Preparation method of early-strength water reducer for first-aid repair work

An early-strength water-reducing agent and engineering technology, applied in the field of retarding water-reducing agents, can solve the problems of slow development of concrete strength, limited use, and failure to consider the influence of concrete thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

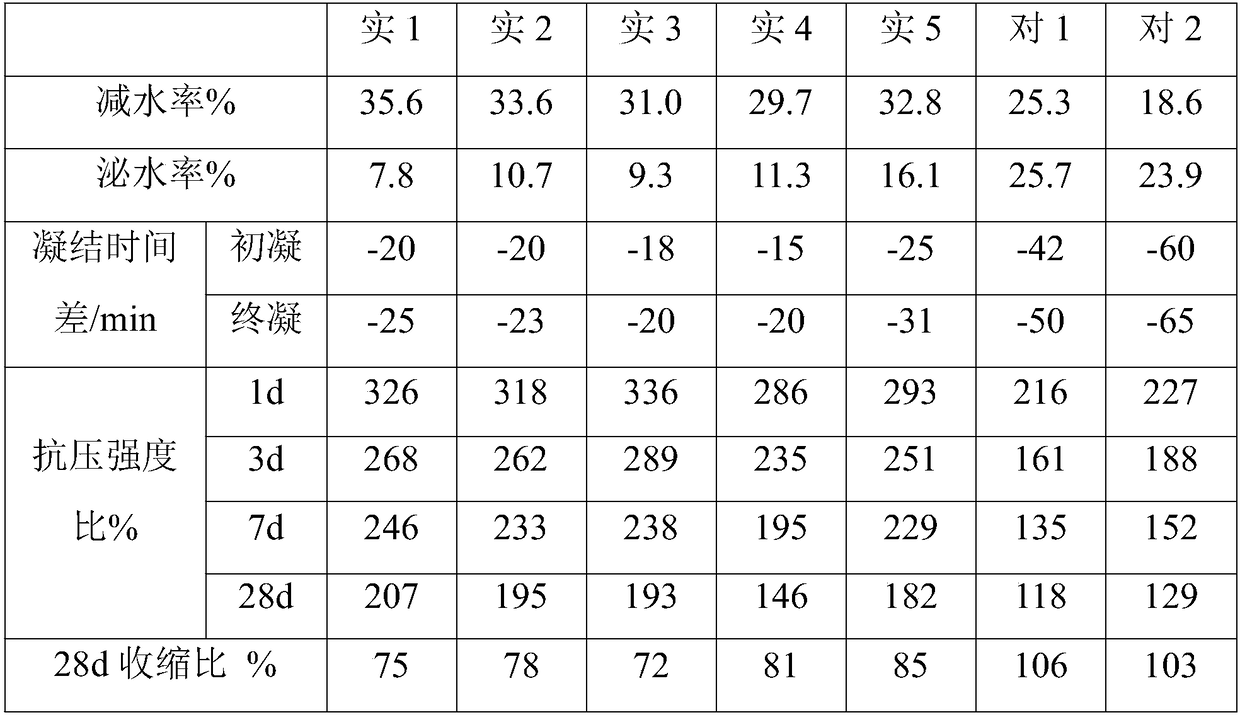

Examples

preparation example Construction

[0017] The present invention also provides a preparation method of the early-strength water reducer for emergency repair projects, the steps are as follows:

[0018] (1) Mixing sepiolite fiber, hexamethylolmelamine hexamethyl ether and pentaerythritol oleate in an aqueous medium at 120-150° C. for 0.5-1 hour to obtain modified sepiolite fiber;

[0019] (2) Polyethylene glycol monomethyl ether acrylate, mono(meth)acrylate monomer, methacrylic acid and unsaturated acid are mixed uniformly in the mixed solution of water and glycerin, then add chain transfer agent, at 70- Stir at 110°C for 1.5-5h to obtain a polyester polycarboxylate water reducer;

[0020] (3) Add asbestos wool and modified sepiolite fiber to the polyester polycarboxylate water reducer, mix thoroughly, then add alkyl organic amine, sodium nitrite, defoamer, mix evenly, and then use Early-strength water reducer for emergency repair projects.

[0021] The invention adopts polyethylene glycol monomethyl ether acry...

Embodiment 1

[0023] (1) Mix 2 g of sepiolite fiber, 1.5 g of hexamethylolmelamine hexamethyl ether and 1 g of pentaerythritol oleate in water for 1 hour at 125° C., centrifugally wash and dry to obtain modified sepiolite fiber;

[0024] (2) 35g polyethylene glycol monomethyl ether acrylate, 8g polyethylene glycol polytetramethylene glycol mono(meth)acrylate and 1.5g maleic acid are mixed uniformly in the mixed solution of 100g water and 25g glycerin, Then add 0.5g of mercaptoacetic acid and stir at 80°C for 2.5h to obtain a polyester polycarboxylate water reducer;

[0025] (3) Add 5g of asbestos wool and modified sepiolite fiber to the polyester polycarboxylate water reducer, mix well, then add 6g of triisopropanolamine, 15g of sodium nitrite, and 0.5g of silicone defoaming agent Agent (Defeng defoamer, DF-1089), mixed evenly, that is, an early-strength water reducer for emergency repair projects.

Embodiment 2

[0027] (1) Mix 1g of sepiolite fiber, 1g of hexamethylolmelamine hexamethyl ether and 2g of pentaerythritol oleate in an aqueous medium at 150°C for 0.5h, centrifuge, wash and dry to obtain modified sepiolite fiber;

[0028] (2) 40g polyethylene glycol monomethyl ether acrylate, 6g propoxy polyethylene glycol polypropylene glycol mono(meth)acrylate and 1g maleic acid are mixed homogeneously in the mixed solution of water and 30g glycerol, then Add 0.2g of mercaptoethanol and stir at 110°C for 1.5h to obtain a polyester polycarboxylate water reducer;

[0029] (3) Add 6g of asbestos wool and modified sepiolite fiber to the polyester polycarboxylate water reducer, mix well, then add 10g of triethanolamine, 12g of sodium nitrite, and 1g of polyether modified silicon defoamer (Defeng defoamer, DF-881), mix evenly, and get the early-strength superplasticizer for emergency repair projects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com