Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Consistent heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

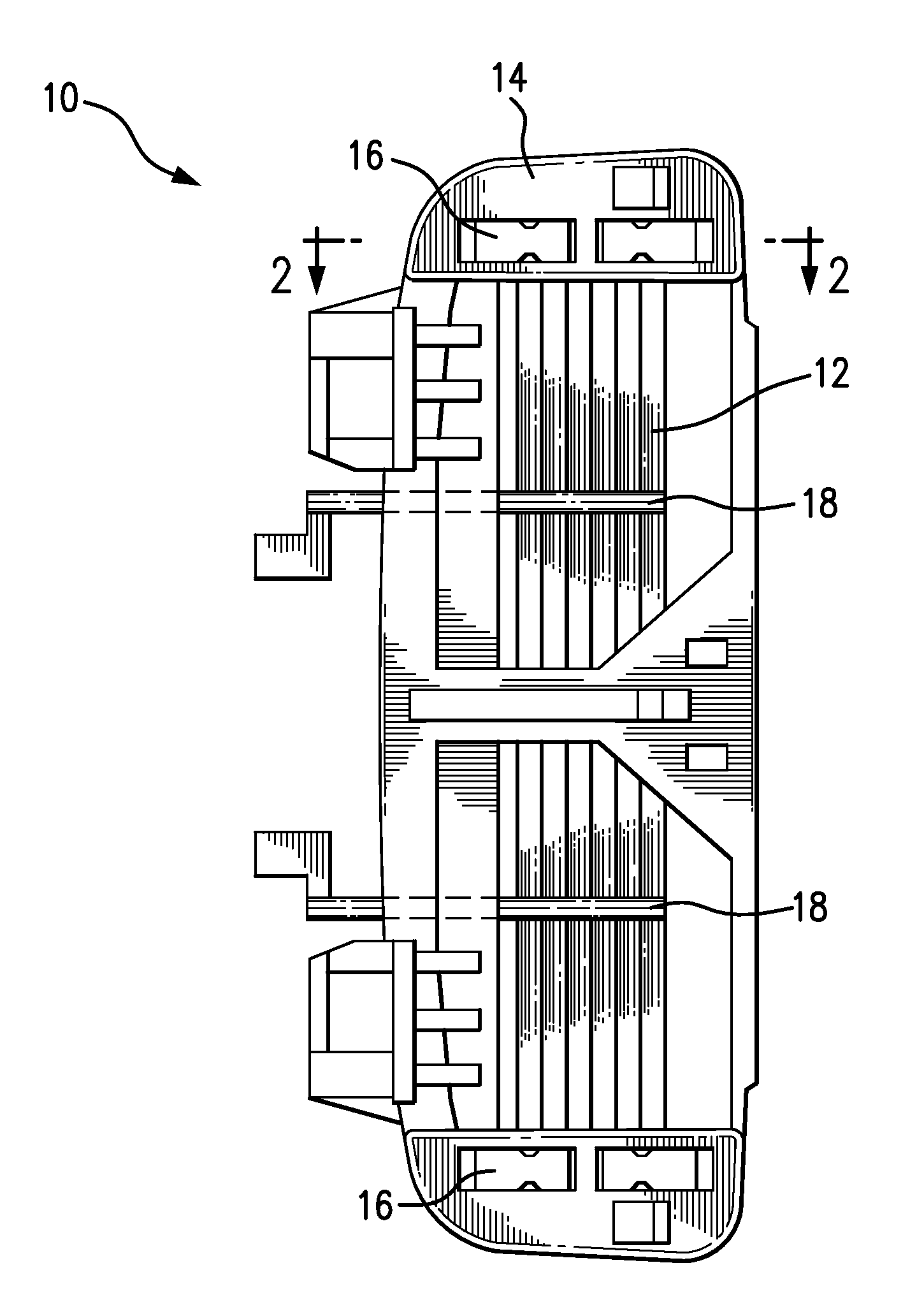

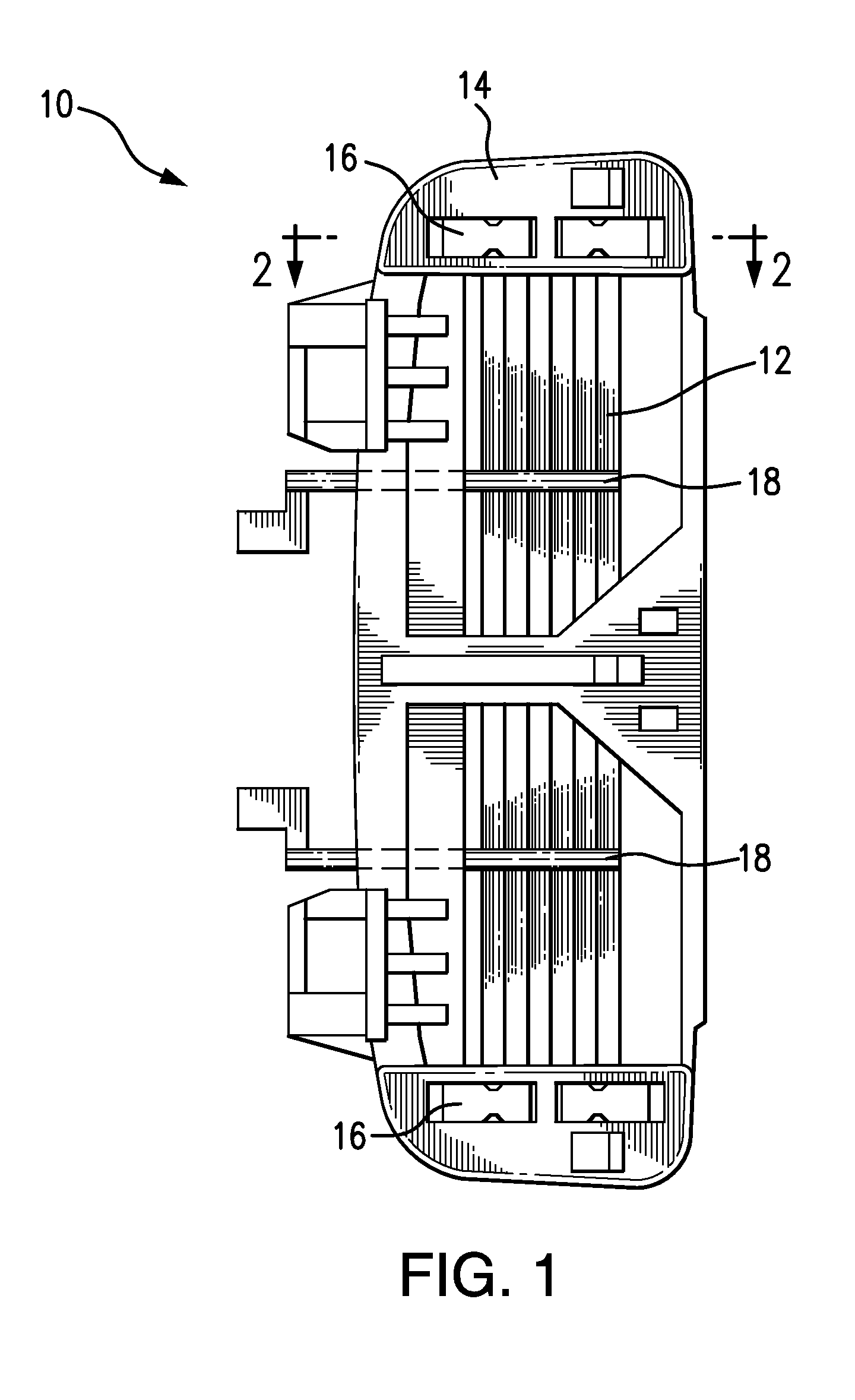

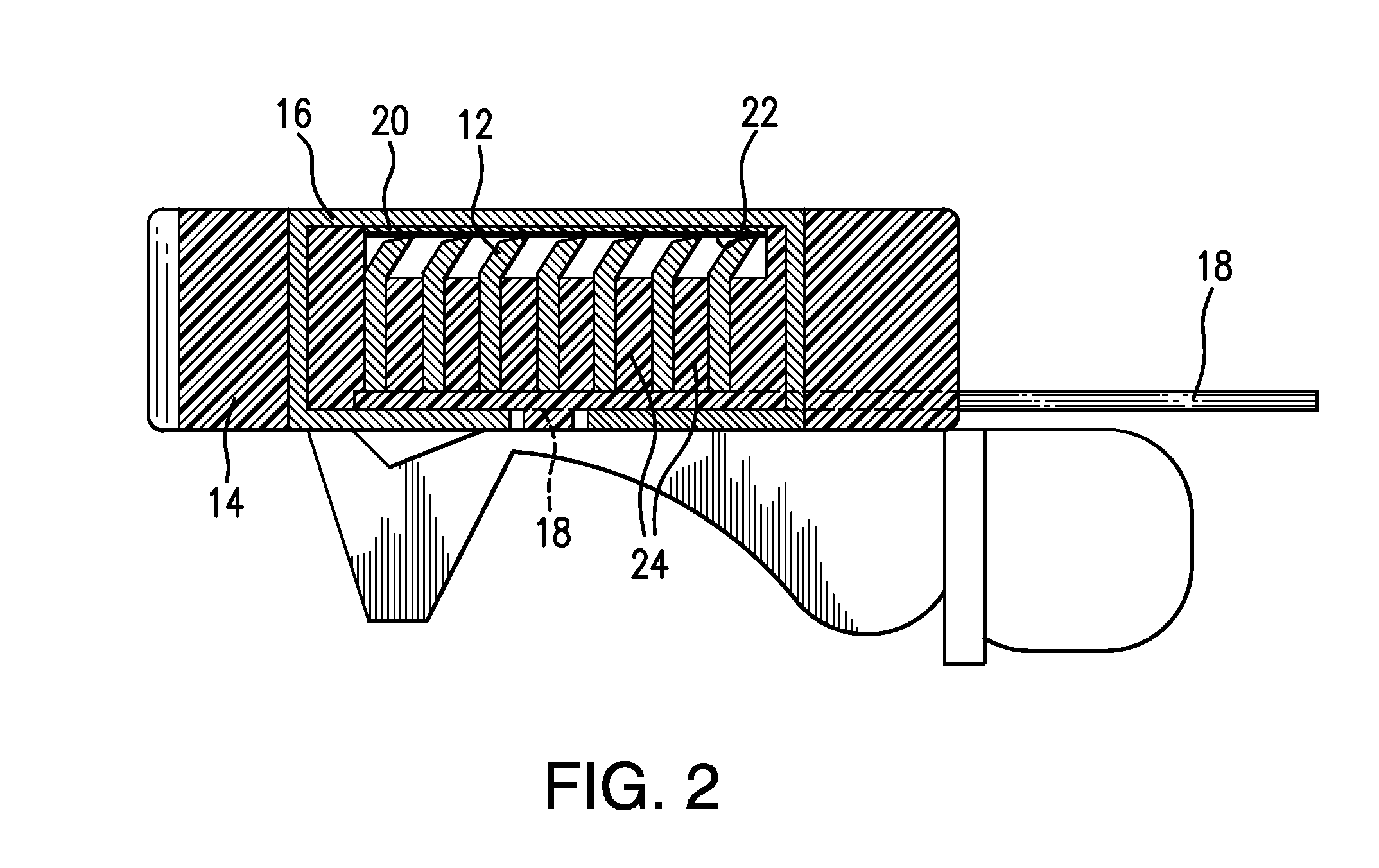

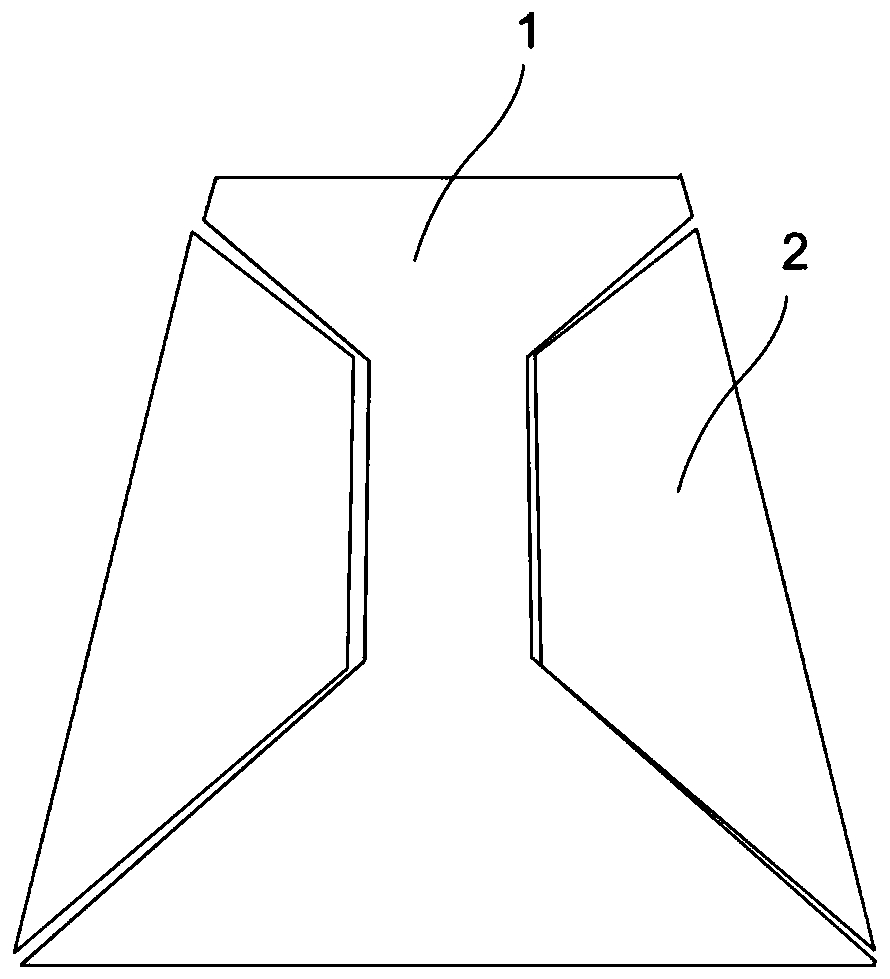

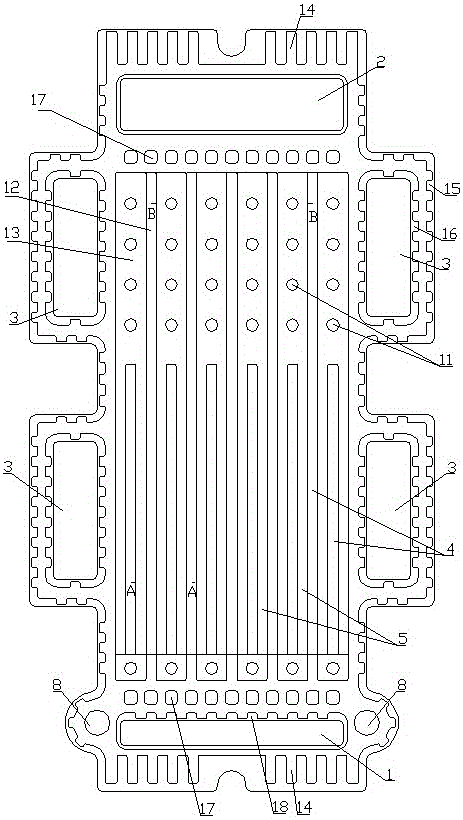

Razor with blade heating system

ActiveUS20120291288A1Uniform heating energyConsistent heatingMetal working apparatusHeat distributionHeating system

A blade cartridge for a shaving razor contains a series of parallel blades, and at least two wire conductors of an electric circuit connected to the blades at spaced intervals to provide an electric current flow through the blades in a manner that provides more efficient heat distribution across the length of the blades. The ends of the blades may be held in place by staples that are insulated from the electric circuit. A thin conductive film may be fitted to be in contact with the ends of the blades to insure conductivity throughout the entire length of each blade. A radiator effect of the heated blades causes the blades to become warmer when the blades are placed against the skin surface and air is unable to circulate between the blades. The blades become less hot when removed from the skin and air circulates between the blades.

Owner:HEATED BLADES HLDG COMPANY

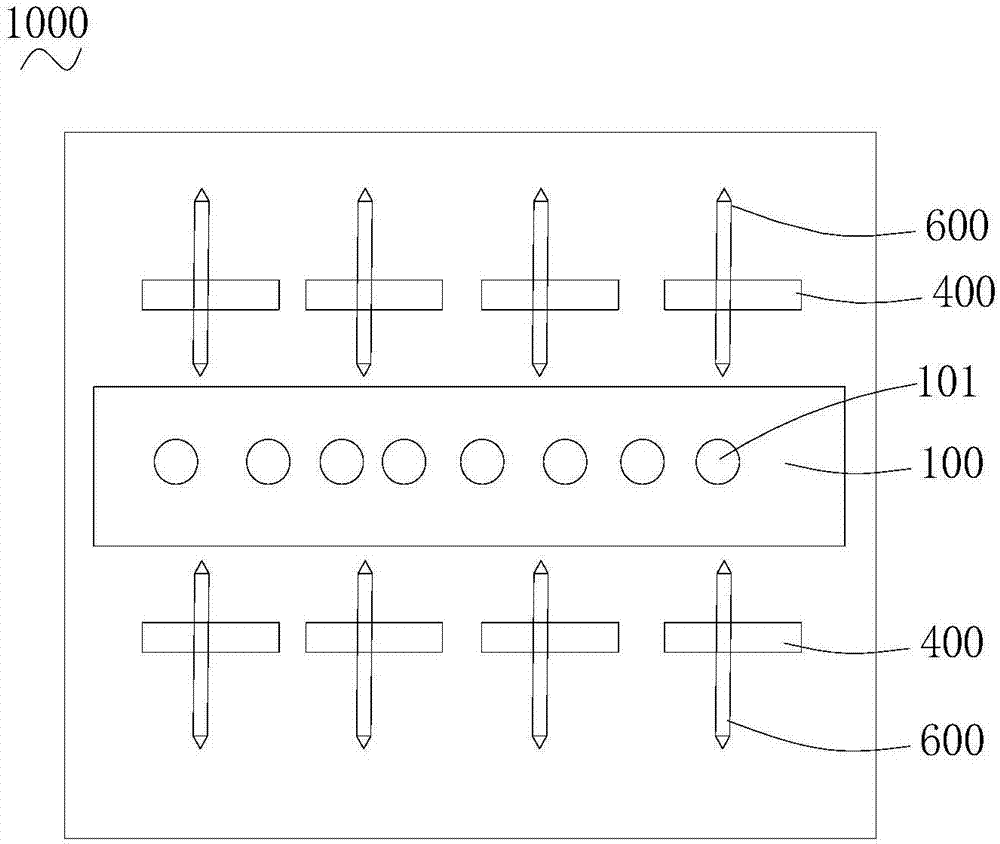

Evaporation crucible heat field control device and evaporation system

InactiveCN106987810AConsistent temperatureConsistent heatingVacuum evaporation coatingSputtering coatingDeposition temperatureCrucible

The invention relates to a thermal field control device for an evaporation crucible, which includes: an evaporation crucible and a heating device; several temperature detection units for detecting the temperature of several detection points on the evaporation crucible; several reflection plates arranged on the evaporation crucible the periphery of the evaporation crucible, and is used to reflect heat to the evaporation crucible; and a control unit, based on the temperatures detected by the temperature detection units, controls the movement of the plurality of reflectors to adjust the relationship between each reflector and the The distance between the above-mentioned evaporation crucibles. In the thermal field control device of the evaporation crucible, the control unit independently controls each reflection plate according to the actual temperature of each detection point, so that the reflection plate near the area with high temperature of the evaporation crucible is far away from the evaporation crucible, and the reflection plate near the area with low temperature is far away from the evaporation crucible. The plate is close to the evaporation crucible, so that the entire thermal field is more uniform, so that the evaporation source is heated uniformly, and the final film thickness is uniform. The invention also provides an evaporation system.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Flue-cured tobacco loose-leaf bundling and curing method

The invention provides a flue-cured tobacco loose-leaf bundling and curing method. The method comprises steps as follows: tobacco leaves are bundled and then placed in a flue-cured tobacco chamber for curing, and curing comprises steps as follows: the tobacco leaves are bundled and then placed in the flue-cured tobacco chamber; then, main veins of the tobacco leaves turn yellow and leaf apexes are dried at the early stage of color fixation; the tobacco leaves are dried at the later stage of color fixation; finally, the main veins of the tobacco leaves turn brown and are dried completely at the stem drying stage. The tobacco leaves are bundled and cured, so that the tobacco leaves are convenient to transport, loading and unloading speeds are high, the tobacco leaves are uniformly stacked, and about 20% of tobacco loading amount is increased; the tobacco leaves are uniformly heated with the reasonable curing method, lodging of the tobacco leaves is relieved during curing, and the cured tobacco leaves are better in expansion and contraction and can regain moisture easily. Proper heat supply and ventilation are performed at the reasonable dry-bulb temperature and the reasonable wet-bulb temperature, so that the appearance quality and the interior quality of the tobacco leaves are well guaranteed.

