of adsorption sulfur capacityReduce circulationDispersed particle filtrationTowerMoving bed

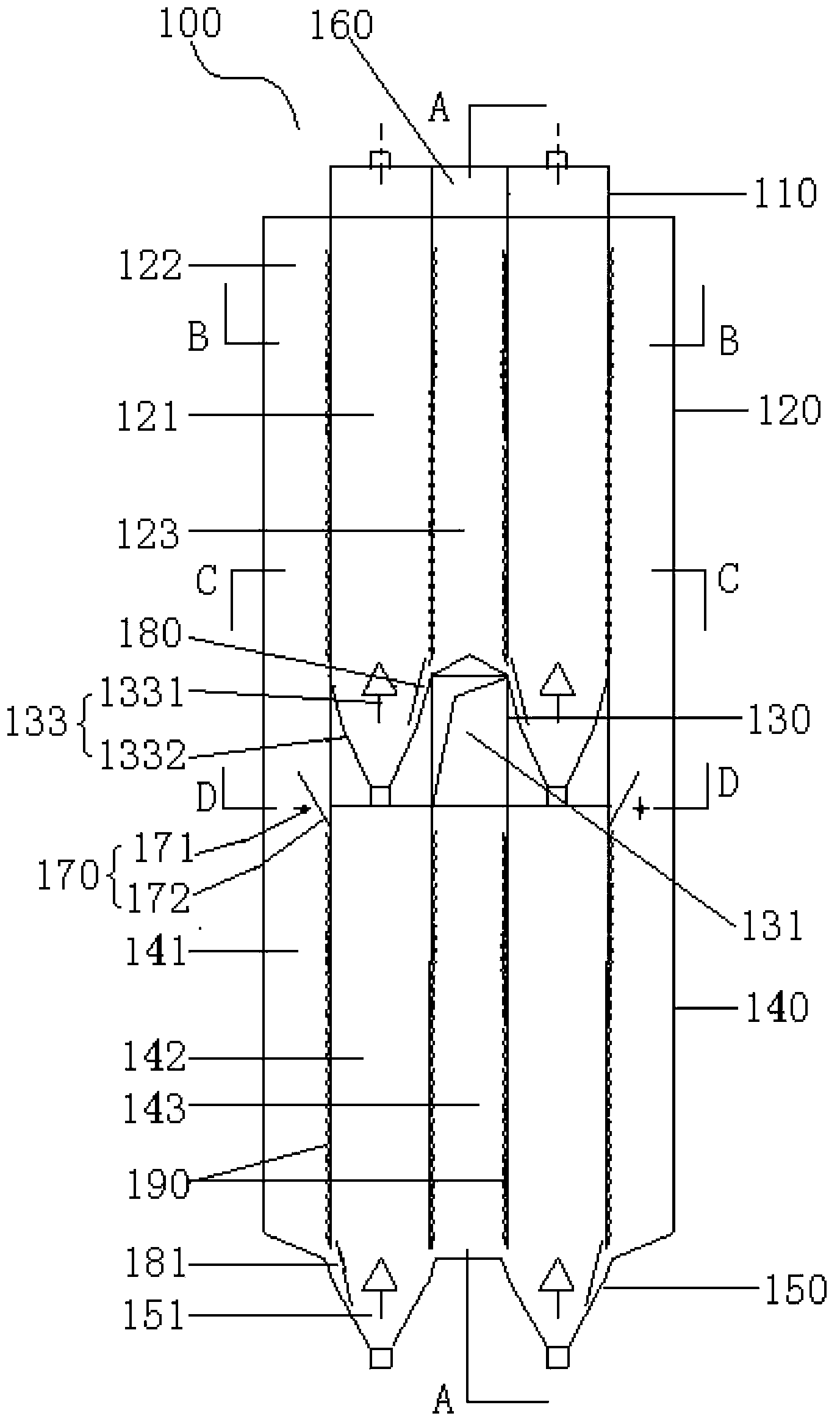

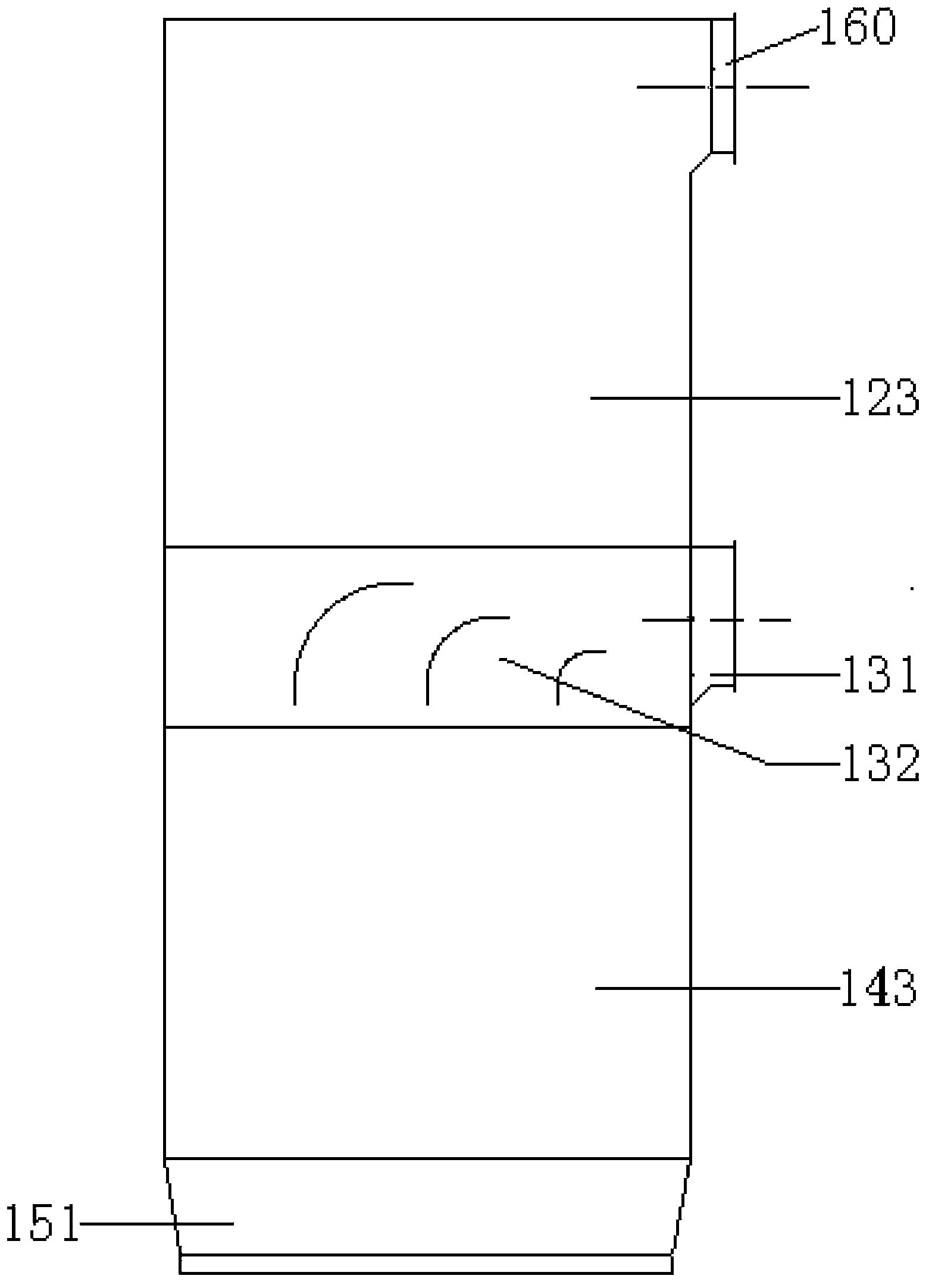

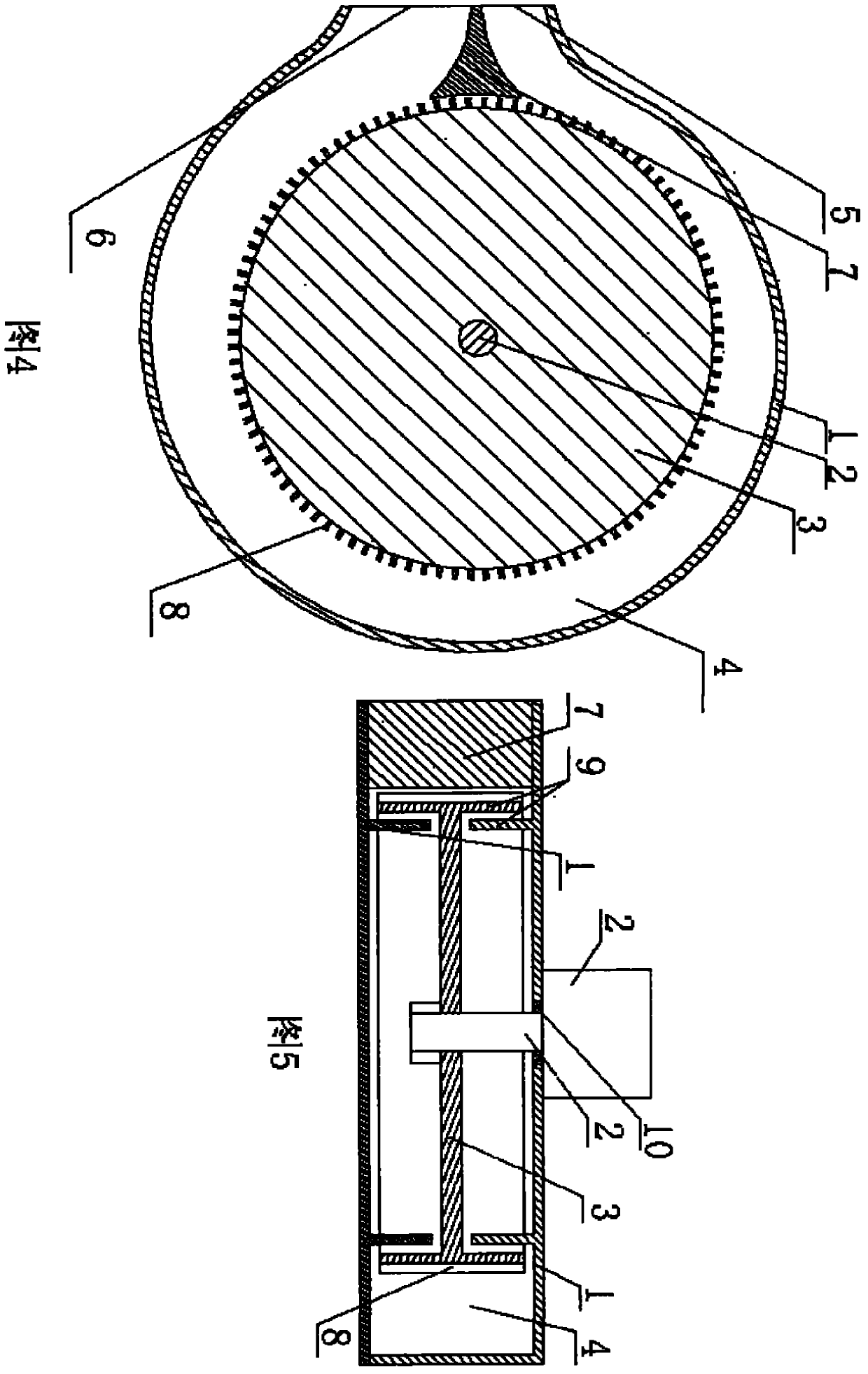

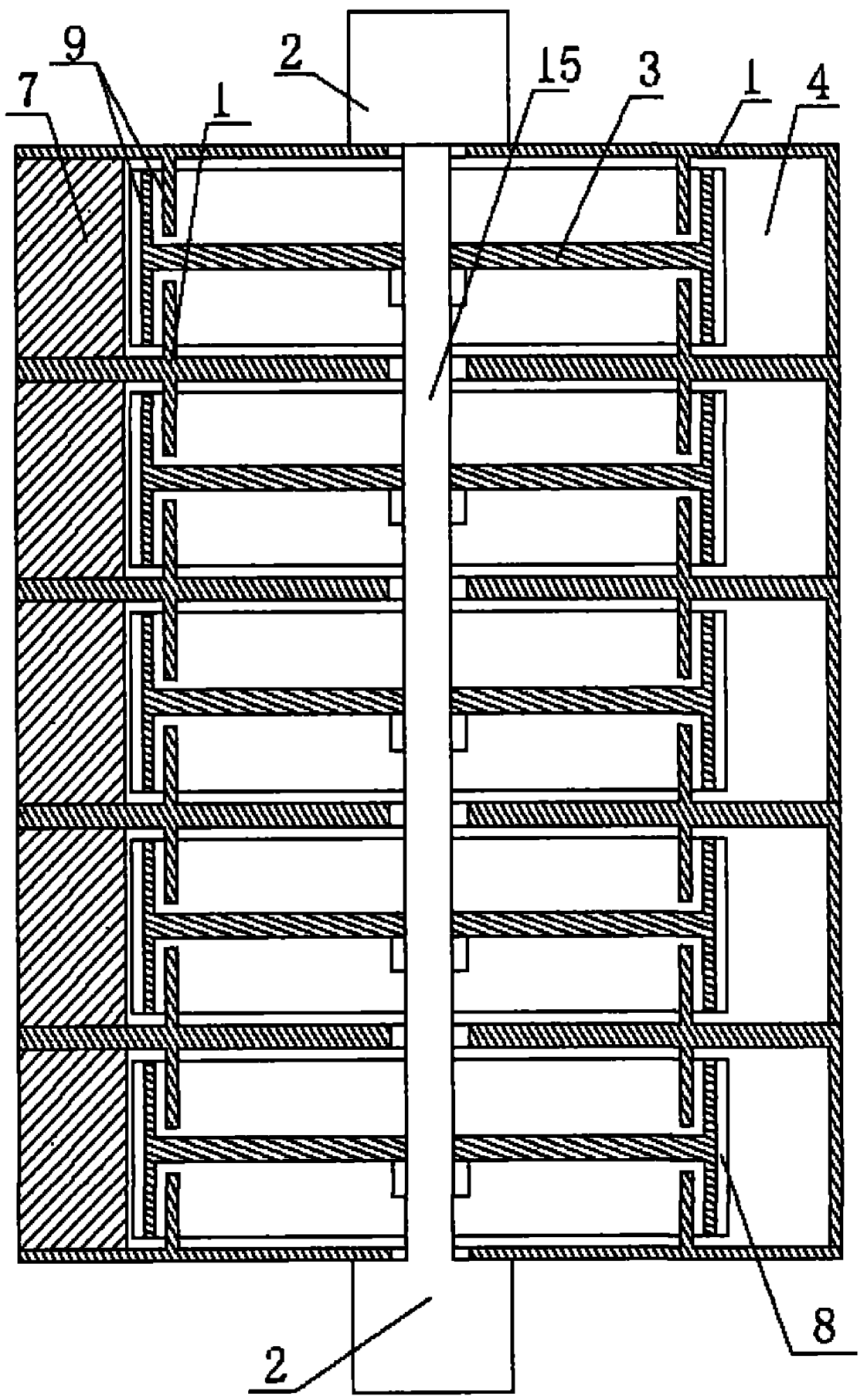

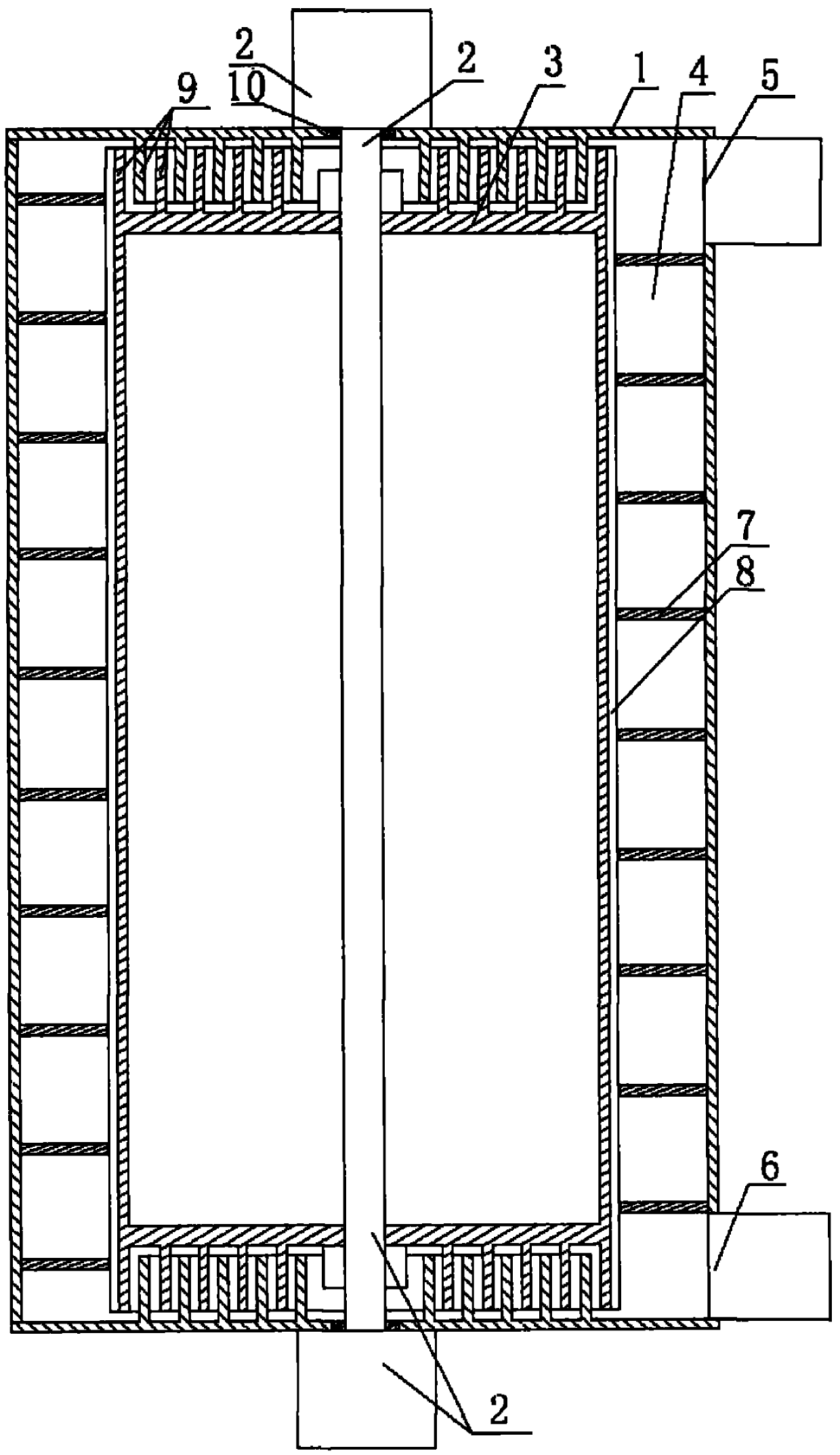

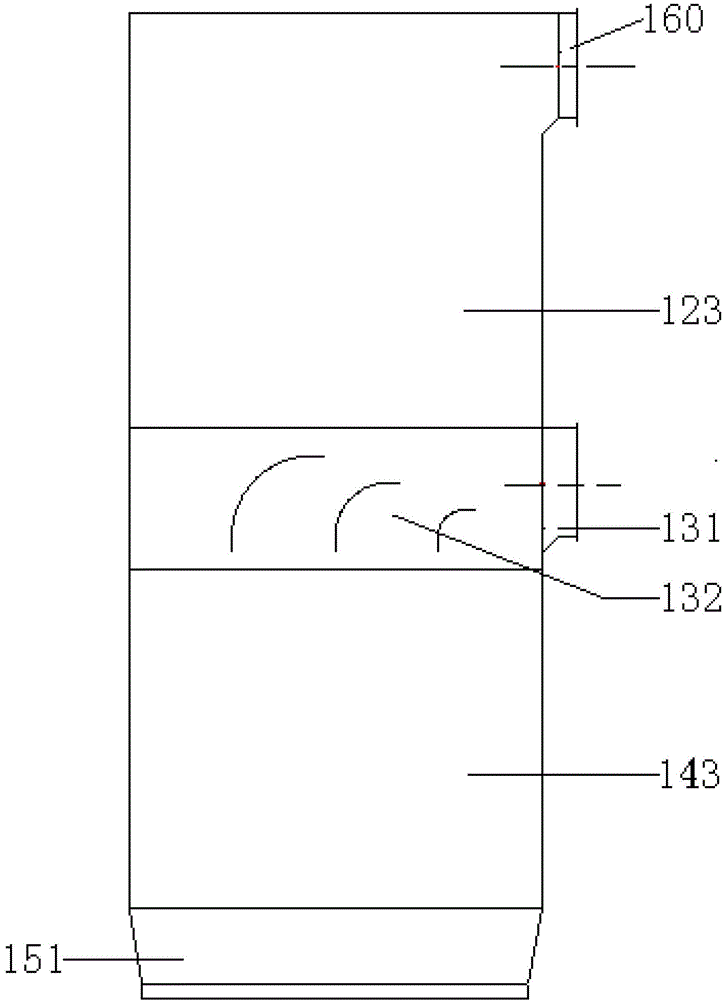

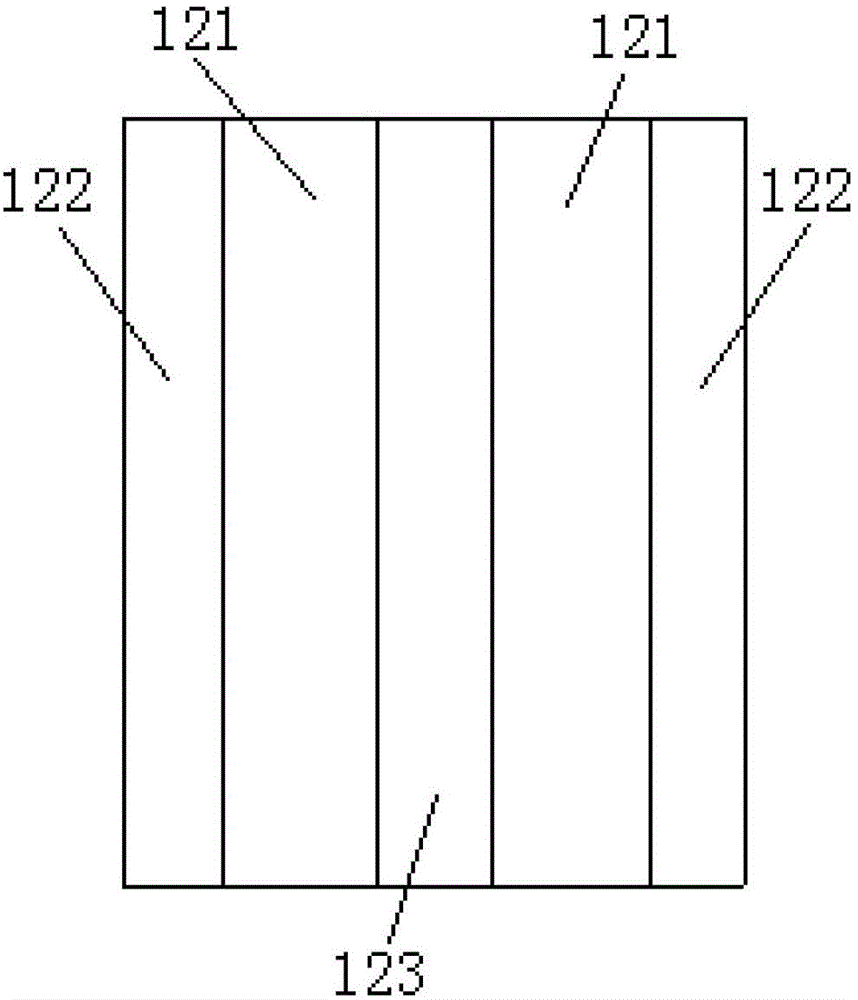

The invention discloses a cross flow type two-stage moving bed active coke waste gas integrated purification tower which comprises a purification tower main body, wherein the purification tower main body is provided with an active coke feeding region, a denitration region, a transitional layer, a desulfuration region and a discharging layer sequentially from top to bottom; the denitration region comprises a denitration region active coke bed layer, a denitration region inlet chamber and a denitration region outlet chamber; the desulfuration region comprises a desulfuration region active coke bed layer, a desulfuration region outlet chamber and a desulfuration region inlet chamber; the transitional layer comprises an inlet chimney flue with a waste gas inlet, and a discharge hopper, the inlet chimney flue is arranged above the desulfuration region inlet chamber in a conducting manner, the denitration region active coke bed layer is connected with the desulfuration region active coke bed layer through the discharge hopper, and the desulfuration region outlet chamber is connected with the denitration region inlet chamber in a conducting manner. According to the invention, the pollution purification efficiency is high, the active coke utilization ratio is high, and the circulation volume is small; airflow distribution is uniform and the resistance is small; the flowing of the active coke is unobstructed and uniform, the denitration efficiency is high, and the operation is stable.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

Method for desulphurizing gasoline

ActiveCN102093907AImprove stabilityIncrease the degree of exchangeOther chemical processesHydrocarbon oils refiningSorbentCerium

The invention relates to a method for desulphurizing gasoline. In the method, a beta molecular sieve serves as a carrier; a selective adsorbent is adopted to adsorb thiophene sulfides in the gasoline and remove the thiophene sulfides from the gasoline; a hydrogen type beta molecular sieve serves as the carrier of the adsorbent; the molecular sieve carries copper, silver, zinc, nickel or gallium metal ions and metal cerium ions; and the exchange amount of the metal ions is 0.001 to 15 percent based on the mass of the hydrogen type beta molecular sieve. The adsorbent is used to selectively adsorb the thiophene sulfides in the gasoline and deeply remove the thiophene sulfides from the gasoline. A result shows that: the bimetallic ions have a synergistic effect, improve the selectivity of adsorptive desulphurization and can reduce the content of the sulfides in the fluid catalytically cracked (FCC) gasoline to below 1mu g / g or zero from 200mu g / g. The reaction condition is mild; the equipment is simple; the activity of the adsorbent is high; and the adsorbent is easy to regenerate. At normal temperature and normal pressure, hydrogen is not consumed and the gasoline is finely desulphurized.

