Steam blackening furnace

A steam and furnace wall technology, applied in cooking furnaces, furnaces, muffle furnaces, etc., can solve the problems of inconsistent thickness of blackened protective layer, unsatisfactory diffusion effect, uneven heating of workpieces, etc., and achieve uniform and dense blackened protective layer thickness , the effect of steam divergence is ideal, and the effect of increasing the heating distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

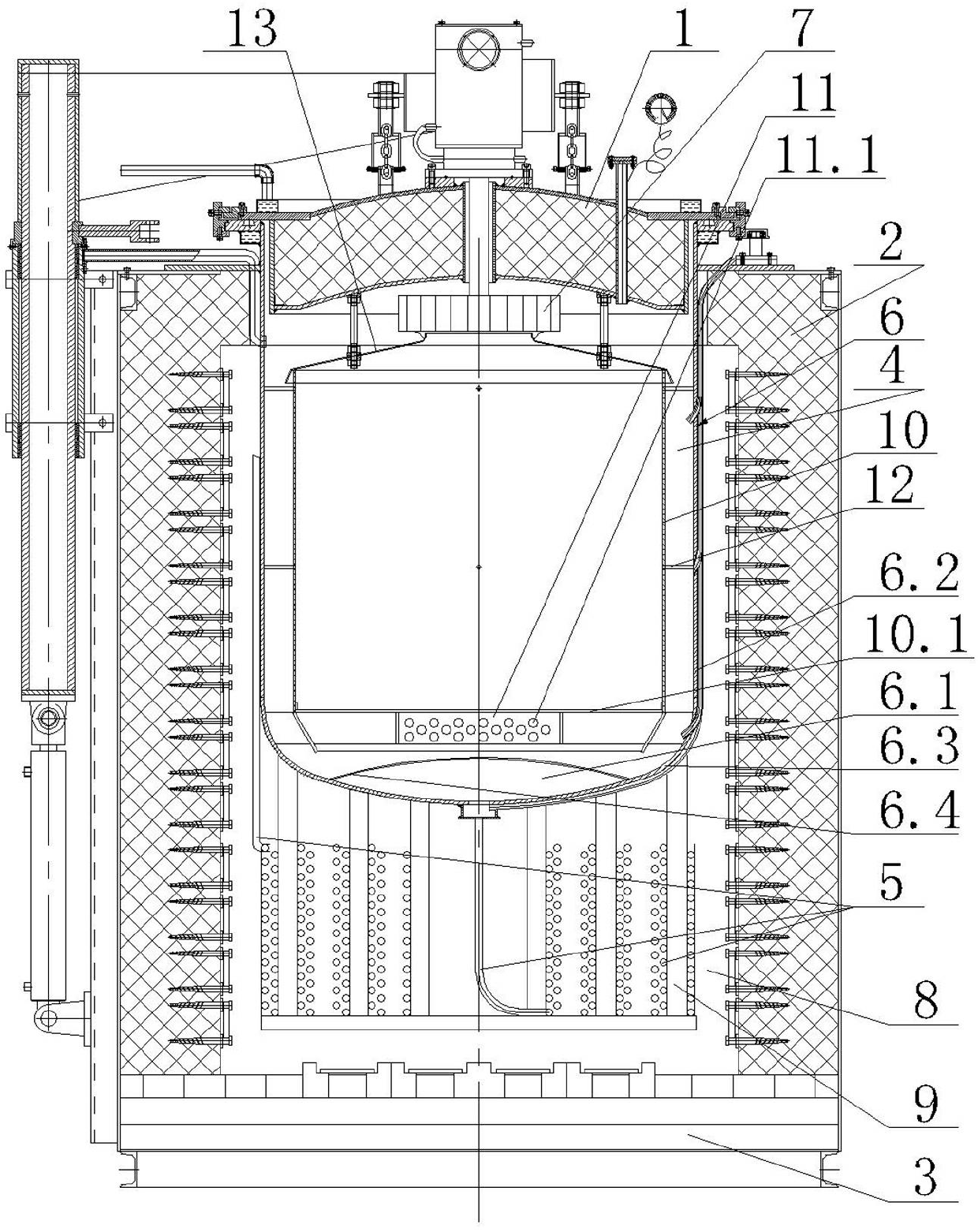

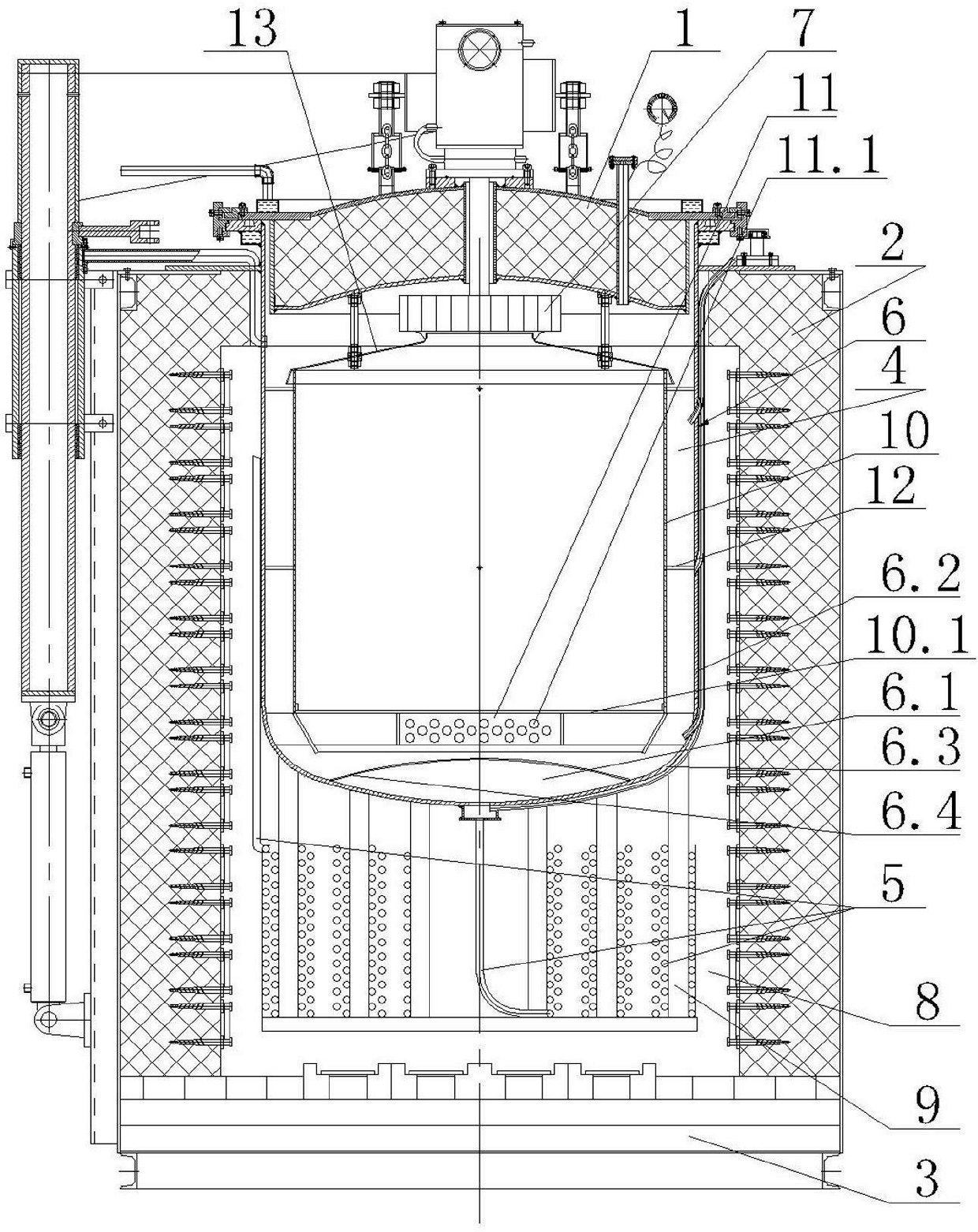

[0016] Such as figure 1 As shown, the steam blackening furnace of the present invention includes a furnace cover 1, a furnace wall 2, a base 3 and a steam delivery pipe 5 introduced from the outside of the furnace. It can be seen from common sense that the front end of the true gas delivery pipe 5 communicates with the gas pump outside the furnace. The furnace cover 1, the furnace wall 2 and the base 3 surround a synthetic furnace chamber 4. The furnace cavity 4 is provided with an inner container 6, and a heating chamber 8 is arranged below the inner container 6. Specifically, the heating chamber 8 is formed by enclosing the top of the base 3, the lower part of the inner container 6 and the lower part of the furnace wall 2. The top of the base 3 And furnace wall 2 bottoms are all provided with heating unit, and heating unit refers to convent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com