Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Take up evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

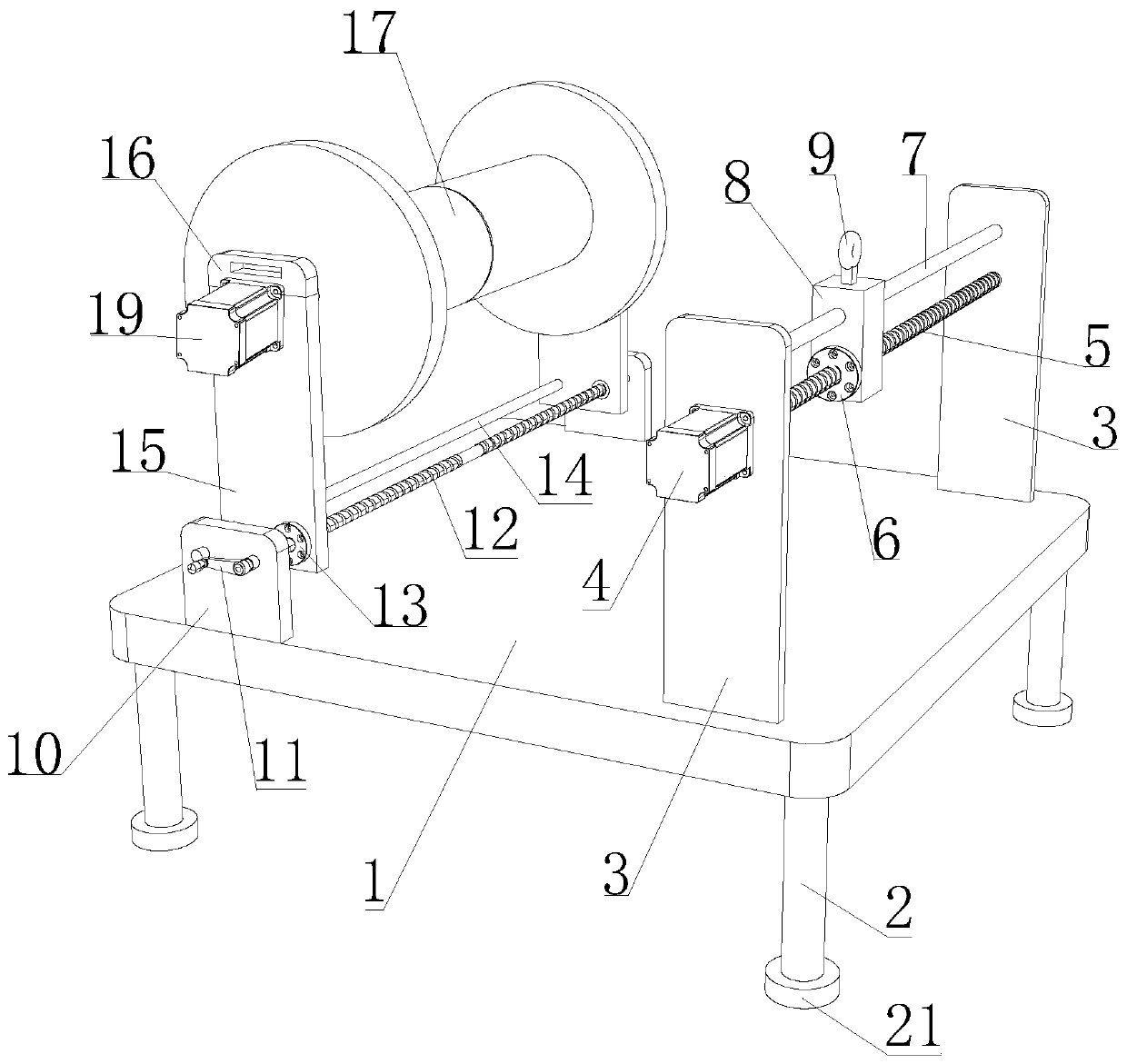

