Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Consistent tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for manufacturing high-strength bolt

The invention provides a process for manufacturing a high-strength (above) bolt. The process comprises the following steps: selecting a proper steel material, and cutting out a cylindrical blank with proper size; molding the head part and the rod part of the bolt by adopting cold extrusion technology; heating; manufacturing the rod part, including coarse grinding and fine grinding; detecting injury by magnetic powder; manufacturing screw; and performing surface mechanical reinforcement and corrosion resistance treatment. The process solves the technical problems of insufficient strength and fatigue fracture which are easily generated on the bolt existing in the prior art for manufacturing the high-strength bolt, and is a high-strength bolt manufacturing process capable of improving tensile and fatigue strength resistance of the bolt.

Owner:浙江裕泰汽车配件有限公司

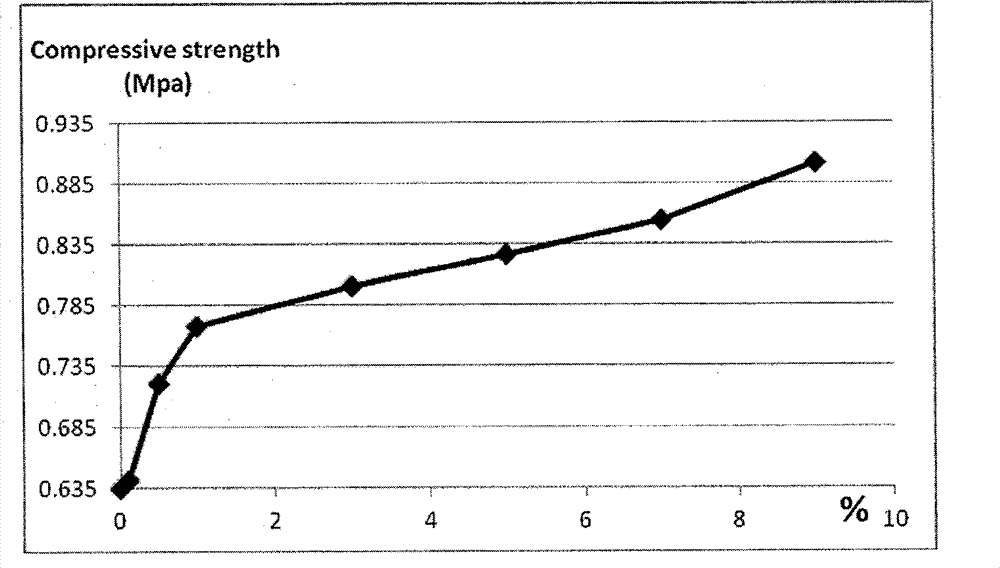

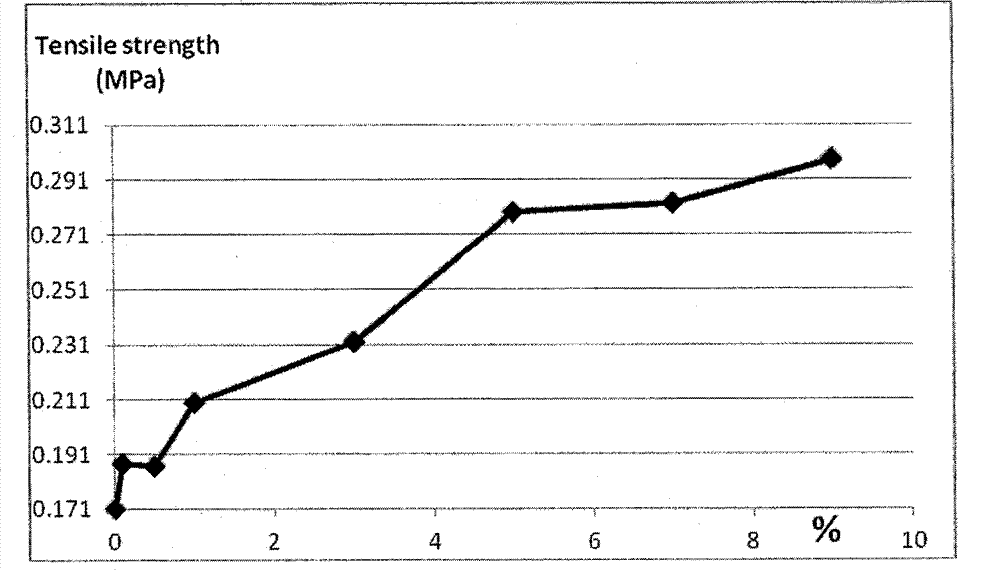

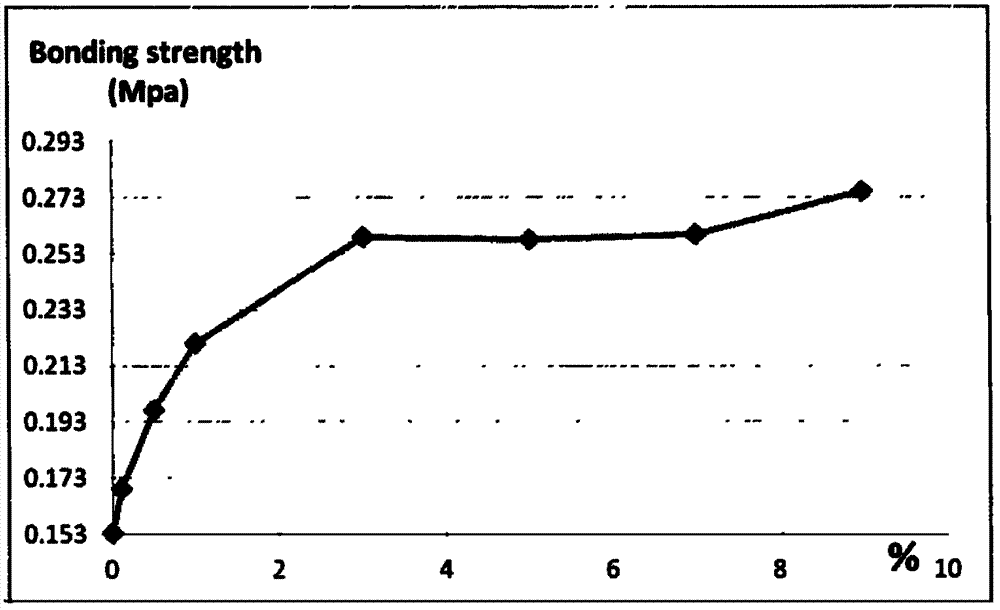

High-strength, high-insulation exterior wall heat-preservation face brick compounded by aluminum plastic and nanometer materials

The invention provides an exterior wall heat-preservation face brick compounded by aluminum plastic and nanometer materials, belongs to the technical field of building materials, and particularly relates to the nanometer materials in application of building an exterior face wall heat-preservation system. The face brick is composed of an outer aluminum plate or aluminum-plastic plate layer, an adhesive layer and a basement heat-preservation layer made of inorganic lightweight materials mixed with nano-particles. The method for producing the face brick includes adding and uniformly mixing the nanometer materials with particle sizes at the nanoscale in a mixed system of cement, auxiliary cementing materials, high polymer adhesives, the inorganic lightweight materials, fibers and water, and pressurizing and molding the mixed system prior to being cross-linked by high polymer materials and hydration drying of the cement, adding the adhesive layer having adhesive function in the basement heat-preservation layer, and adhering the aluminum plate or aluminum-plastic plate to the adhesive layer. With the method, the exterior wall heat-preservation face brick is excellent in fireproof performance, high in crush resistance, tensile strength and adhesive strength and good in heat-preservation effect, and has very good decorative effect.

Owner:平湖市法而特建筑保温科技有限公司

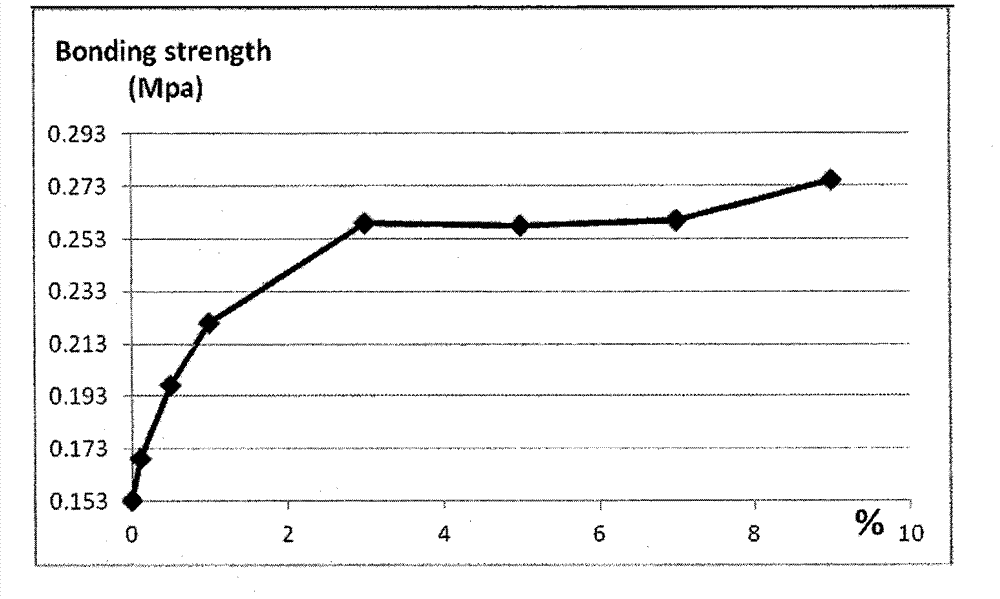

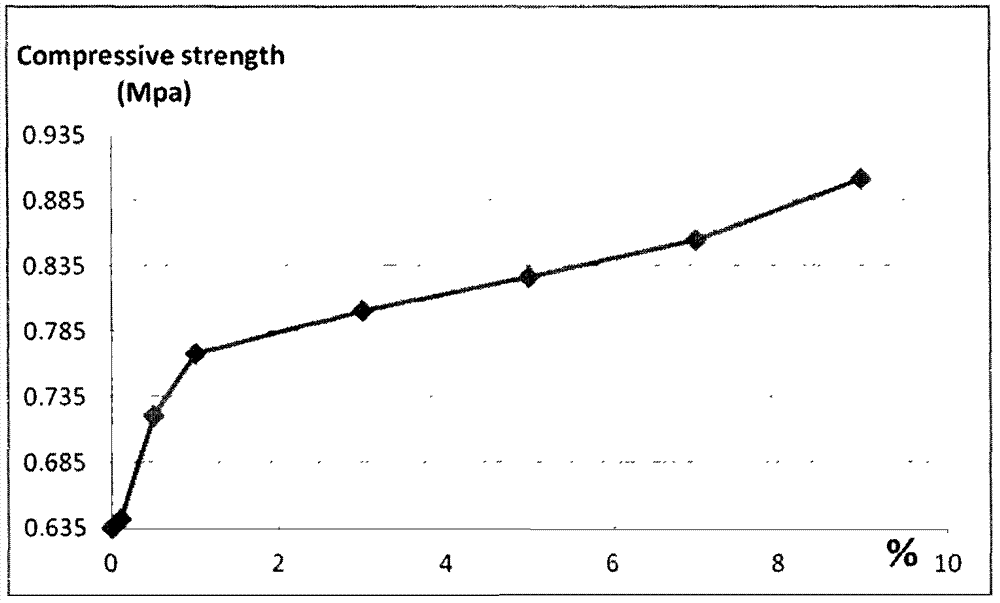

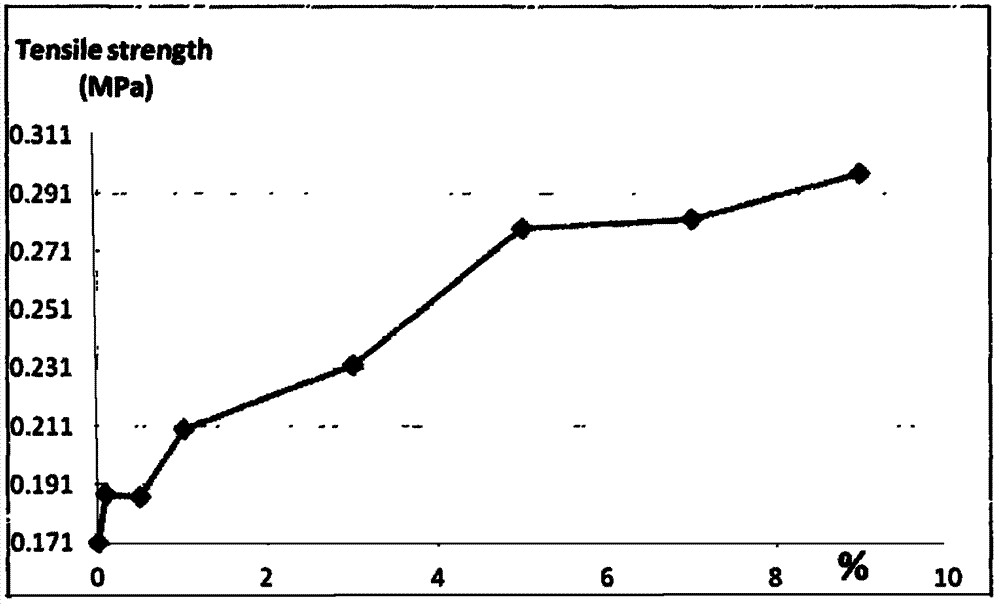

High-strength high-heat-insulation inorganic heat-preservation decorative external wall face brick containing nano materials

The invention belongs to the field of building materials, in particular to nano material applications to a building outer wall heat-preservation system, and provides a high-strength high-heat-insulation inorganic heat-preservation decorative external wall face brick containing nano materials. Base coating, floating coating and decorative surface coating are performed on an inorganic light material base heat-preservation layer added with nano particles to form the face brick. By the aid of the nano particles added to a formula of the base heat-preservation layer, compressive strength, tensile strength and bonding strength of the base heat-preservation layer can be improved. A preparation method of the face brick includes evenly mixing the nano materials with the particle diameter at nanoscale, adding the nano materials to a mixed system of concrete, auxiliary solidifying materials, polymer binders, inorganic light heat-preservation materials, fibers and water and forming the mixed system through compression; after a cross-linking process of organic polymer materials and a hydration and drying process of the concrete, performing the base coating, the floating coating and the decorative surface coating on the inorganic light material base heat-preservation layer to form the inorganic heat-preservation decorative face brick. The outer wall heat-preservation brick prepared by the method is excellent in fireproof performance, high in pressure-resistance strength, tension-resistance strength and bonding strength and good in heat-preservation effects; the surface of the brick can be imitation metal, imitation stone and imitation timber; and decoration effects are great.

Owner:平湖市法而特建筑保温科技有限公司

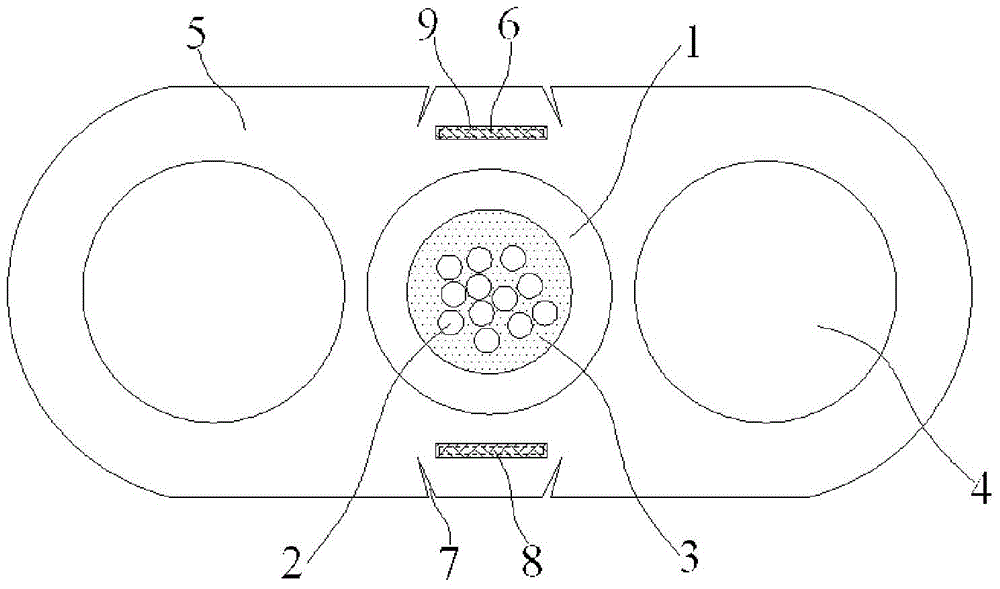

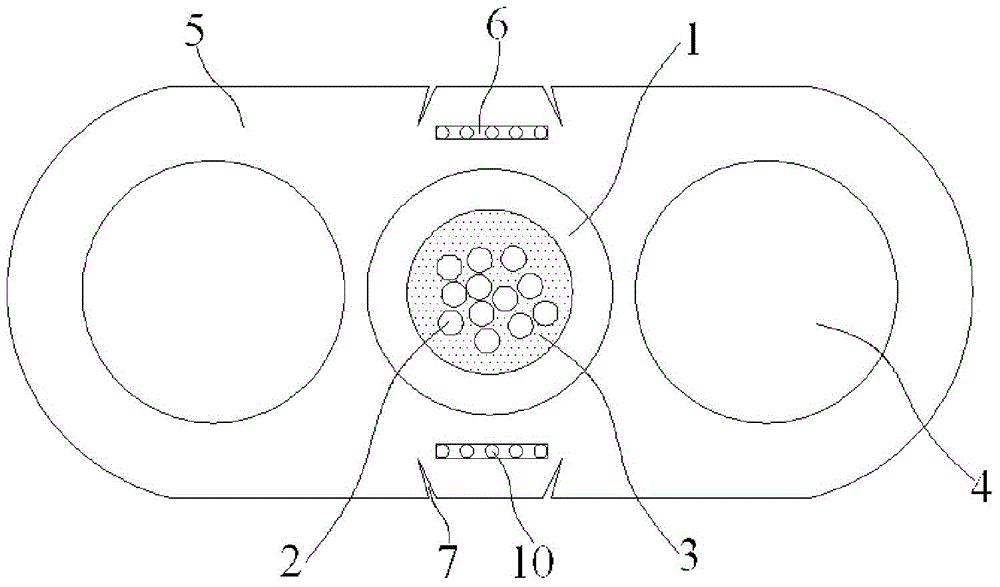

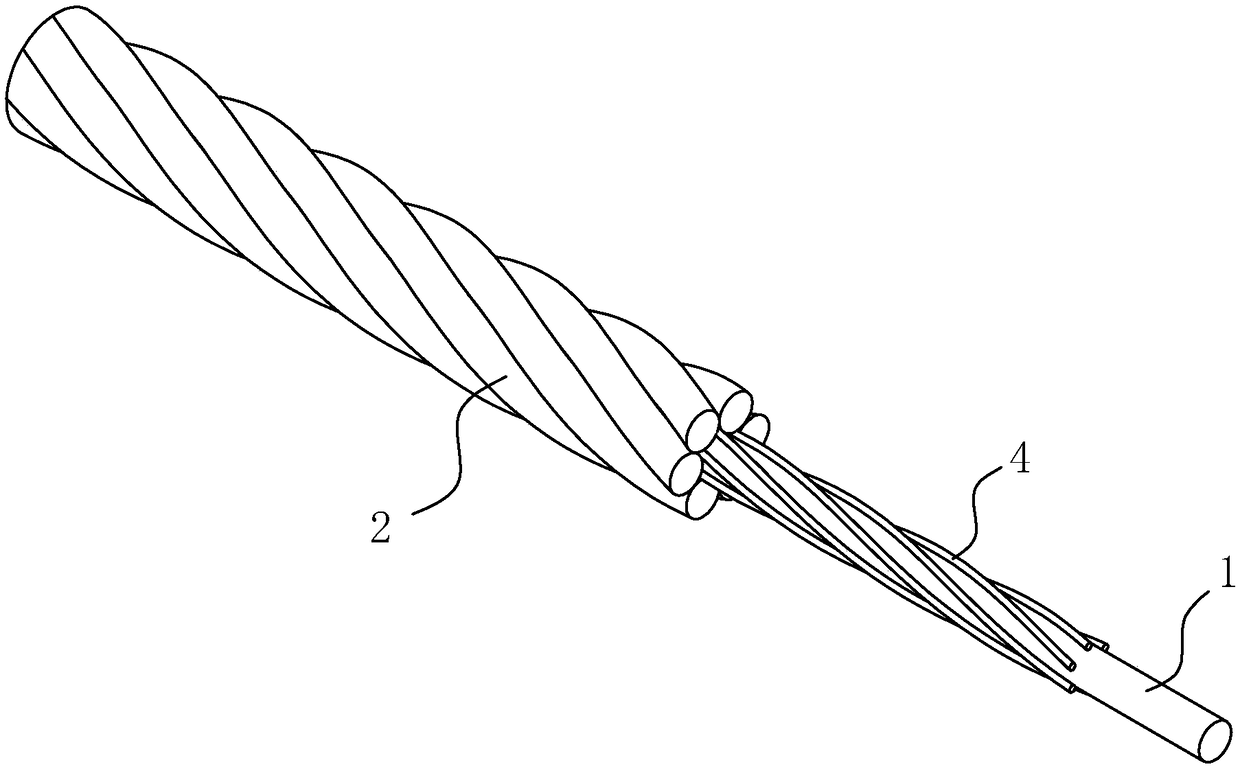

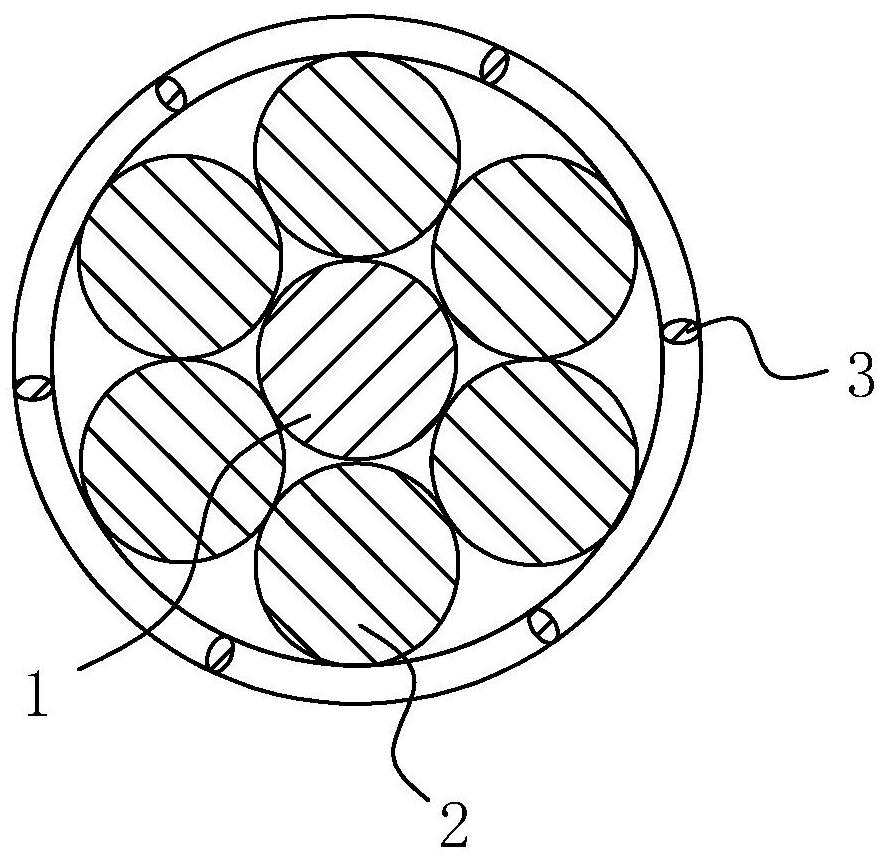

Reinforced type light optical fiber and cable with rat-proof function

InactiveCN104834066AImprove the safety of useHave not been bitten badFibre mechanical structuresYarnEngineering