Owner:贵州省烟草公司遵义市公司正安分公司

Preparation method of seabuckthorn tea

InactiveCN101904373ARetain nutrientsReduce lossesPre-extraction tea treatmentFood preparationAdditive ingredientMicrowave technology

The invention discloses a preparation method of seabuckthorn tea. The tea is prepared from 7 to 9 parts of seabuckthorn tea leaves and 1 to 3 parts of scented tea. The method comprises the following steps of: removing green of the seabuckthorn tea leaves by vacuum microwave technology; kneading the seabuckthorn tea leaves until a small amount of juice is produced on the leaves; drying the leaves with a vacuum microwave drying oven; mixing crushed tea leaves and crushed scented tea; and filling the mixture in bags. The green removing temperature and the drying temperature are relatively low, so that loss of bioactive substance in the leaves is relatively low; nutrient components in the seabuckthorn leaves can be effectively retained; and the nutritional and health-care function of the seabuckthorn tea is improved. Moisture regain and secondary drying are not needed; the process is simple; and the consumed time is short.

Owner:黑龙江省农业科学院园艺分院

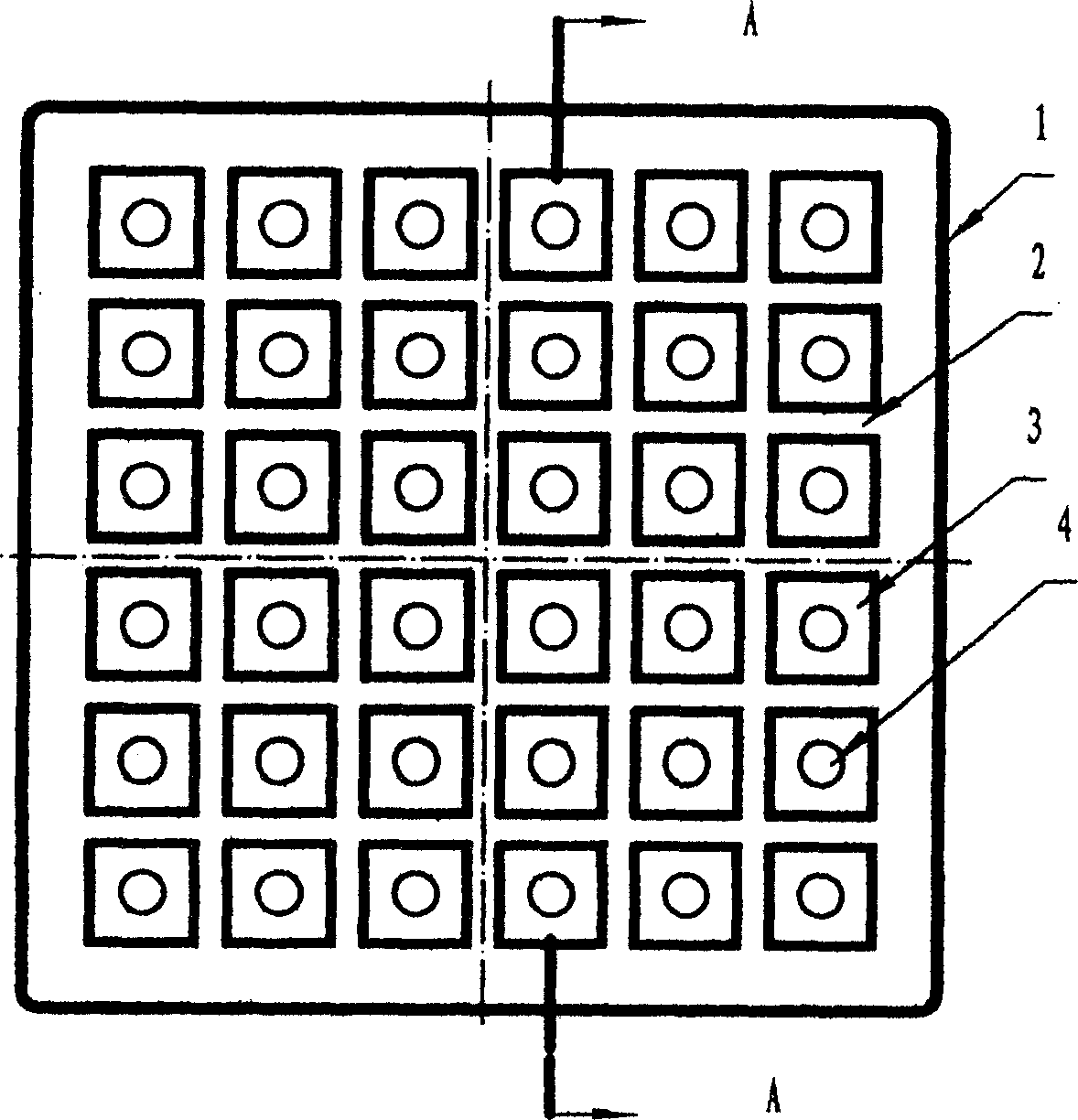

Energy-saving ceramic fire resistant bearing board

InactiveCN1724964AChange the heating methodChange the state of heatingCharge supportsBrickCombustion chamber

The invention is an energy-saving ceramic flame-resistant bearing firing plate, for solving the technical problem of making the glazed outside wall bricks fired by the same kiln have no obvious color difference but small deformation, thus improving the quality of finished products, and besides, for strengthening the intensity of bearing firing plate, reducing its breakage rate. For this, the invention fills ribs and blanks at the bottom of the bearing firing plate, where a through hole is equipped within each blank. The blanks and holes can be regularly shaped or irregularly shaped. The invention is mainly used in ceramic kiln to bear and transport the fired ceramic blanks in the course of firing and especially applied to the glazed outside wall blanks.

