Chemically cross-linked polyethylene foam device

A polyethylene foaming and chemical cross-linking technology, applied in the field of polyethylene foaming equipment, can solve the problems of impeller deformation and damage, affecting the service life of hot air circulation fans, etc., and achieve the effects of improving service life, consistent heating, and uniform gas mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

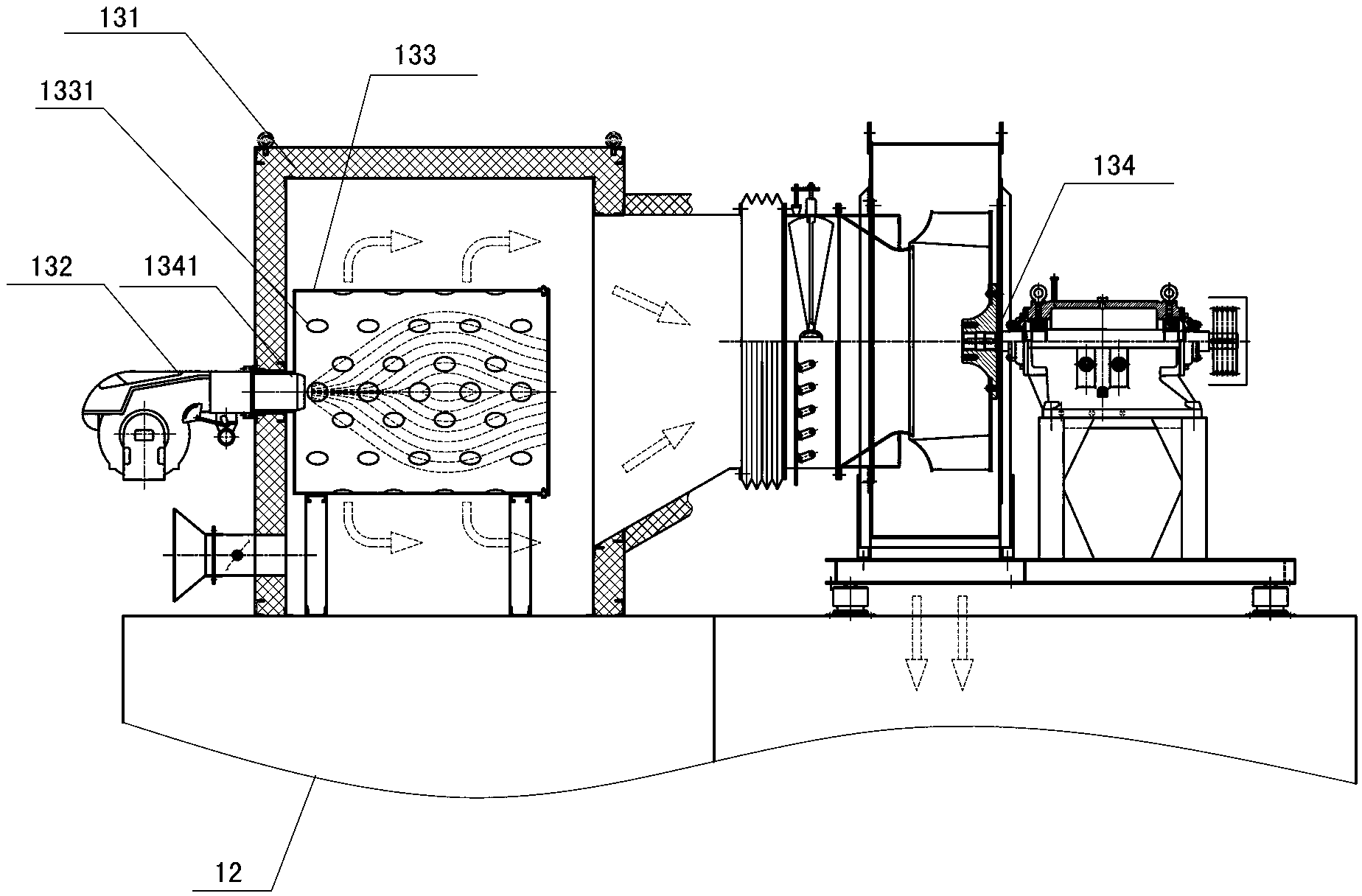

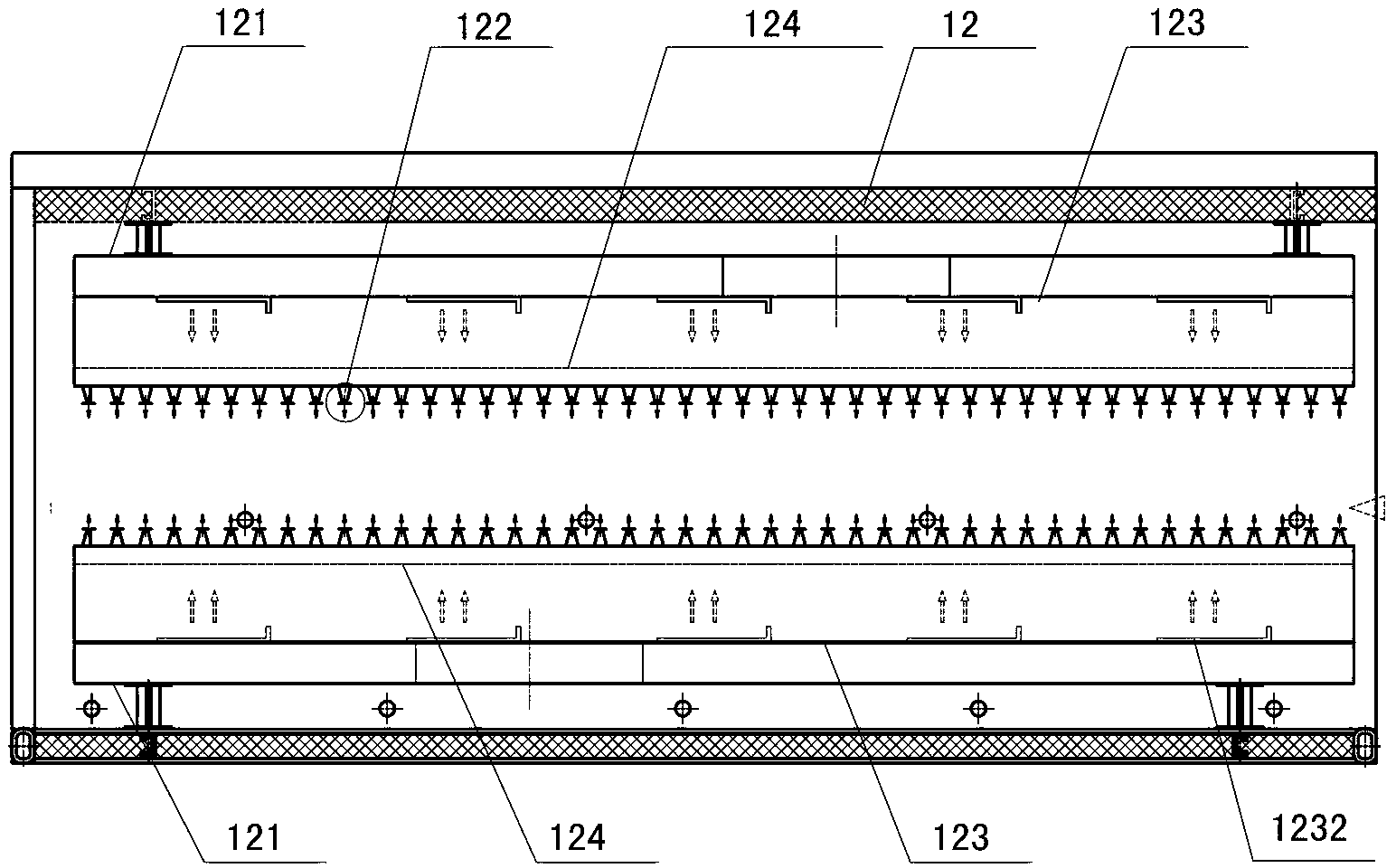

[0035] Example: such as figure 1 and figure 2 As shown, a chemically cross-linked polyethylene foaming equipment includes a feeding device 2, a horizontal foaming device 1, a front and back calendering device 3, and a winding device 4 arranged in sequence, and the horizontal foaming device 1 includes three sequentially arranged The horizontal foaming furnace 12 in the foaming area 11 and the three circulating heating mechanisms 13 that are arranged above the horizontal foaming furnace 12 and communicate with the three foaming areas 11 correspondingly. And the box body 131 that communicates with the horizontal foaming furnace 12, the gas burner 132 fixed on the box body 131, the heat exchange system 133 that is positioned at the box body 131 and is connected with the gas burner 132 and is used to turn the inside of the box body 131 The heat is transported to the hot air circulation fan 134 in the foaming area 11. The heat exchange system 133 includes a combustion tube with on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com