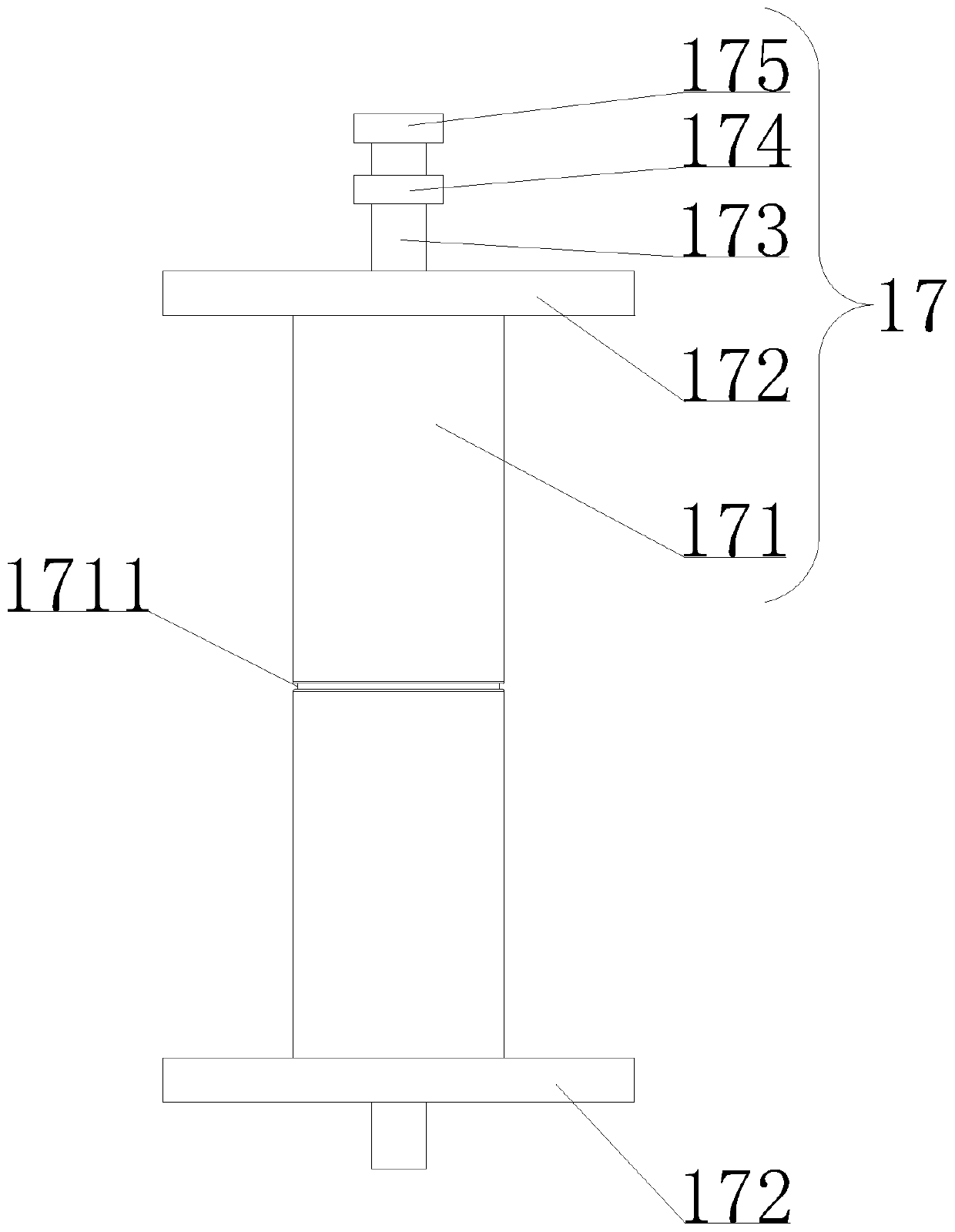

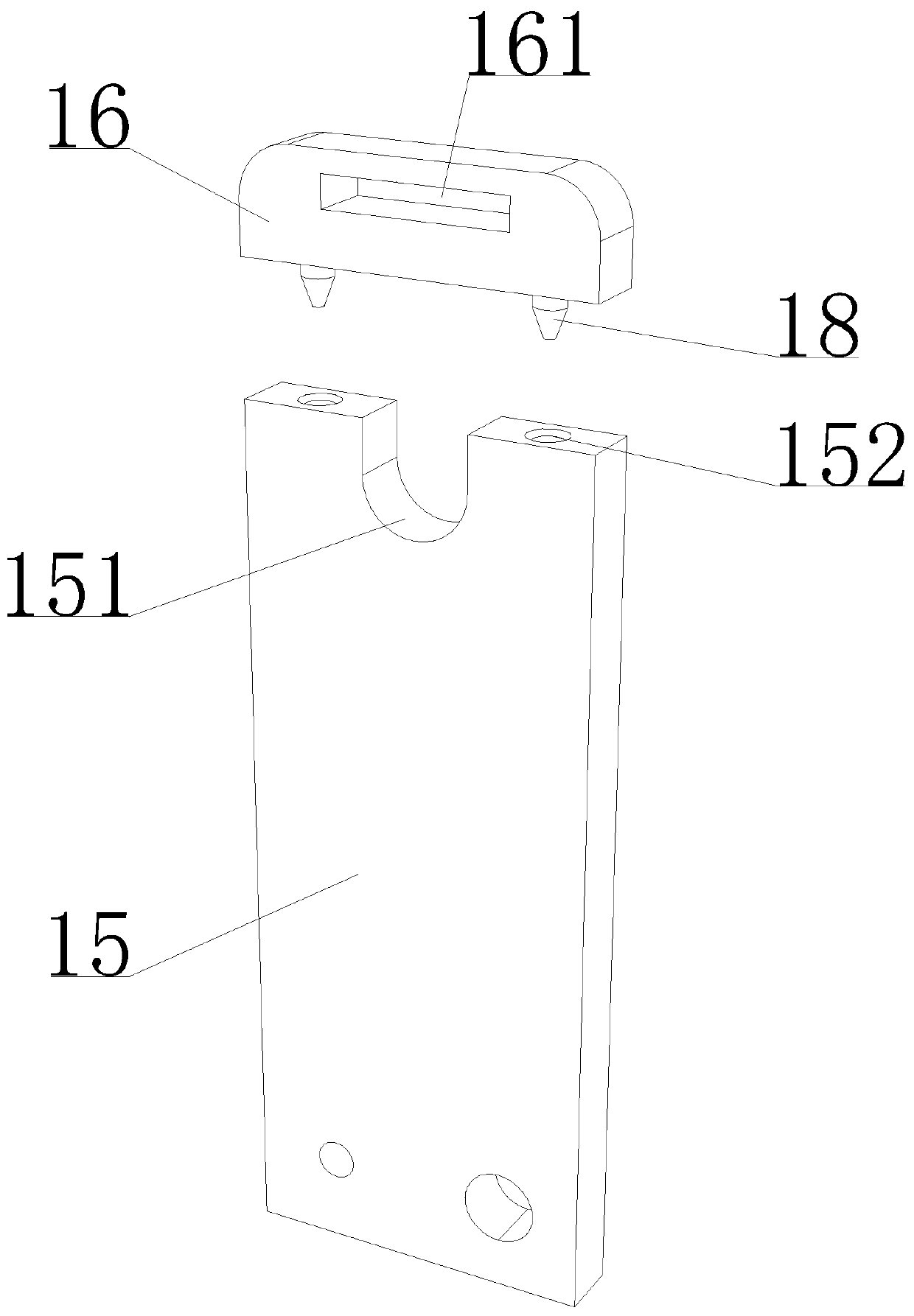

