Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Delayed initial setting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reactive magnesium oxide cements

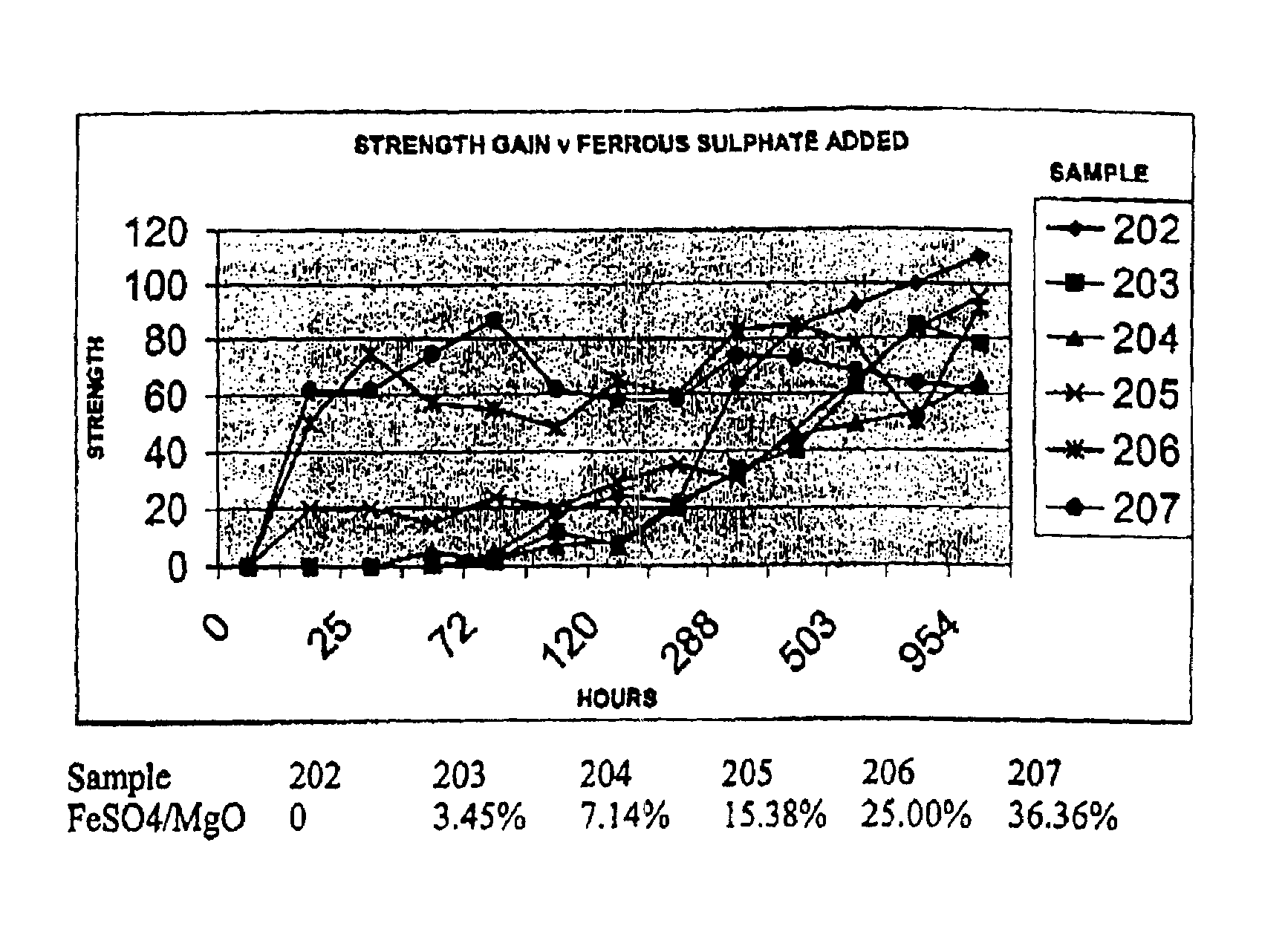

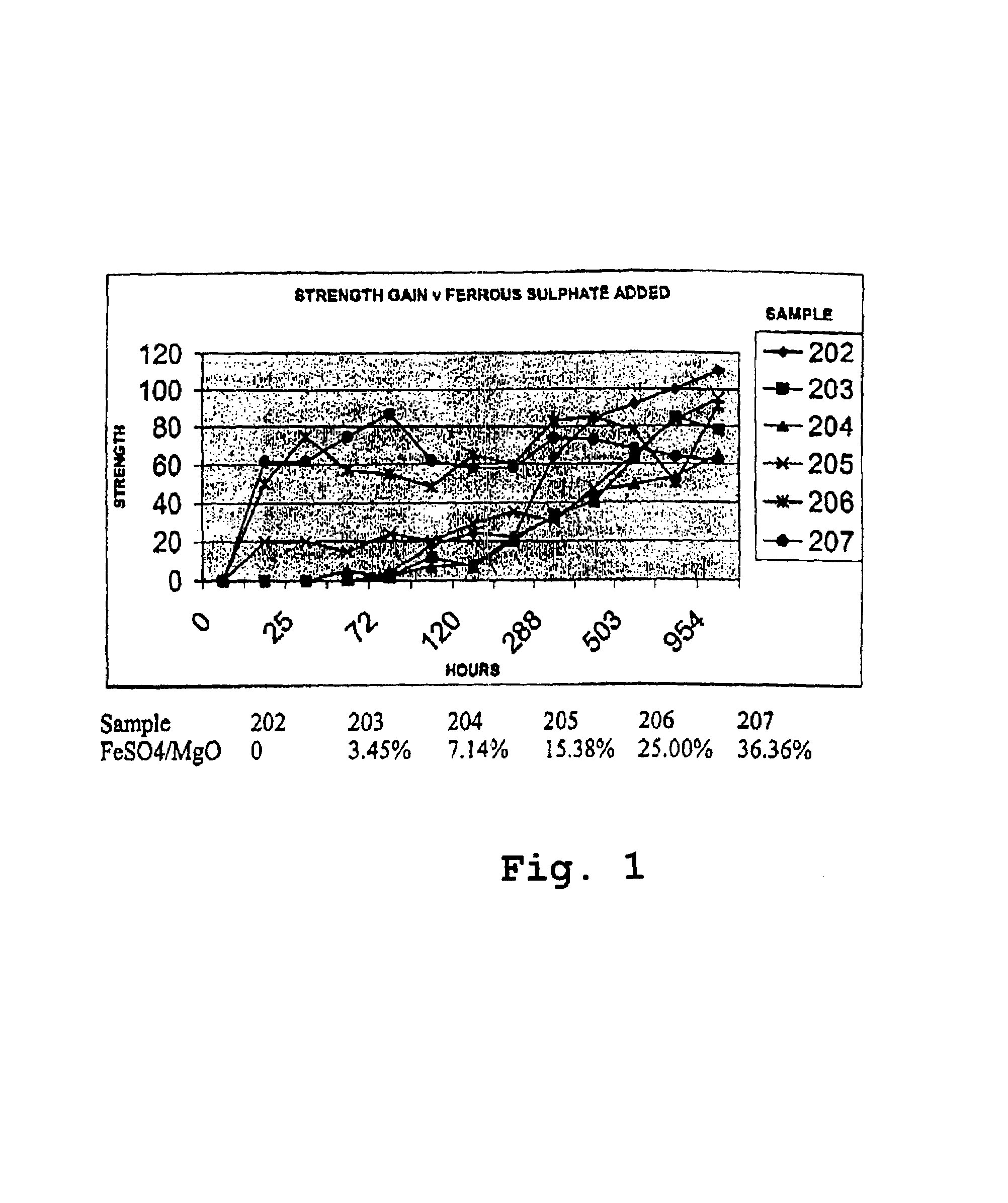

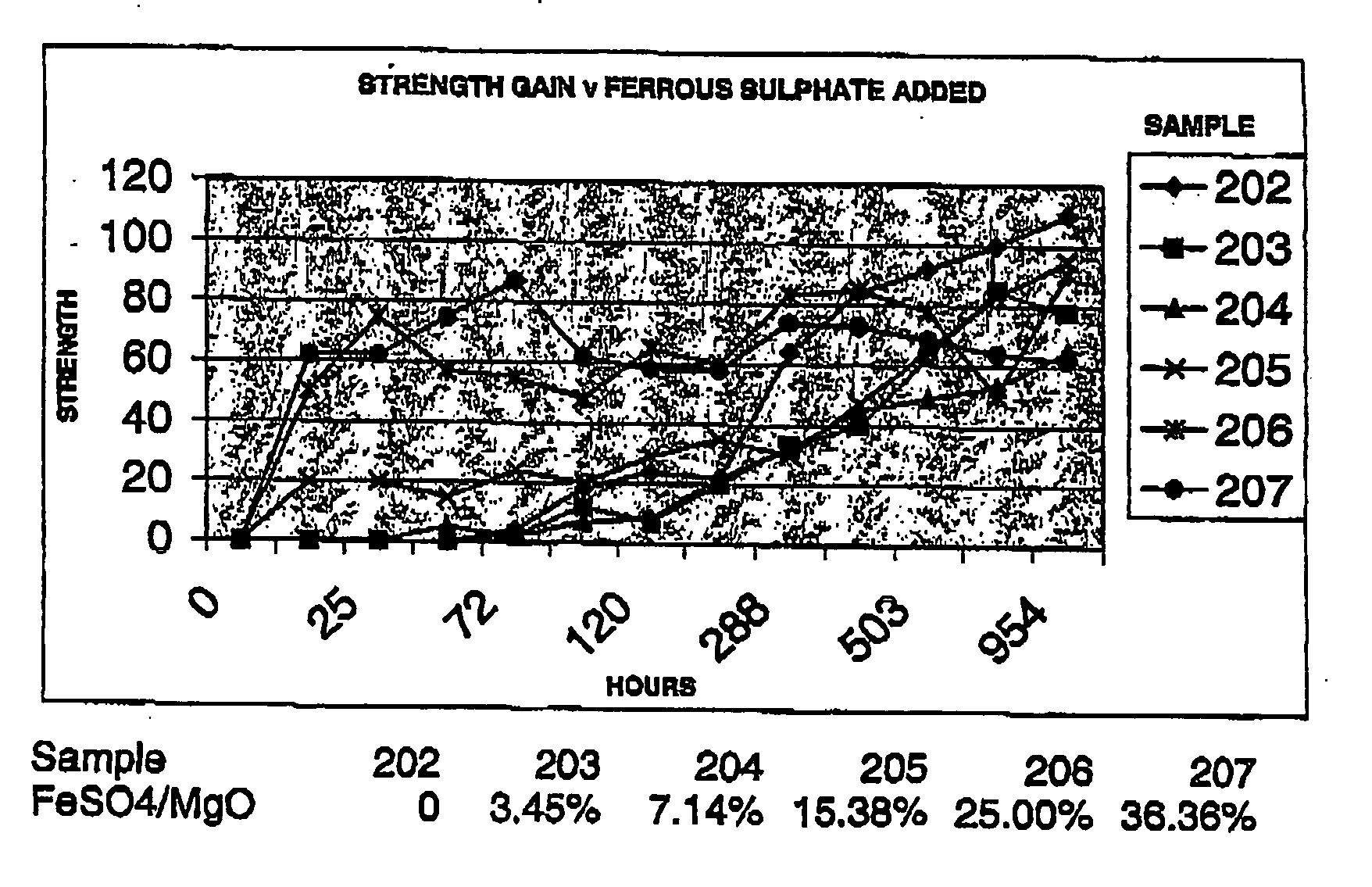

Novel hydraulic cements are disclosed that include reactive magnesium oxide prepared by low temperature calcination. The cements can be formulated to suit a large number of applications with various setting times, strength and levels of sustainability either by adding iron salts such as ferrous sulfate or blending with other compatible faster setting hydraulic cements such as Portland cement or by using both methods.The compositions are able to incorporate relatively large amounts of low cost pozzolans such as fly ash to advantage as well as wastes. Many excellent properties are exhibited and in particular good comprehensive strength and resistance to sulfates is able to be achieved.

