Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Close up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick connector for gas conveying bellows

ActiveCN103244773AWon't leakWill not cause leakageSleeve/socket jointsJoints with sealing surfacesEngineeringBarrel Shape

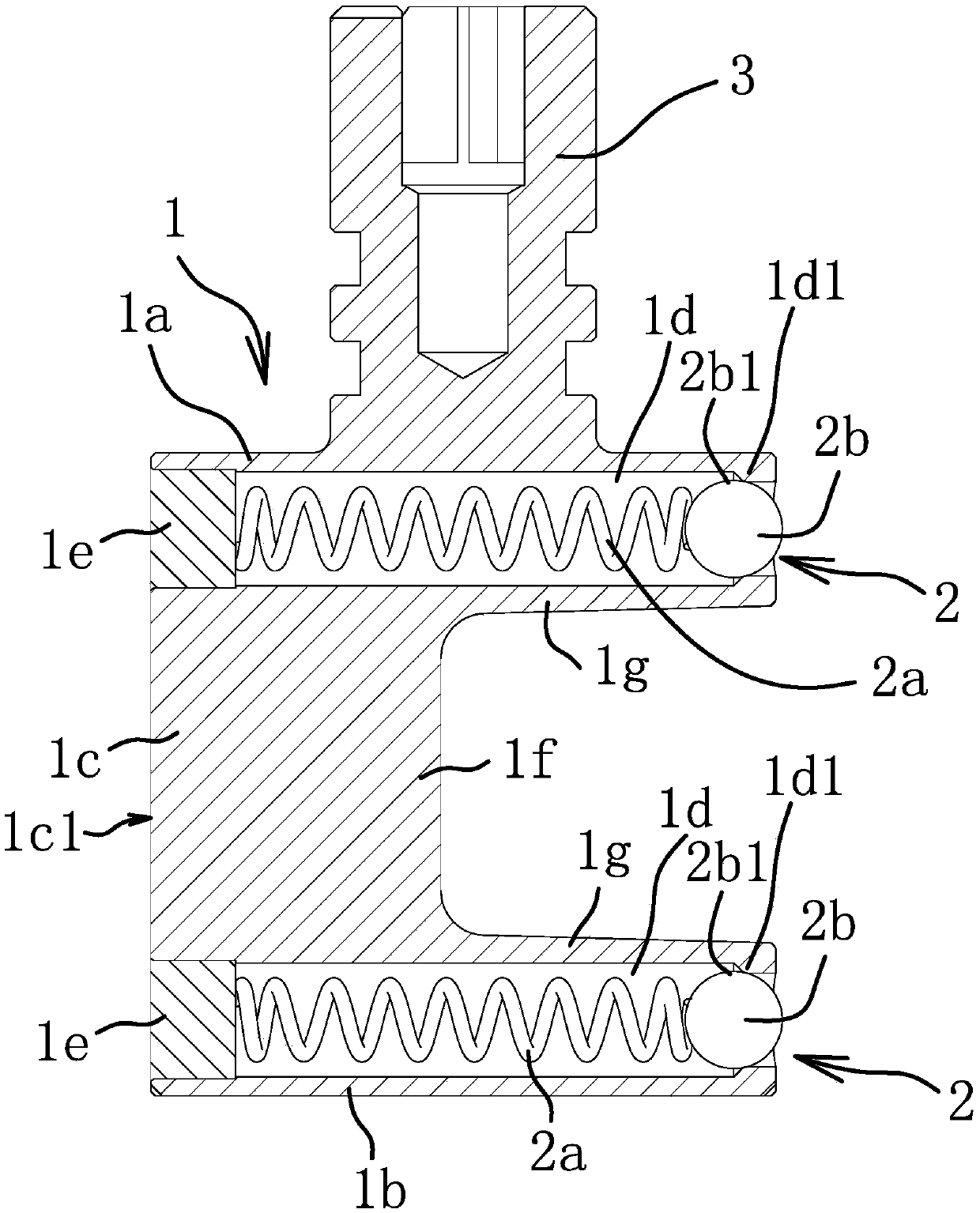

The invention provides a quick connector for a gas conveying bellows and belongs to the technical field of connectors. The quick connector solves the problem that an existing quick connector easily causes gas leakage in use. The quick connector comprises a barrel-shaped connecting head. In installation, a sealing washer is sleeved at the end of the bellows. A locating ring, a safety buckle and a locking nut are further sequentially sleeved on the bellows on one side of the sealing washer. The locating ring can be axially fixedly connected with the bellows, one end of the locating ring abuts against one end of the sealing washer, the safety buckle is barrel-shaped and is sleeved at the other end of the locating ring, a clamping part is arranged on an outer side wall of the safety buckle, an annular groove is arranged on an inner wall of the connecting head, and the clamping part is embedded in the annular groove when the locking nut is connected with the connecting head. After the quick connector is installed, one end of the bellows is always kept in a sealed state, and the bellows is good in safety and sealing effect. In addition, a casing of the quick connector is insulated with a bellows body, and the quick connector is safe to use.

Owner:林仁国

Die used for producing bowl-shaped ornament

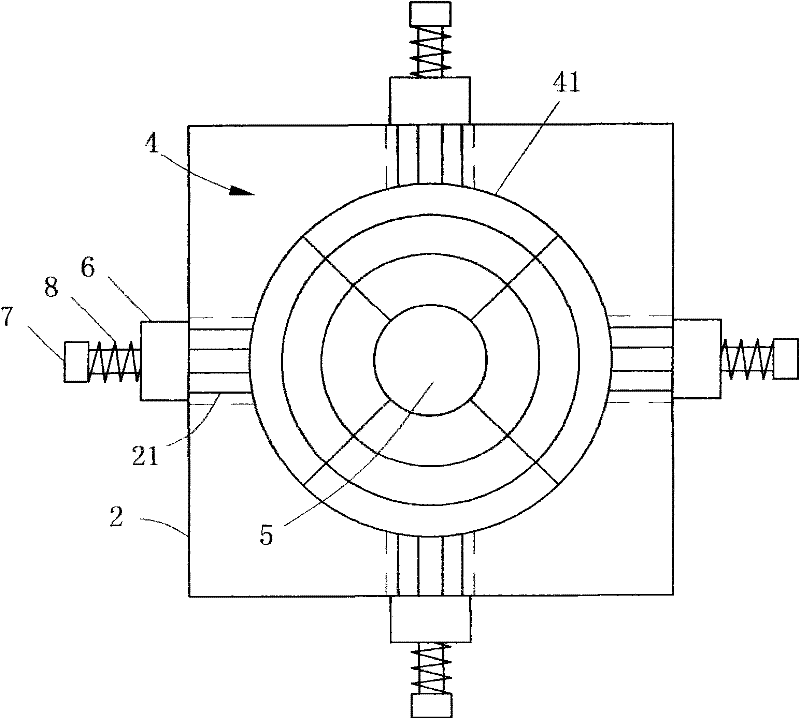

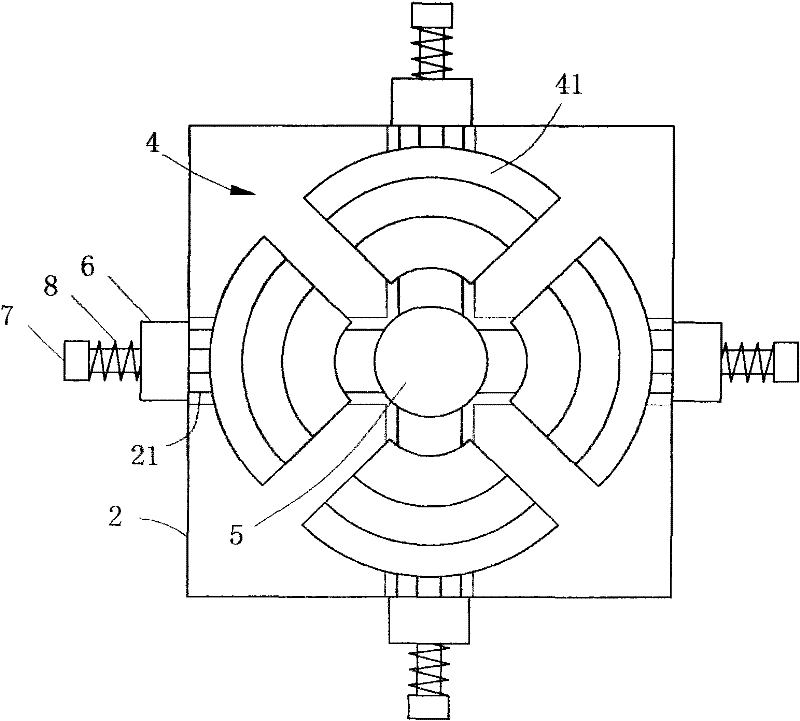

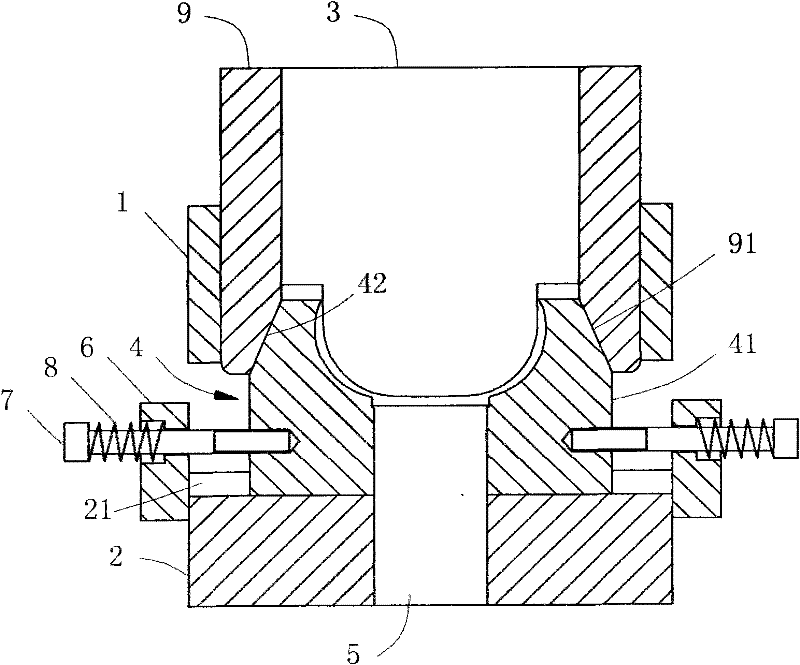

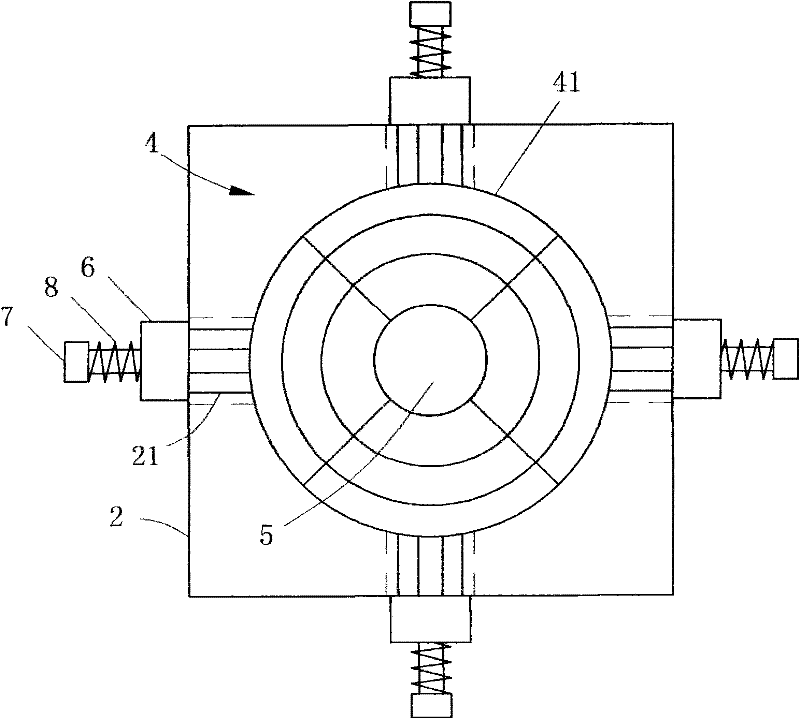

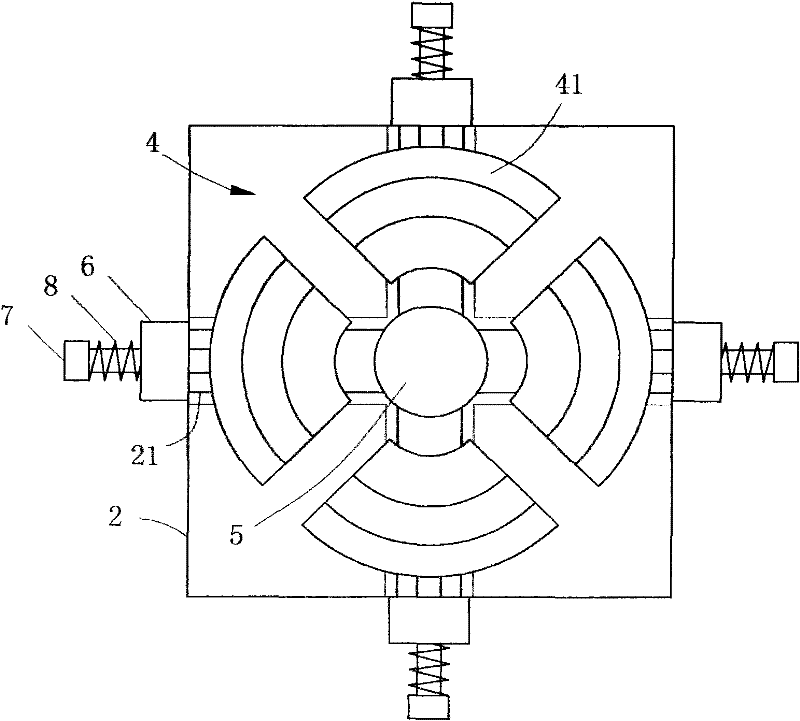

The invention discloses a die used for producing a bowl-shaped ornament, belonging to the technical field of jewellery processing dies. The die mainly comprises an upper die base and a lower die base which are connected together by virtue of a guide rod, wherein a convex die is sheathed on the upper die base; the lower die base is provided with a concave die and an impression die hole, the impression die hole is internally provided with an impression die in a constraint way, and the top of the impression die is provided with an impress; the convex die, the concave die and the impression die are mutually coordinated to form a bowl-shaped die cavity; and the concave die comprises a plurality of concave die section bodies, the concave die section bodies are arranged in an array around the center of the impression die hole and are radially and slidably arranged on the lower die base along the impression die hole. By adopting the die disclosed by the invention, the technical problem that the bowl-shaped ornament can not be produced by adopting a pressing process is solved, the production cycle is shortened, and the production efficiency is improved, thus the die can be widely applied in the jewellery processing industry.

Owner:SHANDONG MOKINGRAN JEWELRY

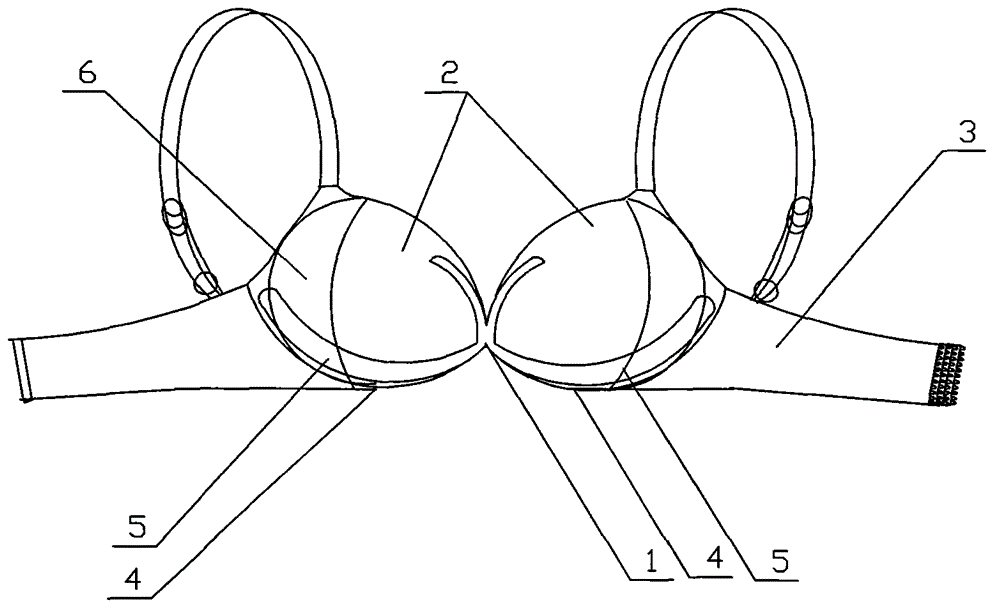

Bra without steel ring

The invention relates to the technical field of bras and discloses a novel and practical bra without a steel ring. The bra comprises two bra cups, wherein the two cups are distributed at the left and right sides of a chest; flanks are arranged outside the cups; lower holders are arranged at the bottoms of the cups; rubber sheets having the functions of supporting and shaping are arranged at the lower half peripheries of the two cups; the rubber sheets are one-piece rubber sheets for connecting the two cups together; and side clamping supports made of fabrics which are manufactured by integrally combining antibacterial woven materials and sponge are arranged at the side parts of the cups. According to the technical scheme of the bra, the rubber sheets have the functions of supporting, modifying the shapes of the breasts and positioning; the side breasts can be squeezed to the cups, so that the breasts are more beautiful; the side clamping supports both have the functions of ventilation, comfort and skin friendliness, and can achieve the feeling of skin friendliness and comfort; and the bra is simple in structure and practical.

Owner:武汉猫人制衣有限公司

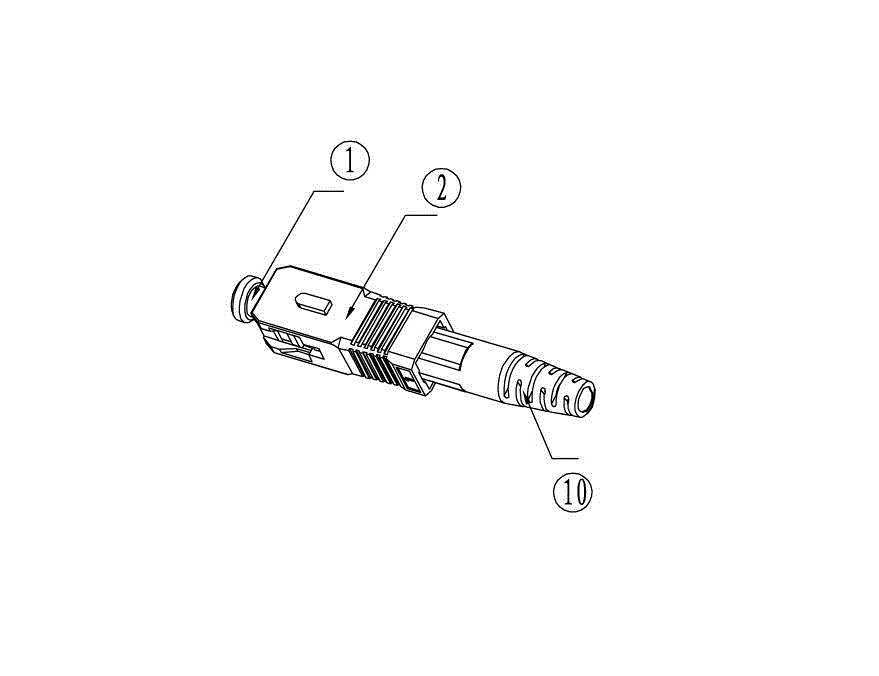

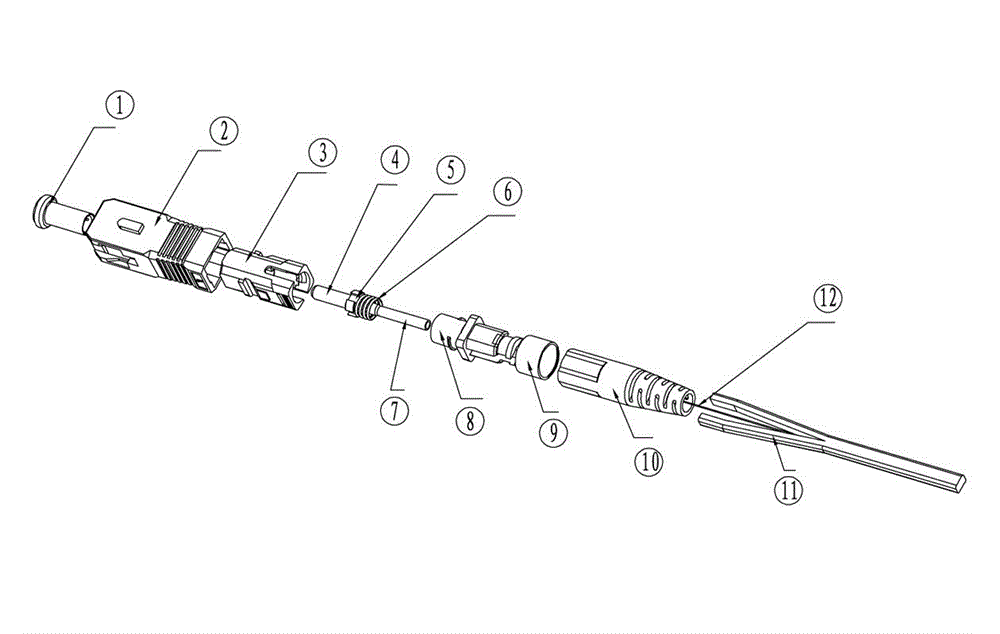

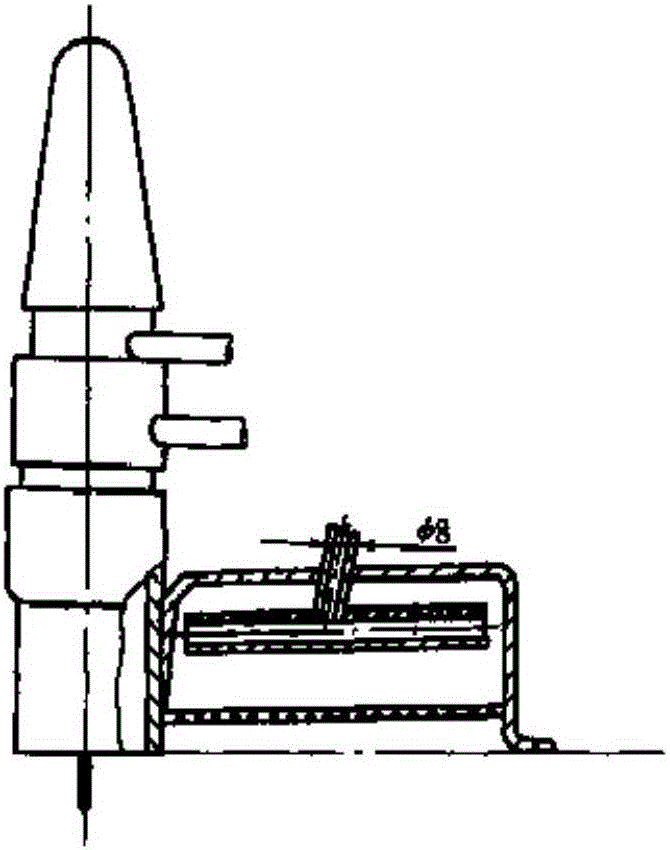

SC-type rubber-insulated optical fiber connector

InactiveCN102981220AImprove connection strengthImprove tensile propertiesCoupling light guidesFibre mechanical structuresClamp connectionEngineering

The utility model relates to an SC-type rubber-insulated optical fiber connector. The SC-type rubber-insulated optical fiber connector is characterized by comprising a shell, a front sleeve, an inserting core, a tail handle, a glue injecting tube and a tail sleeve, wherein the front sleeve is blocked inside the shell; the inserting core is embedded in the front sleeve; the tail handle is positioned at the back end of the inserting core; one end of the glue injecting tube is connected with the tail handle; the tail sleeve is in a clamp connection with the front sleeve; the SC-type rubber-insulated optical fiber connector further comprises a riveting and pressing base and a compression joint tube for riveting and pressing the riveting and pressing base; the riveting and pressing base is internally provided with a through hole for an optical fiber to pass through; the front end of the riveting and pressing base is in a tubular structure in joint with the front sleeve, and the back end of the riveting and pressing base is provided with an extending section; two rubber-insulated grooves for accommodating rubber-insulated wires are formed in the extending section; the compression joint tube is sleeved on the rubber-insulated grooves; and the glue injecting tube is positioned inside the riveting and pressing base. The SC-type rubber-insulated optical fiber connector provided by the invention is high in connection strength and high in reliability.