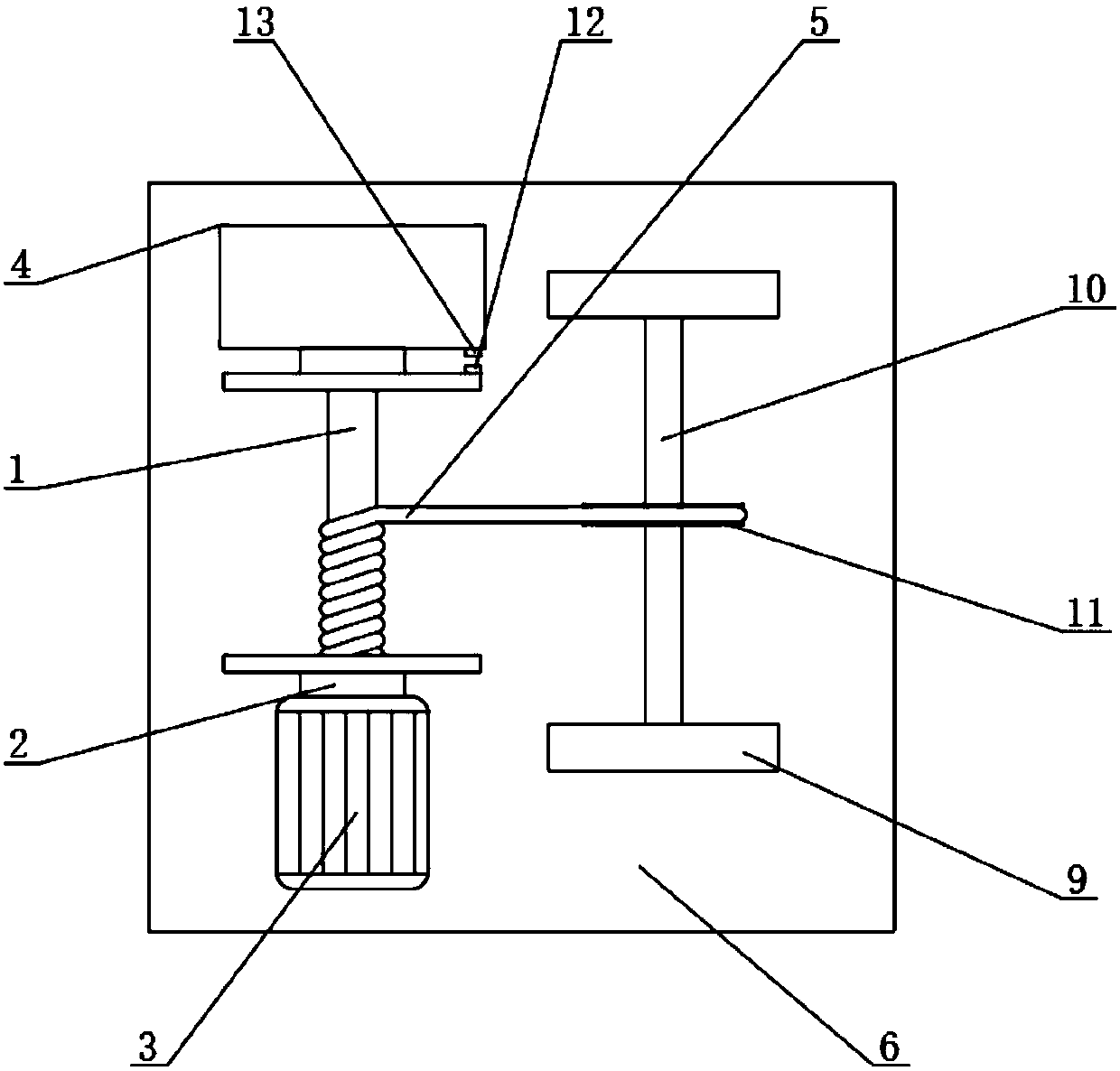

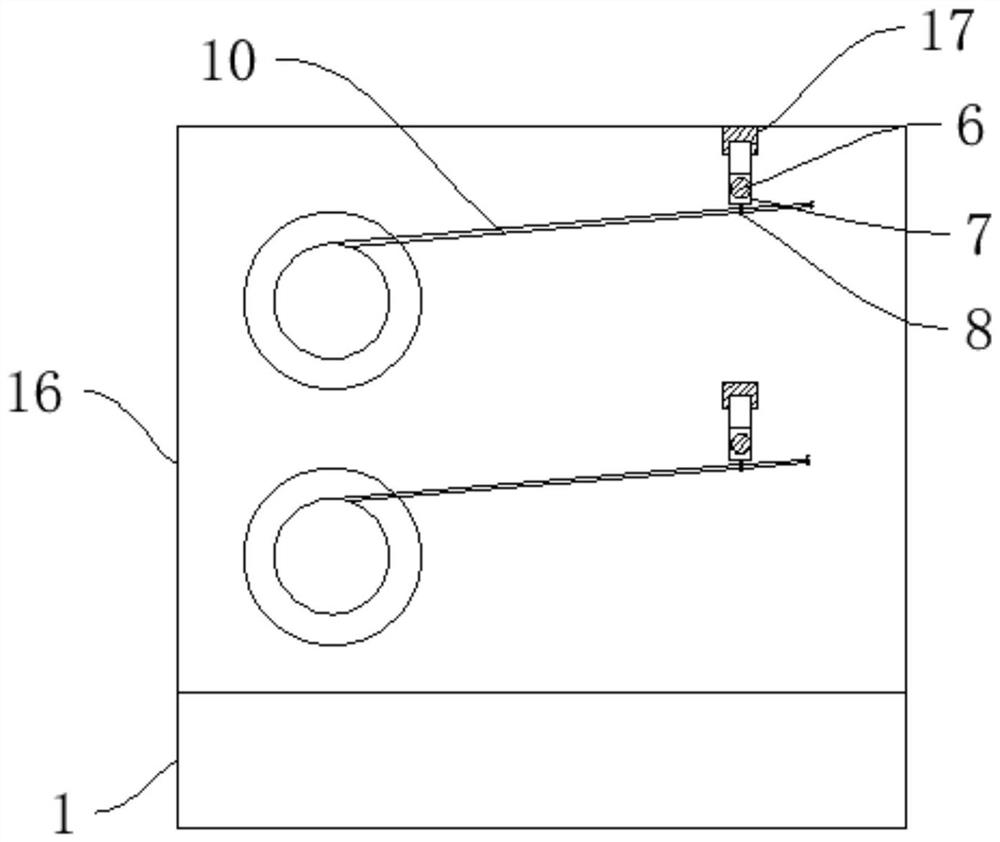