Owner:TECECO

Preparation of gypsum compositions

ActiveUS7070648B1Delayed initial setting timeReduce the amount of waterCeilingsCovering/liningsSulfonateSlurry

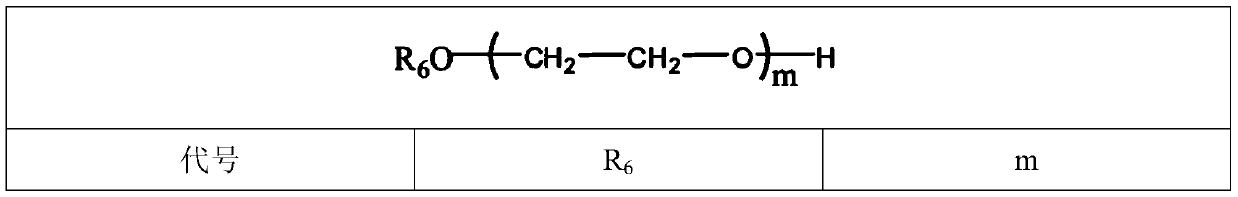

A gypsum composition containing a sulfonate-containing comb-branched copolymer is disclosed. The sulfonate-containing comb-branched copolymer comprises recurring units of a polyether macromonomer, an acrylic monomer, and a sulfonate monomer. The sulfonate-containing comb-branched copolymer not only increases the fluidity of gypsum slurry but also has reduced retardation on the gypsum setting.

Owner:COATEX SA

Reactive magnesium oxide cements

Novel hydraulic cements are disclosed that include reactive magnesium oxide prepared by low temperature calcination. The cements can be formulated to suit a large number of applications with various setting times, strength and levels of sustainability either by adding iron salts such as ferrous sulfate or blending with other compatible faster setting hydraulic cements such as Portland cement or by using both methods. The compositions are able to incorporate relatively large amounts of low cost pozzolans such as fly ash to advantage as well as wastes. Many excellent properties are exhibited and in particular good comprehensive strength and resistance to sulfates is able to be achieved.

Owner:TECECO

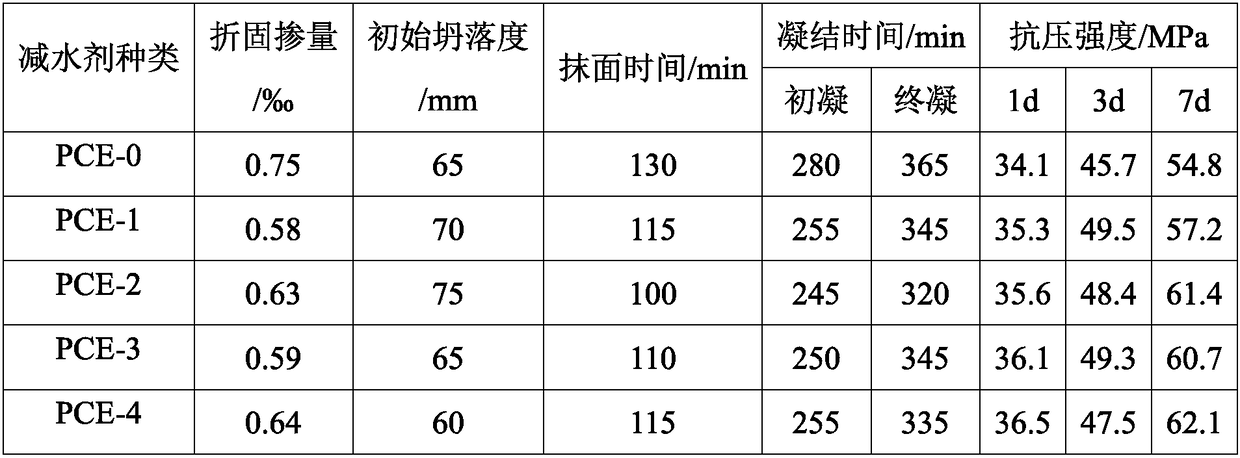

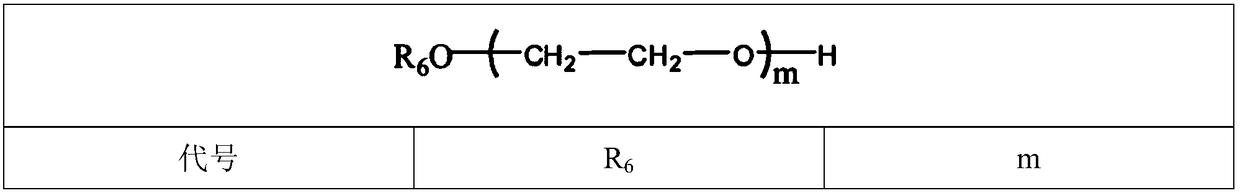

Rapid-hardened super-early strength polycarboxylate water reducer and preparation method thereof

The invention discloses a rapid-hardened super-early strength polycarboxylate water reducer and a preparation method thereof. According to the rapid-hardened super-early strength polycarboxylate waterreducer disclosed by the invention, by using a molecular cutting technique, molecular structures of main chain groups, side chain groups and the like are designed, a polyether monomer of a super-highmolecular weight is adopted as an active large monomer, a structure with a long side chain and a short main chain is formed by molecular chains, a small monomer of self-made unsaturated alcohol aminoester and small monomers such as ethyl methacrylate with N groups and triallylamine are introduced, and solution polymerization is carried out at a low temperature. The synthesized polycarboxylate water reducer has an outstanding function of promoting cement hydration reactions, can be applied to steam-curing concrete, low-temperature environment concrete and concrete with a requirement of demolding in advance, is capable of remarkably shortening the plastering and primary curing time of a molded plate, has a remarkable early strength effect, and is capable of accelerating the construction progress of concrete and increasing the transfer rate of mold plates.

Owner:KZJ NEW MATERIALS GROUP CO LTD

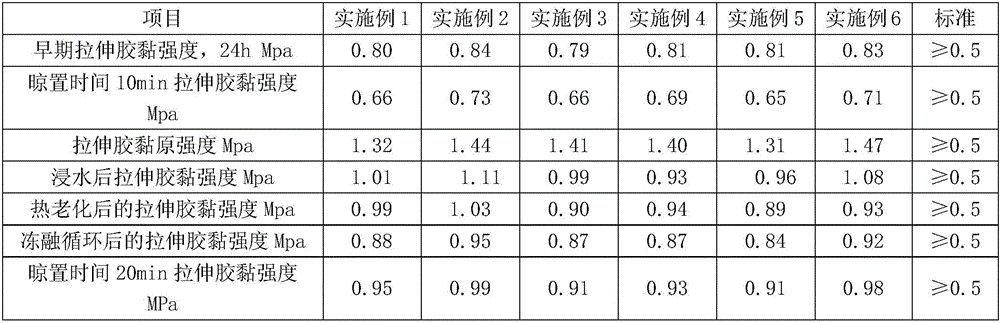

Quickly-solidified tile adhesive

A quickly-solidified tile adhesive comprises the raw materials in parts by weight: 20-40 parts of quick-hardening cement, 40-50 parts of quartz sand, 10-20 parts of fly ash, 10-20 parts of calcium carbonate, 2-4 parts of redispersible latex powder, 0.2-0.5 part of cellulose ether, 0.1-0.3 part of starch ether, 0.2-0.5 part of water repellent, 0.1-0.4 part of retarder and 1-5 parts of early strength agent. The quick-hardening cement, the quartz sand and the fly ash are used as raw materials to prepare the quickly-solidified tile adhesive, the adhesive is short and adjustable in initial setting time, the strength growth is fast, the fixed waste fly ash generated by thermal power plants is effectively utilized, the adhesive also contains organic high-molecular polymer capable of being compounded with the ceramic tile and the indoor environment pollution cannot be caused.

Owner:山东汉诺宝嘉新材料科技有限公司

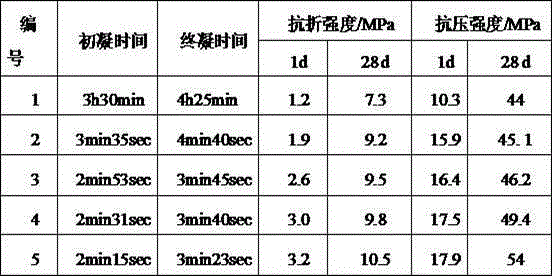

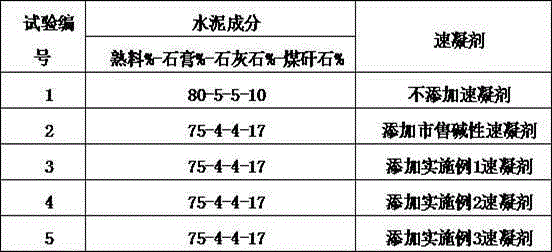

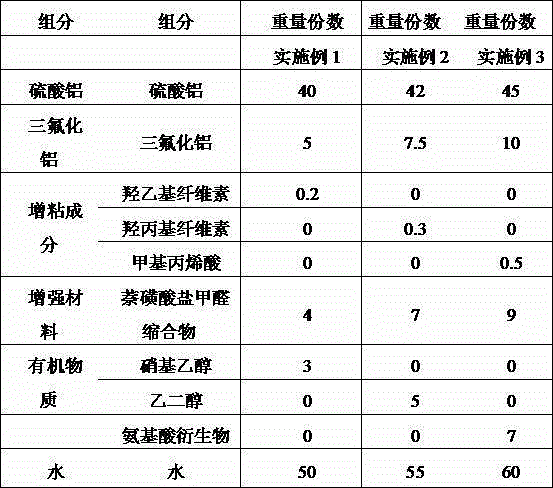

Alkaline-free liquid cement accelerator and using method therefor

The invention belongs to cement auxiliaries and particularly relates to an alkaline-free liquid cement accelerator and a using method therefor. The alkaline-free liquid cement accelerator is prepared from the following components in parts by weight: 40-45 parts of aluminum sulfate, 5-10 parts of aluminum trifluoride, 0.2-0.5 part of a tackifying component, 4-9 parts of a reinforcing material, 3-7 parts of organic matters and 50-60 parts of water. The accelerator for a cement processing process provided by the invention has an adjusting effect on the cohesion time of cement, is free of corrosion and toxicity, causes no corrosive damages on the skin and body of constructors, and has no adverse influence on durability of concrete.

