Pan manufacturing and using method

A frying pan and outer pot technology, applied in applications, household appliances, kitchen utensils, etc., can solve the problems of inability to extinguish the inner flame, affecting the taste of food, burning food waste, etc., achieving good taste, significant technical progress, and solving problems. The effect of wasting food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

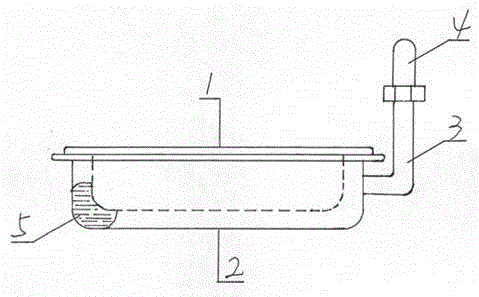

[0010] Such as figure 1 , as shown, provide a kind of making and using method of pan, eliminate above-mentioned defect with this. This frying pan is made up of inner pot 1, outer pot 2, oil filling pipe 3, safety valve 4 and heat transfer oil 5. Wherein the inner and outer pots 1 and 2 are existing (traditional) flat pans with rims, the inner pot 1 can be placed in the outer pot 2, and the pot edges of the inner pot 1 and the outer pot 2 partially overlap after being placed, There must be a gap greater than 1 cm between the bottom and side walls of the inner and outer pots 1 and 2 to facilitate the heat flow of the heat transfer oil 5. During production, the centers of the inner and outer pots 1 and 2 are required to be on the same central axis. After determining the positions of the inner and outer pots 1 and 2, the overlapped parts of the inner and outer pots are sealed and welded together (no oil leakage). On the side wall of outer pot 2, hole is drilled, and a filling pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com