The invention discloses a reinforced type light optical fiber and cable with rat-proof function, comprising a loose tube disposed in the center, and a plurality of glass fibers disposed in the loose tube. Two non-metal reinforced rods are disposed at the left and right side of the loose tube in parallel, and are at the same plane. The loose tube and the outer surfaces of the two non-metal reinforced rods are coated by a flat type outer sheath. The upper surface and the lower surface of the loose tube are respectively coated with a thermosetting glass fiber yarn tape. The flat type outer sheath is respectively provided with two inclined-V-shaped tearing grooves at the upper part and lower part of the loose tube, and the inclined-V-shaped tearing groove directs towards the area between the loose tube and the non-metal reinforced rod. The inner part of the flat type outer sheath is respectively provided with the thermosetting glass fiber yarn tape at the upper part and the lower part of the loose tube. The thermosetting glass fiber yarn tape is composed of a plurality of glass fiber rods in parallel arrangement. The reinforced type light optical fiber and cable with rat-proof function is advantageous in that when the glass fiber protective layer is bitten by rodents, the oral cavity of the rodent will be damaged by the glass fiber protective layer, and the rodent will stop biting the optical cable, and thereby the optical fiber can be protected from being bitten, and usage security is quite high.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

Preparation method of stratified-structure mineral reinforced rubber composite material

The invention relates to a preparation method of a stratified-structure mineral reinforced rubber composite material. The preparation method comprises the following steps: (1) carrying out nano-organic modification on a stratified-structure mineral; (2) preparing an organic modified nano-stratified-structure mineral inserted rubber master batch; (3) preparing the raw materials of an organic modified nano-stratified-structure mineral reinforced rubber composite material; and (4) preparing the organic modified nano-stratified-structure mineral reinforced rubber composite material, wherein the stratified-structure mineral is one or mixture of two of black talc, montmorillonite, kaolin and illite in the same mass ratio. According to the preparation method, the functional rubber composite material with excellent mechanical property, stable weather resistance and good warping strength and humidity resistance is prepared.

Owner:HEBEI UNIV OF TECH

Preparation method of phenol-formaldehyde resin based composite material sleeper

InactiveCN102744753AOvercome the shortcomingsAvoid disadvantagesFlat articlesDomestic articlesMaterials preparationArchitectural engineering

The invention provides a preparation method of a sleeper, which solves a problem that a composite material sleeper is not available in the prior art. A preparation method of a phenol-formaldehyde resin based composite material sleeper comprises processes of prereg preparation, surface material preparation and composite material preparation in sequence. According to the invention, as a large quantity of wood residues are utilized, low cost and good use performance are achieved, defects of a cement sleeper are overcome, saving and substitution of woods are developed, the wood consumption structure is optimized, the situation of domestic wood resource shortage is relieved to a certain degree, and sustainable utilization of forest resources and the ecological environment are improved.

Owner:NORTHEAST FORESTRY UNIVERSITY

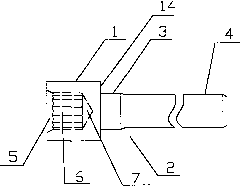

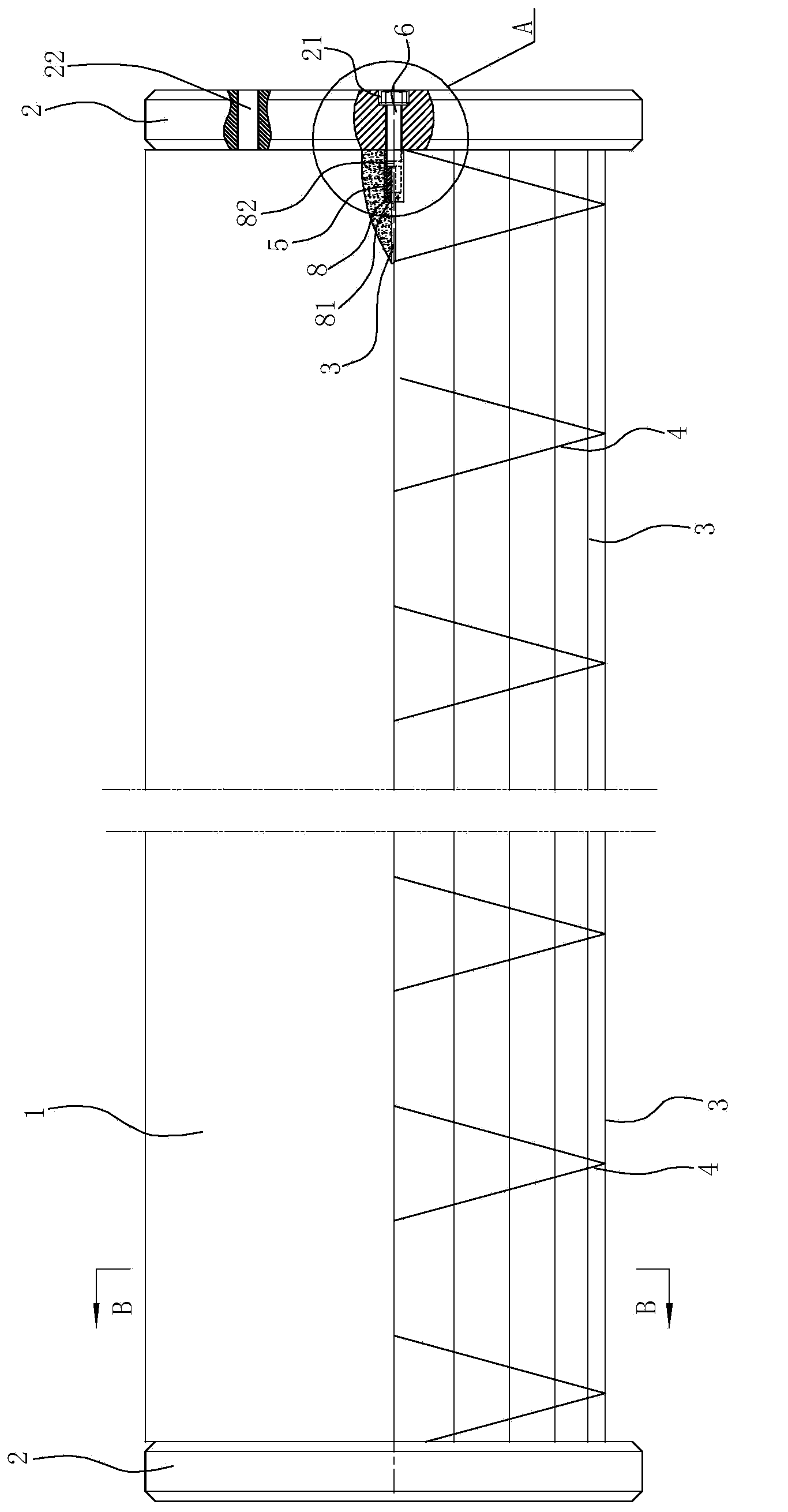

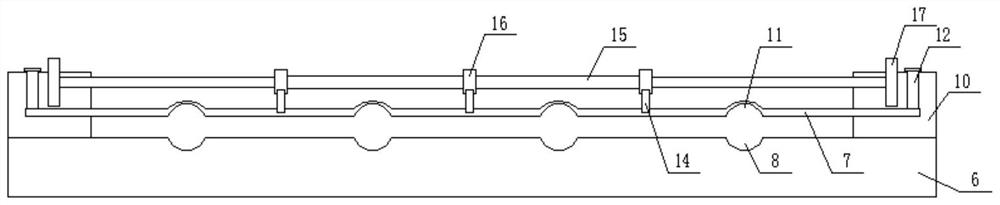

Soil body tensile test device and soil body tensile test method

ActiveCN113533034AConsistent tensile strengthConsistent strengthMaterial strength using tensile/compressive forcesAgricultural engineeringEnvironmental geology

The invention provides a soil body tensile test device and a soil body tensile test method, and belongs to the technical field of slope strength research, the soil body tensile test device comprises: a counterforce frame having a top plate and a bottom plate opposite to each other; a loading assembly which is matched with the top plate; a stress sensor which is connected with one end, close to the bottom plate, of the loading assembly; a displacement sensor which is arranged on the end face of the top plate close to the bottom plate; a fixed clamping seat which is connected with the stress sensor; a soil preparation assembly which comprises an upper matching sleeve detachably connected with the fixed clamping seat, at least two petal type side movable plates detachably connected with the upper matching sleeve, rubber films detachably arranged on the inner sides of the petal type side movable plates, and a lower matching sleeve detachably connected with the petal type side movable plates, at least two petal type side movable plates define a movable sleeve which is connected in the circumferential direction, and the lower matching sleeve is detachably connected to the bottom plate. When a soil body sample is manufactured and a tensile test is carried out, the purposes of manufacturing and stretching the soil body sample can be achieved by disassembling and assembling the soil manufacturing assembly.

Owner:SHIJIAZHUANG TIEDAO UNIV

Heat-insulation construction and energy conservation process for exterior walls

The invention relates to a heat-insulation construction and energy conservation process for exterior walls. The scheme includes that the heat-insulation construction and energy conservation process includes particular steps of cleaning and processing base layers; adjusting control lines and hanging datum lines; adhering graphite and polystyrene foam plates; fixing SEPS (styrene-ethylene / propylene-styrene block copolymer) plates in an adhesion mode by the aid of a point-frame method or a strip adhesion method; constructing surface layers. The heat-insulation construction and energy conservation process has the advantages that the heat-insulation construction and energy conservation process is simple, and good heat-insulation effects can be realized; heat-insulation layers are made of graphite and polystyrene foam and are light and safe as compared with the traditional heat-insulation systems, the weights of the heat-insulation layers only account for 60% of the weights of the traditional molded plasticized polystyrene and thin plasticized polystyrene plastered systems, the thicknesses of the heat-insulation layers are equivalent to 50% of the thicknesses of the traditional plastered systems, and accordingly the purpose of saving energy by 65% can be easily achieved; the graphite and polystyrene foam has a fireproof function and is applicable to optional wall surfaces and wide in application range.

Owner:ZHONGTIAN LIANHE ENERGY SAVING CONSTR DEV TIANJIN

Water-soluble biological polysaccharide with low polymerization degree, using method thereof and obtained product

ActiveCN102180983AReduced prickly sensationReduce woodinessTobacco preparationSugar derivativesDepolymerizationAspergillus

The invention relates to a water-soluble biological polysaccharide with low polymerization degree, a method for preparing papermaking tobacco sheets with low fiber content by using the polysaccharide and a product obtained by the method. The water-soluble biological polysaccharide with low polymerization degree is obtained by hydrochloric acid solution immersion of aspergillus niger or shrimp bran, protein removal treatment, calcium removal, decoloration, acetyl removal treatment, depolymerization and oxidative cutting. The papermaking tobacco sheets are prepared by substituting partial wood pulp fiber for the prepared water-soluble biological polysaccharide with low polymerization degree, and the novel papermaking tobacco sheets with low fiber content has better smoking quality besides the physical properties of the original products.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

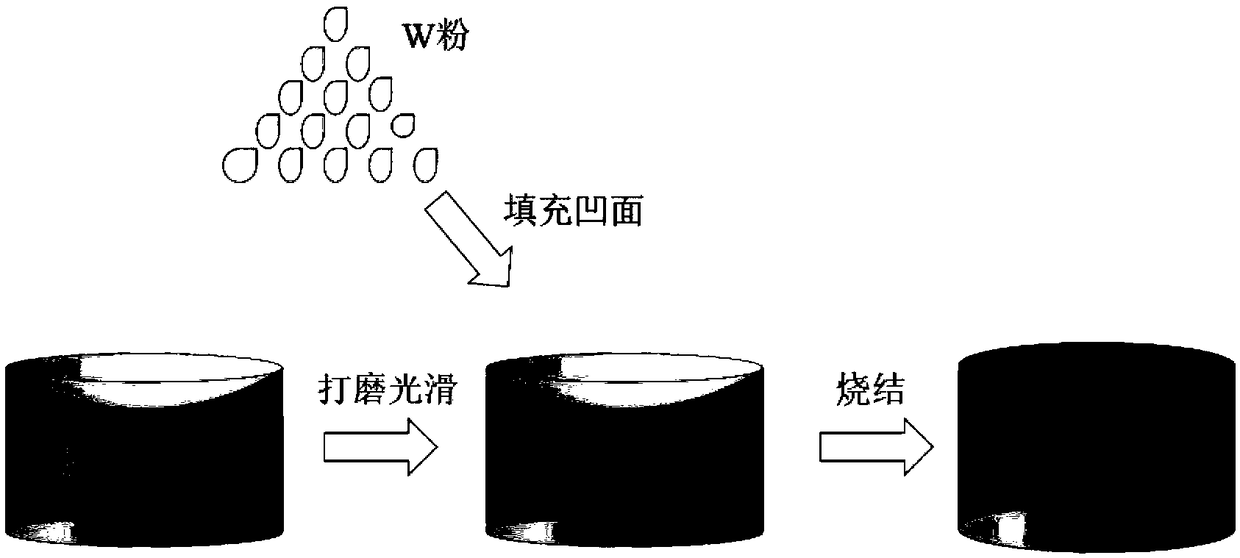

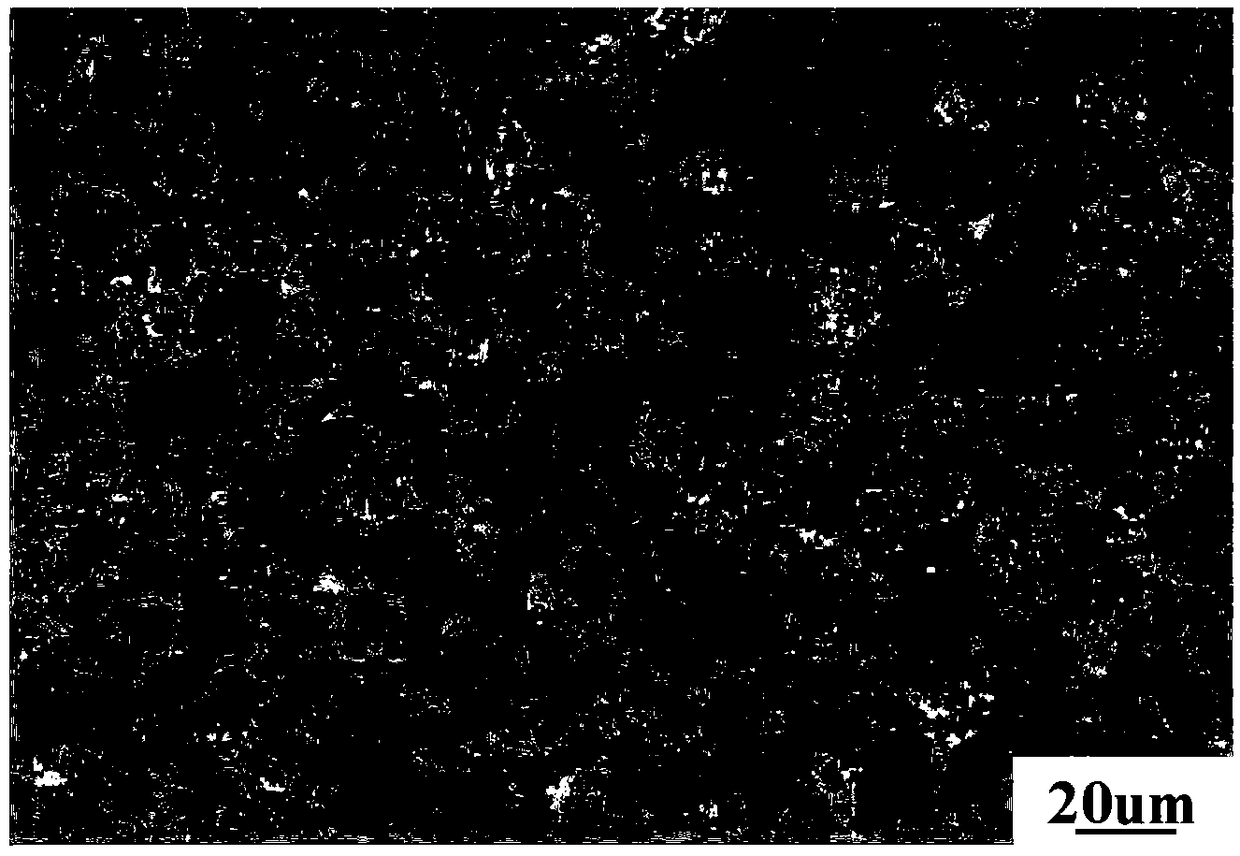

Repairing method of W target material

ActiveCN108817405AReduce use costSolve problems that cannot be patched for reuseVacuum evaporation coatingSputtering coatingGraphiteMaterials science

The invention discloses a repairing method of a W target material. The repairing method comprises the steps that the to-be-repaired W target material is put into a graphite mould, and then W powder required by repairing is added, and the W powder is made to be located on the to-be-repaired surface of the W target material; and after being pre-pressed, the W target material is put into a spark plasma sintering system to be subjected to sintering connection, so that an uneven defect area on the to-be-repaired surface of the W target material is filled with the W powder, and repairing of the W target material is completed. According to the repairing method of the W target material, an SPS technology is adopted, by selecting appropriate sintering parameters, the defect on the surface of the Wtarget material can be completely repaired, and after being repaired, the W target material is fine in structure and high in density; the problem that after defects are generated on the surface of anexisting W target material, the existing W target material cannot be repaired and reutilized is effectively solved; and the technique is simple, the period is short, the production efficiency is high,and the using cost of the W target material can be reduced substantially.