Owner:仇鹏

Preparation method of high-thixotropy early-strength type polycarboxylate superplasticizer

ActiveCN105504180APromotes early hydrationPromotes the function of hydration reactionVinyl etherSuperplasticizer

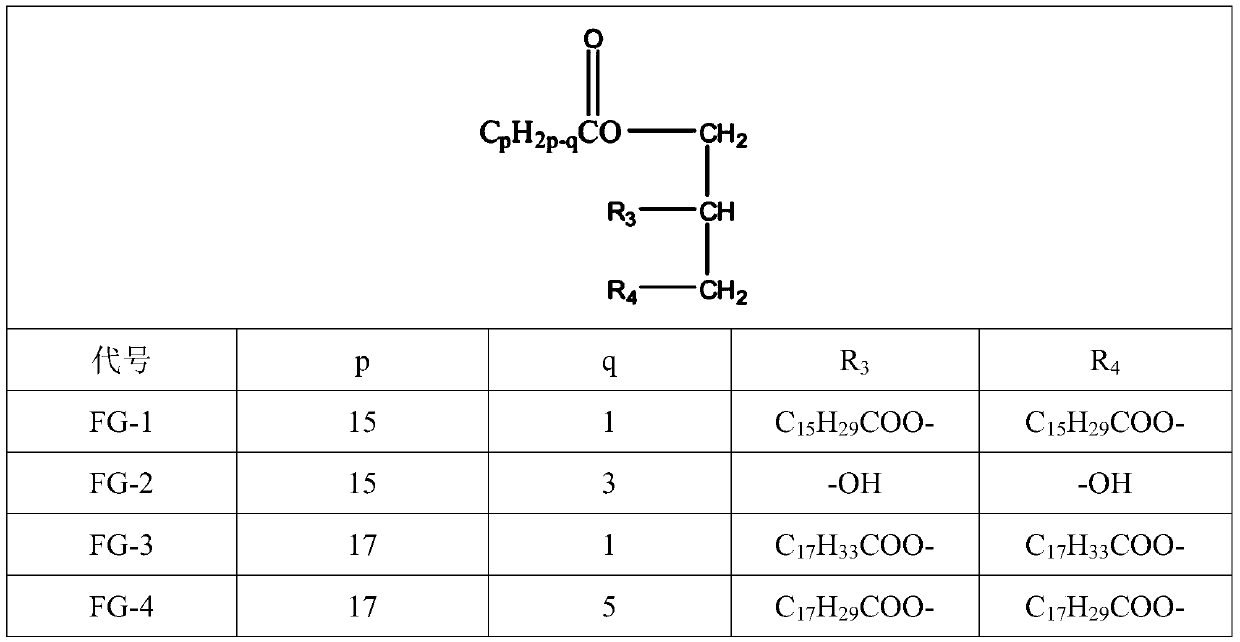

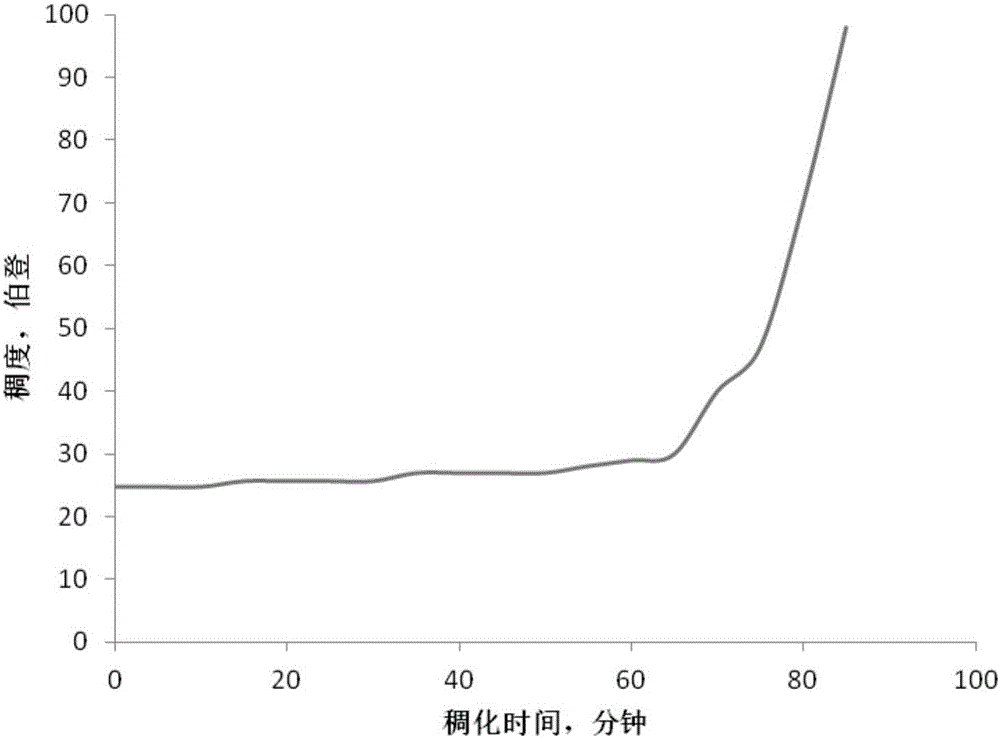

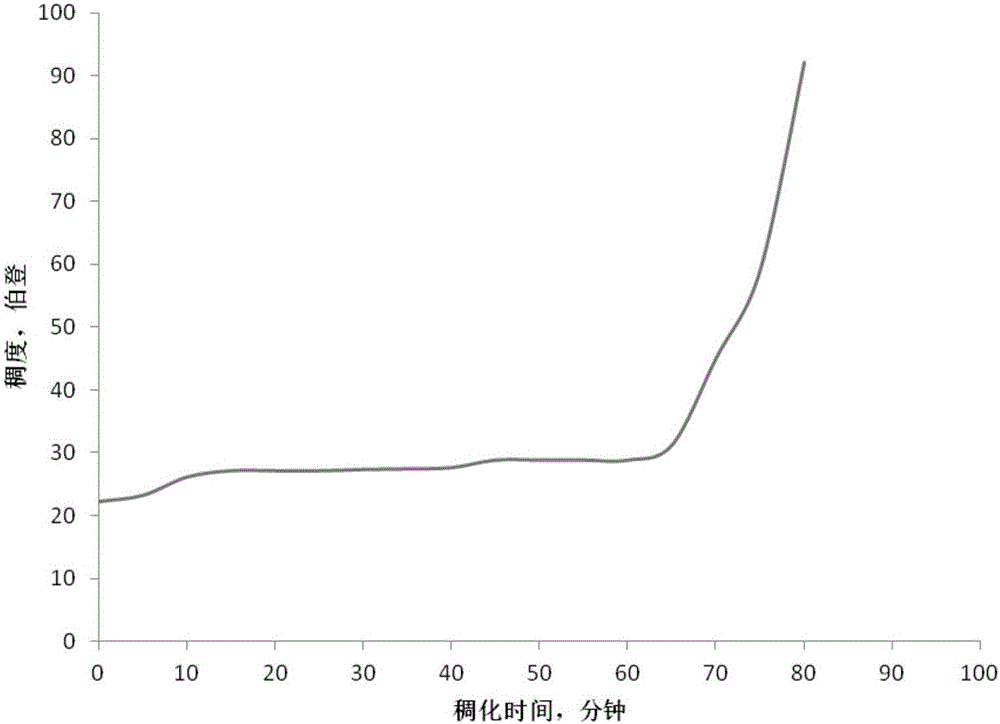

The invention discloses a preparation method of a high-thixotropy early-strength type polycarboxylate superplasticizer. The preparation method comprises the following steps of (1) adding isobutene polyoxyethylene ether and / or isopentene polyoxyethylene ether, micromolecular polyether, unsaturated fatty acid glyceride, a quaternary ammonium salt monomer and an oxidant into water, and stirring the mixture under 15 to 30 DEG C until the mixture is dissolved; (2) preparing a first solution by a reducing agent and water, preparing a second solution by a chain transfer agent and the water, and preparing a third solution by unsaturated monocarboxylic acid, an unsaturated carboxylic ester monomer and the water; (3) dropping the first solution, the second solution and the third solution in materials in step (1) within 3 to 4 hours at the same time, and carrying out a heat-preservation reaction for 1 to 1.5 hours under 35 to 40 DEG C after dropping is completed; (4) adding an alkaline modifier to neutralize the pH (Potential Of Hydrogen) to be 6 to 7 after the reaction of the materials in step (3) is completed, thus obtaining the high-thixotropy early-strength type polycarboxylate superplasticizer. The high-thixotropy early-strength type polycarboxylate superplasticizer prepared by the invention has an excellent thixotropic property.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Wide spectrum chlorine-free coagulation accelerating early strength agent for oil field oil well cement

ActiveCN106186777AImprove anti-channeling abilityImprove top strengthDrilling compositionOXALIC ACID DIHYDRATEApatite

The invention relates to a wide spectrum chlorine-free coagulation accelerating early strength agent for oil field oil well cement. The early strength agent comprises the following raw materials in parts by weight: 1 to 1.5 parts of sodium salts, 1 to 1.5 parts of calcium salts, 1 to 1.5 parts of aluminum salts, and 1 to 1.5 parts of other materials, wherein other materials are one or more of hydroxyl apatite, meta-kaolin, magnesium trisilicate, magnesium oxide, strontium sulfate, strontium carbonate, strontium nitrate, lithium carbonate, and oxalic acid. The provided early strength agent is stable, and has an excellent coagulation accelerating performance and early strength property; the early strength is high, the strength development is fast, the thickening transition time and primary-final setting transition time are short; and the early strength agent is suitable for various cement slurry systems such as cement slurry system with a wide temperature range and large temperature difference, AMPS cement slurry system, and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Early strength type polycarboxylate superplasticizer and preparation method thereof

PendingCN109608594AGood early strength development rateGood flow dispersionPolymer scienceSide chain

The invention relates to the technical field of concrete additives in building materials, specifically to an early strength type polycarboxylate superplasticizer and a preparation method thereof. Theearly strength type polycarboxylate superplasticizer is prepared from the following raw materials through a polymerization reaction: block unsaturated polyoxyethylene ether, acrylic acid, a functionalmonomer, a chain transfer agent, an oxidative initiator and a reductive initiator. According to the invention, the block unsaturated polyoxyethylene ether is adopted as a raw material, and a macromolecular block polyether side chain can improve the water-reducing rate performance of a superplasticizer, also exerts the performances of early strength, viscosity reduction and shrinkage resistance, greatly reduces the content of air, shortens the setting time of concrete and has excellent working performance and adaptability.

Owner:广东奥克化学有限公司

Preparation method of concrete coagulant

InactiveCN108164176ADelayed initial setting timeImprove adsorption capacityUltimate tensile strengthSepiolite

The invention discloses a preparation method of a concrete coagulant, and belongs to the technical field of cement admixtures. The preparation method comprises the following steps: sequentially weighing the following components in parts by weight: 4-6 parts of sodium metaaluminate, 3-5 parts of calcium oxide, 8-10 parts of modified sepiolite, 15-20 parts of a mixed liquid, 10-12 parts of an addition material, 0.4-0.8 parts of an emulsifier and 0.2-0.3 part of a dispersant, firstly mixing the sodium metaaluminate, the calcium oxide and the modified sepiolite in a stirrer, carrying out stirringand mixing for 10-20min at a temperature of 20-35 DEG C and a rotating speed of 300-380 r / min to obtain a mixed blank, then mixing the mixed blank with the mixed liquid in a mixer, adding the additionmaterial, the emulsifier and the dispersant into the mixer, and carrying out stirring and mixing for 4-8min at a rotating speed of 400-600 r / min, so as to obtain the concrete coagulant. The concretecoagulant obtained by the preparation method provided by the invention has excellent condensation speed and strength.