Owner:PETROCHINA CO LTD +1

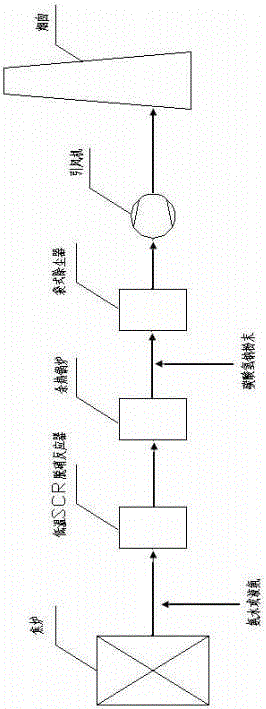

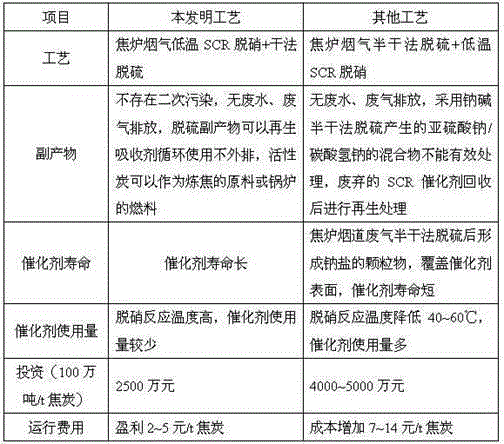

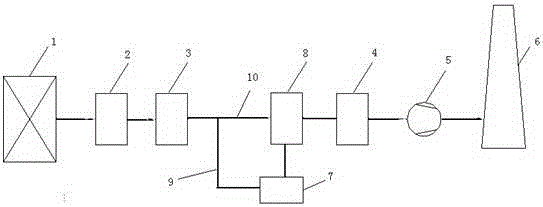

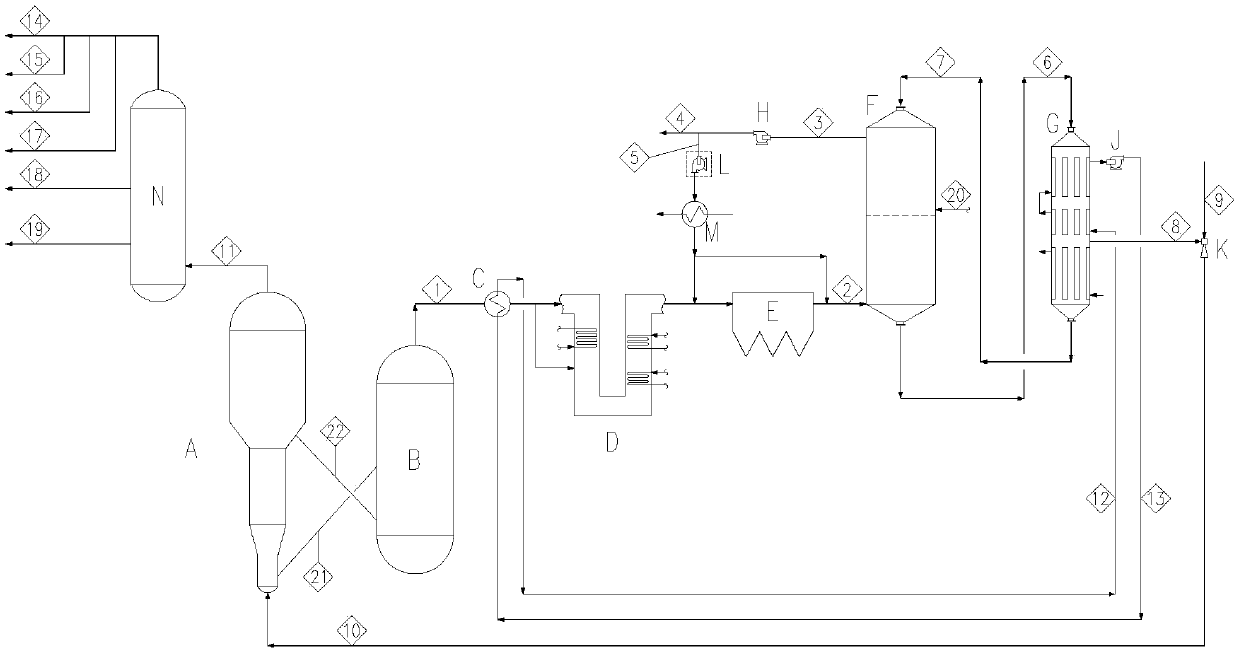

Coke oven flue waste gas desulfurization and denitrification and waste heat recovery integrated process

InactiveCN105214478AMuch waste heat recoveryIncrease evaporationDispersed particle filtrationAir quality improvementFlueFlue-gas desulfurization

The invention provides a coke oven flue waste gas desulfurization and denitrification and waste heat recovery integrated process. Coke oven flue waste gas is subjected to an SCR reaction under the effect of a low-temperature SCR denitrification catalyst to remove nitric oxides in flue waste gas, a sodium-based dry powder absorbent is sprayed to flue waste gas for desulfurization after waste heat is recovered through a waste heat boiler, and desulfurized flue waste gas is discharged up to standard after dust removal is conducted through a filter. The process is free of waste water, waste gas emission and heating, denitrification can be directly conducted, the absorbent can be recycled, investment is reduced, and energy is saved.

Owner:CHENGDU HUAXITANG INVESTMENT

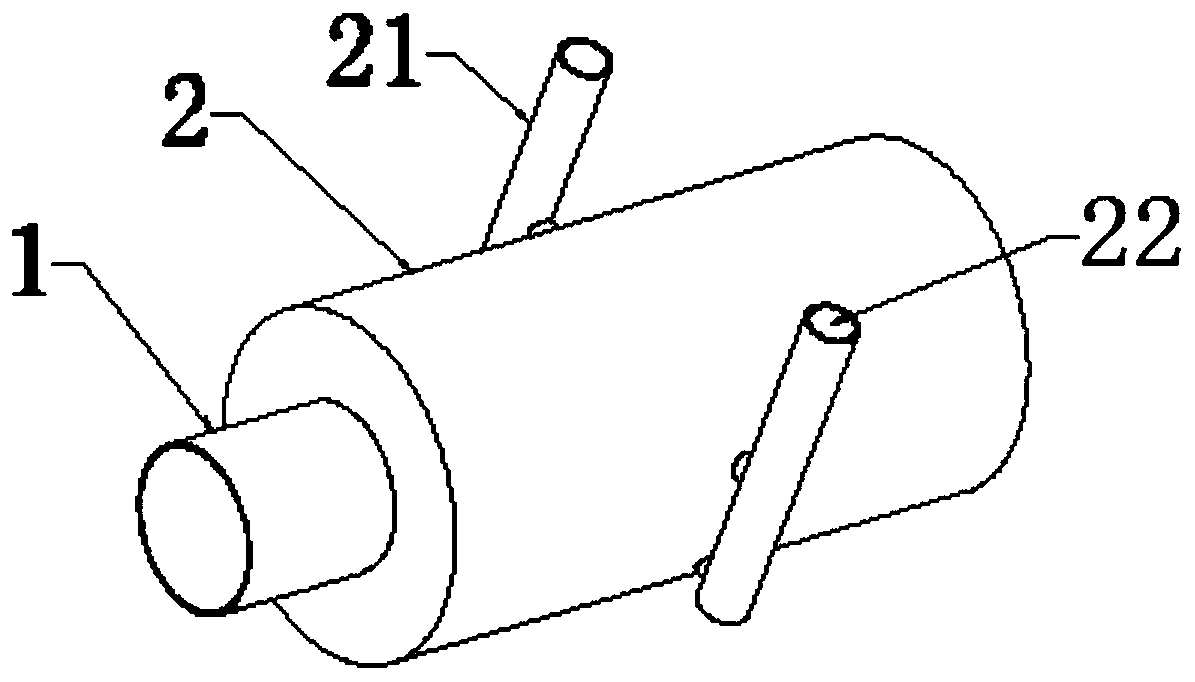

Circulator

InactiveCN103216450AWonder Material PropertiesAchieve separationCircumferential flow pumpsPump componentsDust controlEngineering

The invention relates to a circulator. The circulator comprises a shell body and a transmission device, wherein the transmission device is mounted on the shell body, a rotary wheel is mounted on the transmission device, a plurality of vanes are arranged on the periphery of the rotary wheel, the rotary wheel is arranged in the shell body, a circulation cavity is formed in the inner wall of the shell body at the periphery of the rotary wheel, a circulation cavity port A is formed in one end of the circulation cavity, a circulation cavity port B is formed in the other end of the circulation cavity, and an isolating body is arranged on the inner wall of the shell body between the circulation cavity port A and the circulation cavity port B. According to the circulator provided by the invention, circular motion and fluid motion are used sufficiently; torsion is better converted into pressure through fluid; pressure is better converted into torsion through the fluid; and the fluid separation is realized by using vortex. The circulator provided by the invention can serve as a water pump, a slurry pump, a sewage pump, a blower, a compressor, spray equipment, a reactor, a steam turbine, vacuum equipment or a separator and be applied to wastewater treatment, seawater desalination, marine chemical engineering, mineral processing, waste disposal, hydrogen production, carbon dioxide decomposition, harmful gas decomposition, air purification, dedusting, dust absorption, refrigeration, oxygen production, oil refining and the like; and the blue sky and water can be completely realized, and foamed materials can be produced so as to bring a material revolution.