Owner:康健伟

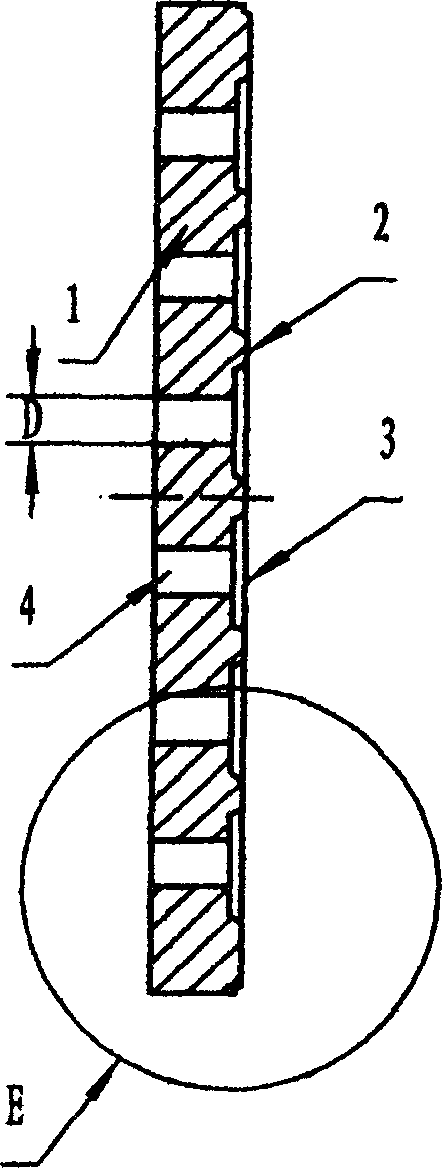

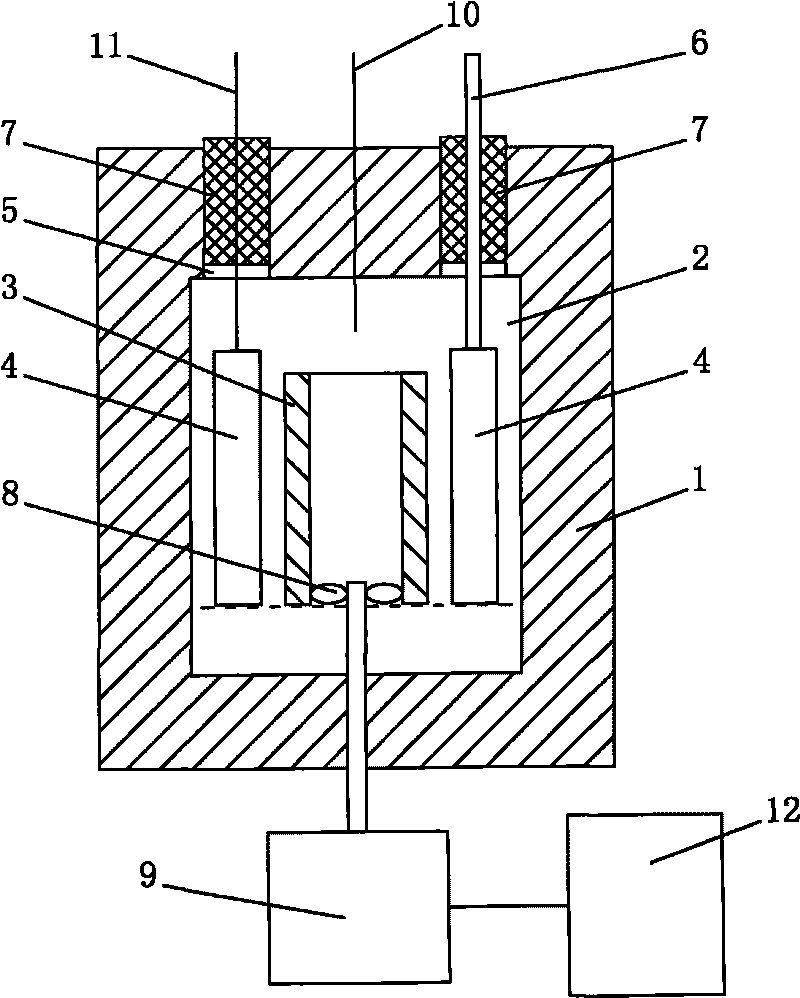

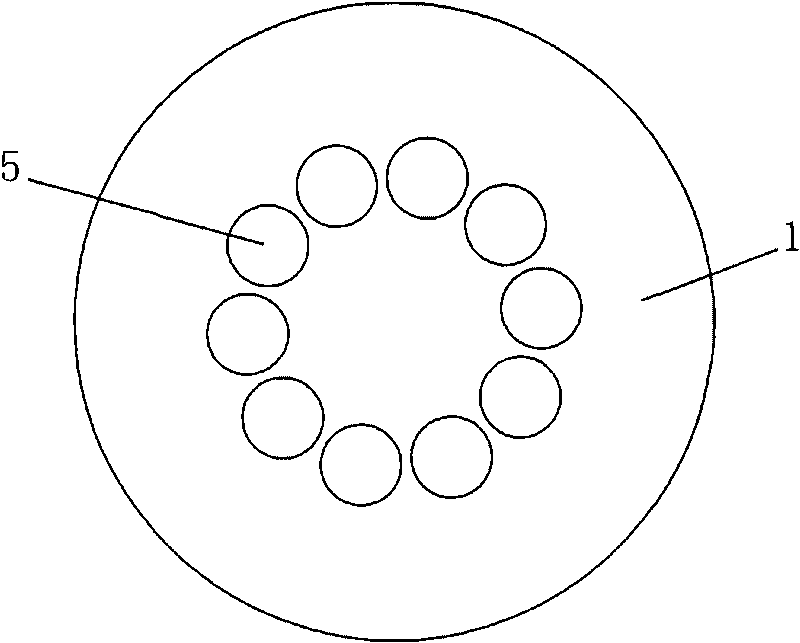

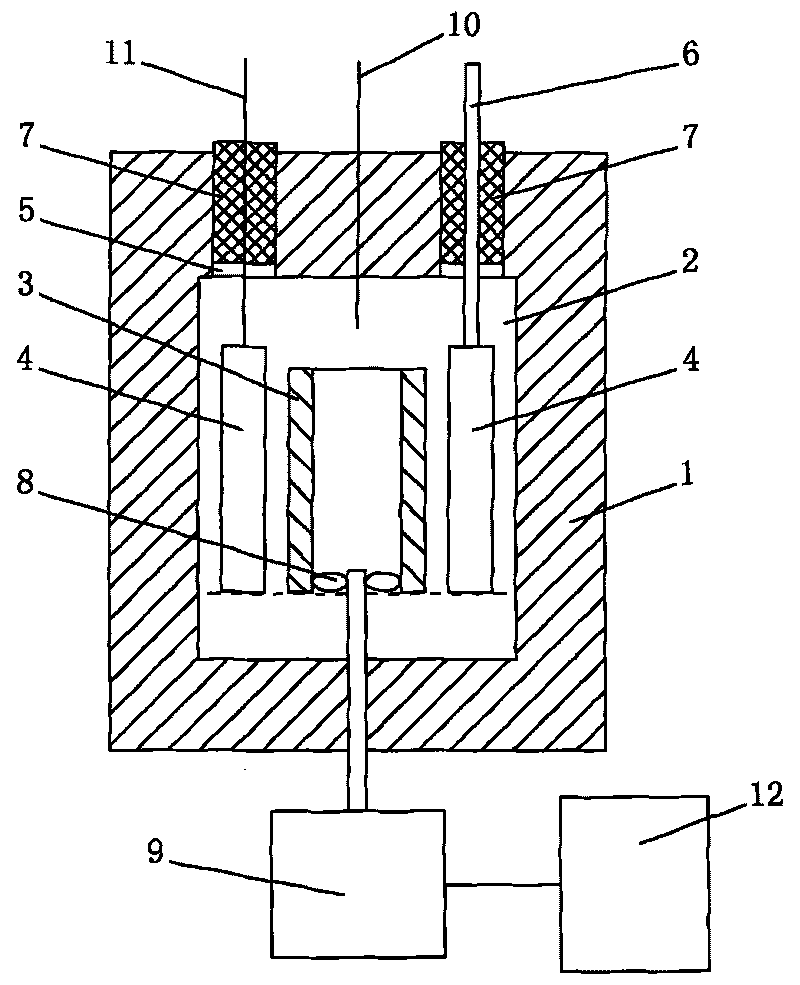

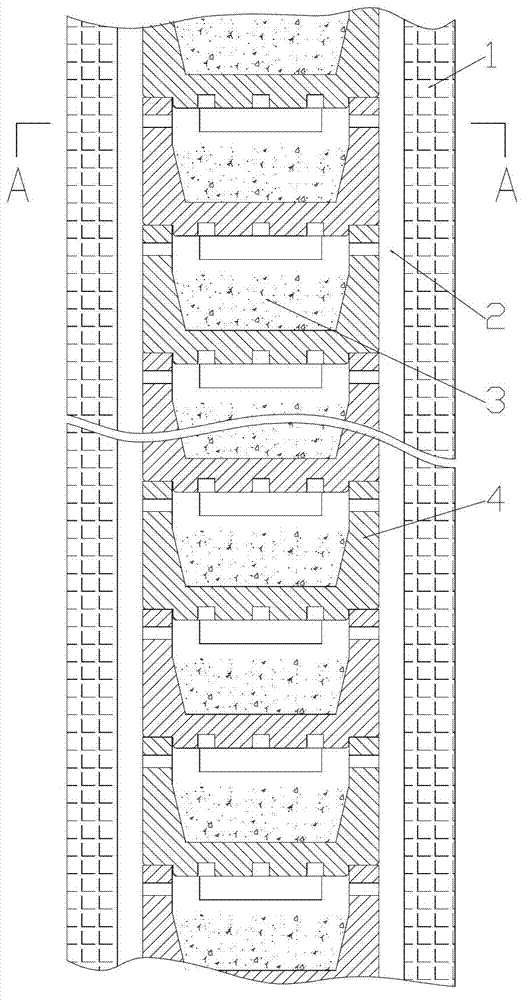

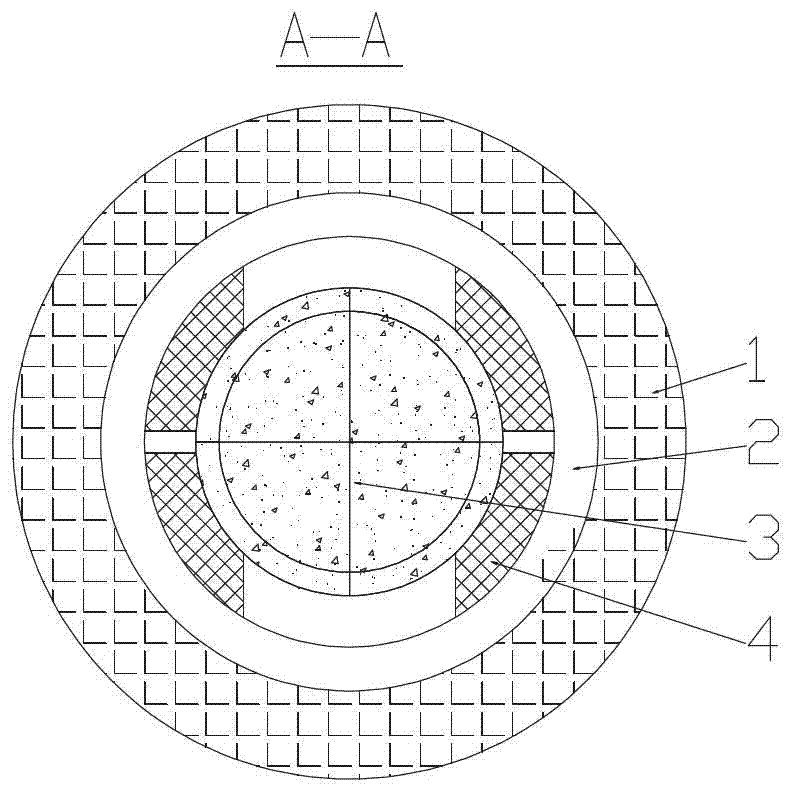

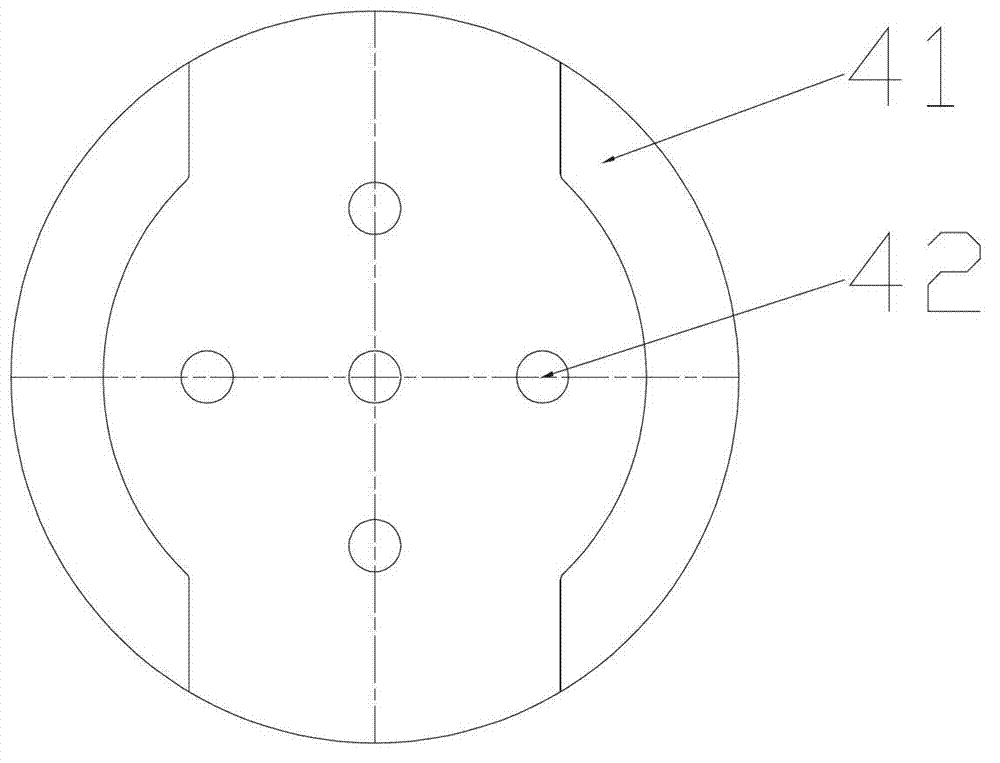

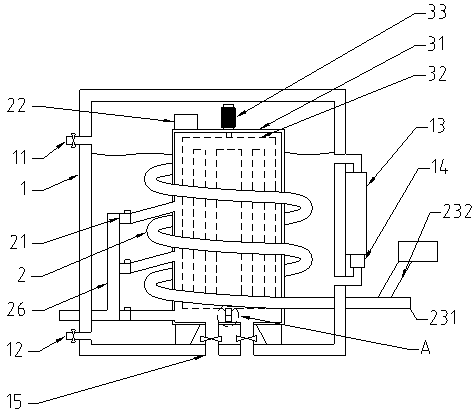

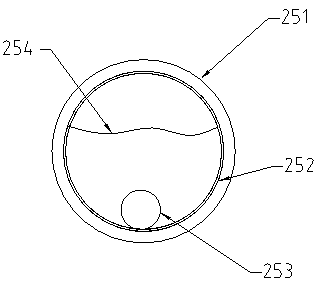

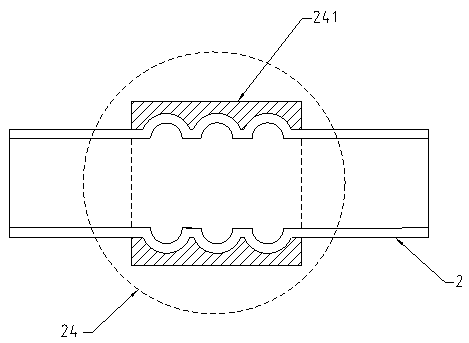

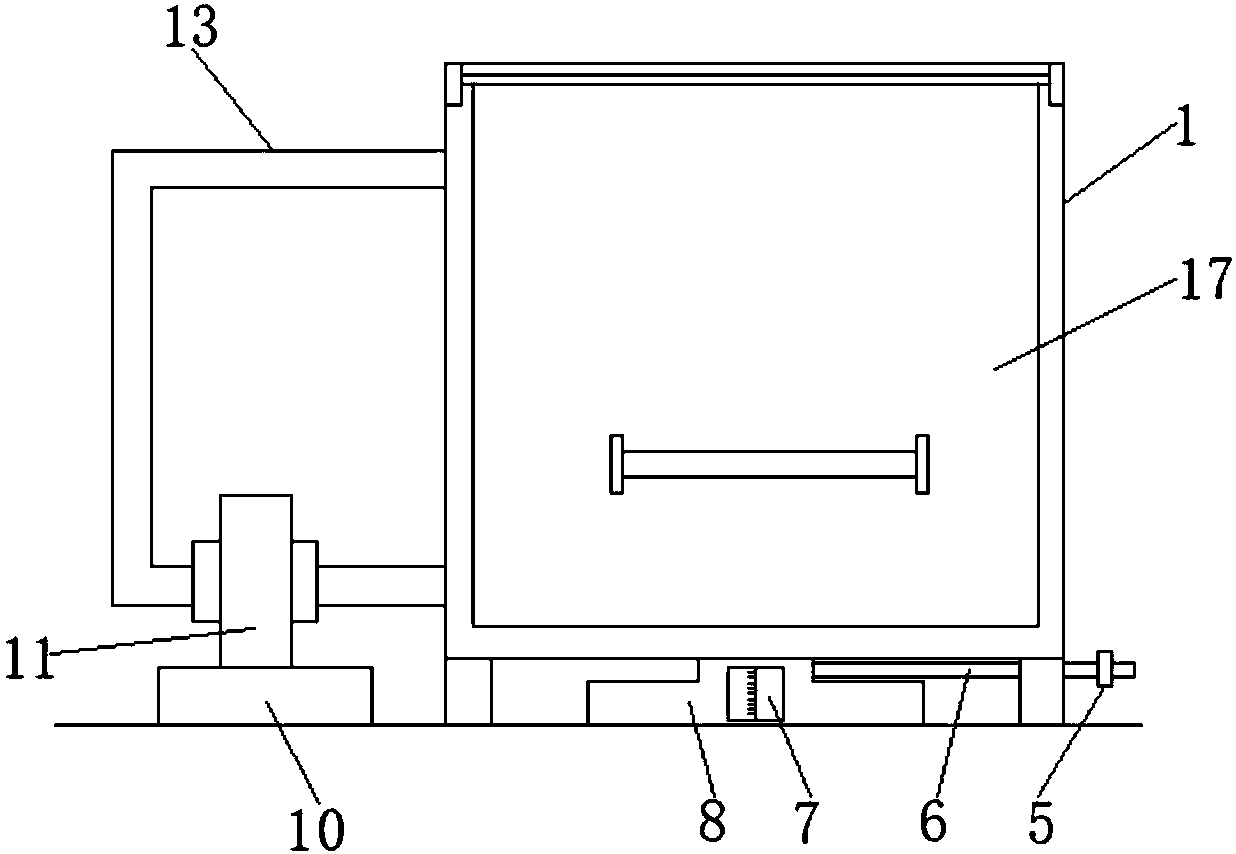

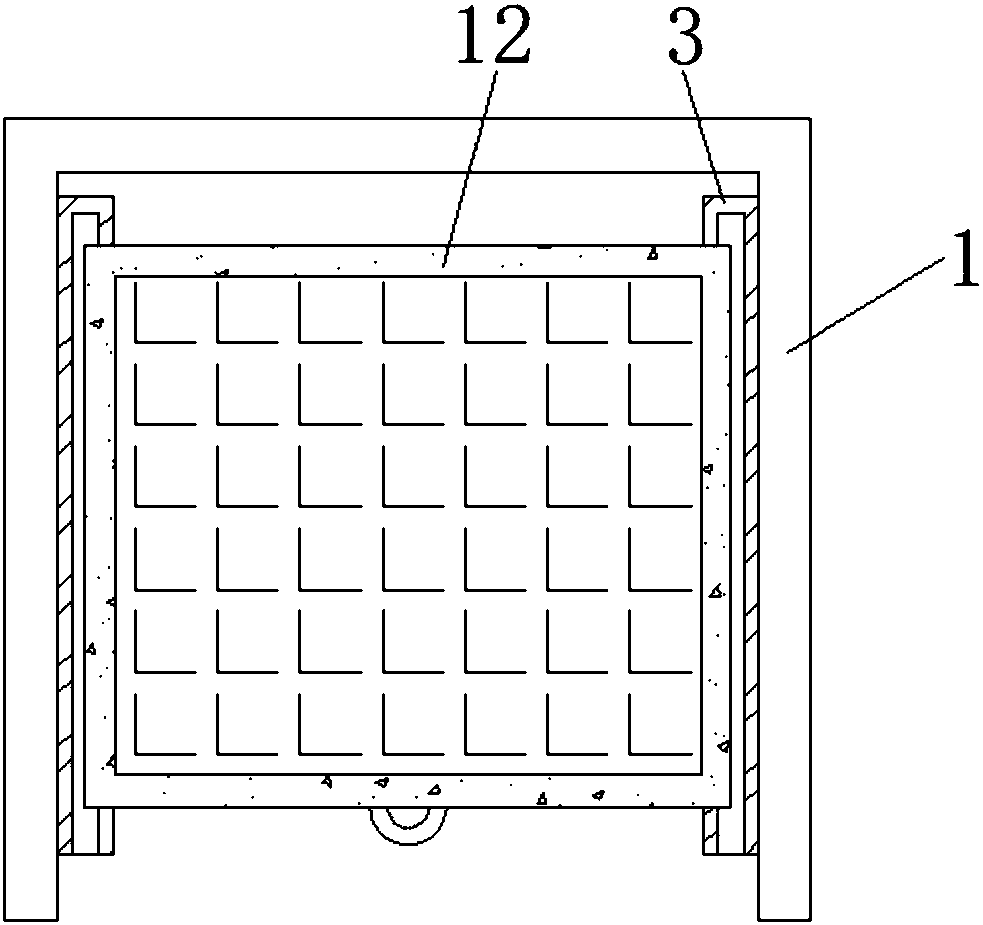

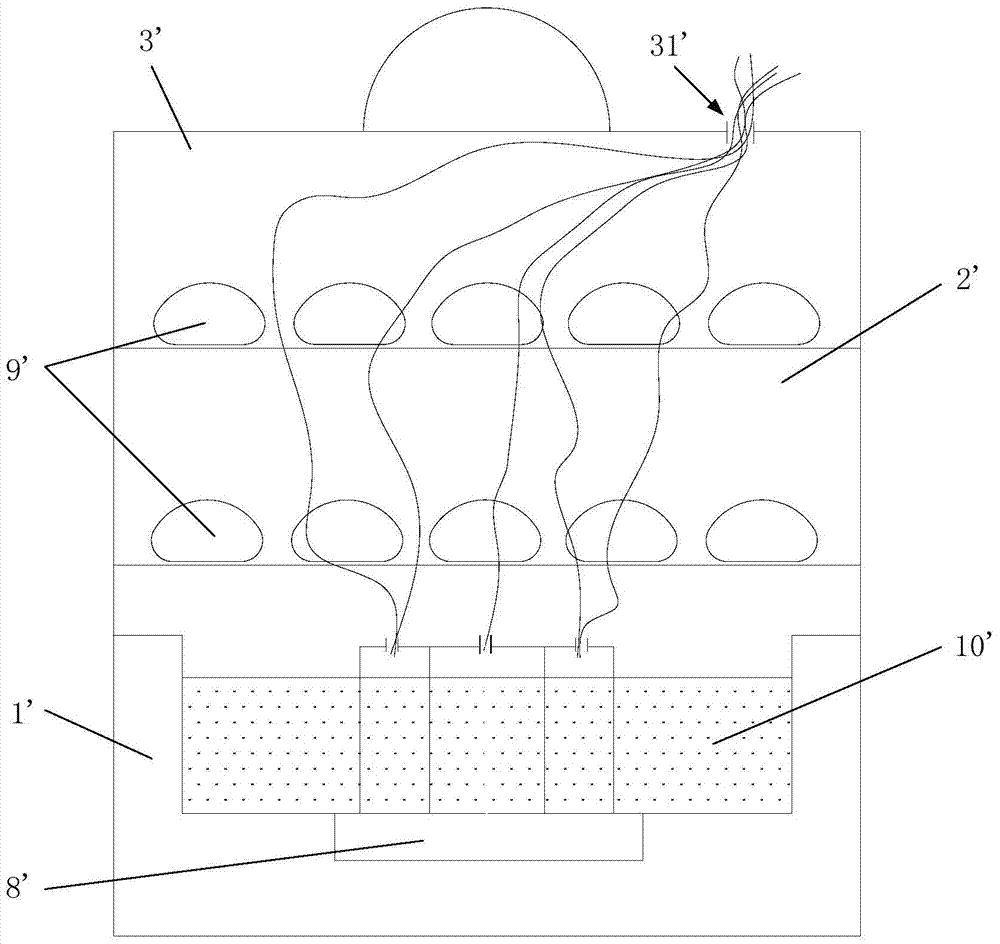

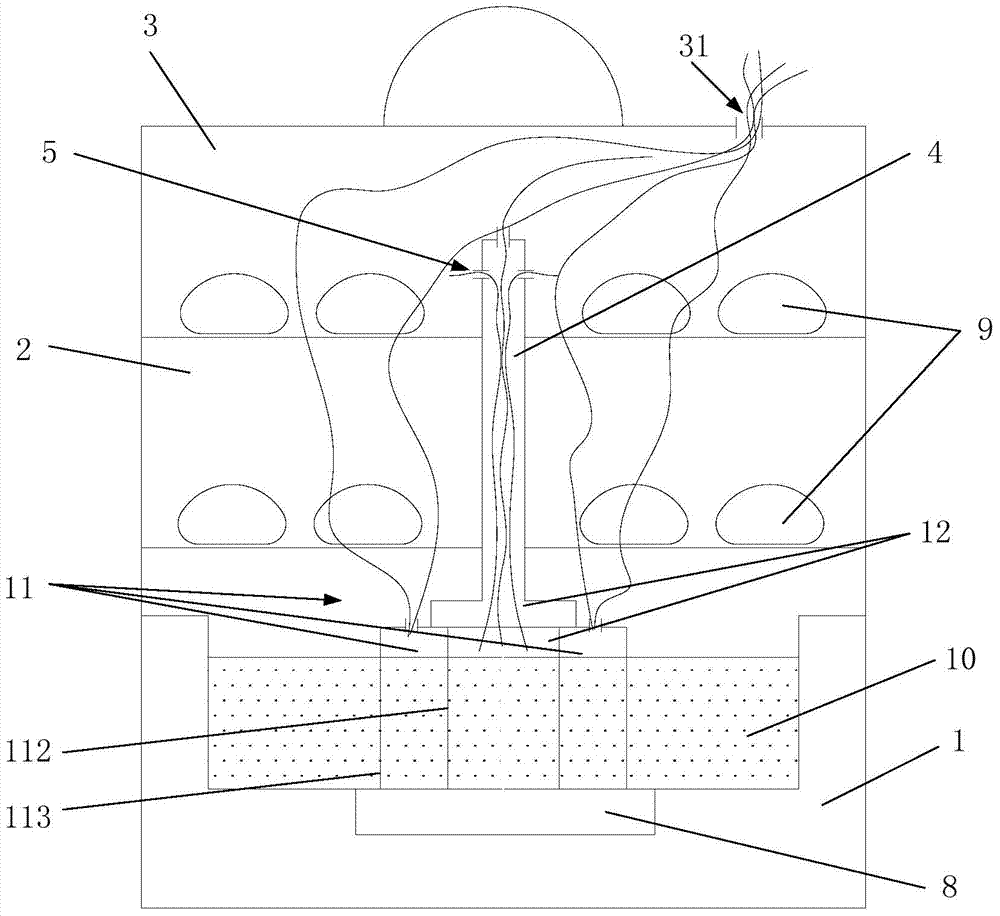

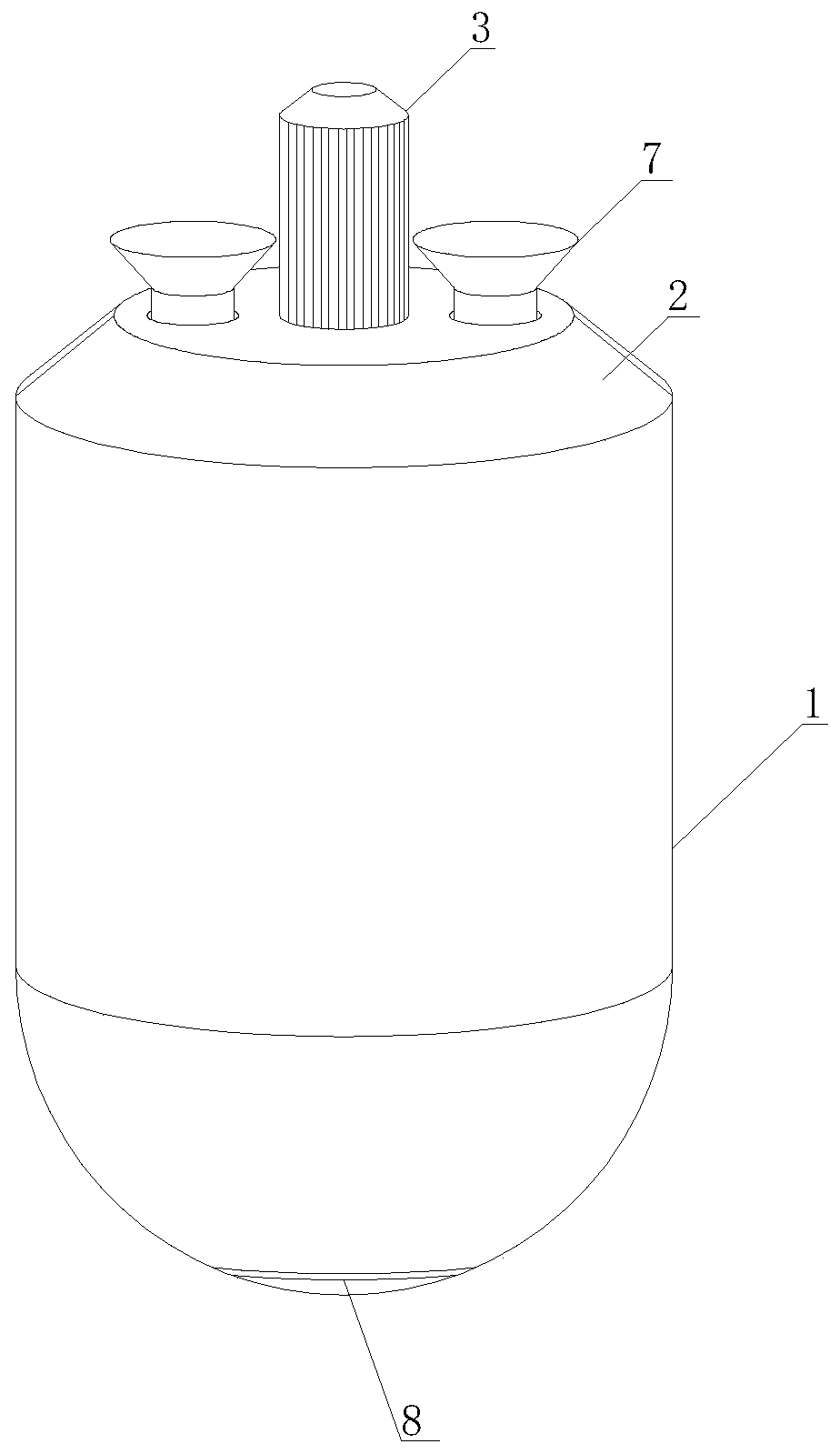

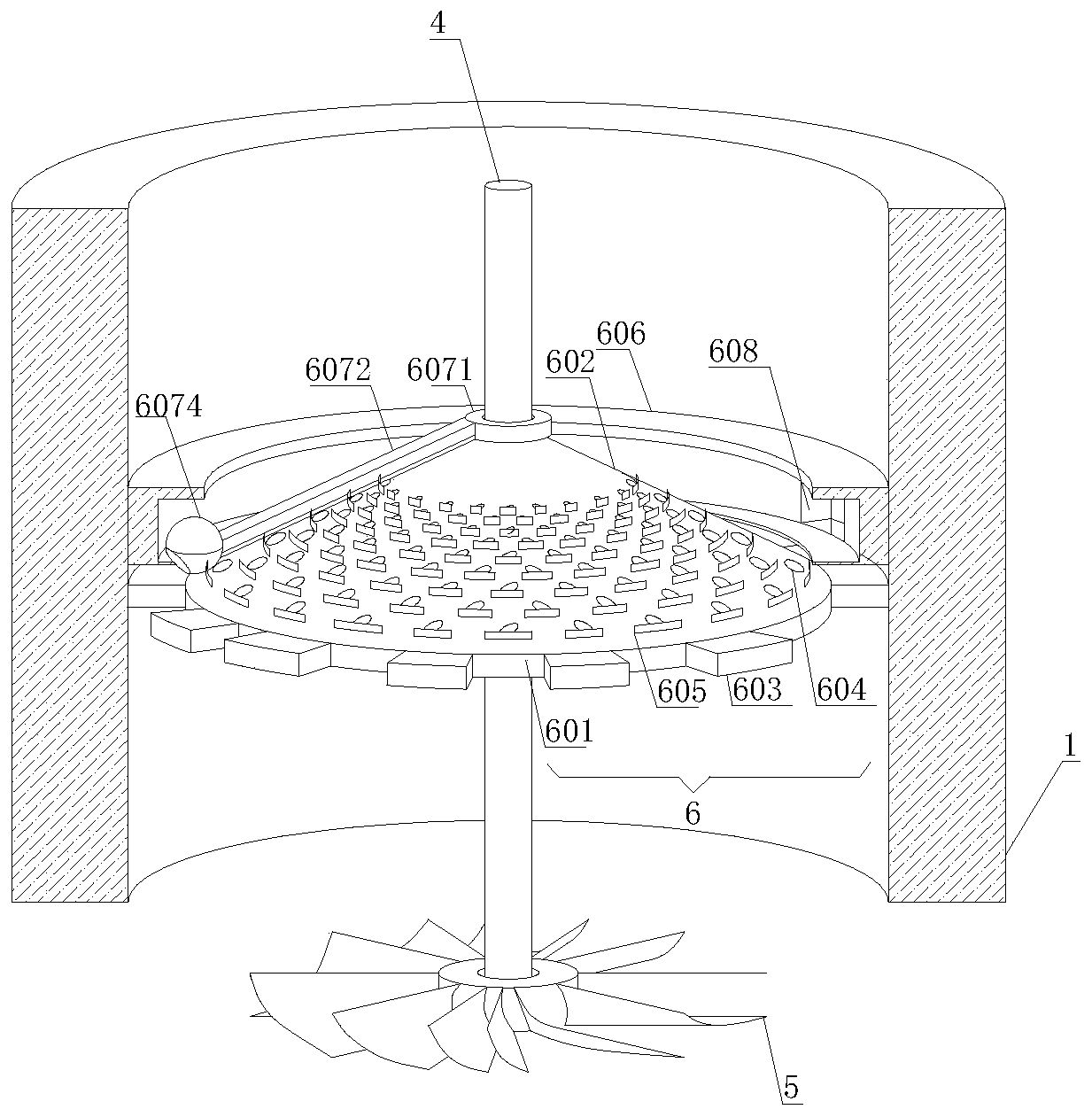

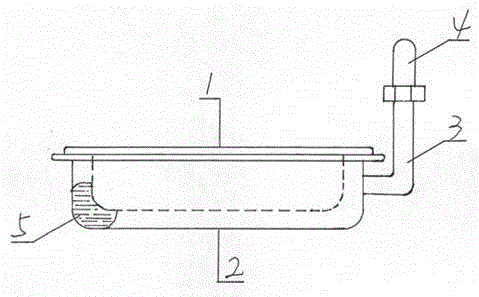

Thermal analogue electric furnace for use in researches on hydrocarbon generation kinetics