Owner:蒋春霞

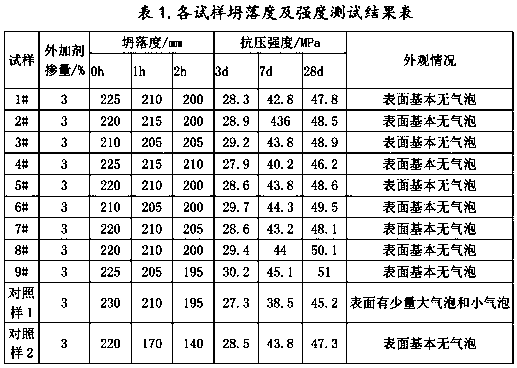

Special additive for bare concrete

The invention discloses a special additive for a bare concrete, relates to the field of concrete additives and aims at solving the problems in the prior art that the adverse effect of the additive onthe fluidity of the concrete is huge and the improvement of the segregation and weeping phenomena is not ideal. The key point of the technical scheme is as follows: the special additive comprises thevarious components by mass percent: 20%-22% of a water reducer, 1.8%-2% of a retarder, 1.5%-1.6% of a thickener, 0.03%-0.05% of an air entraining agent, 0.04%-0.08% of a defoamer, 8%-12% of an early strength agent and the balance of water. The concrete additive at the proportion is low in sensitivity, the influence of the concrete additive on the fluidity of the concrete is easy to control when the additive is doped, the wrapping property and the cohesiveness of a concrete mixture are good, the segregation and weeping phenomena do not occur easily, and the surface of the prepared bare concretebarely has bubbles.

Owner:成都建工预筑科技有限公司

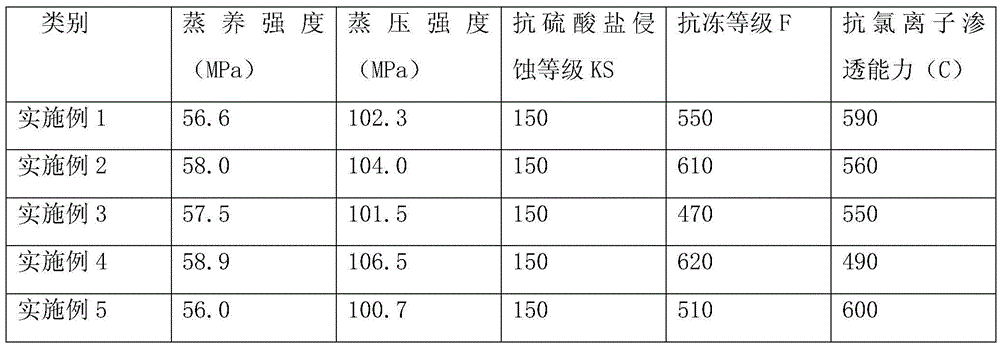

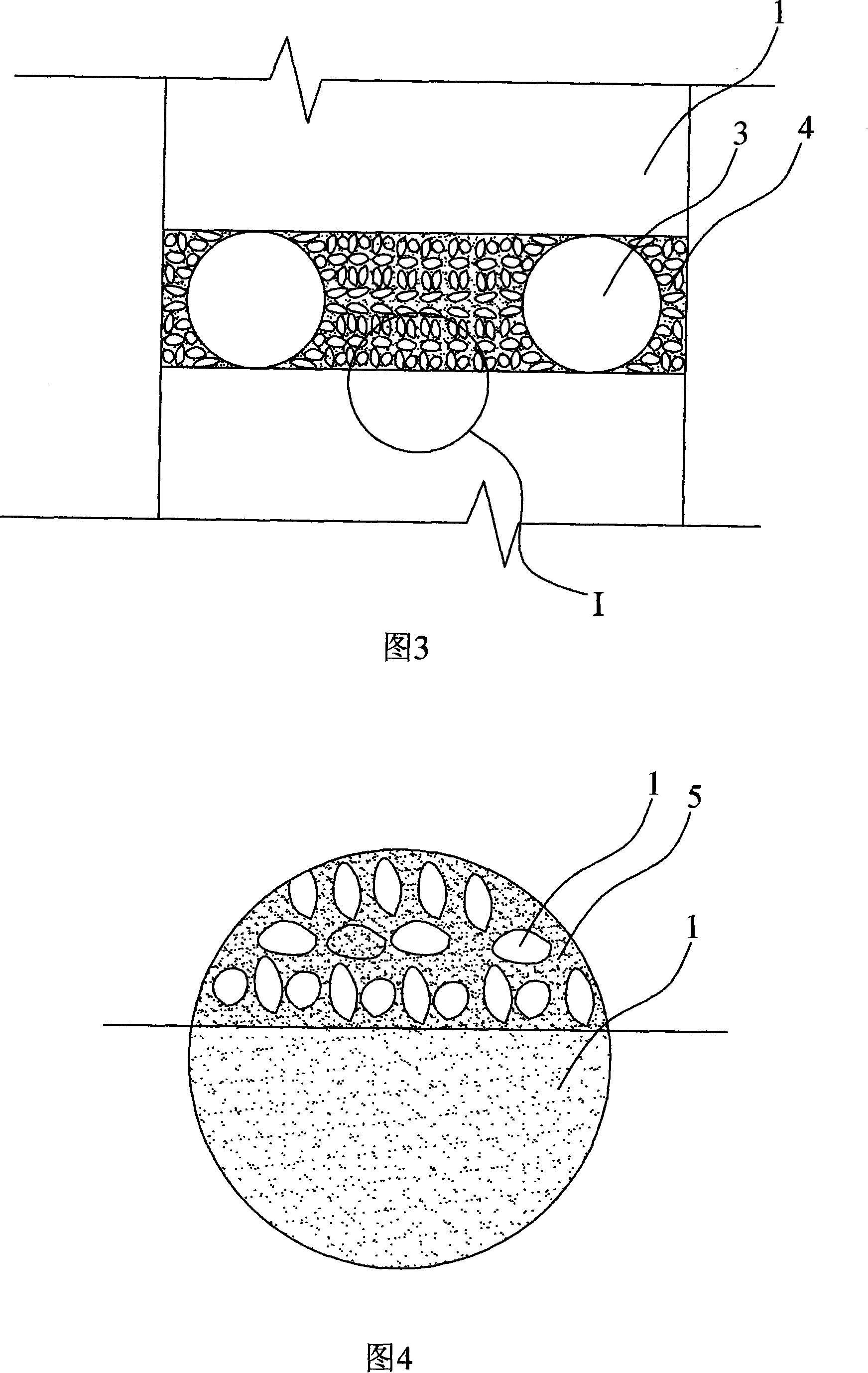

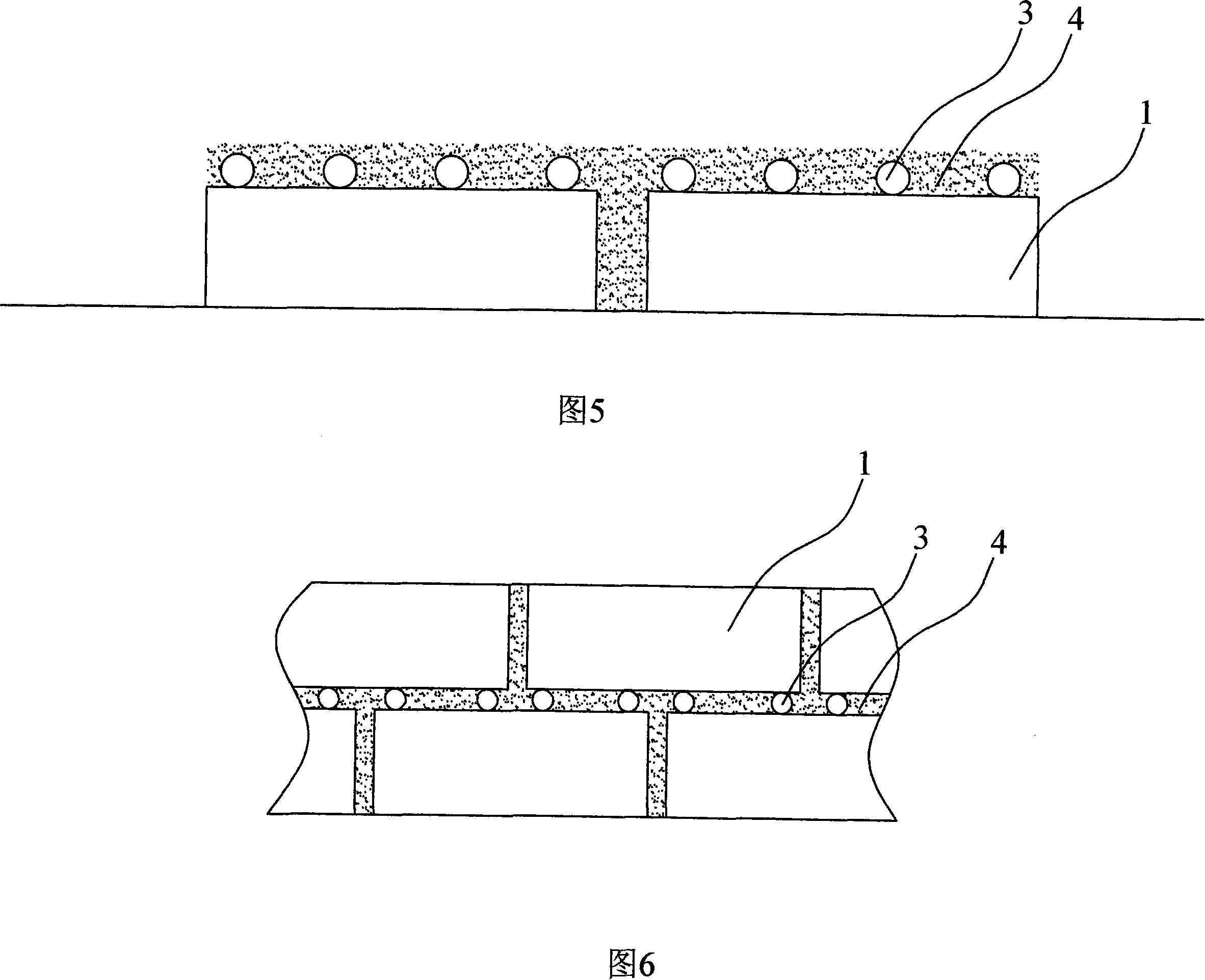

Prestressed concrete pile and production method thereof

InactiveCN104420465AImprove workabilityDelayed initial setting timeCeramic shaping apparatusBulkheads/pilesHigh strength concreteTO-18

The invention discloses a pretressed concrete pile which is casted by pumped high-strength concrete. The pumped high-strength concrete comprises the following ingredients: cement, fine aggregate, coarse aggregate, water, mineral active material, and additive; the additive comprises water reducing agent and retarding admixture; the volume weight of the concrete is 2420 kilograms per cubic meter to 2550 kilograms per cubic meter; in each cubic meter of the concrete, the dosage of the cement is 440 kilograms to 490 kilograms, the dosage of the fine aggregate is 530 kilograms to 560 kilograms, the dosage of the coarse aggregate is 1210 kilograms to 1230 kilograms, the dosage of water is 140 kilograms to 160 kilograms, the mixing amount of the mineral active material is 16% to 18% of the dosage of the cement, the mixing amount of the water reducing agent is 1.8% to 2% of the dosage of the cement, and the mixing amount of the retarding admixture is 0.15% of the dosage of the cement. The invention further discloses a production method of the prestressed concrete pile. The prestressed concrete pile has high strength and good durability.