Owner:NINGBO MINGRI COMM EQUIP

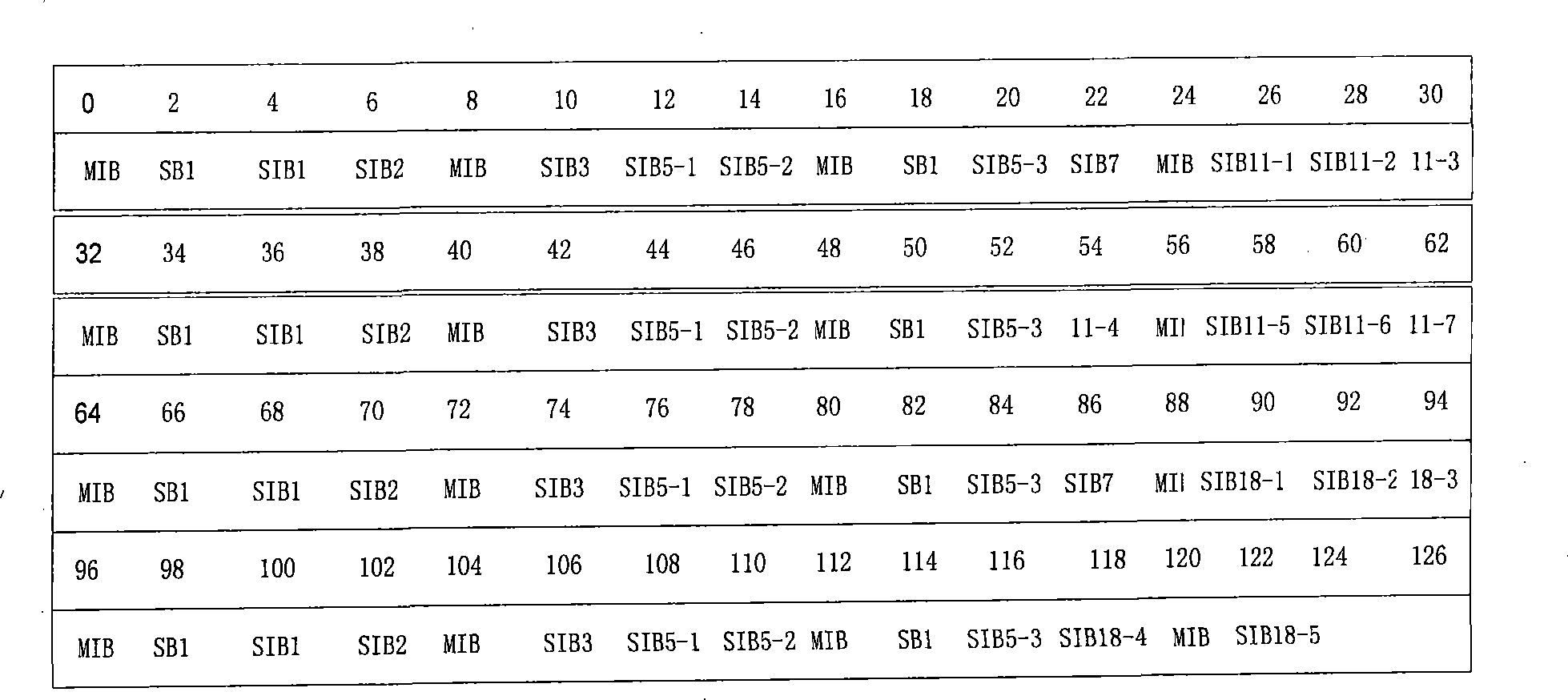

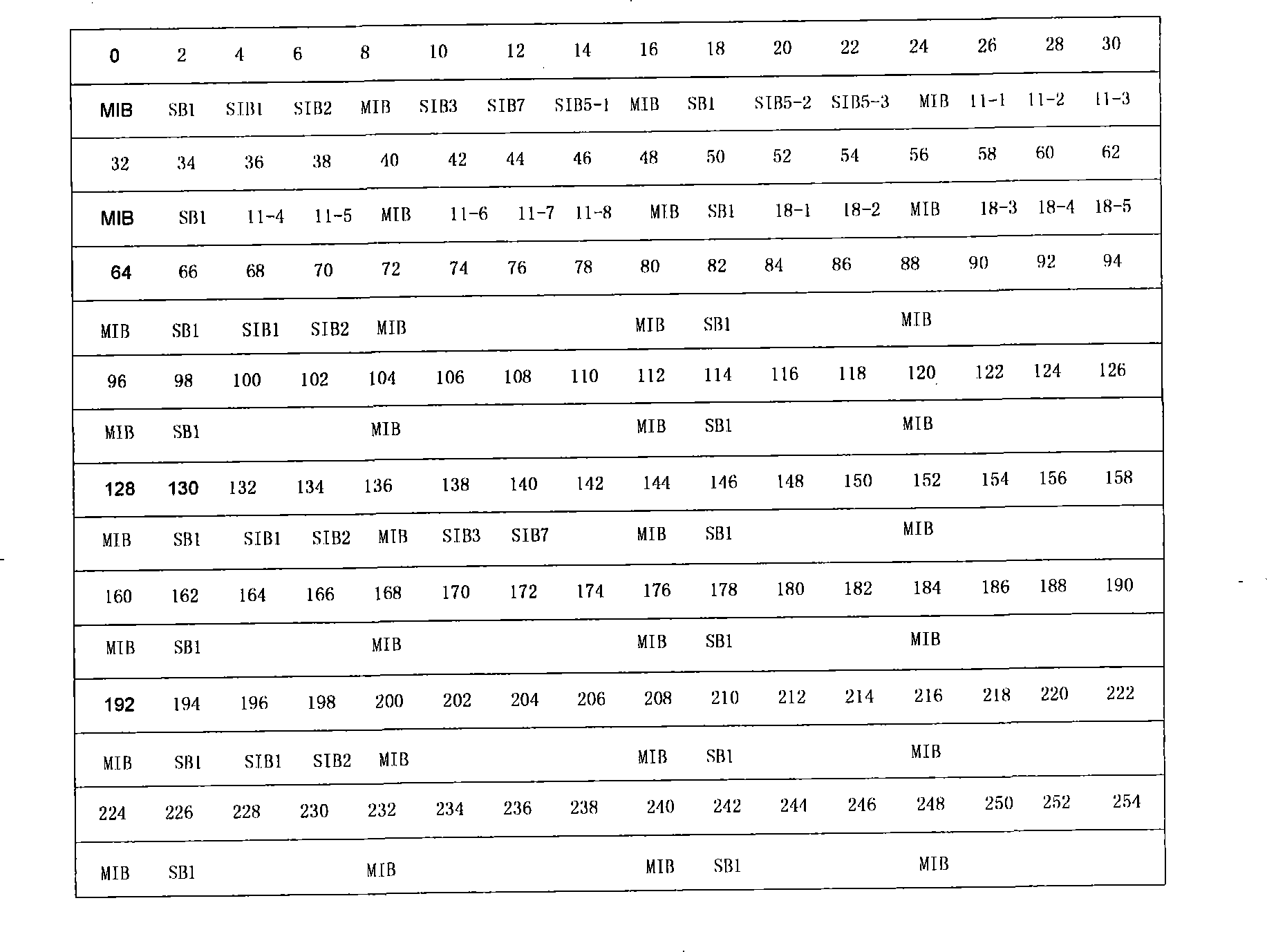

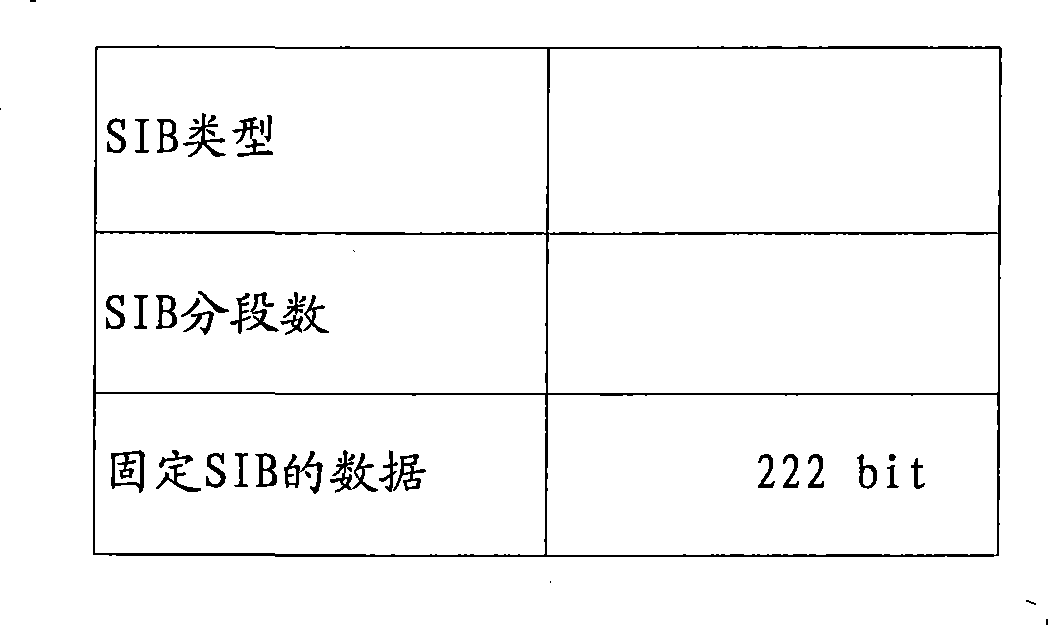

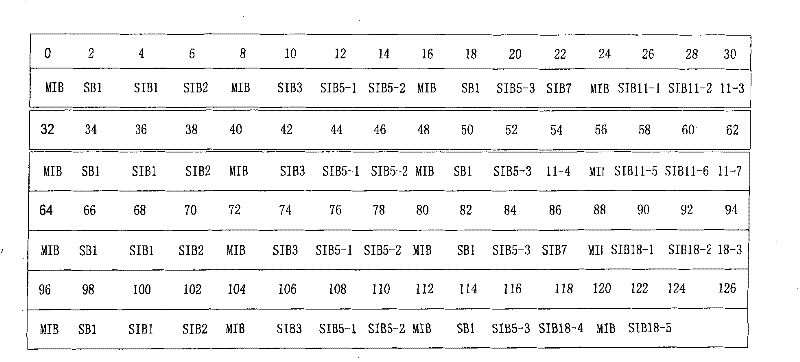

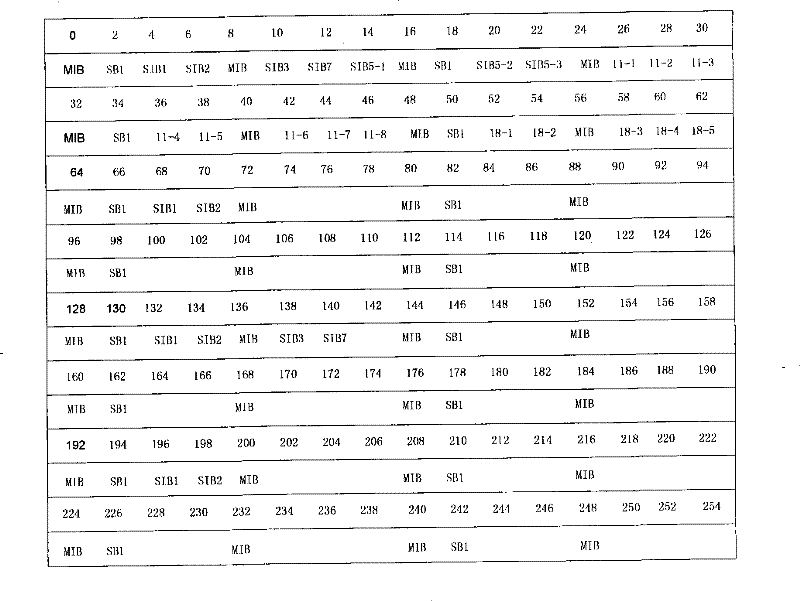

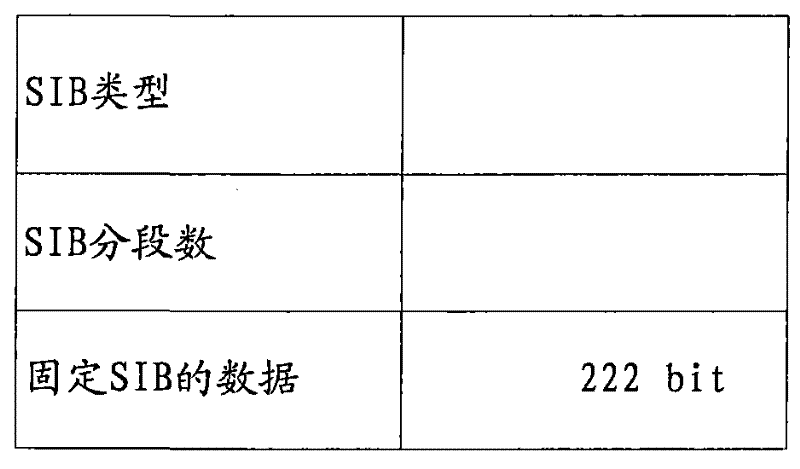

Method for terminal to read broadcast channel and terminal thereof

InactiveCN101252787AShorten the timeLess power consumptionBroadcast service distributionRadio/inductive link selection arrangementsBroadcast channelsResidence

The invention provides a method for reading a broadcast channel through a terminal and the terminal. The method comprises the following steps: step A, a fragment of a system message is read, and the system message comprises a plurality of fragments; step B, the storage position of a read fragment in a buffer zone is defined according to an index of the read fragment, and the fragment is stored into the storage position; step C, the step A is executed if the reading process of all the fragments of the system message is not accomplished; otherwise the flow is stopped. The terminal comprises a broadcast channel reading module and the buffer zone, and the broadcast channel reading module comprises a reading module, a memory module and a continuous reading module. The terminal can realize the disordered reading of the system massage with a plurality of fragments through utilizing the technical proposal, therefore, more system massages can be read in a shorter period of time, the time span for reading the system massage required by the residence is reduced, and the power consumption of the terminal is reduced.

Owner:ST ERICSSON SEMICON BEIJING

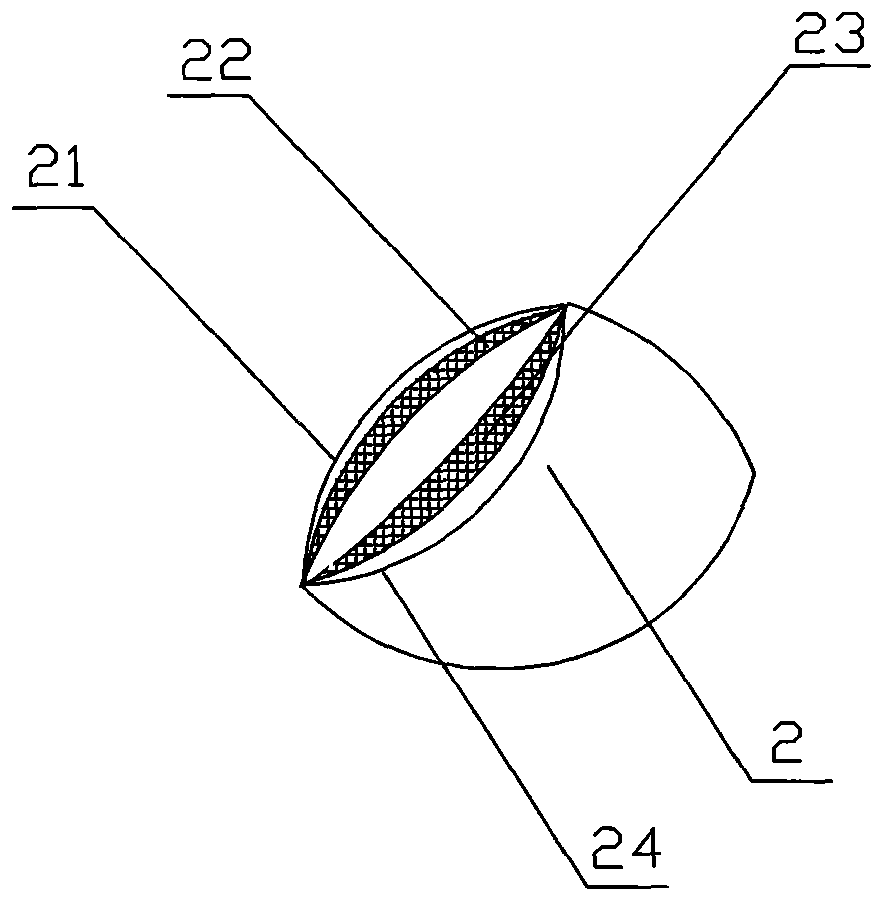

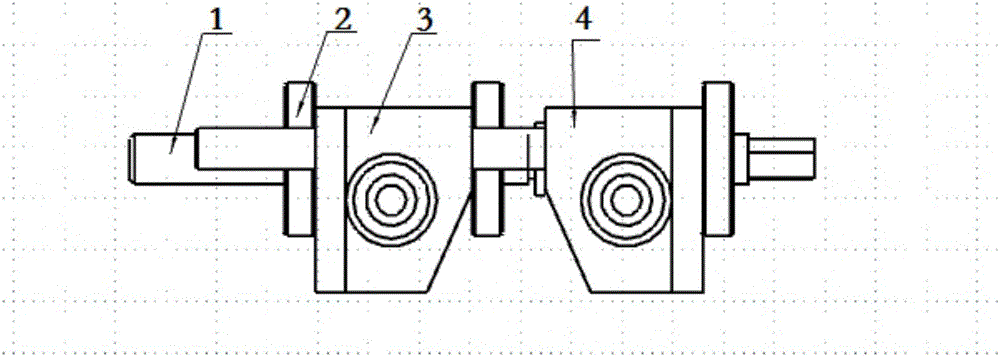

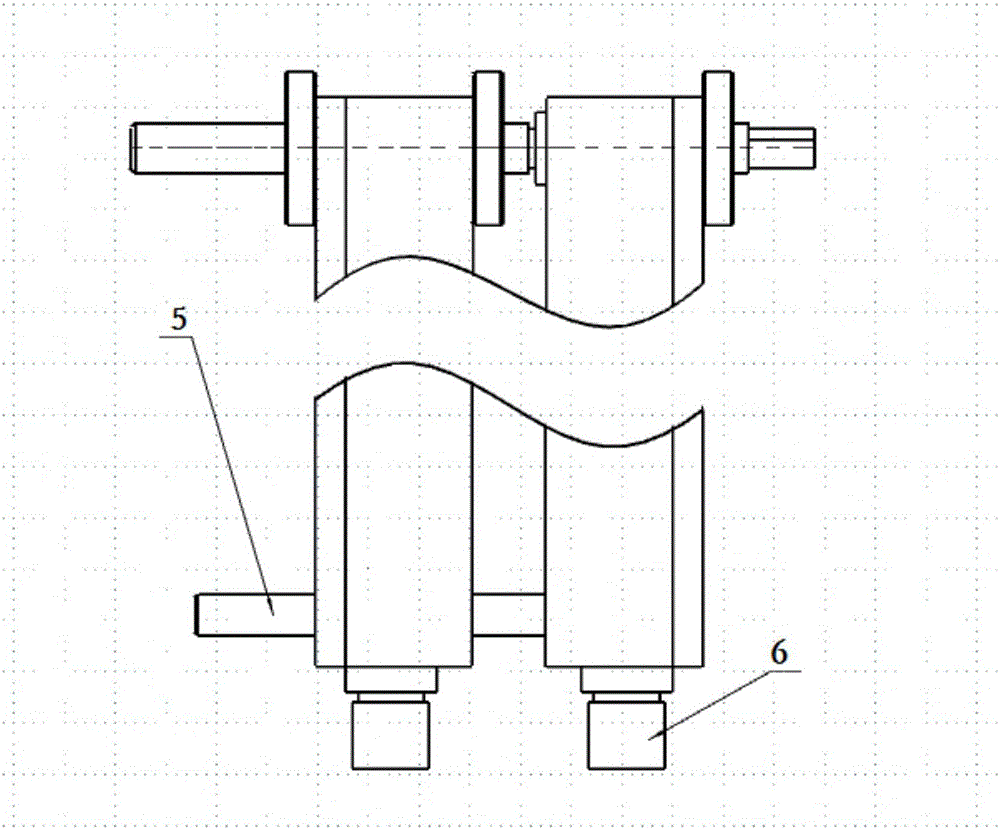

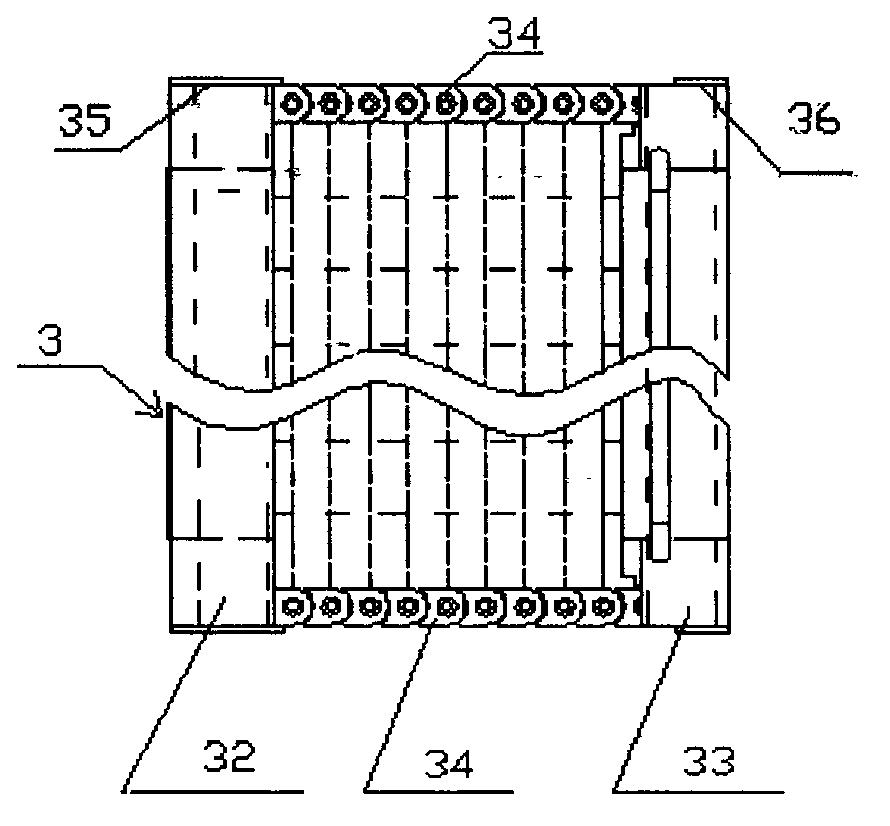

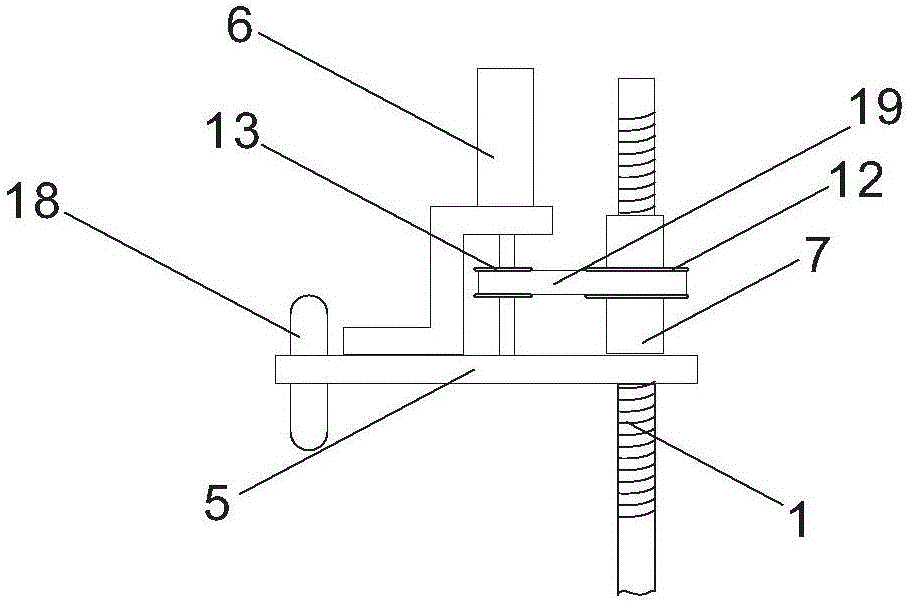

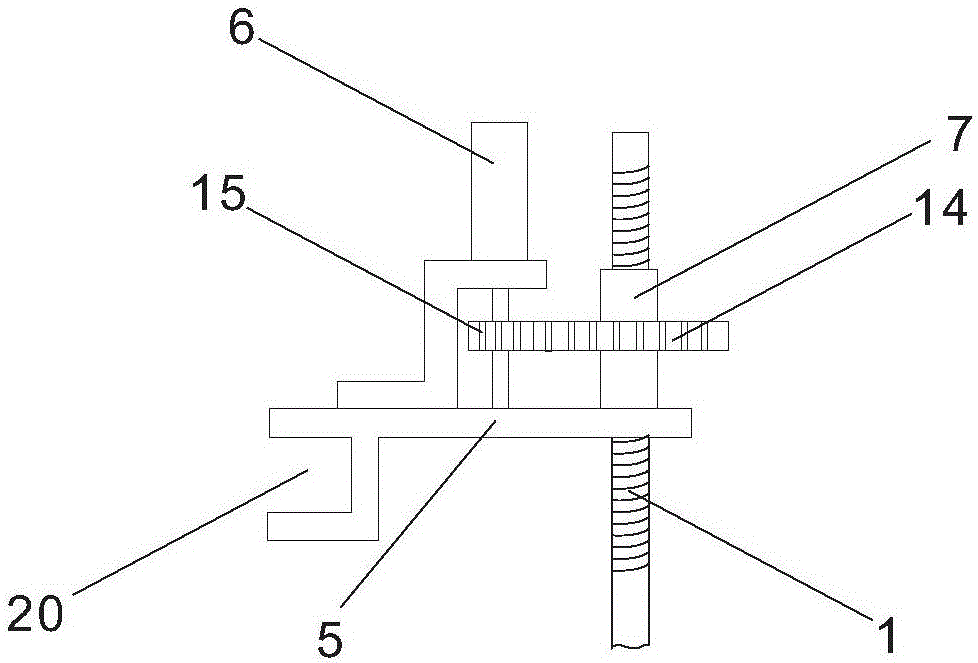

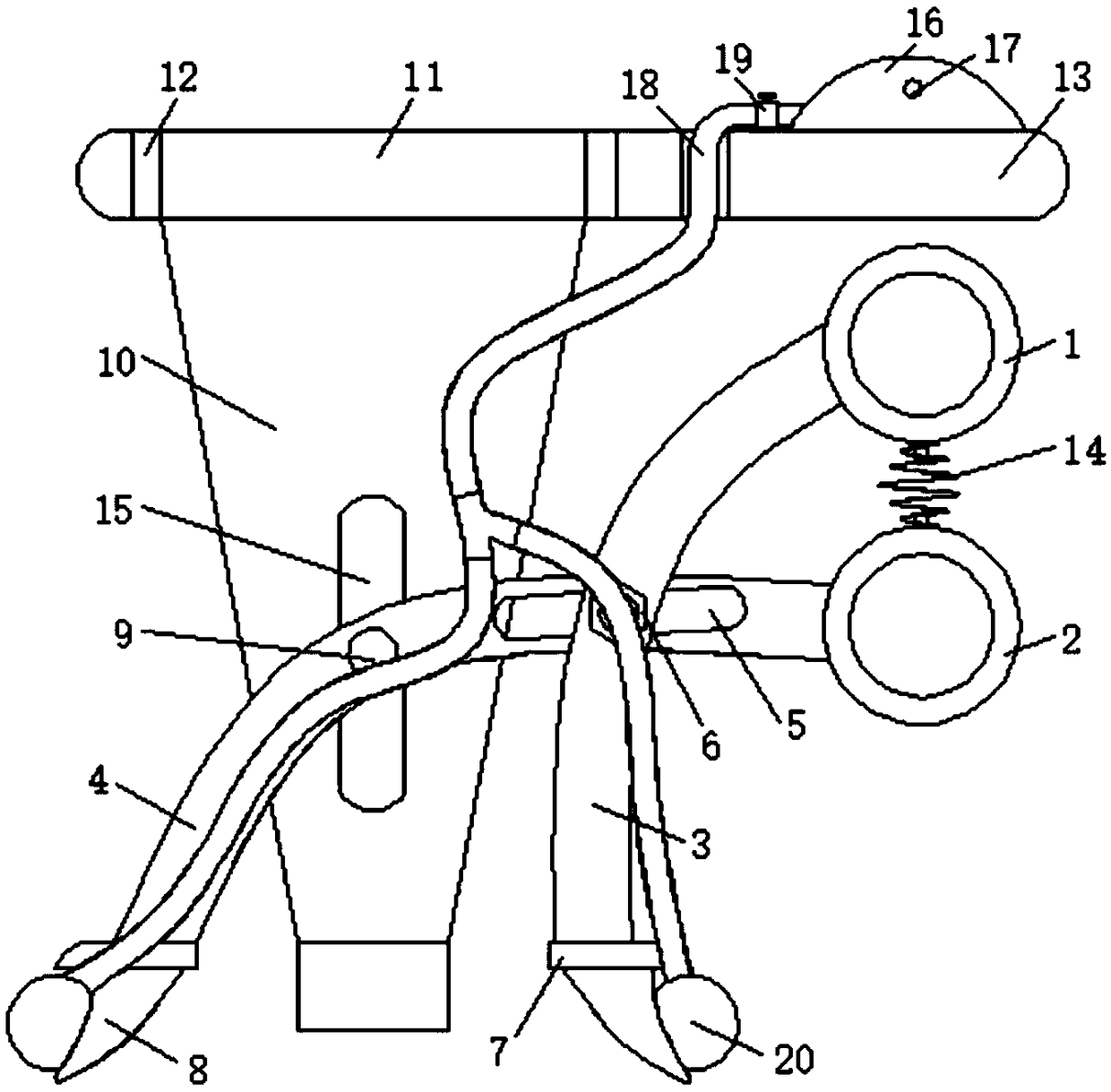

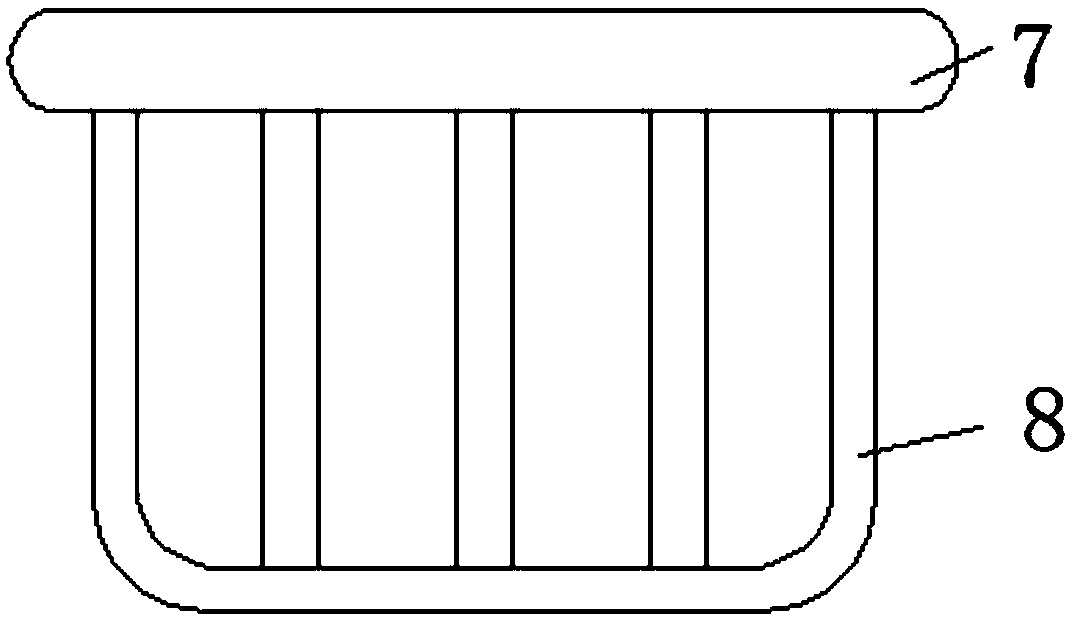

Gas protection device for front side of titanium alloy material weld joint

InactiveCN106112230AClose upAchieve separationShielding gas supply/evacuation devicesInlet channelProduct gas

The invention discloses a gas protection device for the front side of a titanium alloy material weld joint. The gas protection device comprises a threaded rod and two ventilation sliding blocks. The two ventilation sliding blocks are connected through the threaded rod, and the distance between the two ventilation sliding blocks is adjusted through nuts matched with the threaded rod. Each ventilation sliding block is provided with an air inlet, and an air inlet channel is machined in the ventilation sliding block along the air inlet. One or more vent hole sets are machined in the opposite faces of the two ventilation sliding blocks. Each vent hole set comprises one or more vent holes. The vent holes communicate with the air inlet channels. The axes of the vent holes of each vent hole set are distributed in a radial mode on the section perpendicular to the axis of the corresponding air inlet channel with the projection point of the axis of the air inlet channel as the center. By the adoption of the gas protection device, the effect that the gas protection device is separated from a welding gun is achieved, welding operation is not affected by the gas protection device, and flexible operation as conventional welding can be achieved.

