Electrolyte Delivery System

a technology of electrolyzer and electrolyte, which is applied in the direction of engine starters, electric control, machines/engines, etc., can solve the problems of increasing the price of gasoline and other petroleum products, and affecting the efficiency of electrolyzers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

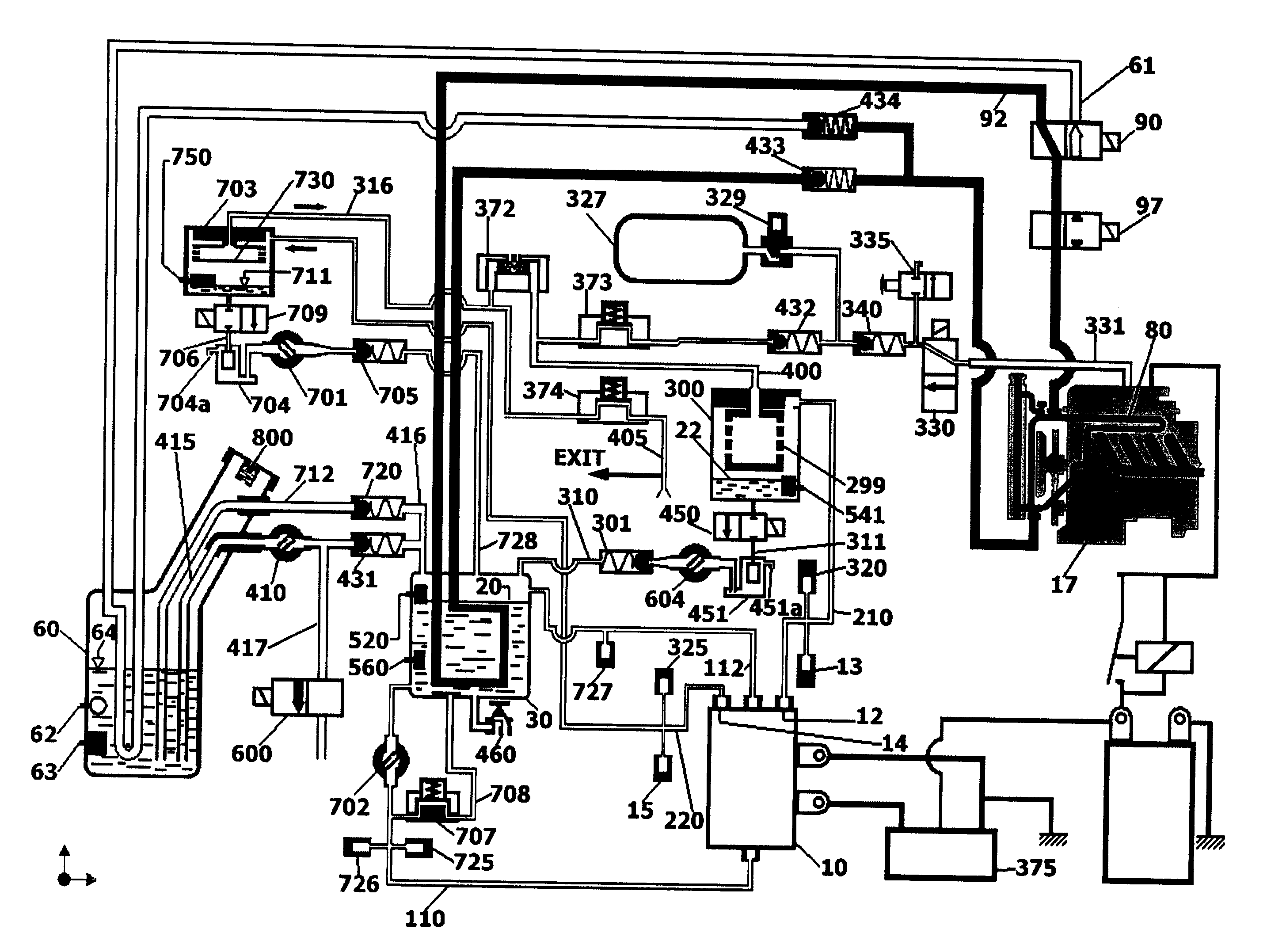

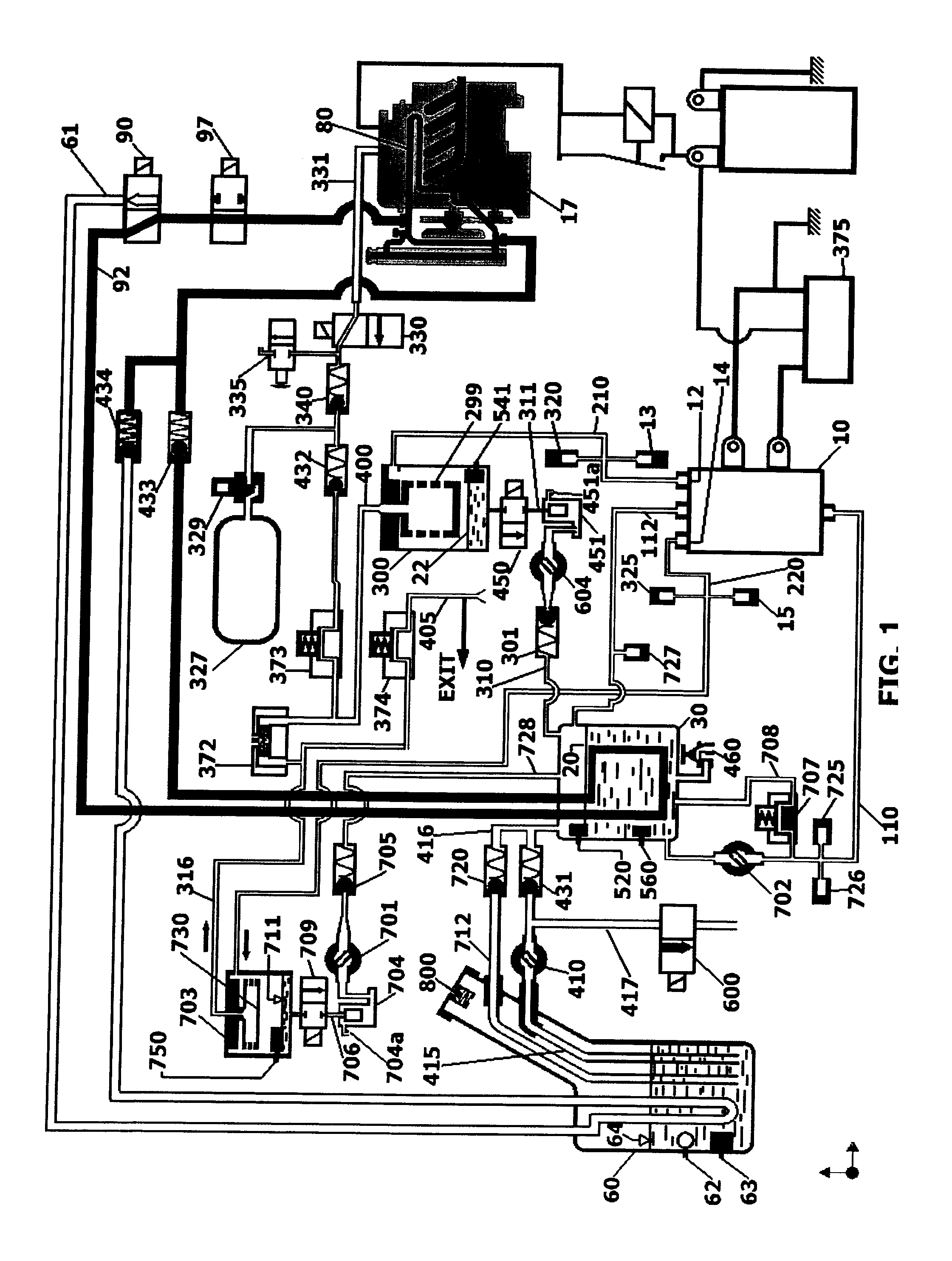

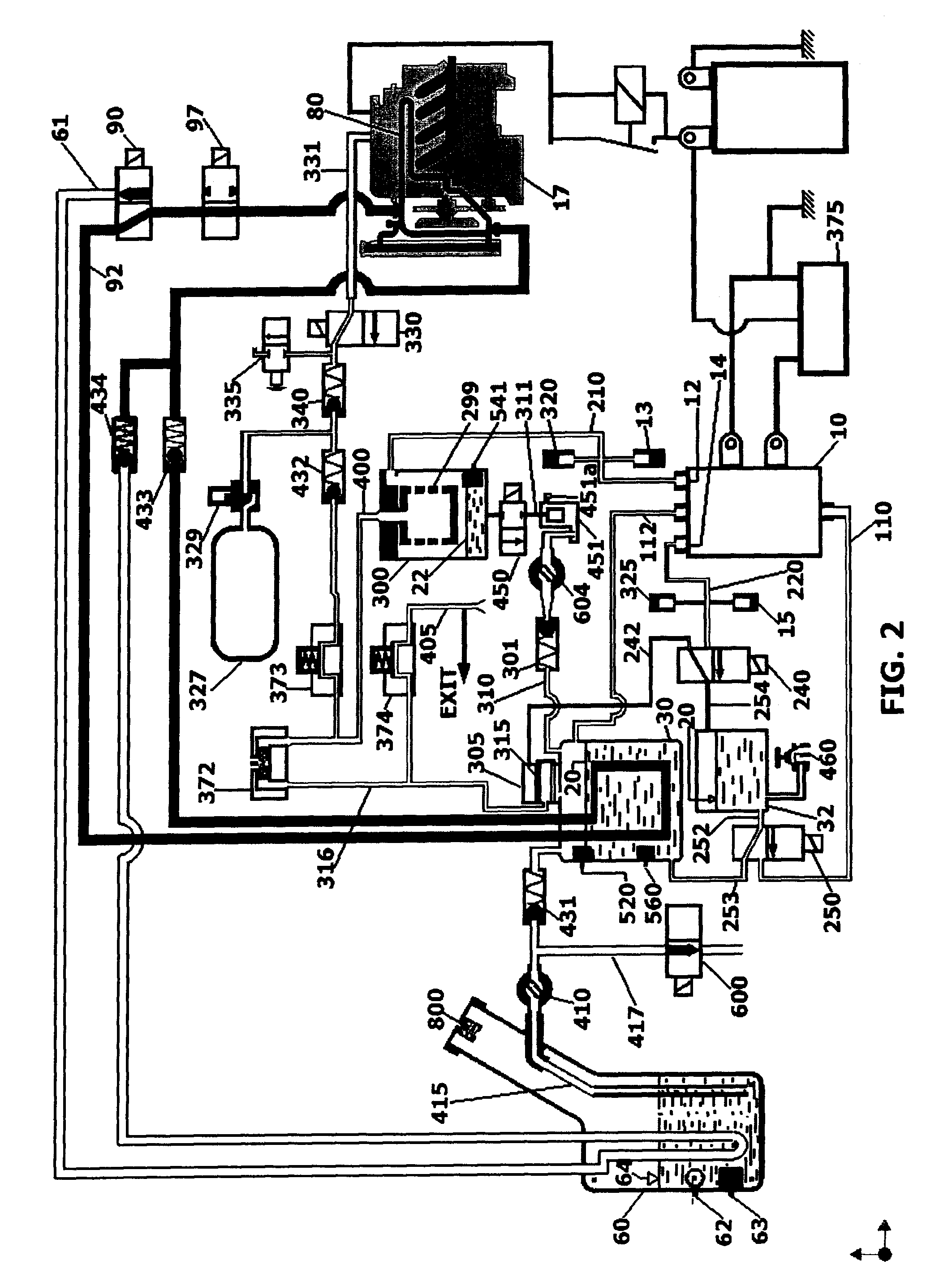

[0012]In one aspect the invention provides an electrolyte supply system for supplying a liquid containing an electrolyte to at least one electrolysis cell providing hydrogen gas to a combustion engine having an engine coolant system for circulating a coolant liquid, comprising at least one coolant liquid conduit in thermal communication with the liquid containing the electrolyte and in fluid communication with a portion of the engine coolant system in which the coolant liquid has been heated by the engine when the engine is running, whereby the heated liquid coolant is diverted from the engine coolant system and circulated through the heating system to transfer heat to the liquid containing the electrolyte.

[0013]In a further aspect the invention provides a method for pre-heating a liquid containing an electrolyte for supplying the electrolyte to at least one electrolysis cell providing hydrogen gas to a combustion engine, the engine having an engine coolant system for circulating a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com