Owner:QINGDAO XINGHE BUILDING MATERIAL

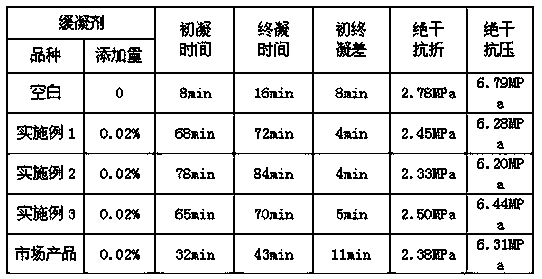

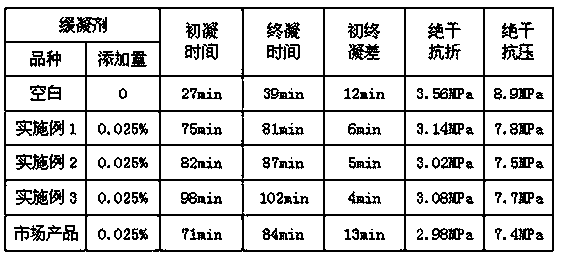

Preparation method of powdery gypsum retarder and product obtained through method

The invention provides a preparation method of powdery gypsum retarder. The method comprises the steps that vegetable protein is preprocessed with alkali liquor, then accelerant is added, and an intermediate product is obtained, the intermediate product and precipitated silica or kieselguhr are mixed at a high speed according to the weight ratio of (2-3):1, and intermediate product powder is obtained; 18.5%-46.5% by weight of intermediate product powder, 53%-79.5% by weight of powdery organic acid or organic acid salt and 0.5%-2% by weight of powdery water reducing agent are placed in a mixingmachine to be stirred for 30 min, and then the powdery gypsum retarder is obtained. The preparation method is simple in technology and mild in condition, and the powdery product can be obtained directly without the drying and grinding processes. The invention further provides the powdery gypsum retarder obtained through the preparation method, the retarder can improve the stability of gypsum based building material setting time when the gypsum based building material setting time is prolonged, the initial set time and final set time difference is reduced, the construction efficiency is improved, and the adaptability to various kinds of gypsum is high.

Owner:广东龙湖科技股份有限公司

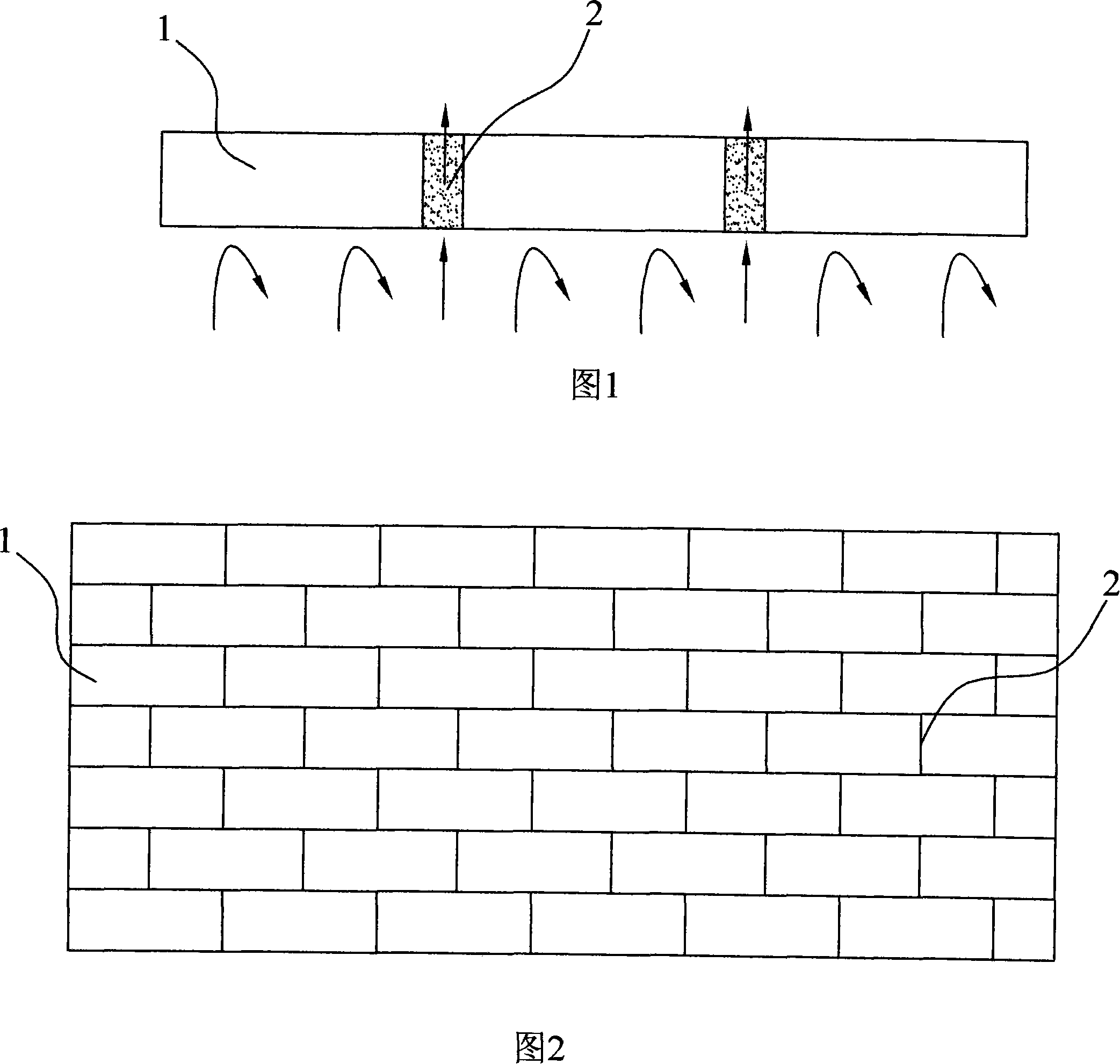

Special masonry mortar for aerated concrete and construction method thereof

InactiveCN101224971ADelayed initial setting timeGuaranteed to proceed normallySolid waste managementCeramicwareHeat resistanceExpanded clay aggregate

The invention discloses a masonry mortar specific to aerated concrete. Each component accounts for weight portions in per 1,000 portion of mortar: 180-250 of cement, 40-62 of gypsum, 120-220 of quick lime, 550-630 of fly ash, 0.07-0.12 of aluminum paste, 0.3-0.5 of retarder. The fly ash ceramisite is blended with the mortar as well. The invention also provides a construction method for masonry mortar specific to the aerated concrete, the steps are that: a. each raw material is measured by the formula; b. then the raw material is stirred by ratio of 1,000 kg of mortar to 515 kg of water; c. 3 to 4.2 percent of the fly ash ceramisite is blended to stir; d. 13 to 15 mm of construction and pulp distribution is made. As the invention has the same heat resistance effect as the aerated concrete, the problem of the heat loss caused by the heat bridge formed by common mortar, which needs to be settled urgently, is resolved.