Owner:BEIJING POWER MACHINERY INST

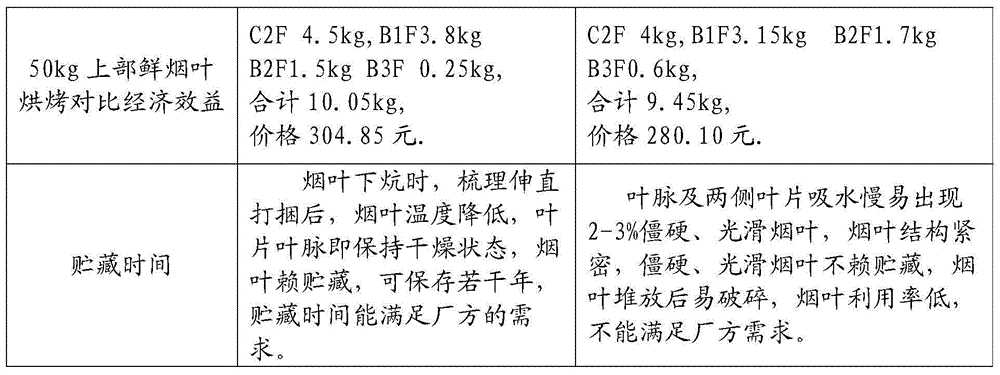

Moisture-regain technology for improving loose tobacco baking quality

The invention belongs to the field of tobacco processing, and particularly relates to a moisture-regain technology for improving the loose tobacco baking quality. By means of the moisture-regain technology, the visual width of stored tobacco is remarkably reduced, the tobacco is well stored and can be stored for a long time, the storage time can meet the requirements of industrial manufacturers, and the tobacco quality also is improved. The moisture-regain technology comprises the following steps of (1) conducting tobacco loading, wherein collected fresh tobacco leaves are placed in a curing barn in a classified mode, and tobacco leaves are loaded to a kang according to the standard of loose tobacco curing; (2) conducting sealing, wherein after each layer of tobacco leaves are placed on the kang, the tobacco leaves and the periphery of the curing barn are completely sealed; (3) conducting curing, wherein curing lasts for 110-130 hours, then colors of the tobacco leaves are fixed, curing is finished, and after stems of the tobacco leaves are dried and cured, a fan is kept normally operating; (4) conducting moisture regain, wherein fuel continues to be added to keep the temperature in the curing barn ranging from 66-68 DEG C, the curing barn is closed, and water is supplied to fan blades to form humid and hot air so that moisture regain can be conducted on the cured tobacco leaves; (5) conducting kang discharging, wherein the moisture-regained tobacco leaves are discharged from the kang; (6) after the tobacco leaves are stacked for 6-8 days, deactivation of enzymes and impurity removing are conducted, the tobacco leaves are classified primarily, and then the tobacco leaves are baled after being naturally folded again.

Owner:贵州省烟草公司遵义市公司湄潭分公司

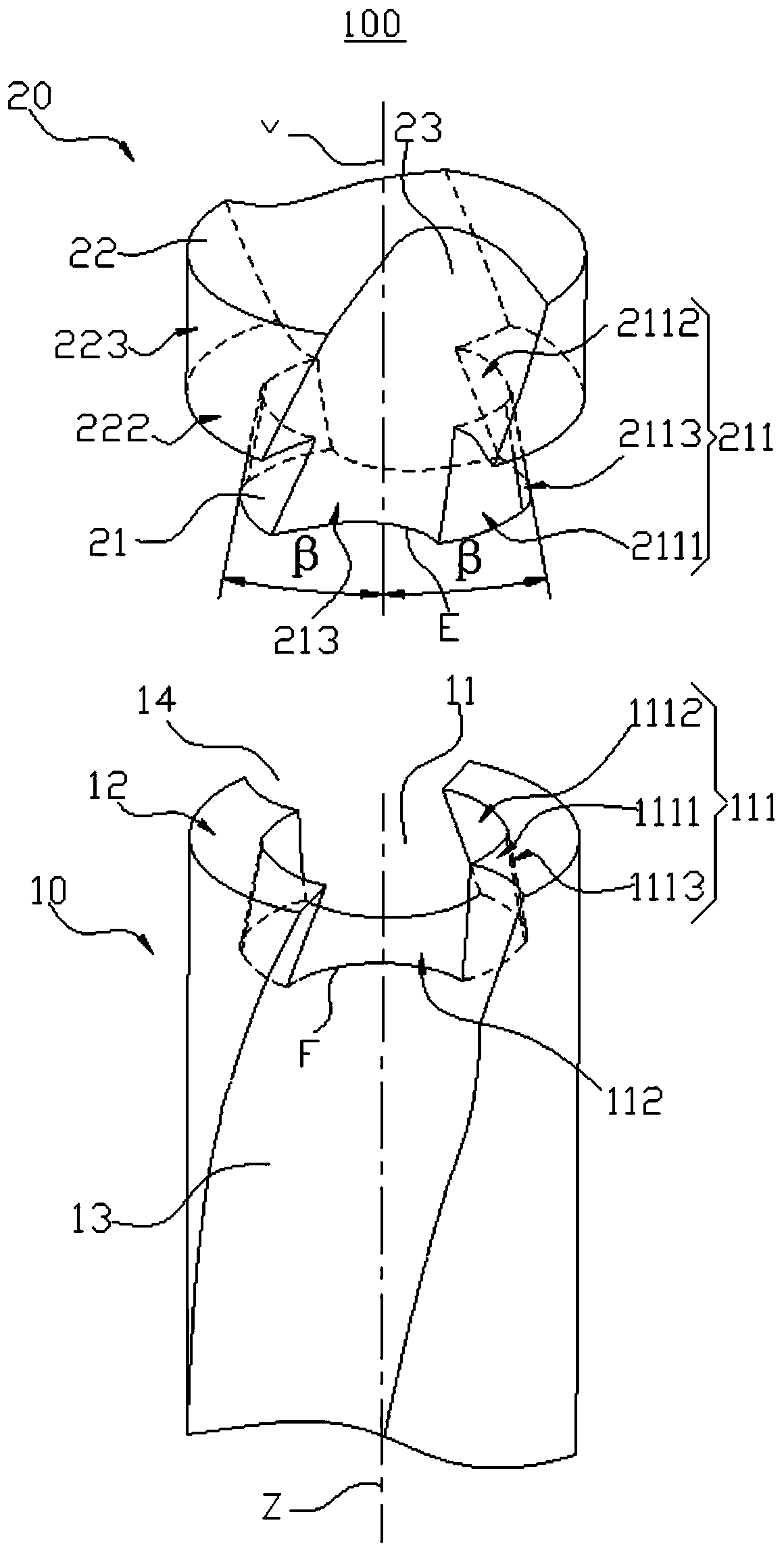

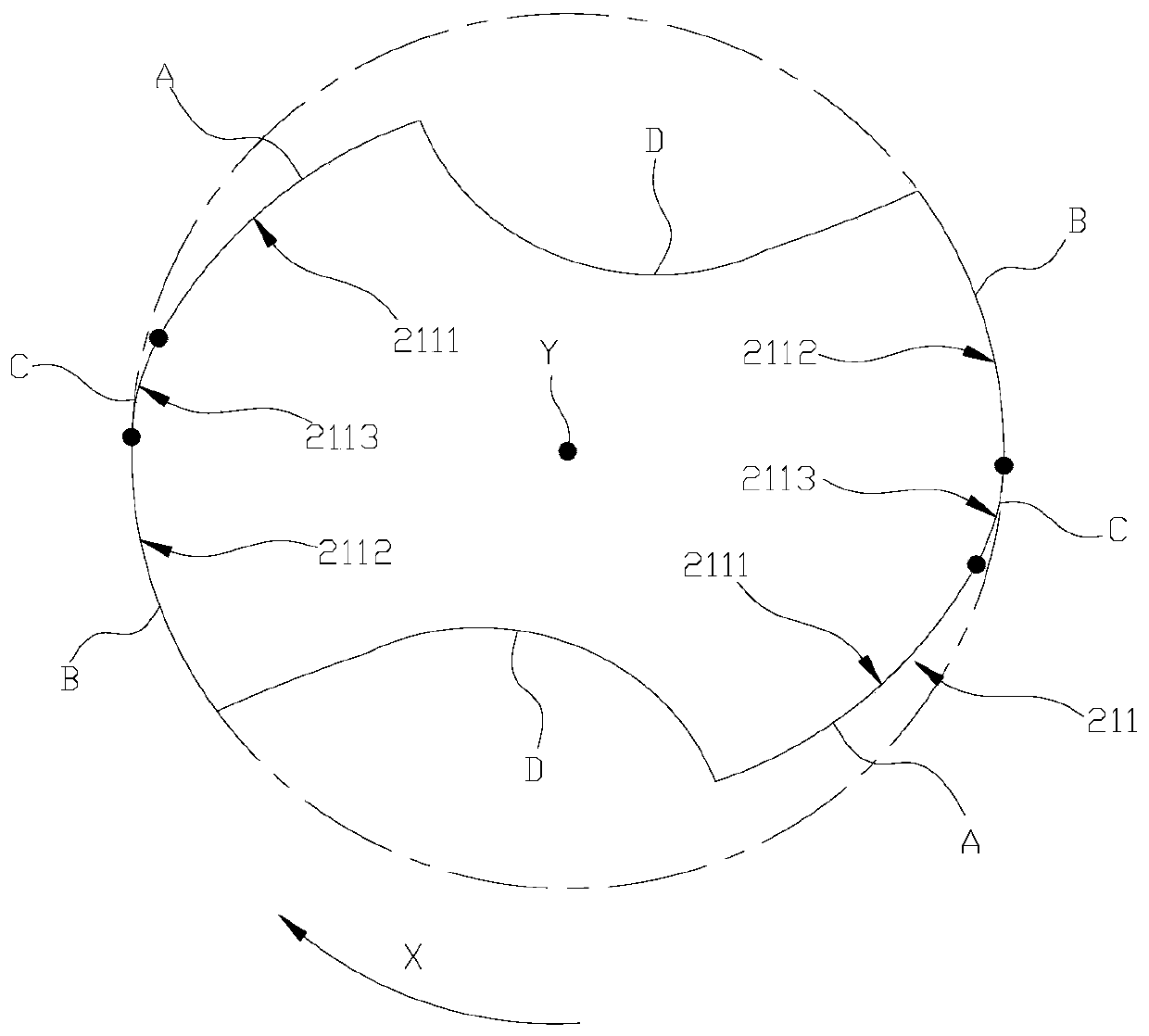

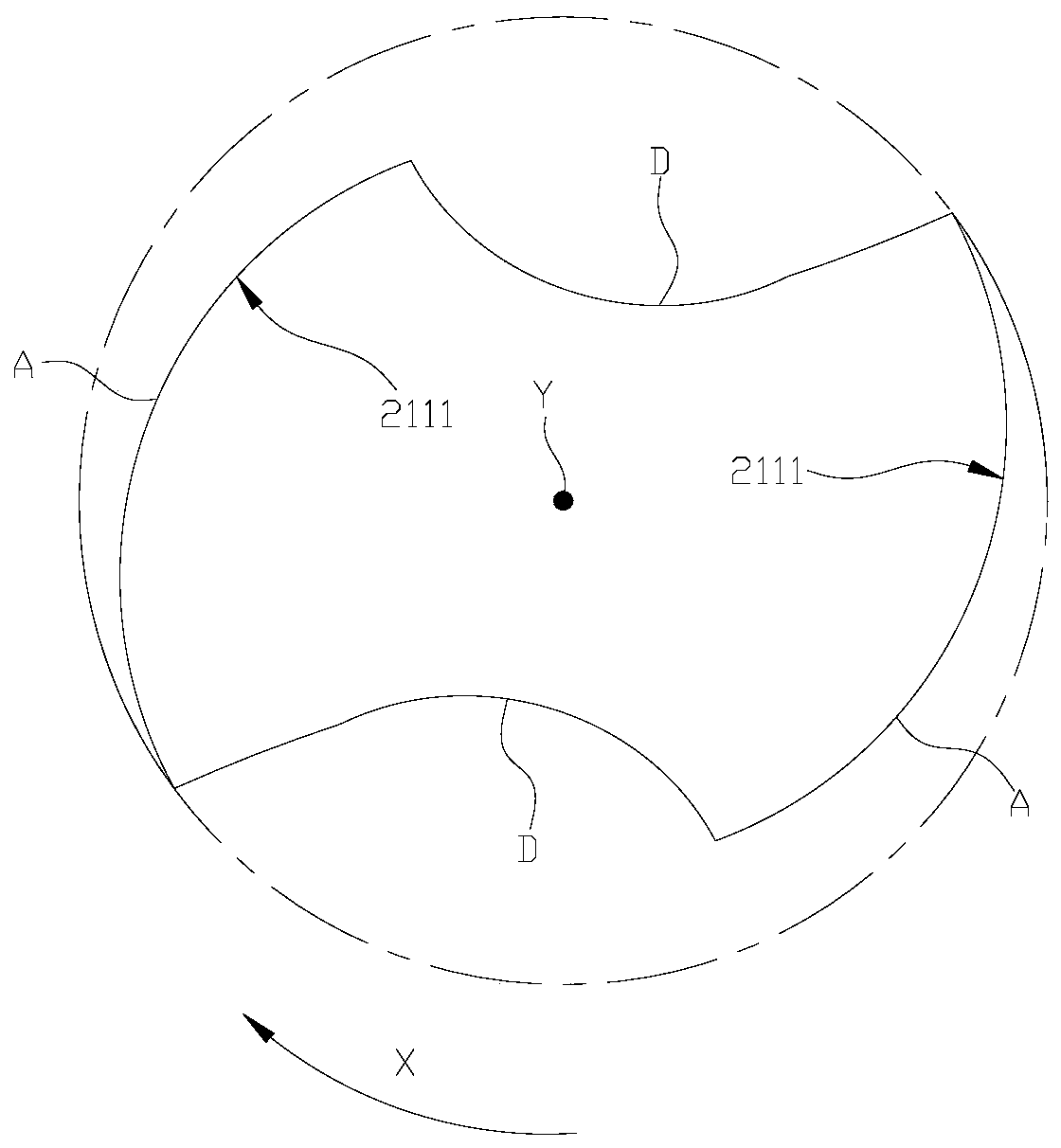

Exchangeable tip drill

PendingCN111151793AClose upAvoid over-positioningTransportation and packagingTrepanning drillsTool bitButt joint

The invention provides an exchangeable tip drill, and belongs to the field of cutting tools. The exchangeable tip drill comprises a drill shank and a drill tip, wherein the end part of the drill shankis provided with a limiting groove. The drill tip is provided with a butt joint part for coaxially arranging the drill tip and the drill shank after being matched with the limiting groove, and the inner peripheral wall of the limiting groove is matched with the outer peripheral wall of the butt joint part; the outer peripheral wall of the butt joint part comprises a first curved surface, the first curved surface comprises a first gradual change surface, and an intersecting line between the first gradual change surface and a cross section of the butt joint part is a gradual change line with adistance to a center line of the drill tip gradually reduced. According to the exchangeable tip drill, rotation stopping of the drill tip is achieved through the gradual change structure, and the rotation stopping structure is simple. In addition, the first gradual change surface of the butt joint part may have a large area of contacting with the inner peripheral wall of the limiting groove of thedrill shank, and torque transmitting capability between the drill shank and the drill tip can be increased.

Owner:CHENGDU FENGYI PRECISION TOOLS MFG

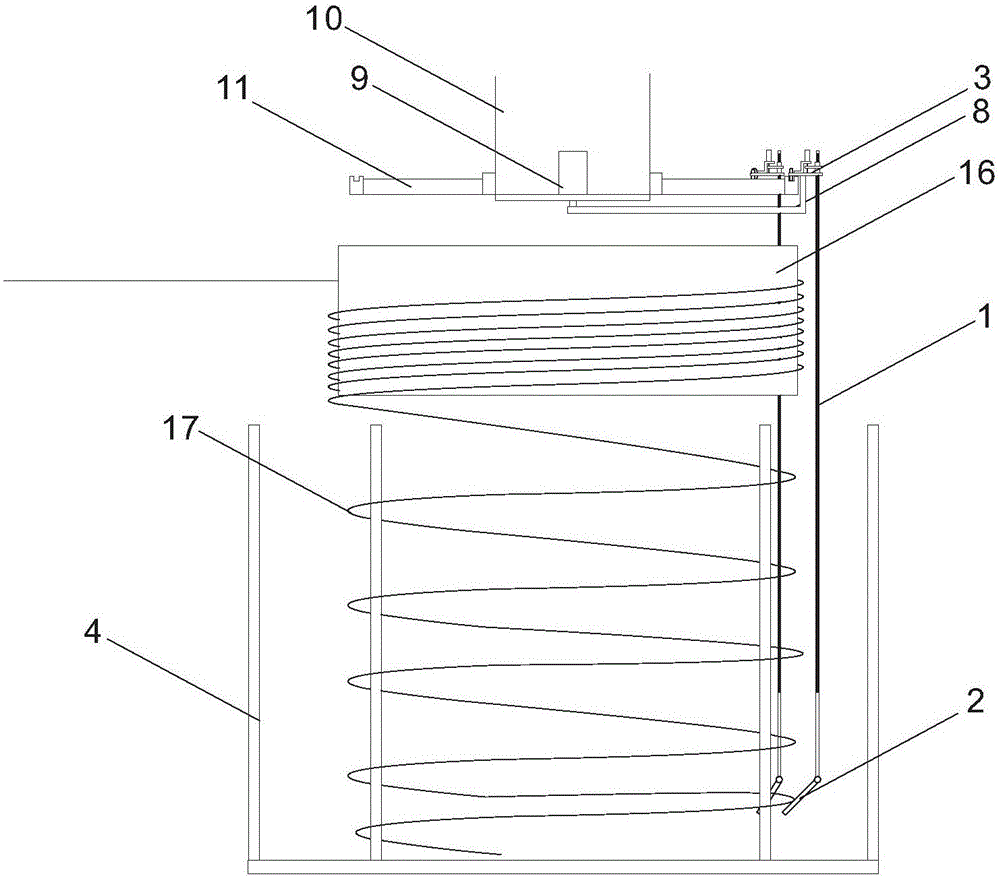

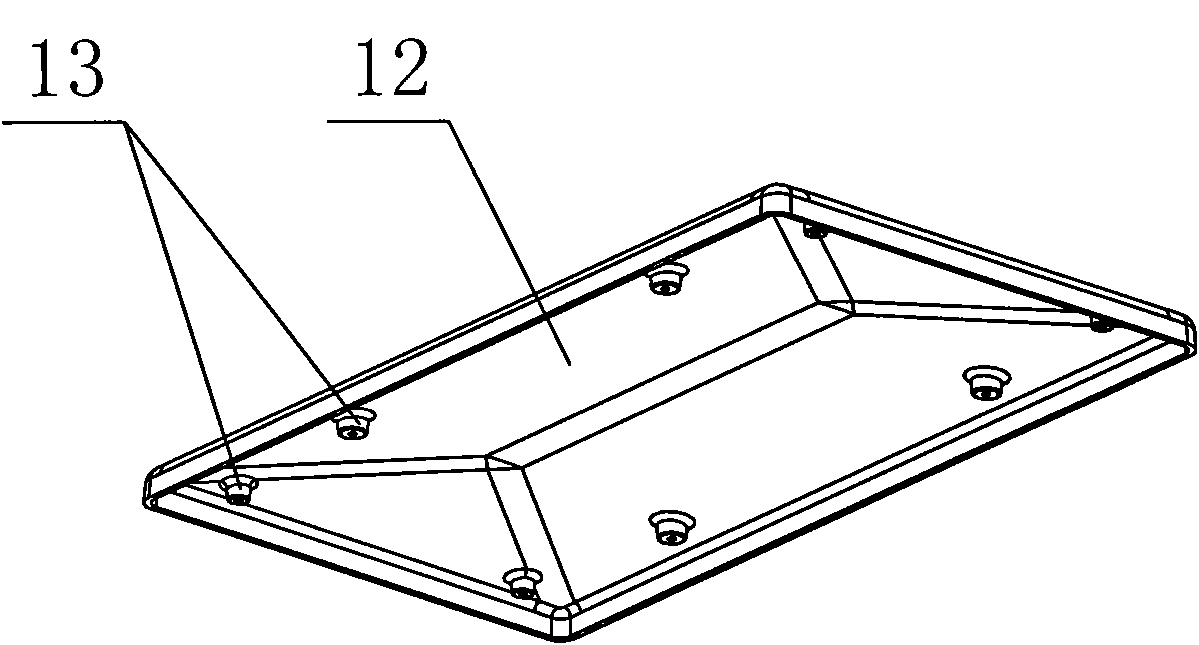

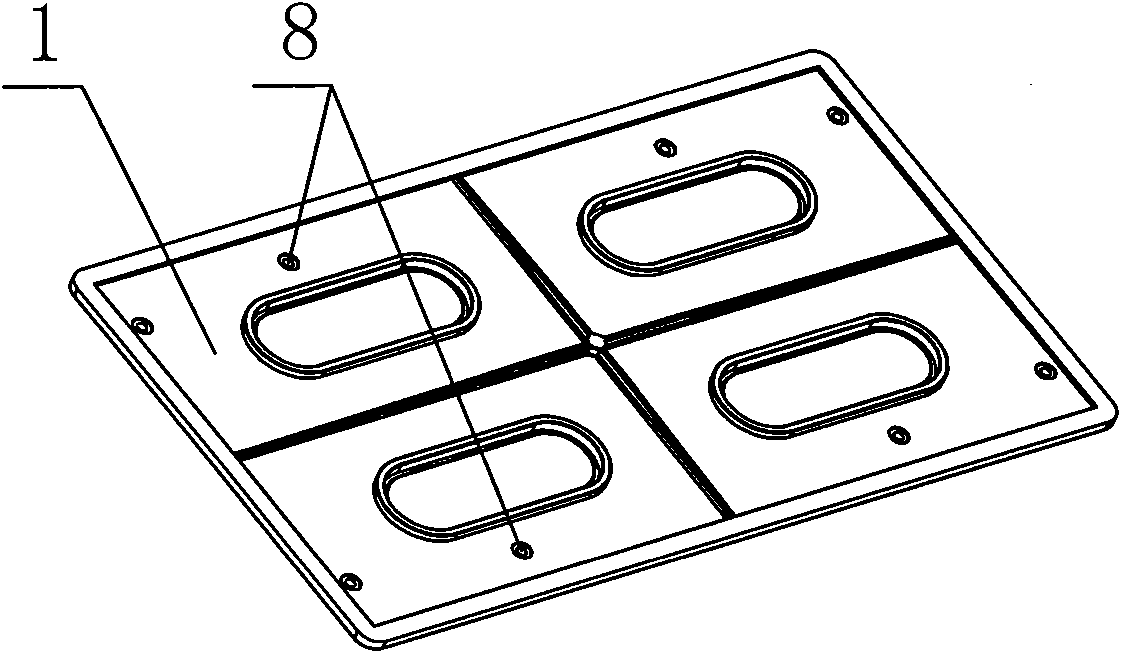

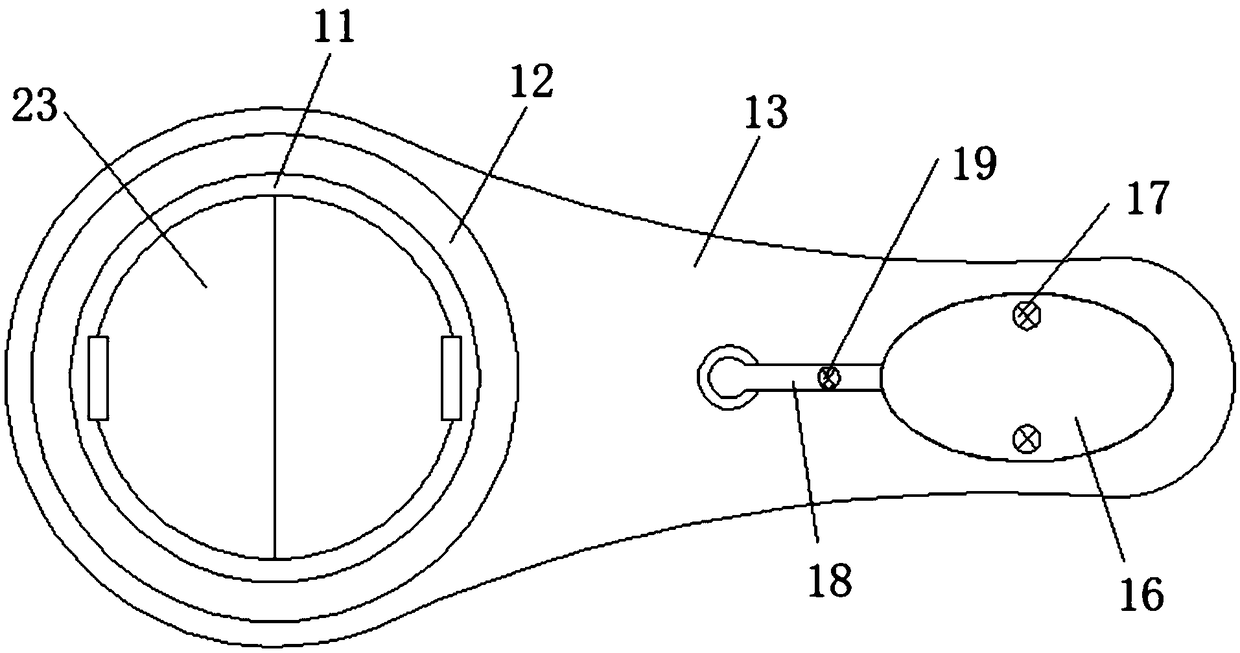

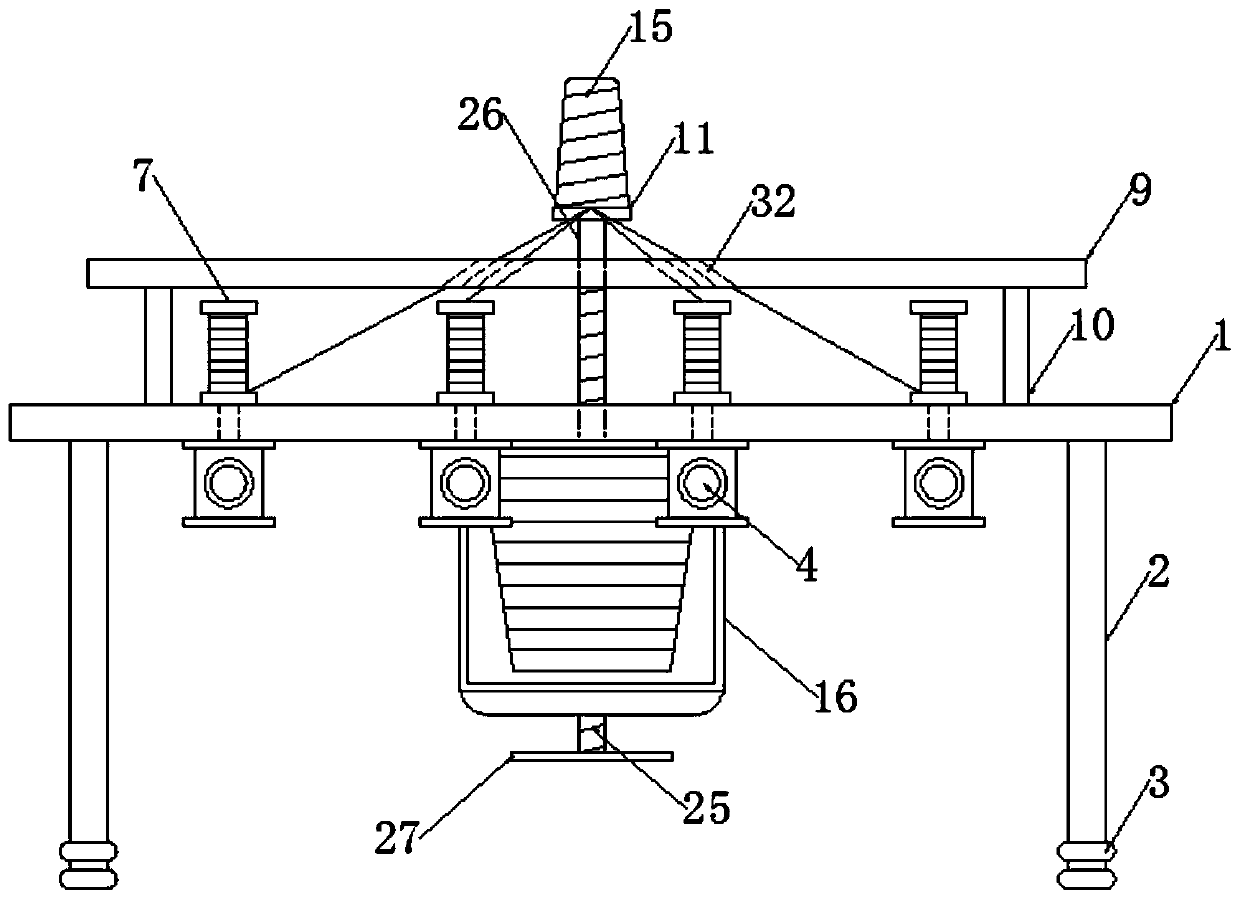

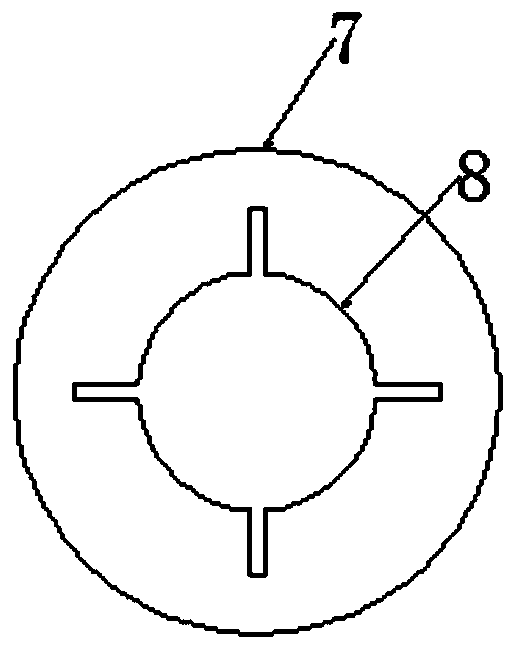

Cable take-up machine

The invention discloses a cable take-up machine, and relates to the technical field of cable production equipment. The technical problems that in a cable take-up machine in the prior art, cables are wound around a take-up reel unevenly, and the take-up effect is poor are solved. The cable take-up machine comprises a support, a cable guide wheel used for cable guide, a cable arrangement device used for cable arrangement and a take-up device used for take-up. The support comprises a first cross beam and a second cross beam. The cable guide wheel is arranged on the first cross beam. A cable arrangement wheel of the cable arrangement device is mounted on the second cross beam. The take-up device is mounted below the support. The cable take-up machine is mainly used for winding cables; due to the fact that the cable arrangement device is arranged, and a plurality of second fixing holes are formed in the straight line, passing through the circle center, on an eccentric wheel of the cable arrangement device, close and even take-up can be achieved, and the connecting position of a connecting shaft and the eccentric wheel can be selected according to needs; and thus, the left-right movement stroke of the cable arrangement wheel is adjusted so as to adapt to take-up work of take-up reels of different lengths.