Owner:陈久斌

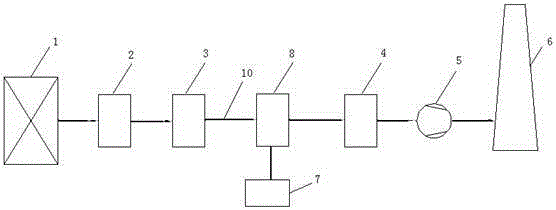

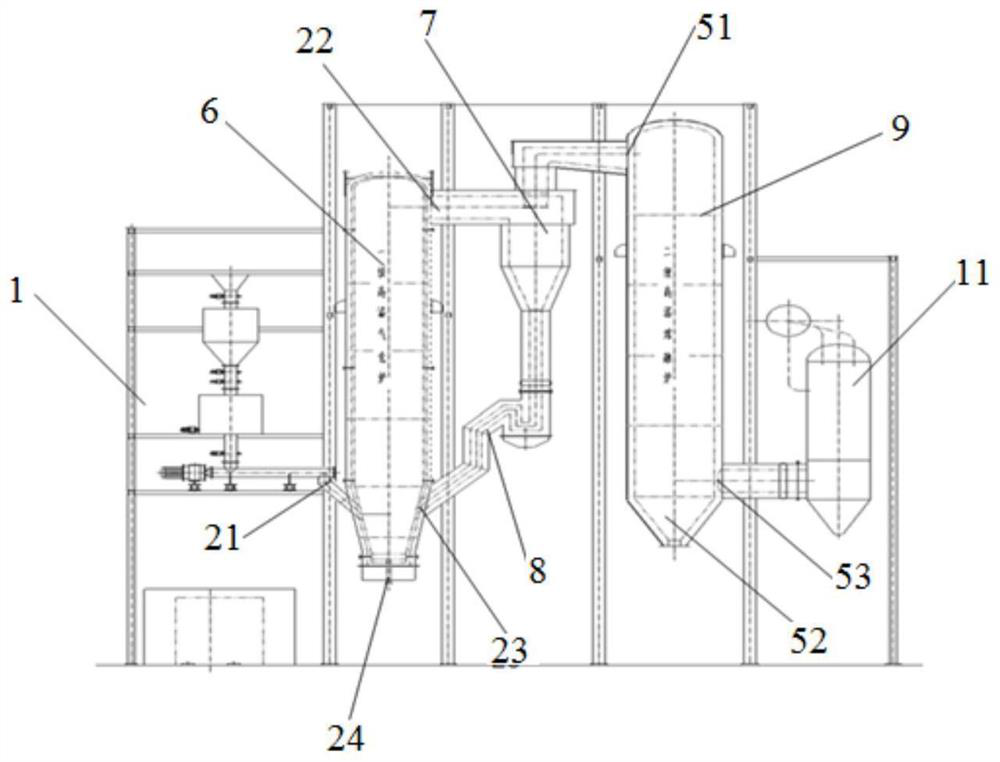

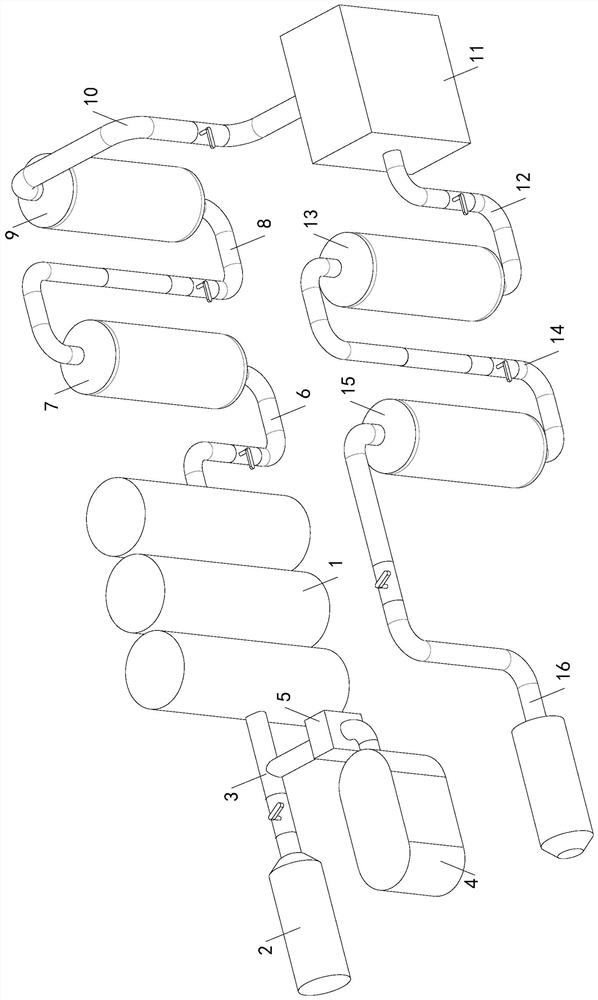

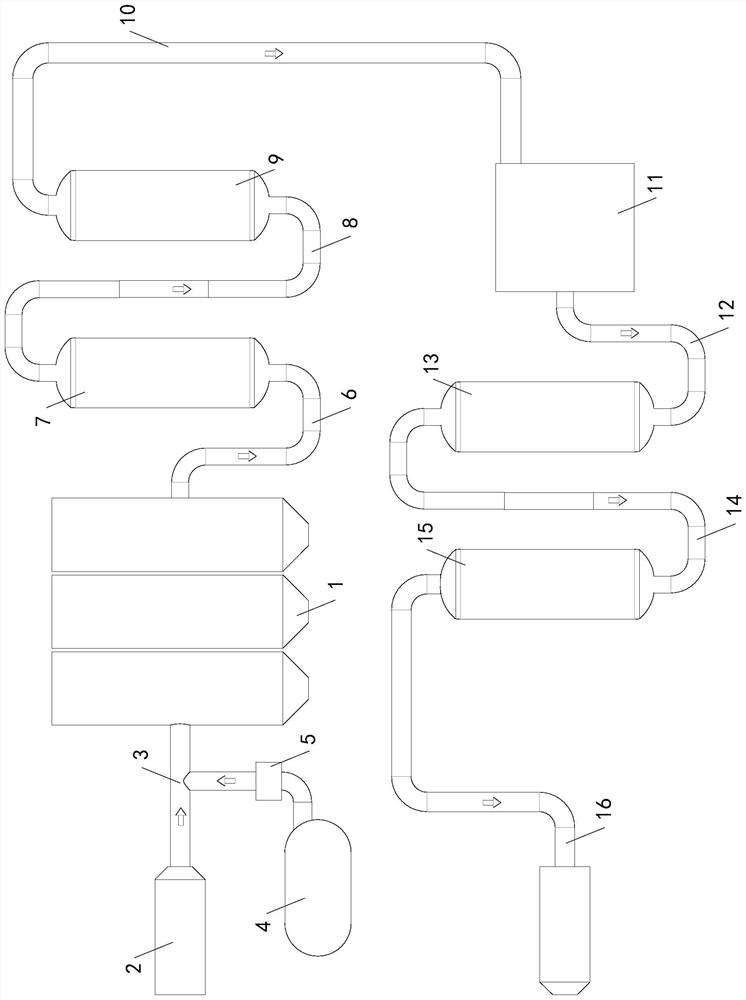

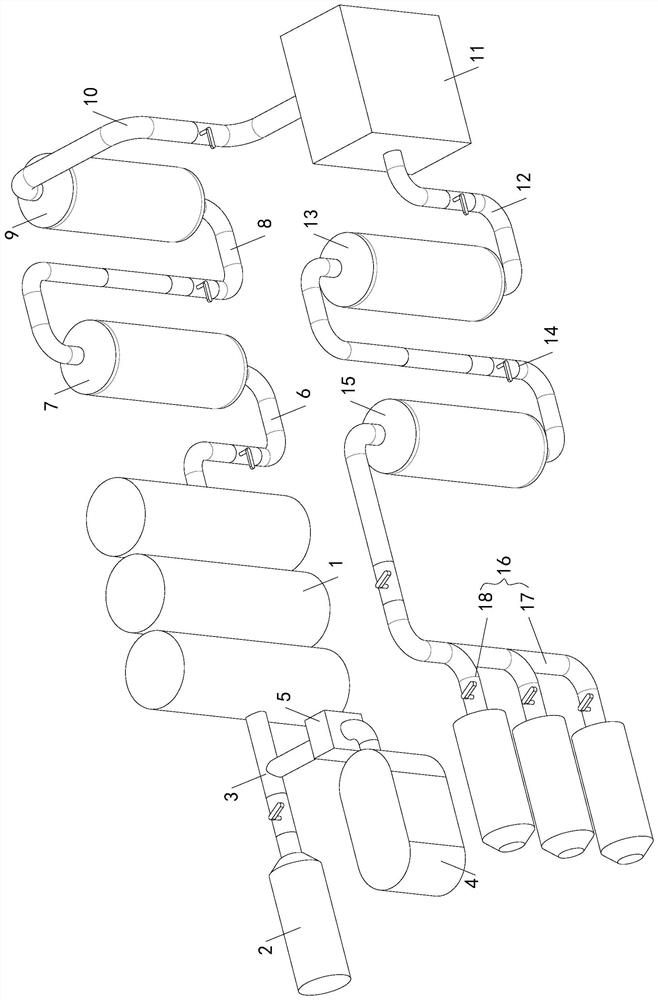

Integrated system for coke oven flue gas desulfurization and denitrification and waste heat recovery

InactiveCN105169943AMuch waste heat recoveryIncrease evaporationDispersed particle filtrationSteam generation using hot heat carriersPulverizerFlue-gas desulfurization

The invention provides an integrated system for coke oven flue gas desulfurization and denitrification and waste heat recovery. The integrated system comprises a coke oven, a low-temperature SCR denitrification system, a waste heat boiler, a flue, a pulverizer, a filtering system and a chimney. The coke oven, the low-temperature SCR denitrification system, the waste heat boiler, the filtering system and the chimney are sequentially connected through the flue, a dry powder absorbent inlet is formed in the portion, between the waste heat boiler and the filtering system, of the flue and is connected with an outlet of the pulverizer through a pipeline, and an absorbent inlet is formed in the pulverizer. The system is free from waste water and gas emission and capable of directly carrying out denitrification without heating, absorbent can be used circularly, investment can be reduced, and energy can be saved.

Owner:CHENGDU HUAXITANG INVESTMENT

Dust removing device for flue gas discharged from boiler

InactiveCN110384993AAchieve heatingExpand recovery areaCombination devicesDispersed particle filtrationWaste heat recovery unitFiltration

The invention discloses a dust removing device for flue gas discharged from a boiler. The dust removing device comprises a flue gas inlet pipe, a filter box, a desulfurization tank and a flue gas exhaust pipe, wherein a flue gas outlet at the right side of the flue gas inlet pipe is connected with a waste heat recovery unit; the flue gas outlet end of the waste heat recovery unit is connected witha flue gas inlet at the left end of the filter box through a pipeline; and the lower end of the filter box is provided with an ash collecting hopper connected with the inner cavity of the filter box.According to the invention, a flue gas distribution arranged in a desulfurization mechanism is used for discharging flue gas conveyed by a fan into clarified lime water in uniform and dispersed way through exhaust vents in a plurality of exhaust pipes; a submersible motor and a propeller connected with the output shaft of the submersible motor stir the clarified lime water to allow the clarifiedlime water to flow downward so as to further disperse the flue gas in the clarified lime water sufficiently, thereby greatly improving the reaction efficiency of the clarified lime water with sulfur dioxide in the flue gas, enhancing desulfurization effect, and realizing while achieving further filtration of dust in the flue gas while realizing desulfurization.

Owner:孙铭婧

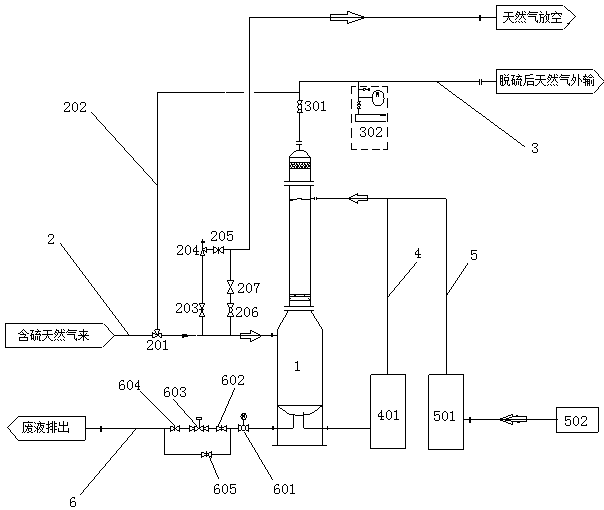

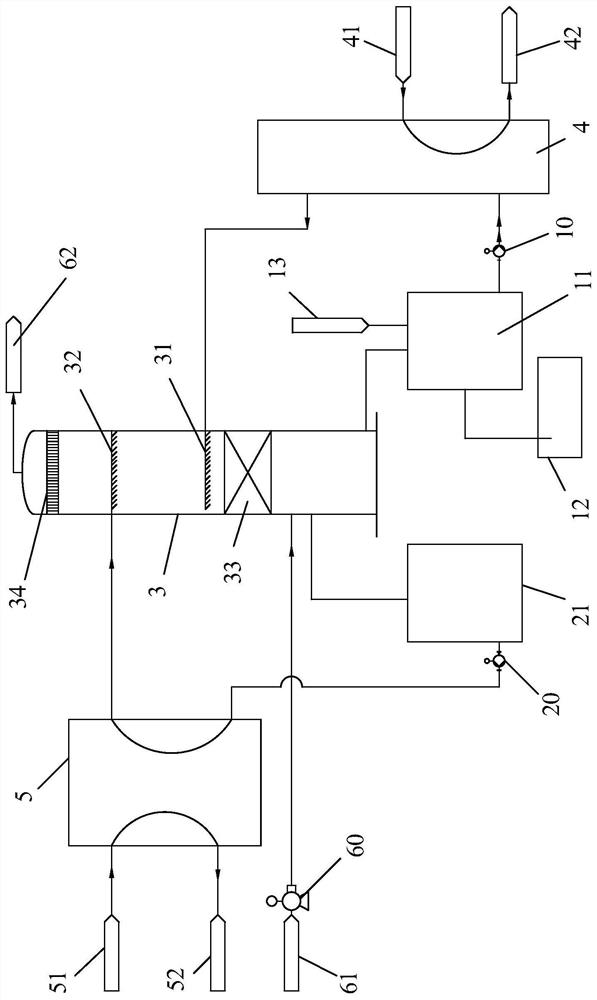

Integration device based on desulfurization of triazine solution and application method of integration device

PendingCN107930372AImprove work efficiencyDesulfurization achievedGaseous fuelsDispersed particle separationElectricityFluid infusion

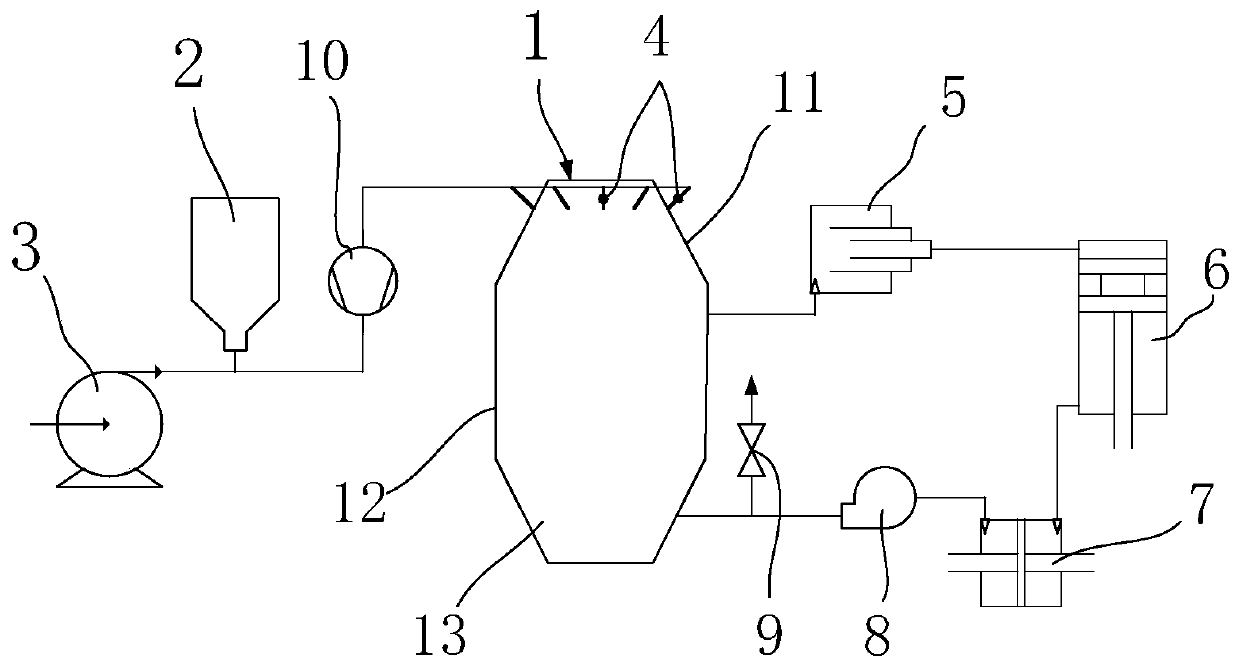

The invention provides an integration device based on desulfurization of a triazine solution and an application method of the integration device. The integration device comprises an absorption tower,wherein an air inlet of the absorption tower is connected with an air inlet pipeline; an air outlet of the absorption tower is connected with an exhaust pipeline; a ball valve 1 and an on-line hydrogen sulfide detector are connected in series with the exhaust pipeline; a desulfurizer inlet and a desulfurizer outlet are connected through a circulating pipeline on which a circulating pump is mounted; the desulfurizer inlet is further connected with a fluid infusion pipeline; the fluid infusion pipeline is connected with an inlet of a fluid infusion pump; an outlet of the fluid infusion pump is connected with a desulfurizer storage tank; a drain outlet is connected with a blowdown pipeline; and the on-line hydrogen sulfide detector is electrically connected with the fluid infusion pump for interconnected control. The integration device based on desulfurization of the triazine solution and the application method of the integration device simultaneously realize desulfurization, automatic circulation and fluid infusion, and the whole process is fully automatic and does not need manual intervention.