Owner:HEFEI UNIV OF TECH

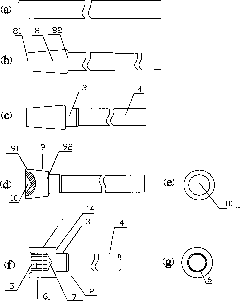

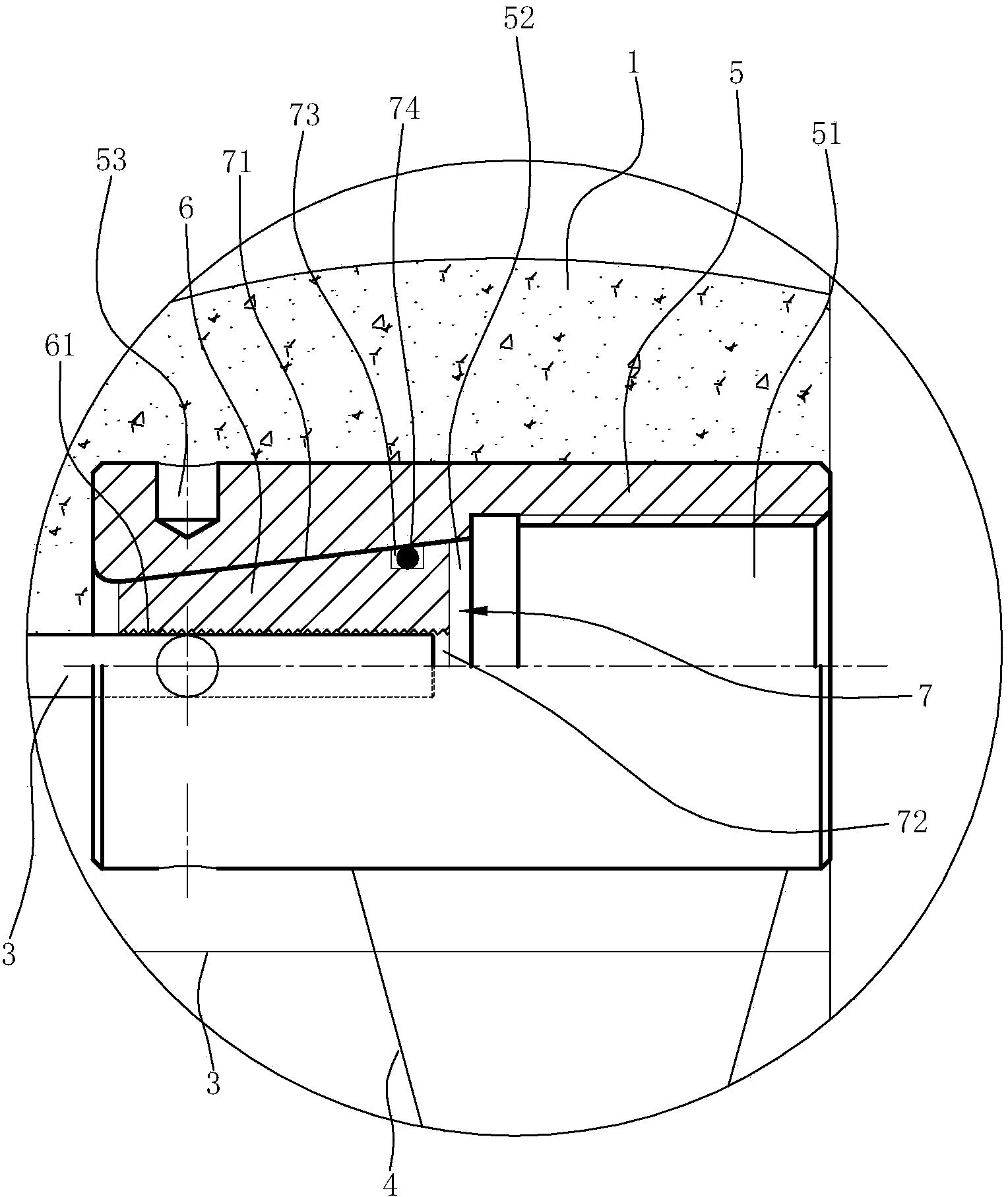

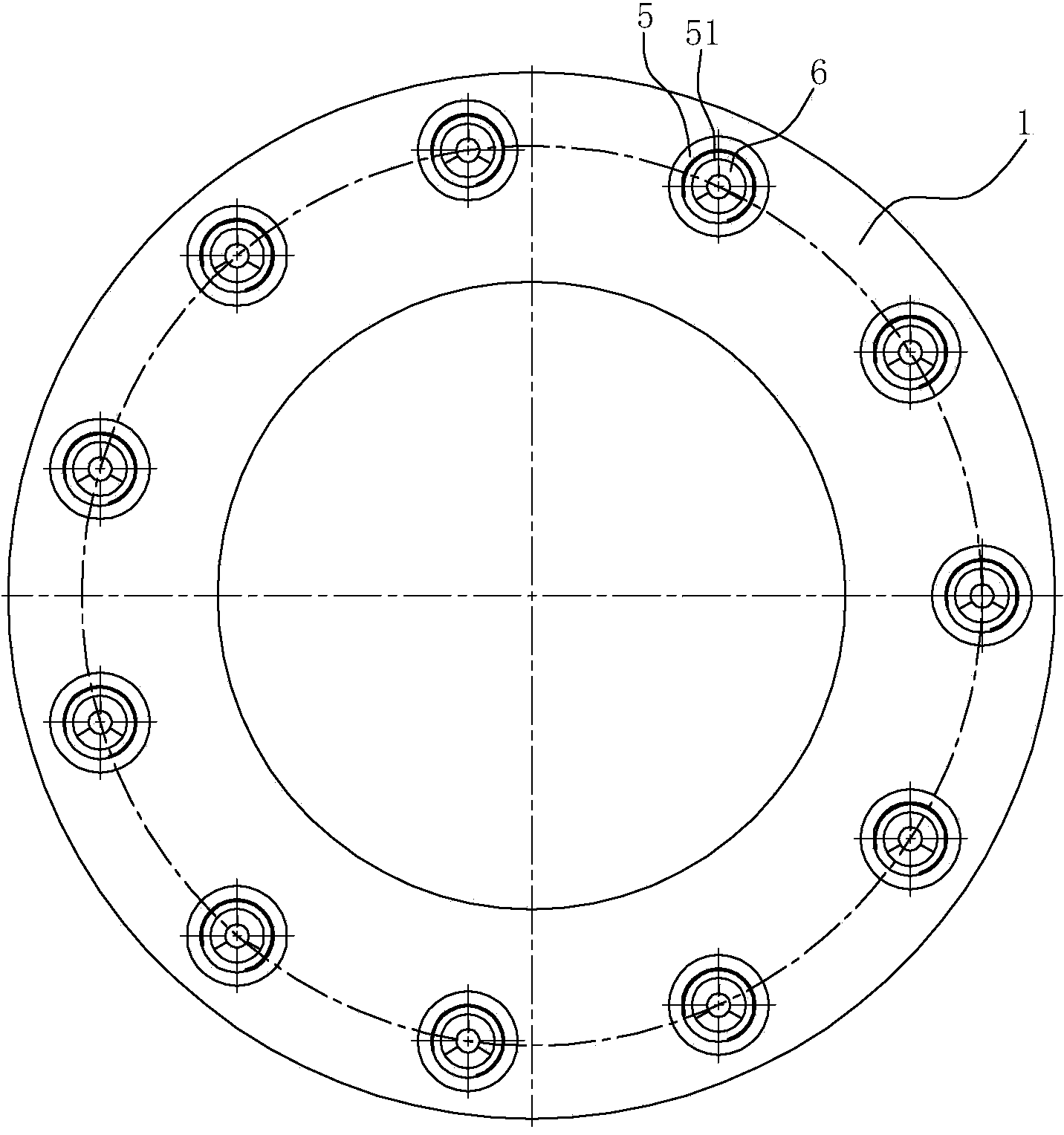

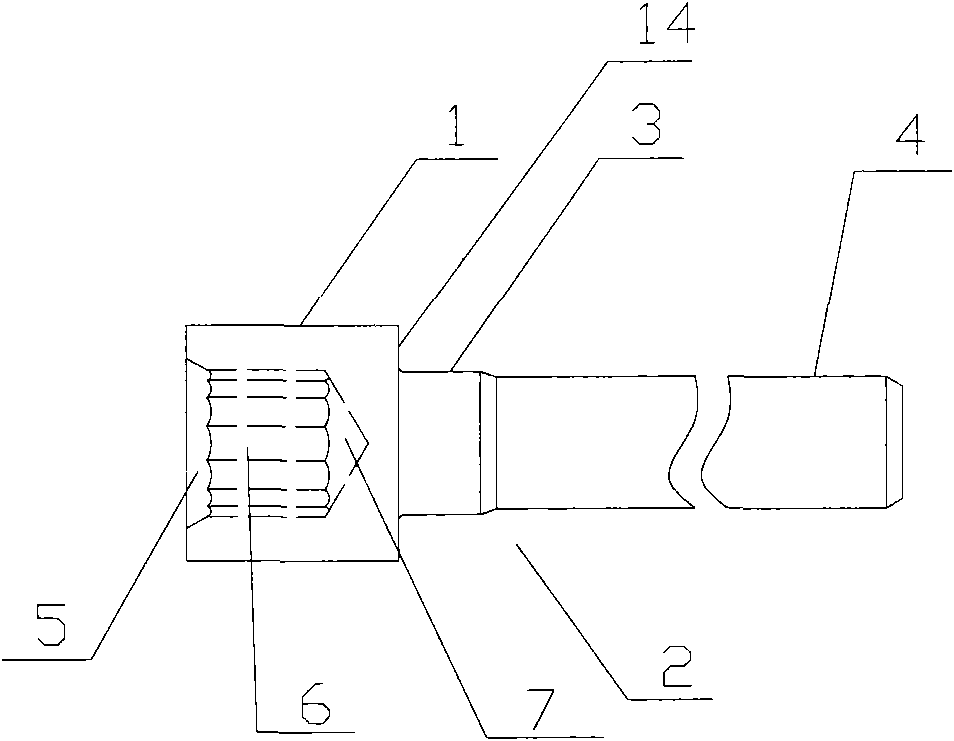

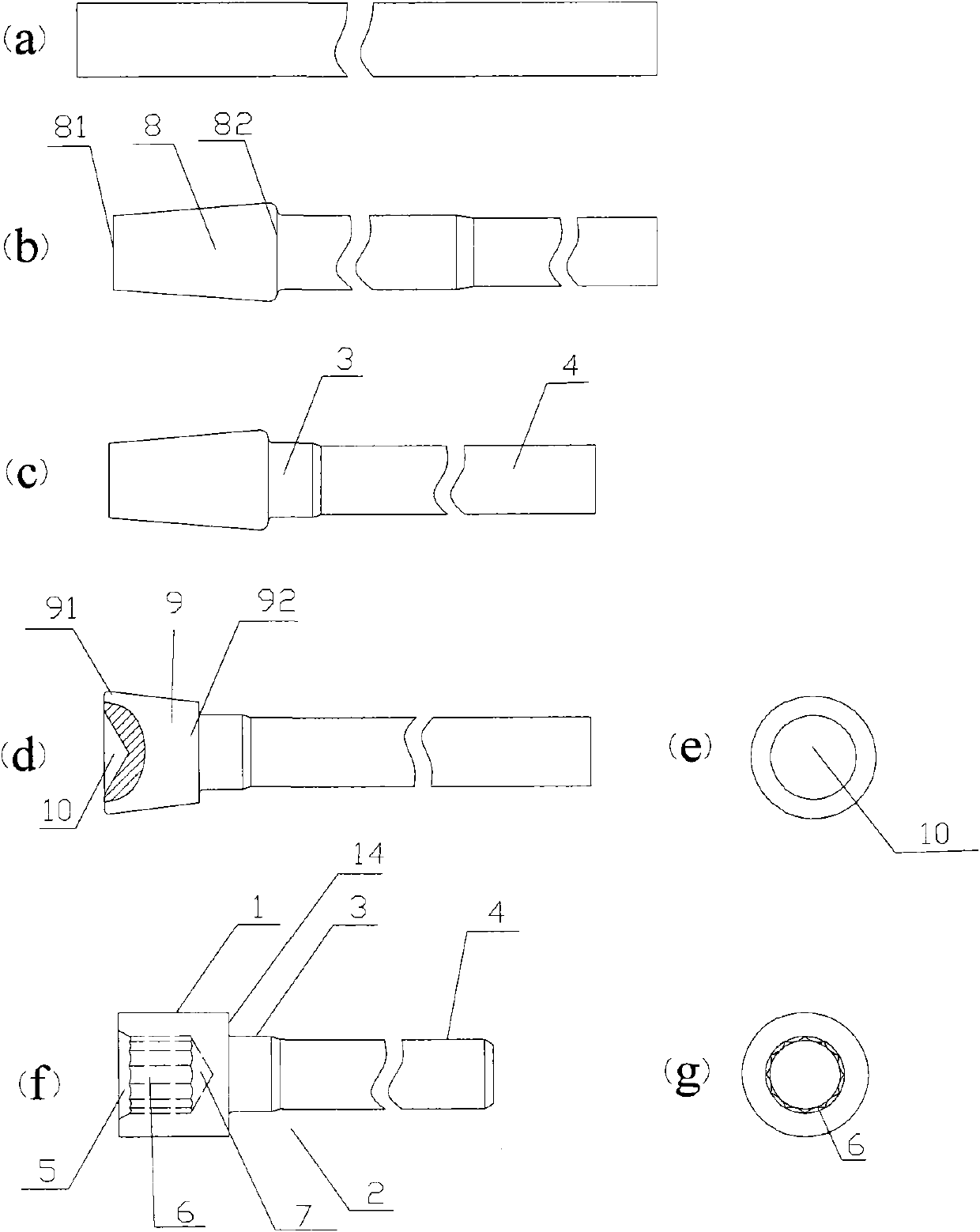

Pre-tensioning-mode centrifugal concrete pile with steel strands and manufacturing method

ActiveCN103758120AImprove performanceAnchor ring slippedCeramic shaping apparatusBulkheads/pilesPre stressRebar

The invention relates to a pre-tensioning-mode centrifugal concrete pile with steel strands. The pre-tensioning-mode centrifugal concrete pile comprises a concrete pile body and a steel reinforcement cage. The steel reinforcement cage comprises prestress main reinforcements and stirrups. The pre-tensioning-mode centrifugal concrete pile is characterized in that the prestress main reinforcements are the steel strands, the steel strands of at least one end of the steel reinforcement cage are tightly combined with anchor rings; each anchor ring is provided with a stepped through hole, the large hole portion of the stepped through hole is a threaded hole, and the small hole portion of the stepped through hole is a taper hole; a plurality of clamping pieces are placed in the taper holes, the inner surface of each clamping piece is provided with clamping teeth, and multiple clamping pieces are spliced to form a chuck assembly; the outer circumferential surface of each chuck assembly is provided with a cone surface matched with the taper holes; an inner tooth hole is formed in the center of each chuck assembly, and the steel strands penetrate through the inner tooth holes of the corresponding chuck assemblies and are locked by the inner tooth holes. In the process of manufacturing the concrete pile body, the anchor rings combined with the ends of the steel strands and a tension plate are fixed together in a threaded connection mode, and consequently the steel strands which are used as the main reinforcements in the steel reinforcement cage can be tensioned and applied, and end plates can be freely installed according to actual requirements. The invention further relates to a manufacturing method of the pre-tensioning-mode centrifugal concrete pile with the steel strands.

Owner:俞向阳

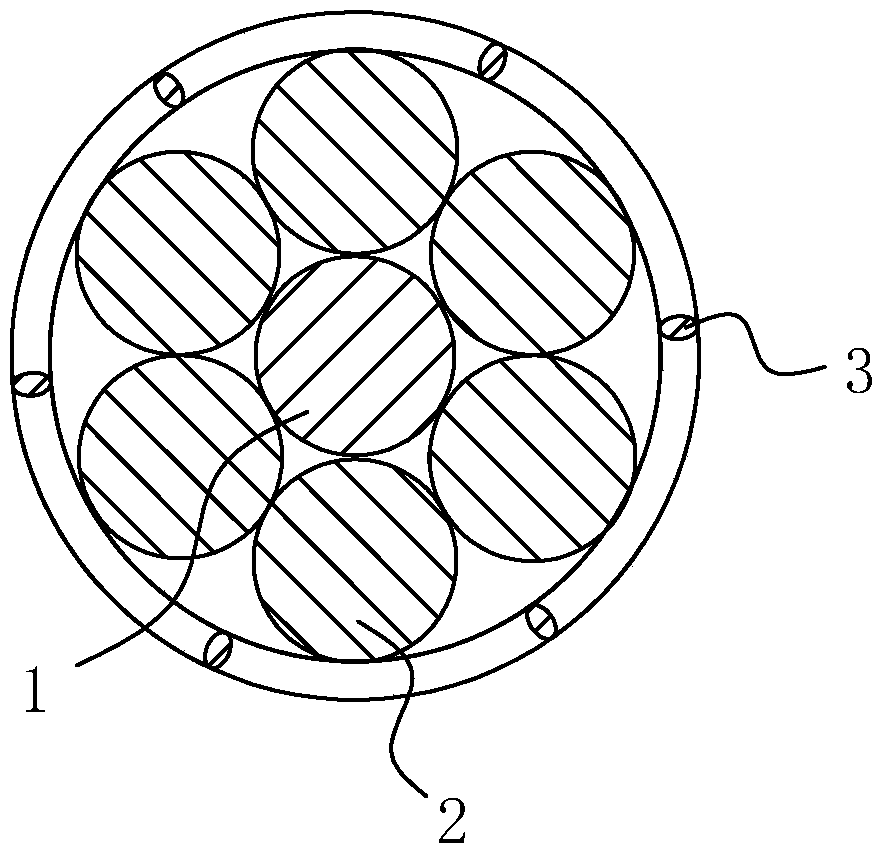

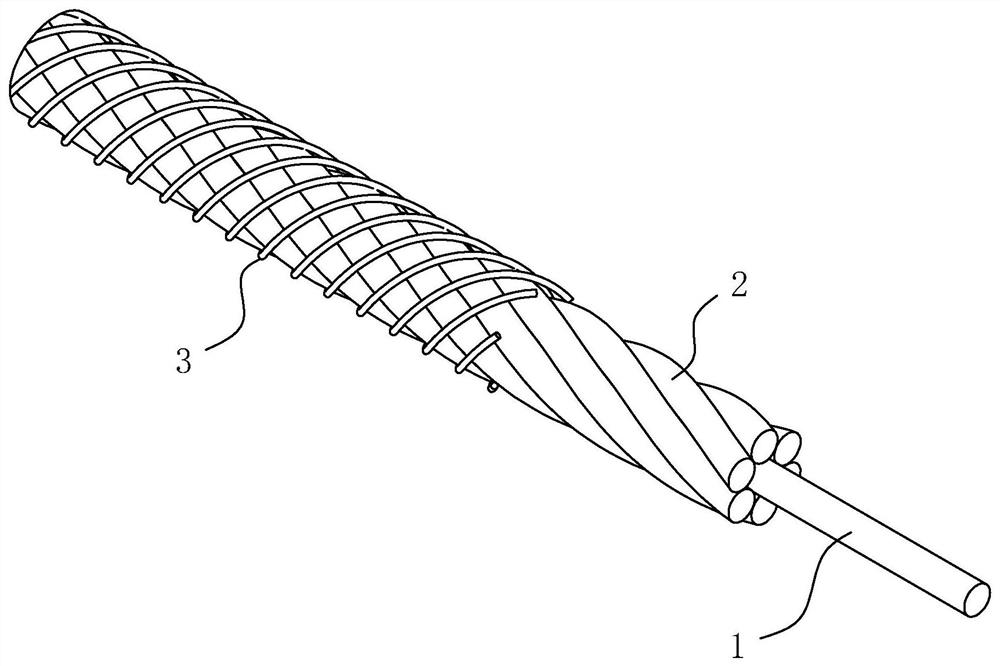

High-clean stainless steel cable and treatment method thereof

ActiveCN108914659AExtended service lifeAvoid wear and tearTextile cablesUltimate tensile strengthMaterials science

The invention discloses a high-clean stainless steel cable and a treatment method thereof and relates to the technical field of rigging production. The key points of the technical scheme comprise a central steel wire; multiple external-layer steel wires are uniformly distributed outside the central steel wire; a reinforced steel strand is installed at the gap between the central steel wire and adjacent two external layer steel wires; multiple external layer steel wires and the reinforced steel strands are twisted and fixed with the central steel wire as the shaft; the surfaces of the central steel wire, the external layer steel wires and the reinforced steel strands are under surface treatment to form carbonitrided layers. The invention solves the problem that the actual tensile strength of the stainless steel cable is lower than the design strength due to mechanical damage during the wire drawing process, and the overall strength is improved by redesigning and surface treatment of thestainless steel cable structure.

Owner:华迪钢业集团有限公司

Process for manufacturing high-strength bolt

The invention provides a process for manufacturing a high-strength (above) bolt. The process comprises the following steps: selecting a proper steel material, and cutting out a cylindrical blank with proper size; molding the head part and the rod part of the bolt by adopting cold extrusion technology; heating; manufacturing the rod part, including coarse grinding and fine grinding; detecting injury by magnetic powder; manufacturing screw; and performing surface mechanical reinforcement and corrosion resistance treatment. The process solves the technical problems of insufficient strength and fatigue fracture which are easily generated on the bolt existing in the prior art for manufacturing the high-strength bolt, and is a high-strength bolt manufacturing process capable of improving tensile and fatigue strength resistance of the bolt.