Owner:TIANJIN LANGXING WIRE & CABLE

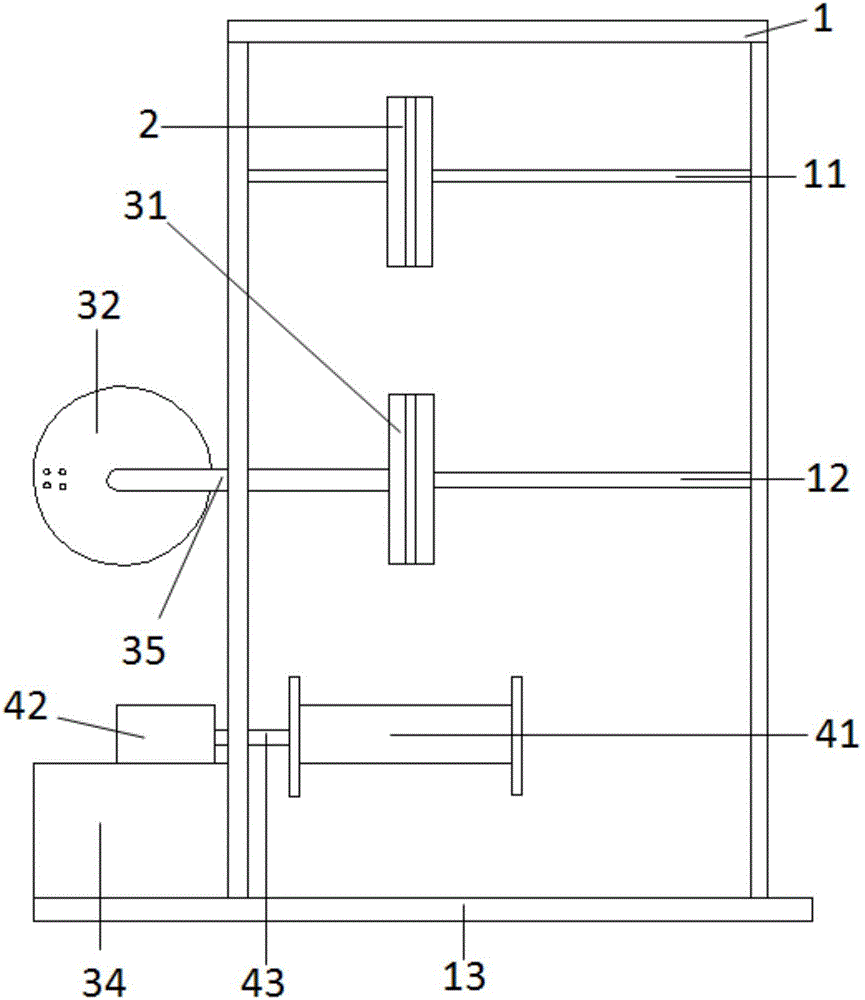

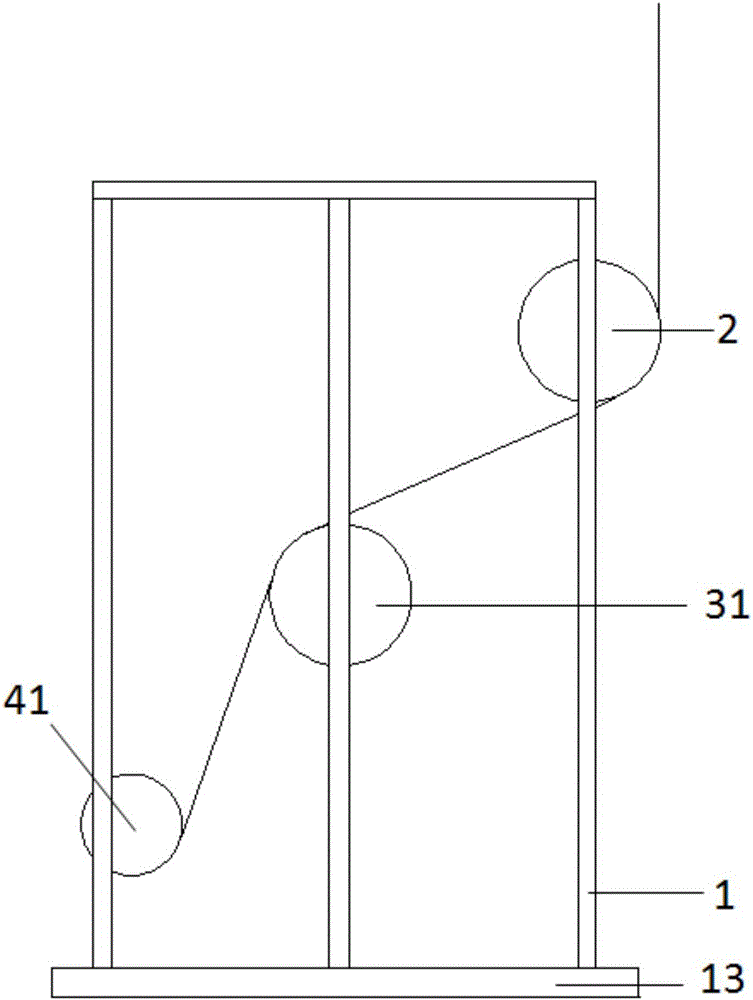

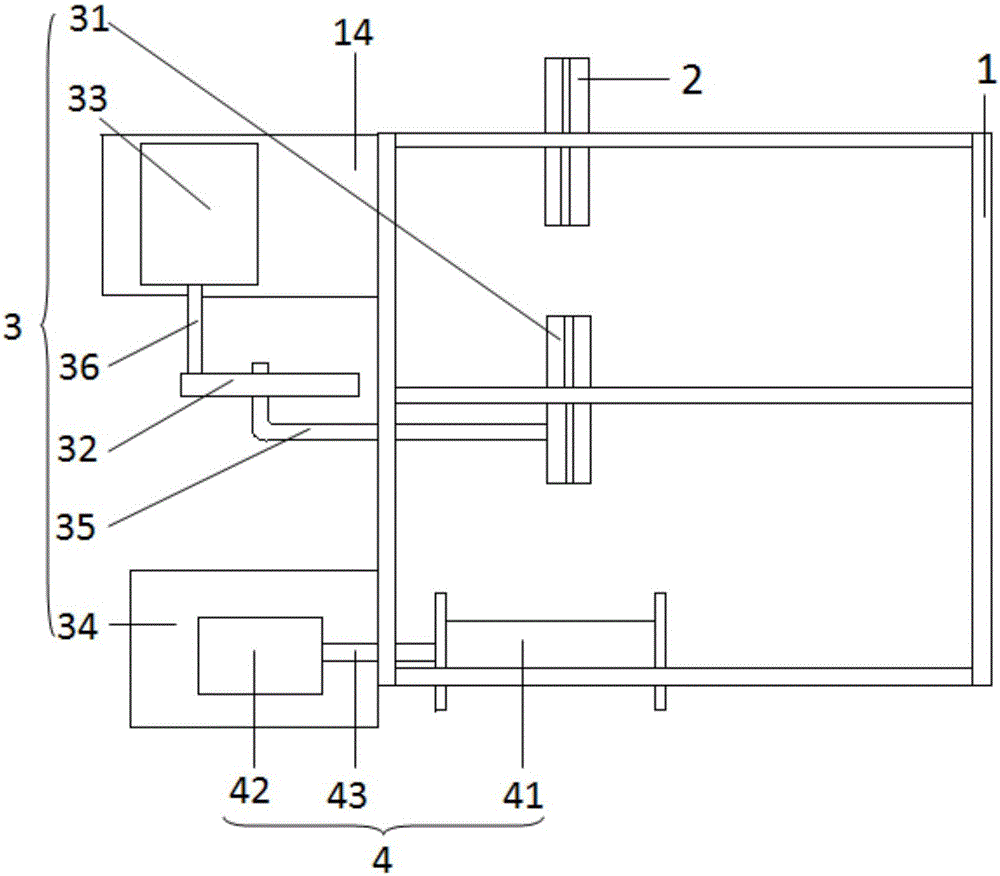

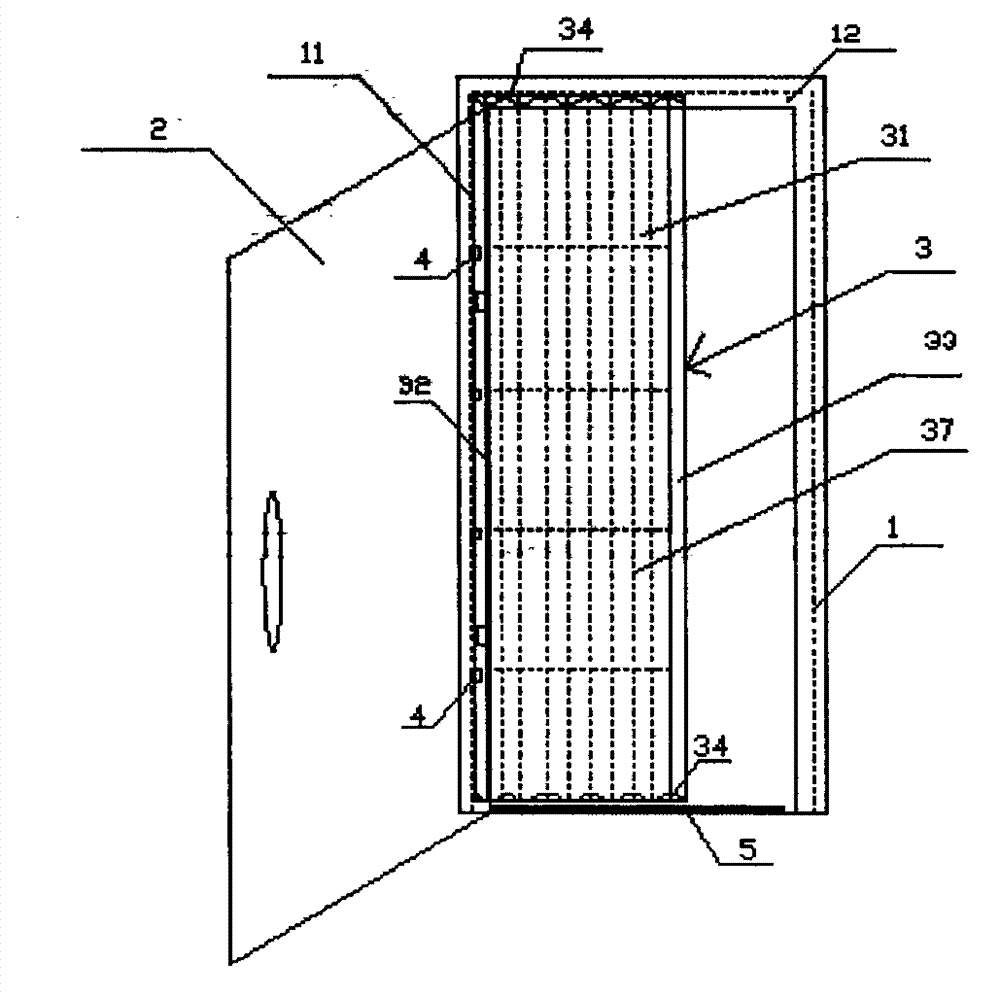

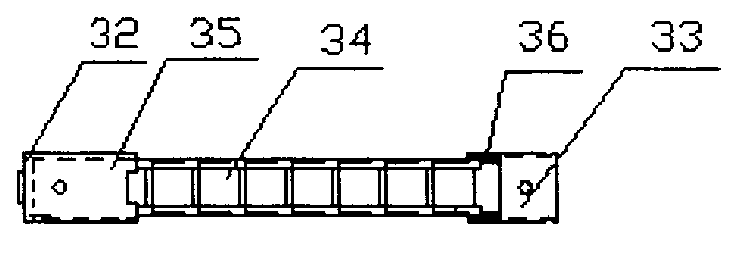

House door with hidden screen door

InactiveCN102900349APlay the role of weightCombined with smooth operationInsect protectionVertical edgeEngineering

The invention relates to a house door with a hidden screen door. The house door comprises a door frame 1 and a solid door 2. The house door with the hidden screen door further comprises the hidden screen door 3, a storage groove 11, a guide groove 12 and a connecting piece 4; the storage groove 11 is arranged in a side vertical frame of the door frame 1, the connecting piece 4 is arranged in the storage groove 11, and the guide groove 12 is arranged on an upper transverse frame on the door frame; the hidden screen door 3 comprises a gauze 31, a fixed rod 32, a pull rod 33 and a guide chain 34, a gauze concealing groove I 35 is arranged in the fixed rod, a gauze concealing groove II 36 is arranged in the pull rod, the left and right vertical edges of the gauze are fixed on the inner walls of the gauze concealing groove I and the gauze concealing groove II, and the upper edge and the lower edge of the gauze are respectively connected with the guide chain 34; two ends of the guide chain are respectively connected with the fixed rod and the pull rod, and the fixed rod and the connecting piece are engaged. The house door with the hidden screen door has the advantages of being capable of meeting the ideas of saving space and fully utilizing space, convenient to mount and dismount and convenient to clean and repair.