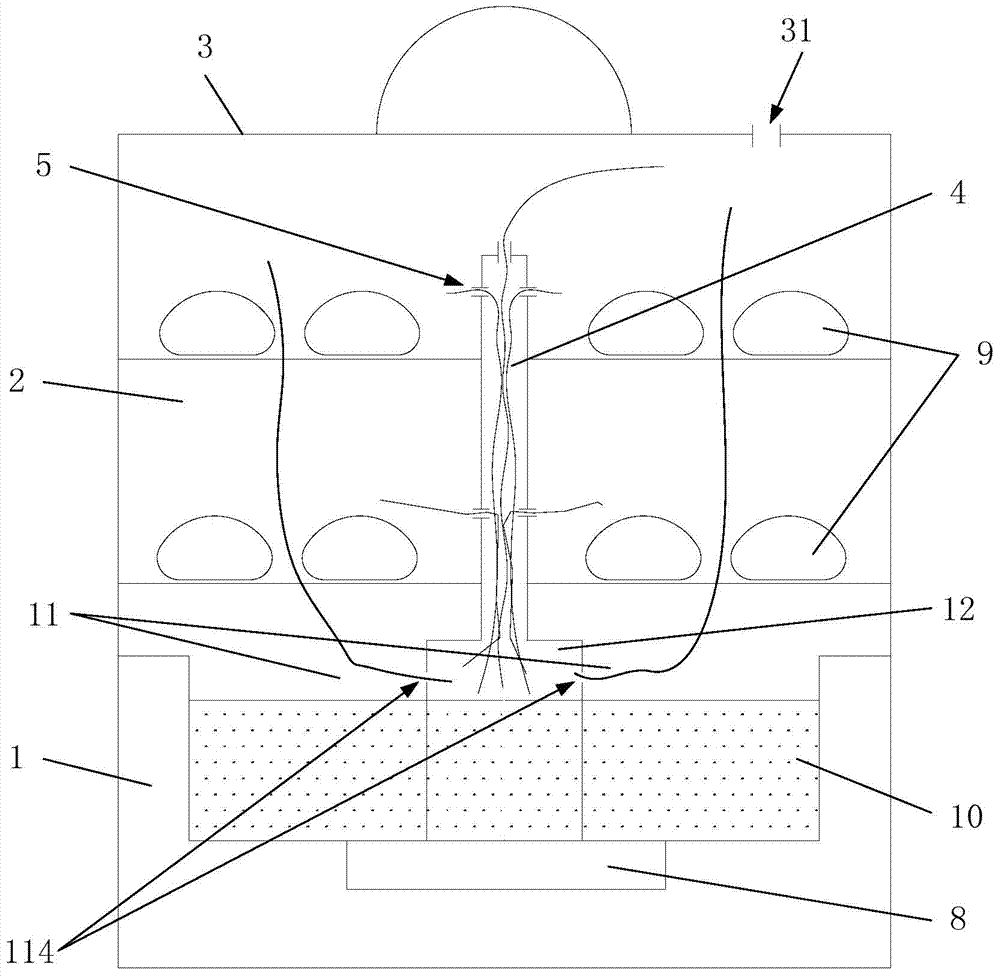

InactiveCN101706208AConsistent heatingSmall temperature differenceFurnace typesElectric machineryHearth

The invention discloses a thermal analogue electric furnace for use in researches on hydrocarbon generation kinetics, which comprises a furnace body (1). A hearth (2) of the furnace body is a cylindrical cavity, the center of the hearth is provided with an annular heating barrel (3), the hearth is provided with at least two high pressure kettles (4) which are arranged vertically, and the high pressure kettles are annularly distributed around the heating barrel; the top of the furnace body is provided with a high pressure kettle sampling aperture (5) corresponding to each high pressure kettle, the top of the high pressure kettle is connected with a high pressure water pipe (6) which is introduced inside through the high pressure kettle sampling aperture, and the inside of the high pressure kettle sampling aperture is provided with a plunger piston (7); and the inside of the heating barrel is provided with a fan (8), the fan is connected with a motor (9) which is arranged at outside the furnace body, and the furnace body is provided with an electric thermo-couple (10) for measuring the air temperature in the hearth and an electric thermo-couple (11) for measuring the air temperature in the high pressure kettle (4). The thermal analogue electric furnace has a requirement on uniformity of heating temperature in the furnace and the temperature difference between the high pressure kettles is less than 1 DEG C.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

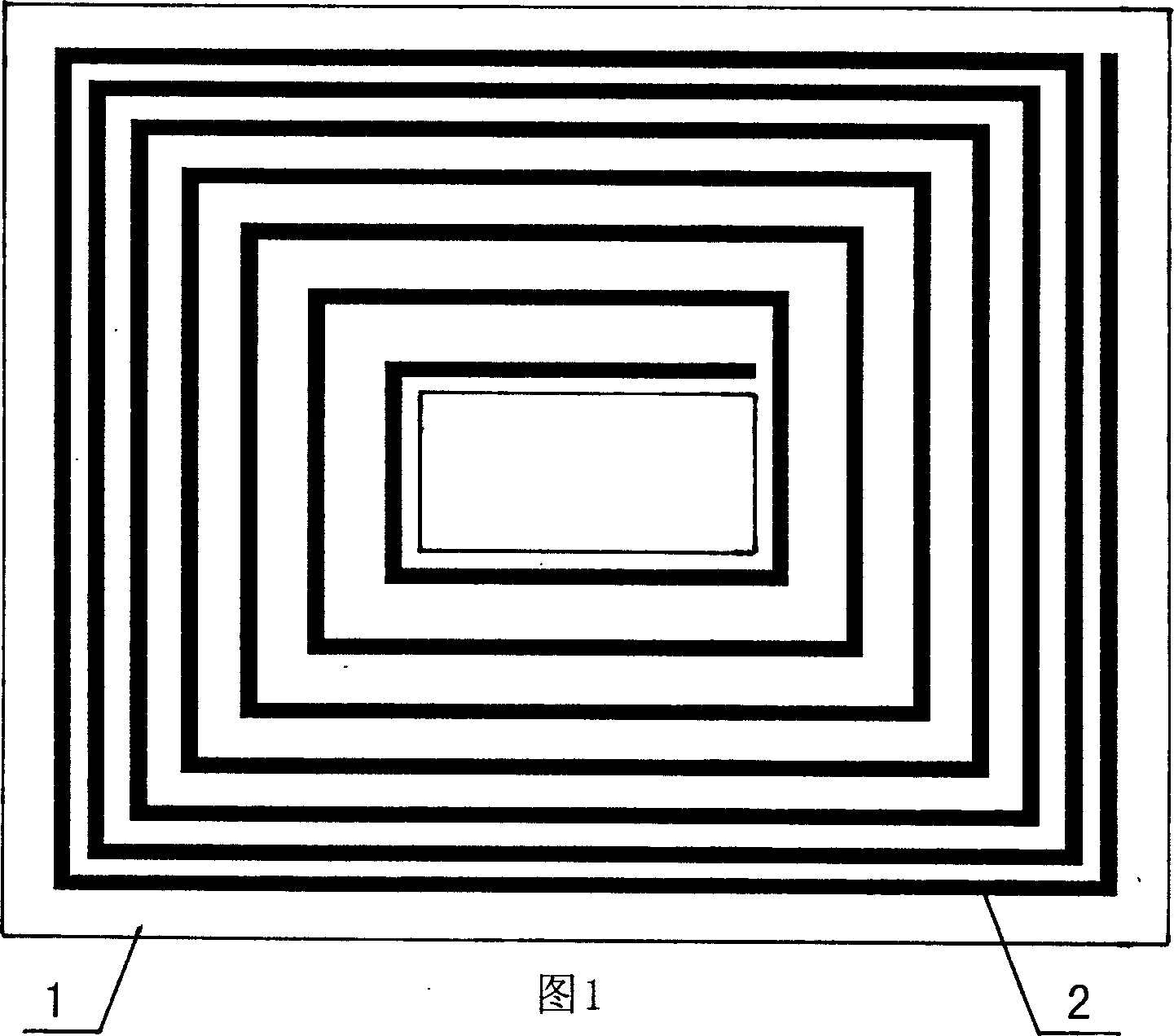

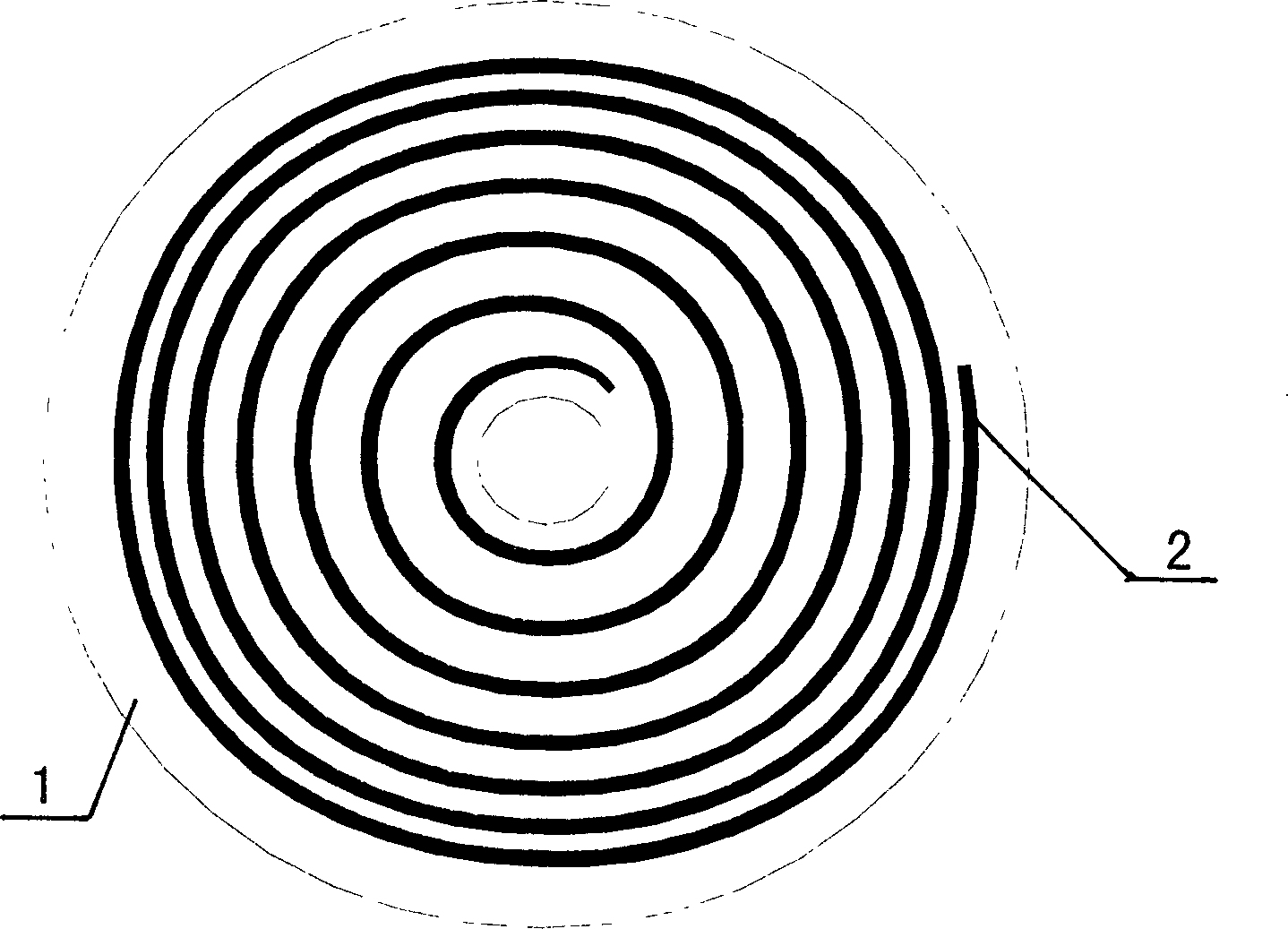

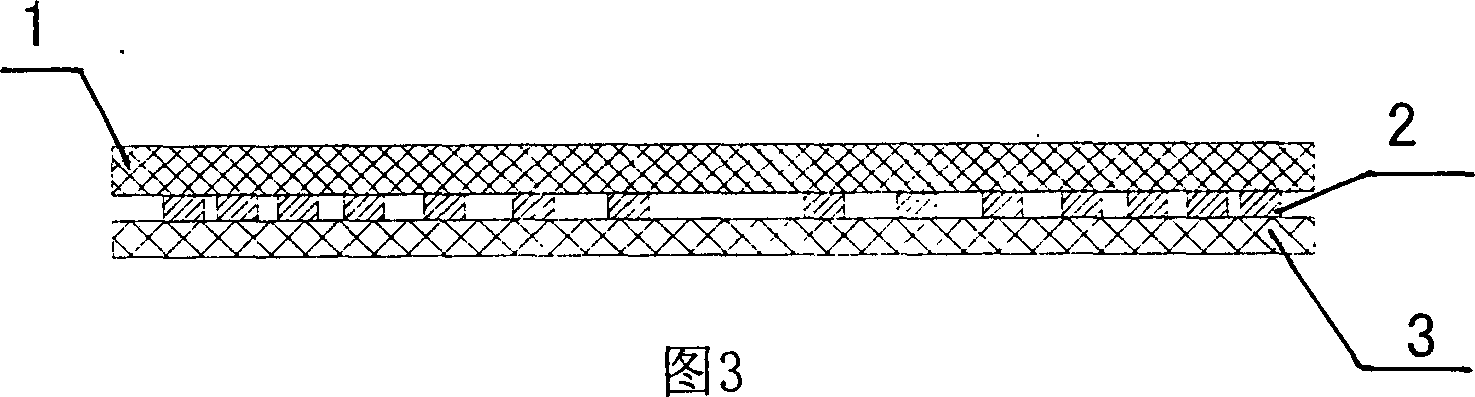

An electromagnetic induction heating coil

The invention discloses a electromagnetic induction heating winding. It includes non- magnetizer basis material covered by copper film, winding covered by copper film and non-magnetizer material board. Its lengthways section from from the top down are non-magnetizer material board, winding covered by copper film and non- magnetizer basis material covered by copper film. The distance of each two wind is equal, or inner wide outer narrow to form the style of inner sparse outer dense bit by bit. It can also be wind which is covered by copper film on double surfaces. The character of the invention is advisable designing, simple technics; average magnetic field strength, the inductive pyrotoxin is not limited by position, it can produce same heating energy; the invention is suitable to all kinds of heating equipment, especially when the inductive pyrotoxin is smaller than heating winding and the position is not be ensured.

Owner:韩秀艳

Continuous preparation method of tungsten carbide powder

ActiveCN102923704AGuaranteed temperature uniformityConsistent heatingTungsten/molybdenum carbideHydrogenHeating time

The invention relates to a continuous preparation method of tungsten carbide powder. The method comprises the steps that tungsten carbide powder is prepared continuously through adopting the way that boats and a heating element are in non-contact relative movement and an induction heating vertical continuous carbide furnace with a uniform temperature field with the temperature of 1,200 to 2,600 DEG C, tungsten powder and carbon powder are uniformly mixed to obtain a mixture, the mixture is put in the boats which are stacked up and down mutually, the boats pass through a continuous carbide furnace step by step in sequence from top to bottom, continuous carbonization heating is finished under the conditions that protective gas is filled in the continuous carbide furnace and the heating time and the heating temperature can be controlled and regulated, and the mixture is cooled to obtain a tungsten carbide product, and in each step of the boats, one boat enters from the upper part of the carbide furnace and another boat exits out of the lower part of the carbide furnace, so that the continuous preparation of tungsten carbide powder is realized. The tungsten carbide powder is prepared by adopting a vertical superhigh-temperature continuous heating way in a nitrogen environment, which breaks through the traditional preparation technology mode that the tungsten carbide powder is prepared by adopting a horizontal continuous heating process or a vertical intermitting heating process in the hydrogen environment.

Owner:株洲弗拉德科技有限公司

Ionic liquid modified bar code carbon strip back coating and preparation method thereof

InactiveCN108485358ASolve heat resistanceFix stability issuesFireproof paintsThermographyOrganic solventDouble bond

The invention relates to an ionic liquid modified bar code carbon strip back coating which is prepared from the following raw materials in parts by weight: 10-50 parts of an acrylic monomer, 0.5-2 parts of a silane coupling agent, 0.5-3 parts of an ionic liquid containing double bonds; 15-30 parts of organic silicon, 13-73.5 parts of an organic solvent and 0.5-2 parts of a catalyst. The inventionprovides the ionic liquid modified bar code carbon strip back coating and a preparation process. By means of block polymerization, the ionic liquid containing double bonds is introduced into a high molecular chain of the polyacrylate back coating, and the high molecular back coating with low resistivity is coated with a bar code carbon strip, so that static electricity generated and accumulated onthe carbon strip are reduced effectively, and therefore, the printing using quality of the back coating is guaranteed.

Owner:HENAN UNIV OF SCI & TECH

Development apparatus for modified asphalt

InactiveCN109652108AGood quality of developmentReduce lossRotary stirring mixersTransportation and packagingCooling effectEngineering

The invention discloses a development apparatus for modified asphalt. The apparatus sequentially comprises an outer shell, a cooling work part and a development tank from the outside to the inside, wherein the outer shell is provided with a plurality of coolers for maintaining the temperature of coolant oil in the outer shell; the cooling work part includes a cooling pipeline, a magnetic ball andcoolant oil, and the cooling pipeline is immersed in the coolant oil in the outer shell and is used for transporting asphalt, the magnetic ball enters the cooling pipeline from a magnetic ball inlet and moves with the asphalt to cool the asphalt, and the cooling pipeline is also provided with magnetic ball cooling portions, used for cooling an energy storage material in the magnetic ball, at intervals to ensure the continuous cooling effect of the magnetic ball; the development tank includes a tank body, a stirring frame and a hierarchical discharging device, and the hierarchical discharging device performs discharging through discharge tubes with different heights in order to reduce the tendency of coking near a single discharging port. The apparatus can effectively solve the problem of coking of the discharging port of the development tank during large-scale production, and also can ensure the development quality of the asphalt.

Owner:南充海丽科技有限公司

Silicon premelting method for evaporation plating

InactiveCN110551977AReduce silicon chipping problemsConsistent heatingVacuum evaporation coatingSputtering coatingAlcoholUnit mass

A silicon premelting method for evaporation plating comprises the following steps of (a) polishing the surface of a crucible, performing flushing with deionized water after polishing, and performing washing with absolute ethyl alcohol after flushing; (b) performing blow drying on the crucible with nitrogen; (c) performing incipient melting operation; (d) performing remelting operation; and (e) performing final melting operation. One third of monocrystalline silicon is added every time in the step of incipient melting, the step of remelting and the step of final melting, thus guaranteeing thatthe monocrystalline silicon can be evenly heated during melting of every time; the melting process of every time is a process of secondary heating and secondary cooling, so that silicon splashing problem during evaporation of the monocrystalline silicon is effectively solved, and the rate of finished product is increased; the electron beam scanning area during remelting is increased in comparisonwith that during incipient melting, and meanwhile, the electron beam power in the heating process of remelting is also increased in comparison with that in the heating process of incipient melting, thus guaranteeing that monocrystalline silicon briquettes per unit mass are consistent in heat; and the electron beam power in the heating process of final melting is increased in comparison with that in the heating process of remelting so as to also guarantee that the monocrystalline silicon briquettes per unit mass are consistent in heat.