Owner:GESHAN CONSTR GROUP

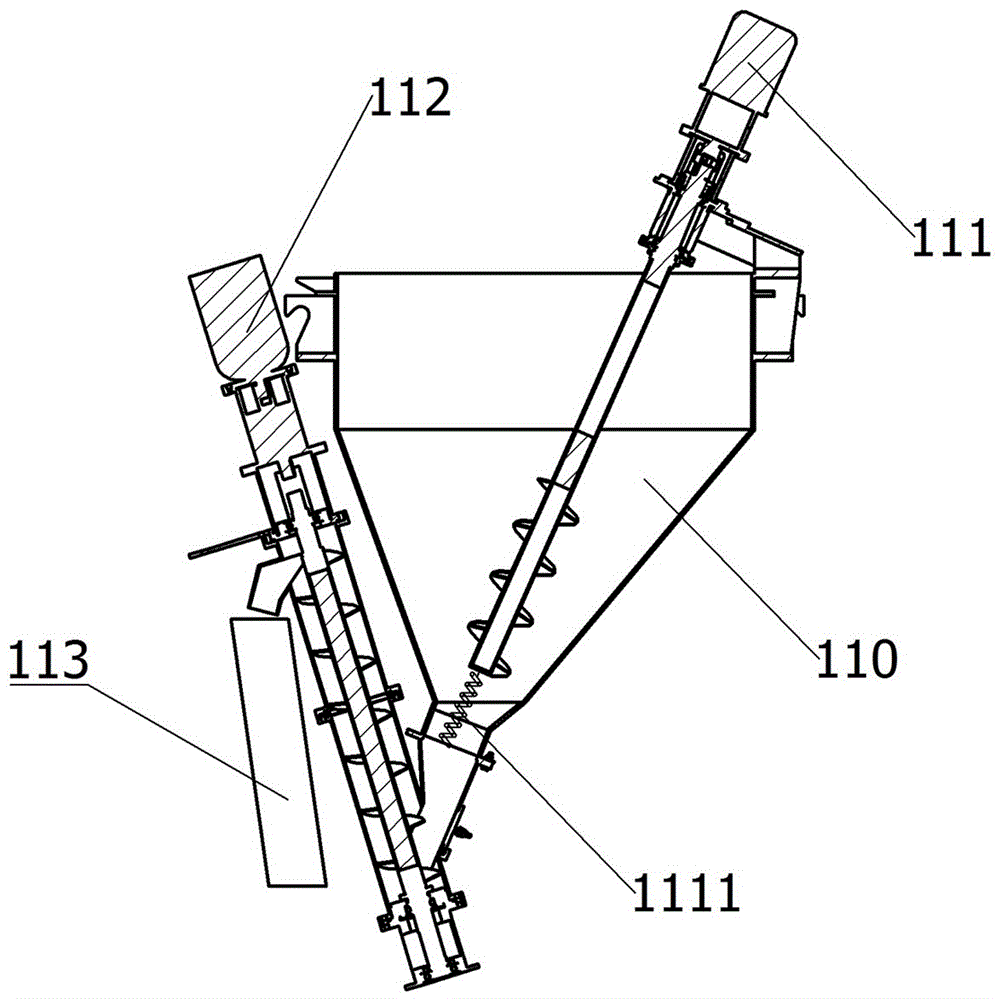

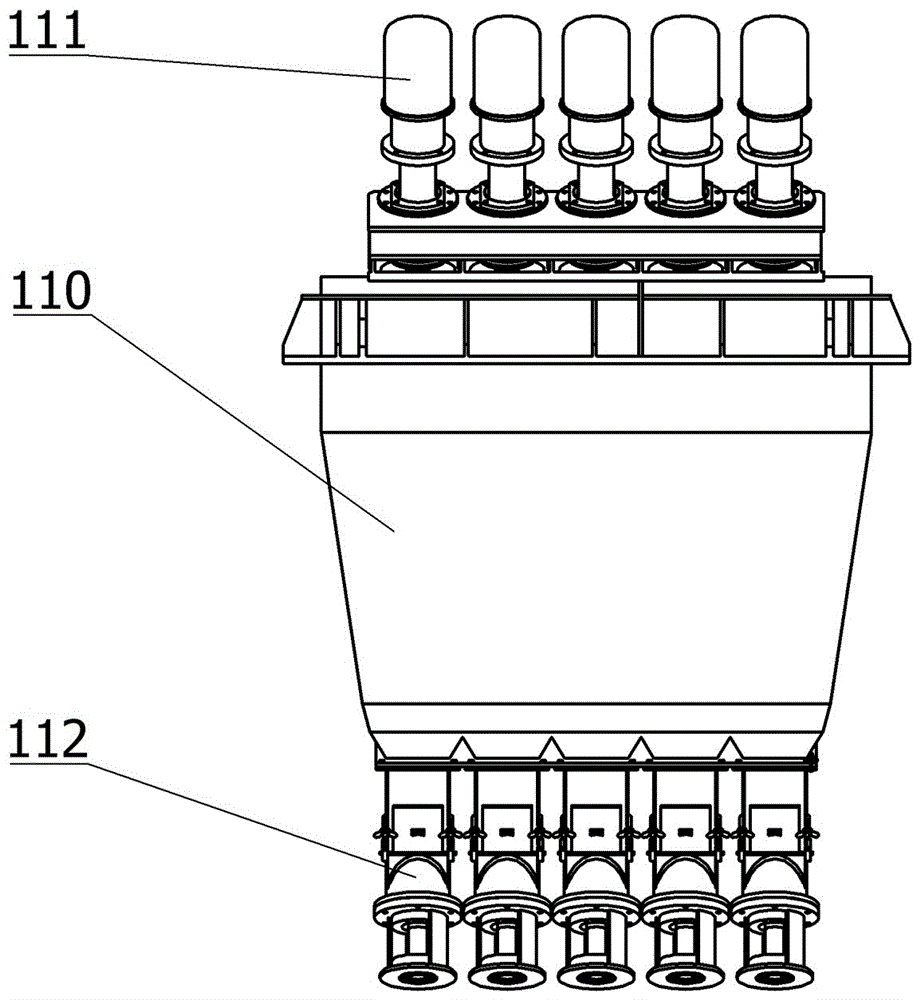

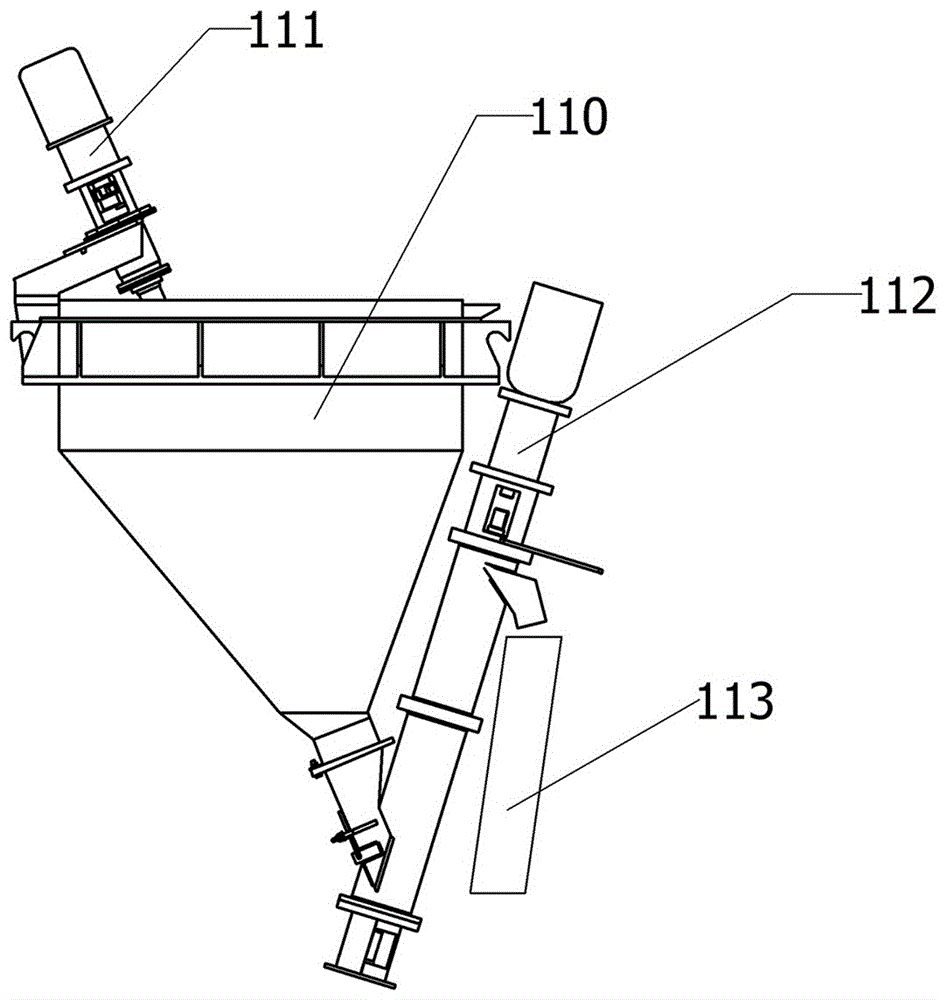

Reactive powder concrete delayed coagulation adjustable constant feeding control method and device

InactiveCN106003421ASudden condensation will notAvoid cloggingDischarging apparatusCement mixing apparatusEngineeringMechanical engineering

The invention relates to a reactive powder concrete delayed coagulation adjustable constant feeding control method and a device, which mainly solve the technical problems that the reactive powder concrete discharging speed is quick, a reactive powder concrete hopper port is blocked, and the like. The technical scheme point is that the device comprises a feed trough (110), an anti-condensation stirring device (111), an adjustable speed spiral discharging machine (112) and a directional chute (113); the adjustable speed spiral discharging machine (112) is arranged on the outer side of the feed trough (110); discharge holes formed on the lower end of the feed trough (110) are connected with feeding holes formed on the lower part of the adjustable speed spiral discharging machine (112); the lower part of the anti-condensation stirring device (111) stretches into an inner cavity of the feed trough (110); the adjustable speed spiral discharging machine (112) is connected with the directional chute (113) in a matching way. According to the reactive powder concrete delayed coagulation adjustable constant feeding control device provided by the invention, the anti-condensation stirring device with the structure is adopted to stir materials in a hopper, so that a discharge hole of the hopper can be prevented from being blocked, and constant regulation can be realized. The device is mainly used for reactive powder concrete production construction.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

Preparation method of high-performance composite gypsum cementing slurry

A preparation method of high-performance composite gypsum cementing slurry belongs to the technical field of building materials. The composite gypsum cementing slurry comprises the components of one of building gypsum powder, coal ash or slag powder, a mixed powder comprising cementing, a water reducer and water as well as the components of an exciting agent formed by mixing a retarder and a sulphate, wherein the water, the water reducer and the exciting agent are proportionally weighed out according to the total mass of the mixed powder, and then poured into a stirring container, and uniformly stirred to obtain a mixed solution, the mixed powder are blended into the stirring container filled with the mixed solution in a stirring state, the mixed powder and the mixed solution are stirred into a slurry at a high speed after being blended so as to obtain the composite gypsum cementing slurry. The composite gypsum cementing slurry has the advantages of excellent pouring performance, adjustable settling time and high compressive strength. The preparation method can be used for producing building material products with different sizes and performances.

Owner:四川吉浦森建材有限公司

Cement concrete pavement rapid repair material and preparation method thereof

ActiveCN112723801ASolve stacking problemsEmission reductionCement productionModified carbonCarbon nanofiber

The invention discloses a cement concrete pavement rapid repair material and a preparation method thereof. The cement concrete pavement rapid repair material comprises the following components in parts by weight: 50-60 parts of fly ash, 8-18 parts of granulated blast furnace slag, 6-8 parts of red mud, 3-6 parts of rice hull ash, 15-30 parts of a composite alkali activator, 9-12 parts of water, 1-3 parts of a silane coupling agent, 0.05-0.06 part of a dispersing agent, 0.1-0.3 part of a cosolvent and 0.06-0.08 part of modified carbon nanofibers. The concrete pavement rapid repair material provided by the invention has good anti-cracking performance, and the silane coupling agent forms a hydrophobic layer in capillary pores and micro-cracks due to excellent hydrophobicity, so that water is prevented from entering; the structure of the geopolymer is improved from the inside of the geopolymer by fully utilizing the filling effect, the volcanic ash effect and the nano nucleation effect of the modified carbon nanofibers, communicating holes are greatly reduced, the pore structure is optimized, the porosity is reduced, and the compressive strength is improved; by adding the slag and other raw materials, the normal-temperature preparation of the pavement repair material is realized, and the initial setting time and final setting time are greatly reduced.

Owner:WUHAN UNIV

Existing road underground drainage pipeline additionally installing method

The invention relates to the technical field of pipeline construction, and provides an existing road underground drainage pipeline additionally installing method. The existing road underground drainage pipeline additionally installing method aims to solve the problem of affecting traffic when an underground drainage pipeline is installed. According to the technical scheme, an underground drainagepipeline comprises a plurality of pipeline units; and the existing road underground drainage pipeline additionally installing method includes the following steps that S1, a construction well is excavated; S2, a construction channel is excavated; S3, an underground construction chamber is excavated and supported; S4, straight holes are drilled and excavated; S5, the straight holes are subjected topretreatment; S6, the underground drainage pipelines are laid, specifically, a plurality of pipeline units are sequentially ejected into the straight holes, and the lubricated cement slurry is sprayedbefore the pipe units are ejected; and S7, grouting is performed, specifically, the lubricated cement slurry is injected to fill the gaps between the underground drainage pipes and the straight holes. By excavating the construction well on one side of a road and excavating the underground construction chamber below the road, the working space is enabled to be an underground space, the whole construction process is completed underground, road excavation is avoided, and the influence on traffic is reduced.

Owner:广州市中港建设工程有限公司

Fluorgypsum-based plastering material as well as preparation method and application thereof

The invention provides a fluorgypsum-based plastering material as well as a preparation method and application thereof. The fluorgypsum-based plastering material is prepared from fluorgypsum, an admixture, aggregate, an expansion inhibitor, an excitant, a water retention thickener and an acid-base regulator. The preparation method comprises the following steps: crushing fluorgypsum to obtain fluorgypsum particles; and mixing the fluorgypsum particles with the admixture, the aggregate, the expansion inhibitor, the excitant, the water retention thickener and the acid-base regulator to obtain thefluorgypsum-based plastering material. The fluorgypsum-based plastering material has the characteristics of short setting time, high strength, small stacking density, good volume stability, high bonding strength, excellent water-retaining property and the like; the preparation method is simple, and the fluorgypsum-based plastering material has a wide application prospect in the field of preparation of building materials.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

Water-soluble setting accelerator and preparation method thereof

The invention provides a water-soluble setting accelerator, which is prepared from the following production raw materials in parts by mass: 174 to 212 parts of sodium hydroxide, 226 to 188 parts of aluminum hydroxide, 1 to 8 parts of potassium sulphate and 1 to 8 parts of sodium carbonate. According to a preparation method, firstly, 100 parts of water is contained in a reaction kettle; the sodiumhydroxide is added; heating and stirring dissolution are performed; then, the aluminum hydroxide is added; the continuous stirring and heating are performed to 100 DEG C to 130 DEG C; after the aluminum hydroxide is completely dissolved; the potassium sulphate and the sodium carbonate are added; the stirring is continuously performed; after the complete dissolution, the materials are pumped into aspraying tower by a pump; drying dewatering is performed; the water-soluble setting accelerator is obtained. The water-soluble setting accelerator has the beneficial effects that the materials are solids in the transportation process; the transportation cost is low; the transportation cost is reduced; the defects of easy leakage, too high packaging cost and great storage occupied area in the liquid setting accelerator transportation process are overcome; the preparation process is simple; the production cost is low; no pollution is caused.

Owner:山西黄河新型化工有限公司

Early strength polycarboxylic acid type water reducer, as well as preparation method and application thereof

InactiveCN106431061AGood early strengthWide range of early strength effectsAir contentUltimate tensile strength

The invention discloses an early strength polycarboxylic acid type water reducer, as well as a preparation method and application thereof. The water reducer is composed of the following raw materials in parts by weight: 25-35 parts of acrylic acid, 7-15 parts of lygodium japonicum, 12-20 parts of polymine and 1-5 parts of polysorbate. The method comprises the following steps: mixing and thermally stirring lygodium japonicum and polymine solution; adding polysorbate and thermally treating; adding acrylic acid and ultrasonically treating; centrifugally treating and taking filter liquor; and thermally stirring and treating, thereby acquiring the water reducer. The early strength polycarboxylic acid type water reducer has the advantages that the early strength effect is excellent, the cost is lowered, and the performance is stable; under the synergistic effects of all the raw materials, the water reduction efficiency of the early strength type water reducer is greatly increased; the flowing property of the net paste is excellent; the bleeding rate and the air content are reduced; the air content is greatly reduced and the initial setting time and final setting time of the concrete are greatly shortened; the durability is increased; and the early strength polycarboxylic acid type water reducer is suitable for low temperature, can be used at -10 DEG C and can be used for effectively solving the problem of slow development of concrete strength under the low temperature condition.