Owner:江西黄金甲门业有限公司

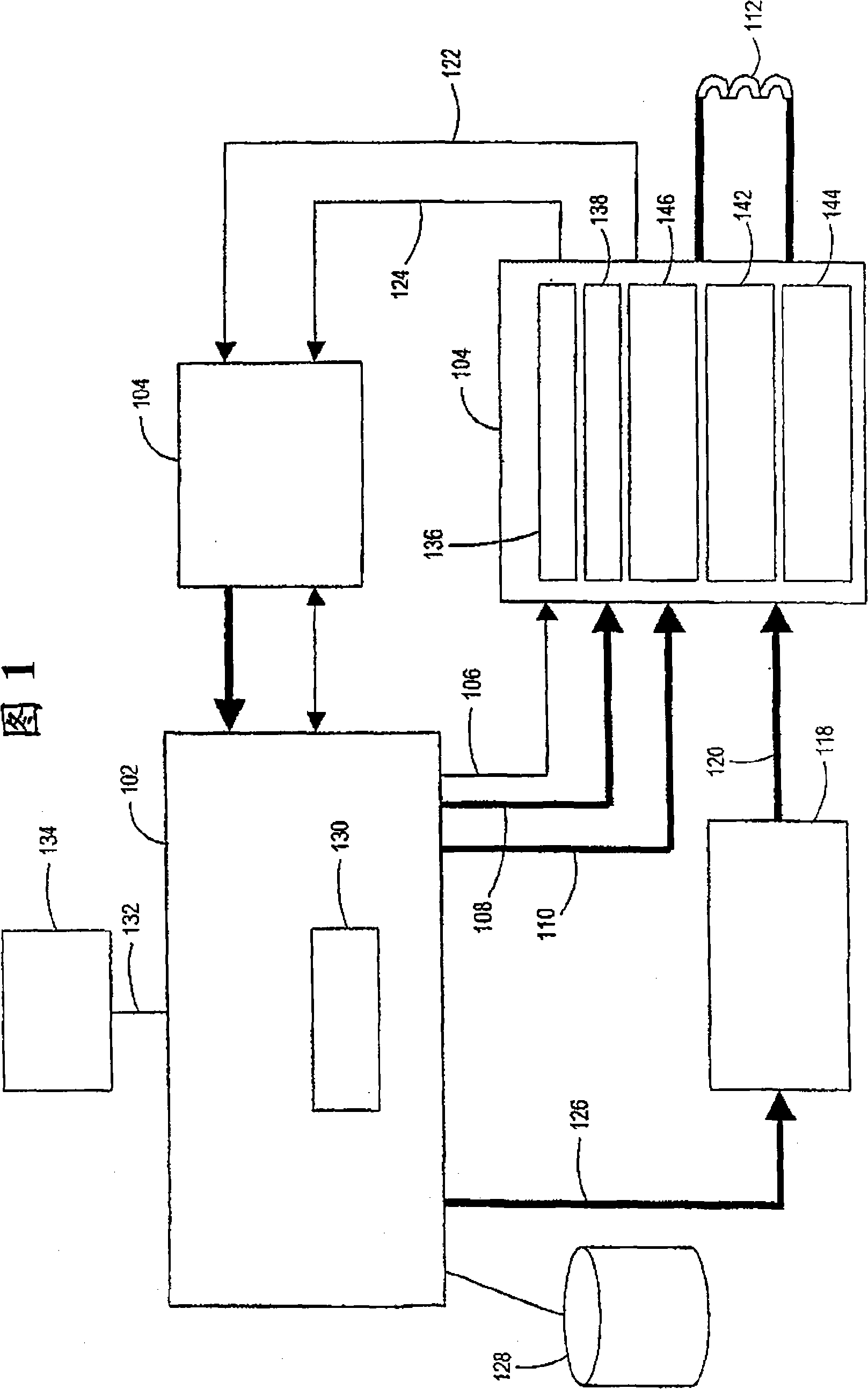

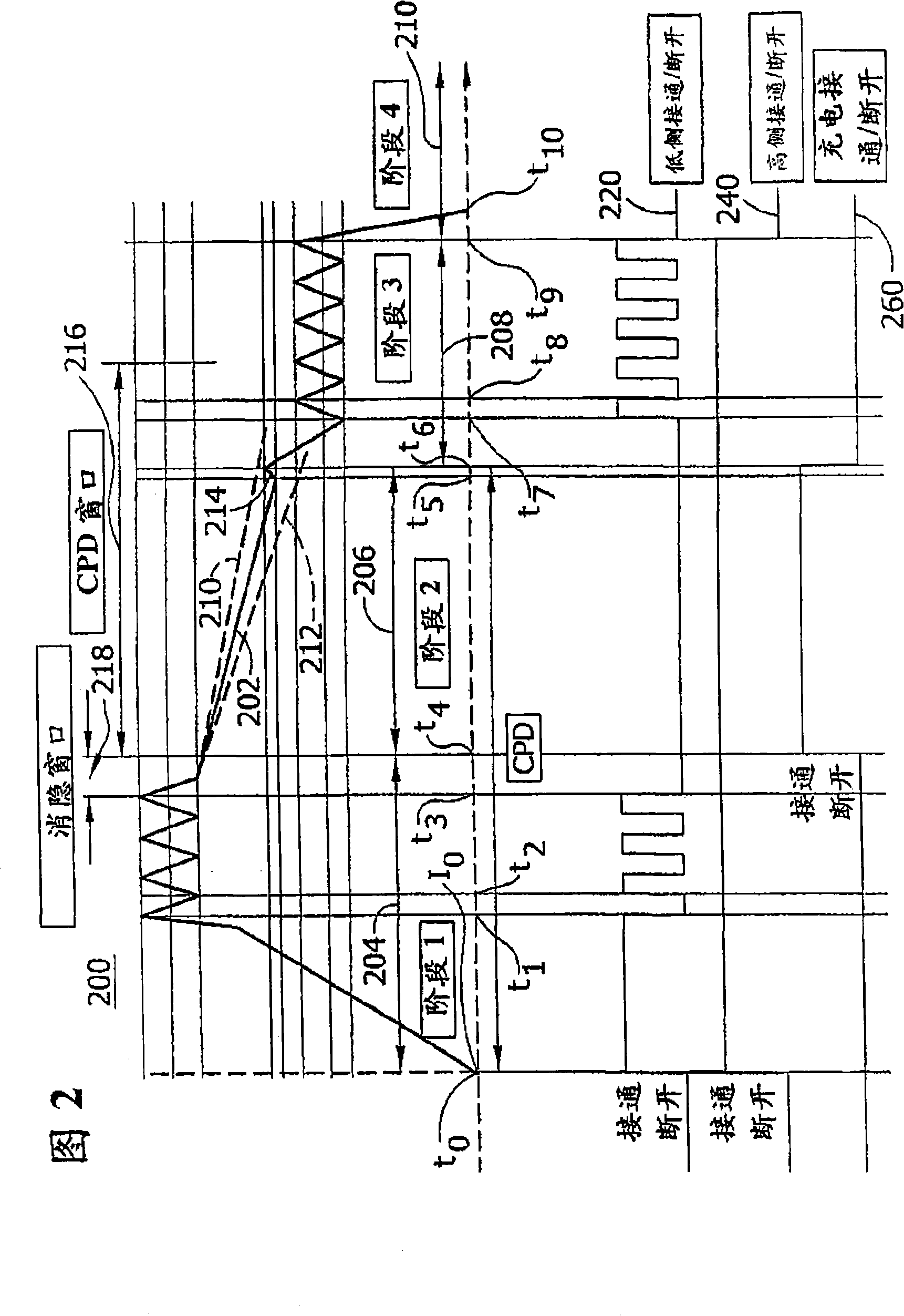

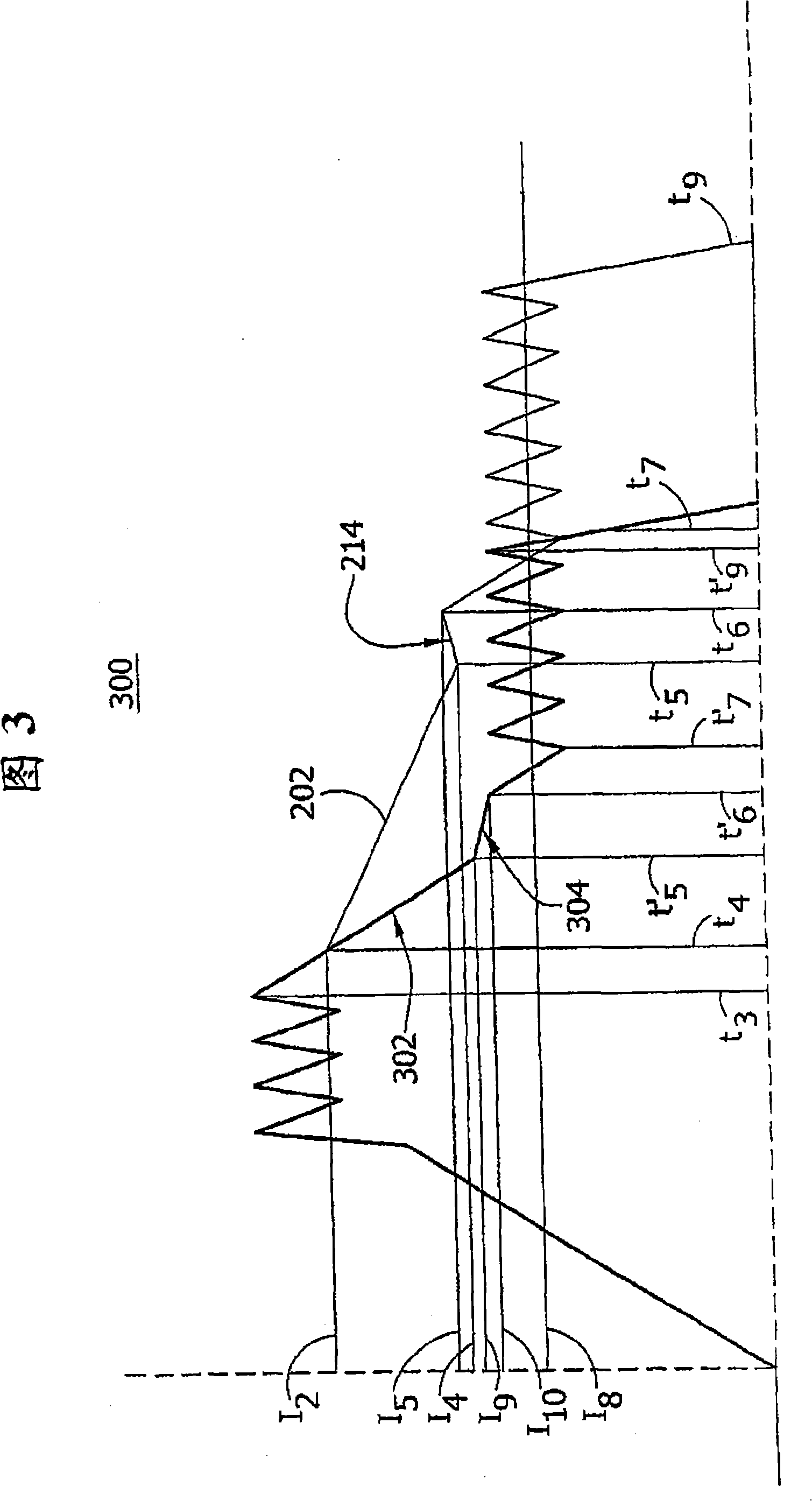

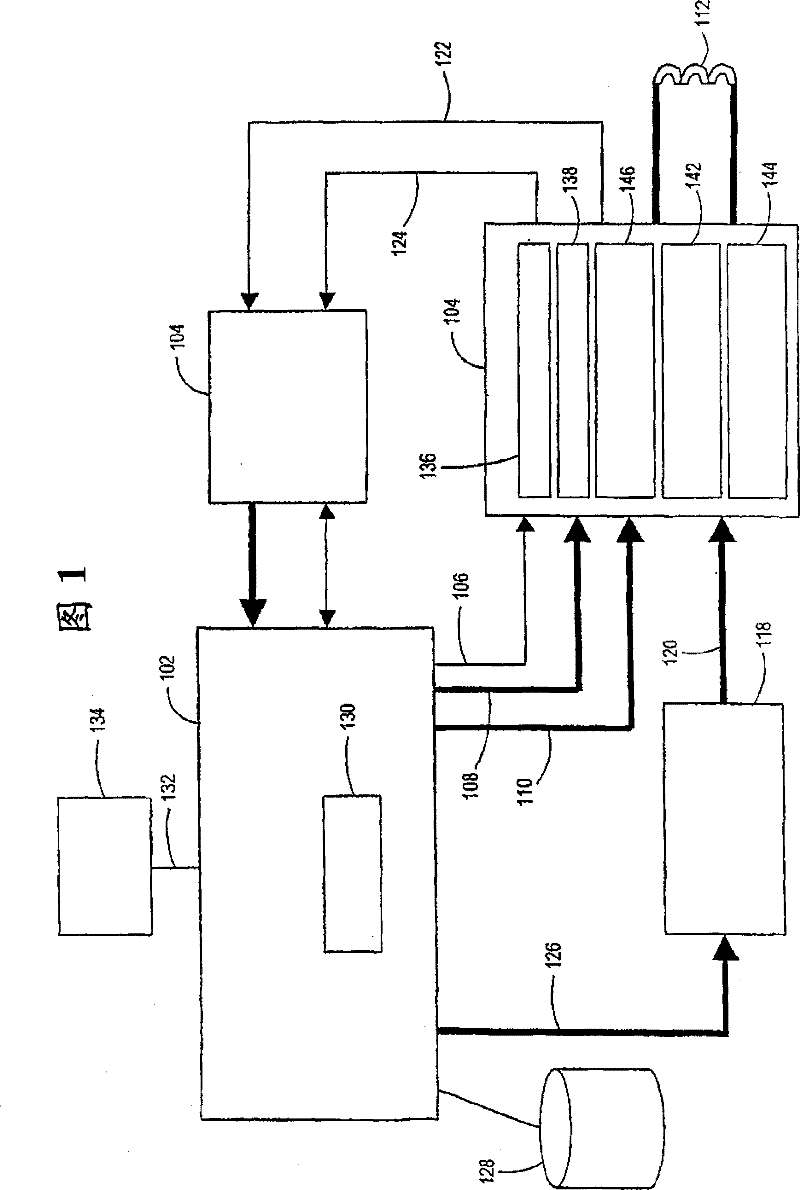

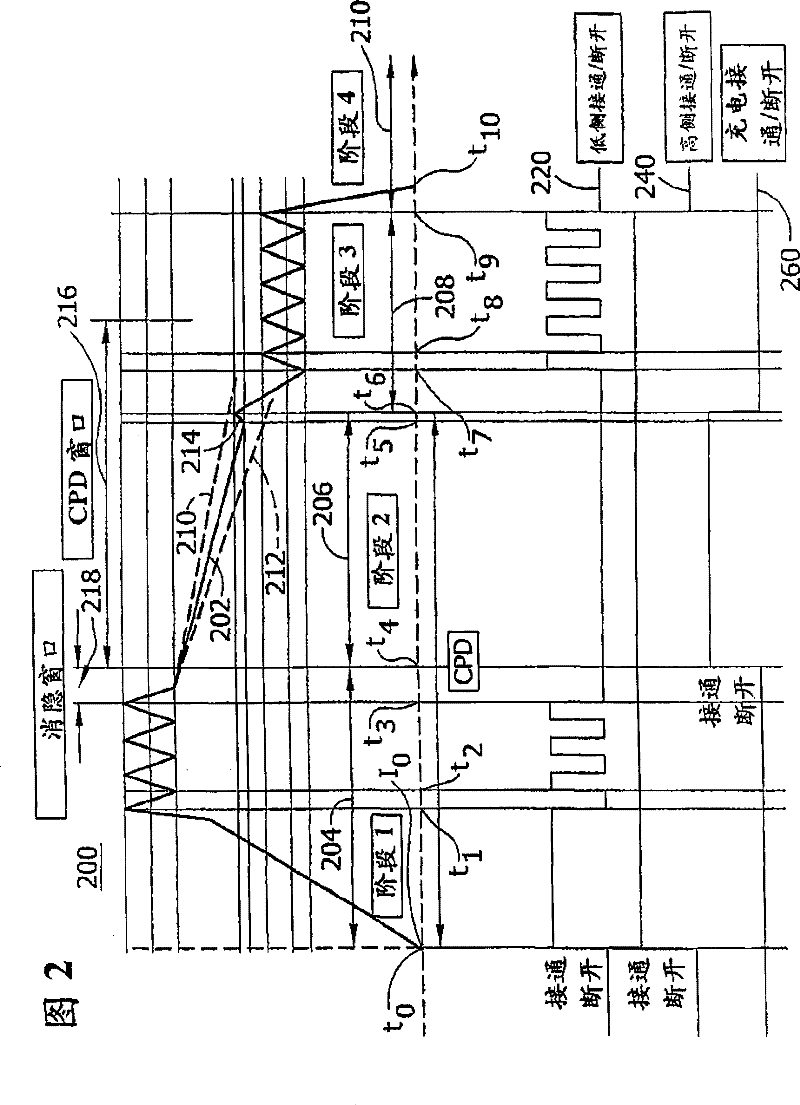

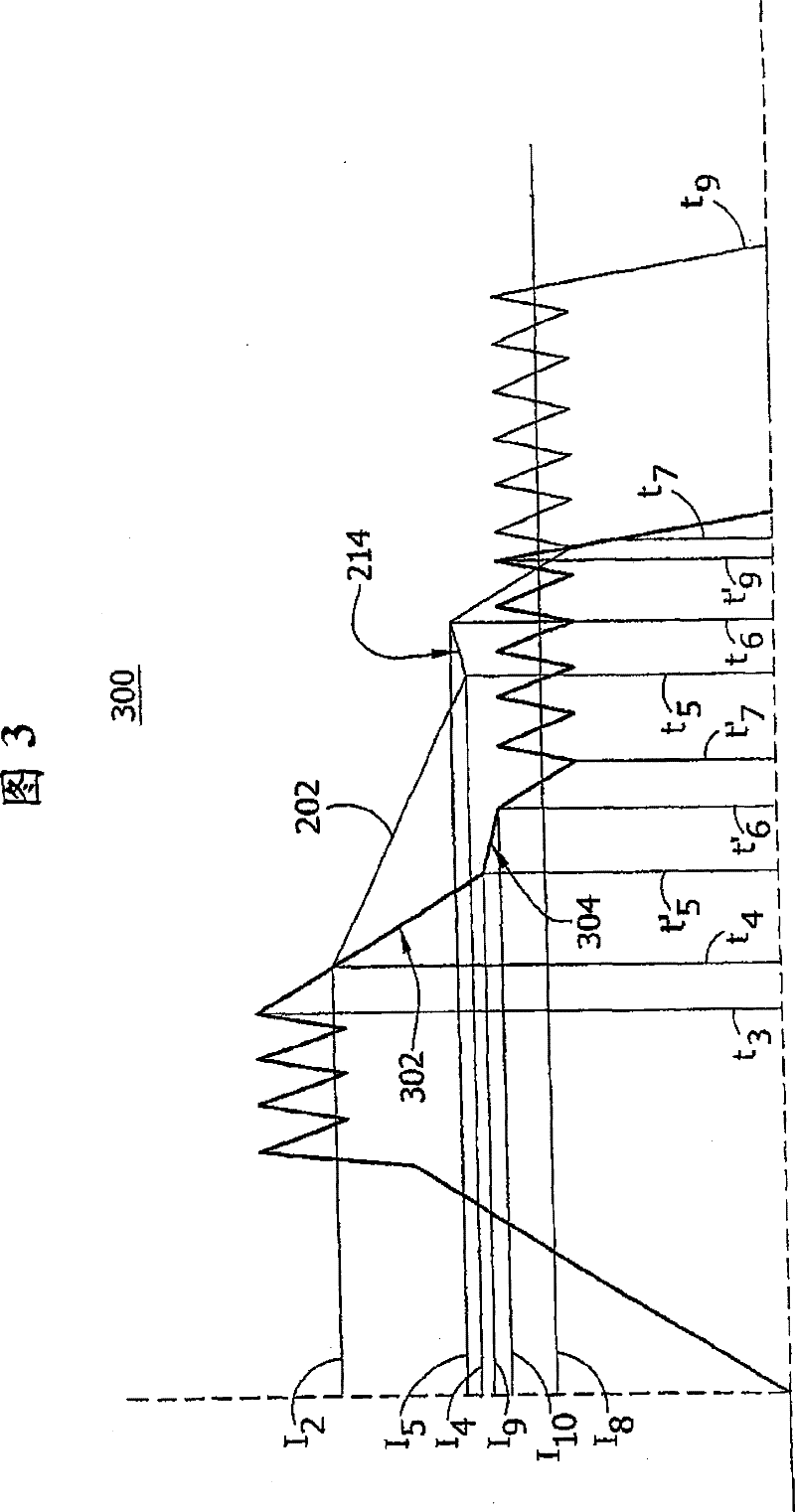

Apparatus and method for accurate detection of locomotive fuel injection pump solenoid closure

The invention relates to a system and method for detecting a closing of a solenoid. The system includes a capacity charge circuit electrically coupled to the solenoid. The capacity charge circuit conditions the current flow through the solenoid to increase the current in response to the closing of the solenoid. The invention also relates to a system and method that includes detecting a current through the solenoid and determining a current slope characteristic. The current slope characteristic is a function of the current and time. The method also includes conditioning an electrical characteristic of the solenoid such that the conditioning is in response to a current slope parameter. The current slope parameter defines a change in the current after removal of an electrical charge to the solenoid.

Owner:GENERAL ELECTRIC CO

Dropping suspended wire retaining arm unit for heavy rod drawing machine

InactiveCN106698074AIncrease profitImprove space utilizationFilament handlingMovement controlConductor Coil

The invention discloses a dropping suspended wire retaining arm unit for a heavy rod drawing machine; the dropping suspended wire retaining arm unit is disposed at a winding unit of the heavy rod drawing machine and comprises retaining arm posts, retaining rods and a retaining arm motion control module; the retaining rods are obliquely connected to the bottom ends of the retaining arm posts, the retaining arm posts are connected to the retaining arm motion control module in lifting manner, the retaining arm posts are disposed between an inner retaining post and outer retaining post of a winding iron frame, the retaining arm motion control module cycles around the axis of the winding iron frame along a fixed path, and the retaining arm motion control module is connected to a PLC (programmable logic control) system. The dropping suspended wire retaining arm unit is capable of smoothening dropping cable coils instead of manual winding and sorting, the cable coils can be stacked neatly, precisely and tightly, spatial utilization rate of a final wire coil is increased, utilization rate of the winding iron frame is increased, manpower can be freed, operation is safe, and working efficiency is high.

Owner:XINXING PIPES ZHEJIANG COPPER

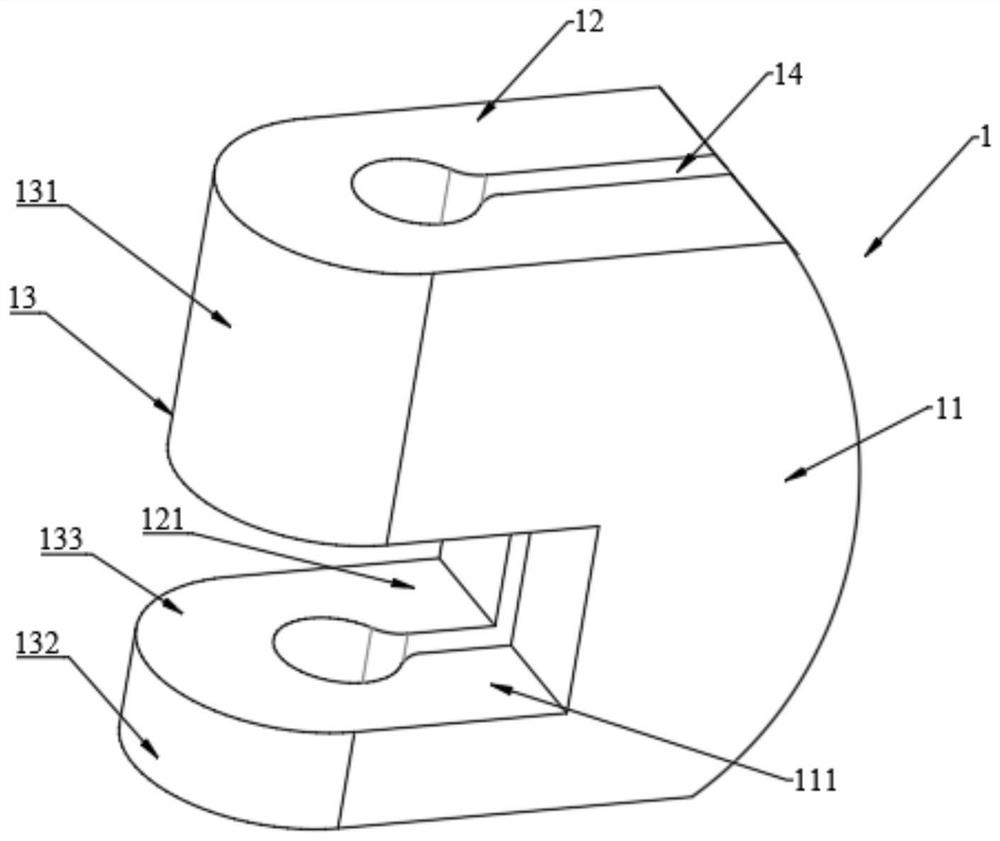

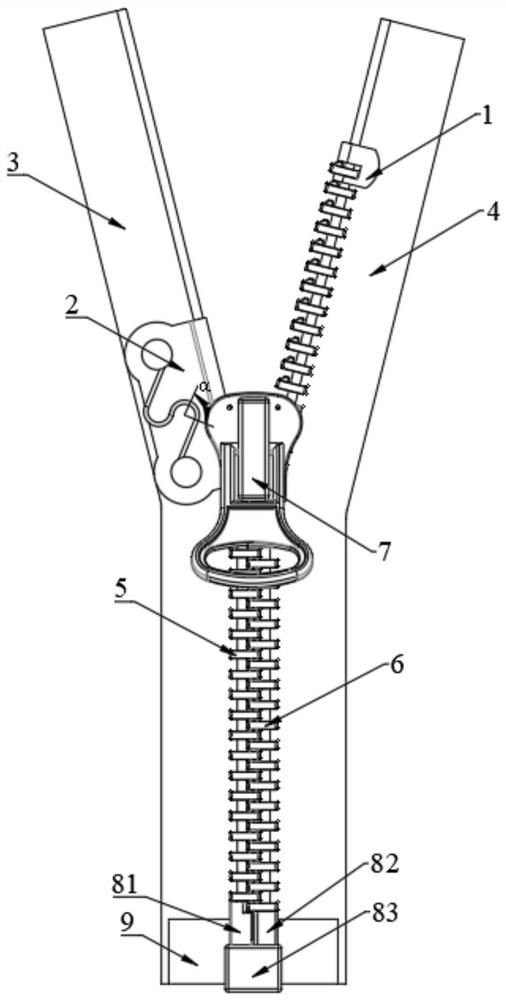

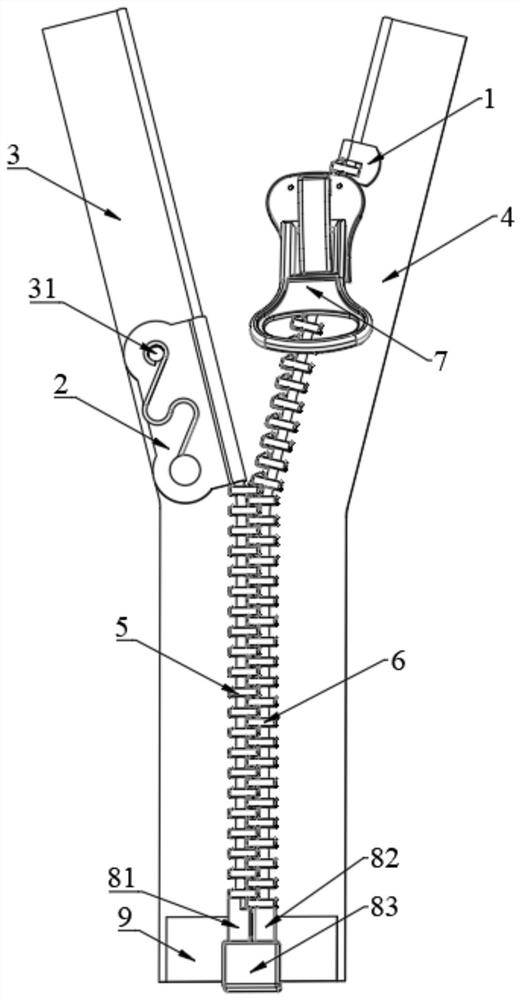

Tooth covering top stopper, metal zipper with special function and using method of zipper

The invention relates to a tooth covering top stopper, a metal zipper with a special function and a using method of the zipper. The tooth covering top stopper comprises a front clamping copper sheet,a rear clamping copper sheet and a transition copper sheet, a front transverse notch is formed in the middle of the front clamping copper sheet, a rear transverse notch is formed in the middle of therear clamping copper sheet, and the transition copper sheet comprises an upper transition copper sheet, a lower transition copper sheet and a transition channel; the metal zipper comprises a left cloth belt, a right cloth belt, left zipper teeth, right zipper teeth, a puller, a left top stopper assembly and a right top stopper, wherein the right top stopper is the tooth covering top stopper. The left top stopper assembly comprises a left copper piece, a first rivet, a second rivet and a spring connecting piece, the first rivet, the second rivet and the spring connecting piece are arranged on the outer surface of the left copper piece, the spring connecting piece is of an S-shaped structure, and the corresponding central angle of an arc at the bent transition position of the spring connecting piece ranges from 75 degrees to 135 degrees. The tooth covering top stopper is fixed on the cloth belt after being embedded with the zipper teeth, so that the connection strength is high; the metalzipper with the special function can be separated from the upper end or the lower end of the zipper belt, quick disassembly of the zipper is achieved, and the zipper is convenient to use and long inservice life.

Owner:JIANGSU CMZ ZIPPER SCI & TECH CO LTD

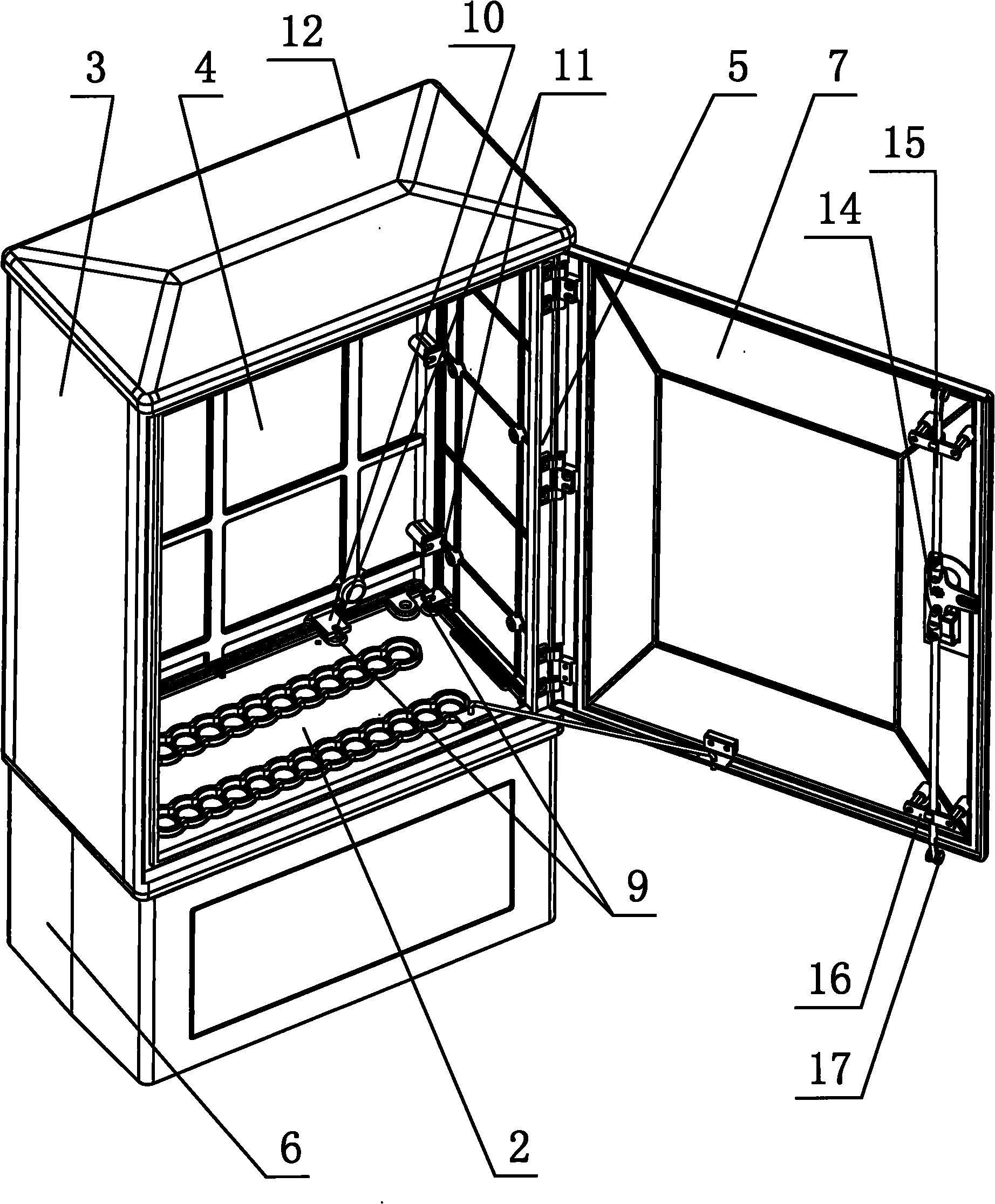

Combined optical cable distribution cabinet

Owner:宁波华缘复合新材料有限公司

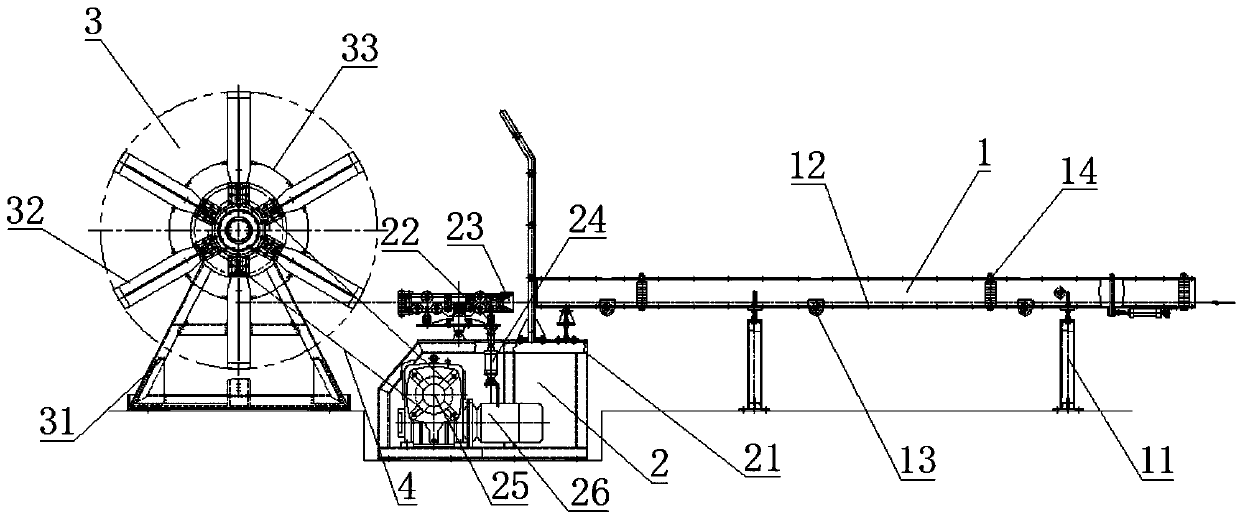

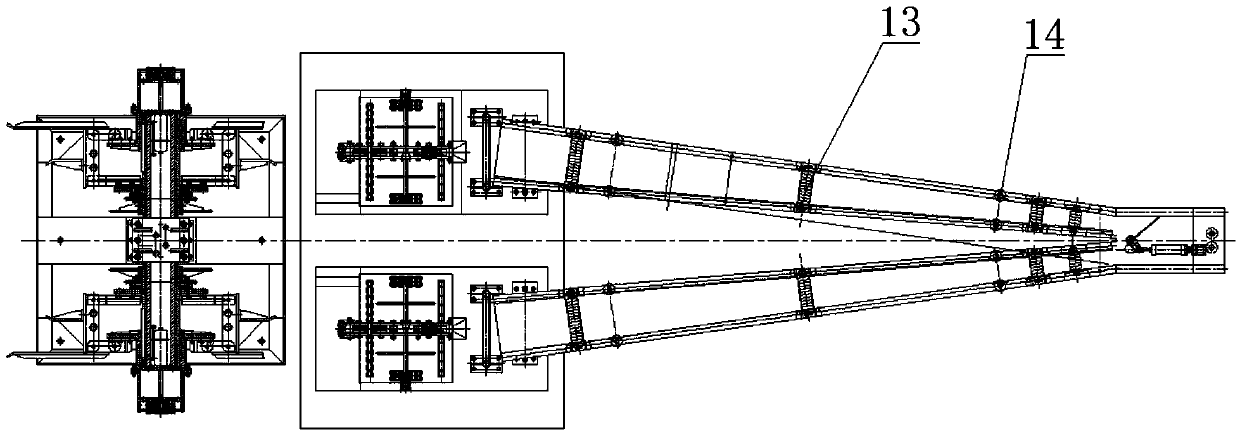

Precision wire-arranging windmill type take-up machine

The invention relates to the technical field of automatic take-up, and is mainly applied to a spring steel wire stabilizing treatment production line and a pre-stress steel wire production line. The invention specifically discloses a precision wire-arranging windmill type take-up machine which comprises a wire guide device, a wire-arranging machine and a take-up machine, wherein the wire guide device comprises a wire supporting rack and two guide wire slots; a plurality of transverse rollers and vertical rollers are mounted in the guide wire slots; the wire-arranging machine comprises a supporting base, a motor positioned in the supporting base, a transmission shaft connected to the motor, a guide rail positioned above the supporting base and a wire-arranging device capable of sliding on the guide rail; and the take-up machine comprises a rack, a rotary body mounted on the rack and a take-up plate. The precision wire-arranging windmill type take-up machine has the advantages that the structure is compact, the problems of un-tight take-up, irregular wire arranging and disordered wires during high-speed wire paying-off are solved, the product packaging external appearance is improved, the use is convenient, the production efficiency is improved, the production cost is reduced, and online once winding and take-up is realized.