Owner:XIAN CHANGQING TECH ENG

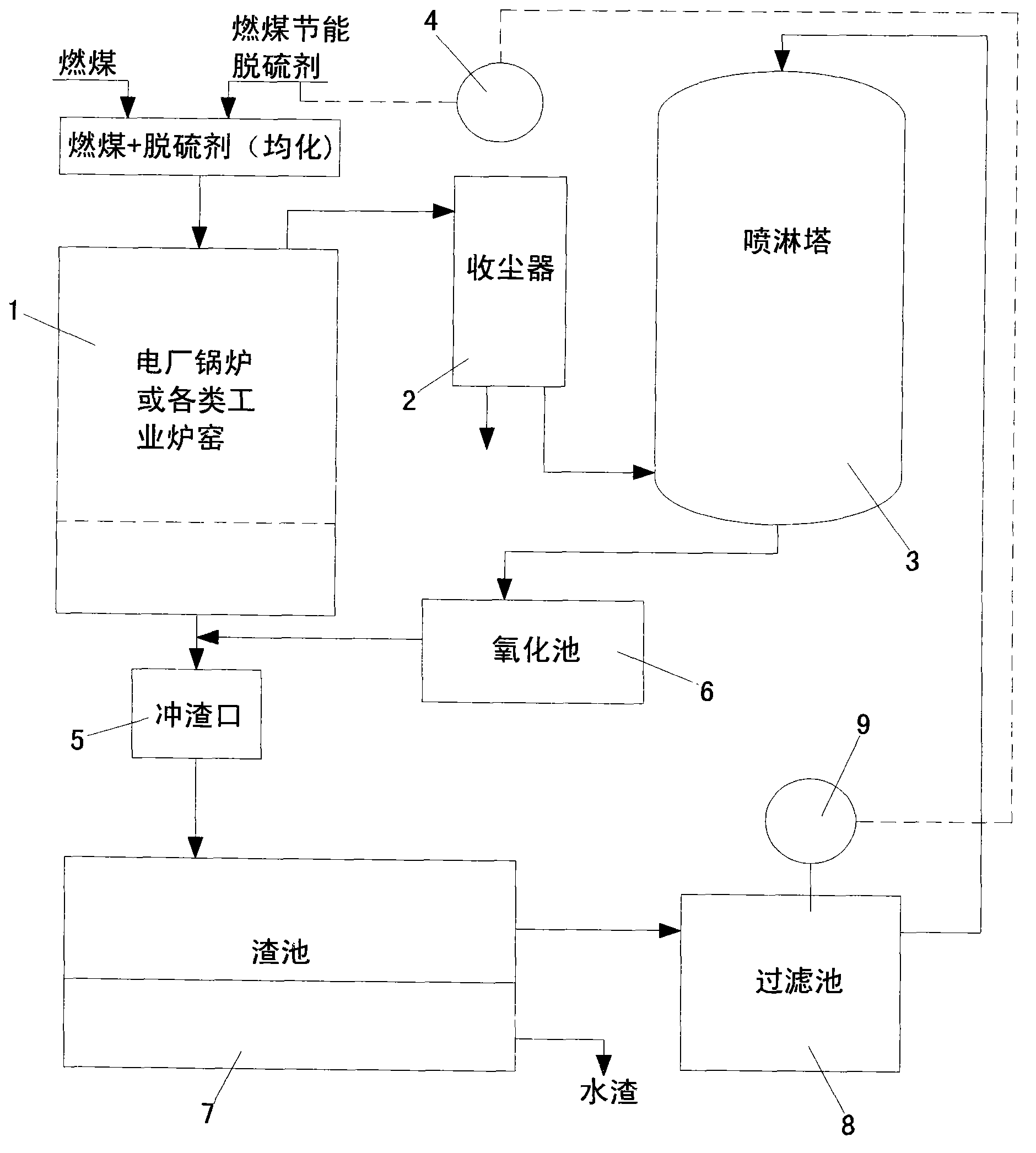

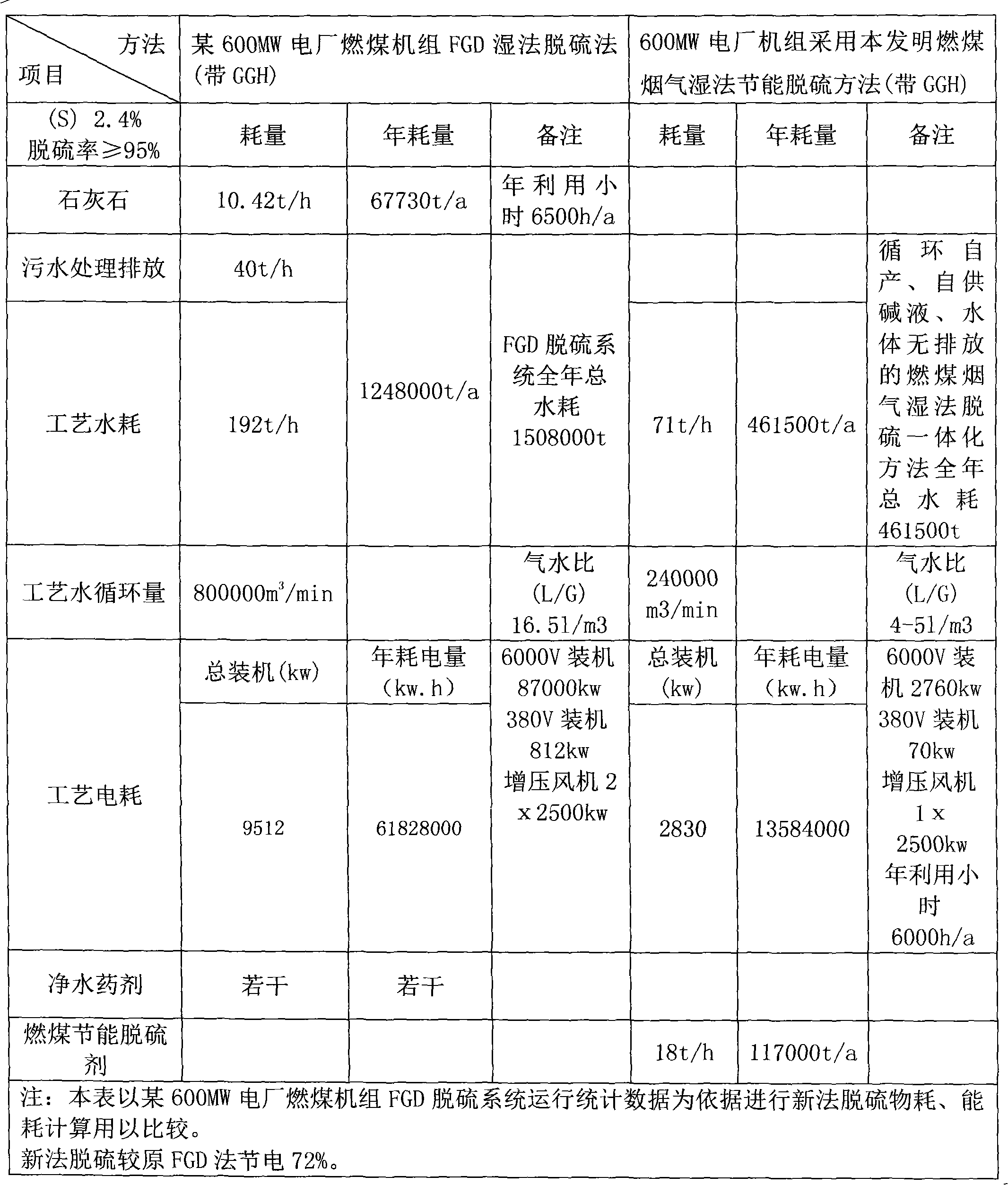

Fire coal flue gas wet method energy-saving desulfurization method

InactiveCN102794092ADesulfurization achievedLow running costUsing liquid separation agentSlagOxidation pond

The invention provides a fire coal flue gas wet method energy-saving desulfurization method, and belongs to the technical field of recycle methods of fire coal flue gas. The method comprises the following steps of: firstly, homogenizing a desulfurizing agent and fire coal, transporting into a hearth for combustion, generating various chemical compounds by SO2 generated by the combustion reaction and elements in furnace burden, and discharging the chemical compounds and the furnace burden which is not completely reacted out from the hearth along with furnace slag; absorbing dust in the flue gas and entering a spray tower, and washing the flue gas by an alkaline wash solution for desulfuration; leading discharged wash solution water body to flow into an oxidation pond, discharging to a slag bath along with discharged materials of the hearth, dissolving water-soluble substances discharged out from the hearth by slag washing water body, hydrolyzing to obtain alkaline liquor, carrying out a reaction between sulfuric acid and hydrochloride solutes in the alkaline liquor to generate ocyhydrate precipitates, and jointly taking away by absorbing of the furnace slag; and leading the reacted alkaline liquor to enter a filter tank, pumping into the spray tower after filtering, and circularly washing the flue gas. A desulfurization system used by the invention is simple, the use level of the fire coal can be saved, sewage does not need to be discharged outwards and secondary pollutants can not be additionally discharged in the whole process, the running cost can be reduced, and the desulfuration and the smoke dust treatment can reach the standard.

Owner:SICHUAN EXTREME ELECTRIC CONTROL SYST MFG

Method for gas-phase desulfurization of glue gas

The invention relates to a method for gas-phase desulfurization of a glue gas. The method comprises the following steps: directly gasifying an efficient desulfurizer or gasifying the efficient desulfurizer in a heating manner; then injecting the gasified desulfurizer into a desulfurization reaction area; and performing a reaction on the gasified desulfurizer and SO2 in the flue gas in a full mixing manner at a certain temperature so as to reach the purpose of desulfurization. The desulfurization rate of the method reaches more than 95%. The method is less in desulfurizer adding amount, simple to run and operate; the running cost of the method is lower than that of an existing desulfurization method, so that the economic advantage of the method provided by the invention is obvious. As the method is used, the problems of high investment, high running and maintenance cost and complicated running operation of basic facilities adopted by the existing desulfurization technology are overcome. Thus, the method is suitable for the flue gas treatment of various industrial boilers and industrial furnaces.

Owner:SHANDONG UNIV

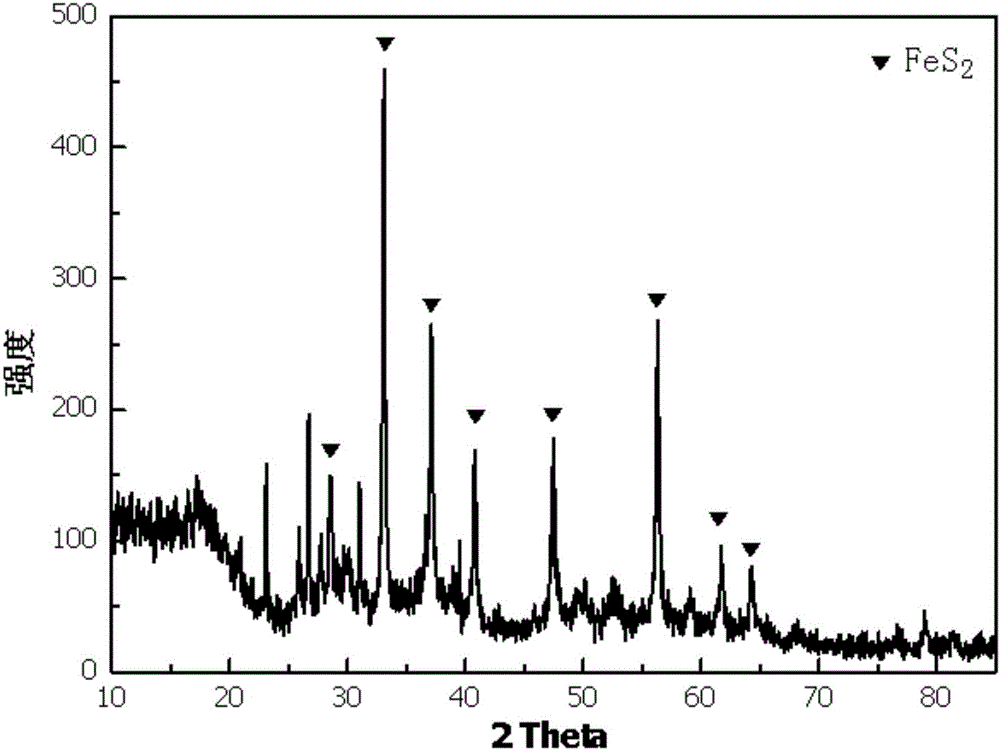

Method for preparing iron disulfide

ActiveCN105712410AHigh yieldEasy to removePhysical/chemical process catalystsIron sulfidesEconomic benefitsBULK ACTIVE INGREDIENT

The invention provides a method for preparing iron disulfide. According to the method, magnetic iron oxide Fe21.333O32 and gas containing H2S are taken as raw materials initiatively and react in the presence of an oxidizing agent, and iron disulfide is prepared. The reaction raw material magnetic iron oxide Fe21.333O32 can be a desulfurizing agent with magnetic iron oxide Fe21.333O32 serving as an active ingredient, the desulfurizing agent is contacted with the gas containing H2S in the presence of the oxidizing agent and performs desulfurization, an obtained material containing iron disulfide can be directly used as a hydrogenation catalyst, the raw material gas is desulfurized, besides, the hydrogenation catalyst is prepared, emission of a waste desulfurizing agent is eliminated, the production cost of iron disulfide is substantially reduced, and the method has great environmental benefits and economic benefits.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

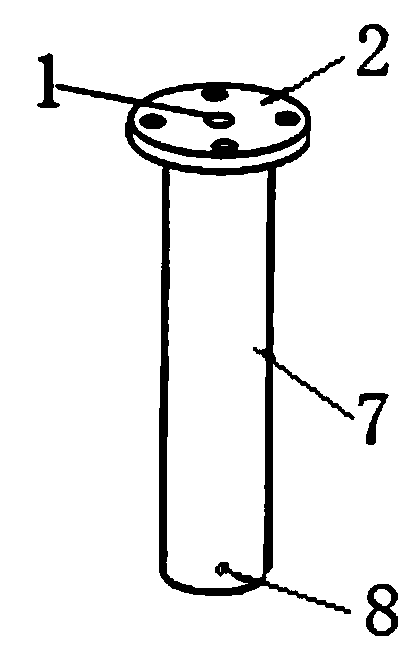

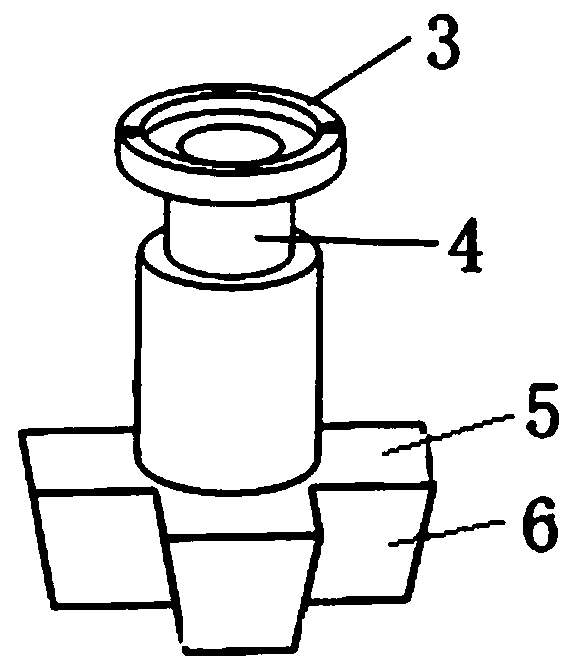

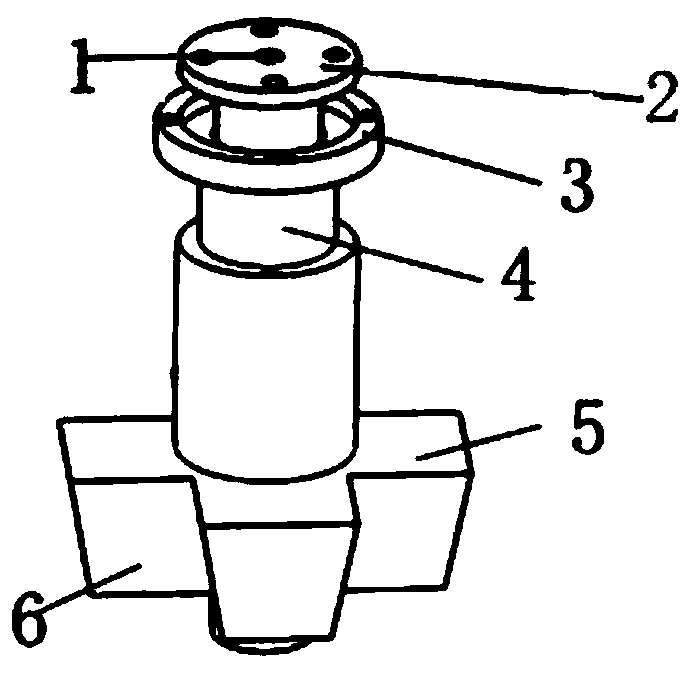

Immersion type desulfurization device with mechanical stirring

The invention relates to an immersion type desulfurization device with mechanical stirring. The desulfurization device comprises an immersion type spray gun and a mechanical stirrer. The immersion type spray gun is inserted into the hollow part of the center of the mechanical stirrer. The immersion type spray gun comprises a spray gun flange connector and a spray gun body that is connected to thespray gun flange connector. The center of the spray gun flange connector is provided with a powder inlet. The center of the spray gun cavity is a hollow cavity. The lower end of the spray gun cavity is provided with a spraying agent outlet. The spray gun flange connector is used to connect a material conveying facility. The mechanical stirrer comprises a stirrer flange connector, a stirring shaft,and a stirring blade. The stirrer flange connector is fixedly connected to the stirring shaft. The lower end of the stirring shaft is fixedly connected to the stirring blade. The stirrer flange connector is used to connect a stirring facility. The provided device can guarantee that in immersion type blowing, materials in a molten pool are fully and evenly stirred and mixed, the powder dispersionand stay time is increased, the dynamic conditions of desulfurization process are greatly optimized, the manufacturing cost of the device is low, and an ideal desulfurization effect is achieved.

