Fine desulfurization device and fine desulfurization method for blast furnace gas

A desulfurization device and blast furnace gas technology, which is applied in the direction of gas dust removal, energy efficiency improvement, combustible gas purification, etc., can solve the problems of high operating costs, scattered user sites, repeated investment, etc., to improve desulfurization efficiency and stability, and facilitate storage with the effect of incorporating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

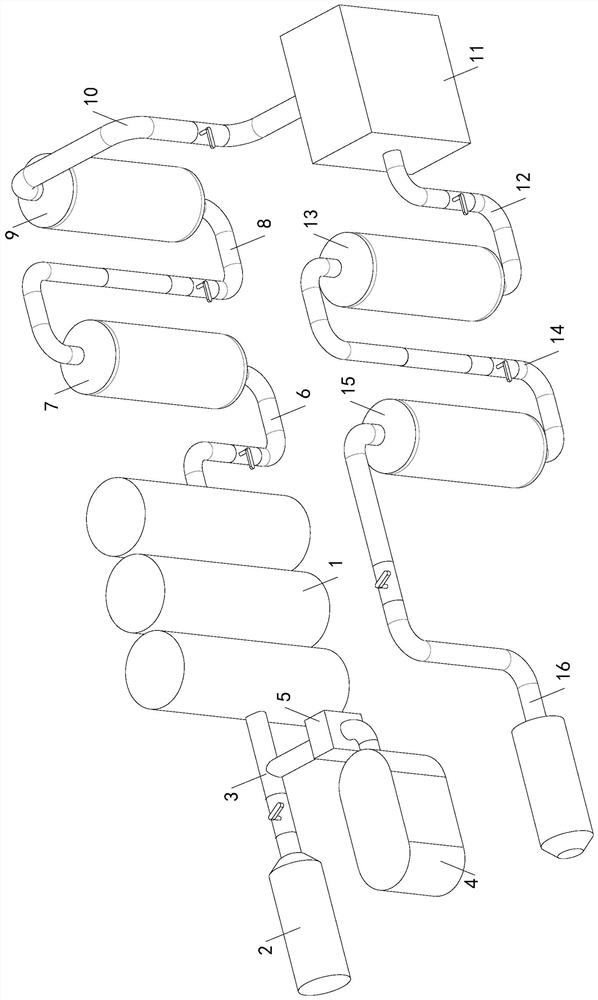

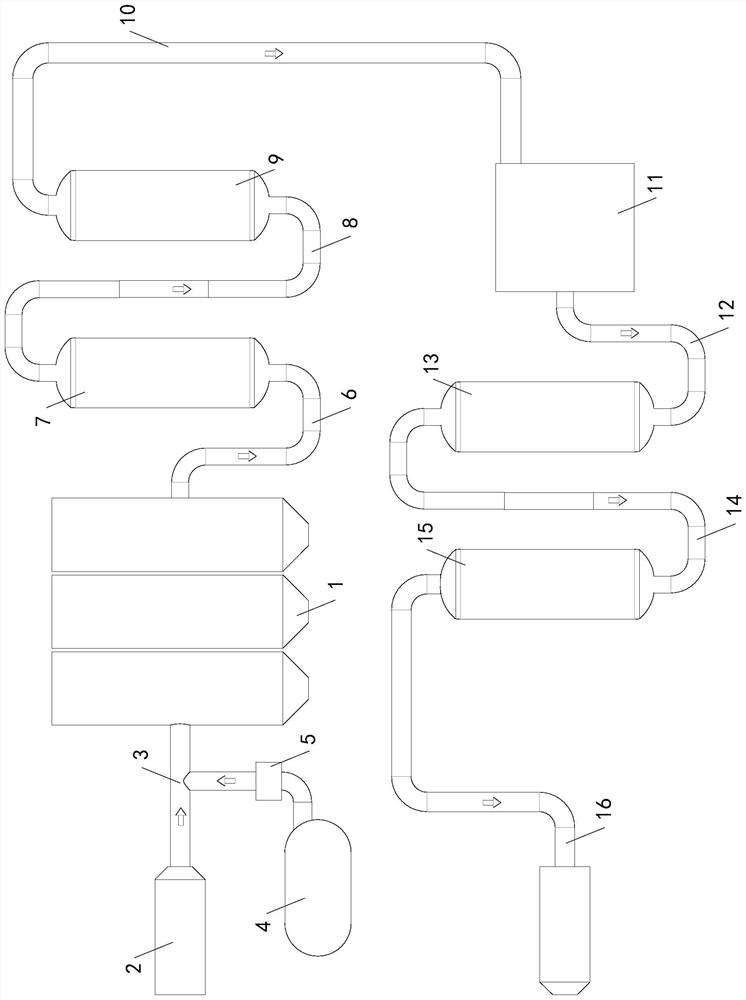

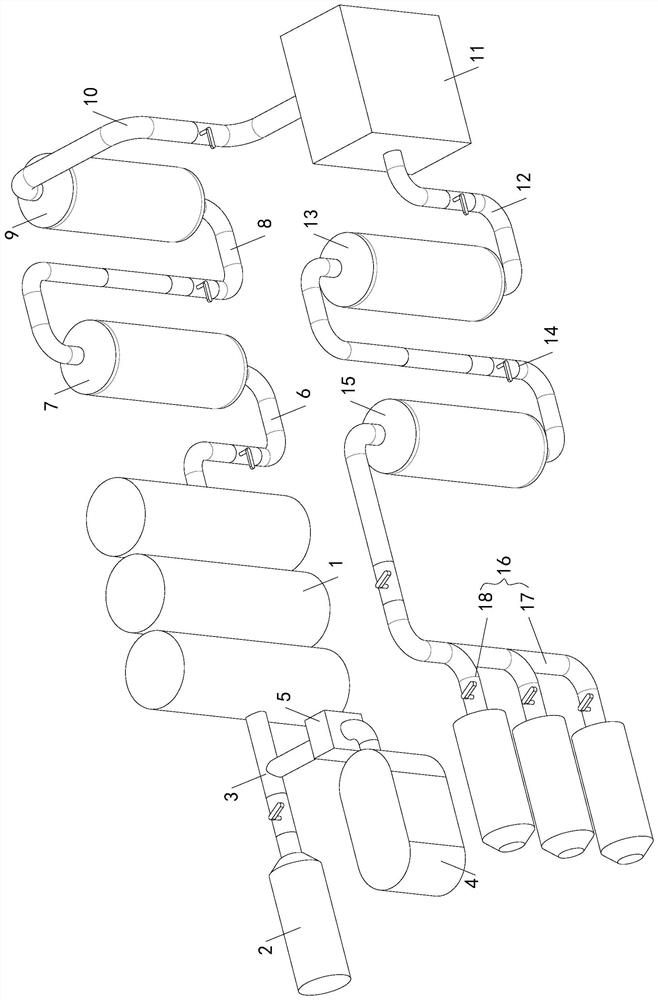

[0031] see Figure 1-4 , a blast furnace gas fine desulfurization device, including a bag filter 1 for bag dust removal, and a heat recovery system 2 for recovering blast furnace gas. The heat recovery system 2 is connected with the bag filter 1 through a three-way front pipe 3, And the tee front pipe 3 is communicated with a liquid phase detoxification catalyst replenishment device 4, a delivery pump 5 is installed between the liquid phase detoxification catalyst replenishment device 4 and the tee front pipe 3, and the liquid phase detoxification catalyst replenishment device 4 There is a liquid phase detoxification catalyst inside, and the liquid phase detoxification catalyst replenishment device 4 is equipped to realize the online injection of the liquid phase detoxification catalyst to assist in the treatment of inorganic acid ions such as HCl, HF, HBr, and HCN in the blast furnace gas. It is convenient to assist the subsequent bag filter 1 to remove most of the poisons in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com