Owner:潍坊华光光电子有限公司

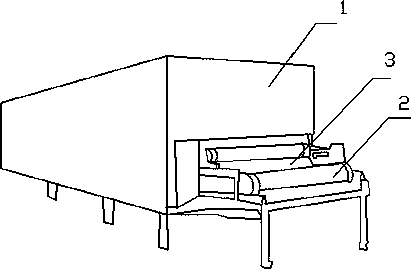

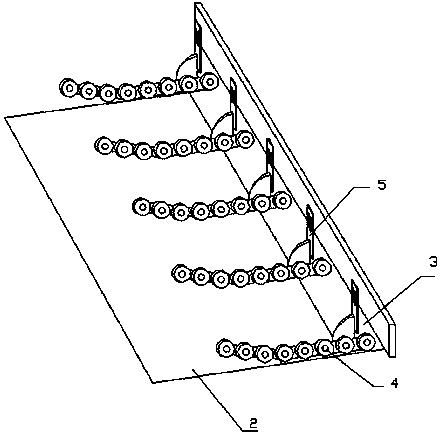

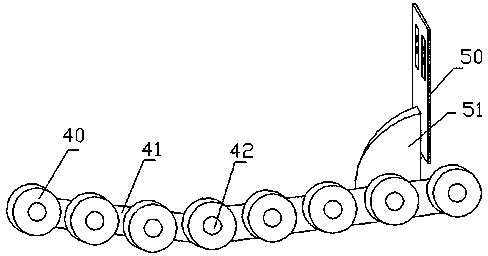

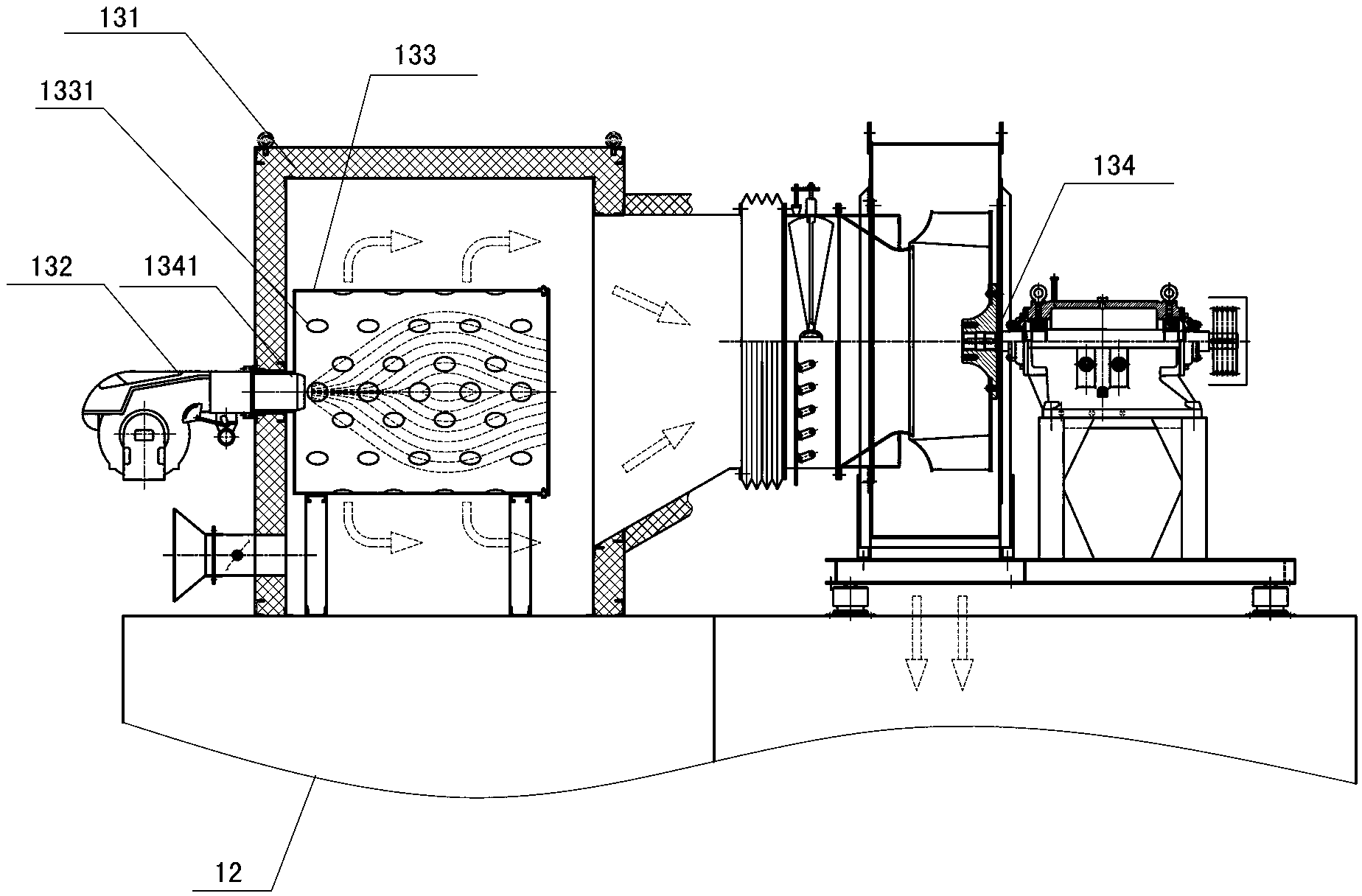

Mesh belt type veneer drier

InactiveCN104215035ASmooth entryFit tightlyOther plywood/veneer working apparatusPreliminary solid treatment for dryingEngineeringConveyor belt

The invention discloses a mesh belt type veneer drier. The mesh belt type veneer drier comprises a mesh belt, a chain wheel and a drying room, wherein the mesh belt is driven by the chain wheel; a feeding hole is formed in the drying room; the mesh belt enters the drying room from the feeding hole; a veneer smoothening device is mounted at the feeding hole; the veneer smoothening device comprises a plurality of smoothening units and a plurality of connecting pieces, one smoothening unit is connected to one connecting piece, the smoothening units are connected to the feeding hole of the drying room through the connecting pieces, each smoothening unit comprises a plurality of pressing wheels and a plurality of pressing wheel connecting pieces, and the pressing wheels are connected together through the pressing wheel connecting pieces. Non-smooth veneers are tightly attached to the mesh belt at the feeding hole of a conveyor belt after the non-sooth veneers are smoothened, so that the veneers can smoothly enter the drying room for drying, and the veneers are uniformly dried.

Owner:凭祥长隆人造板有限公司

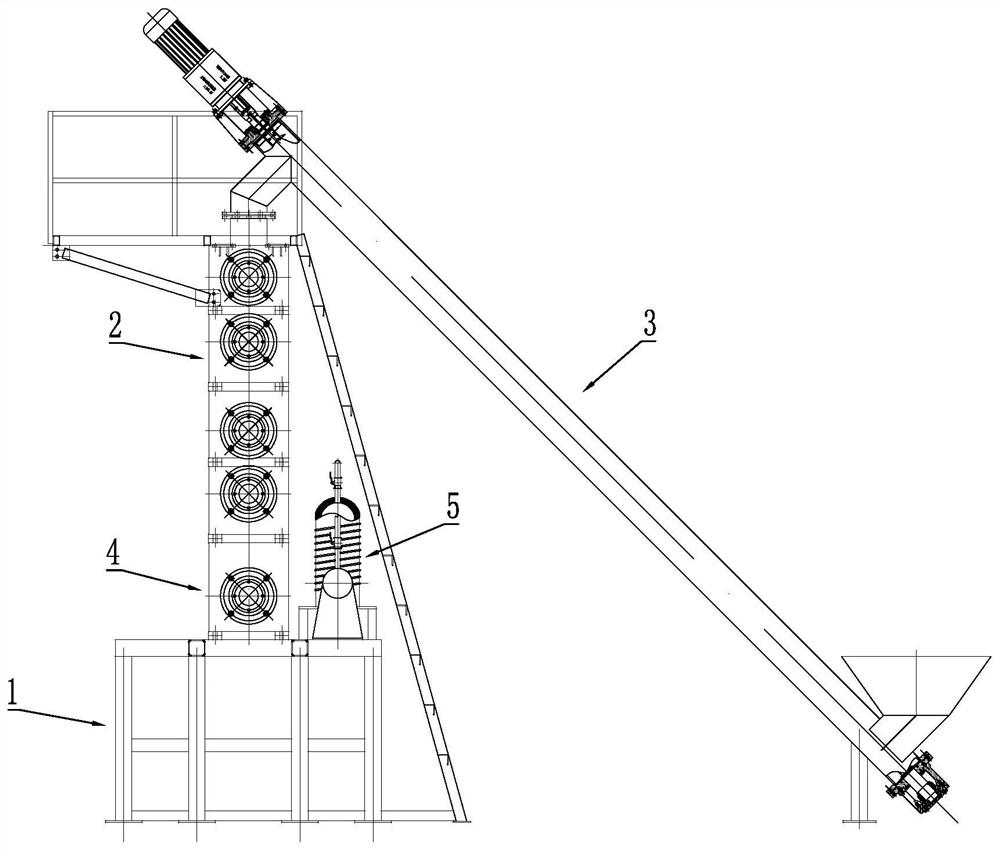

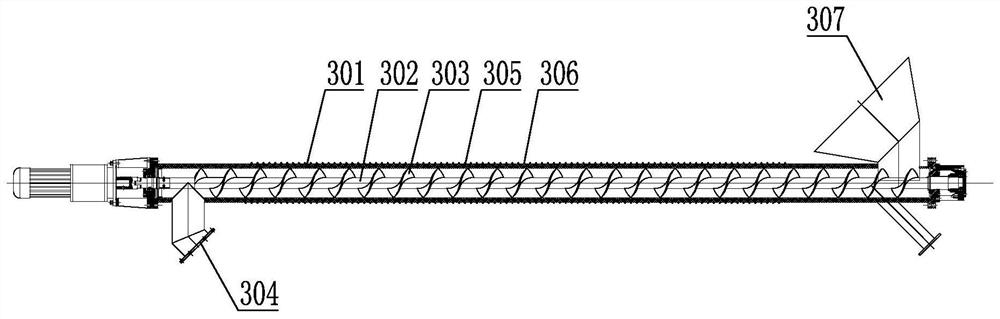

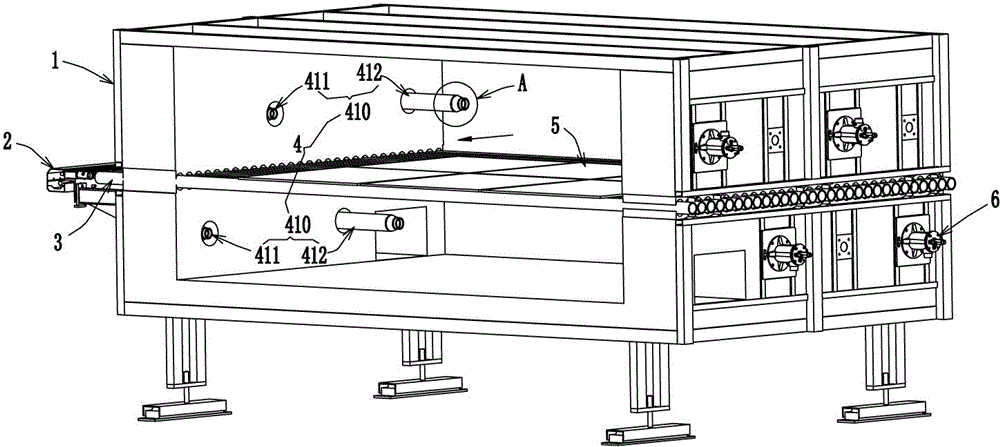

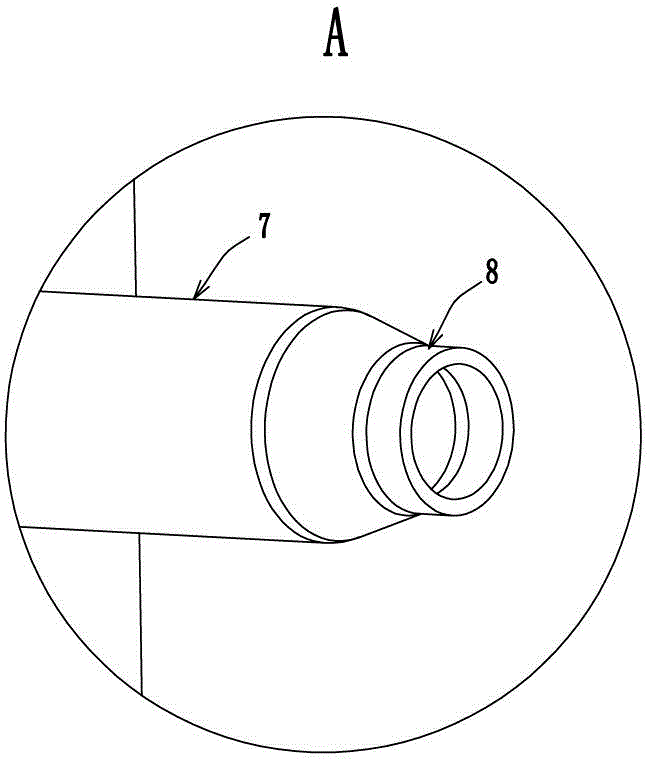

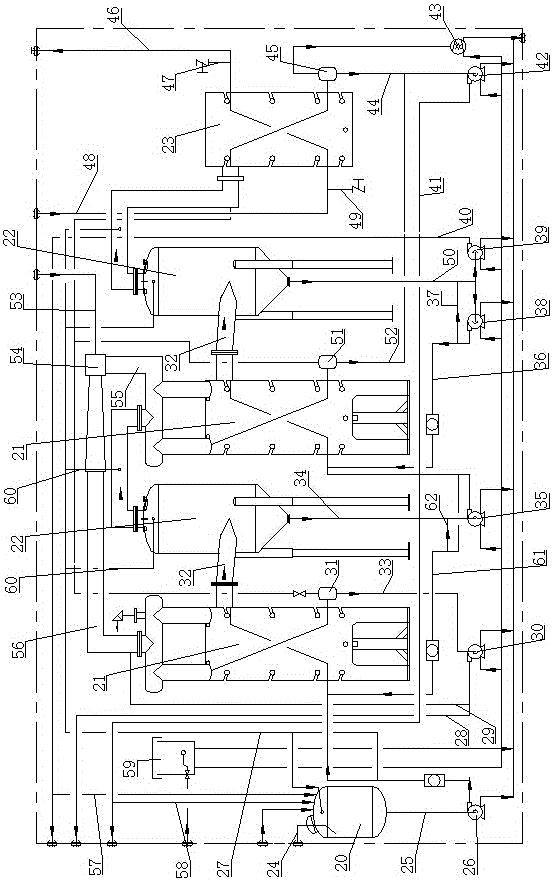

Accurate temperature control continuous seed frying machine

PendingCN112111325AEvenly heatedConsistent heatingFatty-oils/fats productionTemperature controlFood grade

The invention discloses an accurate temperature control continuous seed frying machine which comprises a rack and is characterized in that a temperature control steaming and frying mechanism is installed on the rack, the feeding end of the temperature control steaming and frying mechanism is connected with a heating feeding mechanism, and the discharging end of the temperature control steaming andfrying mechanism is connected with a temperature control discharging mechanism; a high-temperature steam supply mechanism connected with the temperature control steaming and frying mechanism is further mounted on the rack; the equipment has the advantages that automatic continuous production is realized; the temperature is accurately controlled, coking or supercooling or superheating is avoided,which is an important condition for guaranteeing the oil quality grade and the oil yield; the machine has multiple specifications, and can meet the requirements of different scales and batch production; the machine is made of food-grade stainless steel and meets the requirements of sanitation and environmental protection; the sealing performance of the machine is good, and the leakage phenomenon is avoided; the production environment is good and the labor intensity is low; the production efficiency is high and the energy consumption is low; and the feeding mechanism is provided with an electromagnetic preheating device so that the steaming and frying time is saved.

Owner:山东阳光盛世机械装备有限公司

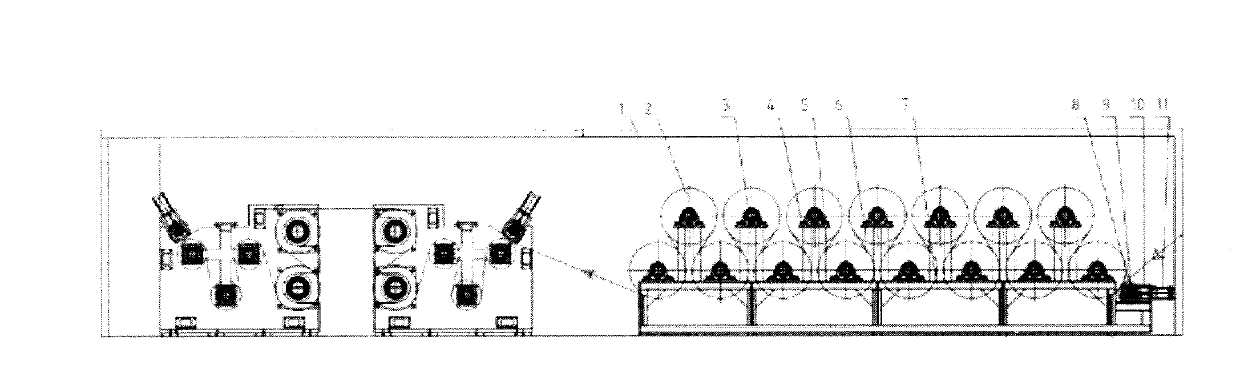

Novel temperature difference control structure for firing equipment

ActiveCN104534872AImprove uneven heating environmentReduce distortionFurnace typesCeramic sinteringTemperature difference

The invention provides a novel temperature difference control structure which can reduce the temperature difference in the wide section direction in a kiln and effectively prevent a product from being deformed or cracked in the ceramic sintering and forming process. The novel temperature difference control structure comprises a frame, a roller bar conveying assembly mounted on the frame, a drive mechanism used for driving the roller bar conveying assembly to rotate, a plurality of sets of burning shunt assemblies which are symmetrically mounted on the two sides of the frame and are distributed in the conveying direction of the roller bar conveying assembly, and a burner used for providing heat for the burning shunt assemblies. When ceramic products are sintered and shaped, due to the structural mode of long-short matched burning shunts, the flames of the long burning shunts are close to the middle, and the flames of the short burning shunts are close to side walls, so that heating of the ceramic products in the kiln is basically kept consistent in the wide section direction, accordingly, the uneven heating environment of the ceramic products at the middle position in the kiln in the sintering process in a traditional mode is improved, and the deformation or cracking phenomenon of the ceramic products due to temperature differences in the sintering process is effectively reduced.

Owner:MODENA TECH LTD

Method for manufacturing puff pastry

ActiveCN103404559AEvenly distributedThere will be no channelingDough treatmentBakery productsManufacturing technologyBeta-Carotene

The invention discloses a method for manufacturing puff pastry. The manufacturing technology comprises material distributing, dough kneading, crisping, pastry manufacturing, shaping, baking, coating, precooling, sterilizing and packaging. The material distributing process is carried out through evenly-mixed materials, by mass ratio, 100 of flour, 3.2-4.5 of white sugar, 43-52 of water, 1-4 of spicy powder, 16-23 of eggs, 10-15 of arrowroot, 8-10 of edible mushroom powder, 1-3 of vitamin E, 1-3 of phospholipids, 1-3 of potassium sorbate, 1-3 of propylene glycol fatty acidate, 1-3 of beta-carotene and 8-10 of table salt; in the crisping process, after being heated until the temperature of butter coincides with the temperature of dough, the butter is wrapped with the dough; in the pastry manufacturing process, the dough kept after the crisping process is repeatedly pressed to be thin and folded to form an eight-layer strip cake. The method for manufacturing the puff pastry has the advantages that material distributing is more reasonable, and manufactured puff pastry is more delicious, and is more unique in taste, has more layers, and is spicy, good in mouthfeel, and not greasy after the arrowroot and the edible mushroom powder are added.

Owner:湖北钟祥金源食品股份有限公司

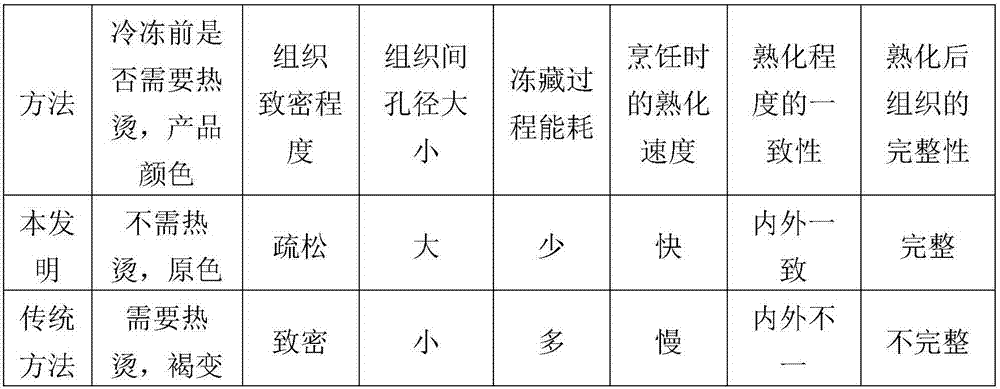

Processing and preservation method of porous tuber vegetables

InactiveCN107173429AReduce energy consumptionReduce processing timeFood freezingFood processingFood gradeSurface water

A processing and preservation method of porous tuber vegetables comprises steps as follows: the tuber vegetables are peeled and cleaned, surface water is drained, and after the tuber vegetables are not packaged or packaged with food-grade plastic bags, the tuber vegetables are stored in the environment of subzero 6 DEG C to subzero 3 DEG C for 3-5 h and can be directly used for cooking or preserved at subzero 10 DEG C to subzero 6 DEG C. The starch-rich tuber vegetables such as Chinese yams, taro and the like are treated at the temperature of subzero 6 DEG C to subzero 3 DEG C, the vegetables can be slowly frozen, water in tissue slowly forms numerous large-particle ice crystals, so that after the frozen vegetables are unfrozen, the vegetable tissue cannot completely absorb water produced during unfreezing again, part of water escapes, holes are formed in the original ice crystals, and the porous characteristic is formed. The blanching process is omitted before processing, and energy consumption is reduced; the preservation time of the tuber vegetables can be prolonged; due to formation of the porous characteristic of the vegetables, the cooking time can be shortened, insides and outsides of products are ensured to be heated uniformly, and the insides and the outsides of the tuber vegetables are cooked simultaneously.