Owner:NORTHEASTERN UNIV

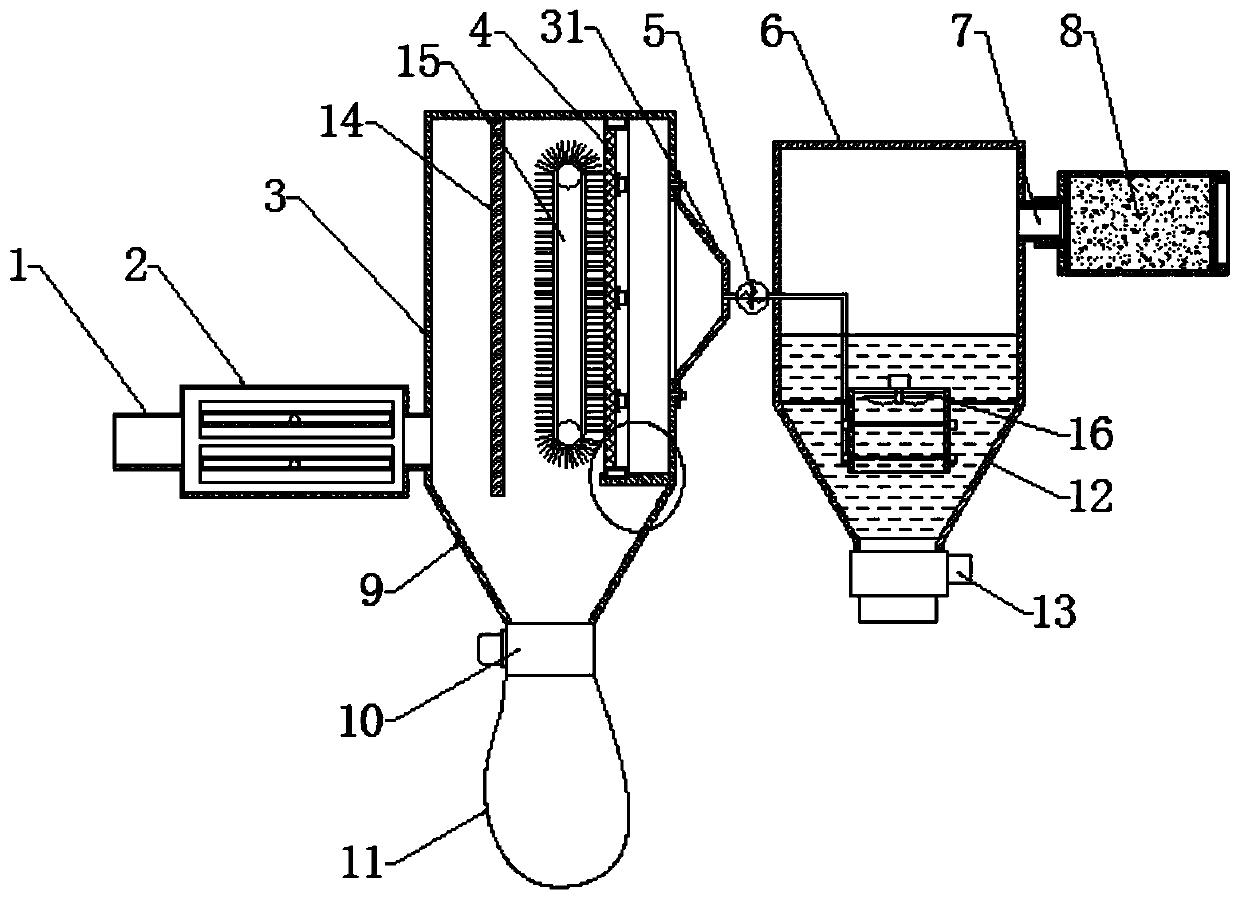

Device and method for desulphurization and dust-removal

InactiveCN105126593ARealize desulfurization and dust removalDesulfurization achievedLighting and heating apparatusDispersed particle separationMagmaFlue gas

The invention discloses a desulphurization and dust-removal device, and a desulphurization and dust-removal method. The desulphurization and dust-removal device comprises a desulphurization tower, and further comprises a vertical type wet-electric type dust remover which is arranged above the desulphurization tower, wherein a desulphurization tower flue gas inlet is formed in the desulphurization tower; the desulphurization tower comprises a housing and a desulphurization device connected with the housing; the desulphurization device comprises a desulphurization magma spraying and circulating system, and a magma tank for accommodating the magma; the magma tank is arranged in the housing and positioned in the lower part of the housing; the desulphurization magma spraying and circulating system comprises a circulating pump which is connected to the magma tank by a pipeline, and four layers of spraying tubes which are connected to the circulating pump; each layer of the spraying tubes comprises at least one spraying tube; the four layers of the spraying tubes are arranged on the upper part of an inner cavity of a housing; a flue gas inlet of the vertical type wet-electric type dust remover is connected to a flue gas outlet of the desulphurization tower; and after being subjected to desulphurization by the desulphurization tower, and dust removal by the vertical type wet-electric type dust remover, the flue gas reaches national environment-friendly emission requirements.

Owner:苏州市江远热电有限责任公司

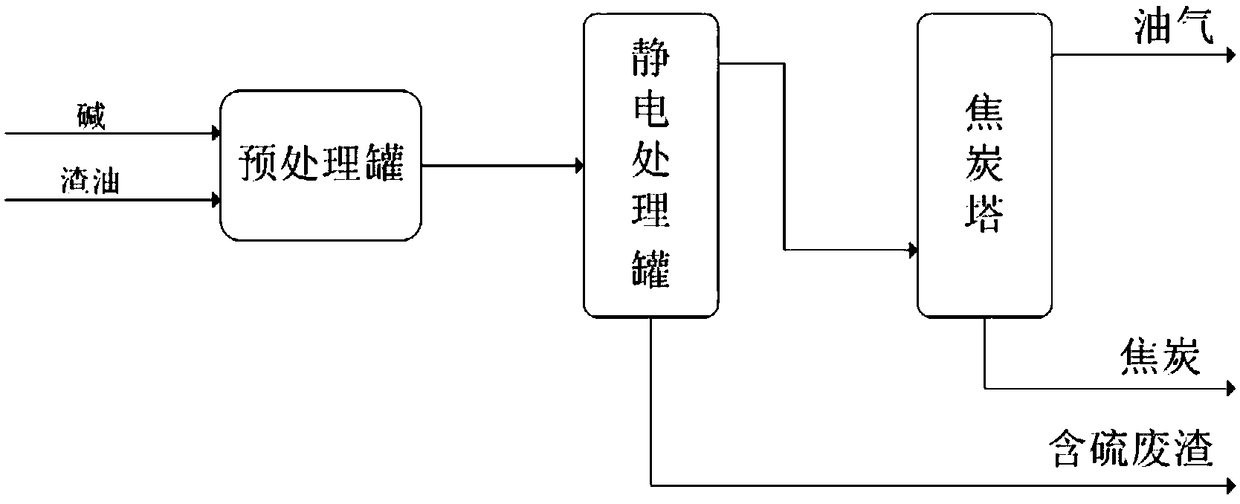

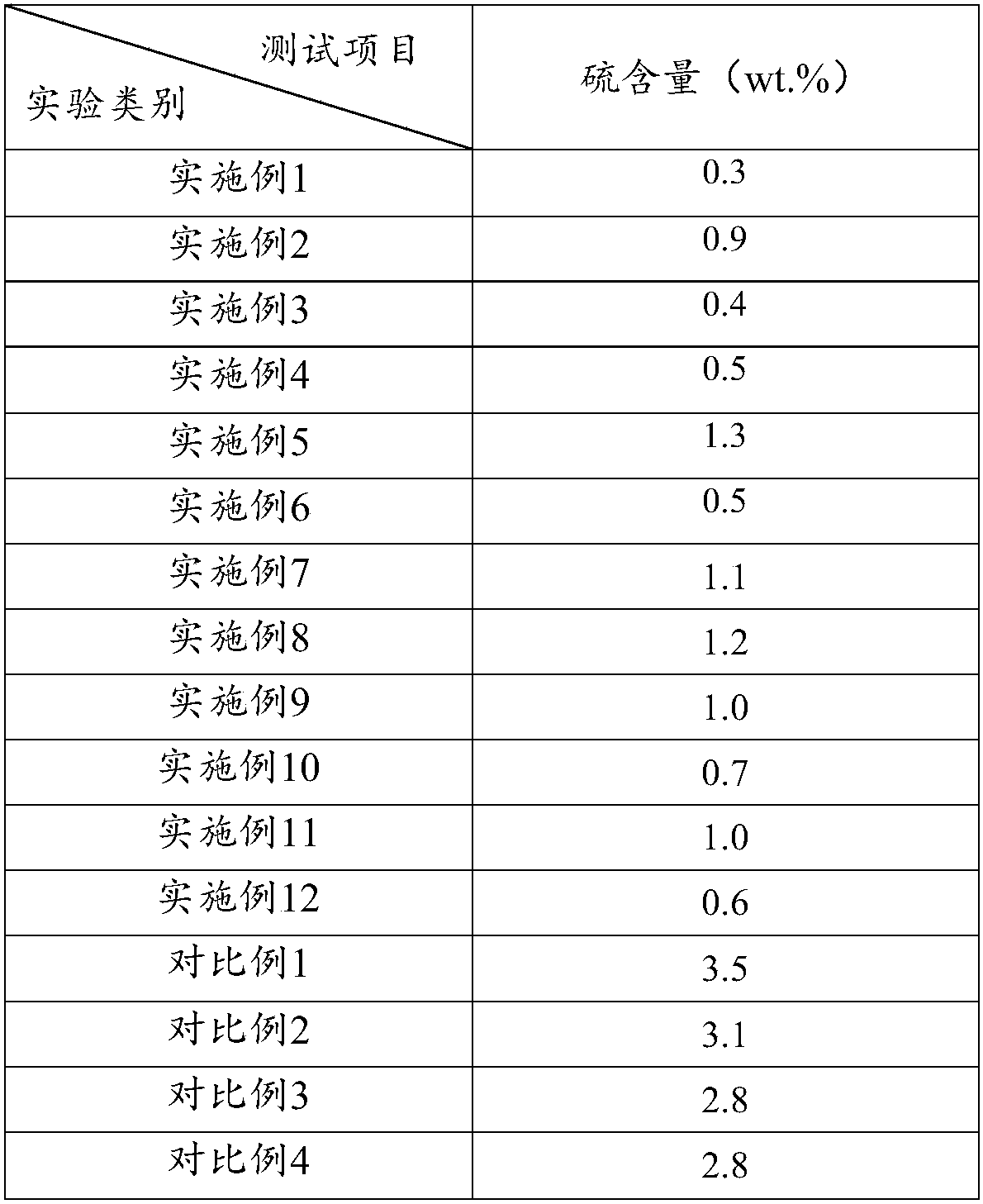

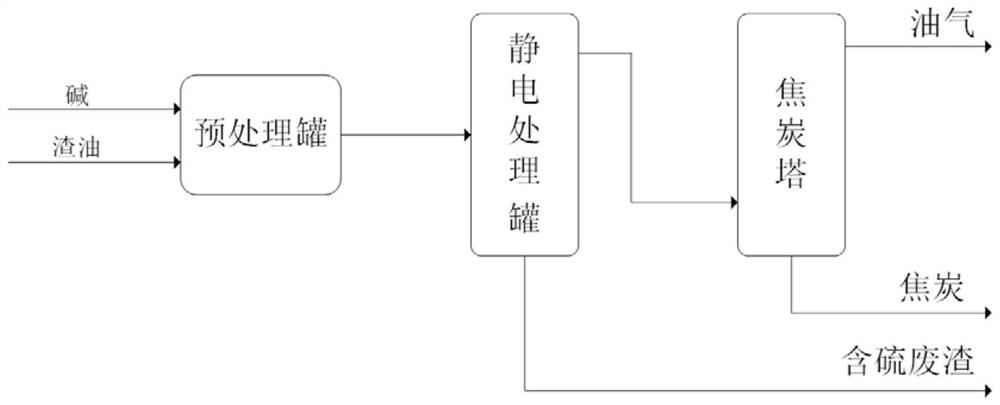

Residual oil desulfurization method as well as preparation method and production equipment of petroleum coke

ActiveCN109135818AReduce energy consumptionSimple processTreatment with plural serial stages onlyTreatment with plural serial refining stagesDesorptionResidual oil

The invention provides a residual oil desulfurization method as well as a preparation method and production equipment of petroleum coke, and relates to the technical field of petroleum coking. The residual oil desulfurization method comprises the following steps: S1) providing residual oil as a reaction raw material, mixing the residual oil and a pretreatment agent and performing pretreatment on the residual oil, wherein the pretreatment agent comprises metal alkali and / or metal carbonate; and S2) putting a pretreatment mixture obtained in the step S1) into an electrostatic field, performing electrostatic desorption and desulfurization treatment and completing desulfurization of the residual oil to obtain the residual oil with low sulfur content. By the residual oil desulfurization method,the technical problems in the prior art that the process difficulty is high, the cost is high and the desulfurization effect is bad when the petroleum coke is desuflurized can be relieved; and desulfurization is conducted from the raw materials, so that the aims of reducing the desulfurization difficulty and improving the desulfurization effect are fulfilled.

