Processing and preservation method of porous tuber vegetables

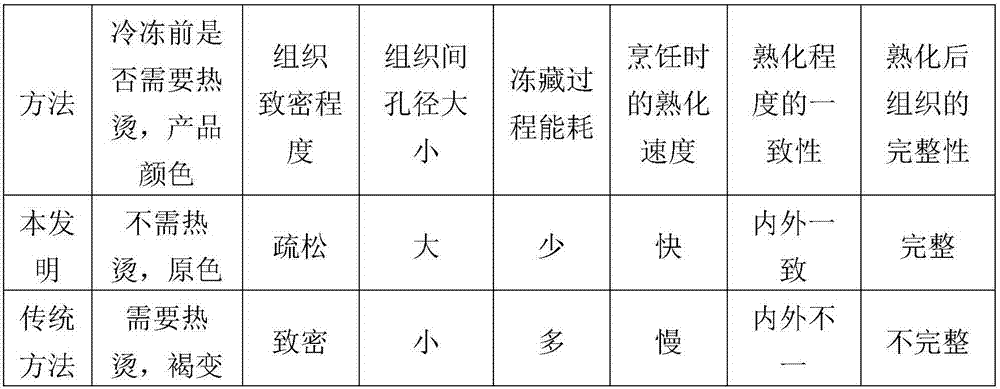

A vegetable, potato taro technology, applied in food processing, preservation of fruits/vegetables through freezing/refrigeration, food science, etc. time, saving processing time, and prolonging the effect of preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Peel, cut, and wash potatoes and taro vegetables such as taro, yam, and potatoes, drain the surface water, pack them in food-grade plastic bags, and send them to a warehouse with a temperature of -3°C to -4°C. Turn on the refrigeration equipment. Keep the warehouse temperature within the range of -3°C to -4°C, and continue the treatment for 5 hours to freeze the moisture in the vegetable tissue and form large and numerous ice crystals; then adjust the warehouse temperature to -6°C to -8°C , and long-term storage at this temperature.

Embodiment 2

[0019] Peel, cut, and wash yam and taro vegetables such as sweet potatoes and yams, drain the surface water, pack them in food-grade plastic bags, and send them to a warehouse with a temperature of -4°C to -5°C. The temperature is maintained in the range of -4°C to -5°C, and the treatment is continued for 4 hours to freeze the water in the vegetable tissue and form ice crystals with large particles and a large number; then adjust the temperature of the warehouse to -8°C to -9°C, and Long-term storage at this temperature.

Embodiment 3

[0021] Peel, cut, and wash yam and taro vegetables such as taro, yam, and sweet potatoes, drain the surface water, and send them to a warehouse with a temperature of -5°C to -6°C. Turn on the refrigeration equipment and maintain the temperature of the warehouse at -5°C. In the range of ℃~-6℃, continue to treat for 3 hours, so that the moisture in the vegetable tissue freezes to form large and numerous ice crystals, and then the product is directly used for cooking, or the temperature of the warehouse is adjusted to -9℃~-10℃ ℃, and stored at this temperature for a short period of time for cooking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com