Owner:浙江裕泰汽车配件有限公司

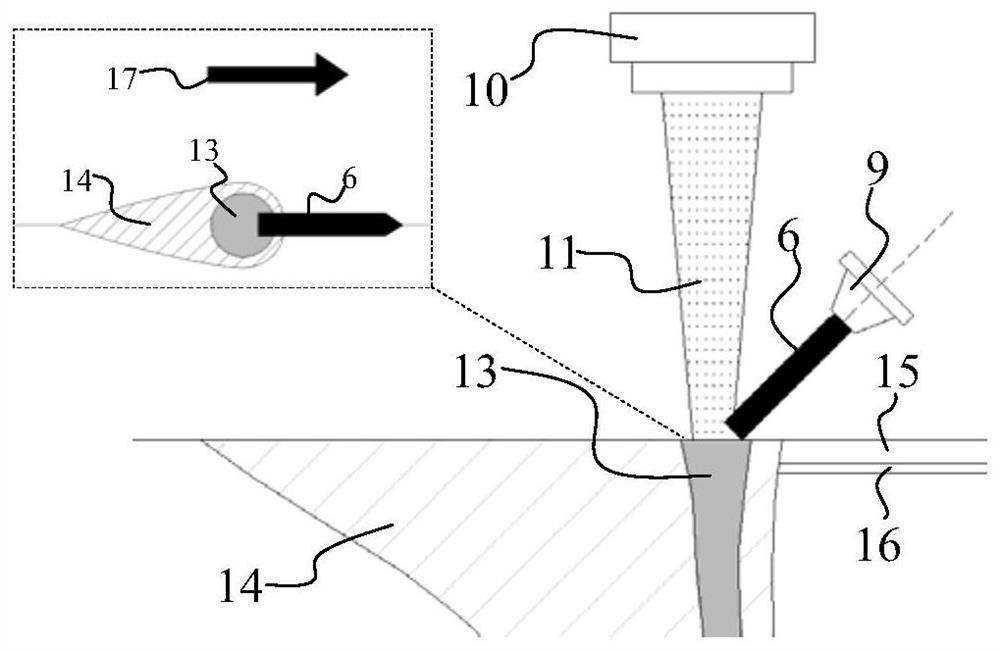

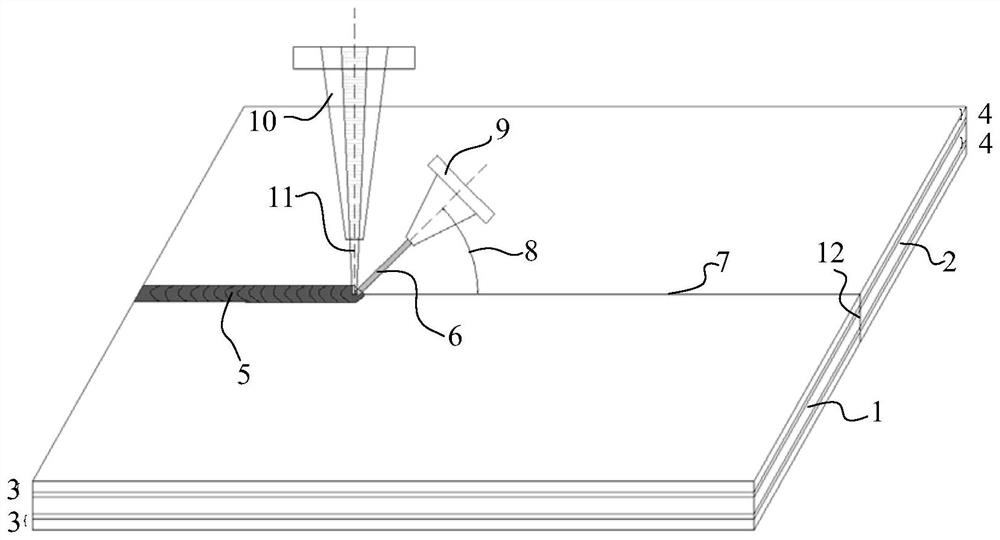

Tailored blank laser welding method for aluminum-silicon coating steel

PendingCN113967789AImprove efficiencyQuality improvementLaser beam welding apparatusStainless steel weldingSteel plates

The invention discloses a tailored blank laser welding method for aluminum-silicon coating steel. The tailored blank laser welding method comprises the following steps that a stainless steel welding wire with the high molybdenum content is selected; two steel plates with aluminum-silicon coatings are taken; butt-joint laser filler wire tailored welding is carried out; and hot stamping is performed after welding. According to the method, the coating does not need to be removed, and splicing of the aluminum-silicon coating steel can be achieved only by filling the welding wires. After hot stamping, a welding head is consistent with a base material in toughness, so that the product quality and the production efficiency are improved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

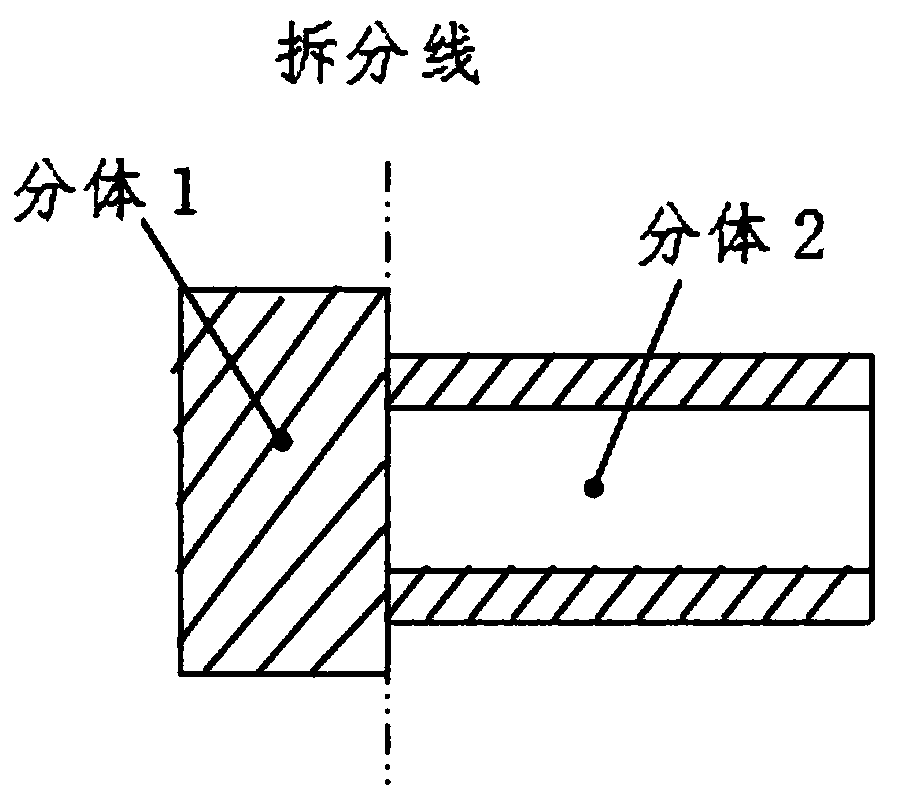

Preparation method of metal pipe fittings not prone to deform

The invention provides a preparation method of metal pipe fittings not prone to deform, and belongs to the field of pipe fitting preparation. The preparation method has the beneficial effects that metal reducer pipes and blind hole pipes not prone to deform are prepared through sequential split preparation and friction welding, the difficulty of overall preparation can be greatly reduced, the preparation cost is reduced, the production efficiency is improved, and the yield is increased. Friction welding is a solid phase welding method and has the technical characteristics of being high in quality, efficient and free of pollution and saving energy, and efficient and high-quality welding of the reducer pipes and blind hole pipes not prone to deform can be achieved. The dimensional precisionof the components obtained after solid phase welding is high, weld joints are narrow and are in micron orders, the tensile strength and the yield strength of the weld joints are kept consistent with those of base metal, the welding coefficients of materials can reach 0.99-1.0, the structures of the weld joints and the structure of the base metal are equivalent, or the structures of the weld jointsare thinner. The preparation method can be used for connection between similar or dissimilar metal pipes, between the pipes and rods and between the pipes and plates.

Owner:WESTERN METAL MATERIAL

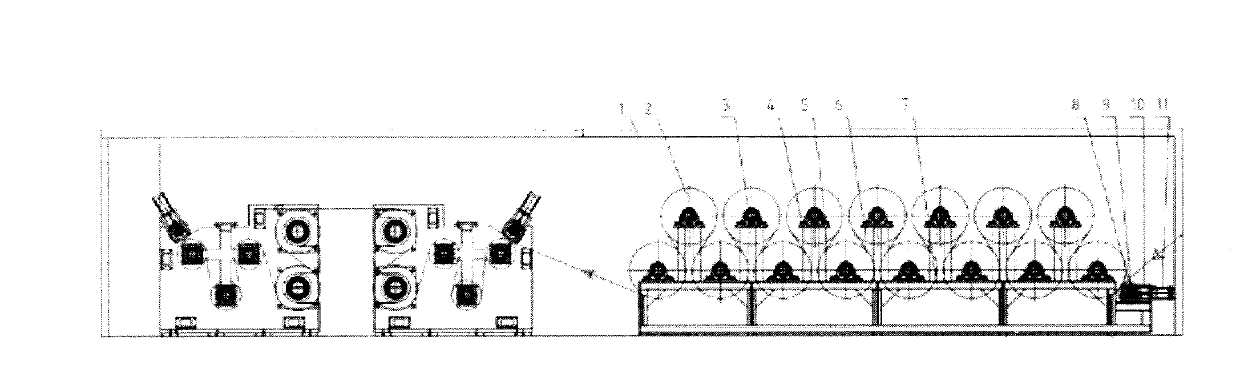

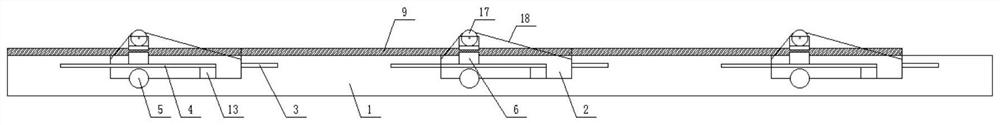

Twenty-five-roller stretcher for uniaxial tension of geogrid

The invention provides a twenty-five-roller stretcher for uniaxial tension of geogrid, belonging to the processing field of plastic state materials. According to the stretcher, a multiroll type multi-point stretching manner, oil heating, whole-course chain drive are utilized, and the tension speed of the front stage and the rear stage can be adjusted by a chain wheel, so that the condition that the weight of a stretching roller is increased and the rotational inertia of the stretching roller is large after the stretching roller is fully filled with hot oil, so that a driven roller of an existing stretcher is difficult to control and is even out of control, and further the tension precision is affected can be avoided, and further various problems related to cost, processing, control and other aspects caused by gradually increased size of the rear-stage stretching roller in the prior art can be also avoided, so that plates can be stretched on each stretching roller, the multi-roller multi-point stretch is realized, the manufactured geogrid can be stretched more uniformly, the thickness of the geogrid is uniform and consistent, the molecular orientation linear distribution is uniform, and the node intensity is high; and the twenty-five-roller stretcher for the uniaxial tension of the geogrid has quite high stretch strength and stretch modulus, and technological requirements on the lateral stretching of the later-stage geogrid are met.

Owner:青岛欣煜升新材料有限公司

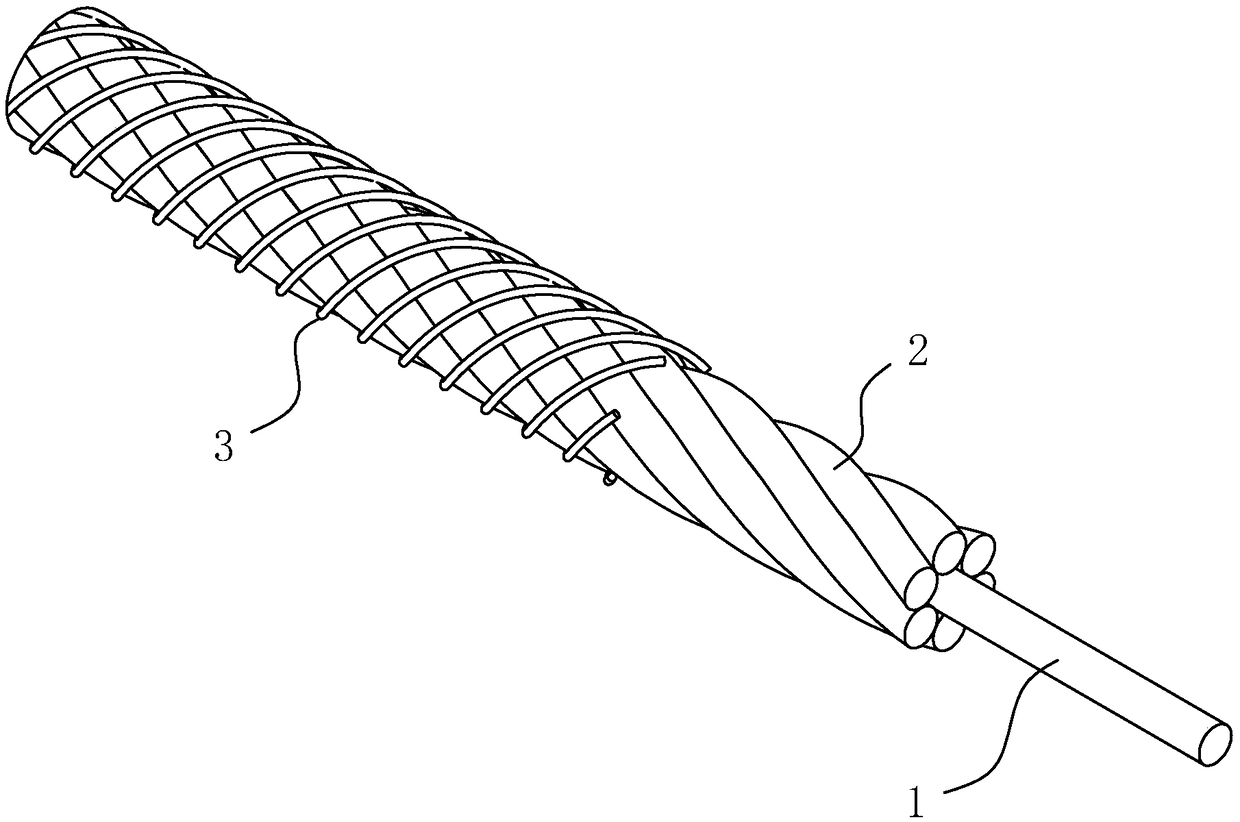

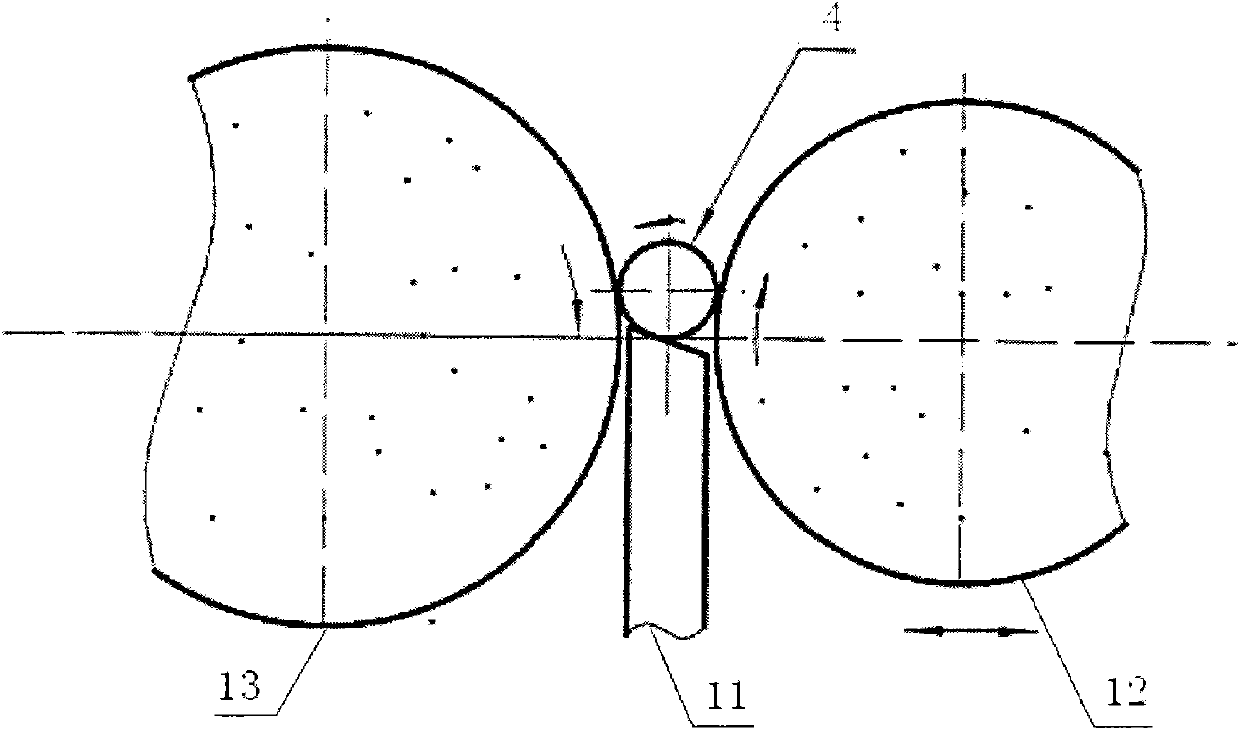

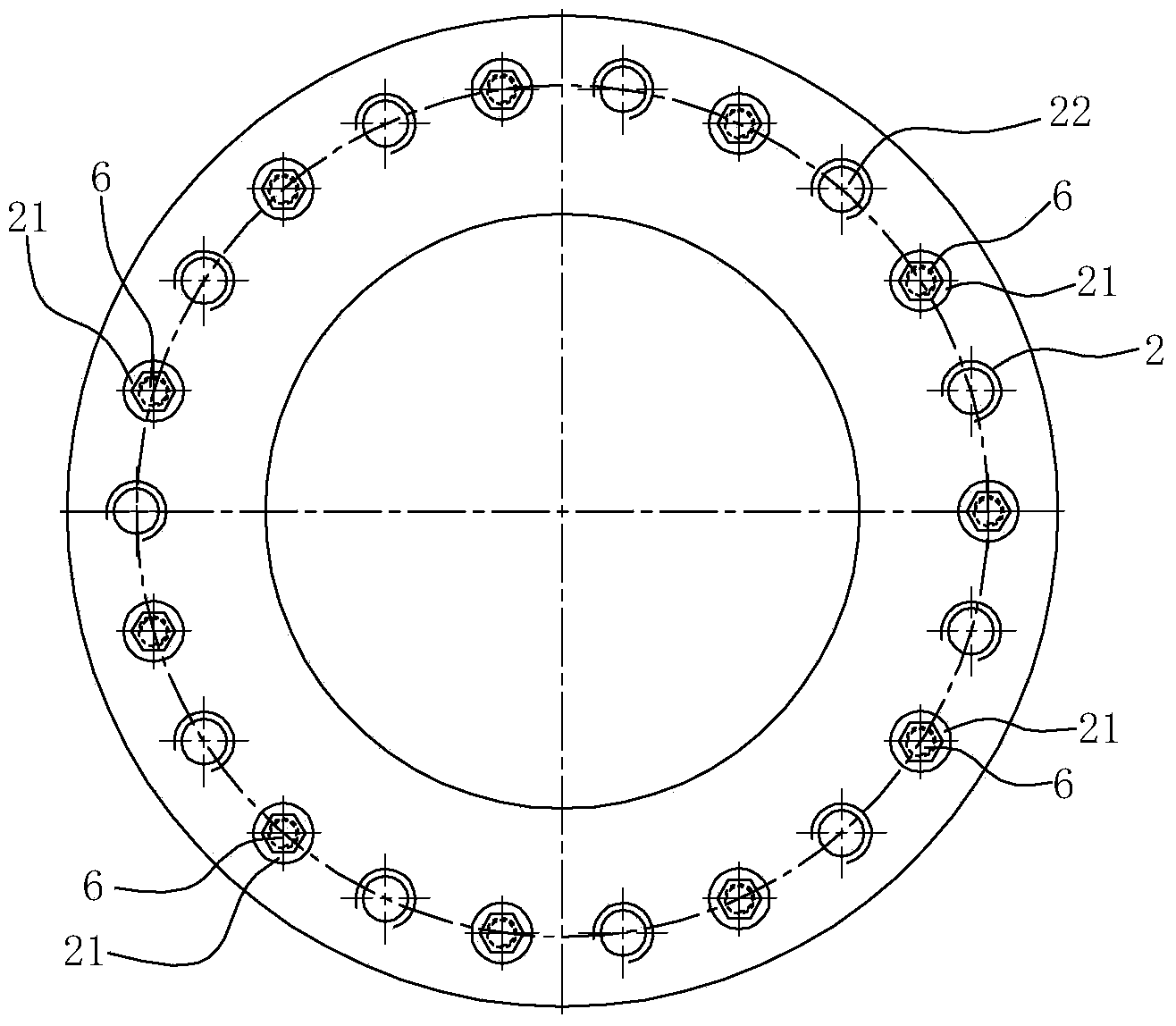

Pre-tensioning method centrifugal concrete pile with steel strands and manufacturing method

ActiveCN103882856AImprove performanceFirmly connectedCeramic shaping apparatusBulkheads/pilesPre stressRebar

The invention relates to a pre-tensioning method centrifugal concrete pile with steel strands. The pre-tensioning method centrifugal concrete pile comprises a hollow concrete pile body, end plates and a steel bar cage. The steel bar cage comprises main prestressing bars and stirrups, wherein the main prestressing bars are axially arranged, and the stirrups are wound around the main bars. The pre-tensioning method centrifugal concrete pile is characterized in that the main prestressing bars are the steel strands, the steel strands of at least one end of the steel bar cage are combined with extrusion anchor devices, the peripheries of the extrusion anchor devices are sleeved with connecting sleeves, the connecting sleeves are provided with stepped through holes, the connecting sleeves are provided with threads for connection, a plurality of connecting counter holes are formed in the end plates, a threaded connecting piece is arranged inside each connecting counter hole, the end plates are connected with the threads for connection on the connecting sleeves through the threaded connecting pieces, and the end plates are further provided with a plurality of threaded connecting holes used for connection. According to the pre-tensioning method centrifugal concrete pile with the steel strands, in the pile manufacturing process, the steel strands combined with the extrusion anchor devices can be fixedly connected with the end plates through the connecting sleeves, tensioning plates of the end plates are fixedly connected in a threaded mode, the steel strands used as the main bars in the steel bar cage are tensioned and applied, and the anti-bending, anti-shearing and anti-tensioning performance is greatly improved. The invention further relates to a manufacturing method of the pre-tensioning method centrifugal concrete pile.

Owner:俞向阳

A pretensioned centrifugal concrete pile with steel strands and its manufacturing method

ActiveCN103758120BImprove performanceAnchor ring slippedCeramic shaping apparatusBulkheads/pilesPre stressRebar

The invention relates to a pre-tensioning-mode centrifugal concrete pile with steel strands. The pre-tensioning-mode centrifugal concrete pile comprises a concrete pile body and a steel reinforcement cage. The steel reinforcement cage comprises prestress main reinforcements and stirrups. The pre-tensioning-mode centrifugal concrete pile is characterized in that the prestress main reinforcements are the steel strands, the steel strands of at least one end of the steel reinforcement cage are tightly combined with anchor rings; each anchor ring is provided with a stepped through hole, the large hole portion of the stepped through hole is a threaded hole, and the small hole portion of the stepped through hole is a taper hole; a plurality of clamping pieces are placed in the taper holes, the inner surface of each clamping piece is provided with clamping teeth, and multiple clamping pieces are spliced to form a chuck assembly; the outer circumferential surface of each chuck assembly is provided with a cone surface matched with the taper holes; an inner tooth hole is formed in the center of each chuck assembly, and the steel strands penetrate through the inner tooth holes of the corresponding chuck assemblies and are locked by the inner tooth holes. In the process of manufacturing the concrete pile body, the anchor rings combined with the ends of the steel strands and a tension plate are fixed together in a threaded connection mode, and consequently the steel strands which are used as the main reinforcements in the steel reinforcement cage can be tensioned and applied, and end plates can be freely installed according to actual requirements. The invention further relates to a manufacturing method of the pre-tensioning-mode centrifugal concrete pile with the steel strands.