Owner:SINOPEC LUOYANG TECH CO LTD +1

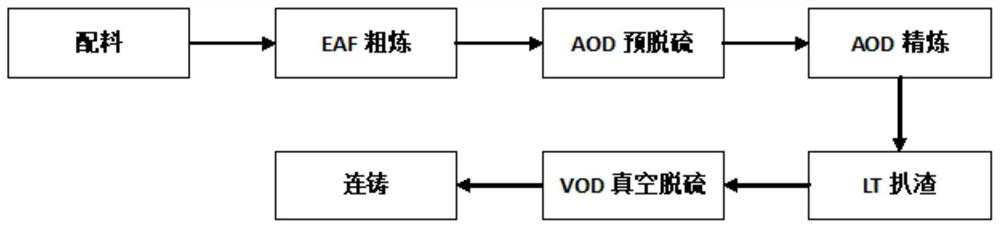

316L stainless steel and preparation method thereof

ActiveCN112342454AGuaranteed desulfurization effectImprove high temperature plasticity and calendering propertiesSmeltingSS - Stainless steel

The invention provides 316L stainless steel and a preparation method thereof. The preparation method comprises the steps that EAF coarse smelting is conducted on on a mixed material of 316L stainlesssteel; AOD pre-desulfurization is conducted on the mixed material subjected to EAF coarse smelting; AOD refining is conducted on the mixed material subjected to AOD pre-desulfurization; LT slagging-off treatment is conducted on the mixed material subjected to AOD refining; VOD vacuum desulfurization is conducted on the mixed material subjected to LT slagging-off treatment; and continuous casting is conducted on the mixed material subjected to VOD vacuum desulfurization to obtain the 316L stainless steel. The 316L stainless steel prepared through the method can effectively overcome the line scale defect of the edge portion of a cold (hot) rolled plate.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

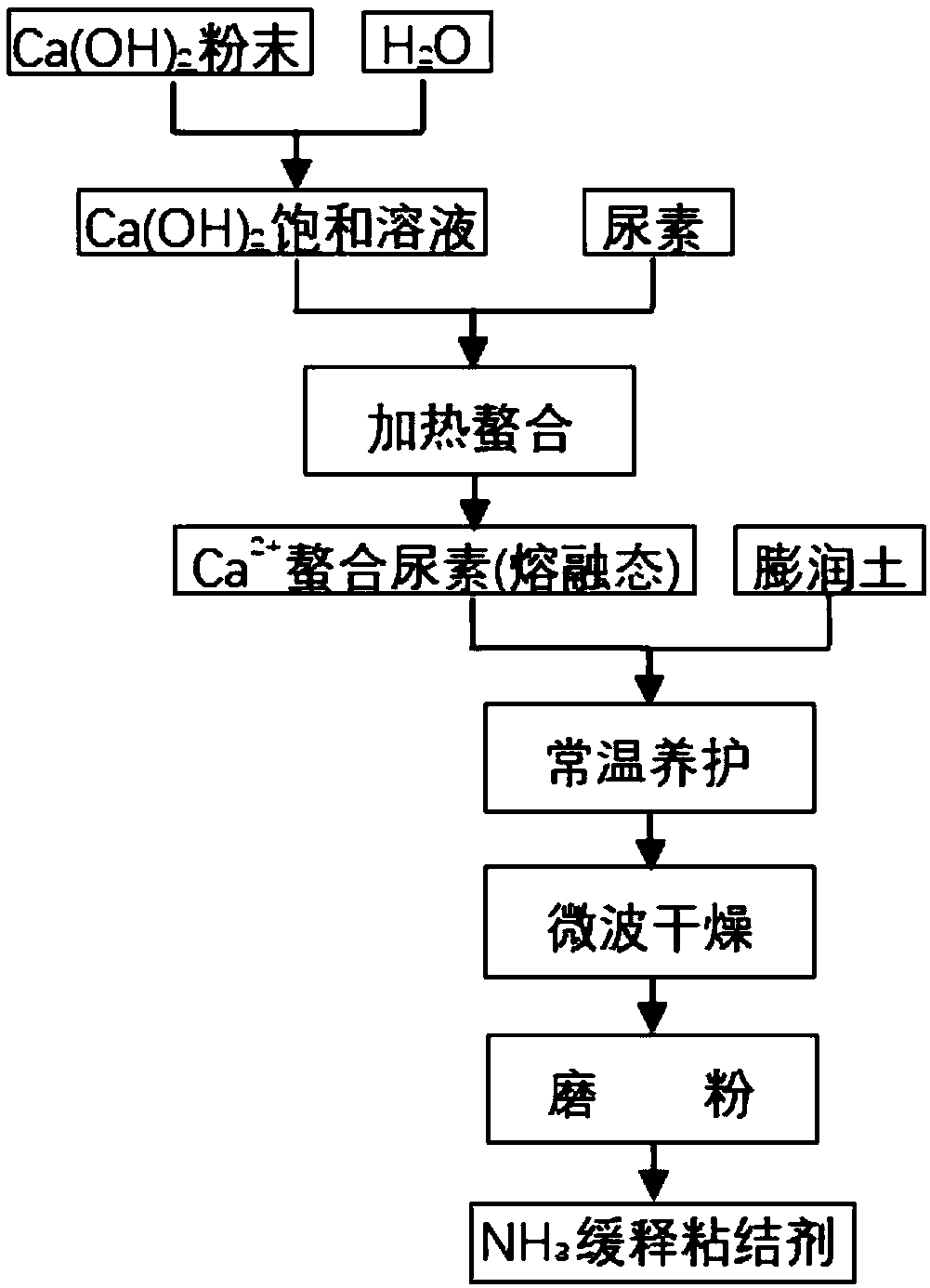

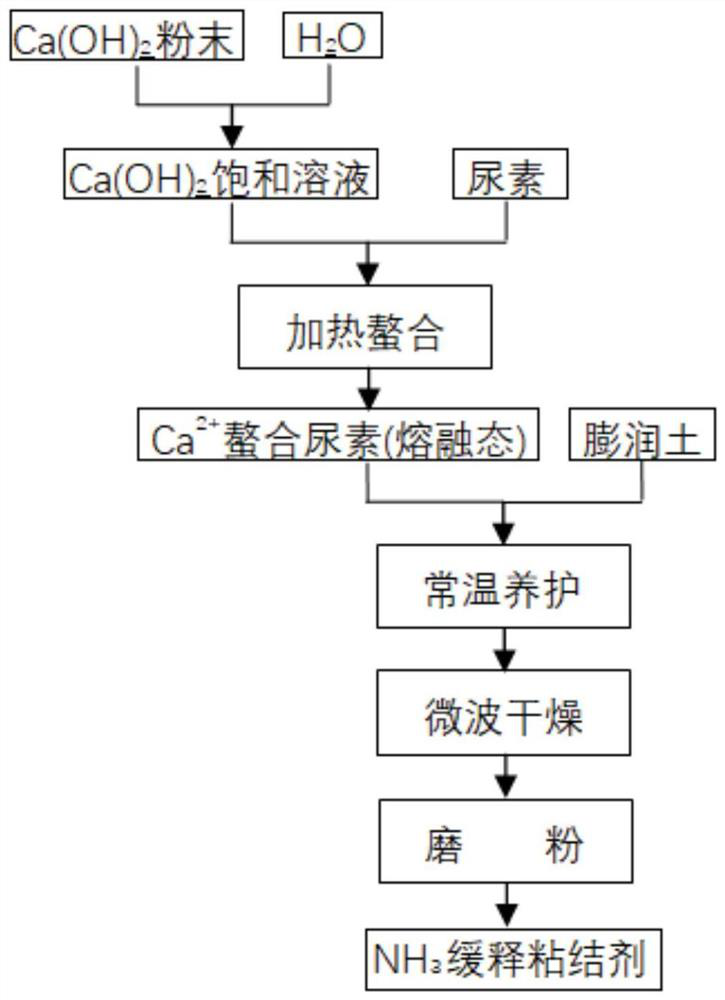

Pelletizing binder with desulfuration function and preparation method and application of pelletizing binder

ActiveCN109371234AWith desulfurization functionDesulfurization achievedSodium BentoniteMaterials science

The invention discloses a pelletizing binder with a desulfuration function and a preparation method and application of the pelletizing binder and belongs to the field of preparation of ferrous metallurgy blast furnace materials. The pelletizing binder with the desulfuration function contains the following components including, by weight, 2.5-10 wt.% of urea, 2.5-10 wt.% of Ca(OH)2 and 80-95 wt.% of bentonite. The pelletizing binder is powder which contains at least 95 wt.% of particles smaller than 0.074 mm in particle size. The defect of high cost of iron ore pellet production and desulfuration in the prior art is overcome. The pelletizing binder has the desulfuration function, can be applied to desulfuration in a pellet production process, can effectively reduce the content of SO2 in pellet smoke, relieves burden of a desulfuration system and does not affect normal pellet production. The preparation method has the advantages of being low in preparation cost and high in efficiency and is suitable for being applied and popularized.

Owner:句容康泰膨润土有限公司

A cross-flow dual-stage moving bed active coke waste gas integrated purification tower

ActiveCN103349892BImprove the utilization rate of adsorption sulfur capacityReduce circulationDispersed particle filtrationTowerMoving bed

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

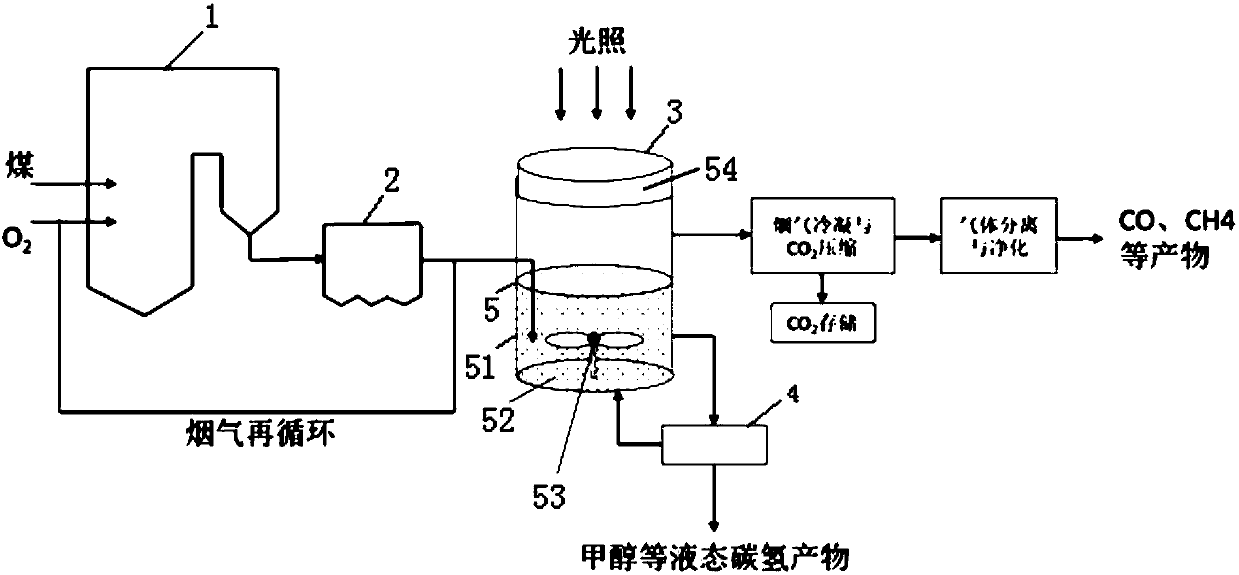

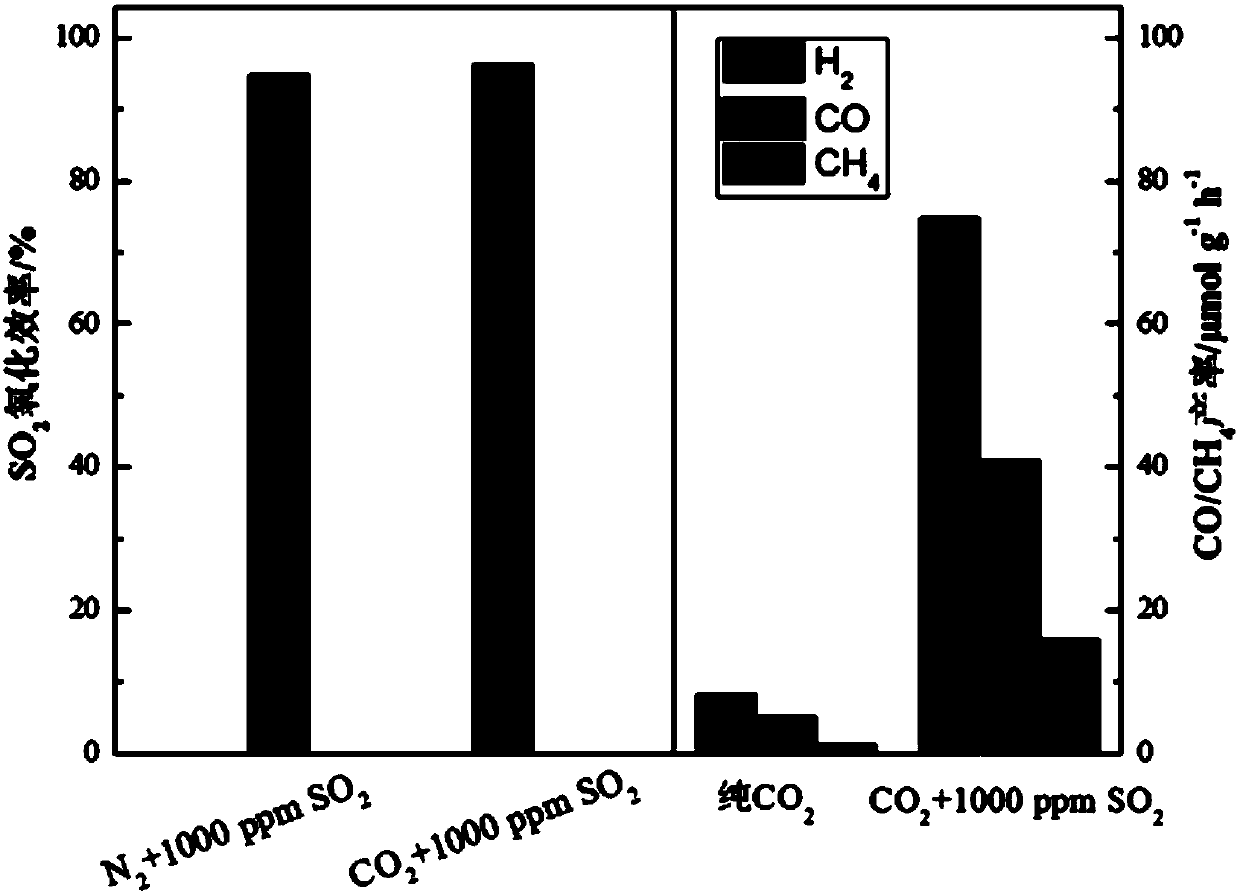

Fume produced hydrocarbon fuel synergic desulfurization method and photocatalysis device for achieving same

ActiveCN107837679ADesulfurization achievedRealize transformation and utilizationGas treatmentEmission preventionGlass coverDesorption

The invention belongs to the technical field of fume purification and discloses a fume produced hydrocarbon fuel synergic desulfurization method and a photocatalysis device for achieving same. According to the method, photocatalytic reduction is implemented on CO2 in fume between an oxygen-enriched combustion power plant electrostatic dust collector and a fume condensation and CO2 compression device, and meanwhile SO2 in the fume is subjected to oxidation desorption. The device comprises a reaction unit and a separation unit, wherein the reaction unit comprises a reaction container; a stirringdevice, a bicarbonate solution and a photocatalyst suspended in the bicarbonate solution are arranged inside the reaction container; a fume inlet, a gas outlet, a liquid outlet and a liquid inlet arerespectively formed in the reaction container; a quartz glass cover plate is arranged at the top end of the reaction container; and the separation unit is a centrifugal extraction device. By virtue of solar energy, oxygen-enriched combustion fume conversion and fume desulfurization are achieved simultaneously, and in addition, the method ahs the advantages of being low in energy consumption, lowin cost, and the like, and has great significances for popularization and application of oxygen-enriched combustion techniques.

Owner:HUAZHONG UNIV OF SCI & TECH

Recovery process of lead plaster of waste lead-acid storage battery

ActiveCN111934043AAchieve regenerationWill not polluteFinal product manufactureCell electrodesElectrical batteryProcess engineering

The invention provides a recovery process of lead plaster of a waste lead-acid storage battery, which comprises the steps of pulverizing the lead plaster, carrying out desulfurization reaction to obtain desulfurized lead plaster, adding the desulfurized lead plaster into a muffle furnace, introducing water gas, and carrying out reduction reaction to obtain powder of elemental lead generated by reduction, wherein the elemental lead can be reused in the production of lead-acid batteries. The method is simple in process and low in cost, does not corrode equipment or pollute the environment, can obtain high-purity lead without refining by using sodium hydroxide and sodium nitrate refining agents in a refining pot, and has a wide application prospect.

Owner:湖南省长城新能源科技有限公司

High-temperature flue gas desulfurization, dust removal and waste heat recovery self-balancing system

PendingCN111744333ADesulfurization achievedAchieve purification effectCombination devicesGas treatmentSprayerFlue gas

The invention discloses a high-temperature flue gas desulfurization, dust removal and waste heat recovery self-balancing system which comprises an absorption tower, a first-stage sprayer, a first heatexchanger, a first circulation loop, a second-stage sprayer, a second heat exchanger and a second circulation loop; a solution in the first circulation loop exchanges heat with heating water in the first heat exchanger; the second circulation loop extends out of a second solution outlet and extends into the second-stage sprayer; and a solution in the second circulation loop exchanges heat with cooling water in the second heat exchanger. The system is suitable for the integration of desulfurization, dust removal and waste heat recovery of high-temperature flue gas, meanwhile, can realize hot and wet flue gas desulfurization, dust removal purification and waste heat recovery; the system has multiple purposes; a solution spraying method and a double-layer heat exchange system are adopted, sothat the concentration and the liquid level of circulating liquid are kept in a balanced state, the requirement that conventional desulfurization needs water supplementation is met, and waste heat recovery and a desulfurization and dust removal cooperative treatment effect are realized.

Owner:HEIMDALLR SHANGHAI ENERGY SAVING TECH

Desulfurization process for burning of mixing coal slime mixed with dolomite

ActiveCN101664632BHigh thermal efficiencyReduce heat lossDispersed particle separationComing outFlue gas

The invention discloses a desulfurization process for burning of coal slime mixed with dolomite. The process solves the problems that a present circulating fluidize beds has high desulfurization cost, unstable desulfurization index, influencing the load capacity of boilers, and the like, and has the advantages of low cost, convenient use, effective improvement of desulfurization efficiency, guarantee of boiler stability, and the like. The process comprises the following steps: (1) mixing coal slime and dolomite into mixed coal slime according to the weight part proportion of 100:(8-12) parts;(2) then uniformly mixing the coal slime and the mixed coal slime in a coal cabin in a mode that the mass percent of the coal slime is larger than 60 percent and then sending an obtained mixture intoa coal feeder; (3) sending the mixture of the coal slime and the mixed coal slime into a hearth by the coal feeder for burning; and (4) recovering burnt coal slag. Flue gas after burning is treated by electric precipitation, then stove ashes are recovered, and the flue gas treated by the electric precipitation is desulfurized after coming out of the hearth and exhausted.

Owner:JINAN QIQUAN THERMOELECTRICITY

Pellet binder with desulfurization function, preparation method and application thereof

ActiveCN109371234BWith desulfurization functionDesulfurization achievedFerrous metallurgyBlast furnace

The invention discloses a pelletizing binder with a desulfuration function and a preparation method and application of the pelletizing binder and belongs to the field of preparation of ferrous metallurgy blast furnace materials. The pelletizing binder with the desulfuration function contains the following components including, by weight, 2.5-10 wt.% of urea, 2.5-10 wt.% of Ca(OH)2 and 80-95 wt.% of bentonite. The pelletizing binder is powder which contains at least 95 wt.% of particles smaller than 0.074 mm in particle size. The defect of high cost of iron ore pellet production and desulfuration in the prior art is overcome. The pelletizing binder has the desulfuration function, can be applied to desulfuration in a pellet production process, can effectively reduce the content of SO2 in pellet smoke, relieves burden of a desulfuration system and does not affect normal pellet production. The preparation method has the advantages of being low in preparation cost and high in efficiency and is suitable for being applied and popularized.

