Dust removing device for flue gas discharged from boiler

A technology of dust removal device and flue gas, which is used in combination devices, transportation and packaging, dispersed particle filtration, etc., can solve the problems of inconvenient disassembly and replacement of filter components, time-consuming and laborious cleaning of filter components, and poor desulfurization effect. Save time and effort, enhance the desulfurization effect, and improve the efficiency of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

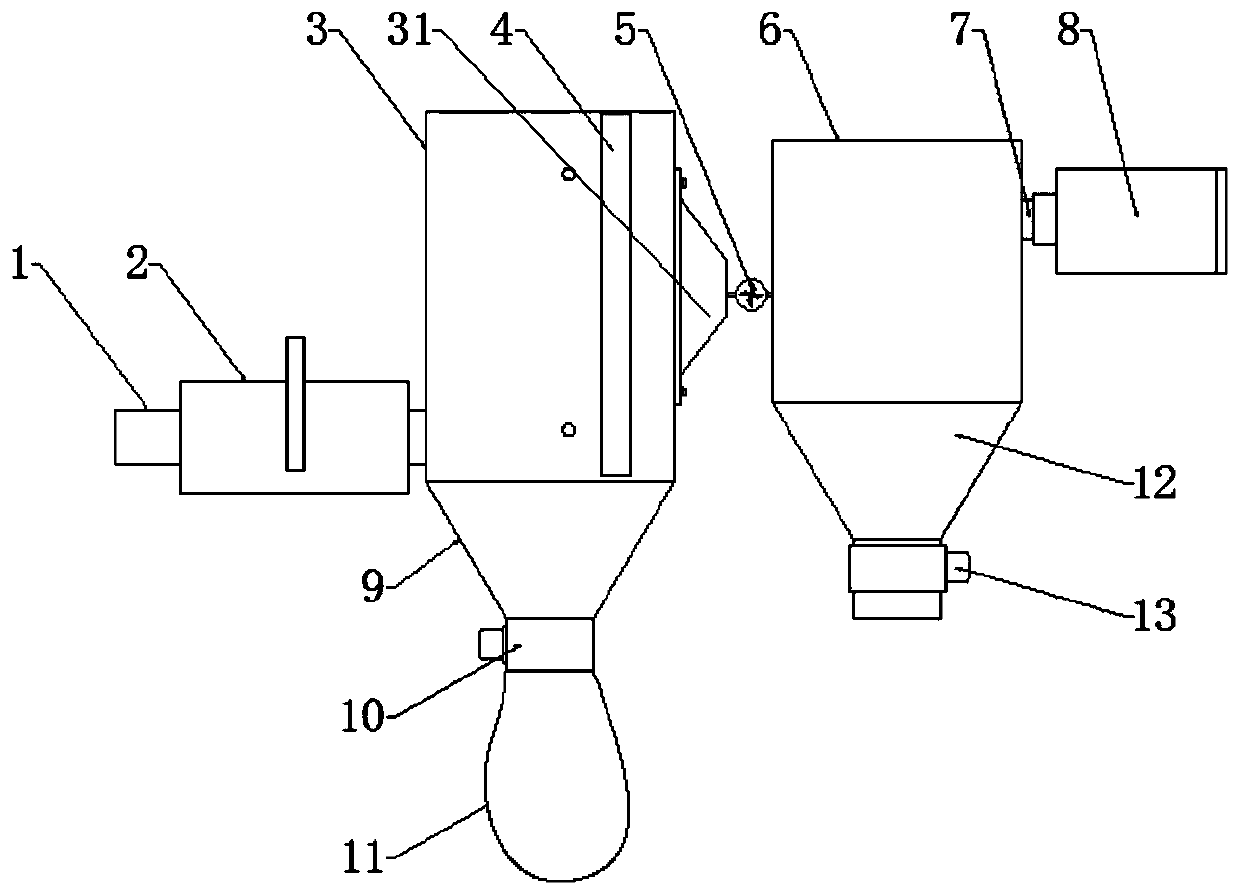

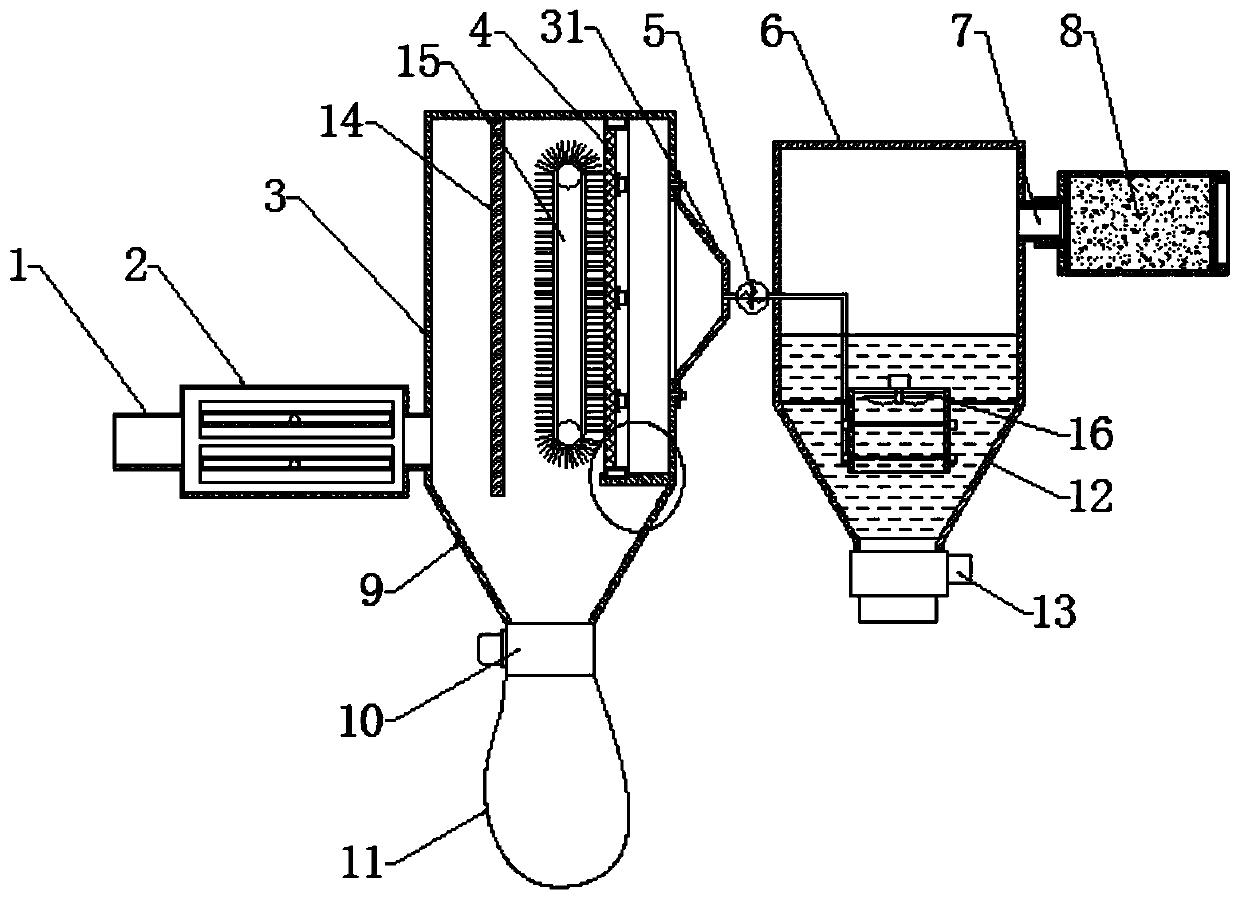

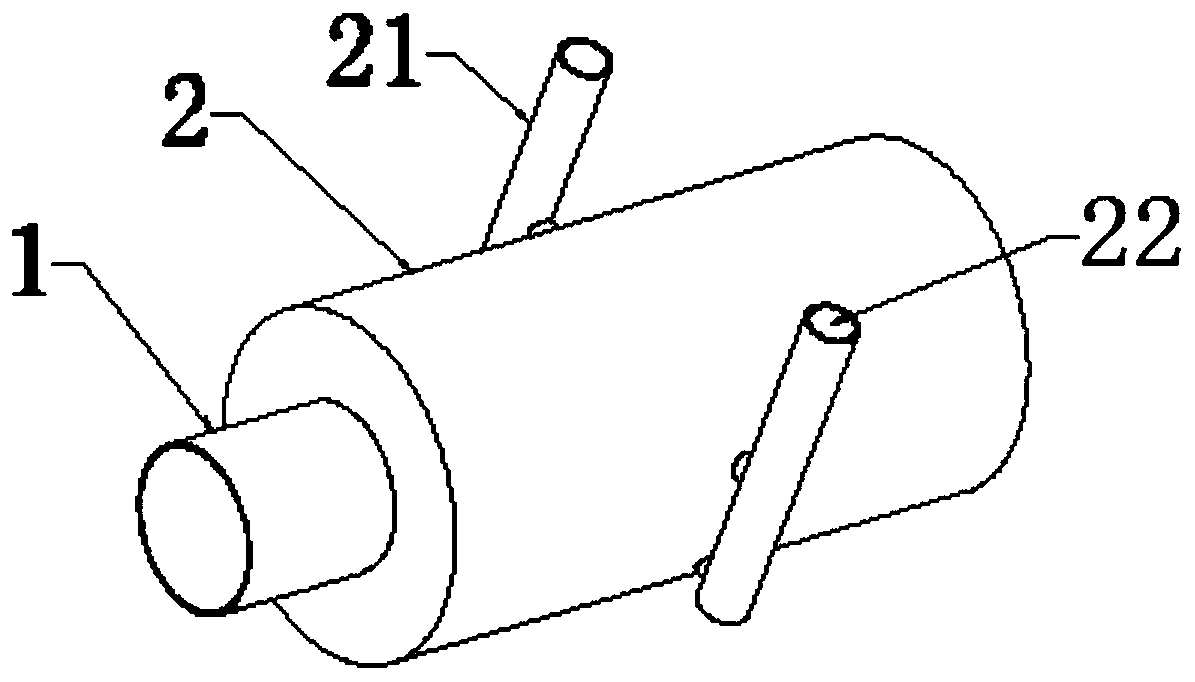

[0034] Embodiment 1, please refer to figure 1 and photos figure 2 , including a smoke inlet pipe 1, a filter box 3, a desulfurization box 6 and a smoke exhaust pipe 7, the smoke inlet pipe 1 inhales the boiler flue gas, and the smoke outlet at the right end of the smoke inlet pipe 1 is connected with a waste heat recovery device 2, and the waste heat recovery device The outlet end of 2 is connected to the air inlet at the left end of the filter box 3 through a pipeline. The waste heat recovery device 2 realizes the recovery and utilization of the waste heat in the flue gas. The lower end of the filter box 3 is provided with an ash collecting hopper that communicates with the inner cavity of the filter box 3. 9, and a first electric valve 10 is arranged at the outlet of the lower end of the ash collecting hopper 9, and a dust collecting bag 11 is set at the outlet of the lower end of the first electric valve 10, and the ash collecting hopper 9 realizes the concentration of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com