Owner:俞向阳

A method of manufacturing a pretensioned centrifugal concrete pile with steel strands

ActiveCN103741674BImprove performanceSimple locking methodCeramic shaping apparatusBulkheads/pilesPre stressPore diameter

The invention relates to a pretensioned centrifugal concrete pile with steel stranded wires. The pretensioned centrifugal concrete pile comprises a concrete pile body and a rebar cage, and the rebar cage comprises prestressed main rebars, stirrups and end plates. The pretensioned centrifugal concrete pile is characterized in that the prestressed main rebars are the steel stranded wires, multiple conical holes which gradually expand from inside to outside in pore diameter are formed in at least one end plate and correspond to the steel stranded wires one by one, multiple clamping pieces are placed in each conical hole, clamping teeth are arranged on the inner surface of each clamping piece, the clamping pieces are spliced to form clamping head components used for hooping the steel stranded wires, the outer peripheral face of each clamping head component forms a cone face matched with the corresponding conical hole, the center of each clamping head component forms an inner tooth hole, and each steel stranded wire penetrates the inner tooth hole in the corresponding clamping head component and is locked by the inner tooth hole. The pretensioned centrifugal concrete pile is practical. The invention further relates to a manufacturing method of the pretensioned centrifugal concrete pile.

Owner:俞向阳

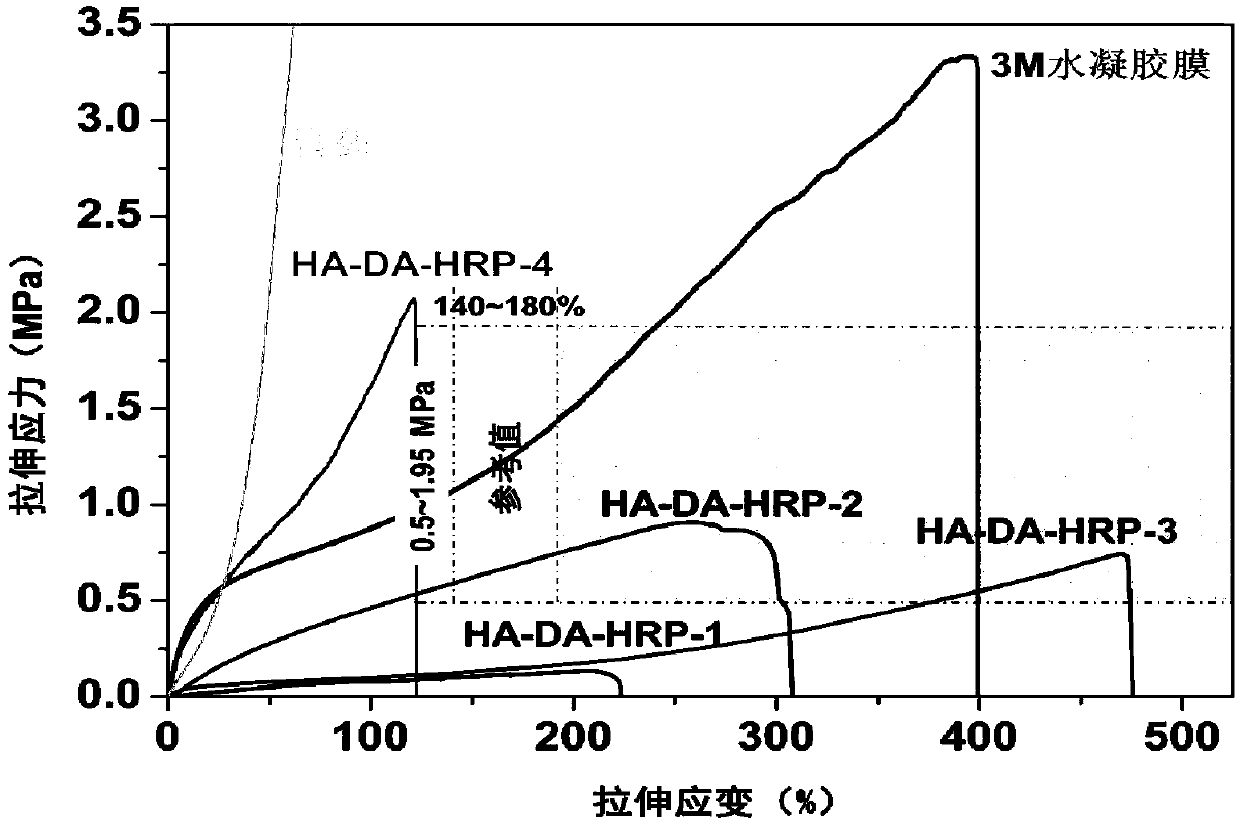

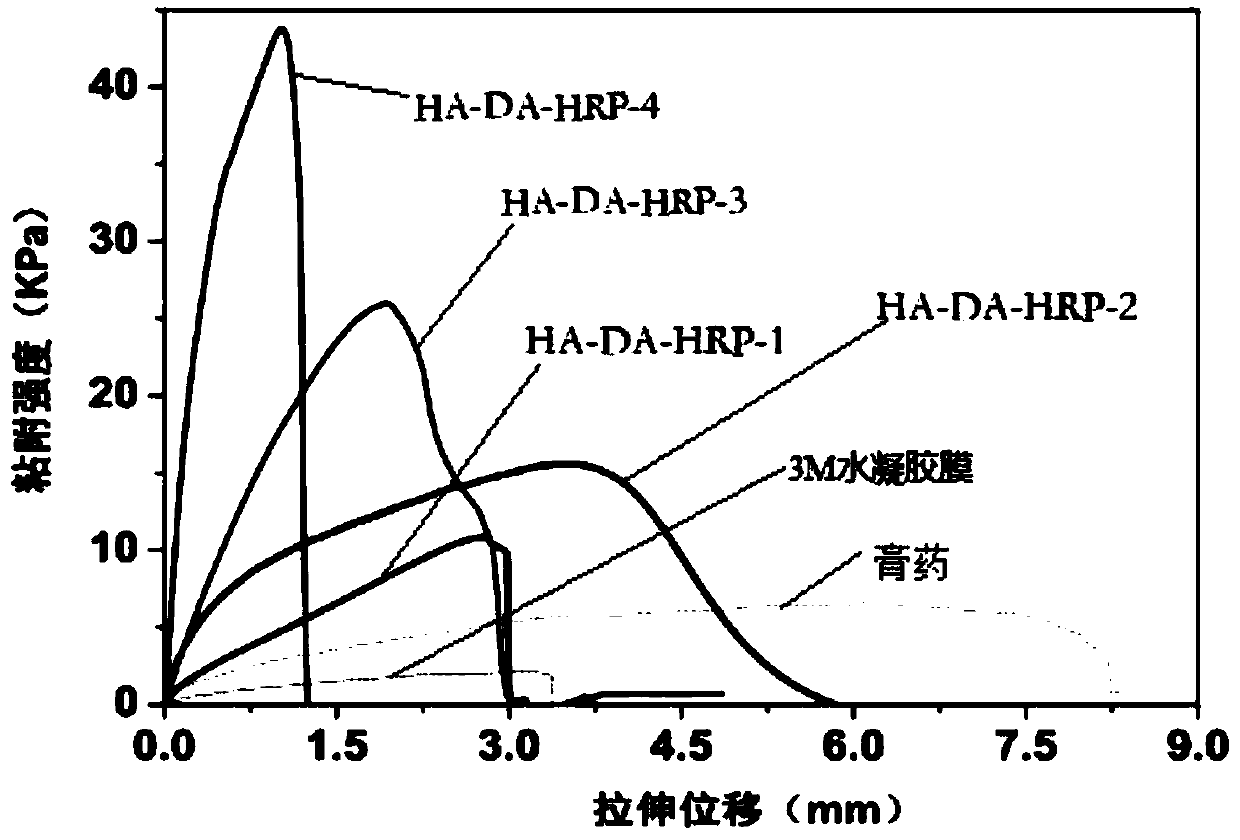

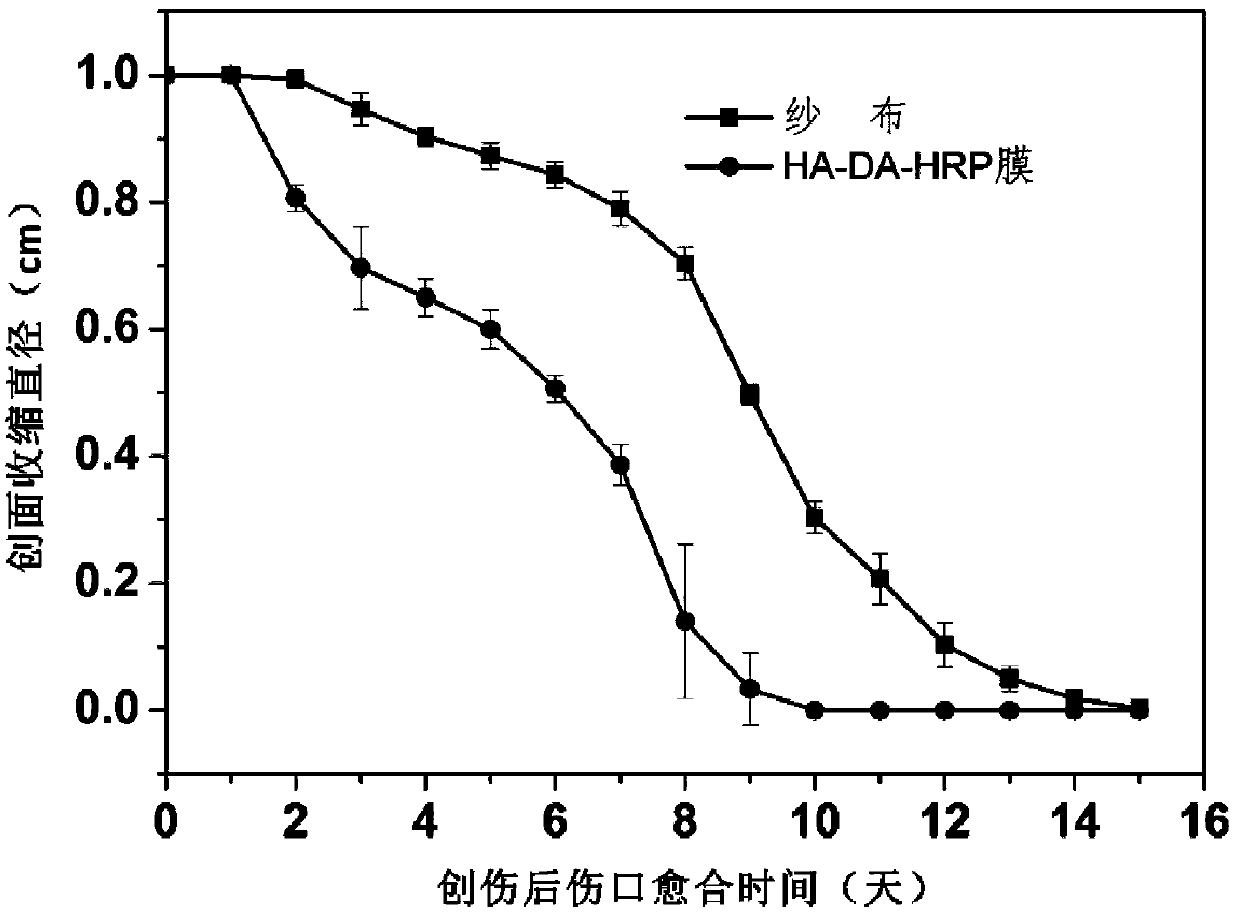

Preparation method of hydrogel film with high adhesion to skin and function of promoting wound healing

ActiveCN109602729AGood biocompatibilityImprove breathabilityMacromolecular non-active ingredientsDermatological disorderWater bathsBiocompatibility Testing

The invention discloses a preparation method of a hydrogel film with high adhesion to the skin and a function of promoting wound healing. The method is characterized by comprising the steps of: adding1-ethyl-(3-dimethyl aminopropyl) carbodiimide hydrochloride and 1-hydroxybenzotriazole to a 1% hyaluronic acid aqueous solution, adjusting the pH value of a reaction system, performing activation inice water bath for 2h, adding mono-6-deoxy-dopamine cyclodextrin derivative to an obtained solution, performing uniform mixing with stirring, adjusting pH value, performing reaction at 50 DEG C for 48-120h, performing reduced-pressure distilling to remove solvent, adding horseradish catalase and 30% hydrogen peroxide for cross-linking reaction, performing standing overnight, dialysing small molecule catalyst and unreacted substrate, then performing film casting, and volatilizing moisture to obtain the hydrogel film. The hydrogel film prepared by the method has excellent biocompatibility and good gas permeability, and can load drugs to synergistically promote wound healing, and particularly has a stress strain range corresponding to skin tissue under the disturbance of external environmentand stress reaction in the body.

