An electromagnetic induction heating coil

An electromagnetic induction heating and coil technology, which is applied in the direction of induction heating and coil devices, can solve the problems of complex manufacturing process, heavy weight, and large volume, and achieve the effects of simple process, consistent heat, and uniform magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

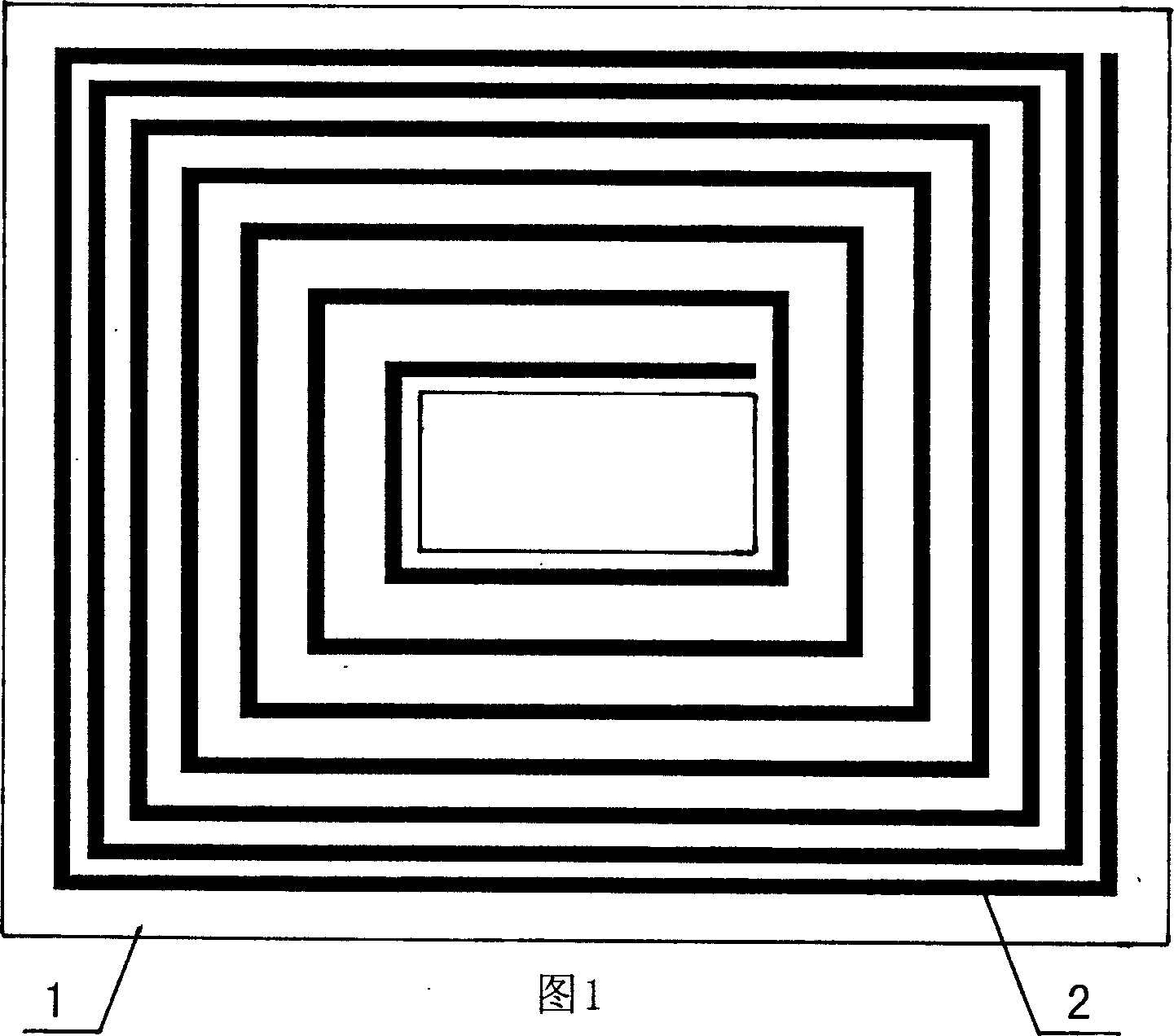

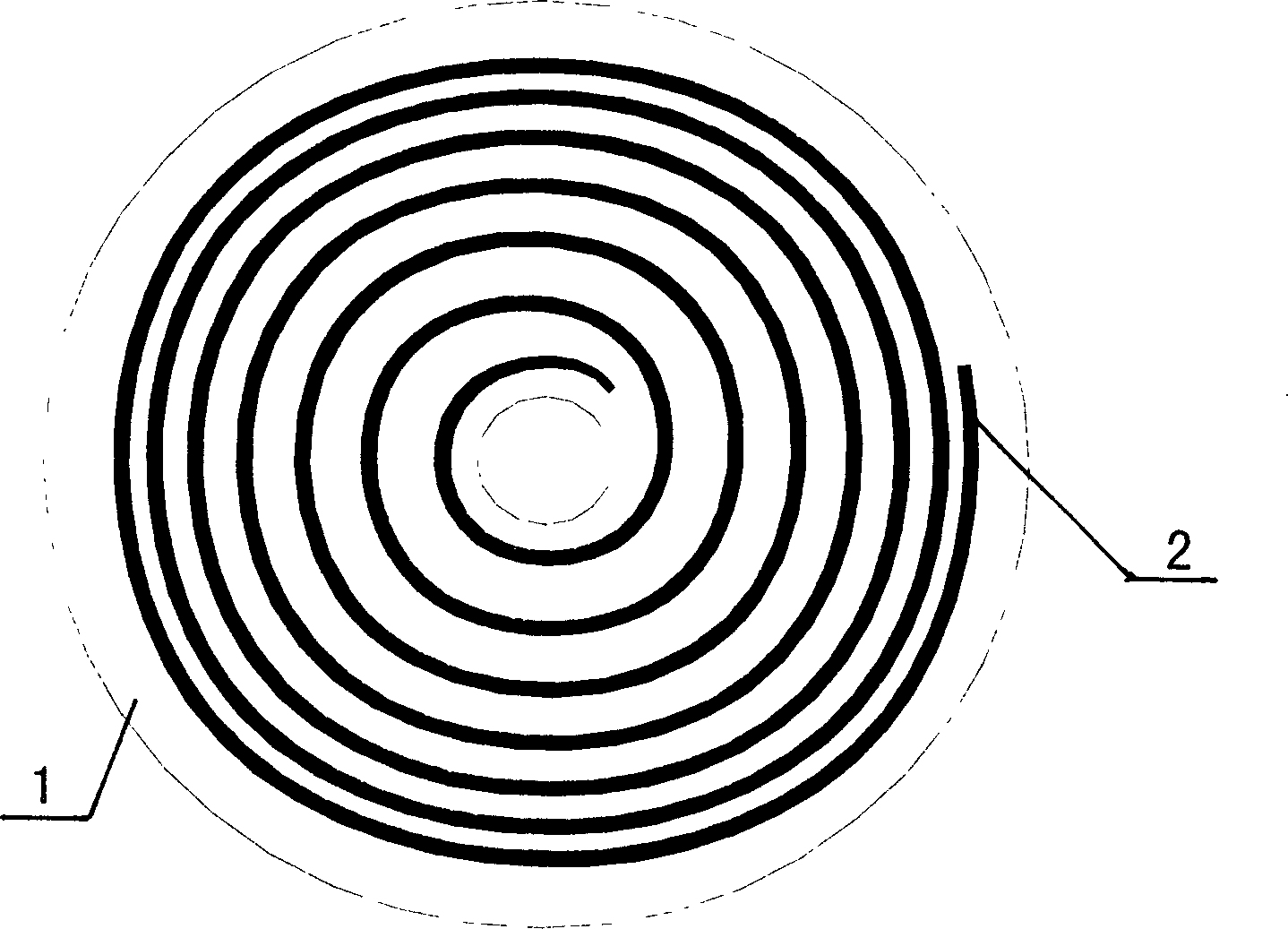

[0023] The first embodiment given by the present invention is an electromagnetic induction heating coil of a copper-clad coil with rectangular and circular pitches of equidistant or gradual change, and rectangular and circular pitches of double turns with gradual changes.

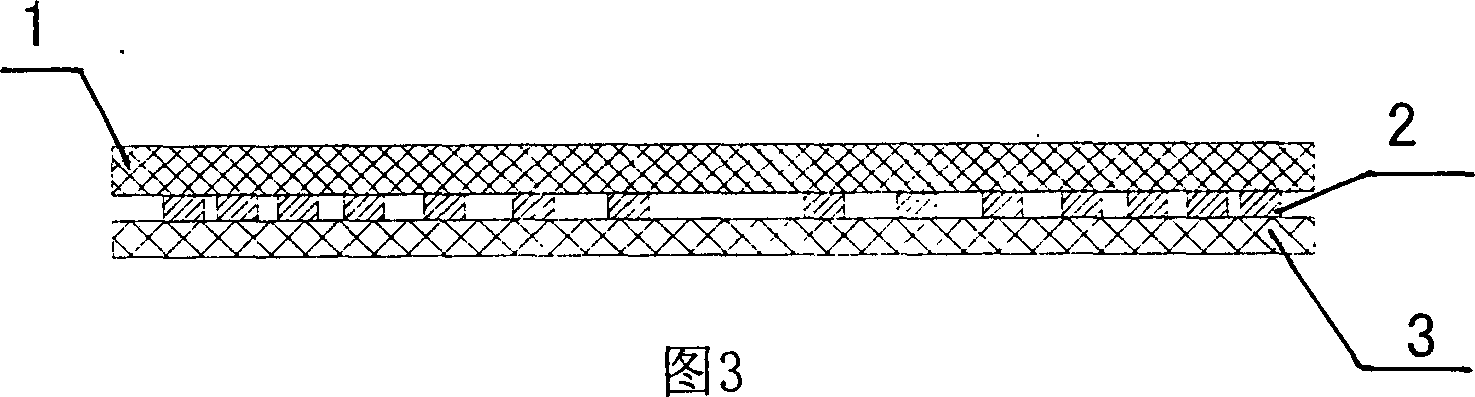

[0024] As shown in accompanying drawings 1-6, 9, and 10, an electromagnetic induction heating coil includes a copper-clad non-magnetic-conductive substrate 1, a copper-clad coil 2 and a non-magnetic material plate 3; its longitudinal section is from From bottom to top there are non-magnetic material plates 3 , copper-clad coils 2 , and non-magnetic base materials 1 of copper-clad boards. The non-magnetic material plate 3 is a non-magnetic, insulating, waterproof, high-strength material adhered or molded on one side of the copper-clad coil. The distance between each turn of the copper-clad coil 2 is equidistant.

[0025] The distance between each turn of the copper-clad coil 2 of the electromagnetic inducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com