Twenty-five-roller stretcher for uniaxial tension of geogrid

A geogrid and unidirectional stretching technology, applied in the field of special stretching equipment for plastic geogrids, can solve the problems of easy rust, affect the stretching accuracy, increase the weight of the stretching roller, etc. Easy oil temperature control and consistent tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The stretching machine of the present invention will be further described below in conjunction with the accompanying drawings.

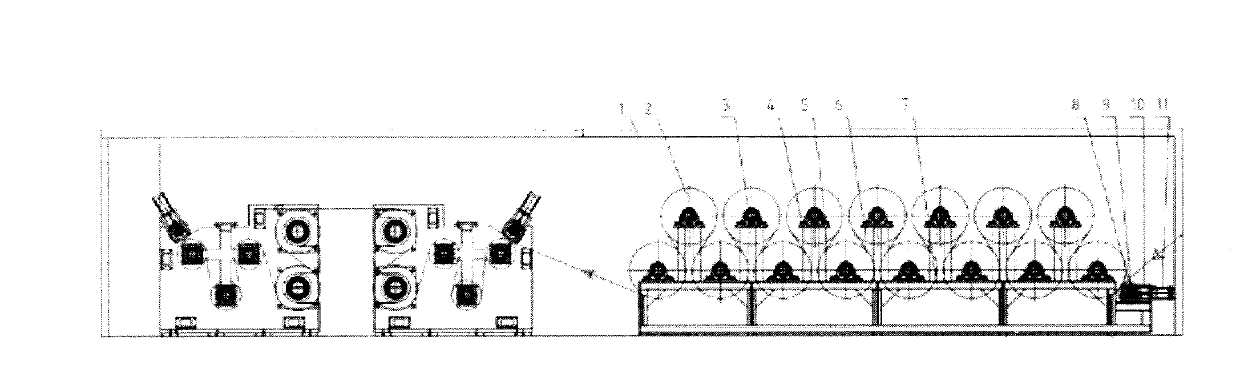

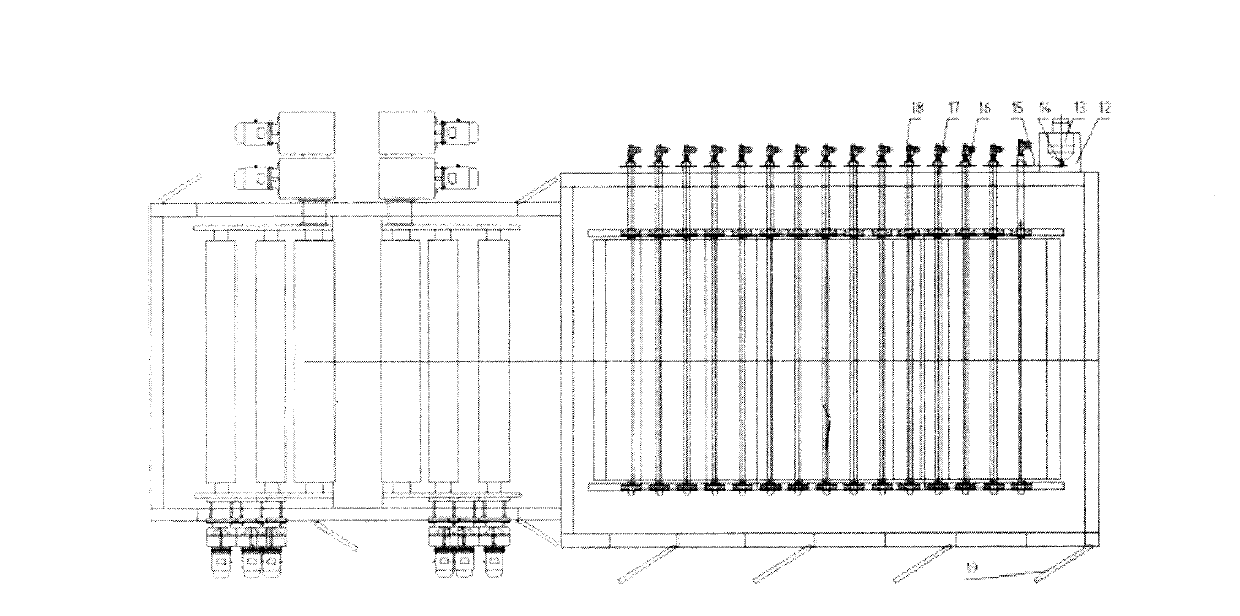

[0020] Such as figure 1 and 2 As shown, the unidirectional stretching geogrid twenty-five-roll stretching machine of the present embodiment includes a thermal insulation frame 1 welded by channel steel, a stretching roller 2, a bearing seat 3, a bearing seat plate 4, a tight Set screw 5, square tube 6, twenty-five roller frame 7, adjusting pressure roller 8, sliding bearing seat 9, guide rail 10, cylinder 11, motor bottom plate 12, reducer 13, sprocket 14, transmission chain 15, transmission chain Wheel 16, hollow shaft 17, swivel joint 18, operating door 19, the interior of the heat preservation frame 1 is provided with a twenty-five-roller frame 7 welded by square tubes 6 and rib plates, and a twenty-five-roller frame 7 The upper stretching roller is connected to the bearing seat plate 4 through the bearing seat 3, the bearing seat 3 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com