Owner:JIANGNAN UNIV

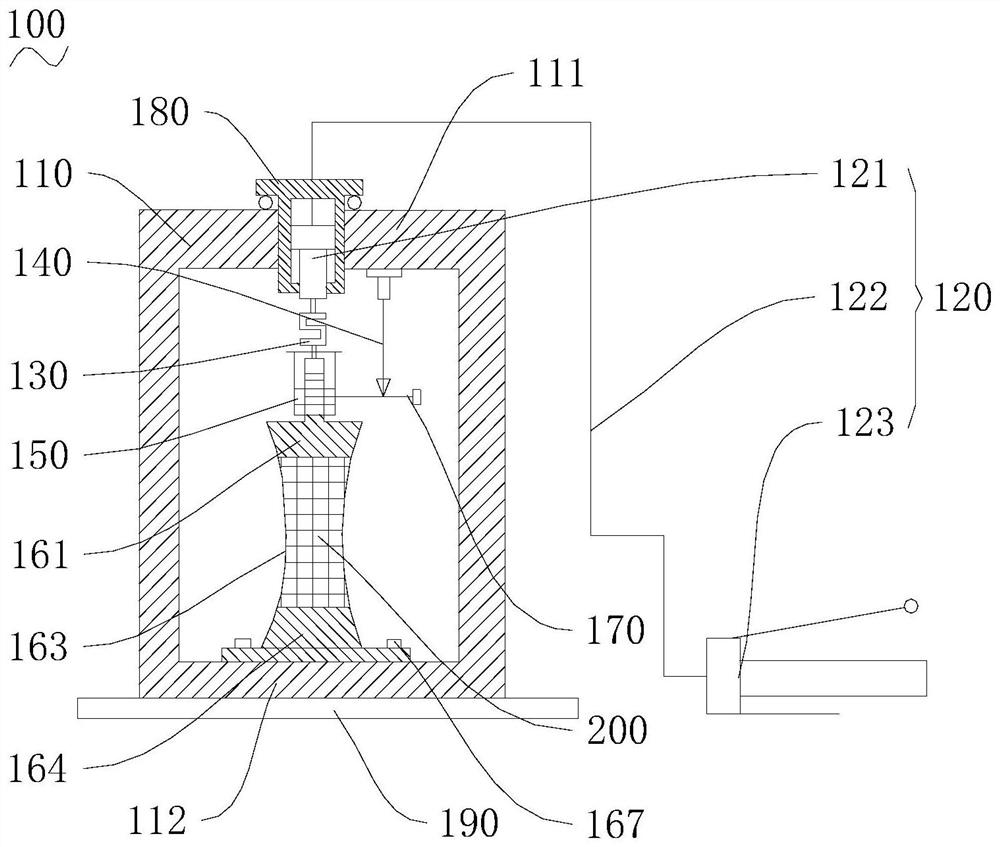

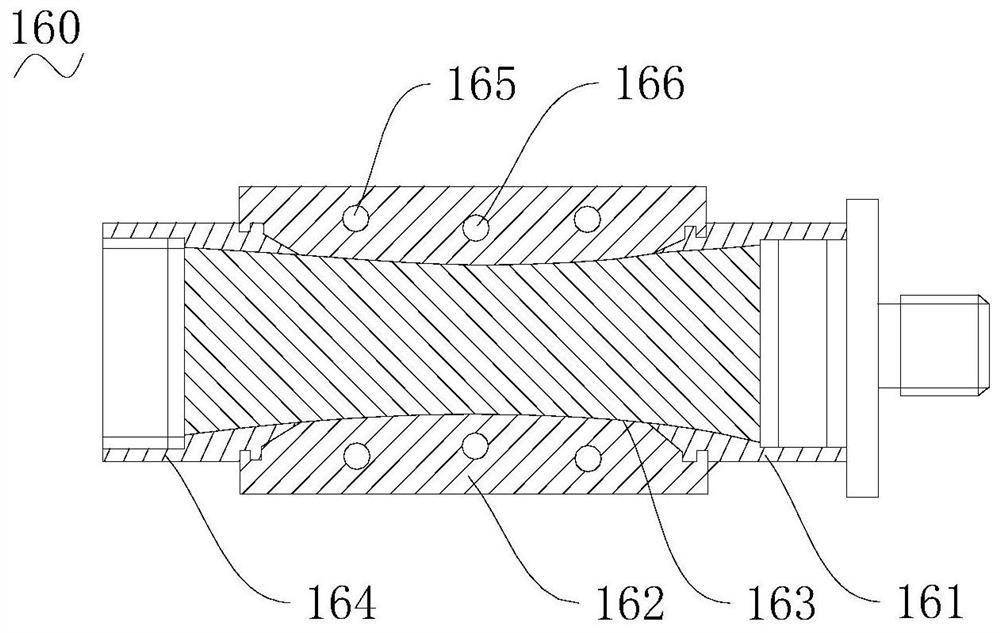

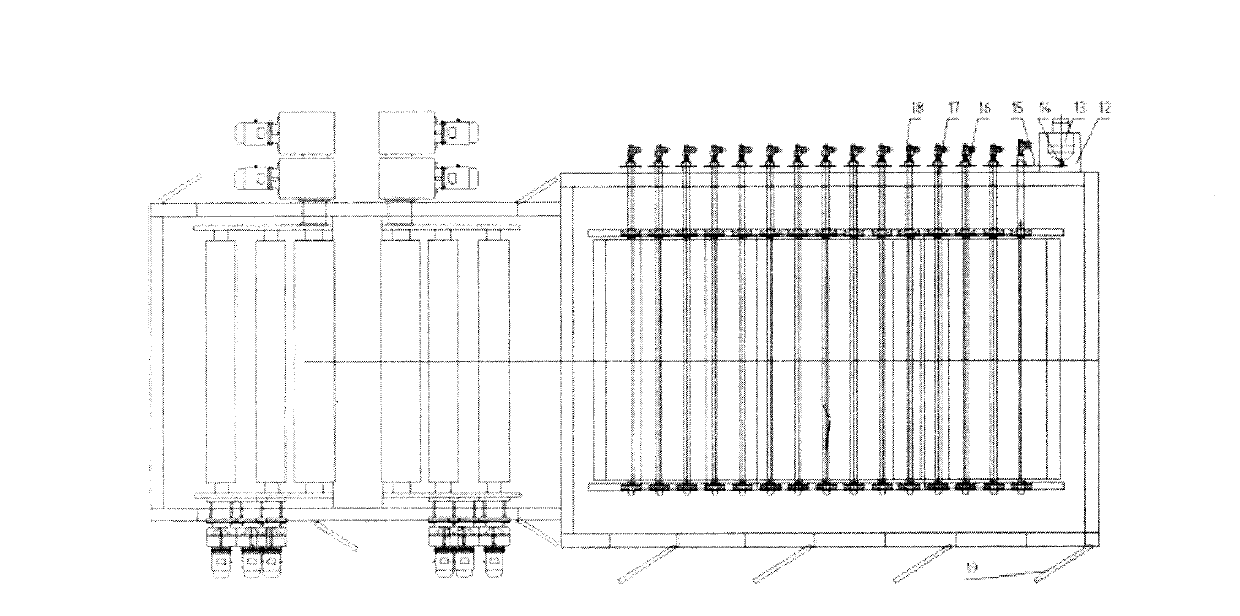

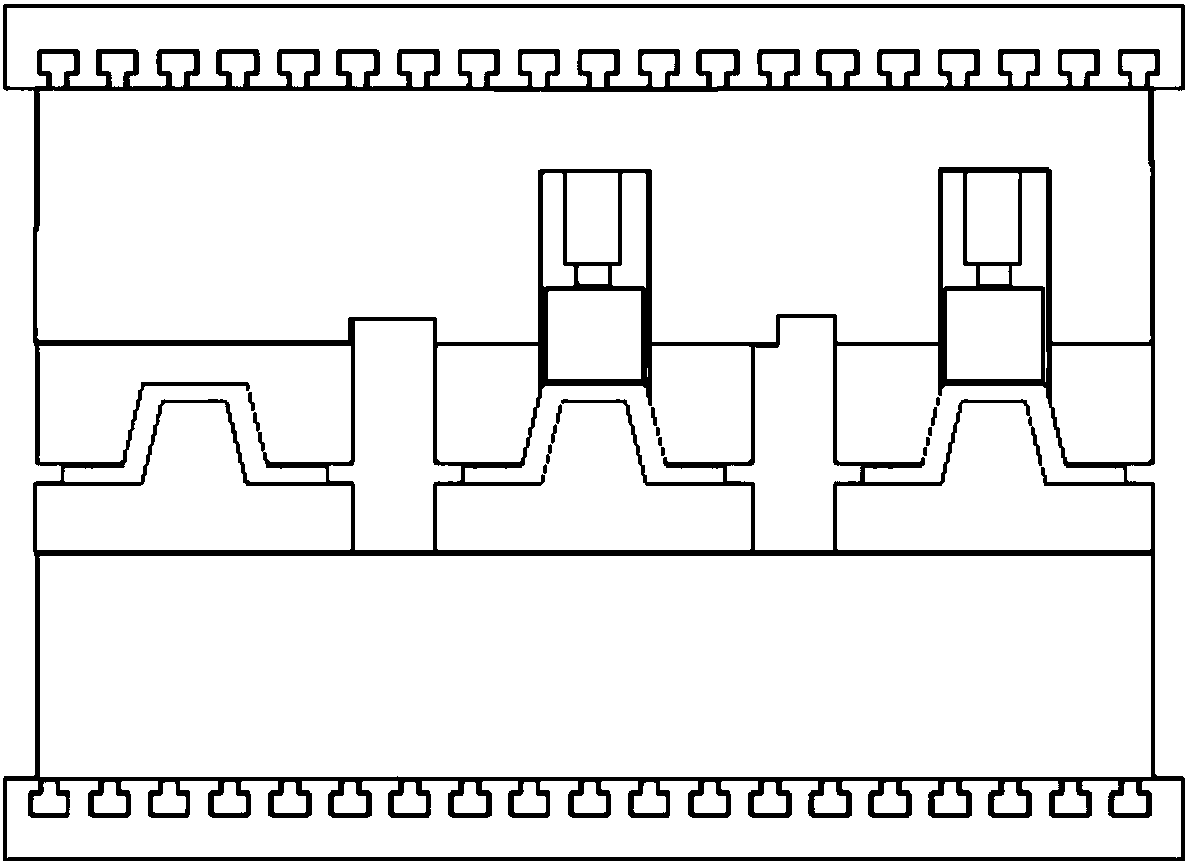

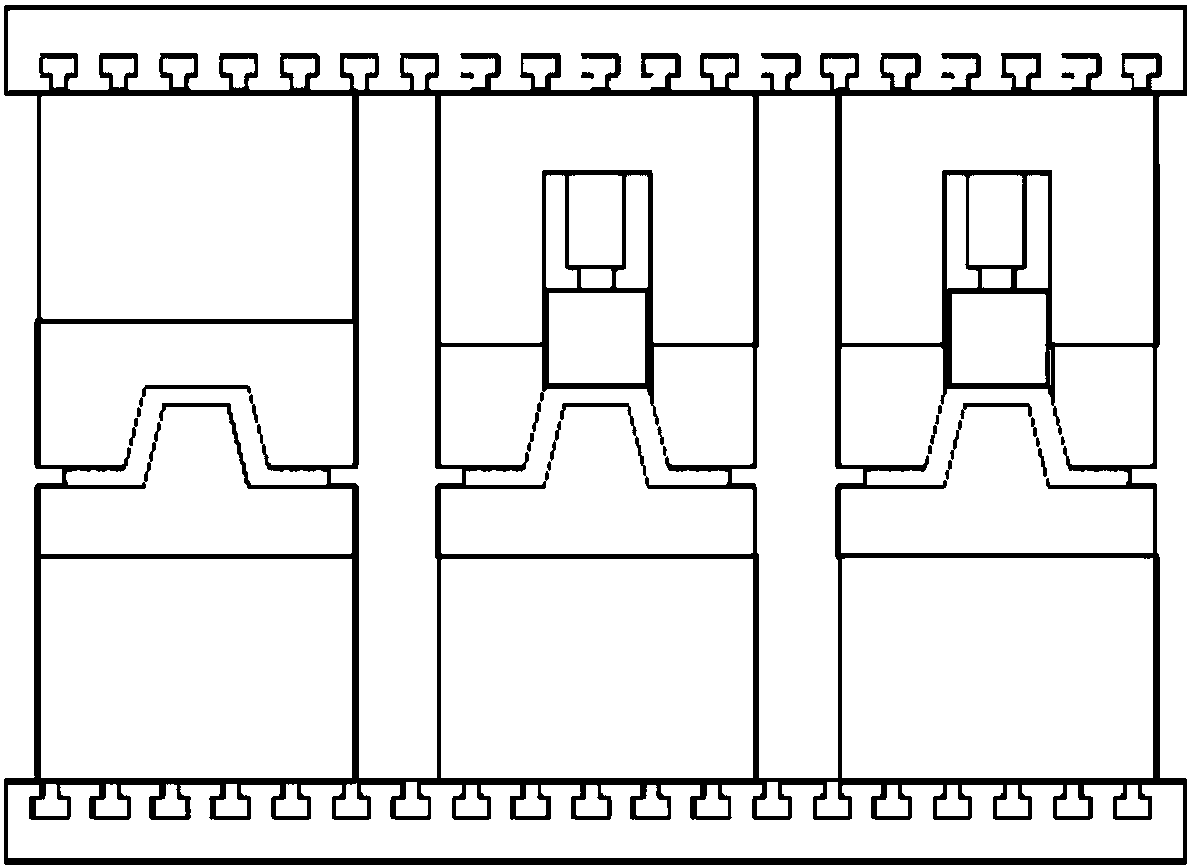

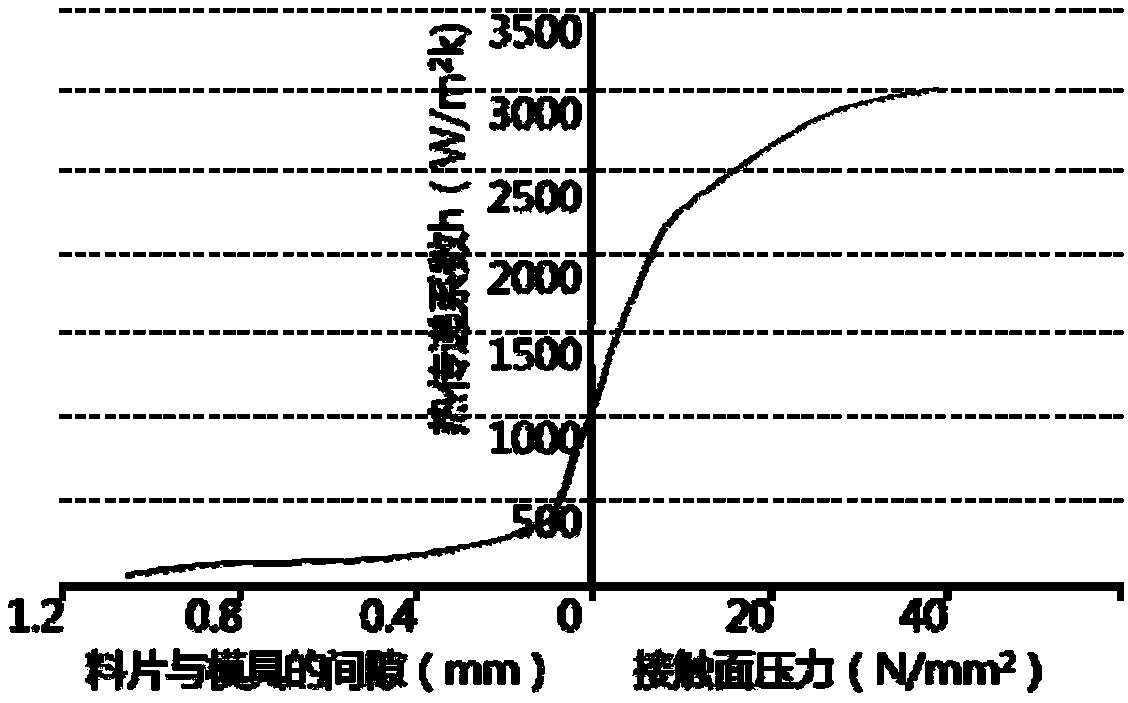

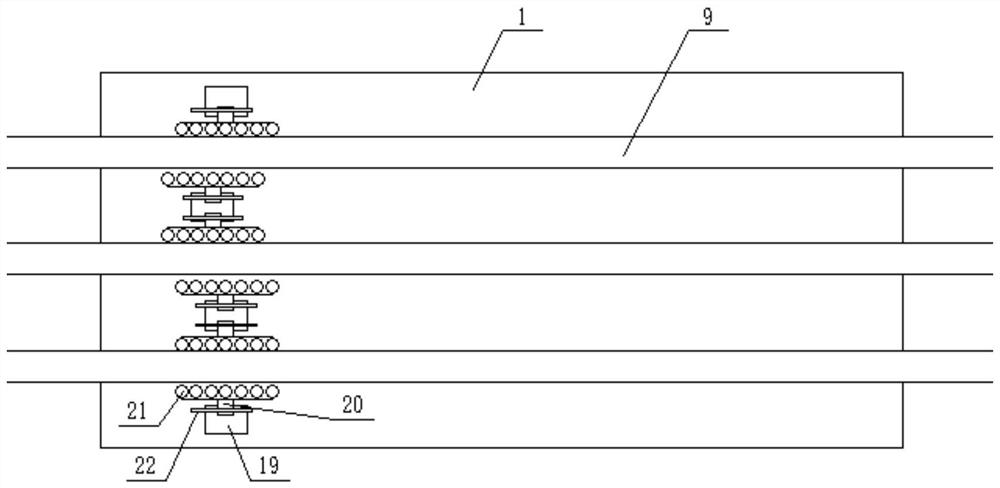

Thermal forming device

InactiveCN108043959AUniform cooling rateConsistent tensile strengthShaping toolsContact pressureMachining

The invention relates to the field of machining, in particular to a thermal forming device. The device comprises a first substrate, a second substrate and a plurality of molds arranged between the first substrate and the second substrate, each mold comprises an upper mold and a lower mold which cooperate with each other, the upper molds comprise upper mold bases and upper mold bodies, and the lower molds comprise lower mold bases and lower mold bodies; the upper mold bases are installed on the first base plate, the tops of the upper mold bodies are connected with the upper mold bases, the lower mold bases are installed on the second base plate, and the bottoms of the lower mold bodies are connected with the lower mold bases, and mold cavities for accommodating workpieces are formed betweenthe bottoms of the upper mold bodies and the tops of the lower mold bodies; and the upper mold bodies or the lower mold bodies are provided with movable parts, and the movable parts are used for changing the sizes of the mold cavities, so that contact pressure between the surface of the mold cavity of each mold in the device and the surface of the corresponding workpiece tends to be consistent. According to the thermal forming device, production efficiency and the product yield of machining multiple workpieces at the same time can be improved.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

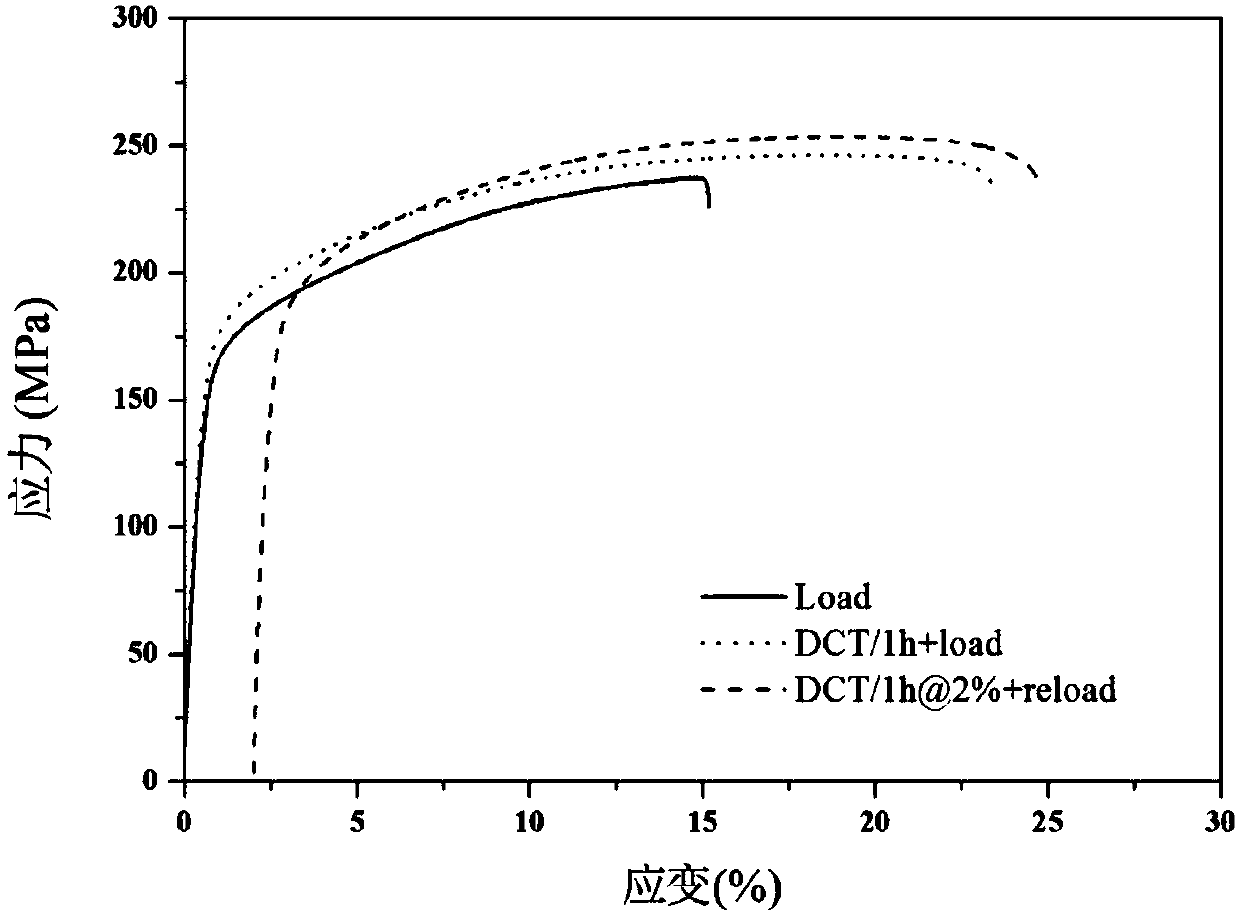

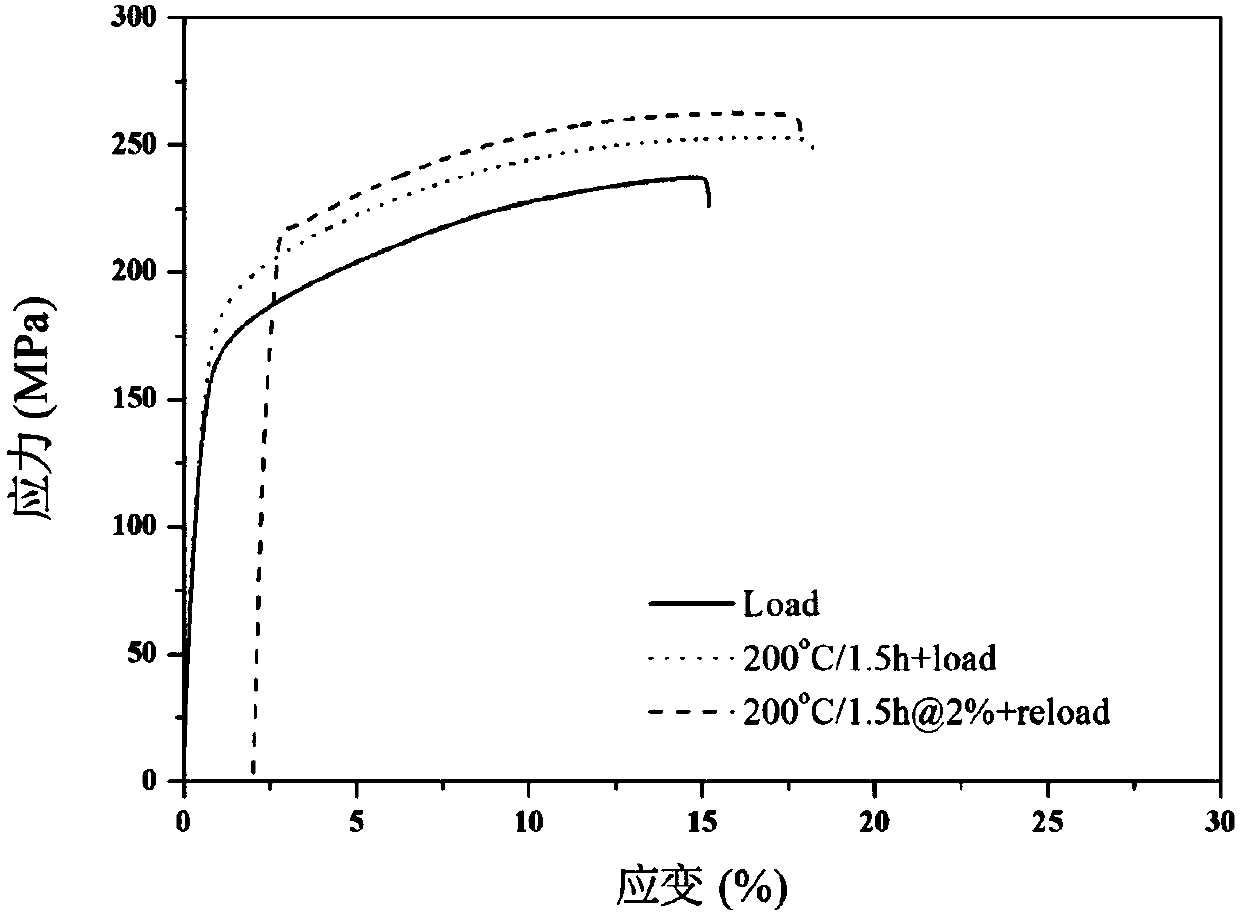

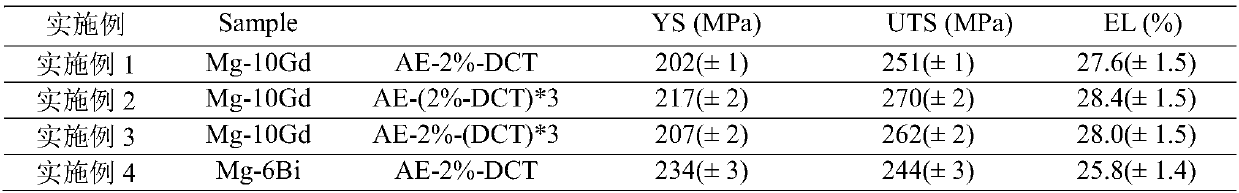

Pretreatment method for improving mechanical property of wrought magnesium alloy

The invention discloses a pretreatment method for improving the mechanical property of wrought magnesium alloy. The pretreatment method comprises the following steps of (1) homogenization treatment and compression deformation; (2) predeformation treatment, wherein bars are machined into tensile test bars, and then the tensile test bars are placed into a tensile testing machine to be subjected to predeformation treatment (stretching or compression), and the amount of deformation ranges from 0.5% to 20%; and (3) subzero treatment, wherein the magnesium alloy tensile test bars subjected to predeformation treatment in the step (2) are placed into a liquid nitrogen environment to be subjected to subzero treatment for 0.5 hour to 24 hours, and the tensile test bars are taken out and placed intoair to naturally recover to the room temperature. With the pretreatment method for improving the mechanical property of wrought magnesium alloy, the purposes of improving the strength and the flexibility of magnesium alloy can be achieved at the same time, and the current situation that the relationship between strength and flexibility is inverted after common annealing treatment or T5 and T6 aging thermal treatment is relieved.

Owner:HEBEI UNIV OF TECH

High-clean stainless steel cable and its treatment method

ActiveCN108914659BFlat surfaceConsistent tensile strengthTextile cablesStructural engineeringSS - Stainless steel

The invention discloses a high-clean stainless steel rope and a processing method thereof, and relates to the technical field of rigging production. The key point of the technical solution is to include a central steel wire with a plurality of outer steel wires evenly distributed outside the central steel wire. The central steel wire is connected to the adjacent There are reinforced steel wire strands in the gap between the two outer steel wires. Multiple outer steel wires and reinforced steel wire strands are twisted and fixed with the central steel wire as the axis; the surface layers of the central steel wire, outer steel wires and reinforced steel wire strands are all formed by surface treatment. Carbonitrided layer. The invention solves the current safety problem of stainless steel cables due to mechanical damage during the steel wire drawing process, which results in the actual tensile strength being lower than the design strength and affecting the safety. The overall strength is improved by redesigning the stainless steel cable structure and performing surface treatment.

Owner:华迪钢业集团有限公司

Preparation method of phenol-formaldehyde resin based composite material sleeper

InactiveCN102744753BOvercome the shortcomingsAvoid disadvantagesBallastwayDomestic articlesMaterials preparationArchitectural engineering

The invention provides a preparation method of a sleeper, which solves a problem that a composite material sleeper is not available in the prior art. A preparation method of a phenol-formaldehyde resin based composite material sleeper comprises processes of prereg preparation, surface material preparation and composite material preparation in sequence. According to the invention, as a large quantity of wood residues are utilized, low cost and good use performance are achieved, defects of a cement sleeper are overcome, saving and substitution of woods are developed, the wood consumption structure is optimized, the situation of domestic wood resource shortage is relieved to a certain degree, and sustainable utilization of forest resources and the ecological environment are improved.

Owner:NORTHEAST FORESTRY UNIVERSITY

An energy-saving process for exterior wall thermal insulation construction

The invention relates to an energy-saving process for exterior wall thermal insulation construction, which is realized by the following scheme. The specific steps are as follows: first, clean the base layer, adjust the control line and hang the reference line, and then stick the graphite polystyrene foam board, use points Fix the SEPS board by frame method or strip bonding method, and then carry out the surface layer construction. The invention has simple process and good heat preservation effect, adopts graphite polystyrene foam as the heat preservation layer, is lighter and safer than the traditional heat preservation system, and only has 60% of the weight of the traditional molded polystyrene thin plastic polystyrene plastering system , while the thickness value is equivalent to 50% of the traditional plastering system, it is easy to meet the goal of saving energy by 65%. At the same time, graphite polystyrene foam has the function of fire prevention, and is suitable for any wall surface, and has a wide range of applications.

Owner:ZHONGTIAN LIANHE ENERGY SAVING CONSTR DEV TIANJIN

Steel bar tensioning device used in building construction

ActiveCN113000619BImprove stretching efficiencyEven by forceWire straightening devicesGear wheelArchitectural engineering

The invention discloses a steel bar stretching device used in building construction, comprising: a base, the upper surface of which is provided with a plurality of recessed sliding tables at intervals, and the sliding table just accommodates a rack to pass through horizontally. The rack is matched with the gear; the clamping mechanism includes a moving block and a matching block. The upper surface of the moving block is provided with a plurality of concave arc-shaped bottom grooves at intervals, and the lower parts of the multiple steel bars are respectively fitted in a plurality of arc-shaped bottom grooves Among them, after the two ends of the matching block respectively pass through the abutting grooves of the fixed block provided above the moving block, the multiple arc-shaped top grooves of the described matching block coincide with the multiple arc-shaped bottom grooves one by one. a steel bar, and the lower end of the screw is tightly against the matching block. The invention is a steel bar stretching device integrating multiple functions, which has simple structure, convenient operation, high stretching efficiency, high safety, good steel bar stretching effect, can meet the actual construction requirements and can simultaneously realize the stretching of steel bars Subsequent straighter function.