Owner:赖高生

Solid waste-based super-retarded cement as well as preparation method and application thereof

The invention belongs to the technical field of cement materials, and particularly relates to solid-waste-based super-retarded cement as well as a preparation method and application thereof. The cement comprises the following components in parts by weight: 60-68 parts of clinker, 10-14 parts of fly ash, 8-10 parts of slag powder, 2-4 parts of dihydrate gypsum, 3-4 parts of phosphogypsum, 2-4 parts of desulfurized gypsum and 4-8 parts of superfine slag powder. A certain mass ratio of sugar residue is added in the production of the clinker to improve the SO3 content of the cement clinker, the characteristics of different solid waste materials are deeply combined, industrial waste residues such as non-ferrous metal slag, sludge residue and polluted soil are cooperatively used, a large amount of solid waste materials are consumed, and the characteristics of different materials are cooperated to prepare the cement clinker with the characteristics of obviously prolonged retarding time and high stability. The solid waste-based super-retarded cement for the road base is low in production cost, simple in process and applicable to a three-layer continuous paving process of a water-stable base. The strength of the obtained cement is high, the strength grade of 42. 5 cement for the road base is met, the initial setting time is longer than 440 min, and the final setting time is longer than 590 min.

Owner:山东高速工程检测有限公司

Waterproof geopolymer material and preparation method thereof

The invention discloses a waterproof geopolymer material and a preparation method thereof. The geopolymer material is formed by mixing fly ash, the ordinary Portland cement and other raw materials with the nano magnesium oxide and other additives, has good construction performance, and meanwhile has the advantages of being good in compressive strength and bonding strength development, good in shrinkage performance, good in anti-permeability performance and the like. The fly ash solid waste can be fully utilized, the problem of solid waste stacking can be solved, waste is turned into wealth, and the prepared waterproof geopolymer material can be used for tunnel lining crack repairing and other parts. According to the waterproof geopolymer material, the preparation process of an alkali-activated solution is omitted, normal-temperature preparation is achieved, and the preparation method is simple, low in cost and easy to popularize.

Owner:WUHAN UNIV

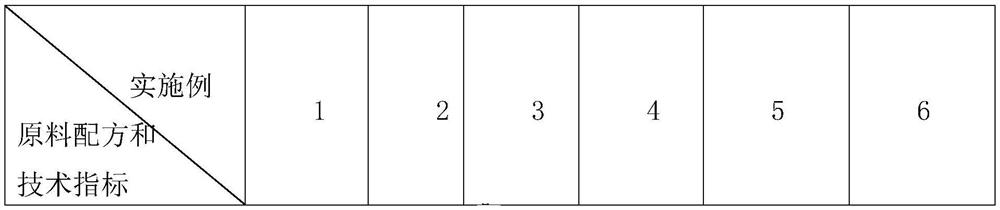

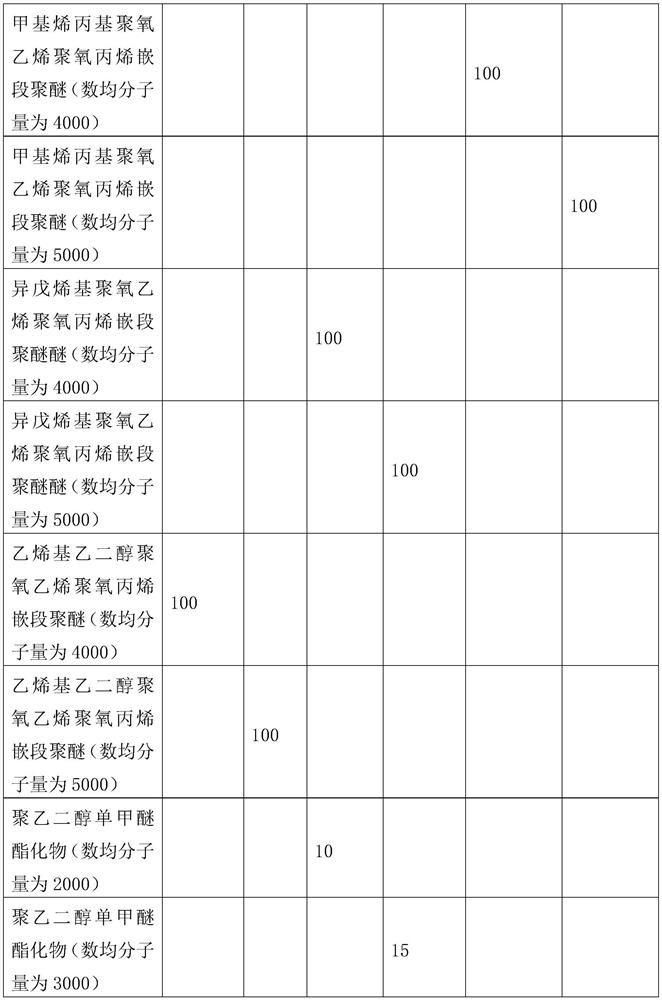

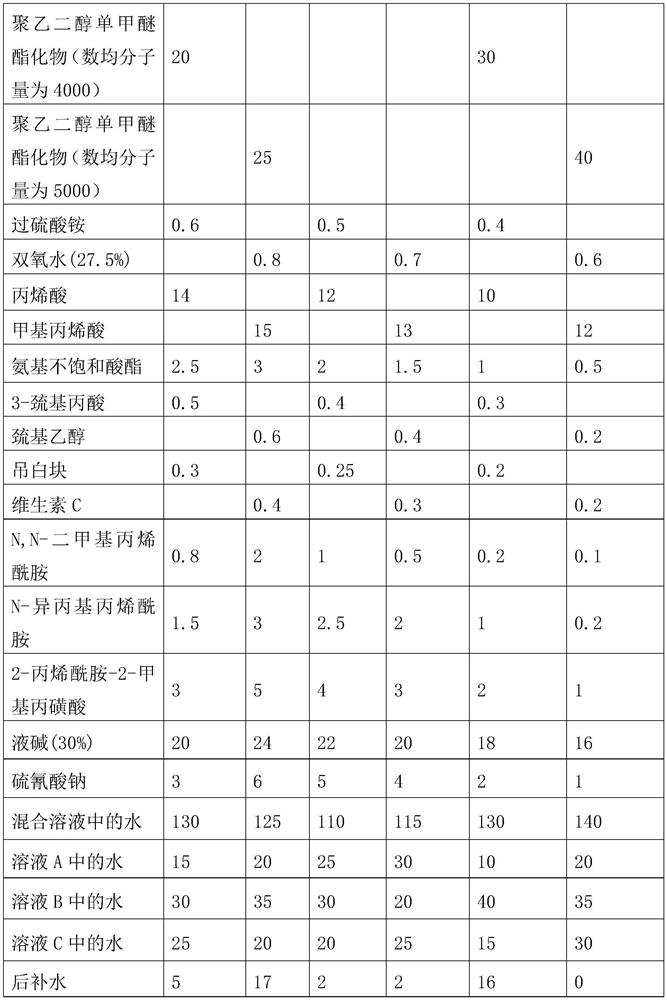

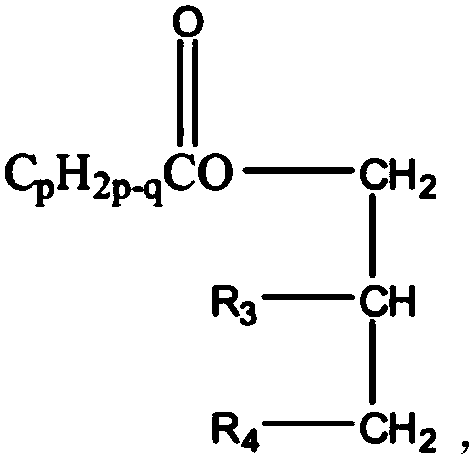

Super-early-strength polycarboxylate-type water reducing agent as well as preparation method and application thereof

The invention relates to a super-early-strength polycarboxylate-type water reducing agent. The super-early-strength polycarboxylate-type water reducing agent is prepared from the following raw material components: unsaturated polyoxyethylene polyoxypropylene block amine ether, polyethylene glycol monomethyl ether ester, unsaturated monocarboxylic acid, amino unsaturated acid ester, acrylamide monomers, an alkali metal hydroxide solution, a thiocyanate early strength agent, an oxidizing agent, a reducing agent, a chain transfer agent and water. Wherein the polyethylene glycol monomethyl ether ester is an esterification product obtained by reacting polyethylene glycol monomethyl ether with unsaturated monocarboxylic acid under an acidic condition; wherein the amino unsaturated acid ester is an esterification product of unsaturated monocarboxylic acid and N, N-dialkylethanolamine. The invention further relates to a preparation method and application of the super-early-strength polycarboxylate-type water reducing agent. The super-early-strength polycarboxylate-type water reducing agent promotes hydration of cement, does not contain any active reinforcing admixture, and has remarkable economic benefits, social benefits and environmental benefits; and the preparation process is simple and convenient to operate.

Owner:SHANGHAI DONGDA CHEM

A kind of preparation method of high thixotropic early-strength polycarboxylate water reducer

ActiveCN105504180BPromotes early hydrationPromotes the function of hydration reactionHydrogenAcid water

The invention discloses a preparation method of a high-thixotropy early-strength type polycarboxylate superplasticizer. The preparation method comprises the following steps of (1) adding isobutene polyoxyethylene ether and / or isopentene polyoxyethylene ether, micromolecular polyether, unsaturated fatty acid glyceride, a quaternary ammonium salt monomer and an oxidant into water, and stirring the mixture under 15 to 30 DEG C until the mixture is dissolved; (2) preparing a first solution by a reducing agent and water, preparing a second solution by a chain transfer agent and the water, and preparing a third solution by unsaturated monocarboxylic acid, an unsaturated carboxylic ester monomer and the water; (3) dropping the first solution, the second solution and the third solution in materials in step (1) within 3 to 4 hours at the same time, and carrying out a heat-preservation reaction for 1 to 1.5 hours under 35 to 40 DEG C after dropping is completed; (4) adding an alkaline modifier to neutralize the pH (Potential Of Hydrogen) to be 6 to 7 after the reaction of the materials in step (3) is completed, thus obtaining the high-thixotropy early-strength type polycarboxylate superplasticizer. The high-thixotropy early-strength type polycarboxylate superplasticizer prepared by the invention has an excellent thixotropic property.

Owner:KZJ NEW MATERIALS GROUP CO LTD

A kind of early-strength polycarboxylate water reducer and preparation method thereof

The invention discloses an early-strength type polycarboxylate superplasticizer and a preparation method thereof. The polycarboxylate superplasticizer comprises the following raw materials: polyether, hydrogen peroxide, acrylic acid, thiohydracrylic acid, vitamin C, caustic soda flakes, calcium nitrate, sodium nitrite, triethanolamine, deionized water and softened water. The ratio of an initiator to a linker to other raw materials is optimized, the deionized water which does not contain chlorine is selected, and the softened water with excellent dispersing performance is used. Moreover, the polycarboxylate superplasticizer, the softened water, the calcium nitrate, sodium nitrite and the triethanolamine are simultaneously used, and the reaction parameters are optimized, so that the early-strength type polycarboxylate superplasticizer has advantages in key indexes such as the water-reducing rate, bleeding rate, gas content, difference in setting time, ratio of compressive strength and ratio of shrinkage. The early-strength type polycarboxylate superplasticizer is excellent in service effect and obvious in cost advantage and is worthy of wide-range popularization.