Owner:张谊马

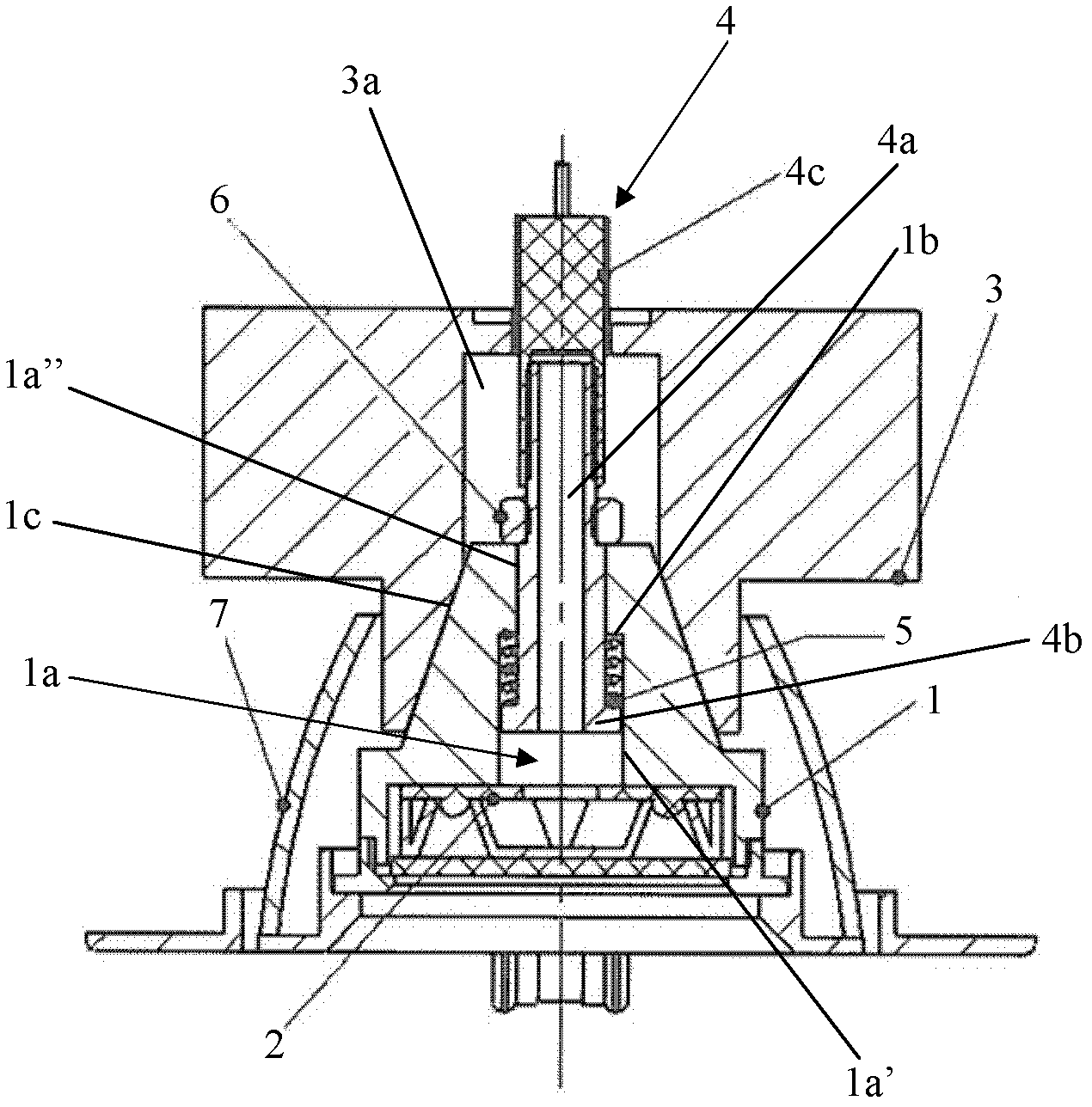

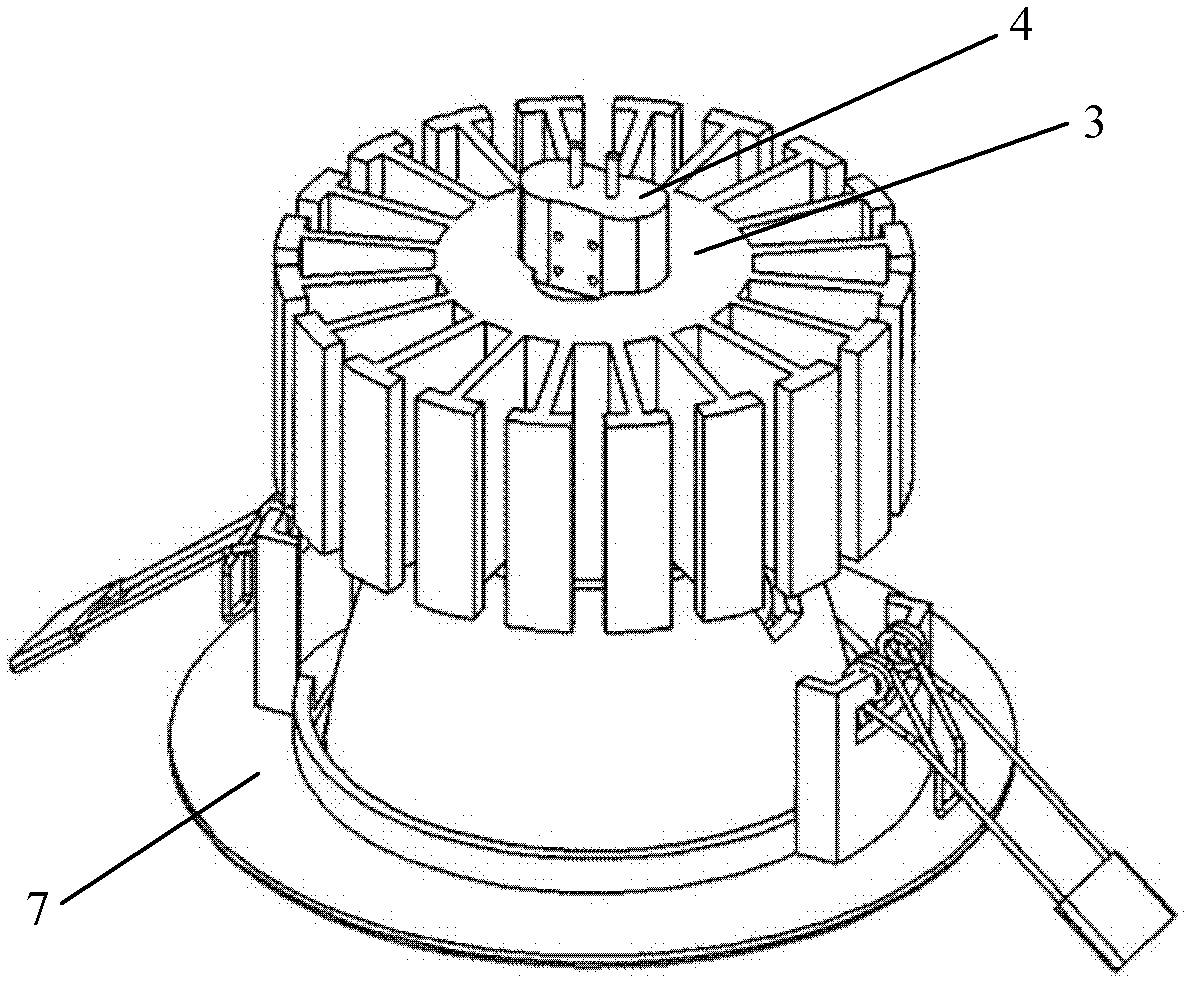

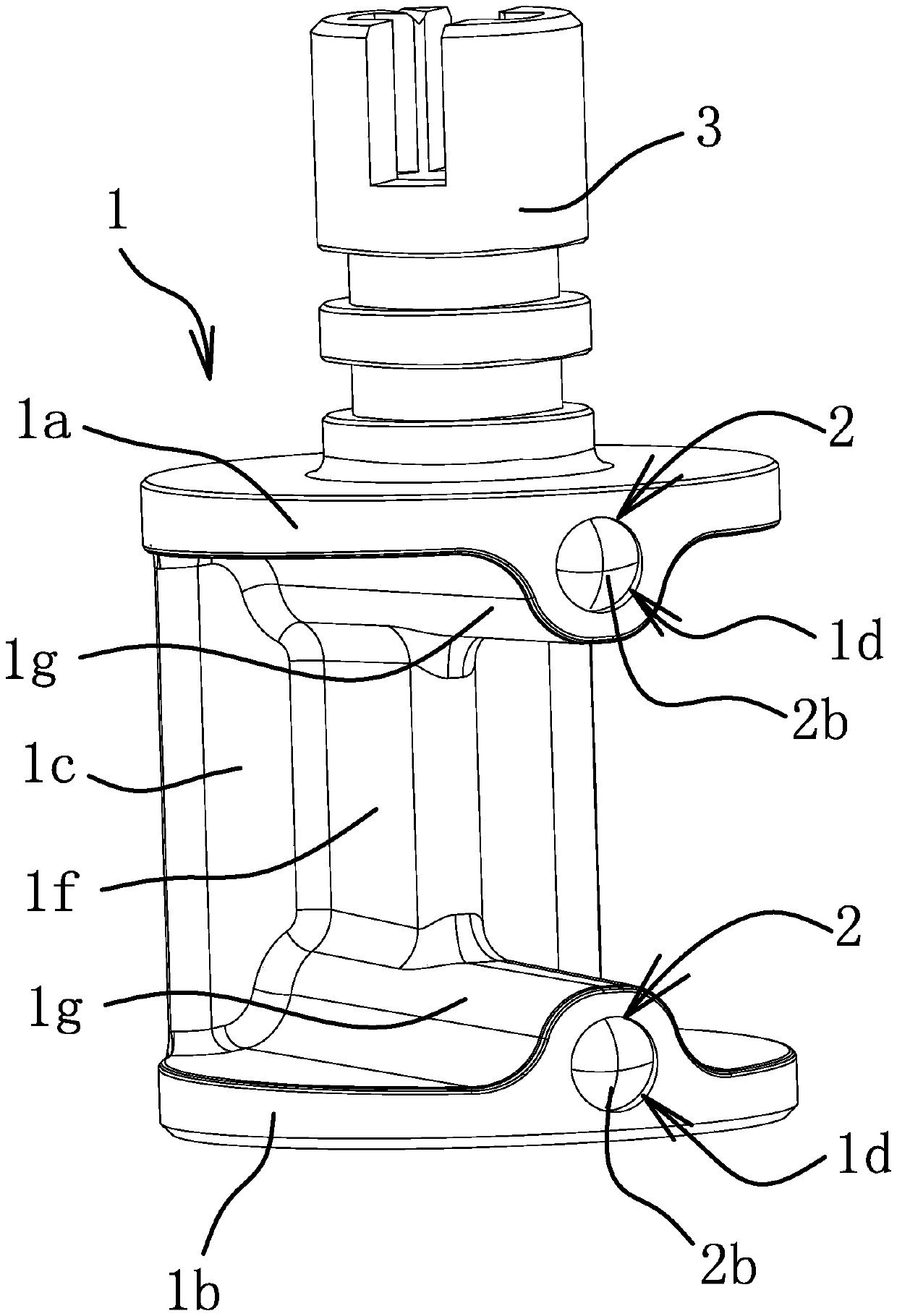

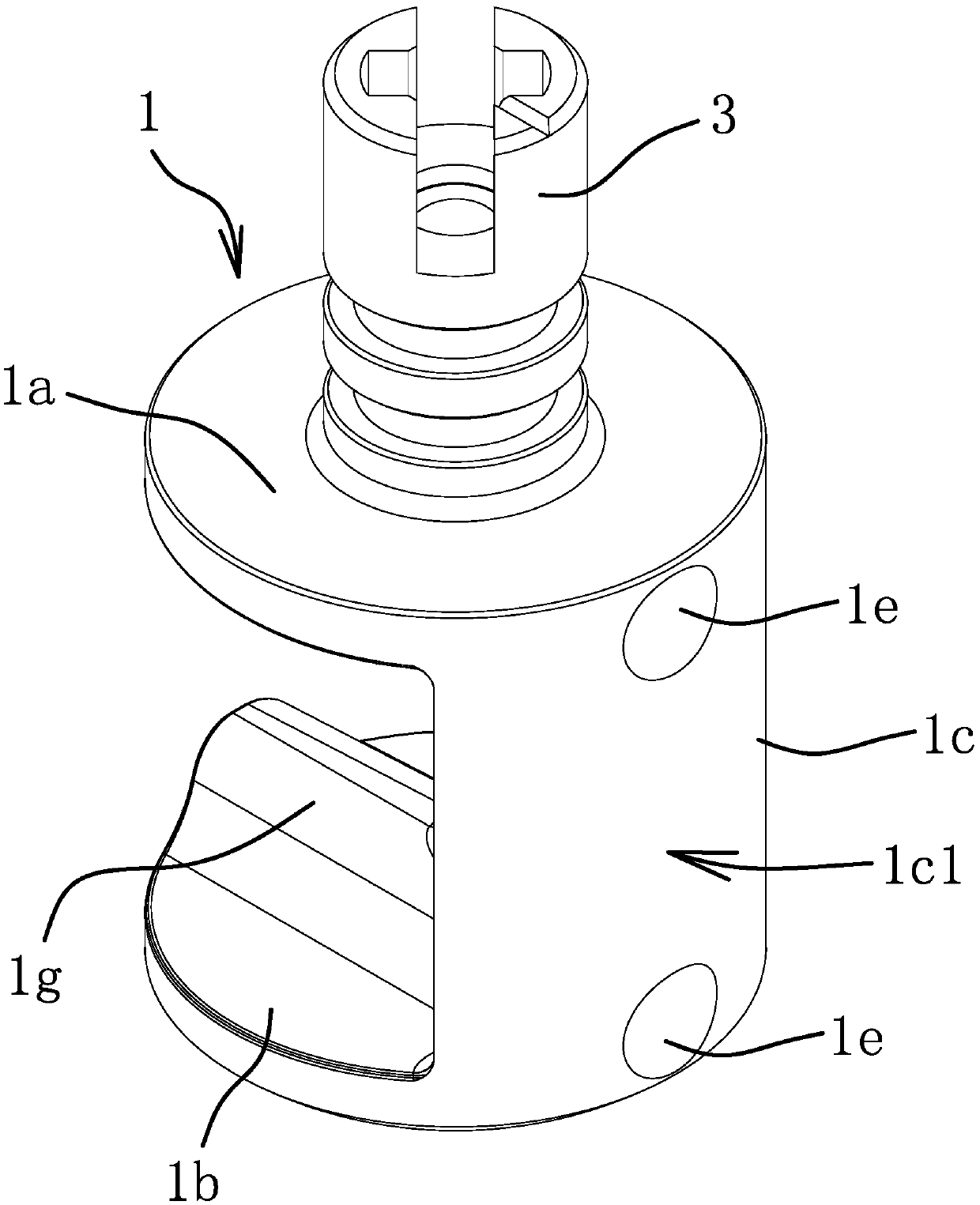

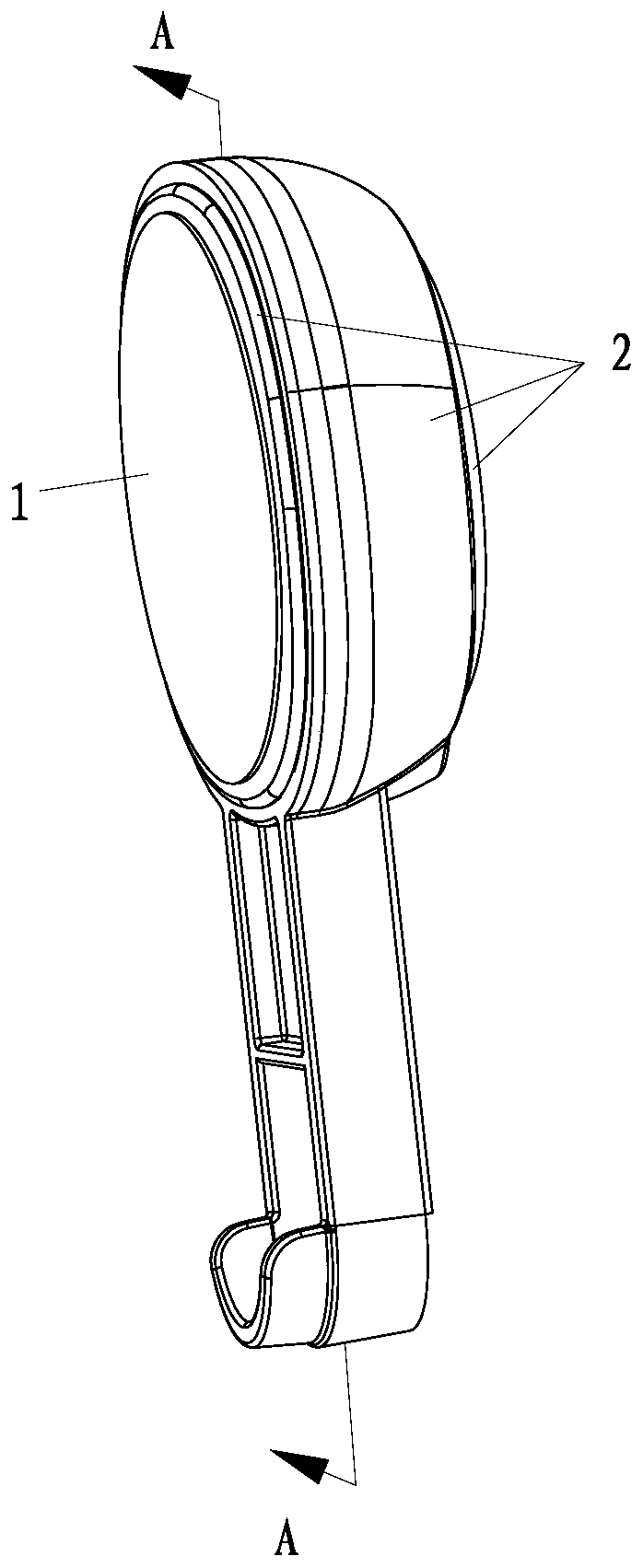

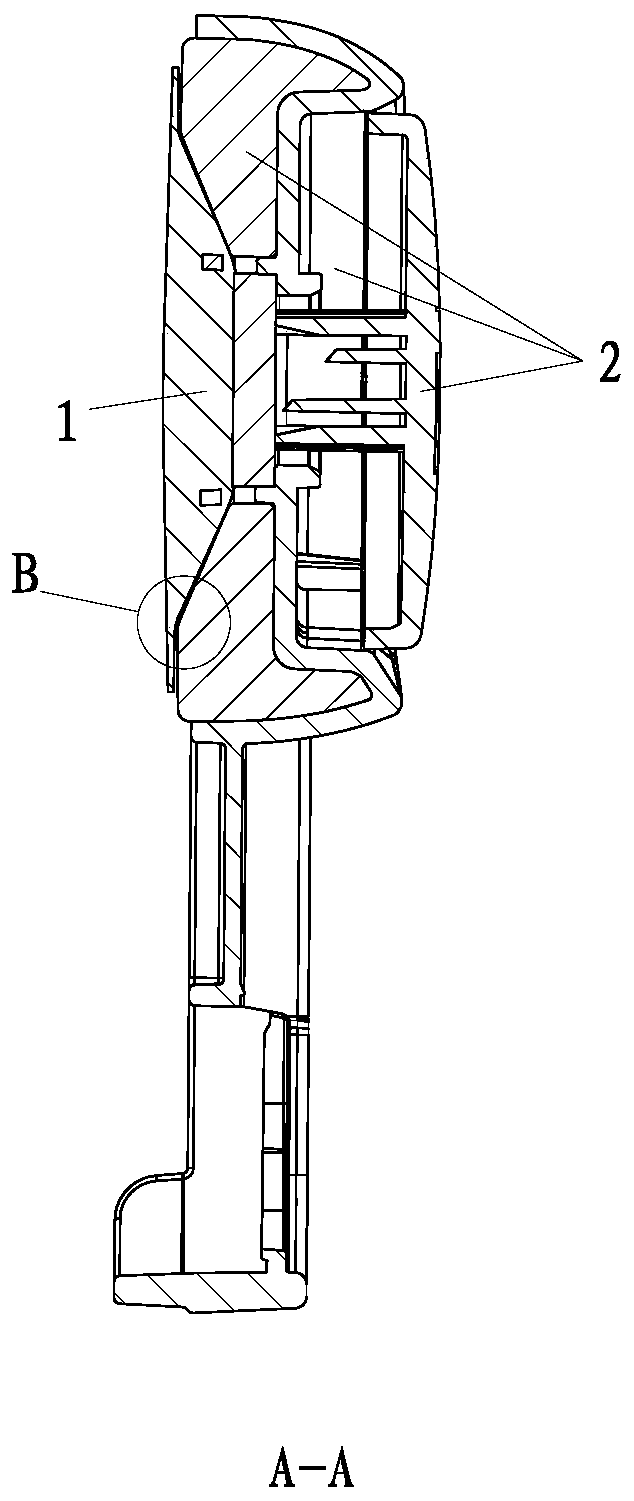

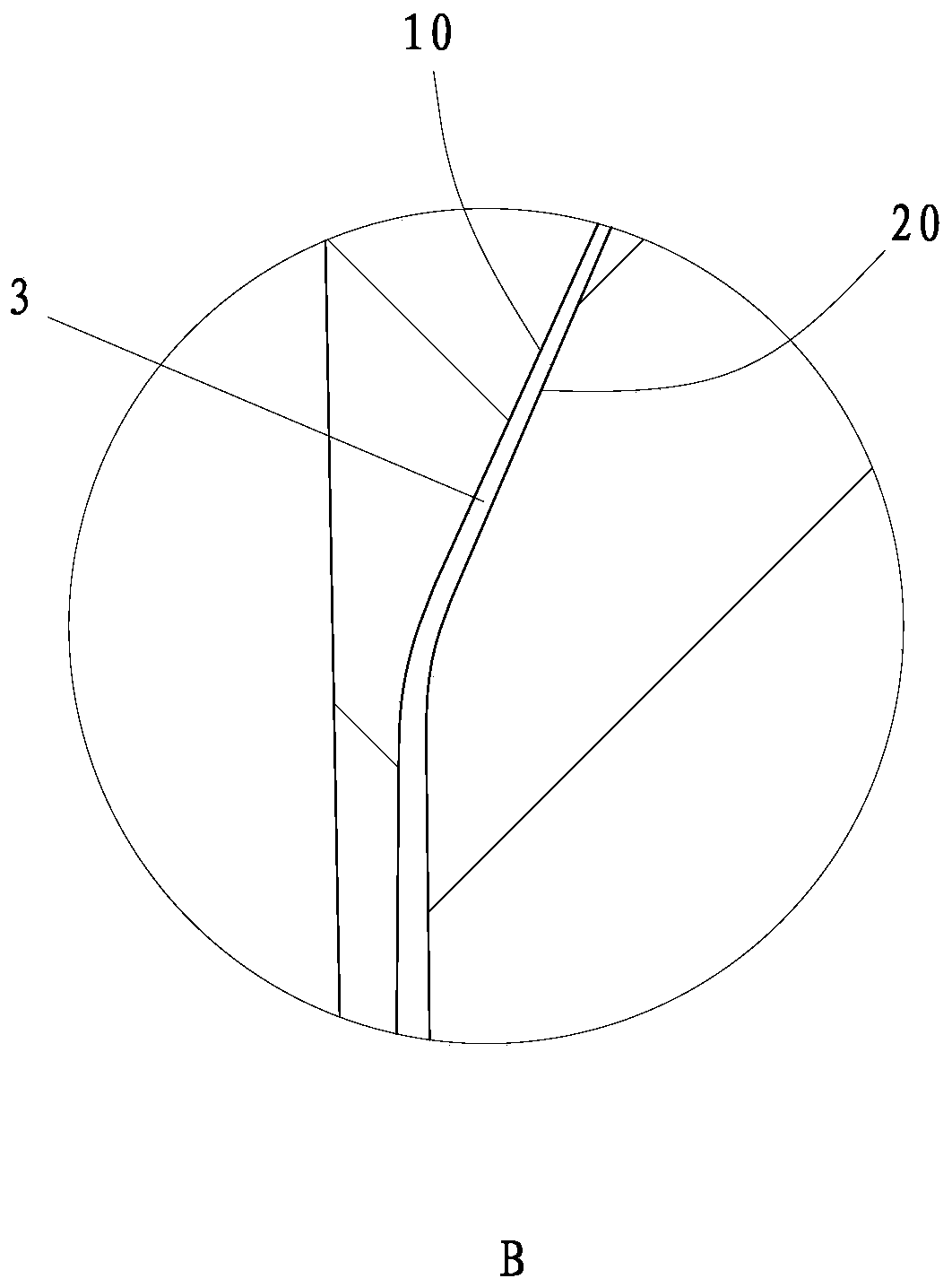

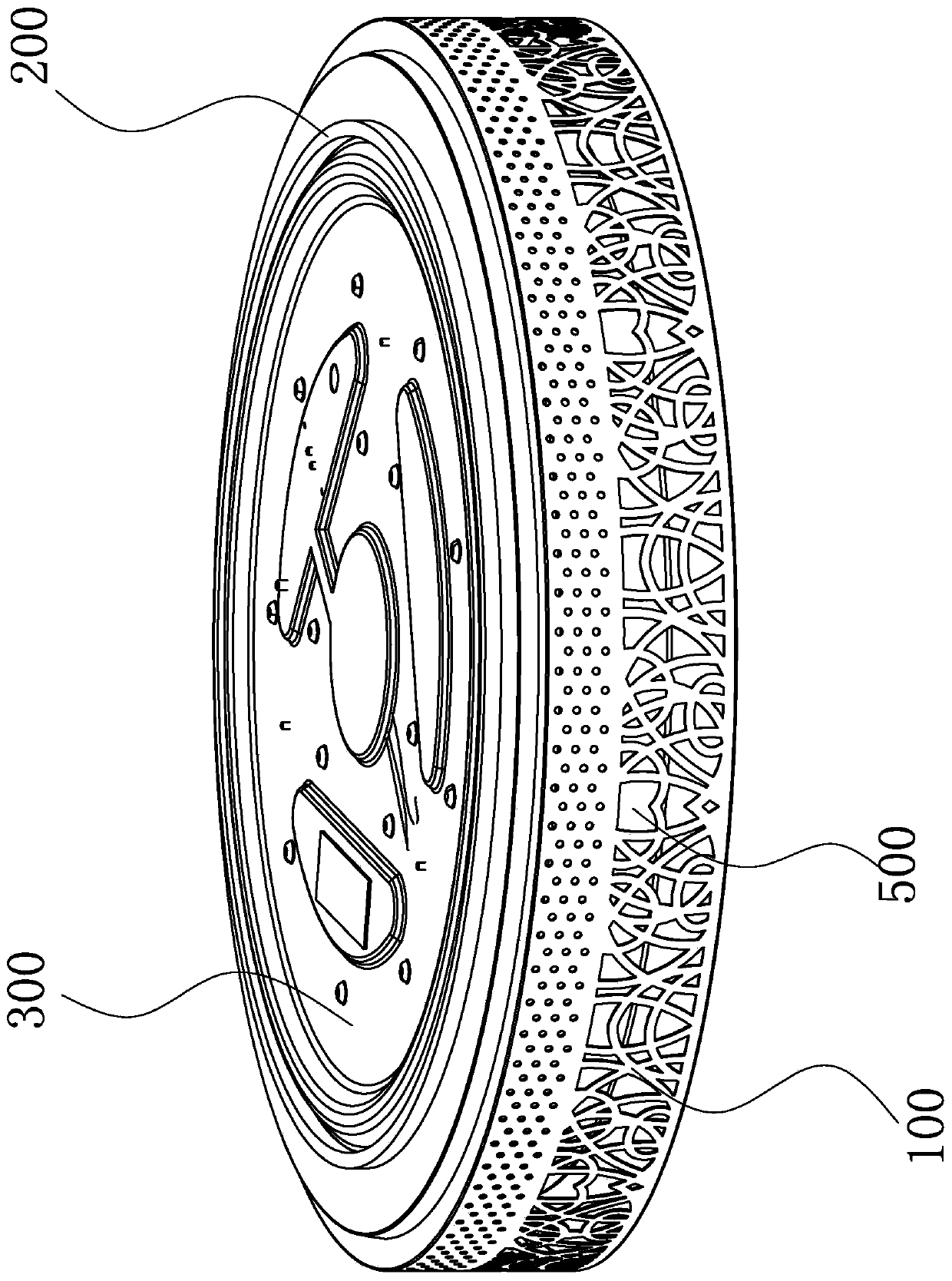

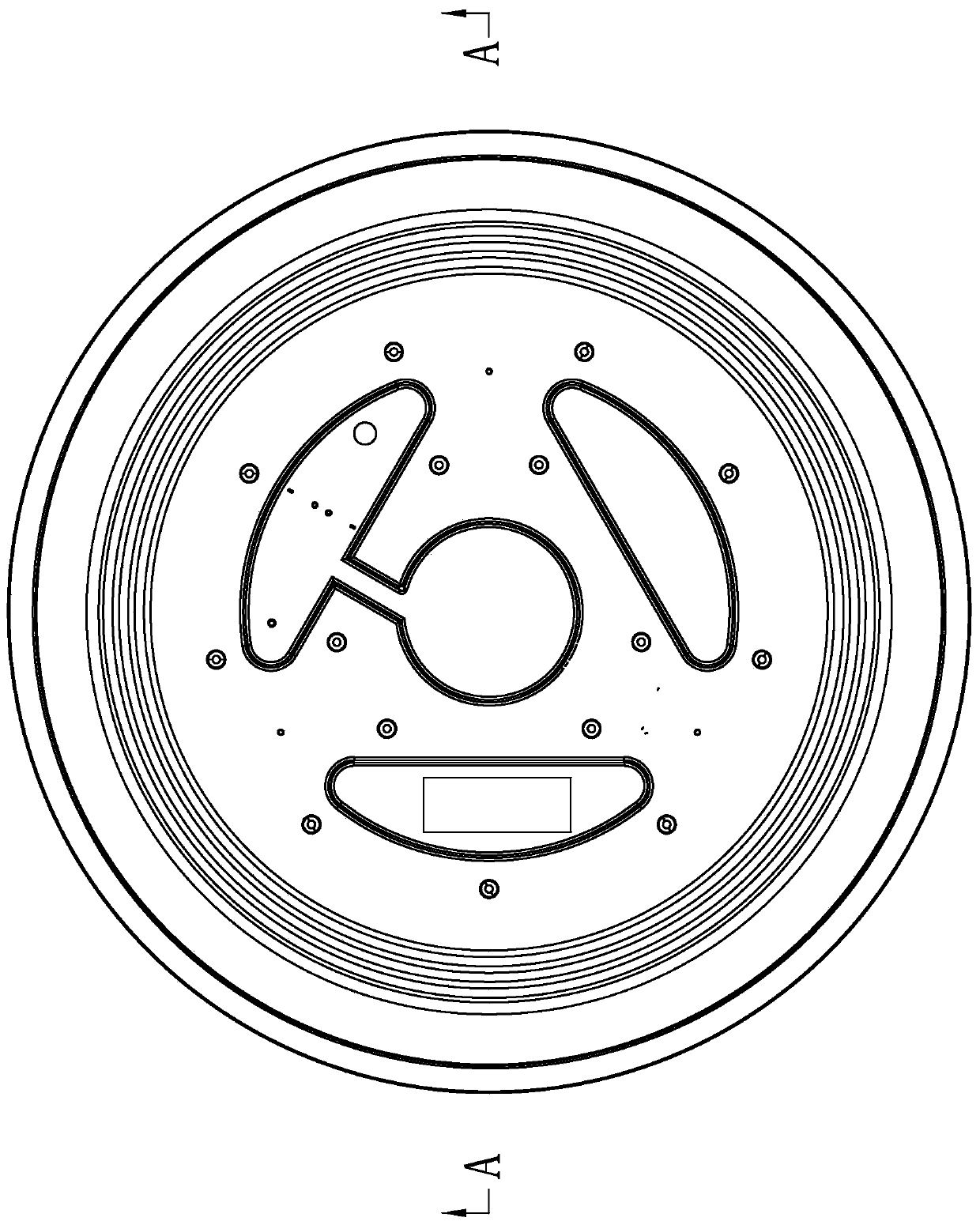

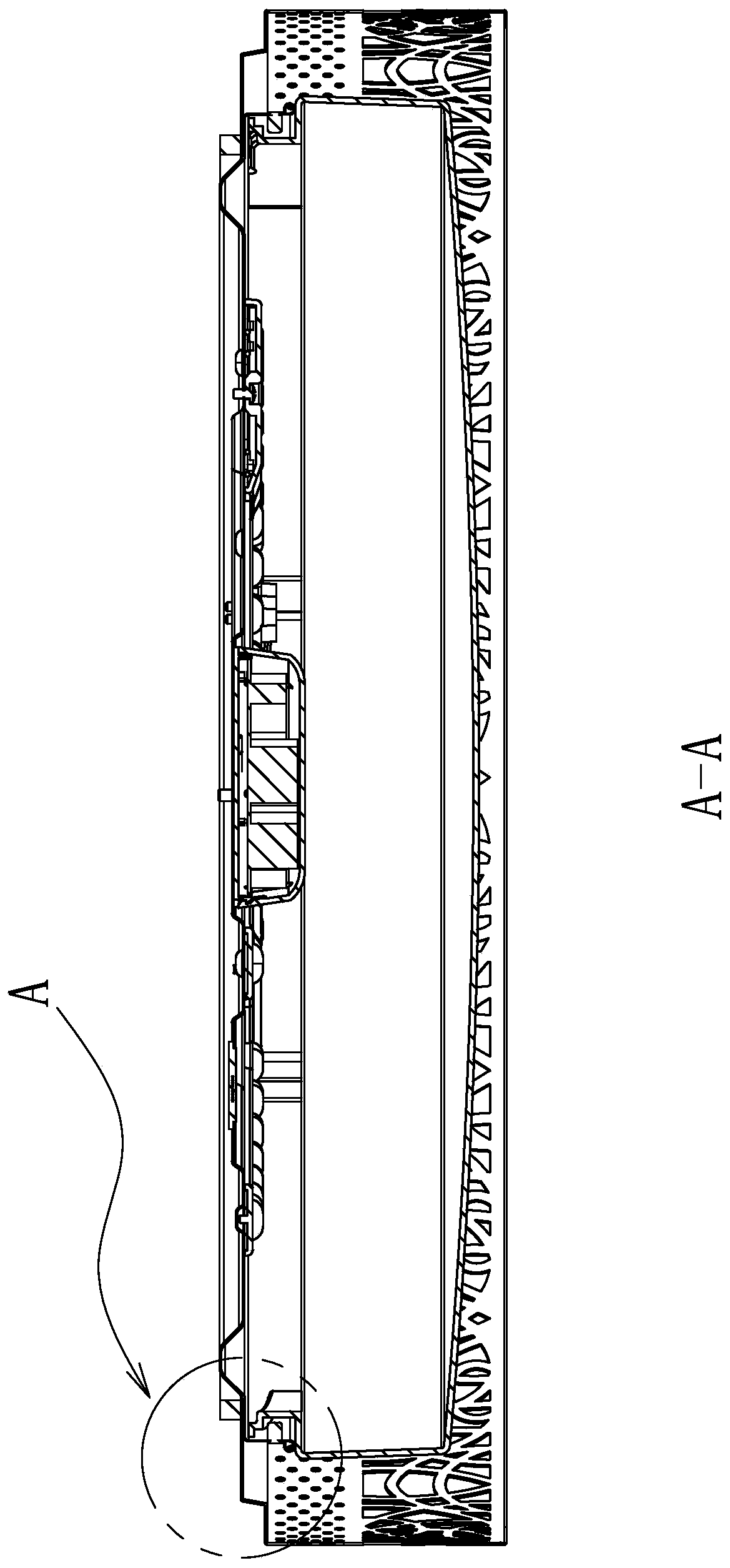

Luminous assembly, light-emitting diode (LED) modified lamp and assembling method of LED modified lamp

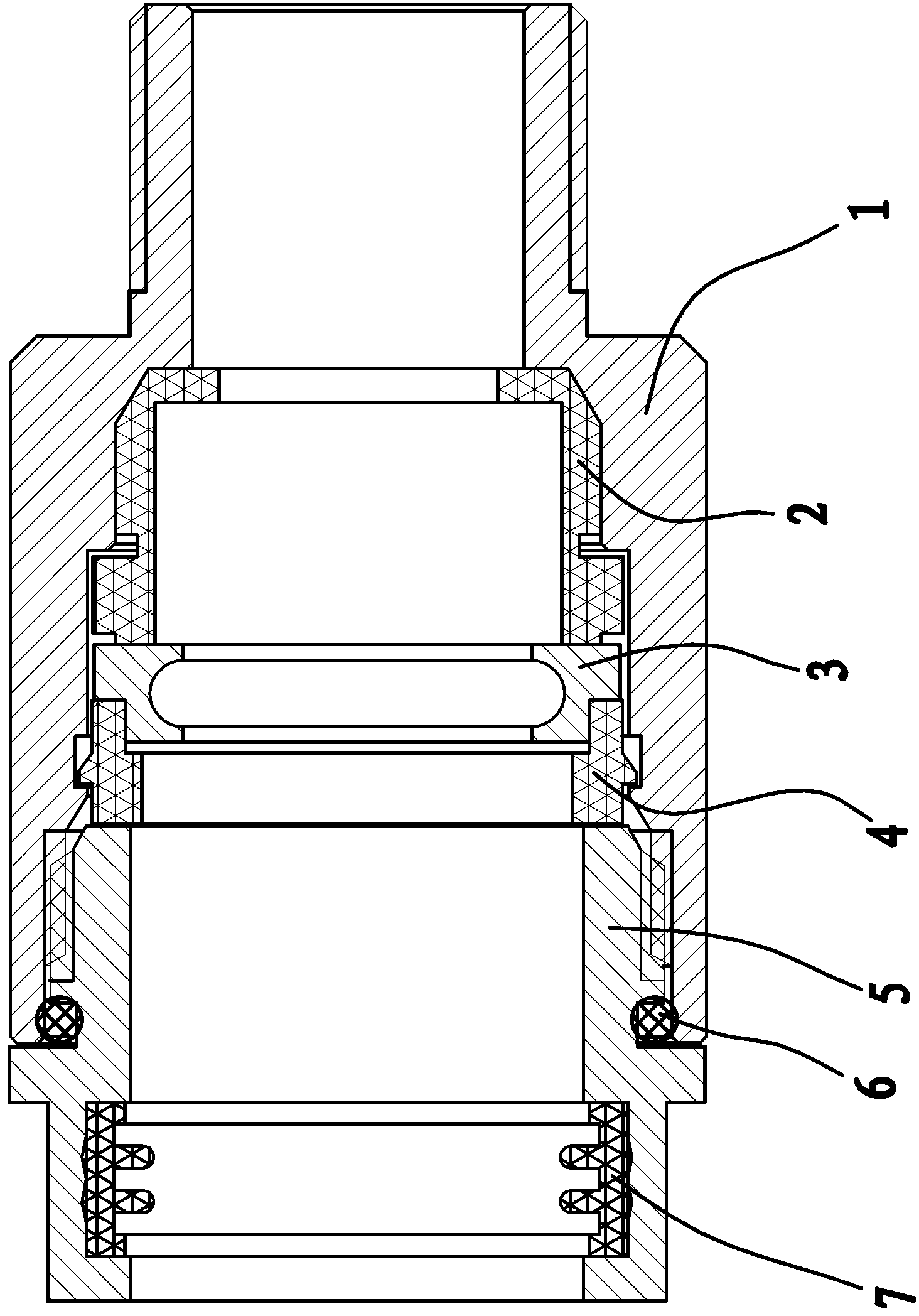

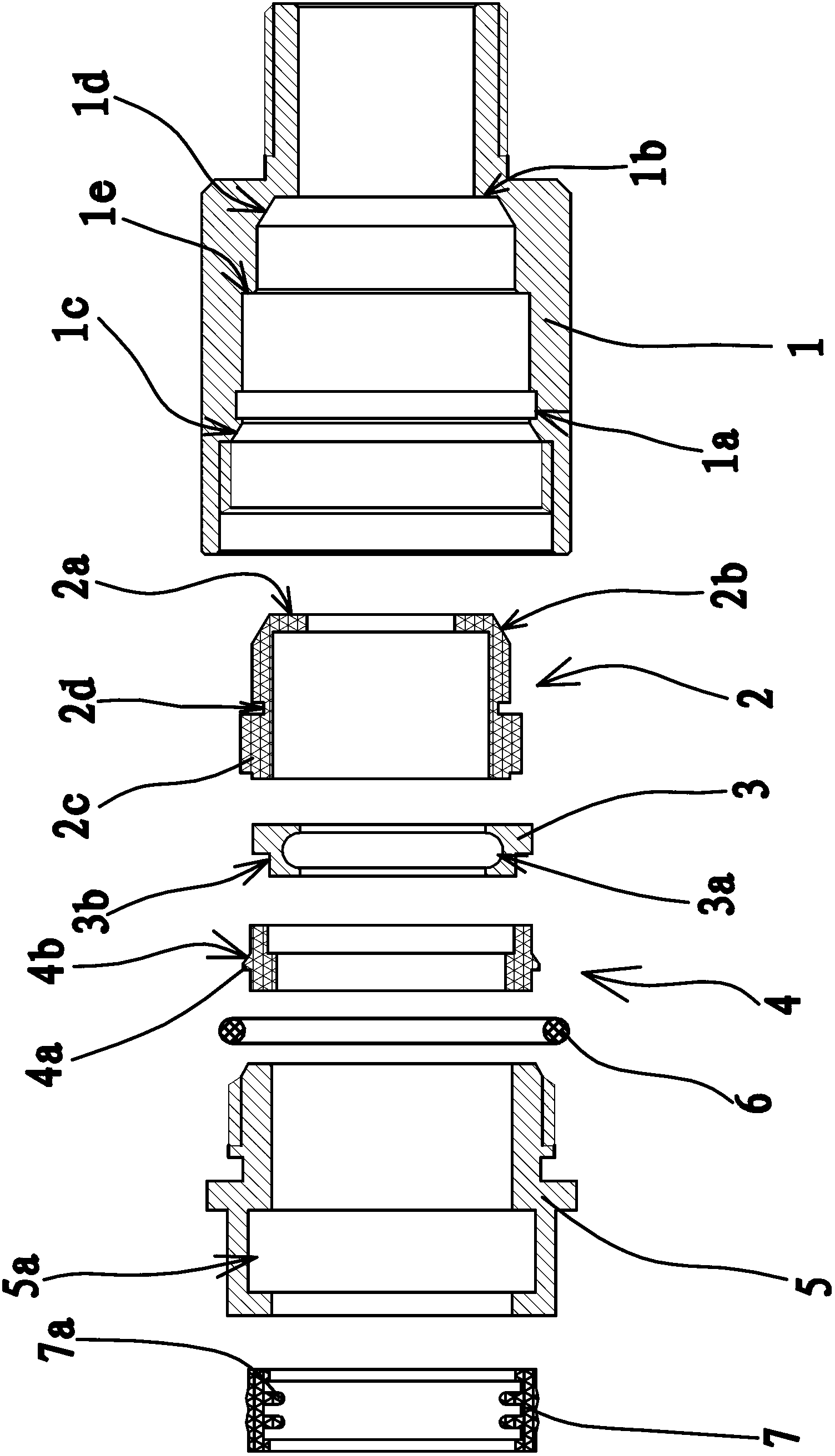

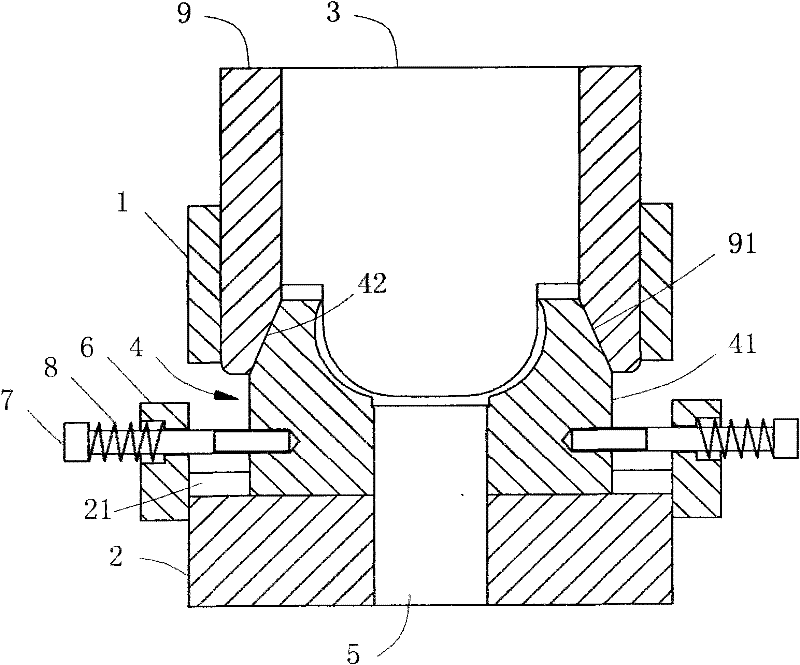

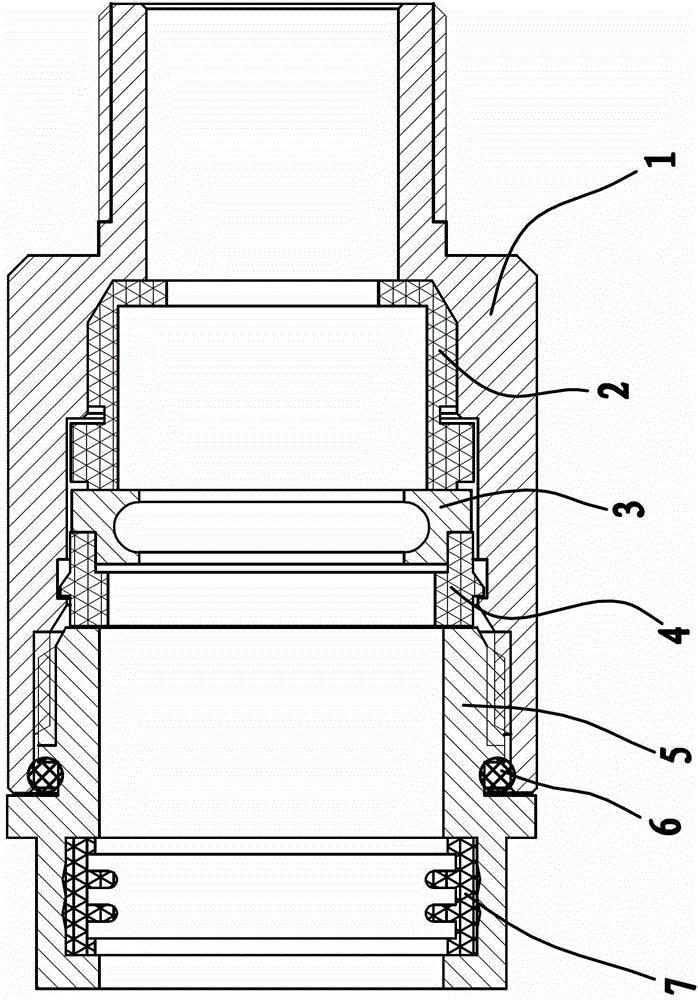

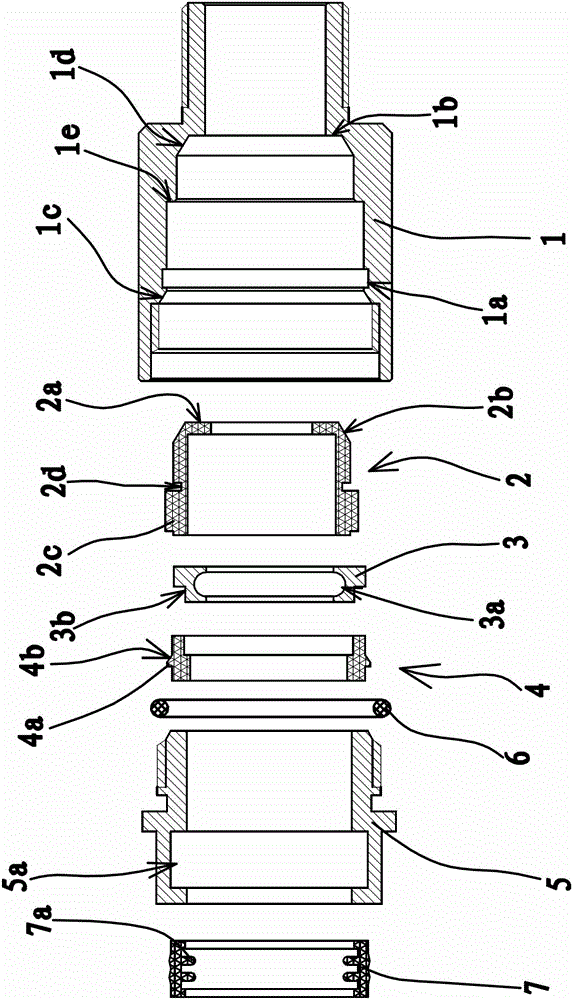

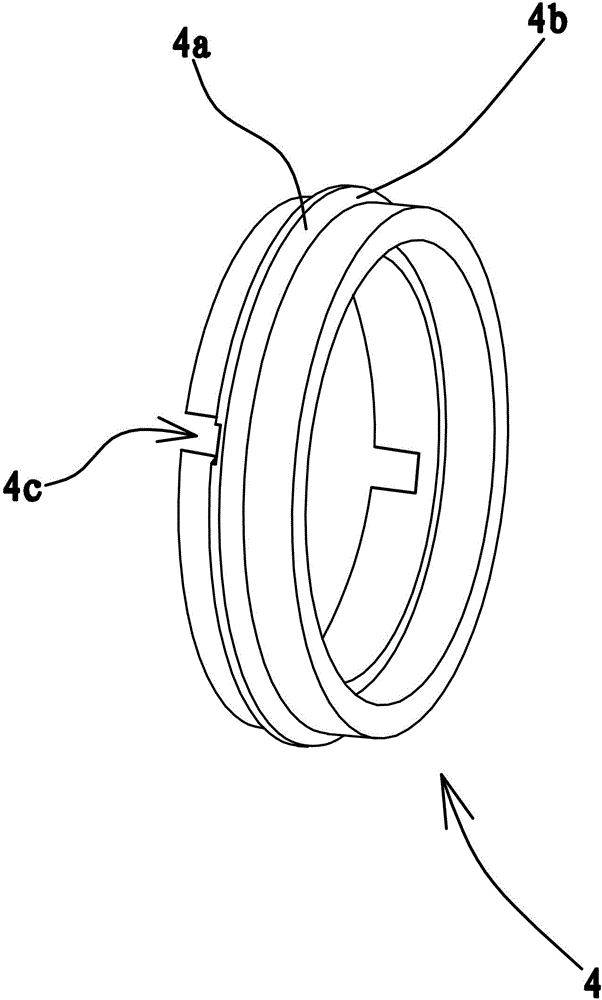

InactiveCN103133891AClose upSpeed up heat transferPoint-like light sourceLighting heating/cooling arrangementsEngineeringLight-emitting diode

The invention relates to a luminous assembly. The luminous assembly comprises a shell body (1), a light source (2) which is arranged inside the shell body (1), and a radiator (3) which is arranged on an outer side face (1c) of the shell body (1), and the luminous assembly further comprises a maintaining assembly. The maintaining assembly comprises a maintaining rod (4), wherein the maintaining rod (4) protrudes out partly from the shell body (1) and can move between an initial position and a locking position, and the maintaining rod (4) penetrates into the radiator (3) at the initial position and enables the radiator (3) at the locking position (3) to abut against the outer side face (1c) of the shell body (1). Besides, the invention further relates to a light-emitting diode (LED) modified lamp with the luminous assembly and an assembling method of the LED modified lamp.

Owner:OSRAM GMBH

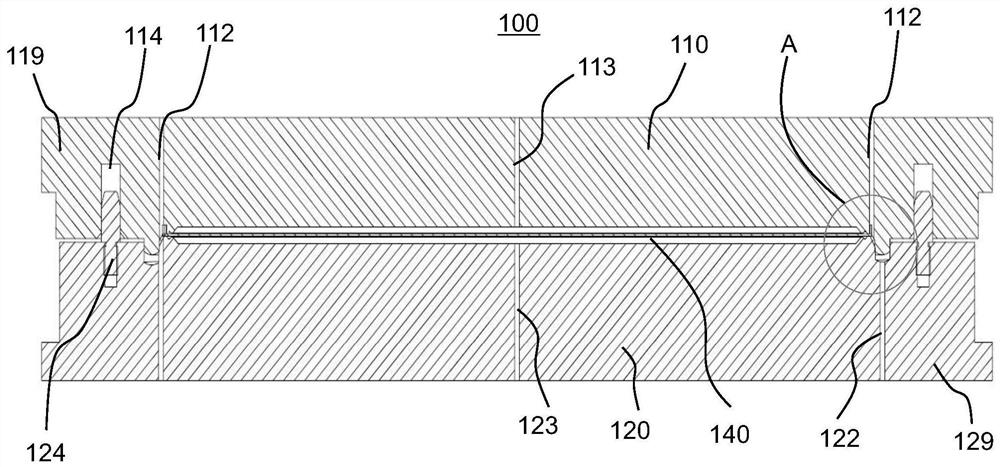

Semiconductor processing apparatus

PendingCN114188266AAchieve sealingReduce volumeSemiconductor/solid-state device manufacturingWaferEngineering