Owner:句容康泰膨润土有限公司

Chemical tail gas deodorization device and deodorization method

InactiveCN105056728AHigh purityReduce sulfur dioxide contentDispersed particle separationExhaust gasProcess engineering

The invention discloses a chemical tail gas deodorization device. The device comprises a high-pressure gas dissolution pump connected with chemical equipment through a pipeline, the high-pressure gas dissolution pump is connected with an airtight water tank through a pipeline, a jet pump is arranged at the output end of the airtight water tank, the output end of the jet pump is connected with a gas-liquid separation chamber, and a gas-liquid separator is arranged in the gas-liquid separation chamber; a liquid storage tank is arranged at the lower end of the separation chamber, and a one-way valve connected with a desulfuration chamber is arranged at the upper end of the gas-liquid separation chamber; an adsorption layer is arranged in the desulfuration chamber and adopts a honeycomb structure, a calcification desulfuration agent is arranged on the surface of the adsorption layer, a gas outlet is formed in the end, away from the one-way valve, of the desulfuration chamber, a steam purifier is arranged at the gas outlet, and the output end of the steam purifier is connected with the gas storage tank through a gas sucking pump. The chemical tail gas deodorization device is simplified, and ammonia and sulfur are separated.

Owner:CHANGZHOU JINHAILONG MACHINE MFG

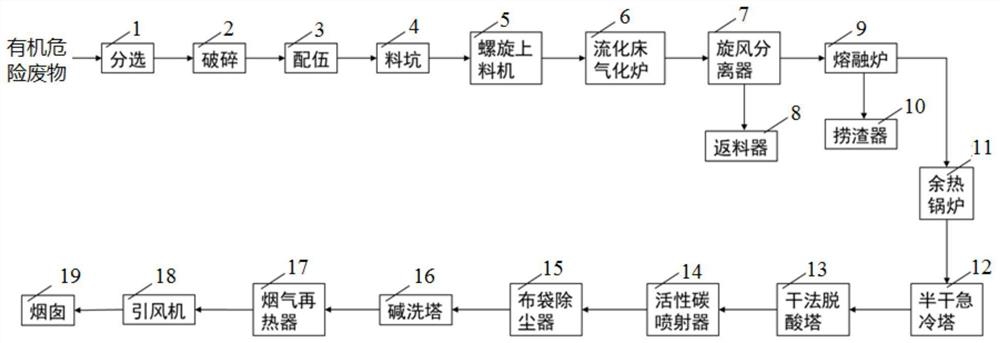

Organic hazardous waste gasification melting treatment system and method

PendingCN114110606AFluidized state is goodLess coking problemsIndirect carbon-dioxide mitigationIncinerator apparatusCarbonizationMolten slag

The invention discloses an organic hazardous waste gasification and melting treatment system and method.The gasification and melting treatment system comprises a material matching and feeding system used for matching and conveying materials; the circulating fluidized bed gasification melting system comprises a circulating fluidized bed gasification furnace, a cyclone separator, a return feeder, a melting furnace and a slag dredger which are connected in sequence, the circulating fluidized bed gasification furnace is connected with the spiral feeding machine of the feeding system, and organic hazardous waste is subjected to pyrolysis gasification to obtain pyrolysis gas, carbonized coarse particles and carbonized fine particles; the cyclone separator separates the pyrolysis gas, the carbonized fine particles and the carbonized coarse particles, the carbonized coarse particles are returned to the circulating fluidized bed gasification furnace through the return feeder, and the pyrolysis gas and the carbonized fine particles enter the melting furnace; the melting furnace is used for carrying out oxygen-enriched combustion on the pyrolysis gas and melting the carbonized fine particles at a high temperature, and molten slag forms a glass body in a slag salvaging device; the waste heat boiler is used for recovering sensible heat of flue gas discharged by the melting furnace; and the flue gas purification system is used for purifying flue gas generated after sensible heat is recovered by the waste heat boiler.

Owner:中广核环保产业有限公司

Fine desulfurization device and fine desulfurization method for blast furnace gas

PendingCN114591765ADesulfurization achievedRealize online injectionGas purification by catalytic conversionIncreasing energy efficiencyThermodynamicsPtru catalyst

The invention relates to the technical field of flue gas desulfurization, and provides a blast furnace gas fine desulfurization device and a fine desulfurization method, a front-end treatment technology is adopted, i.e., desulfurization is carried out before blast furnace gas is sent out of a system, according to the characteristic that the COS content of the blast furnace gas is high, desulfurization can be realized by adopting a COS hydrolysis process, and because the blast furnace gas contains trace toxicants such as HCl, HF and HCN, the content of the toxicants in the blast furnace gas is low, and the content of the toxicants in the blast furnace gas is low. Therefore, a liquid-phase detoxification catalyst and a hydrolysis protective agent which are specially used for removing toxicants in the blast furnace gas are adopted, most toxicants in the blast furnace gas can be removed, the desulfurization efficiency and stability of the system are improved, and the device comprises a bag-type dust collector and a heat recovery system for recovering the blast furnace gas, the heat recovery system is communicated with the bag-type dust collector through a three-way front pipe, the three-way front pipe is communicated with a liquid-phase detoxification catalyst supplementing device, a delivery pump is arranged between the liquid-phase detoxification catalyst supplementing device and the three-way front pipe, and a liquid-phase detoxification catalyst is arranged in the liquid-phase detoxification catalyst supplementing device.

Owner:HEBEI ZHONGKE LANGBO ENVIRONMENTAL PROTECTION TECH CO LTD

Method for treating catalytic cracking regeneration flue gas

ActiveCN110898606ARealize dust removal and purificationReduce energy consumptionGas treatmentDispersed particle separationPtru catalystFlue gas

The invention relates to a method for treating catalytic cracking regeneration flue gas. The method comprises the following steps that (1) catalytic cracking regeneration flue gas containing sulfur oxide enters an adsorption tower, and is subjected to contact adsorption with active coke to obtain purified flue gas and to-be-regenerated coke adsorbing sulfur oxide; (2) the to-be-regenerated coke isregenerated under a regeneration condition to obtain regenerated coke and regenerated tail gas containing sulfur oxide; and (3) the regenerated tail gas returns to a catalytic cracking reactor to make the sulfur oxide in the regenerated tail gas contact a catalytic cracking catalyst, a raw material and a product to convert into hydrogen sulfide, the hydrogen sulfide is subjected to fractionation,absorption stabilization and desulfurization along with the catalytic cracking product to realize recovery of sulfur resources, and the coke powder in the regenerated tail gas enters a catalytic cracking regenerator along with the catalytic cracking catalyst so as to be subjected to combustion removal. With the method, catalytic cracking regeneration flue gas can be purified, equipment for treating active coke regeneration tail gas and recovering sulfur is not to be independently arranged, and a small amount of coke powder carried in the regeneration tail gas can be treated.

Owner:SINOPEC ENG +1

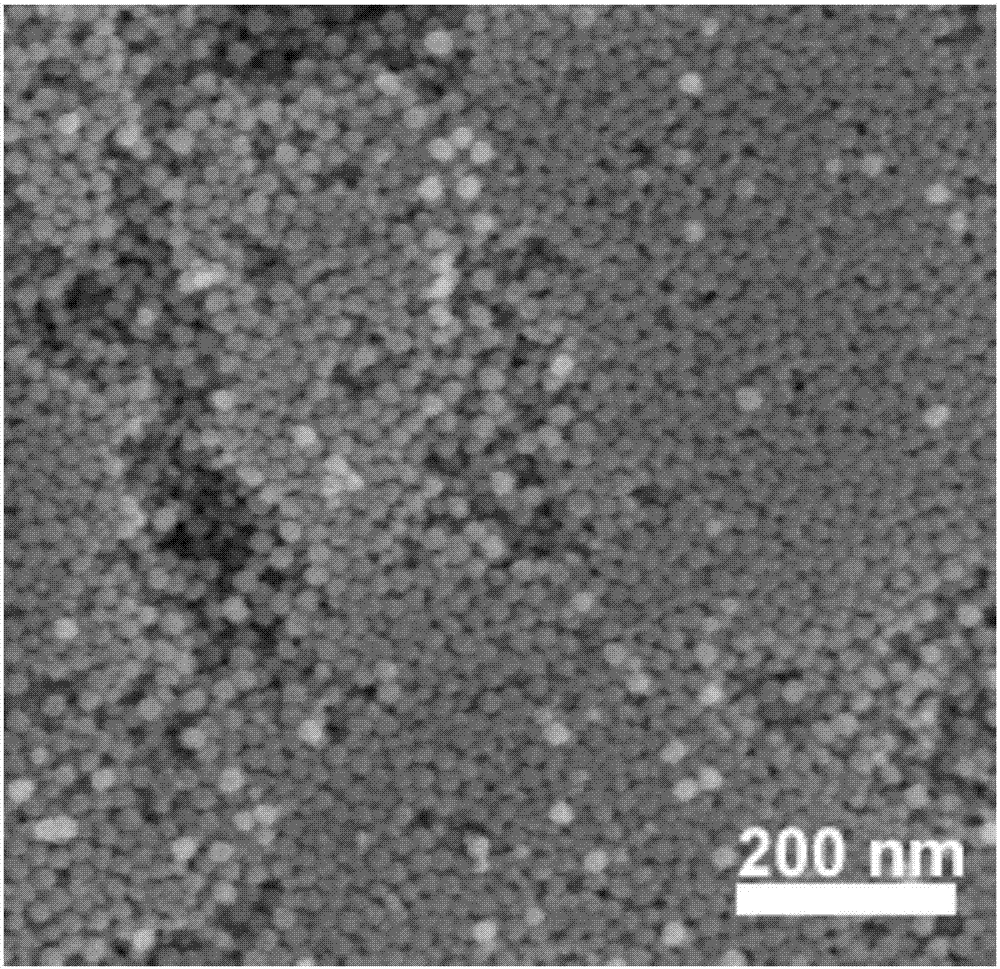

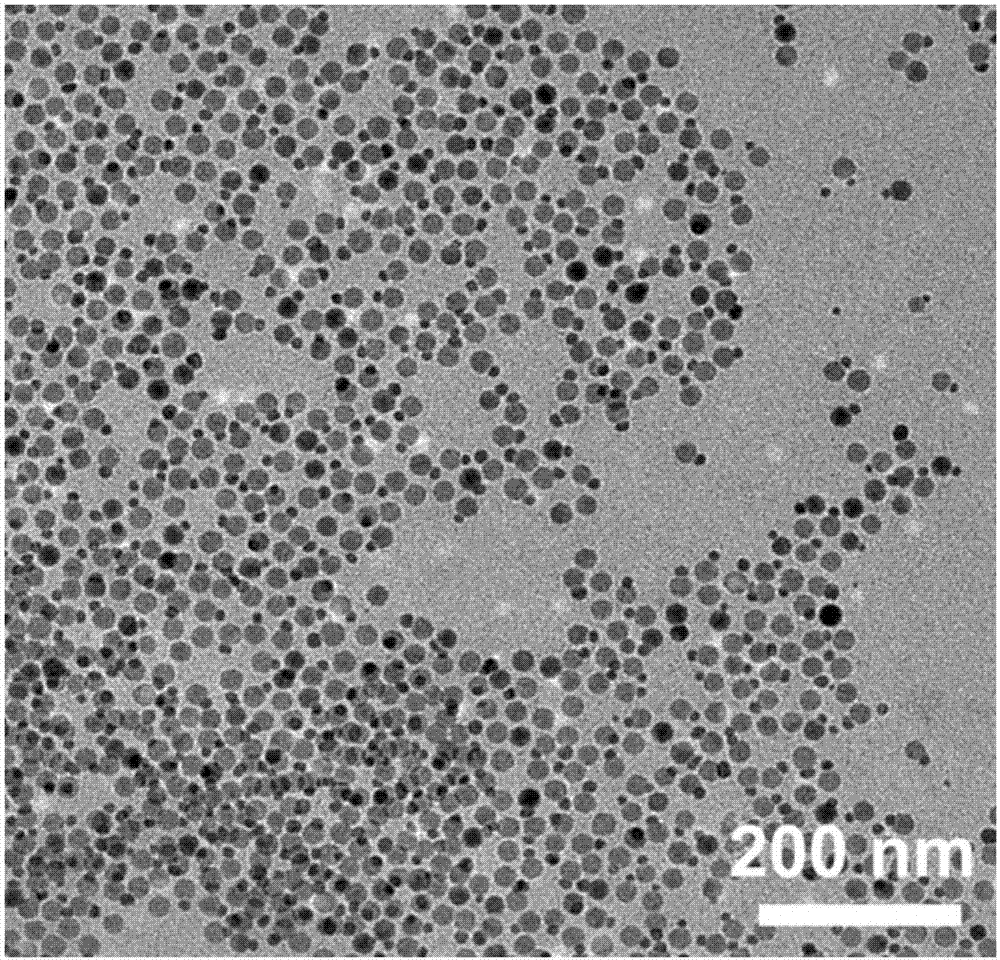

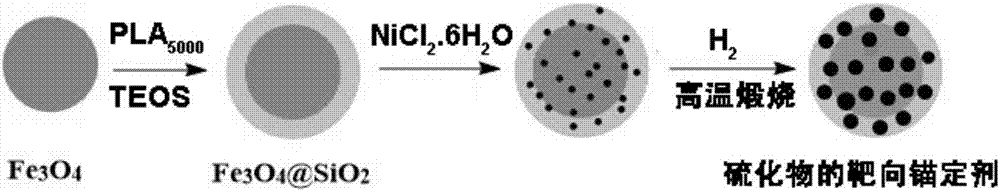

Target anchorage agent for sulfide in oil and preparation method and application thereof

ActiveCN106861603ADesulfurization achievedAchieving Disruptive ChangeOther chemical processesHydrocarbon oils refiningIonChemistry

The invention relates to a target anchorage agent for sulfide in oil and a preparation method and application thereof. The preparation method of the target anchorage agent for sulfide comprises the following steps of loading precursor-metal ion of the anchorage agent for the sulfide on the surface of magnetic nanoparticle coated by a silicon dioxide shell layer through an impregnating method, obtaining a stable magnetic nanoparticle-metal nanocluster complex structure through roasting and preparing to obtain the target anchorage agent for the sulfide. The magnetic nanoparticle is utilized as a target agent, metal nanocluster is utilized as an anchorage agent for the sulfide, and a magnetic nanoparticle-metal nanocluster complex structure is constructed. The target anchorage agent not only avoids reducing oil octane value, but also reduces energy consumption; thus, clean low-sulfur oil can be obtained, vehicle emission level can be reduced, environmental air quality is improved, and the target anchorage agent has a very good application prospect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Petroleum coke preparation method and production equipment

ActiveCN109135818BDesulfurization achievedChange shapeTreatment with plural serial stages onlyTreatment with plural serial refining stagesProcess engineeringPetroleum coke

The invention provides a residual oil desulfurization method, a petroleum coke preparation method and production equipment, and relates to the technical field of petroleum coking. The residual oil desulfurization method comprises the following steps: S1) providing residual oil as a reaction raw material, and combining the residual oil with the pre- Mixing the treatment agent to pretreat the residual oil; wherein, the pretreatment agent includes metal alkali and / or metal carbonate; S2) placing the pretreatment mixture obtained in step S1) in an electrostatic field for electrostatic adsorption desulfurization treatment, and then completing Desulfurization of residual oil to obtain residual oil with low sulfur content. The residual oil desulfurization method can alleviate the technical problems of high process difficulty, high cost and poor desulfurization effect in desulfurization of petroleum coke in the prior art, and desulfurization from raw materials can reduce the difficulty of desulfurization and improve the desulfurization effect.