Owner:山西中铁铁诚建材科技有限公司

A kind of fast hardening super early strength polycarboxylate water reducer and preparation method thereof

The invention discloses a rapid-hardened super-early strength polycarboxylate water reducer and a preparation method thereof. According to the rapid-hardened super-early strength polycarboxylate waterreducer disclosed by the invention, by using a molecular cutting technique, molecular structures of main chain groups, side chain groups and the like are designed, a polyether monomer of a super-highmolecular weight is adopted as an active large monomer, a structure with a long side chain and a short main chain is formed by molecular chains, a small monomer of self-made unsaturated alcohol aminoester and small monomers such as ethyl methacrylate with N groups and triallylamine are introduced, and solution polymerization is carried out at a low temperature. The synthesized polycarboxylate water reducer has an outstanding function of promoting cement hydration reactions, can be applied to steam-curing concrete, low-temperature environment concrete and concrete with a requirement of demolding in advance, is capable of remarkably shortening the plastering and primary curing time of a molded plate, has a remarkable early strength effect, and is capable of accelerating the construction progress of concrete and increasing the transfer rate of mold plates.

Owner:KZJ NEW MATERIALS GROUP CO LTD

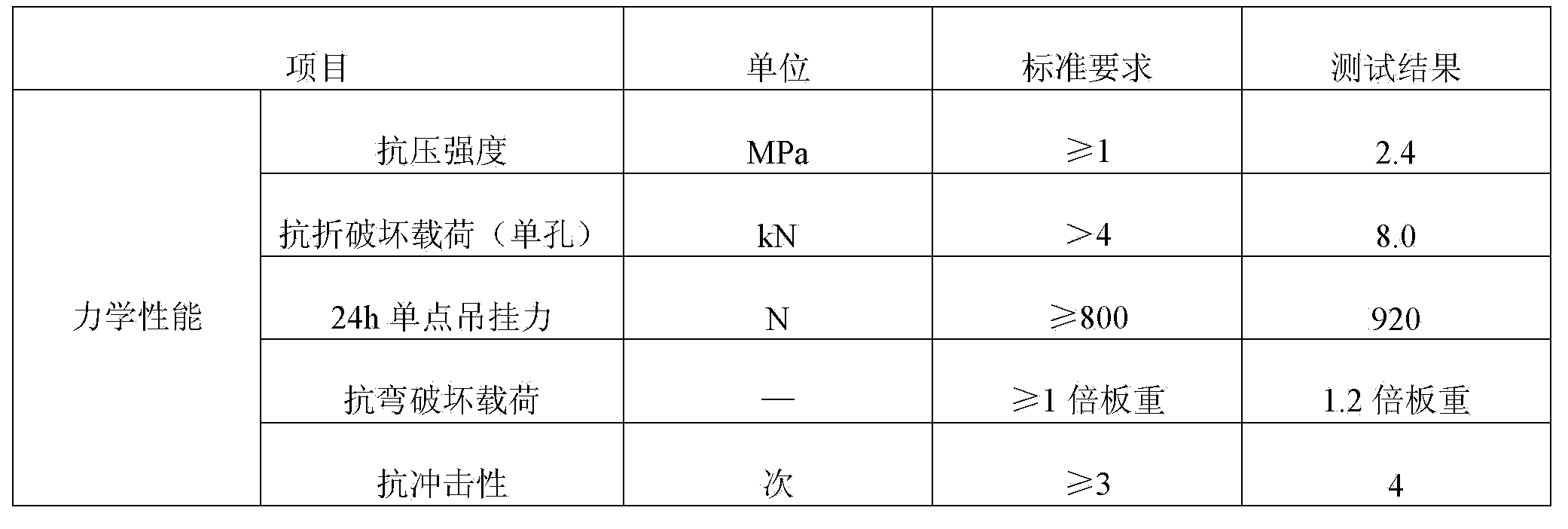

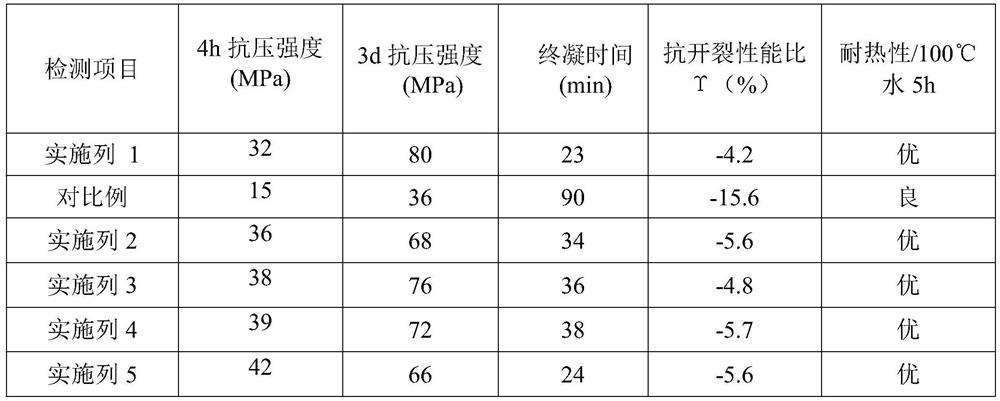

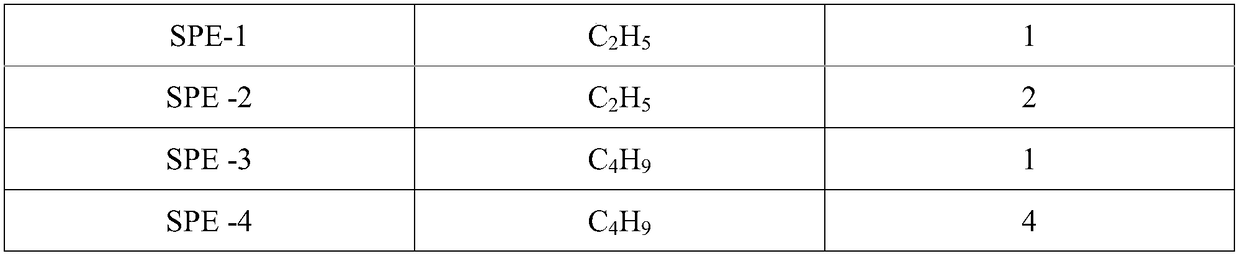

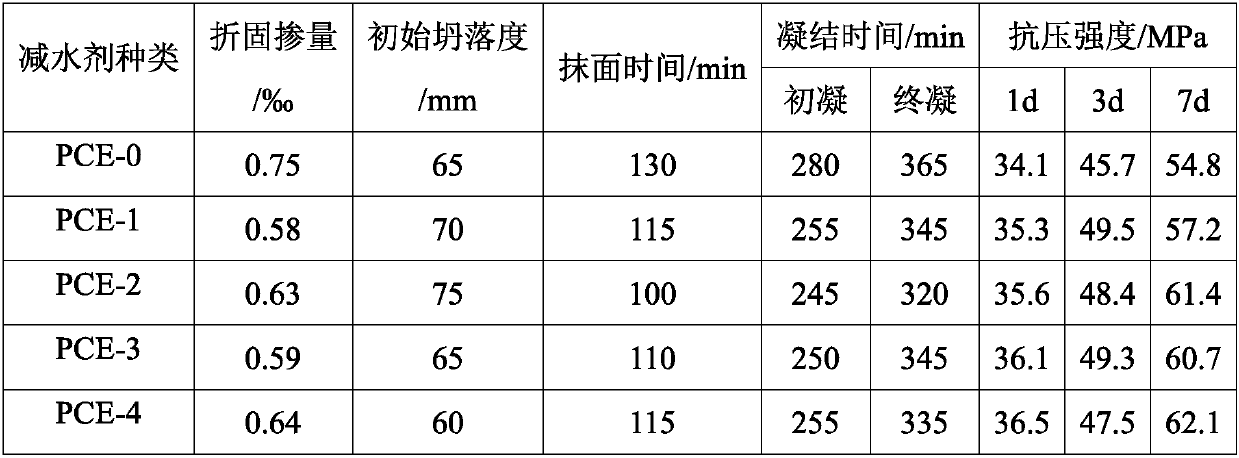

A kind of anti-cracking agent and its preparation method, and the preparation method of ultra-high performance concrete prefabricated component

ActiveCN111995282BDelayed initial setting timeShort maintenance timeCeramic shaping apparatusAluminiteChemical reaction

An anti-cracking agent and its preparation method, and a preparation method of ultra-high performance concrete prefabricated components belong to the technical field of building materials. The raw material of the anti-cracking agent comprises the first component, and the first component comprises 30-60 parts by weight of fly ash, 10-30 parts by weight of calcium sulfate, 5-15 parts by weight of slaked alumina, 5-15 parts by weight of slaked lime and 3 ~7 parts by weight magnesium oxide. Magnesium oxide can react with water to produce magnesium hydroxide, a volume-expanding hydration product, and boiled alum, calcium sulfate and slaked lime can undergo chemical reactions to produce volume-expanding ettringite. The above two expansion mechanisms can synergistically supplement UHPC from the initial stage. The volume shrinkage in the process of setting to final setting and later strength development greatly reduces the risk of cracking in the whole life cycle of ultra-high performance concrete precast components.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

A coagulation-accelerating early-strength polycarboxylate water-reducer and its preparation method

The invention discloses a coagulation-accelerating and early-strength polycarboxylate water-reducer and a preparation method thereof. The water-reducer is made of the following raw material components in parts by weight: a quaternary ammonium salt cationic monomer with terminal double bonds 1 ~3 parts by weight, polyether monomer 190~210 parts by weight, unsaturated monocarboxylic acid and its derivatives 16~18 parts by weight, oxidizing agent 1.5~2.0 parts by weight, first reducing agent 0.1~0.3 parts by weight, second reducing agent 0.1-0.3 parts by weight of agent, 0.8-0.9 parts by weight of chain transfer agent, 14-18 parts by weight of alkaline regulator and 210-230 parts by weight of water. The coagulation-accelerating early-strength polycarboxylate superplasticizer of the present invention has a prominent function of promoting cement hydration reaction, and can be used in steam-cured concrete, low-temperature environment concrete and concrete that requires early formwork removal, and can significantly shorten the forming formwork Excellent plastering and initial setting time, notable early strength effect, but also good thixotropic properties, which can speed up the construction progress of concrete and improve the turnover rate of formwork.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Preparation method of early-strength water reducer for first-aid repair work

The invention relates to the technical field of early-strength water reducers, specifically to a concrete early-strength water reducer for first-aid repair work. A preparation method of the early-strength water reducer for first-aid repair work comprises the following steps: (1) uniformly mixing polyethylene glycol monomethyl ether methyl acrylate, mono(methyl)acrylate monomer and unsaturated acidin a mixed solution of water and glycerin, adding a chain transferring agent, and stirring at 70-110 DEG C for 1.5-5 h so as to obtain a polyester polycarboxylic acid water-reducer; and (2) adding asbestos wool and modified sepiolite fiber into the polyester polycarboxylic acid water-reducer, fully mixing, adding alkyl organic amine, sodium nitrite and an antifoaming agent, and uniformly mixing to obtain the early-strength water reducer for first-aid repair work. According to the early-strength water reducer of the invention, gas content of concrete is greatly reduced and initial setting timeand final setting time of concrete are shortened, and durability is enhanced.

Owner:芜湖恒固混凝土材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com