Owner:BAOYE HUBEI CONSTR ENG GRP

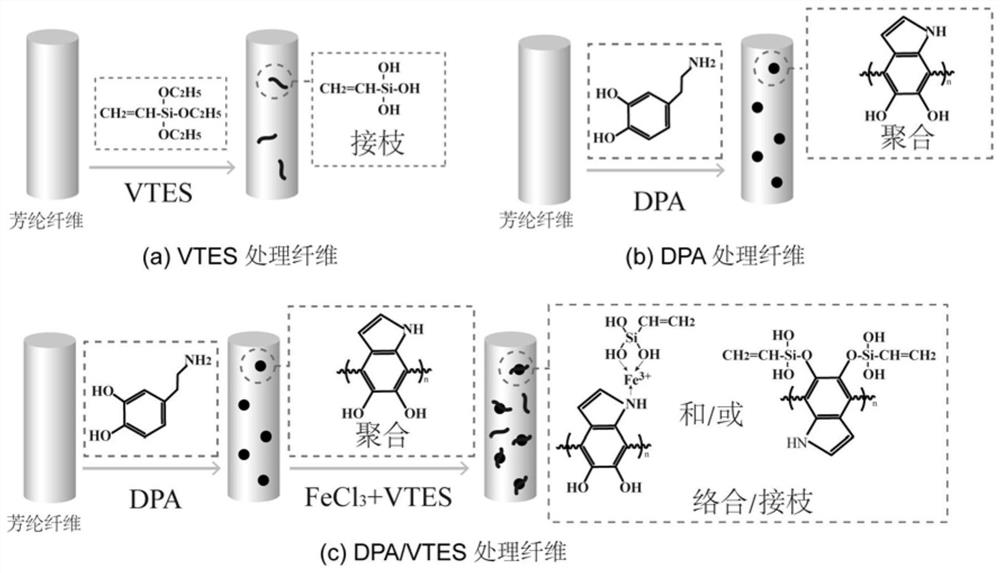

A Method for Reinforcing Wood Flour/Polyolefin Composites Using Surface-Treated Continuous Aramid Fibers

ActiveCN112322064BIncrease surface polarityImprove the interface bonding strengthPolymer sciencePolyolefin

Owner:NORTHEAST FORESTRY UNIVERSITY

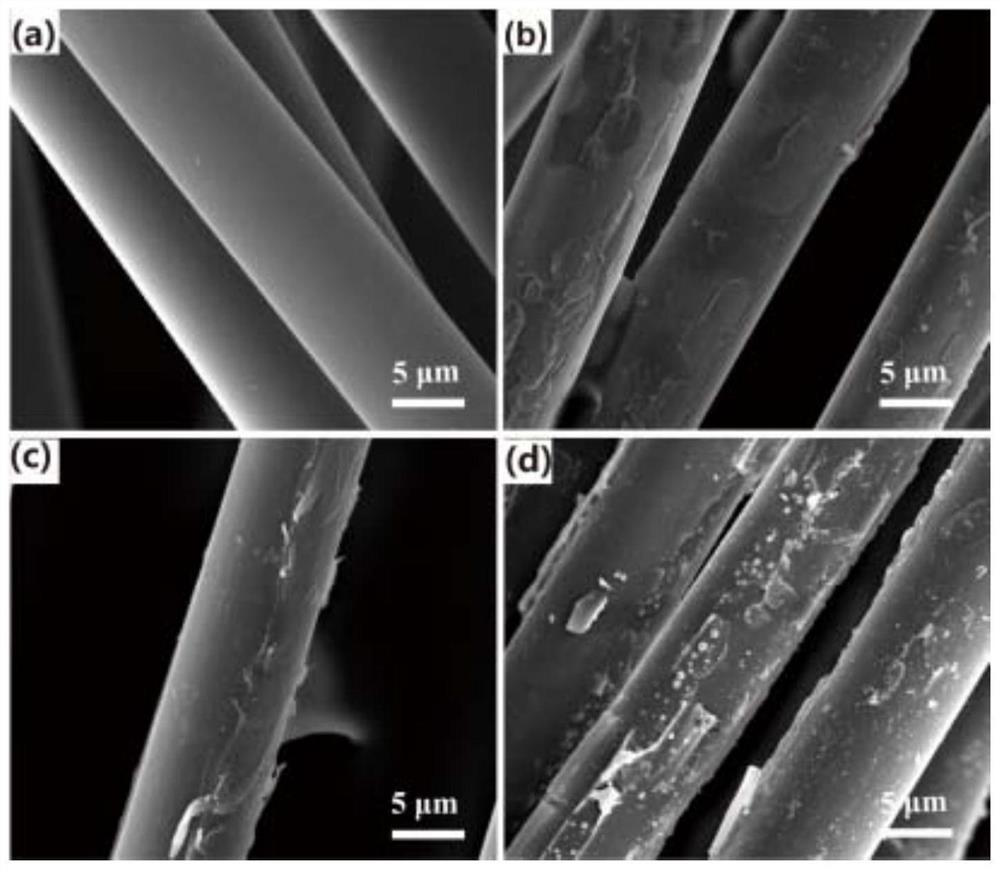

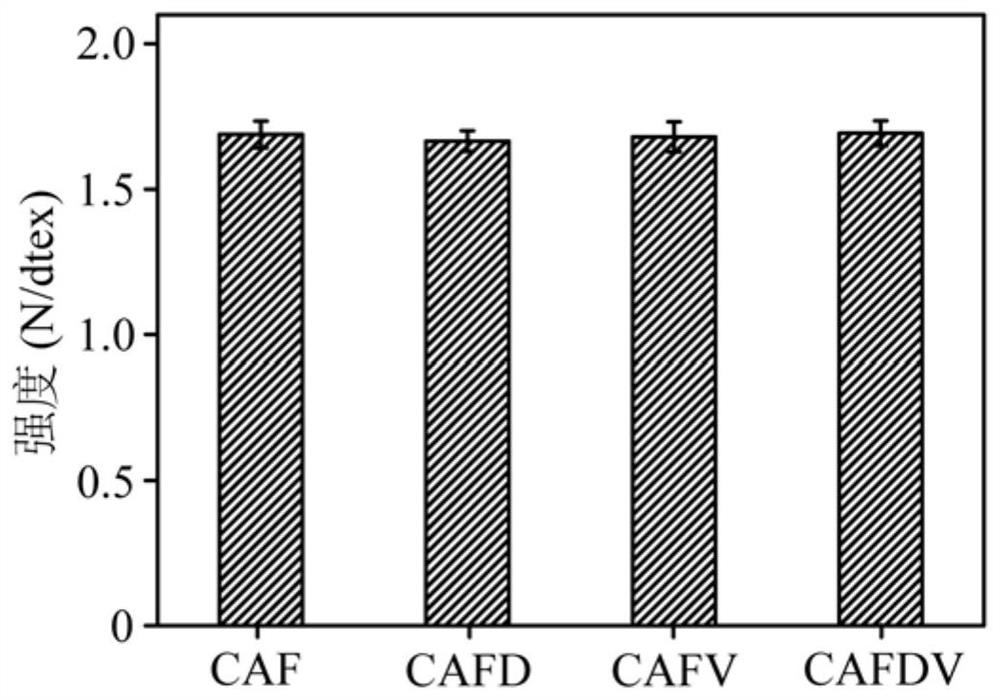

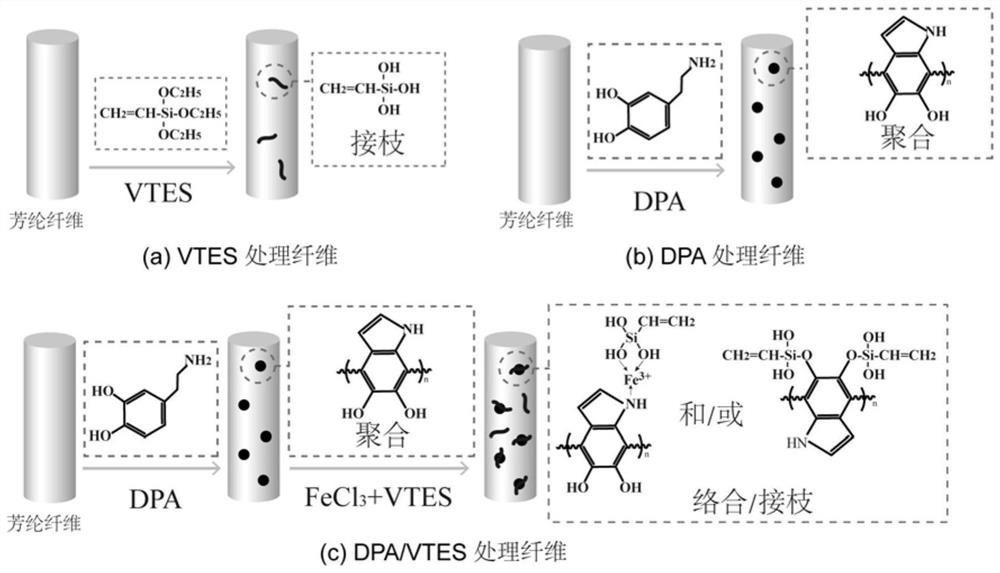

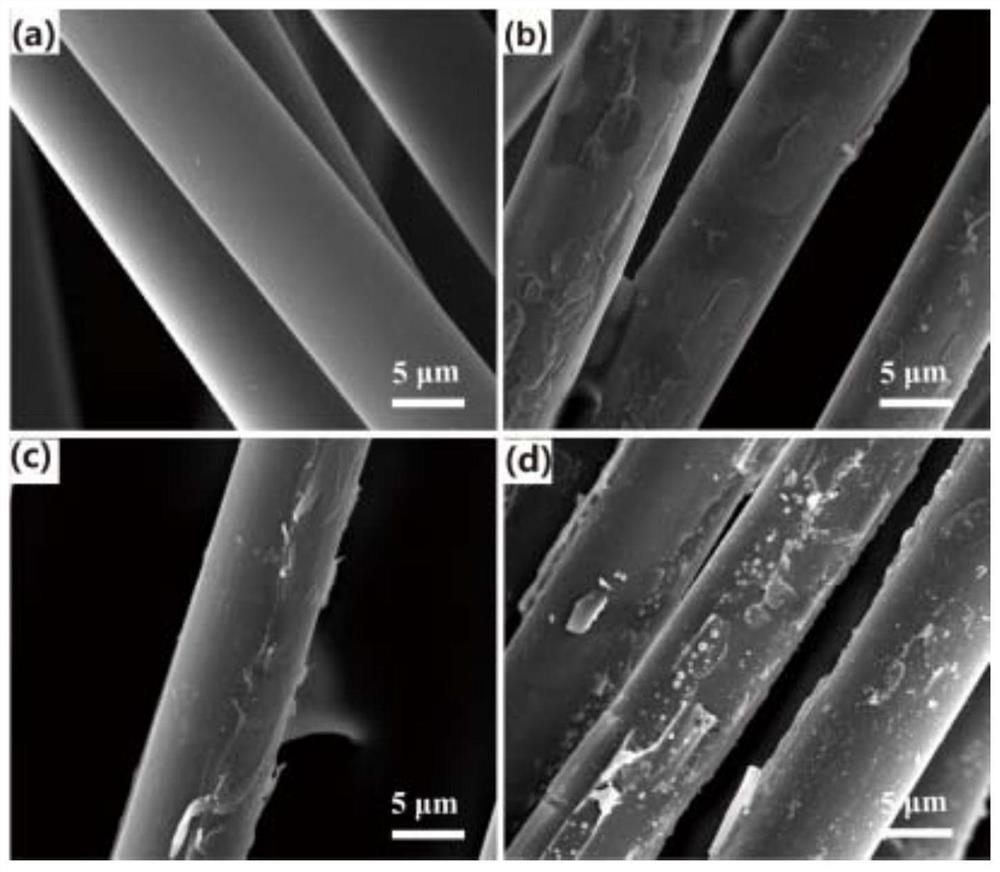

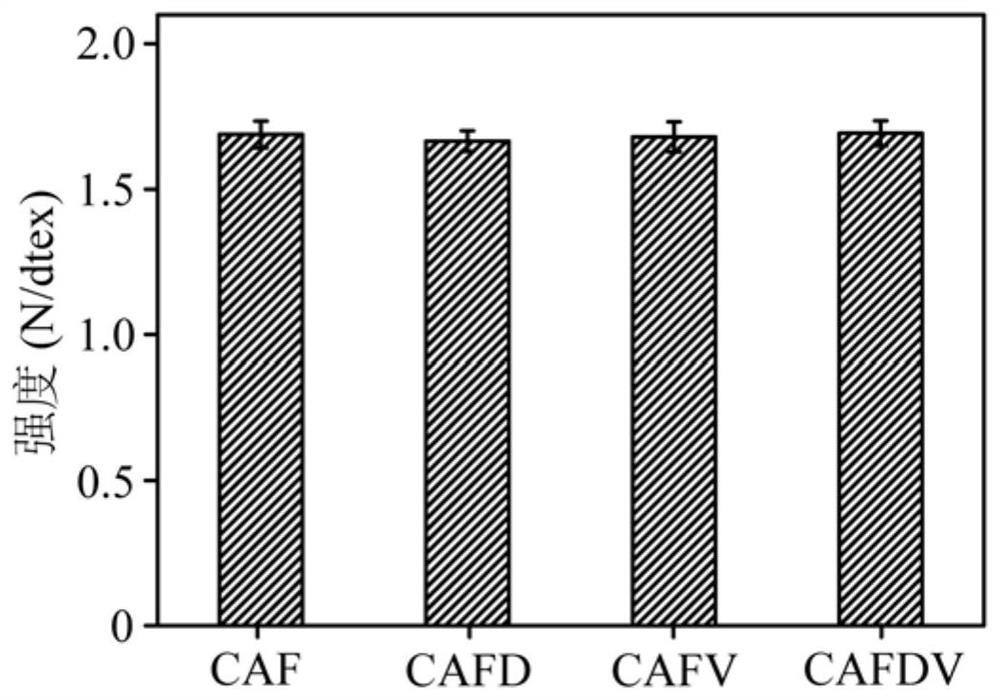

Method for reinforcing wood powder/polyolefin composite material by utilizing surface-treated continuous aramid fibers

ActiveCN112322064AIncrease surface polarityImprove the interface bonding strengthPolyolefinFiber bundle

The invention relates to a method for reinforcing a wood powder / polyolefin composite material, in particular to a method for reinforcing a wood powder / polyolefin composite material by utilizing surface-treated continuous aramid fibers, which aims to solve the problem of poor interface bonding strength between fibers and a wood-plastic matrix in the existing fiber-reinforced wood-plastic compositematerial, and the problem that the existing fiber modification method is high in cost or can influence the surface structure of aramid fibers so as to reduce the strength of the aramid fibers. The preparation method comprises the following steps of 1, pretreatment, 2, carrying out dopamine coating treatment on the continuous aramid fiber bundle, 3, performing dopamine-VTES cooperative treatment onthe continuous aramid fiber bundle; and 4, preparing the continuous aramid fiber reinforced wood powder / polyolefin composite material. The continuous aramid fiber reinforced wood powder / polyolefin composite material is used for surface treatment.