The invention provides a semiconductor processing apparatus. The semiconductor processing apparatus comprises a first chamber part; and a second chamber part. The first cavity part is provided with a first channel, the second cavity part is provided with a second channel, and when the second cavity part is located at a closed position relative to the first cavity part and a semiconductor wafer is accommodated in the microcavity, the first channel and the second channel are communicated and jointly form an edge microprocessing space at the edge of the wafer; the outer edge of the semiconductor wafer accommodated in the microchamber extends into the edge microprocessing space. The first cavity part is provided with a sealing joint part located on the outer side of the first channel, the second cavity part is provided with a joint groove corresponding to the sealing joint part, and by means of the edge micro-processing space, processing of the outer edge of the semiconductor wafer can be achieved.

Owner:WUXI HUAYING MICROELECTRONICS TECH CO LTD

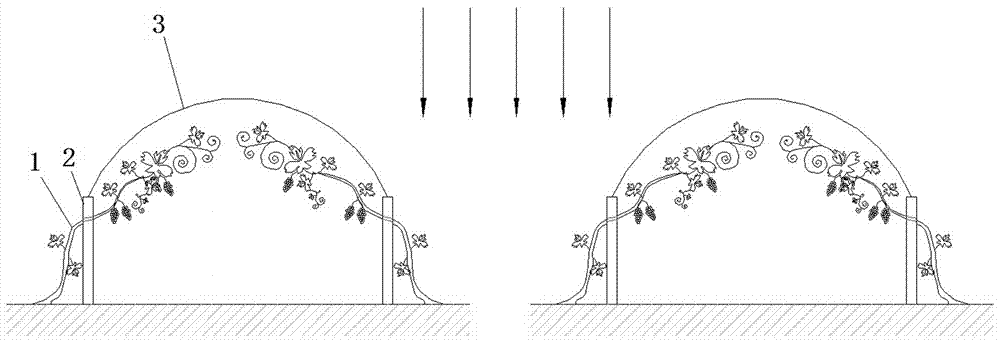

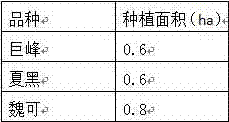

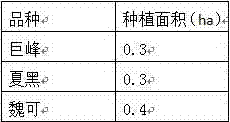

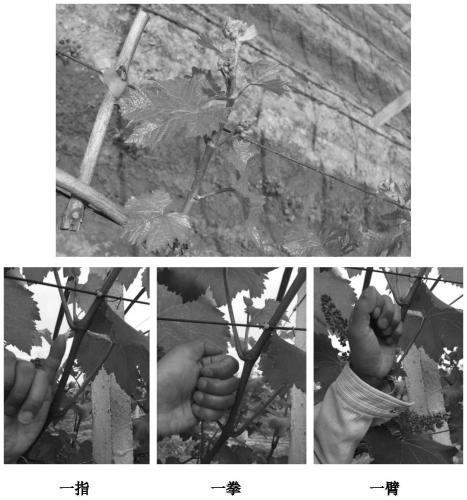

How to grow organic double-season grapes

InactiveCN105052668BRich varietyNo pollution in the processCultivating equipmentsVitis viniferaPest control

The invention discloses a method for planting double-season grapes in subtropical regions. The method comprises site selection, vineyard planning, breed selection, land preparation, digging, seedling selection and planting, seedling management, field management, grain sorting, harvesting, empty stage management and a circular planting process of a second season. "Jufeng", "summer black" and " Weike" are three species introduced for the first time, and pilot planting is achieved successfully. The planting method enriches types of grapes in subtropical regions; fertilizer application and pest and disease control adopt organic fertilizers and harmless prevention methods, and produced grapes are high in glucose, high in yield and zero in pollution. Planting success of the organic double-season grapes provides theoretical and practical basis for income generation of local farmers, and has significant meaning in improving local soil environment and social environment.