Owner:HUNAN AGRICULTURAL UNIV

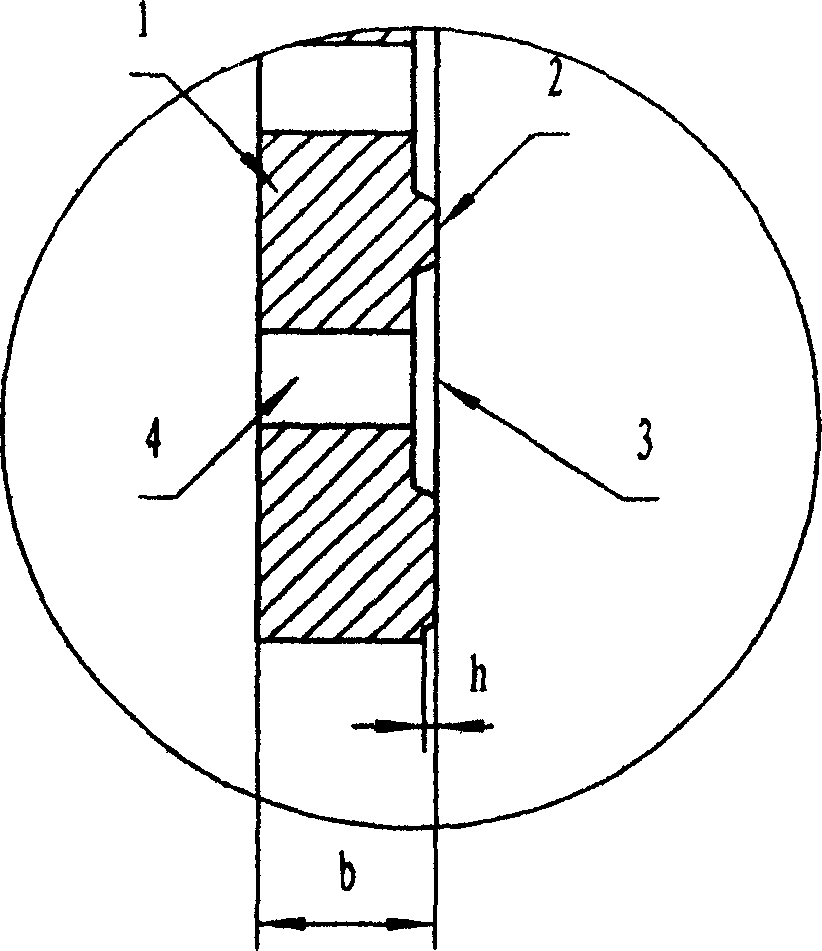

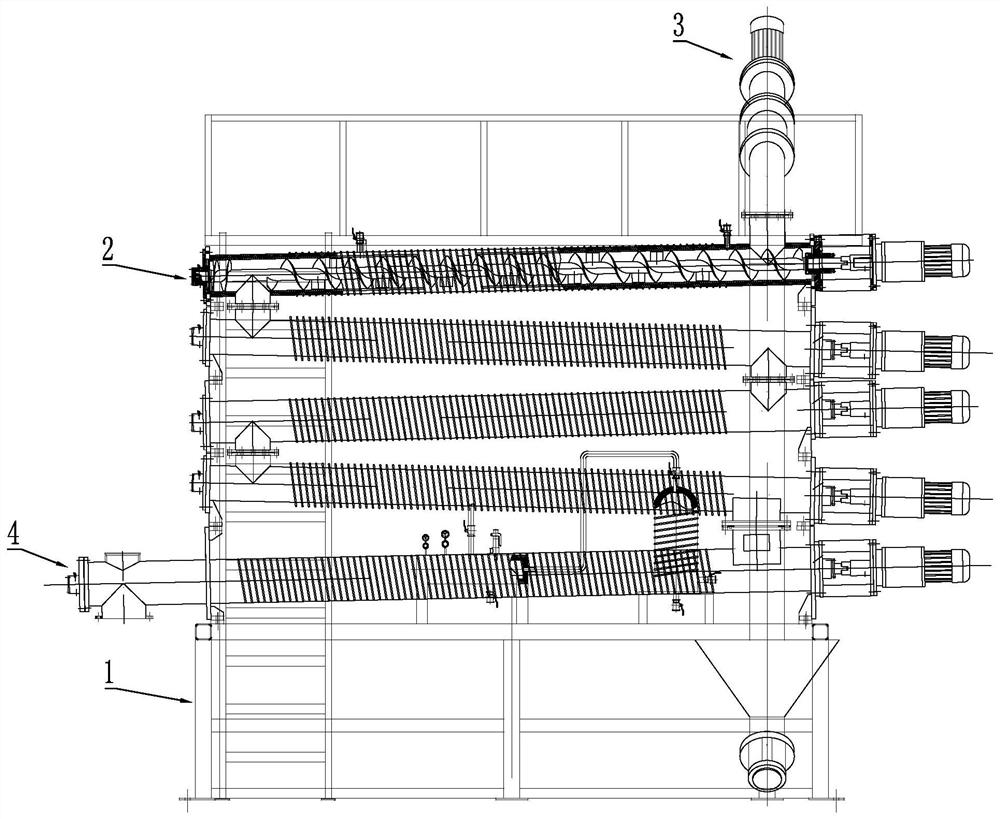

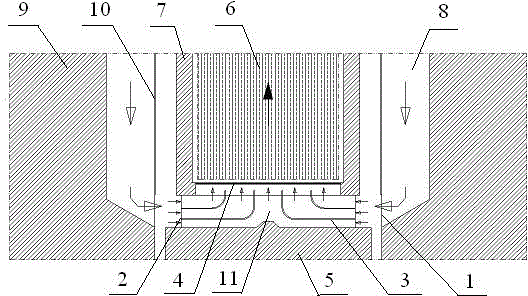

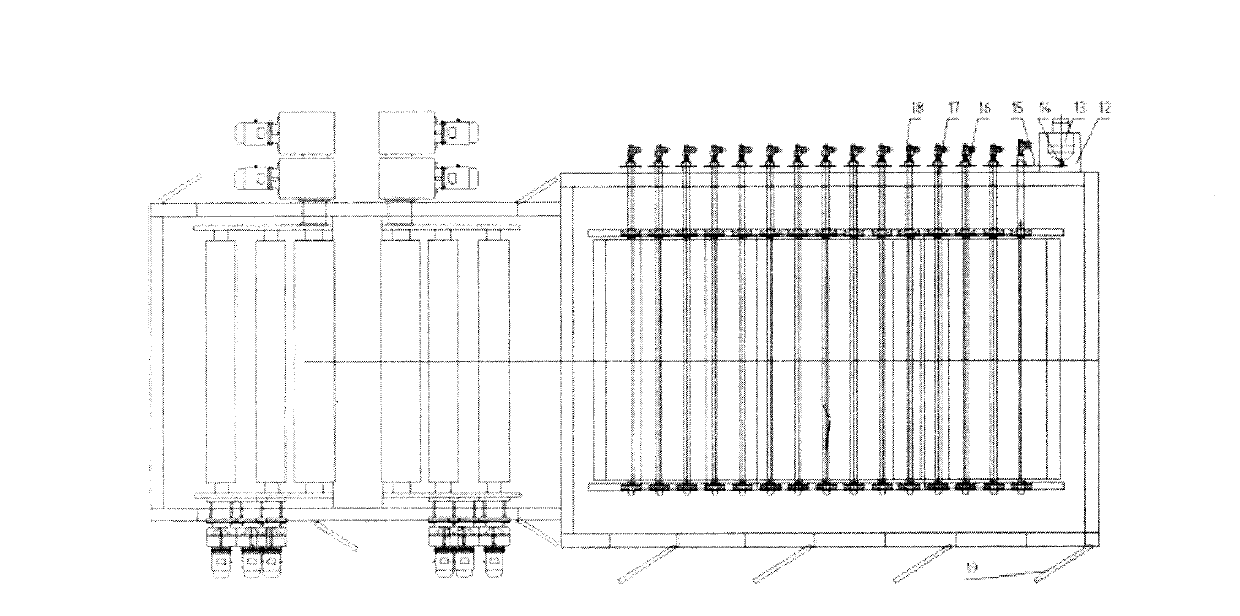

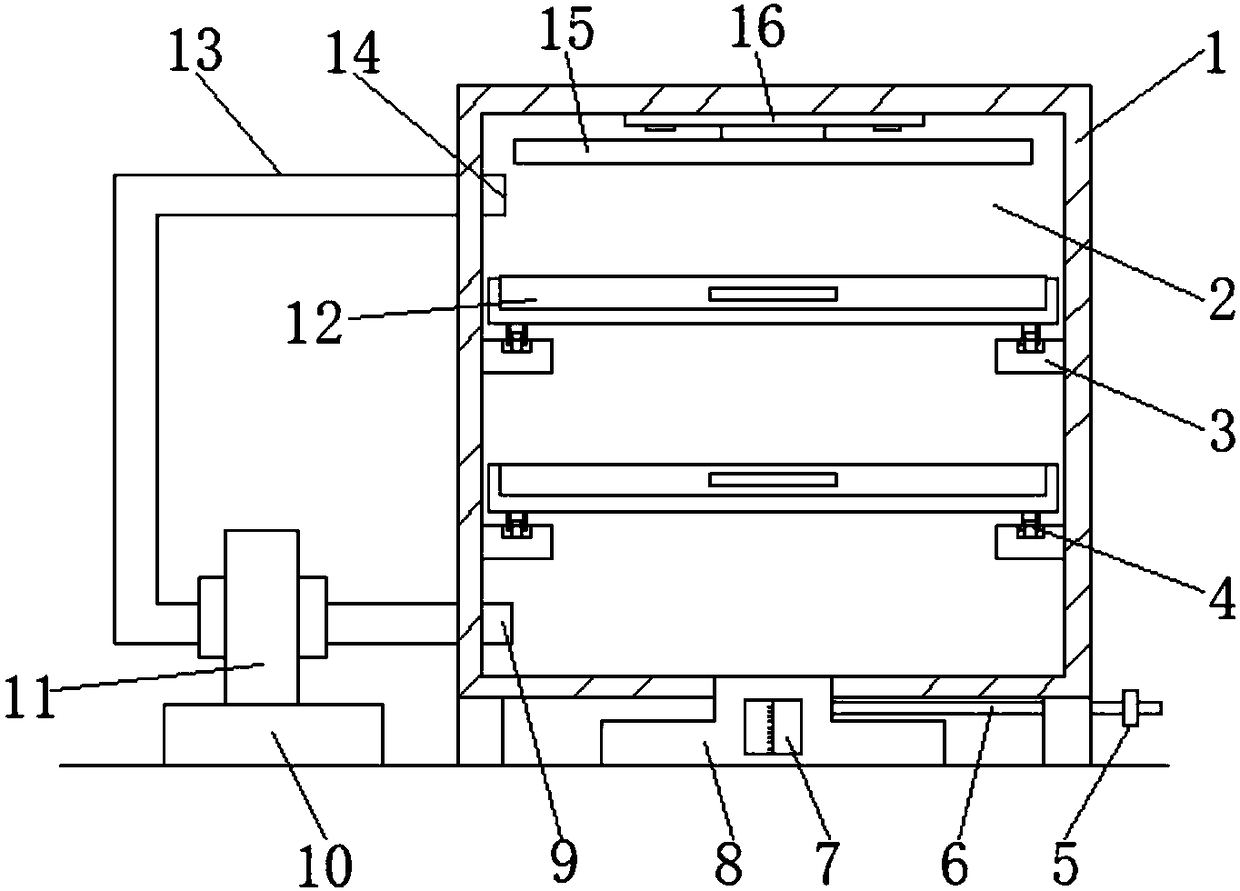

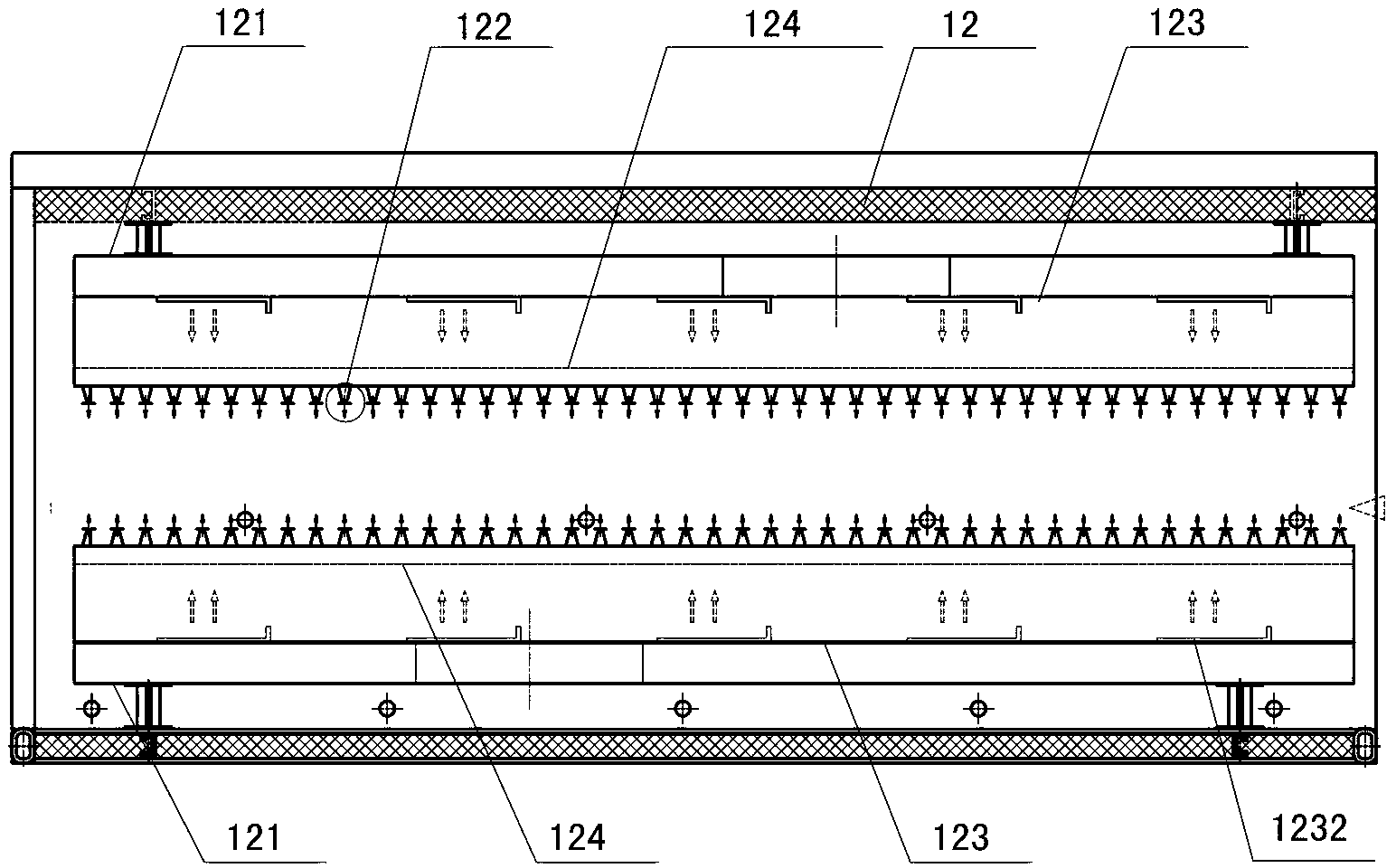

Air distribution system for SCR plate-type catalyst continuous calcining furnace

InactiveCN104457282AHigh activityGuarantee the quality of calcinationMaintainance of heating chambersDistribution systemCalcination

The invention discloses an air distribution system for an SCR plate-type catalyst continuous calcining furnace. The air distribution system solves the problem that in the prior art, the product quality is affected because hot air enters calcinated products unevenly. The air distribution system is characterized in that a sieve plate (4) used for carrying a catalyst product (6) is arranged at the bottom of a product loading box (7), and an air inlet duct (11) is arranged between the sieve plate (4) and a trolley (5); the two sides of the air inlet duct (11) are each provided with an upper air distribution plate (3) and a lower air distribution plate (3), and the air distribution plates (3) divide the air inlet duct (11) into three branch air ducts, so that circulating hot air enters all section gaps of the catalyst product (6) evenly; air inlets (2) on the two sides of the air inlet duct (11) are communicated with air outlets (1) formed in the lower portion of a circulating air duct (8) in the calcining furnace (9). The air distribution system has the advantages of being reasonable in structure, easy to manufacture, convenient to install, good in uniform distribution and the like, and can fully meet the technological requirements for product calcination and guarantee the quality of the catalyst product.