Owner:SINOPEC LUOYANG TECH CO LTD +1

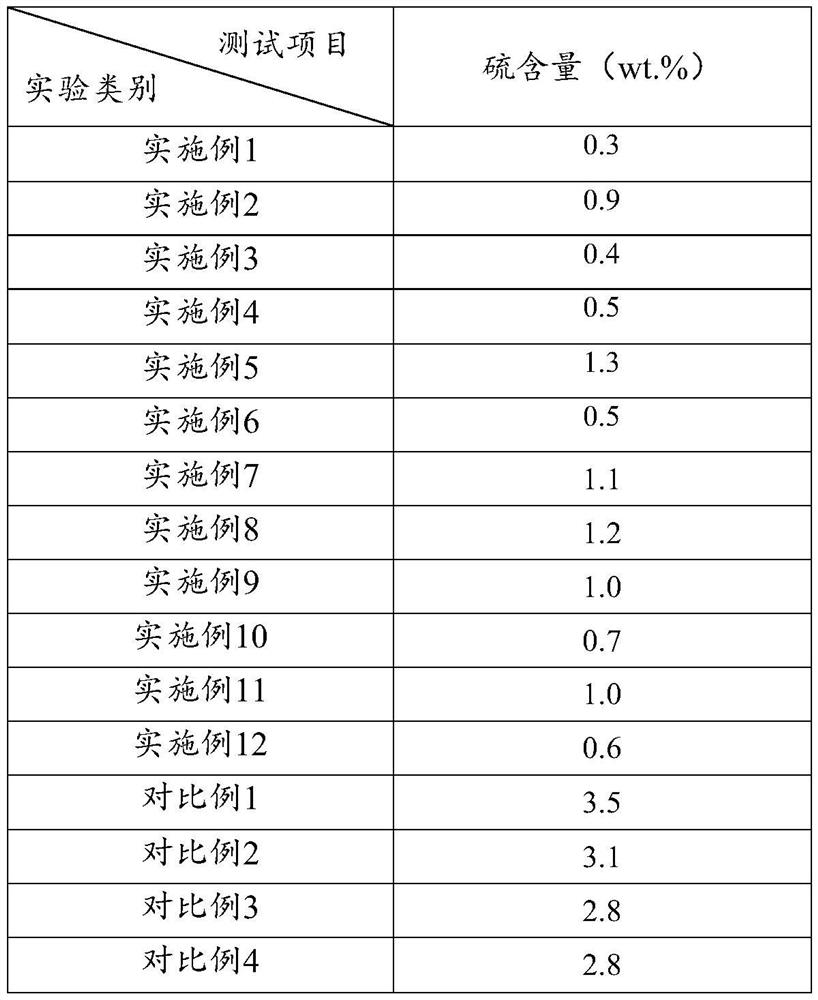

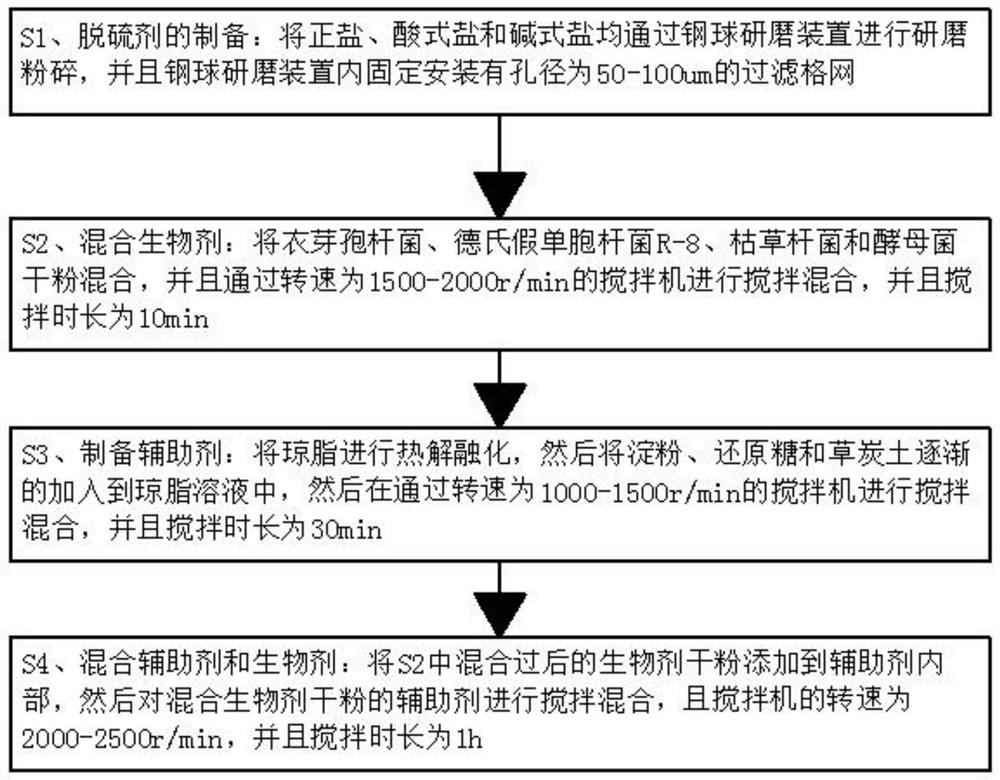

Biogas in-situ desulfurization biological agent

PendingCN112126602ADesulfurization achievedFast desulfurizationFungiBacteriaBiotechnologyBacillus licheniformis

The invention discloses a biogas in-situ desulfurization biological agent. The biogas in-situ desulfurization biological agent comprises a desulfurizer, a microbial preparation, and an adjuvant; the desulfurizer is prepared from ferric salt consisting one or more selecting from normal salt, acid salt and basic salt; the microbial preparation is mixed strains of various microorganisms, and consistsof bacillus licheniformis, pseudomonas delbrueckii R-8, bacillus subtilis and microzyme; and the adjuvant is prepared by mixing agar, starch, reduced sugar, turfy soil and the like. According to thebiogas in-situ desulfurization biological agent, the desulfurizer and the microbial preparation are mixed for use, so that dry and wet desulfurization is achieved through the desulfurizer while further desulfurization is achieved through the microbial preparation; and thus, rapid desulfurization can be achieved through the two modes. In addition, the desulfurizer contains multiple sets of ferric salt so that the desulfurizer can adapt to environments in biogas digesters of different forms; and thus, desulfurization can be achieved.

Owner:归尚(上海)新能源科技有限公司

Dry quenching furnace system with tail gas desulfurizing function and desulfurizing method thereof

PendingCN109758887ADesulfurization achievedEfficient removalCoke quenchingDispersed particle filtrationSulfateProduct gas

The invention discloses a dry quenching furnace system with a tail gas desulfurizing function and a desulfurizing method thereof. The dry quenching furnace system is characterized in that a spraying pipe is distributed in the circumferential direction of a top cone of a dry-quenching furnace; a powdery desulfurizing agent is sprayed into the furnace body through a pneumatic conveying device; the powdery desulfurizing agent reacts with SO2 in recycle gas inside the furnace in a falling process to generate sulfate particles; a part of the sulfate particles fall into a coke layer and is conveyedinto a blast furnace along with coke to participate in smelting, and the other part of the sulfate particles enter a deduster along with the recycle gas for dedusting and filtering; residual filteredrecycle gas is discharged by a gas exhaust device. Thus, SO2 in exhaust tail gas is effectively removed, so that the SO2 emission value can reach 80 mg / m<3> or below. In the system, a desulfurizing reactor and dedusting equipment do not need to be added, and tail gas desulfurization can be realized in the dry-quenching furnace, so that the production cost is effectively lowered, and the influenceon the space of the field equipment is lowered.

Owner:NANJING IRON & STEEL CO LTD

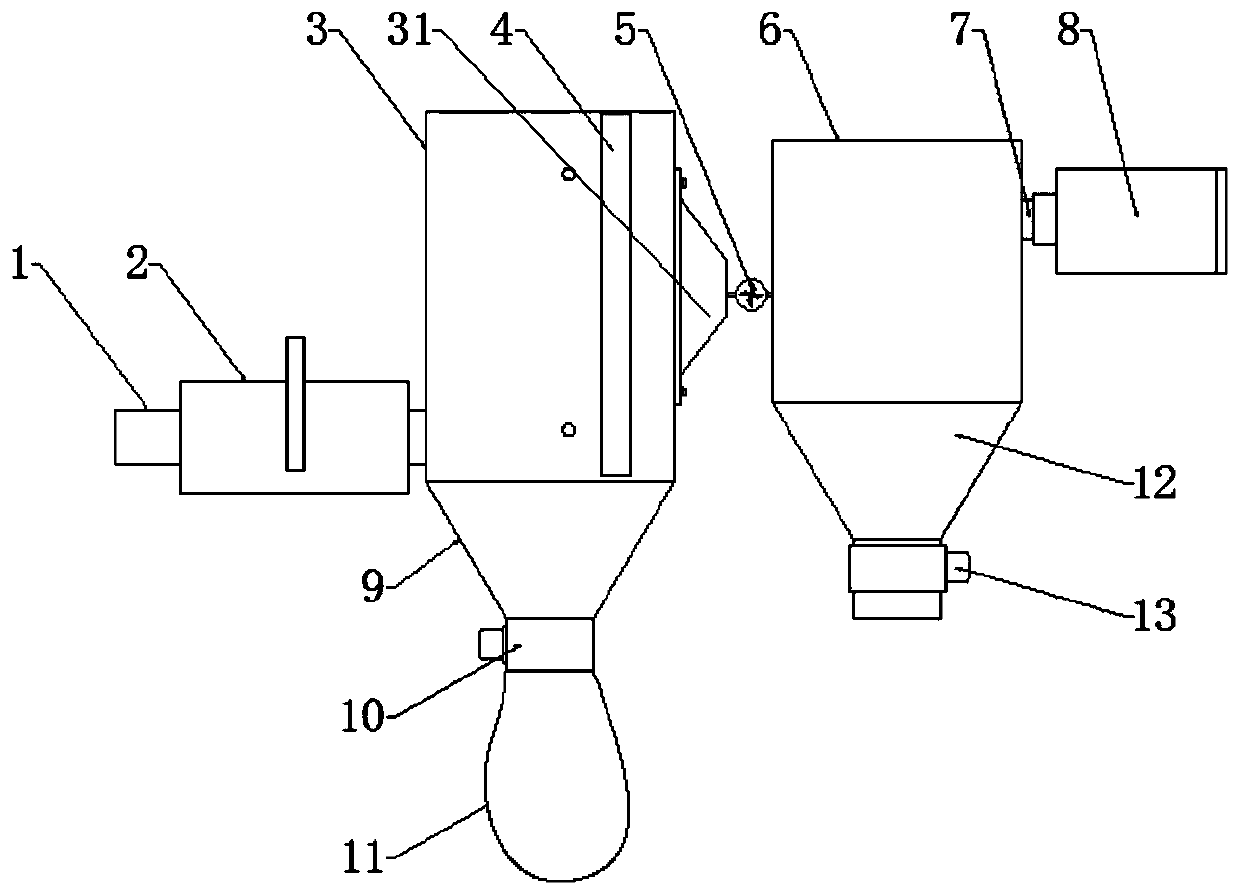

Dust removal and desulfurization process for industrial waste gas

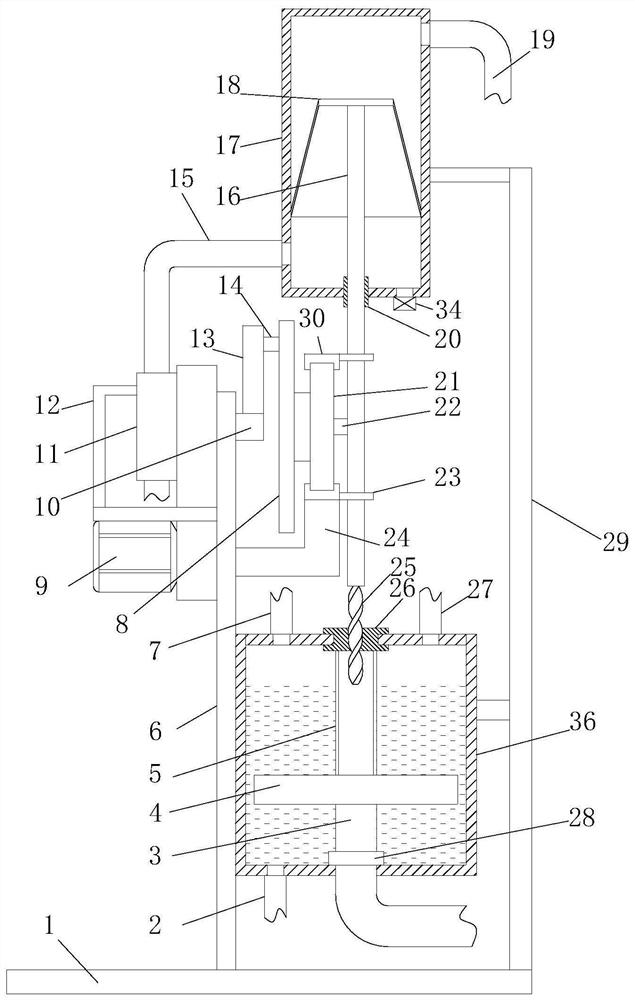

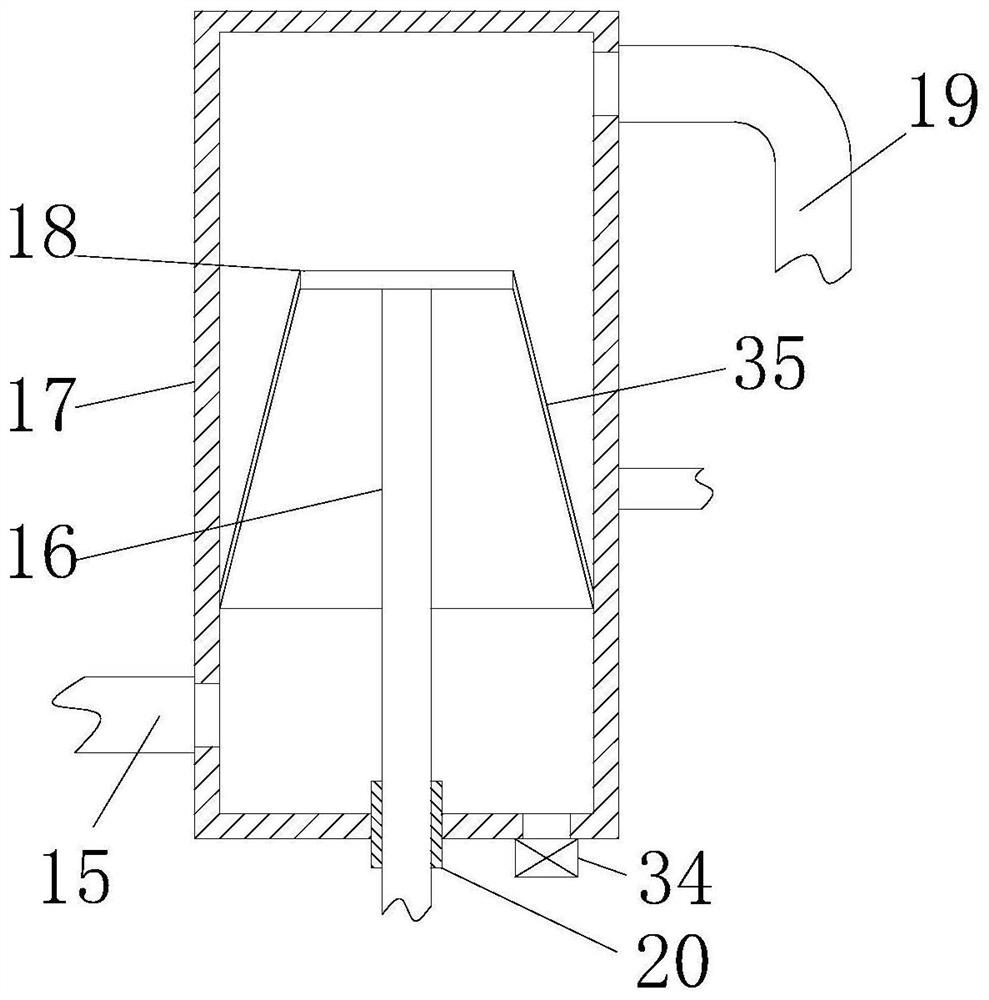

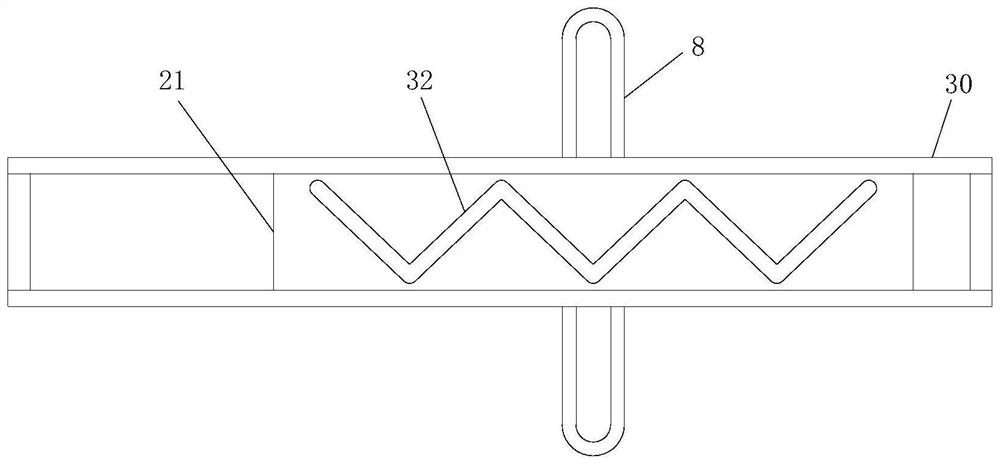

PendingCN114011215AAchieve dust removalDesulfurization achievedGas treatmentDispersed particle filtrationFiltrationExhaust fumes

The invention relates to a dust removal and desulfurization process for industrial waste gas. The dust removal and desulfurization process is characterized by comprising the following steps: S1, designing a waste gas dust removal and desulfurization device; S2, during working, starting a motor (9) of the waste gas dust removal and desulfurization device, allowing the motor to drive an impeller in a pump impeller (11) to rotate through a rotating shaft (10), so that the pump impeller conveys the industrial waste gas to be subjected to dust removal and desulfurization into a dust filtering mechanism through a second gas pipe (15) for dust removal treatment, and smoke dust in the industrial waste gas is removed before the industrial waste gas is subjected to desulfurization treatment; and S3, conveying the industrial waste gas subjected to smoke dust filtration into a sleeve (28) through a first gas pipe (19), conveying the industrial waste gas into a gas spraying pipe (4) through the sleeve, then spraying the industrial waste gas into desulfurization treatment liquid in a desulfurization cylinder (36) through small holes in the side wall of the gas spraying pipe to realize desulfurization treatment on the industrial waste gas, and conveying the industrial waste gas subjected to desulfurization treatment to a next treatment process through an exhaust pipe (7).

Owner:成天洪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com