Owner:GUANGXI ZUIXIAN AGRI SCI & TECH CO LTD

Die used for producing bowl-shaped ornament

ActiveCN102172714BShorten the production cycleOvercome the technical problem of being unable to take out the bowl-shaped ornamentsShaping toolsJewelleryEngineeringProduction cycle

The invention discloses a die used for producing a bowl-shaped ornament, belonging to the technical field of jewellery processing dies. The die mainly comprises an upper die base and a lower die base which are connected together by virtue of a guide rod, wherein a convex die is sheathed on the upper die base; the lower die base is provided with a concave die and an impression die hole, the impression die hole is internally provided with an impression die in a constraint way, and the top of the impression die is provided with an impress; the convex die, the concave die and the impression die are mutually coordinated to form a bowl-shaped die cavity; and the concave die comprises a plurality of concave die section bodies, the concave die section bodies are arranged in an array around the center of the impression die hole and are radially and slidably arranged on the lower die base along the impression die hole. By adopting the die disclosed by the invention, the technical problem that the bowl-shaped ornament can not be produced by adopting a pressing process is solved, the production cycle is shortened, and the production efficiency is improved, thus the die can be widely applied in the jewellery processing industry.

Owner:SHANDONG MOKINGRAN JEWELRY

Mouth opening device for remains during encoffining make-up

The invention relates to the technical field of funeral supplies and discloses a mouth opening device for remains during encoffining make-up. The mouth opening device includes a first fingerstall, a second fingerstall and a conical cylinder. A first movable arm is welded to the outer side wall of the first fingerstall, a second movable arm is welded to the outer side wall of the second fingerstall, an adjusting groove runs through the top of the front surface of the second movable arm, the middle of the first movable arm is movably connected with the second movable arm through an adjusting pin, the adjusting pin is positioned in the adjusting groove, and the outer surface of the adjusting pin is slidingly connected with the inner wall of the adjusting groove. Through the radian of a supporting plate, the mouths of the remains can be opened easily, fillers can be added into the mouths of the remains through the conical cylinder to render the countenances of the remains more serene and natural, and meanwhile, the hands of remains dressers are prevented from touching the mouths of the remains. The cleanness of the remains is well ensured, bacterial infection is prevented, and the faces of the remains are repaired by the remains dressers conveniently.

Owner:嘉兴松宇科技有限公司

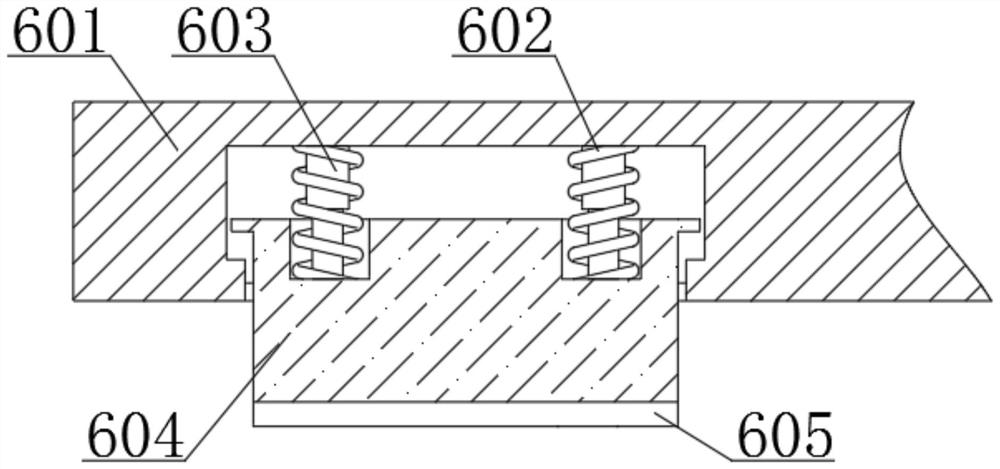

Columnar valve element

The invention provides a columnar valve element, and belongs to the technical field of valves. The problem that an existing valve element is not good in sealing performance is solved. The columnar valve element comprises a body in a horizontal right-angle-n shape. The body comprises a round top plate, a round bottom plate and a connecting plate connected between the top plate and the bottom plate.The outer side face of the connecting plate is a sealing face in an arc columnar shape. The side, opposite to the connecting plate, of the top plate and / or the bottom plate is provided with an ejecting assembly. The ejecting assembly comprises an ejecting head. The ejecting head protrudes out of the side surface of the top plate and / or the bottom plate elastically. The columnar valve element hasthe advantage that the sealing performance can be enhanced.

Owner:TAIZHOU TONGSHENG BRASS

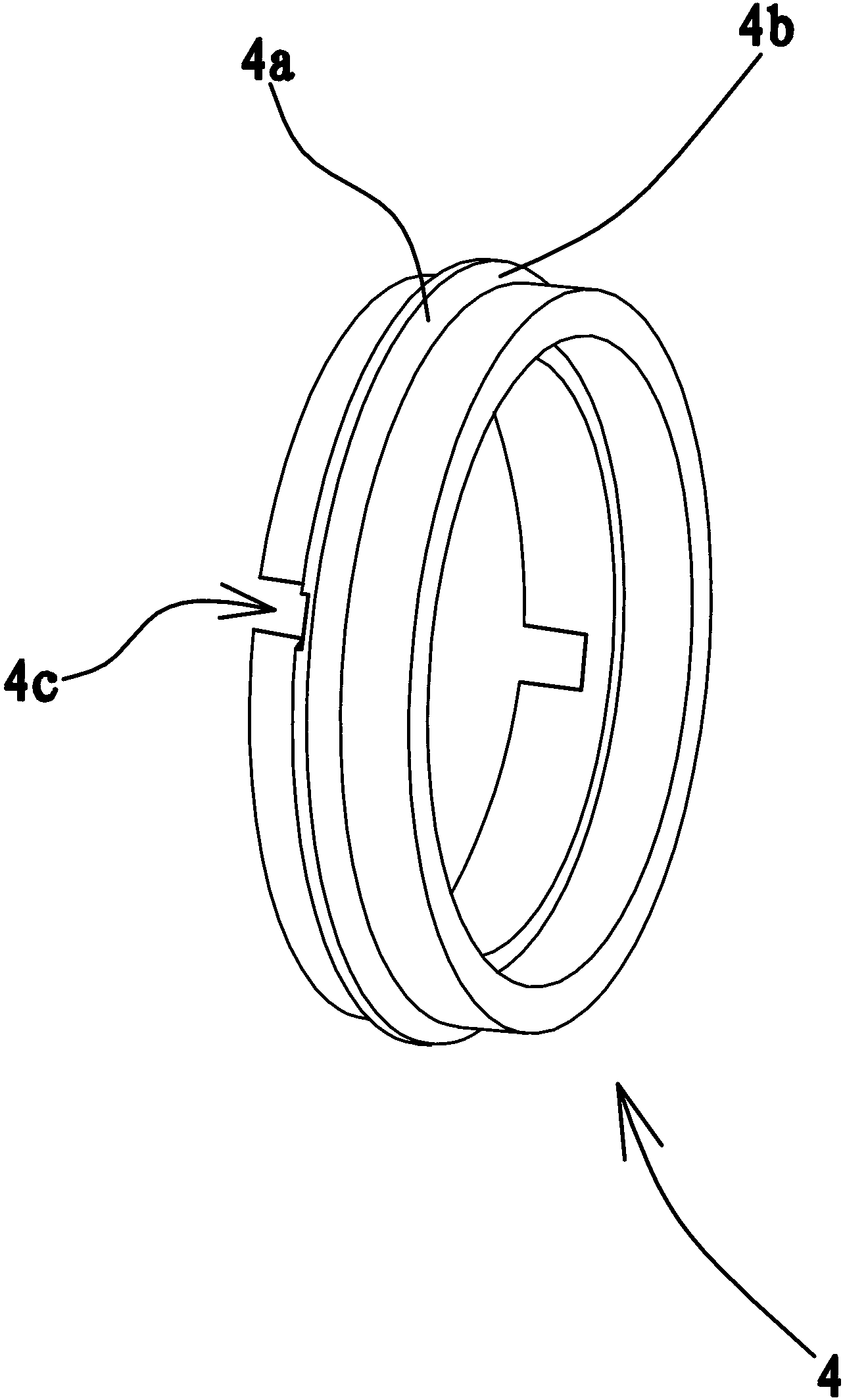

Quick connector for gas conveying bellows

ActiveCN103244773BWon't leakWill not cause leakageSleeve/socket jointsJoints with sealing surfacesBarrel ShapedEngineering

The invention provides a quick connector for a gas conveying bellows and belongs to the technical field of connectors. The quick connector solves the problem that an existing quick connector easily causes gas leakage in use. The quick connector comprises a barrel-shaped connecting head. In installation, a sealing washer is sleeved at the end of the bellows. A locating ring, a safety buckle and a locking nut are further sequentially sleeved on the bellows on one side of the sealing washer. The locating ring can be axially fixedly connected with the bellows, one end of the locating ring abuts against one end of the sealing washer, the safety buckle is barrel-shaped and is sleeved at the other end of the locating ring, a clamping part is arranged on an outer side wall of the safety buckle, an annular groove is arranged on an inner wall of the connecting head, and the clamping part is embedded in the annular groove when the locking nut is connected with the connecting head. After the quick connector is installed, one end of the bellows is always kept in a sealed state, and the bellows is good in safety and sealing effect. In addition, a casing of the quick connector is insulated with a bellows body, and the quick connector is safe to use.

Owner:林仁国

Yarn beating device for rope production

The invention discloses a yarn beating device for rope production. The device comprises a workbench; the workbench is arranged in a disc shape; four supporting columns are fixedly mounted on the lowerend surface of the workbench; the four supporting columns are consistent in specification and are arranged in a rectangular array with respect to the lower end surface of the workbench; supporting legs are fixedly mounted on the lower end surfaces of the four supporting columns; the four supporting legs are consistent in specification; a plurality of shaft seats are fixedly mounted on the lower end surface of the workbench; the multiple shaft seats are consistent in specification; the shaft seats are equidistantly circumferentially distributed with respect to the center of the lower end surface of the workbench; shaft rods are rotatably mounted at the upper ends of the multiple shaft seats; four first limiting strips are fixedly mounted at each of rod heads of the multiple shaft rods; andthe four first limiting strips of the rod head of the same shaft rod are equidistantly circumferentially distributed with respect to the rod center of the shaft rod. The invention relates to the yarnbeating device for rope production; the yarn beating device for rope production performs winding operation by the characteristic of lifting rotation of a screw rod, and has the characteristics of stable structural function and tight winding.

Owner:浙江省三门南方工业有限公司

Method for terminal to read broadcast channel and terminal thereof

InactiveCN101252787BShorten the timeLess power consumptionBroadcast service distributionData switching networksBroadcast channelsResidence

Owner:ST ERICSSON SEMICON BEIJING

Sucking disc convenient to use

PendingCN110432734AFit tightlySimple structureKitchen equipmentDomestic articlesSoft materialsMechanical engineering

The invention discloses a sucking disc convenient to use, and the sucking disc is simple in structure and easy to realize, an adsorption piece is made of soft materials and can be slightly compressedwhen being pressed, and a pressing piece is arranged backwards on the back surface of the adsorption piece. Thus, the front surface of the pressing piece is gradually in contact with the back surfaceof the adsorption piece from the center to the peripheral direction when the pressing piece is pressed towards the direction of the adsorption piece, so that air between the adsorption surface and a base surface of the adsorption piece is gradually extruded from the center to the peripheral direction, and the adsorption surface of the adsorption piece is sequentially attached to the base surface from the center to the peripheral direction. The sucking disc is convenient to use, the adsorption piece and the base surface are tightly attached, and the sucking disc is good in practicability.

Owner:ZHONGSHAN TAILI HOUSEHOLD PROD MFG

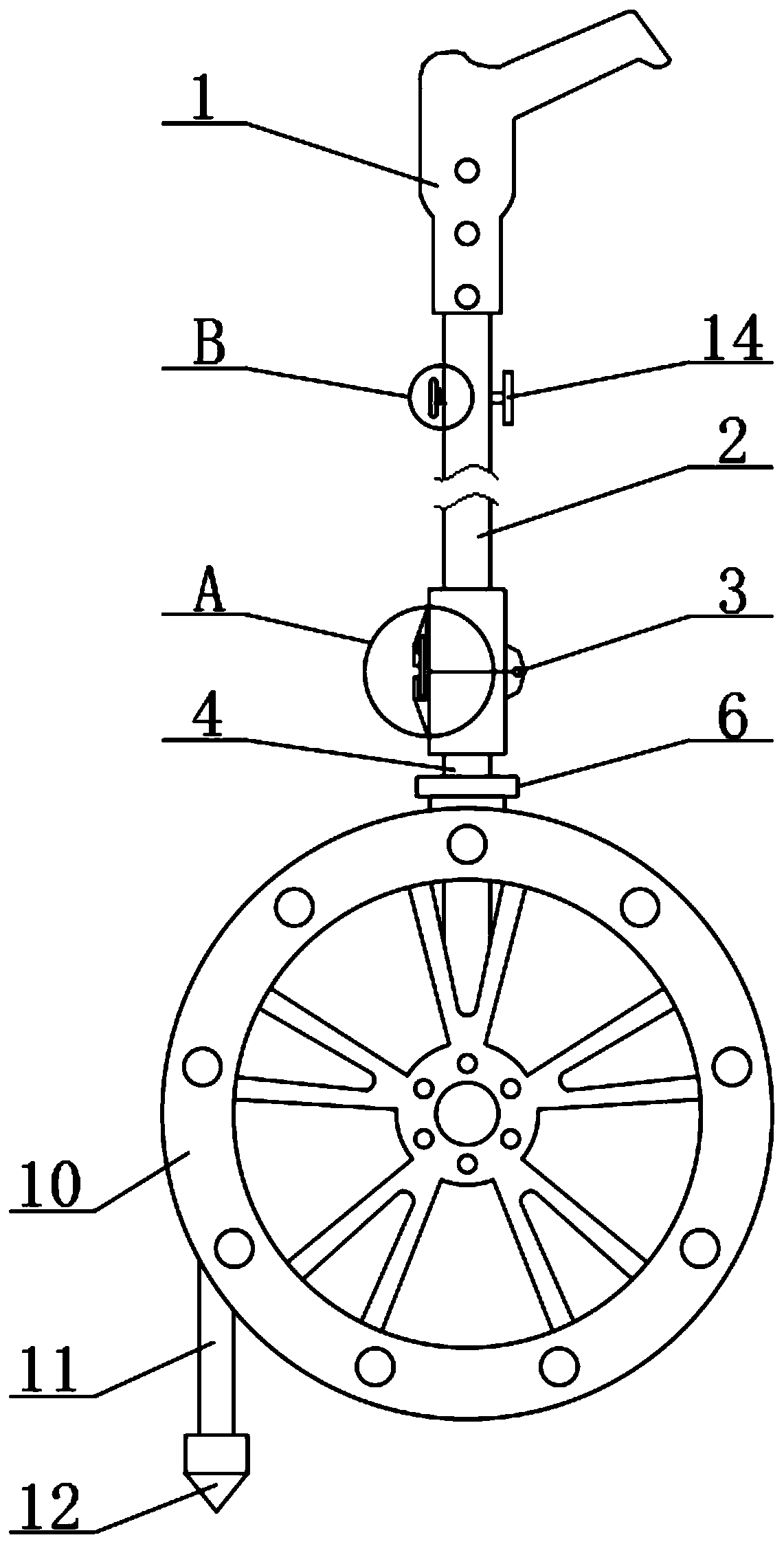

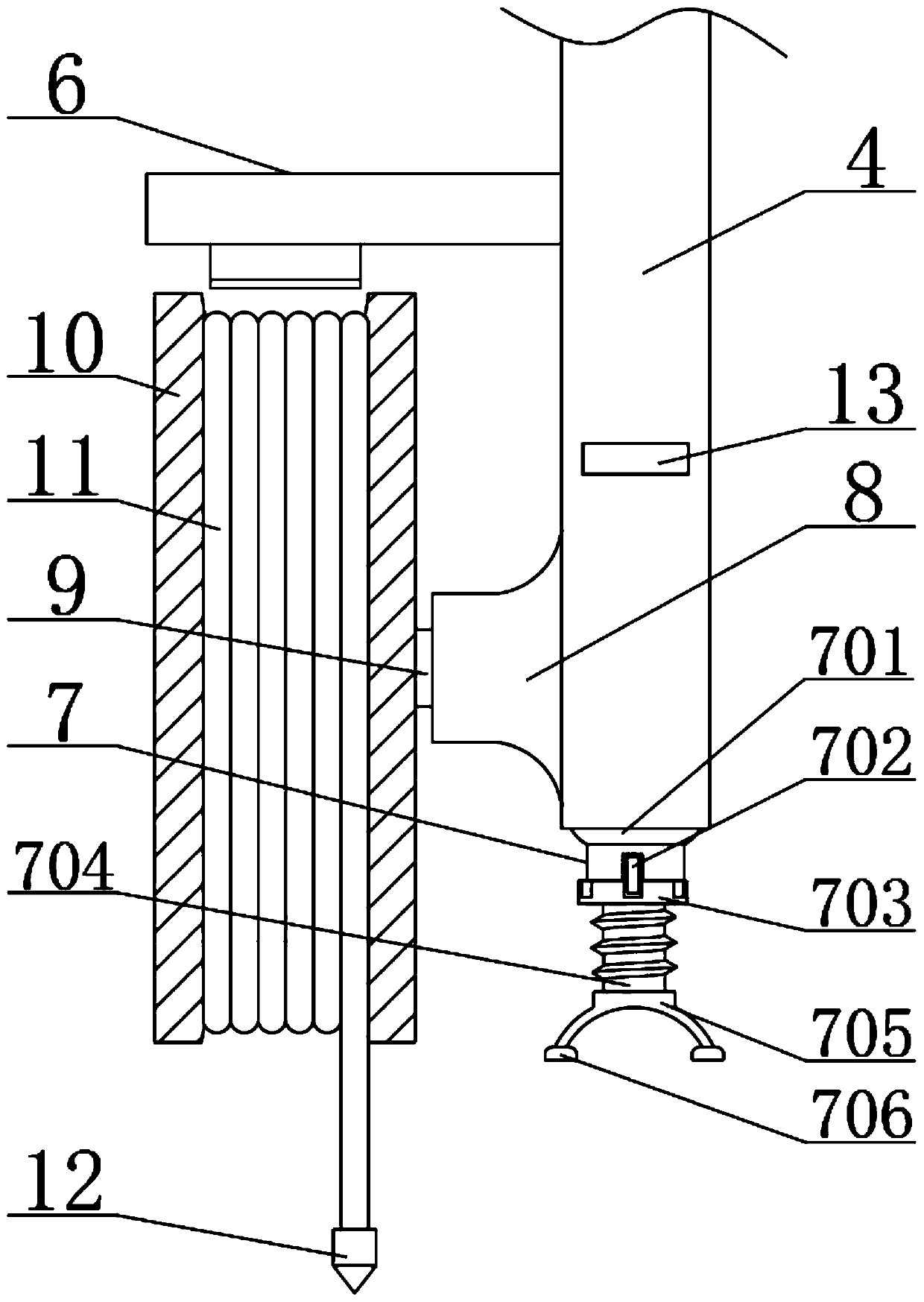

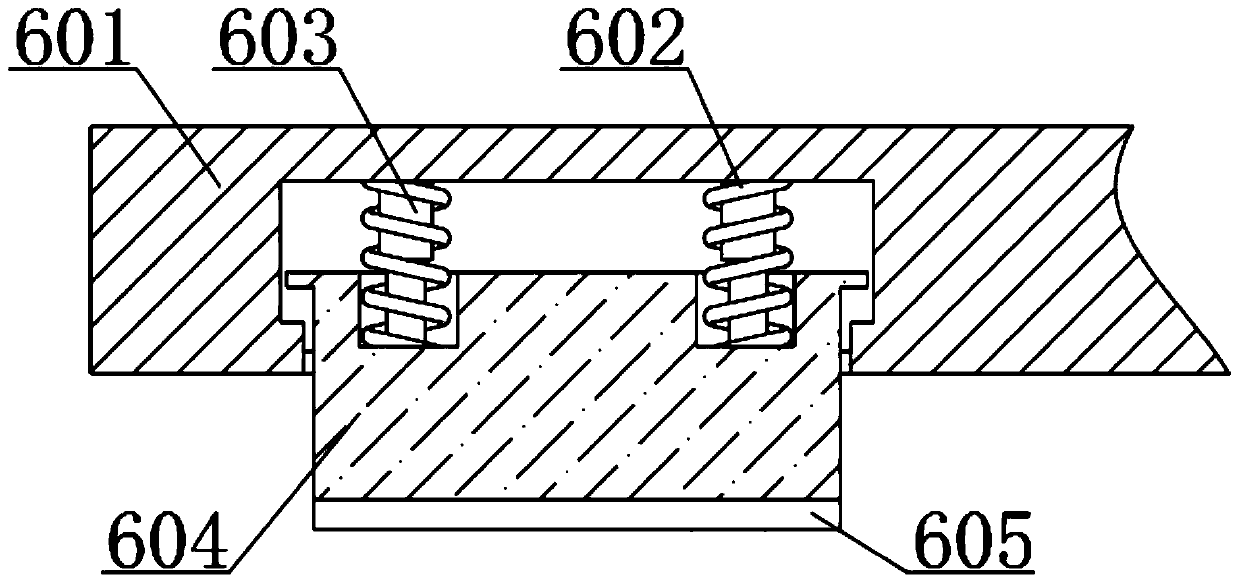

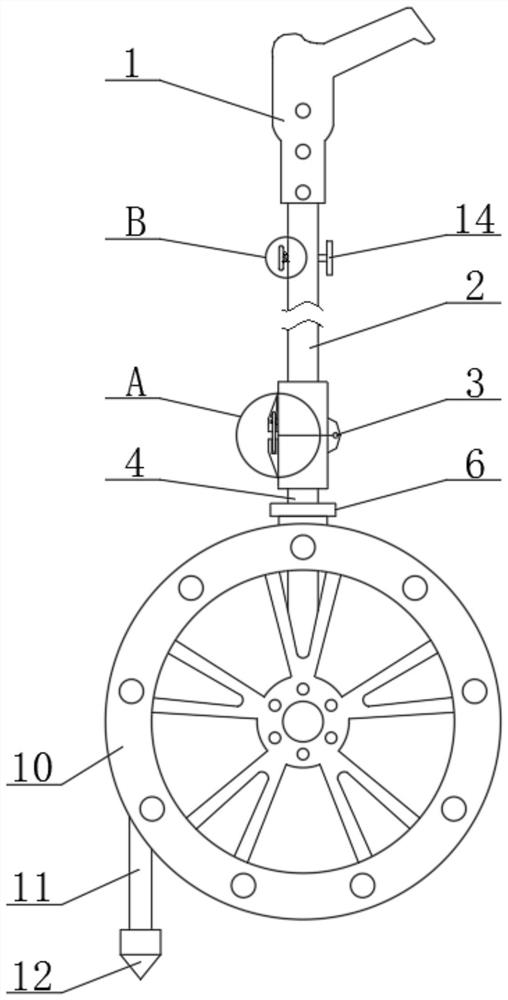

Electric portable coal bunker depth detector

ActiveCN110671995AImprove work efficiencyEasy to operateMechanical depth measurementsElectrical and Electronics engineeringMechanical engineering

The invention relates to the technical field of coal bunker depth measurement, in particular to an electric portable coal bunker depth detector. The electric portable coal bunker depth detector comprises a handle, an upper unit fixing rod, a rotating shaft and a lower unit fixing rod, the front end face of the handle is fixedly connected with buttons which are distributed in an upper-middle-lowermode. The lower end face of the handle is fixedly connected with the upper unit fixing rod. The rotating shaft is fixedly connected to the right side of the lower end face of the upper unit fixing rod, the upper unit fixing rod is rotationally connected with the lower unit fixing rod through the rotating shaft, a limiting device is slidably connected to the front end face of the lower unit fixingrod, and connecting devices are fixedly connected to the left end face of the upper unit fixing rod and the left end face of the lower unit fixing rod respectively. According to the device, through the arrangement of a take-up wheel, a measuring rope and a gravity cone, the take-up wheel is driven to rotate through rotation of a rotating motor, the rope unwinding and winding speed can be increased, manual hand-held pay-off and take-up are not needed, the working efficiency is greatly improved, operation is easy, labor is saved, manual contact is not needed, cleanness and sanitation are achieved, and good practical value is achieved.

Owner:SHAANXI ZHENGTONG COAL IND CO LTD

A method of grape cultivation

The invention provides a cultivation method for 'Jinying' novel grape species. Hard branches of dozens of Kyoho grapes are selected as scions; tens of summer black grape trees are selected as stock and pollinizers; in May, the hard branches of the Kyoho grapes and the summer black grape trees are grafted, after survival, only one Kyoho grafting branch can be reserved on each tree, and the other branches are sheared off; in the current year, after to-be-grafted Kyoho grapes bloom, the Kyoho grapes are mated with blooming summer black grapes, and isolation pollination is performed; in the current year, the grafted Kyoho grapes on the summer black grape trees are fruited, seeds are taken and embedded into sandy soil, in the next March, seedling growing is performed, and in the current July, green branch transplanting is performed. The average fruit weight of the species is about 12 grams, and the sugar content is about 16-18%. The mature period is about 20 days ahead of the schedule of the Kyoho grapes and about 10 days later than the summer black grapes, and the problems that the Kyoho grapes are seriously different in size and hard in fruit bearing in the flowering phase are effectively solved. The species has the only defect that the species has no immunity to gray mold and the gray mold needs to be prevented one more time compared with other species.

Owner:中化(临沂)作物营养有限公司

Apparatus and method for accurate detection of locomotive fuel injection pump solenoid closure

The invention relates to a system and method for detecting a closing of a solenoid. The system includes a capacity charge circuit electrically coupled to the solenoid. The capacity charge circuit conditions the current flow through the solenoid to increase the current in response to the closing of the solenoid. The invention also relates to a system and method that includes detecting a current through the solenoid and determining a current slope characteristic. The current slope characteristic is a function of the current and time. The method also includes conditioning an electrical characteristic of the solenoid such that the conditioning is in response to a current slope parameter. The current slope parameter defines a change in the current after removal of an electrical charge to the solenoid.

Owner:GENERAL ELECTRIC CO

Ceiling type lighting lamp and mounting method thereof

PendingCN111365657APrevent free spinsImprove connection reliabilityLighting support devicesProtective devices for lightingEngineeringLight fixture

The invention provides a ceiling type lighting lamp and a mounting method thereof, and belongs to the technical field of lamps, wherein the ceiling type lighting lamp comprises a decorative frame, a base disc and a lamp shade, the decorative frame is provided with a protruding part, the protruding part and the decorative frame are arranged integrally or in a split manner, the base disc is connected with the decorative frame in a nested manner, a lighting assembly is arranged on the base disc, and the thickness of the protruding part is larger than the height difference formed between the basedisc and the decorative frame; the lampshade is connected to the base disc. According to the ceiling type lighting lamp and the mounting method thereof provided by the invention, the decoration frameand the base disc are arranged in a split mode, cost reduction and product diversification are achieved, in addition, foam is bonded to the decorative frame, all-around fixing of the decorative frameis achieved, the scattering phenomenon caused by shaking of the decorative frame is avoided, and the user experience is improved.

Owner:宁波公牛光电科技有限公司

An electric portable coal bunker depth detector

InactiveCN110671995BIncrease the speed of the ropeImprove work efficiencyMechanical depth measurementsElectric machineBunker

The invention relates to the technical field of coal bunker depth measurement, in particular to an electric portable coal bunker depth detector, which includes a handle, an upper unit fixing rod, a rotating shaft and a lower unit fixing rod, and the front end of the handle is fixedly connected with the upper, middle and lower distribution button, the lower end of the handle is fixedly connected with an upper unit fixing rod, the right side of the lower end of the upper unit fixing rod is fixedly connected with a rotating shaft, and the upper unit fixing rod is connected with a lower unit fixing rod through the rotation of the rotating shaft, and the lower unit fixing rod The front end of the unit fixed rod is slidingly connected with the limit device, and the left end face of the upper unit fixed rod and the left end face of the lower unit fixed rod are fixedly connected with a connecting device; By rotating the motor to drive the take-up wheel to rotate, the speed of releasing and receiving the rope can be increased, and there is no need for manual hand-held take-up and take-up, greatly improving work efficiency, easy operation, labor-saving, no manual contact, clean and hygienic, and has good practical value .

Owner:SHAANXI ZHENGTONG COAL IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com