Owner:湖北华夏窑炉工业(集团)有限公司

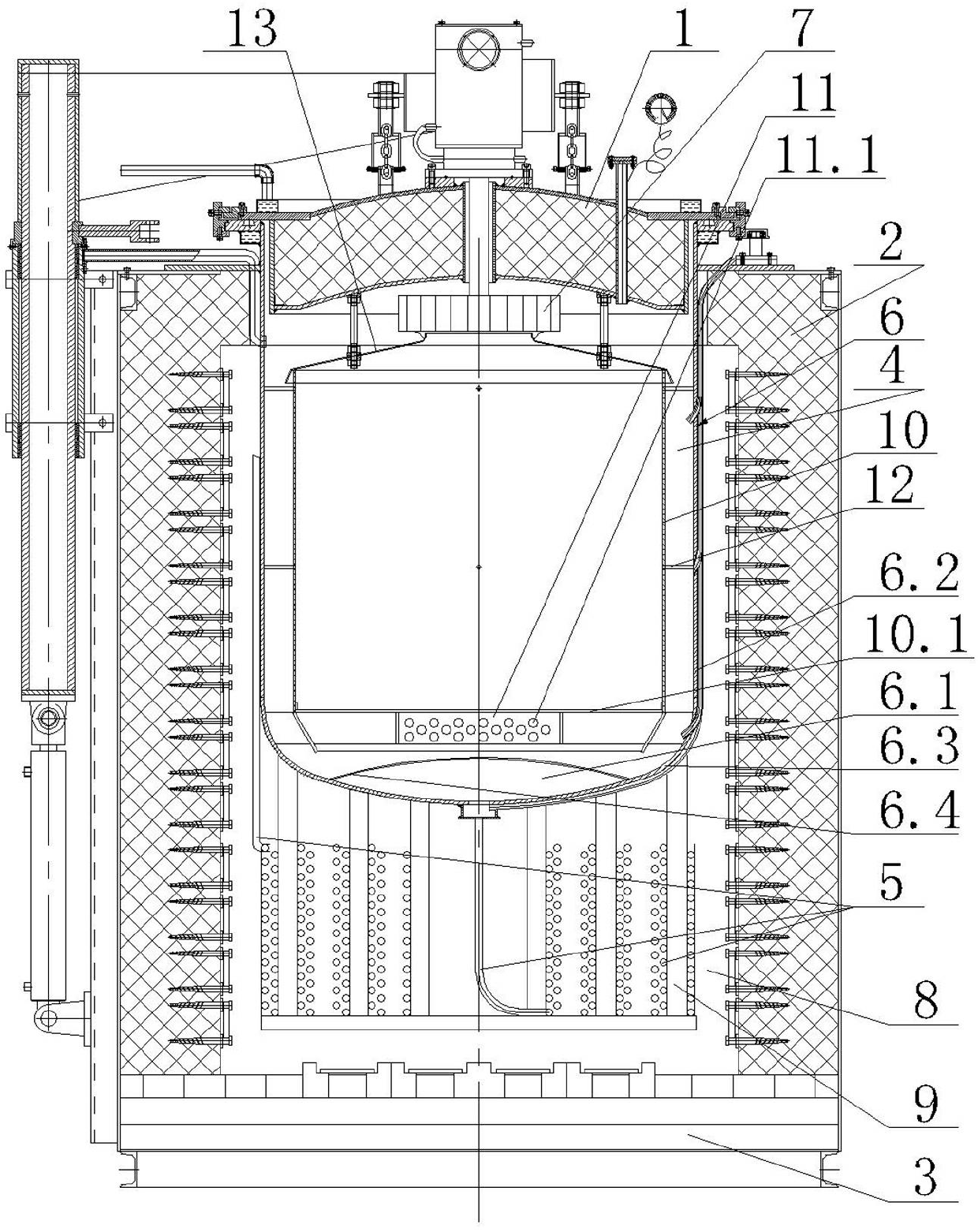

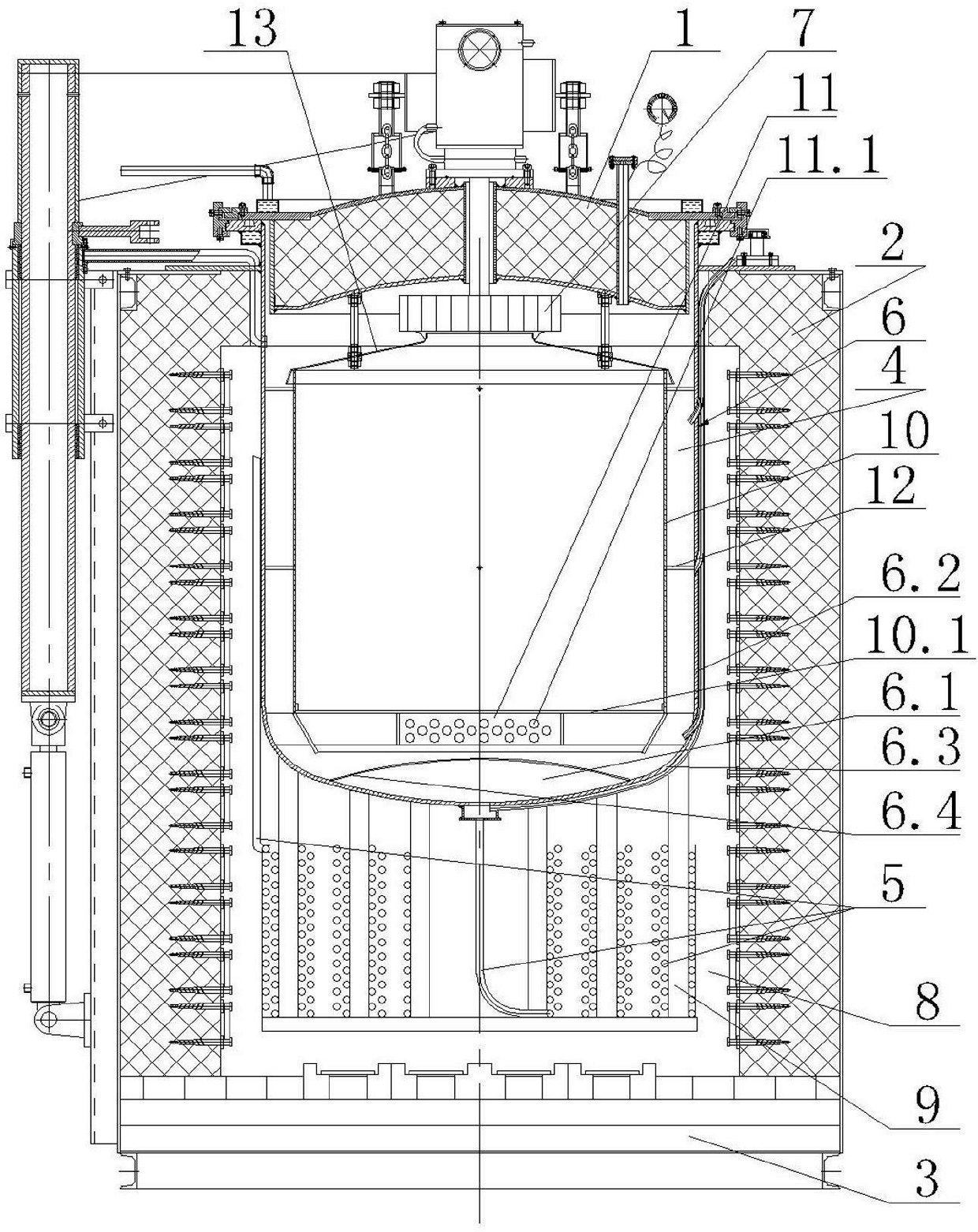

Steam blackening furnace

InactiveCN102605313AIncrease temperatureIncrease the speed of blackeningMuffle furnacesSolid state diffusion coatingGratingEngineering

The invention discloses a steam blackening furnace, which comprises a furnace lid (1), a furnace wall (2), a base (3) and a steam delivery pipe (5). An inner container (6) is disposed in a furnace chamber (4). A steam diffusion chamber (6.1) is reserved at the lower end of the inner container (6). A heating chamber (8) is reserved below the inner container (6). A plurality of vertical posts (9) are disposed in the heating chamber (8). The middle of the steam delivery pipe (5) is wound on the vertical posts (9) by multiple circles on each post. A guide cylinder (10) is further disposed in the inner container (6). A gap is reserved between the outer wall of the guide cylinder (10) and the inner wall of the inner container (6). A grating plate (10.1) is disposed on the lower portion of the guide cylinder (10). A steam diffusion cylinder (11) is fixed to the lower end face of the grating plate (10.1). The wall of the steam diffusion cylinder (11) is provided with a plurality of diffusion holes (11.1). Steam entering the inner container of the steam blackening furnace is high in temperature, diffusion of the steam from the steam diffusion chamber of the inner container is effective, and the effect of convection of gas in the furnace chamber is ideal.

Owner:宁波东方加热设备有限公司

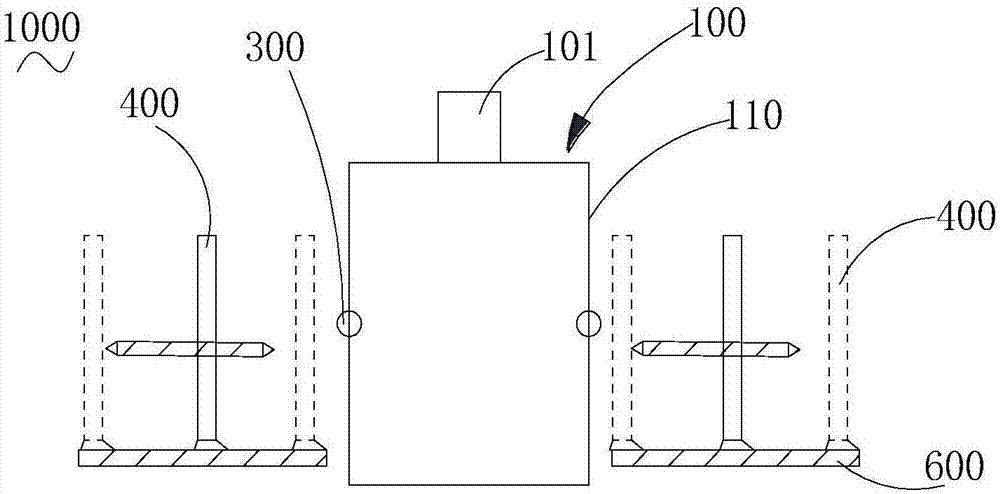

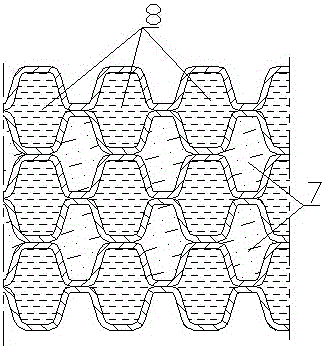

Twenty-five-roller stretcher for uniaxial tension of geogrid

The invention provides a twenty-five-roller stretcher for uniaxial tension of geogrid, belonging to the processing field of plastic state materials. According to the stretcher, a multiroll type multi-point stretching manner, oil heating, whole-course chain drive are utilized, and the tension speed of the front stage and the rear stage can be adjusted by a chain wheel, so that the condition that the weight of a stretching roller is increased and the rotational inertia of the stretching roller is large after the stretching roller is fully filled with hot oil, so that a driven roller of an existing stretcher is difficult to control and is even out of control, and further the tension precision is affected can be avoided, and further various problems related to cost, processing, control and other aspects caused by gradually increased size of the rear-stage stretching roller in the prior art can be also avoided, so that plates can be stretched on each stretching roller, the multi-roller multi-point stretch is realized, the manufactured geogrid can be stretched more uniformly, the thickness of the geogrid is uniform and consistent, the molecular orientation linear distribution is uniform, and the node intensity is high; and the twenty-five-roller stretcher for the uniaxial tension of the geogrid has quite high stretch strength and stretch modulus, and technological requirements on the lateral stretching of the later-stage geogrid are met.

Owner:青岛欣煜升新材料有限公司

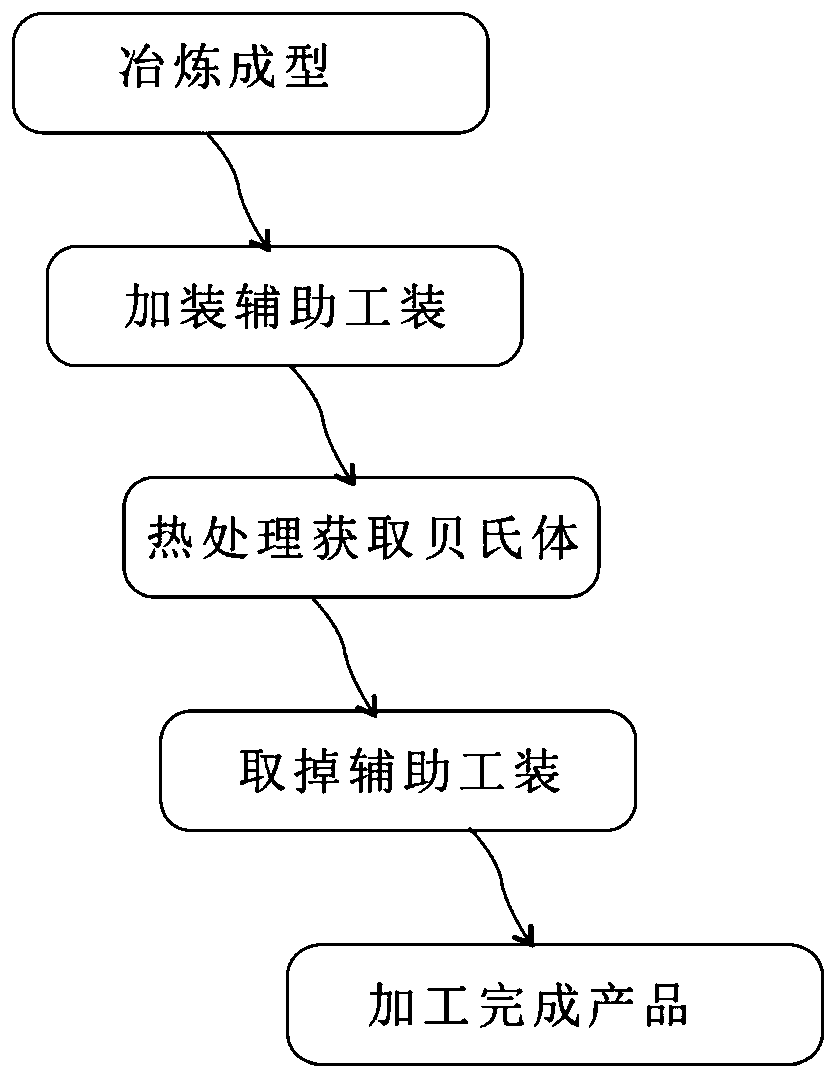

Method for acquiring bainite complex phase tissue with workpieces with different cross section thicknesses

The invention provides a method for acquiring bainite complex phase tissue with workpieces with different cross sections thicknesses. In the heat treatment method of products with different cross sections in the bainite complex phase tissue, performance requirements for different regions of the cross-sections on different workpieces in the bainite complex phase tissue are different or the performance requirements of different thicknesses for different parts of the same workpiece are the same, an additional protective layer is adopted, when the workpieces are subjected to quenching treatment and tempering treatment, and the same performance or different performance requirements of the workpiece quality can be ensured.

Owner:紫荆浆体管道工程股份公司

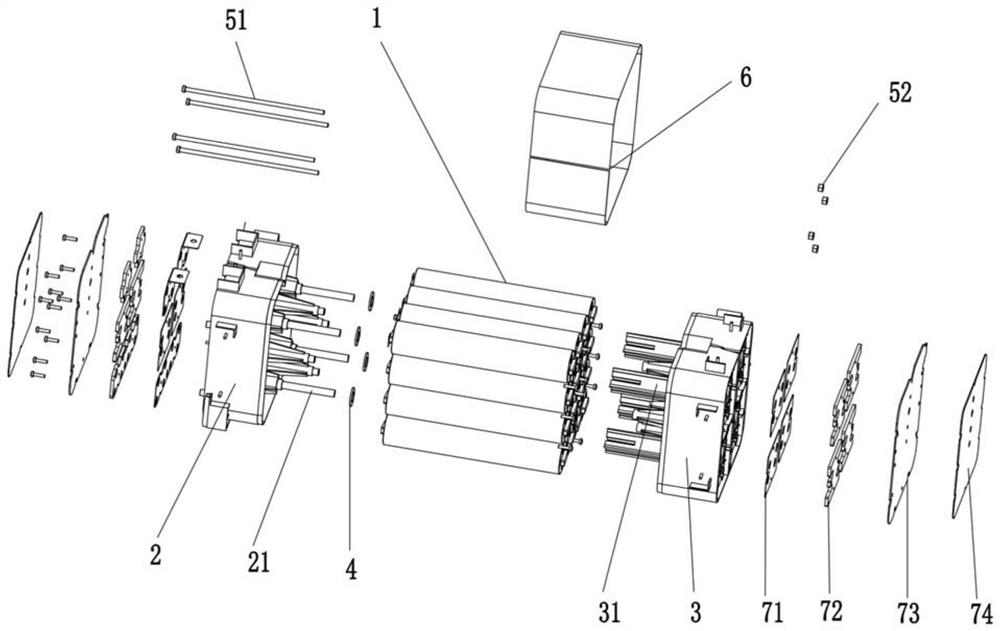

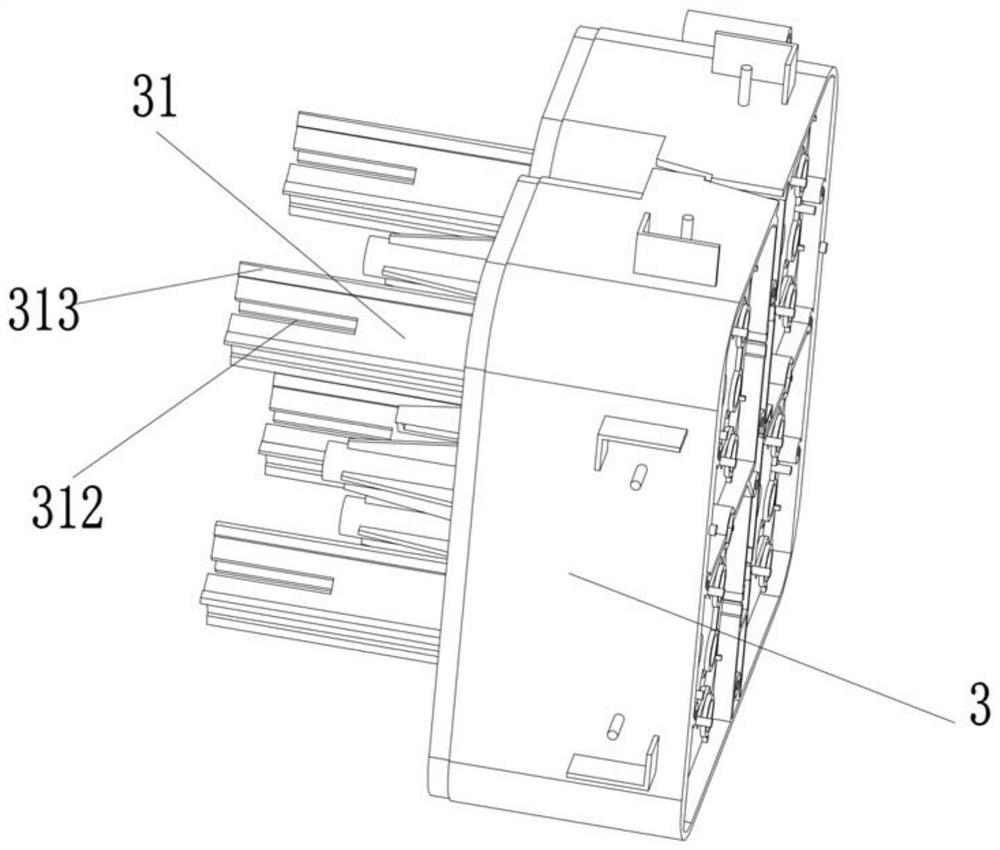

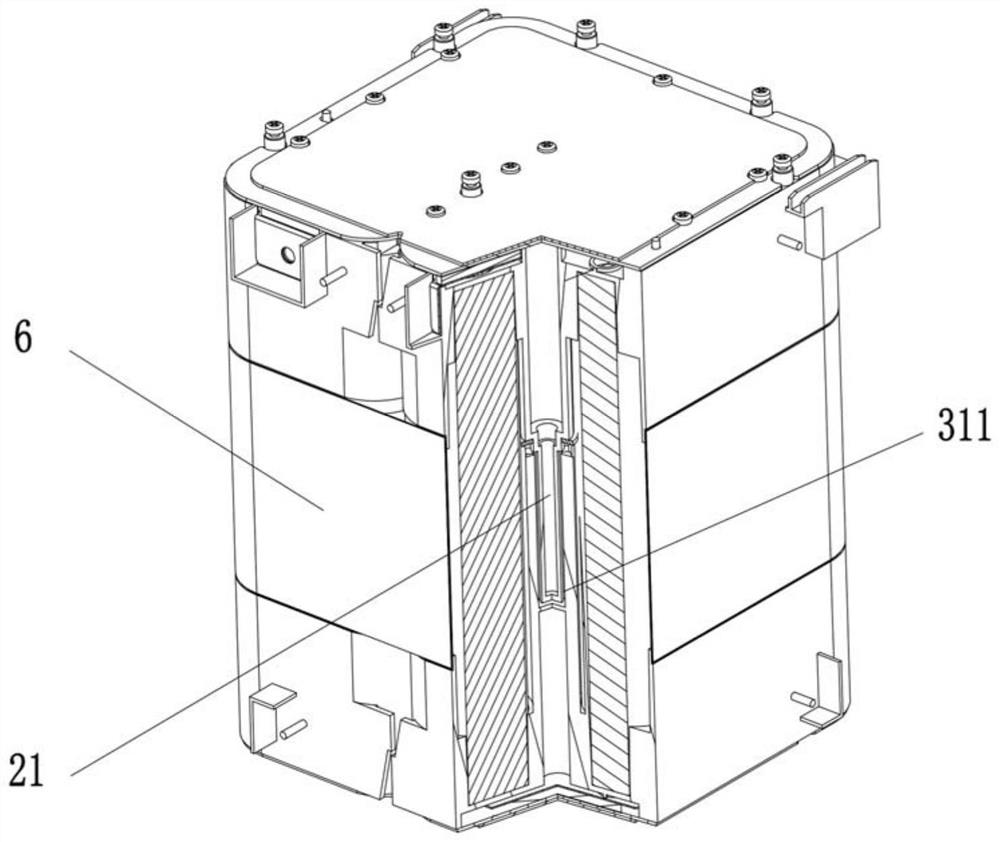

Novel grouping structure of large cylindrical battery cells

PendingCN114094269AImprove stabilityEnsure a reasonable distanceVent arrangementsSecondary cellsBusbarEngineering

The invention discloses a novel grouping structure of large cylindrical battery cells. The novel grouping structure comprises a plurality of battery cells, and a battery cell group consisting of an upper bracket and a lower bracket at two ends of the battery cells; the middle parts of the upper bracket and the lower bracket are respectively provided with a plurality of filling columns and glue pouring columns which are matched with each other; the filling columns are provided with gaskets for interfering the movement of the circumferential battery cells; glue filling holes matched with the filling columns are formed in the centers of the glue filling columns; glue is arranged in the glue filling holes; busbars are arranged at the two ends of the battery cell group; and a heat conduction pad, a heating film and a heat preservation pad are sequentially arranged on the outer sides of the busbars. The invention provides a novel grouping structure of large cylindrical battery cells, which can improve the welding tear resistance of an aluminum tab of the large cylindrical battery cell, balance the heating area of a single battery cell and ensure the temperature rise consistency.