Owner:NORTHEAST FORESTRY UNIVERSITY

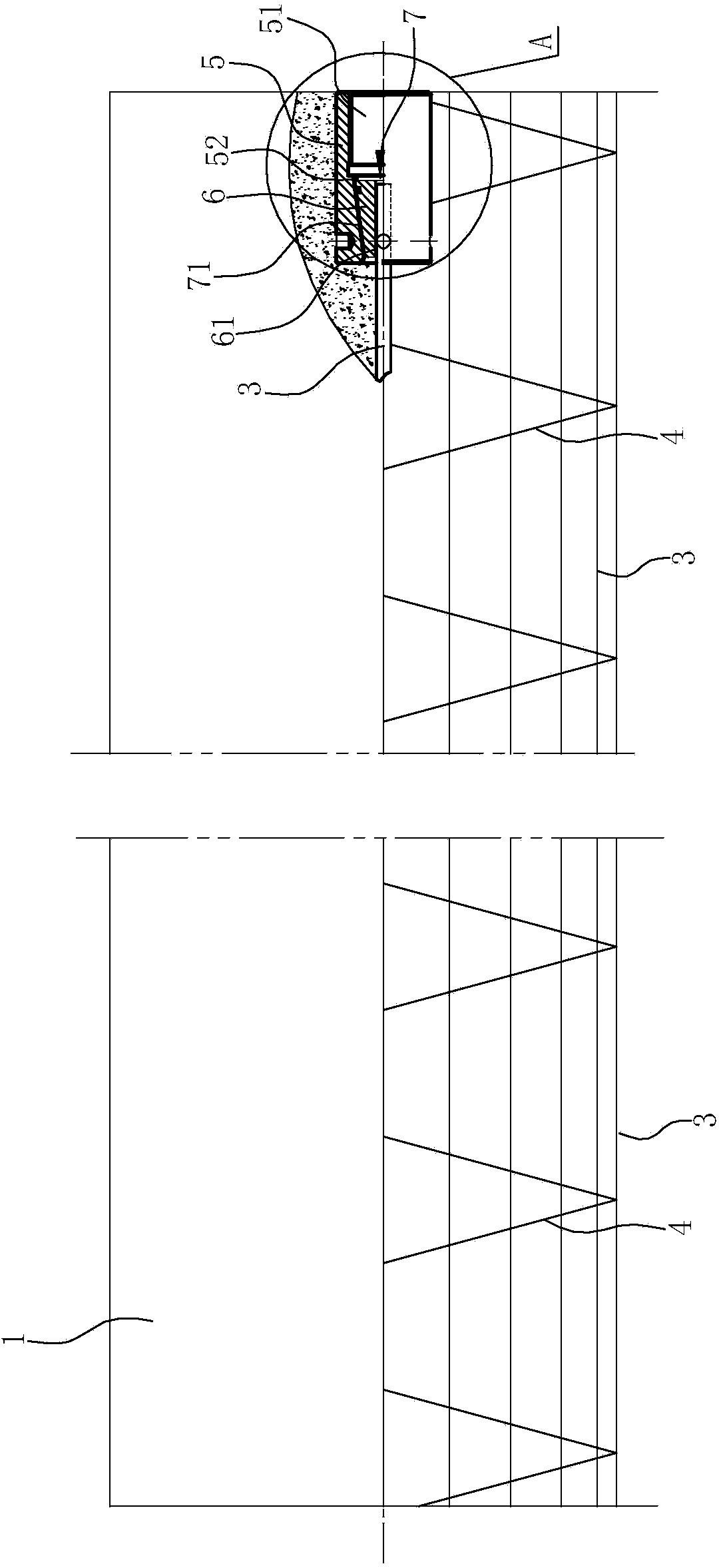

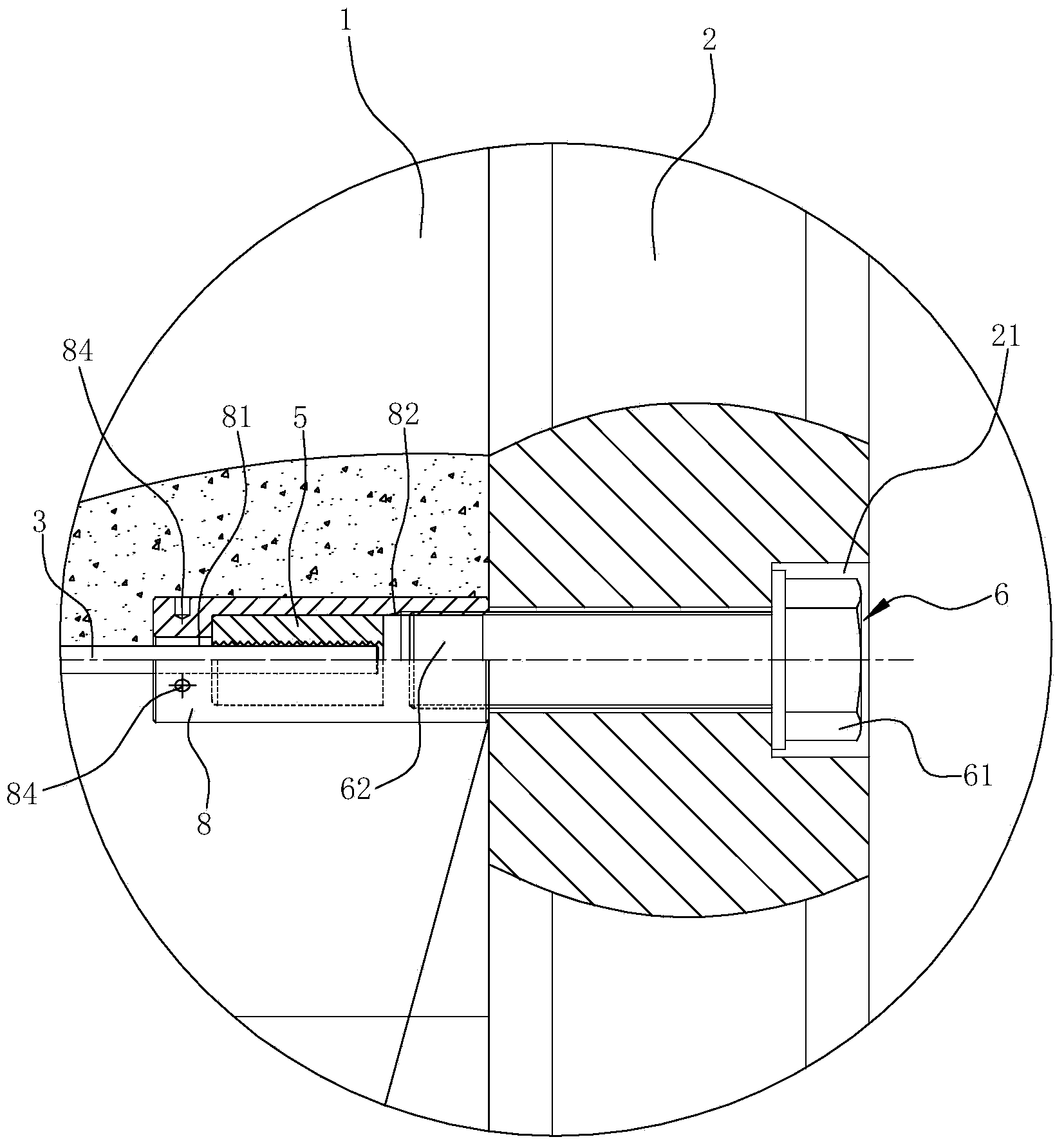

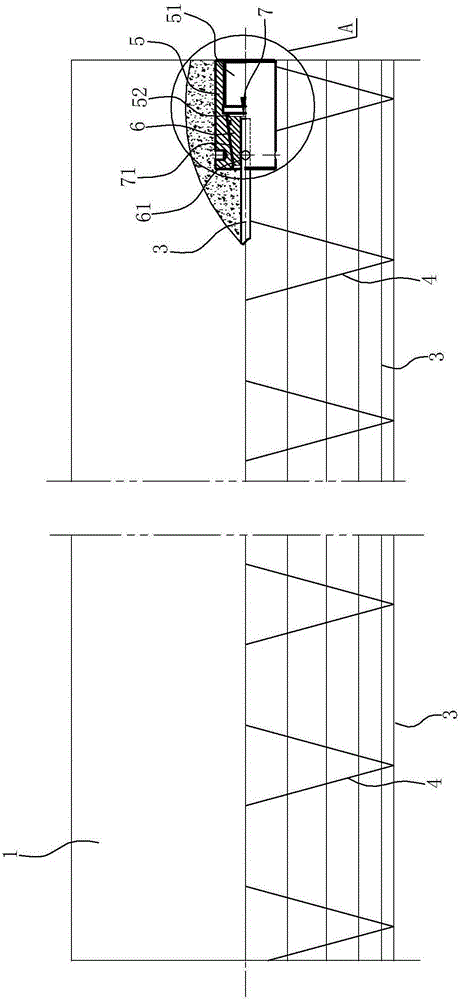

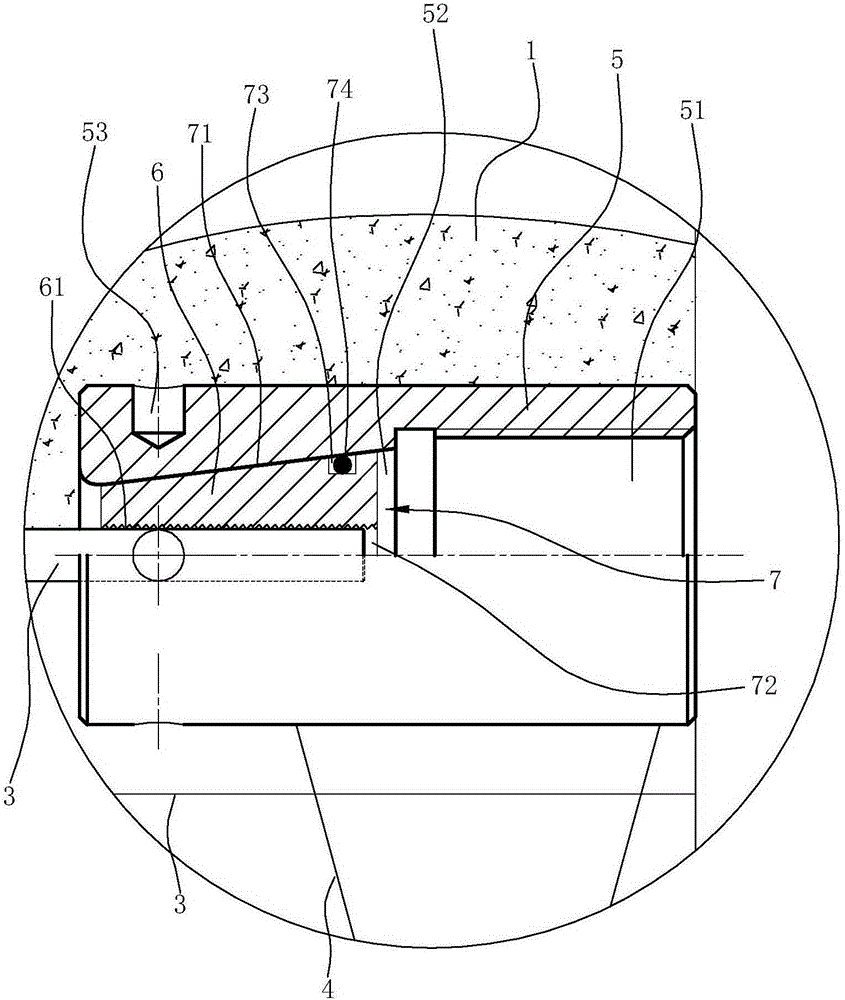

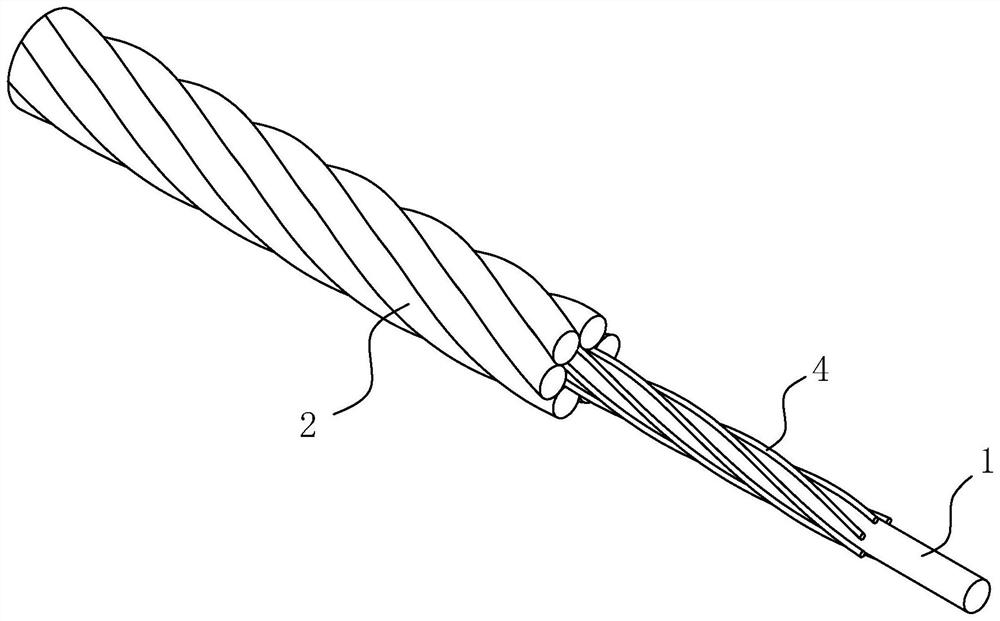

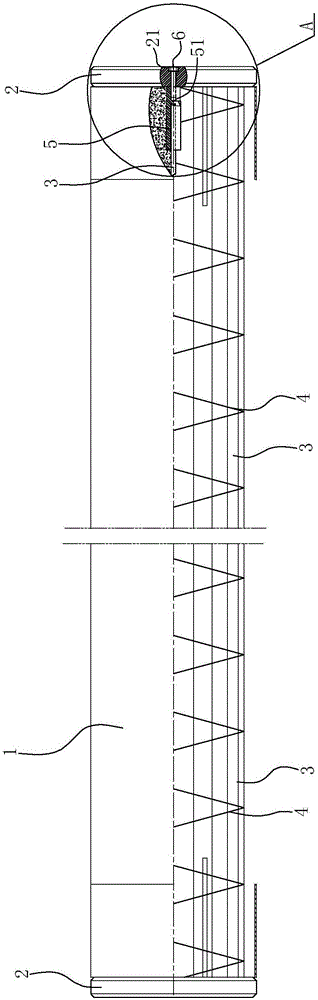

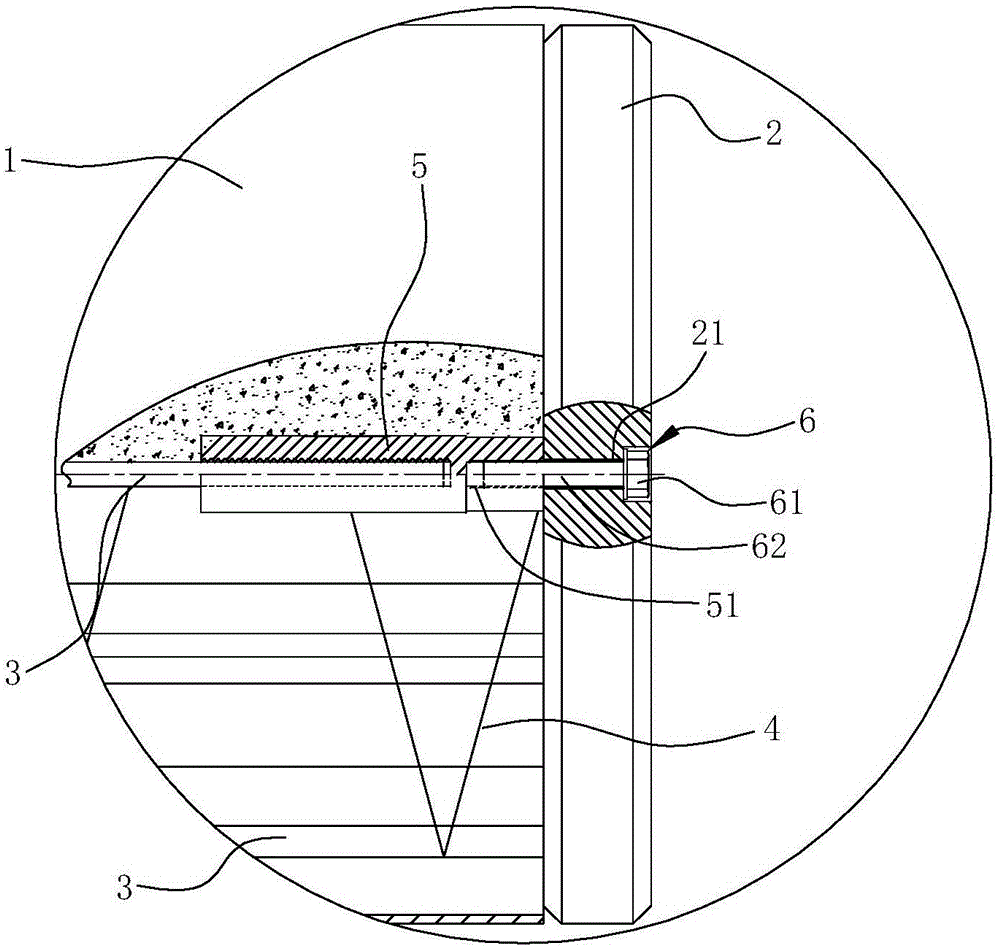

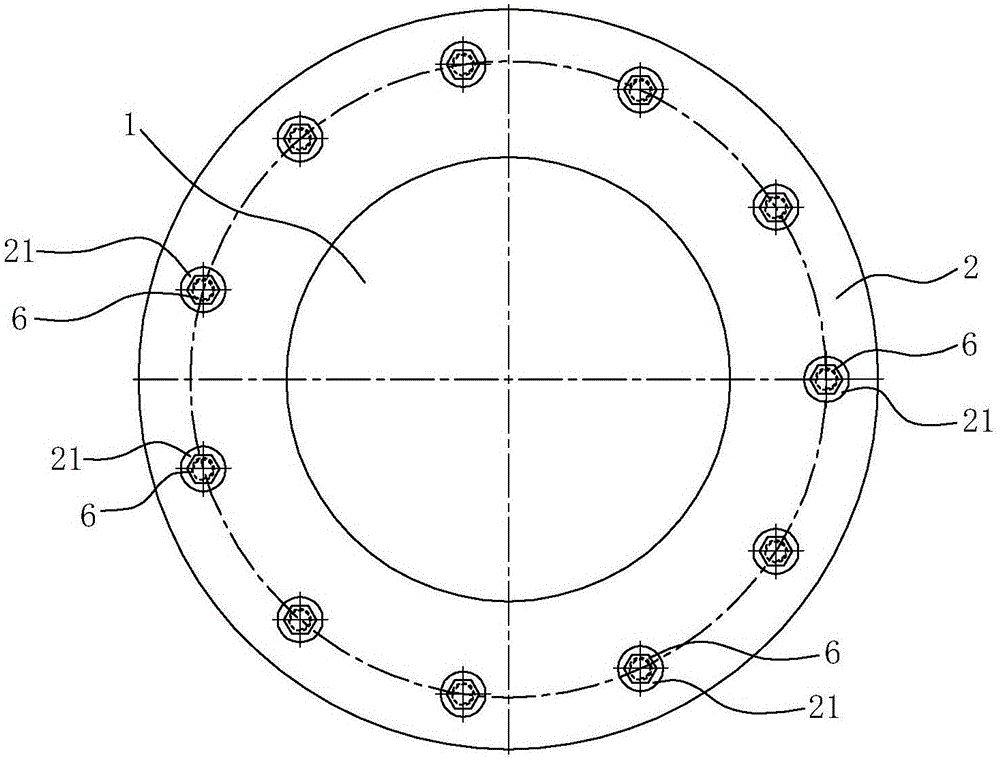

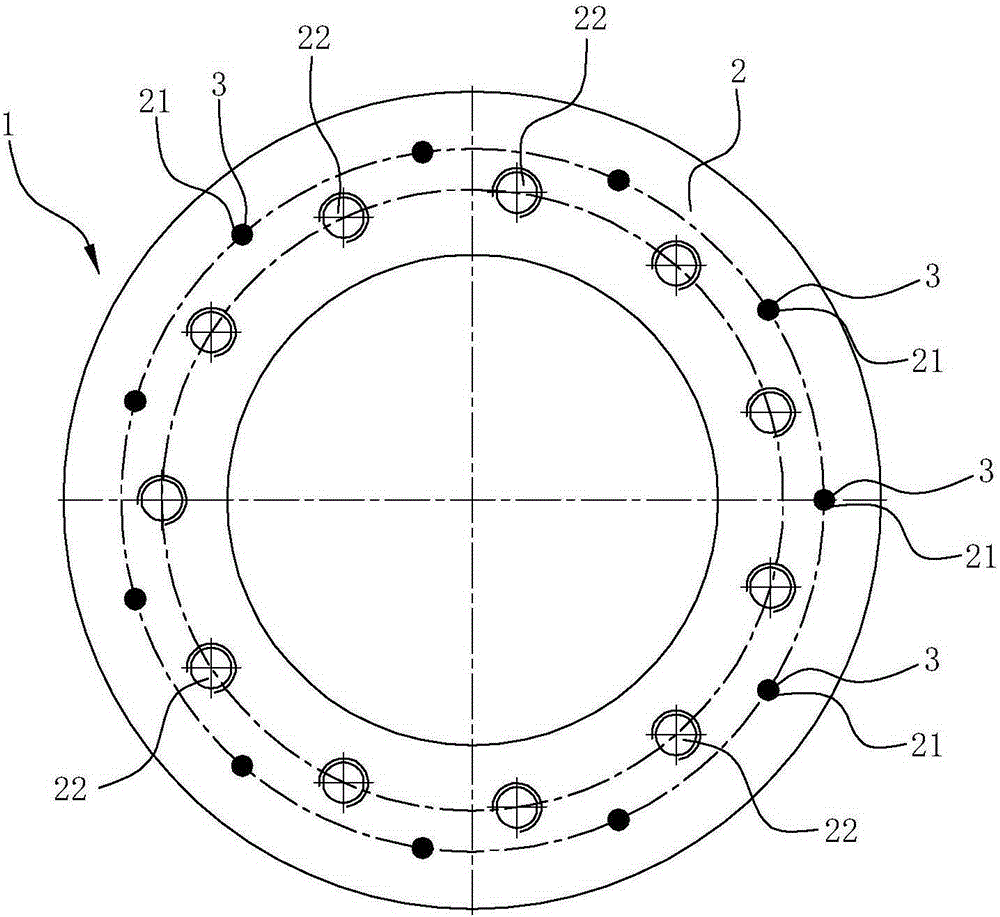

A pretensioned centrifugal concrete pile with steel strands and its manufacturing method

ActiveCN103741675BConsistent tensile strengthImprove performanceCeramic shaping apparatusBulkheads/pilesPre stressRebar

The invention relates to a pretensioned centrifugal concrete pile with steel stranded wires. The pretensioned centrifugal concrete pile comprises a concrete pile body (1) and a rebar cage positioned in the concrete pile body (1), and the rebar cage comprises axially-arranged prestressed main rebars and stirrups (4) wound outside the main rebar. The pretensioned centrifugal concrete pile is characterized in that the prestressed main rebars are the steel stranded wires (3), the steel stranded wires (3) at at least one end of the rebar cage are combined with squeezing-type anchors (5) by means of squeezing, the outer end faces of the squeezing-type anchors (5) are flush with or slightly lower than that of the concrete pile body (1), and a thread for connection is arranged on each squeezing-type anchor (5). In the process of manufacturing of the pile body, the squeezing-type anchors and a tensioning plate can be fixed together through threaded connection to realize tensioning and applying of the steel stranded wires as the main rebars in the rebar cage, and bending resistance, shearing resistance and tensioning resistance of the pretensioned centrifugal concrete pile are greatly improved; end plates can be freely mounted according to actual needs. The invention further relates to a manufacturing method of the centrifugal concrete pile.

Owner:俞向阳

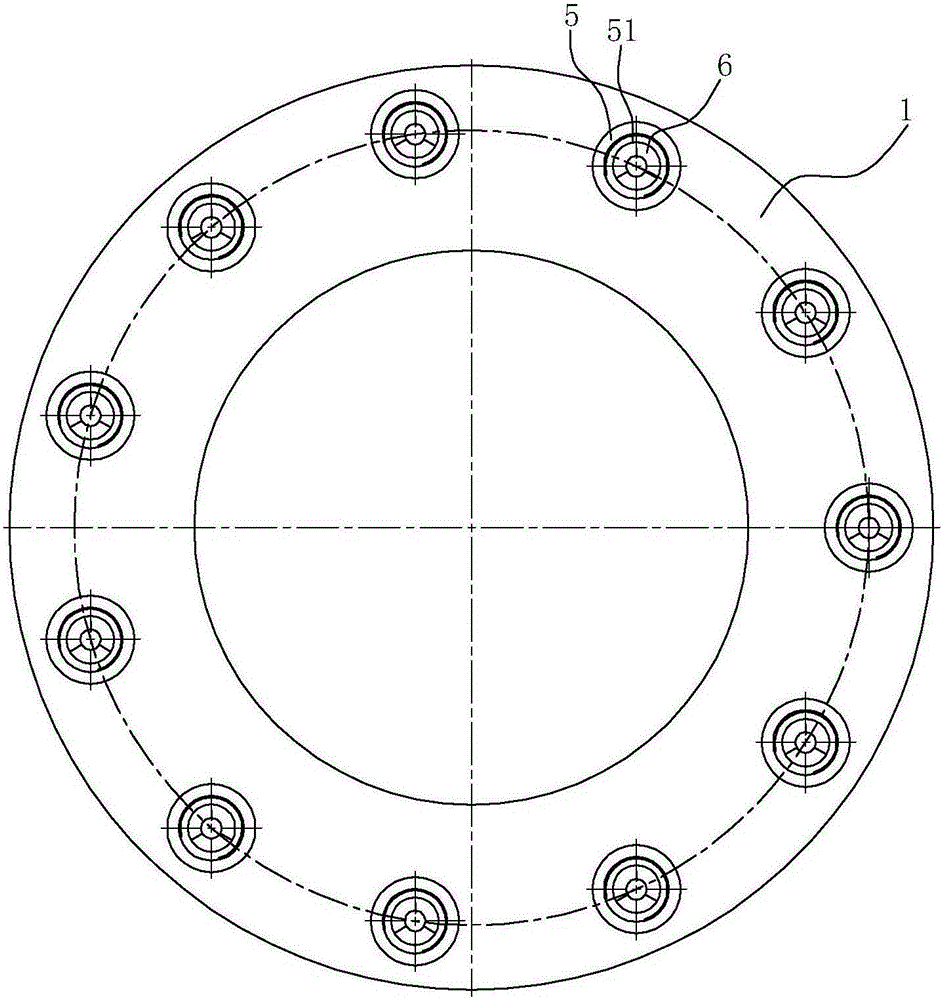

A self-anchored steel strand pretensioned centrifugal concrete pile and its manufacturing method

ActiveCN103741673BConsistent tensile strengthImprove performanceCeramic shaping apparatusBulkheads/pilesCentrifugationPre stress

The invention relates to a self-anchored steel strand pretensioned centrifugal concrete pile. The self-anchored steel strand Pretensioned centrifugal concrete pile comprises a hollow concrete pile body and a steel reinforcement cage located in the concrete pile body, wherein the steel reinforcement cage comprises prestressed main reinforcements arranged in the axial direction, stirrups and end plates. The self-anchored steel strand Pretensioned centrifugal concrete pile is characterized in that the prestressed main reinforcements are steel strands, a plurality of through holes allowing the steel strands to pass through are formed on each end plate, the through holes correspond to the steel strands one to one so that the steel strands passing through the through holes of the end plates can be connected with an external steel strand locking structure, and a plurality of threaded connecting holes for connection with the steel strand locking structure are further formed on the end plates. In this way, the steel strands can be tensioned through the steel strand locking structure outside, and then centrifugal molding is carried out, after molding is finished, an anchor plate is unloaded, and finally, the steel strands exposed out of the end plates are cut off and ground; the finished centrifugal concrete pile has no anchor part projecting from the end plate, and the centrifugal concrete pile with the steel strands is practicable and feasible.

Owner:俞向阳 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com