Owner:福建飞毛腿动力科技有限公司

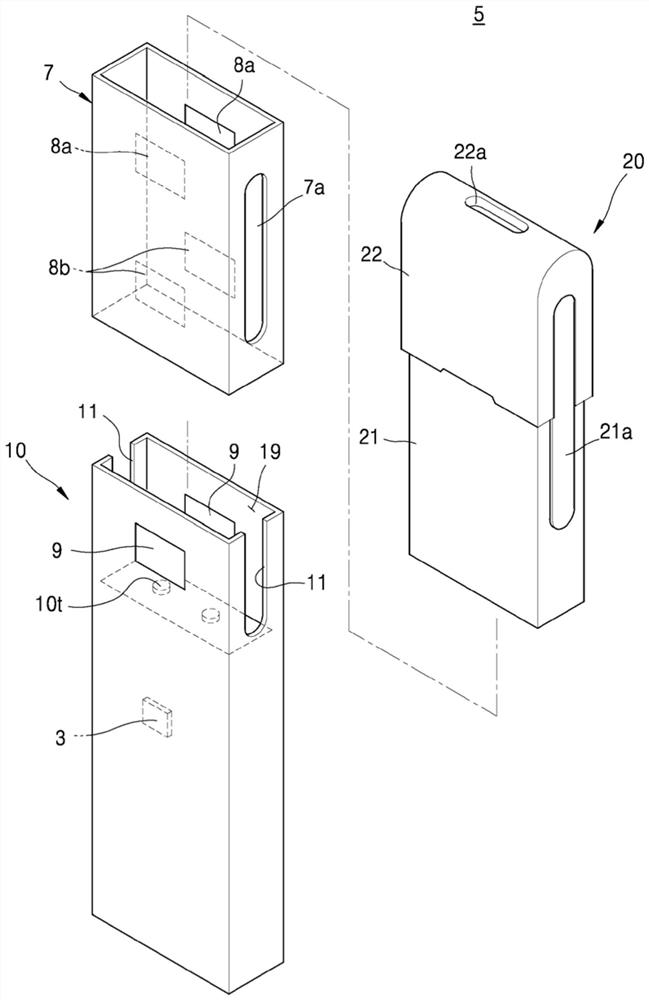

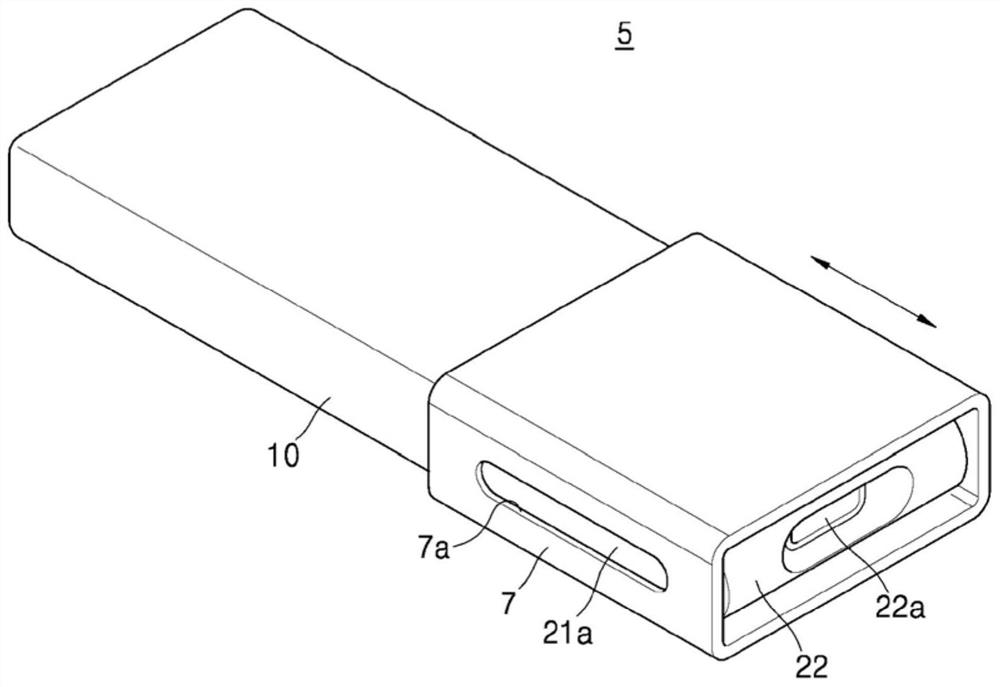

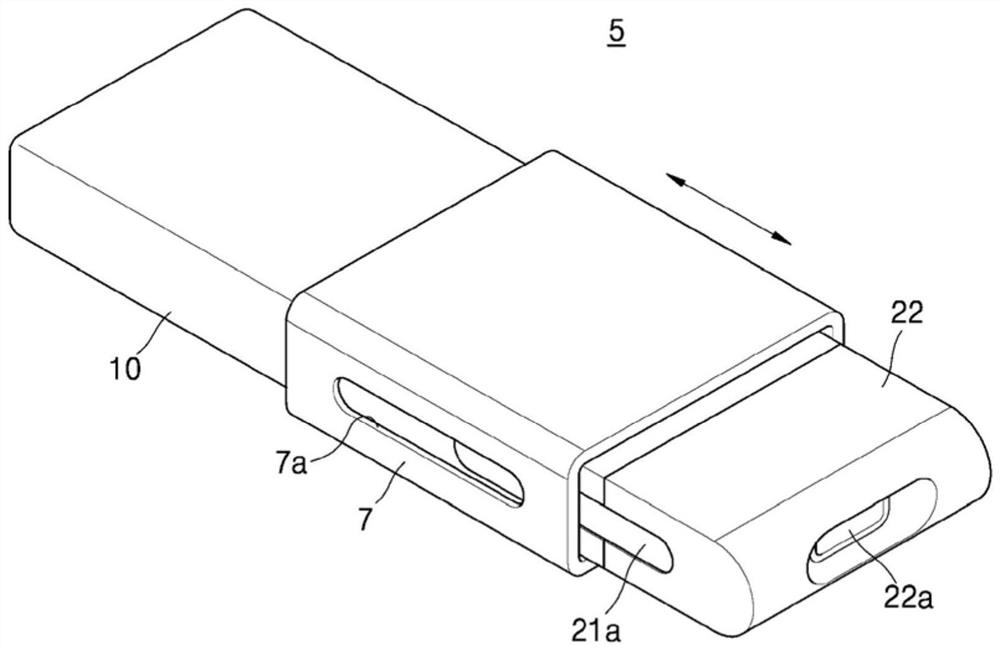

Aerosol generating device and operation method thereof

Provided is an aerosol generating device including a heater that heats an aerosol-generating material and a controller that controls power supplied to the heater. The controller may measure a resistance value of the heater by using at least one electrical characteristic associated with the heater, select any one power profile from among a plurality of pre-stored power profiles including values ofpower to be supplied to the heater, such that a temperature of the heater reaches a target temperature within a predetermined time from a time point at which power supply to the heater is initiated regardless of variation in the resistance value of the heater, and control power supplied to the heater according to the selected power profile.

Owner:KT&G CO LTD

Heap-yellowing apparatus used for yellow-bud tea processing

The invention discloses a heap-yellowing apparatus used for yellow-bud tea processing. The heap-yellowing apparatus used for yellow-bud tea processing comprises an apparatus body; a heap-yellowing chamber is formed inside the apparatus body; a material inlet is formed in a front end surface of the apparatus body; a set of sealing doors are installed at a top end of the material outlet of the apparatus body via door hinges; two sets of supporting frames are welded at left and right side walls of the internal part of the heap-yellowing chamber; roller wheel grooves are formed at top ends of thesupporting frames; semicircular flutes are formed at one ends of bottom end surfaces of the roller wheel grooves, and the bottom end surfaces of the roller wheel grooves gradually elevate from the semicircular flutes to the other ends; the other end of the bottom end surfaces of the roller wheel grooves are aligned with top end surfaces of the supporting frames; a movable plate is placed above each supporting frame; and a pair of symmetrically arranged roller wheels are installed at one side, far away from the sealing doors, of a bottom surface of each movable plate via support feet. The heap-yellowing apparatus used for yellow-bud tea processing has the advantages of simple application method, high heap-yellowing efficiency and so on; and thus, the heap-yellowing apparatus used for yellow-bud tea is suitable for common promoted use.

Owner:福建省鑫福智能机电科技有限公司

Steamer

ActiveCN103919451AConsistent heatingGreat tasteSteam cooking vesselsEngineeringMechanical engineering

The invention provides a steamer comprising a pot, a steaming basket, and an upper cover. The steaming basket is mounted on the pot. The upper cover covers the steaming basket. A chamber is enclosed between the pot and the steaming basket; another chamber is enclosed between the upper cover and the steaming basket. The steamer further comprises a steam delivery pipeline mounted on the pot. The steam delivery pipeline guides steam from inside of the pot to the chamber enclosed between the upper cover and the steaming basket and / or the chamber enclosed between the pot and the steaming basket. The steam delivery pipeline in the steamer is used to guide the steam to the chambers, gradient difference between interior temperatures of the chambers is decreased, the interior temperatures of the chambers are synced, food in the chambers can be evenly heated, taste of the steamed food can be improved effectively, and application needs of consumers can be better met.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Chemically cross-linked polyethylene foam device

The invention discloses a chemically cross-linked polyethylene foam device which comprises a feed apparatus, a horizontal foaming apparatus, a front-back press polish apparatus and a roll apparatus sequentially arranged, wherein the horizontal foaming apparatus is sequentially provides with a horizontal foaming furnace with three heating areas, three cyclic heating mechanisms arranged above the horizontal foaming furnace and correspondingly communicated with heating areas, the cyclic heating mechanisms comprises a box body fixed on and communicated with the horizontal foaming furnace, a gas combustion machine fixed on the box body, a heat exchange system located in the box body and connected with the gas combustion machine, and a hot air circulation fan used for transferring the heat in the box body to the foaming areas; the heat exchange system comprises a combustion cylinder with one opened end and one closed end, the opened end of the combustion cylinder is communicated with a flame port of the gas combustion machine, and sidewalls of the combustion cylinder is provided with a plurality of output holes in intervals. The device is advantageous by preventing entry of the flames into impellers to deform and damage the impellers, and improving service life of the hot air circulation fan.

Owner:宁波辉门科技有限公司

Method for manufacturing puff pastry

ActiveCN103404559BEvenly distributedThere will be no channelingDough treatmentBakery productsCooking & bakingBeta-Carotene

Owner:湖北钟祥金源食品股份有限公司

Efficient concentrator

ActiveCN106110694AReduce the temperatureRelieve pressureEvaporator accessoriesMultiple-effect evaporationGas phaseAgricultural engineering

The invention discloses an efficient concentrator. A discharging hole of a balance tank is connected with a discharging pipe; a separation device comprises a plate type evaporator and a separation tank; two or more than two groups of separation devices are arranged; the discharging pipe is connected with a raw material inlet of the first-grade plate type evaporator; a liquid-phase outlet of the former grade of separation tank is communicated with the raw material inlet of the plate type evaporator of the next grade of separation device; the liquid-phase outlet of the final grade of separation tank is connected with a liquid outlet pipe; a gas-phase outlet of the former grade of separation tank is communicated with a steam inlet of the next grade of plate type evaporator; the gas-phase outlet formed in the top of the separation tank of the final grade of separation device is communicated with a solvent inlet of a plate type condenser; a steam inlet pipe of the first-grade plate type evaporator is connected with an outlet of a spraying pump; an inlet of the spraying pump is connected with a fresh steam general pipe; an air suction hole of the spraying pump is communicated with a steam channel of each plate type evaporator; a steam condensed water outlet of the first-grade plate type evaporator is connected with a water discharging pipe and the water discharging pipe is communicated with the steam inlet pipe of the first-grade plate type evaporator through a pipeline.

Owner:山东精鹰机械制造有限公司

High-speed hot mixer for PVC plastic film production

The invention discloses a high-speed hot mixer for PVC plastic film production. The high-speed hot mixer comprises a mixing barrel, a sealing cover, a mixing motor, a mixing shaft, stirring blades, alarge particle processing mechanism, a feeding mechanism and a discharging port. The sealing cover is detachably installed at an opening in the top of the mixing barrel. The mixing motor is detachablyinstalled in the center of the top of the sealing cover. The top of the mixing shaft is fixedly connected with an output shaft of the mixing motor through a coupler. The stirring blades are installedat the bottom of the mixing shaft. The large particle processing mechanism is arranged in an inner cavity of the mixing barrel. The feeding mechanism is arranged at the top of the sealing cover. Thedischarging port is formed in the center of the bottom of the mixing barrel. The high-speed hot mixer for PVC plastic film production adopts a vertical layered working mode, first particles of different sizes in one batch are separated, raw material particles are heated and mixed in two ways specifically, and the problems that small particles are overheated, and the large particles are under-heated are solved.

Owner:海宁市沪明塑钢有限公司

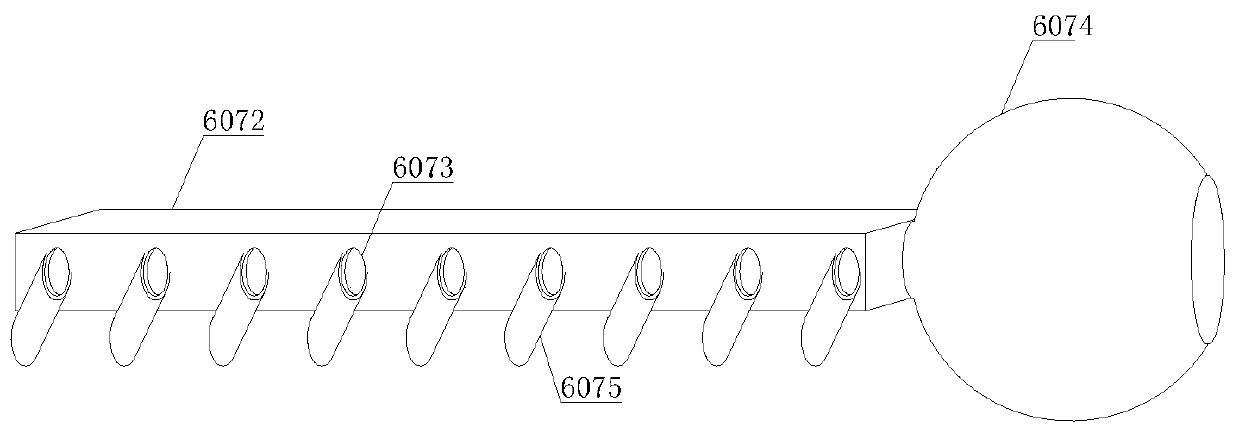

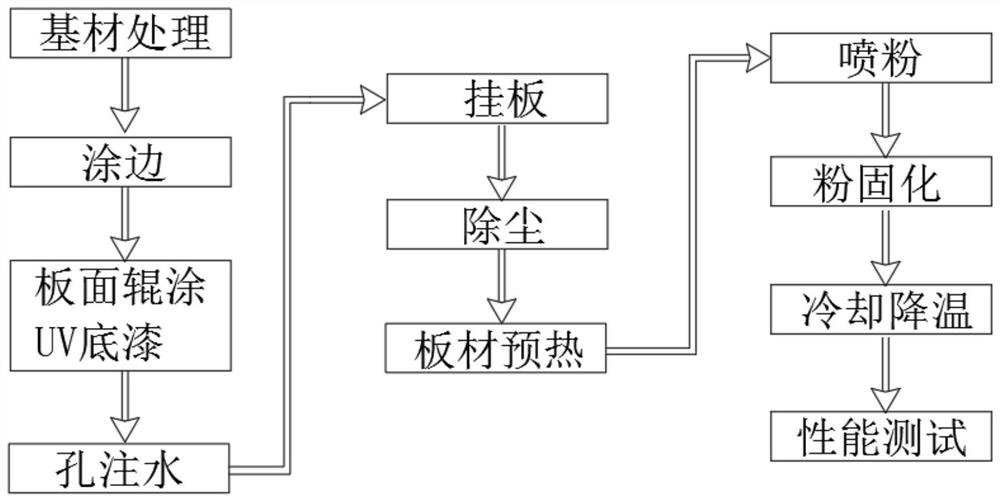

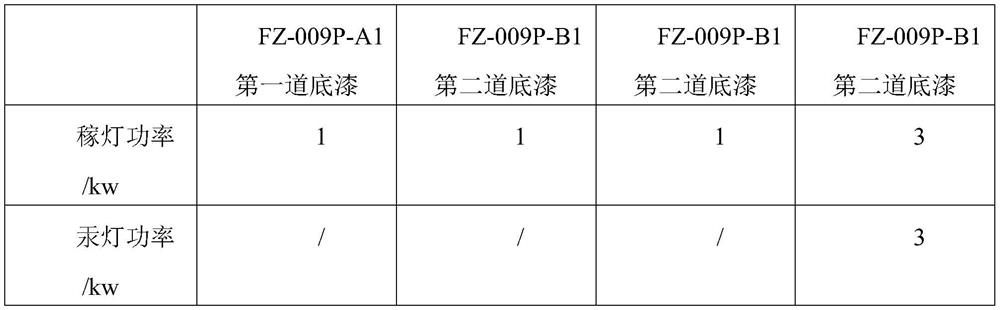

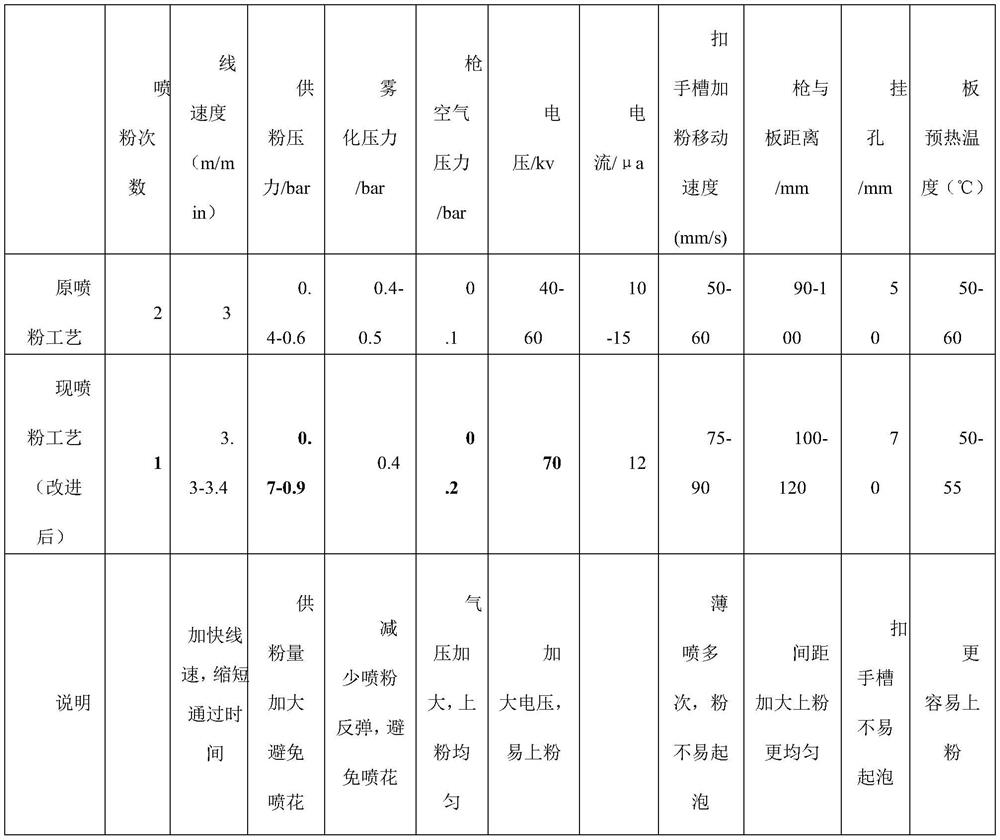

Wood base material powder coating method

PendingCN114653561AImprove water resistanceImprove mechanizationPretreated surfacesCoatingsSanderManufactured material

The invention relates to the technical field of base material powder coating, and discloses a wood base material powder coating method which comprises the following steps: S1, base material treatment: adopting a medium density fiberboard as a base material; s2, edge coating; s3, the board surface is coated with UV primer in a roller mode, and during coating, the board surface sequentially passes through a sanding machine, a dusting machine, a conveyor, a putty coating machine, a three-lamp curing machine, a conveyor, a sanding machine, a conveyor, a double-roller coating machine, a double-lamp curing machine, a conveyor, a double-roller coating machine, an infrared leveling machine, a three-lamp curing machine and a conveyor; and S4, hole water injection. The oil-based UV white primer and the oil-based laser white primer are adopted for sealing, the water resistance is better than that of water-based paint sealing primer, the water resistance is better, the original two-time powder spraying forming is improved into one-side powder spraying forming, the product quality performance is qualified, the powder raw material cost is reduced, and the production efficiency is improved.

Owner:江苏无锡欧派集成家居有限公司

Pan manufacturing and using method

The invention provides a pan manufacturing and using method. A pan consists of an inner pan body, an outer pan body, an oil feeding tube, a safety valve and heat-conduction oil, wherein the inner pan body can be placed in the outer pan body; the edge of the inner pan body and the edge of the outer pan body are connected to each other integrally in a welded manner; the top of the side wall of the outer pan body is welded with the oil feeding tube; the heat-conduction oil is injected in a gap of the pan through the oil feeding tube; and outer threads are arranged at the upper end of the oil feeding tube and are connected with the safety valve. When the pan is used, the oil is injected through the oil feeding tube, the safety valve is arranged on the pan, work pressure is adjusted, and then the pan can be used on an ignited stove.

Owner:冯政

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com