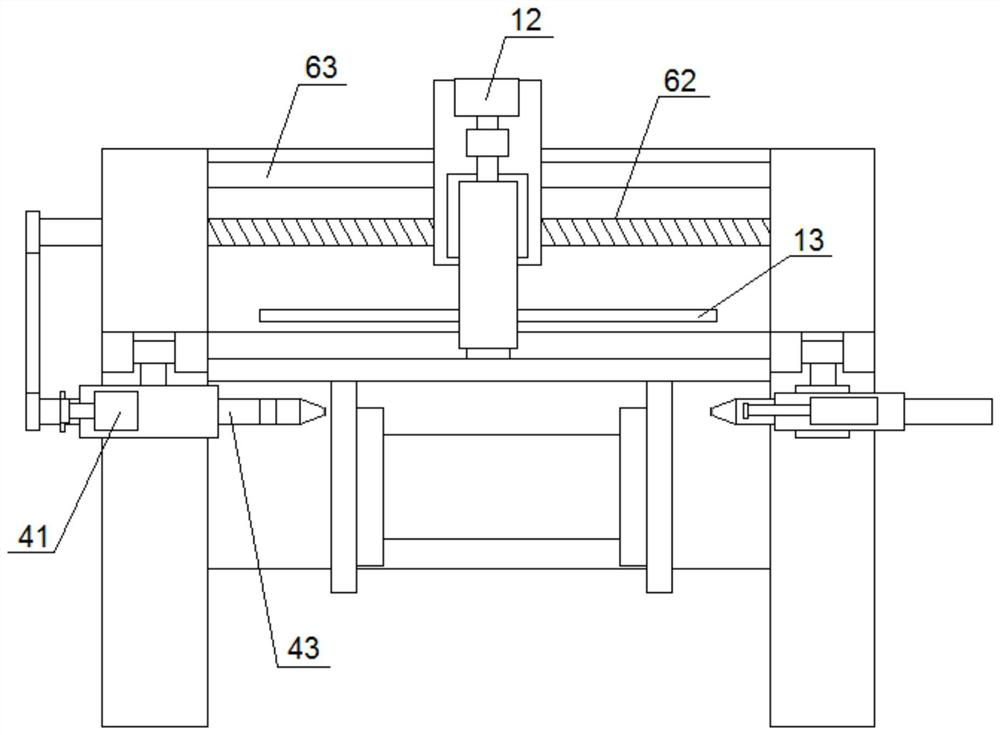

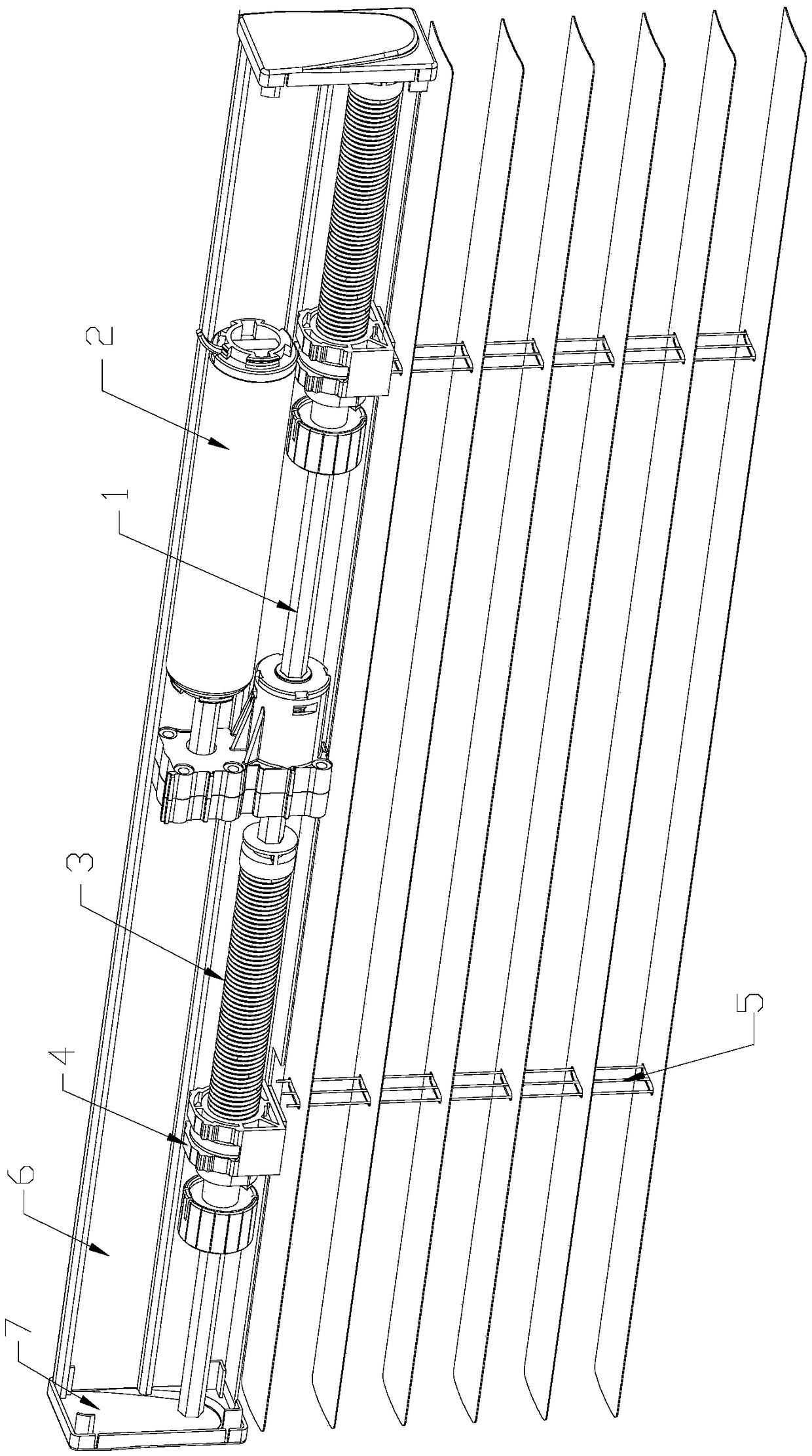

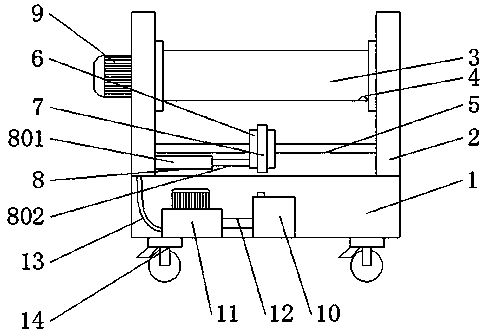

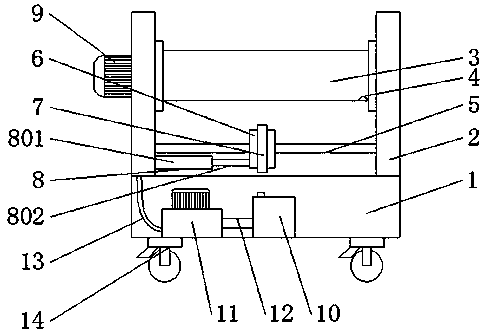

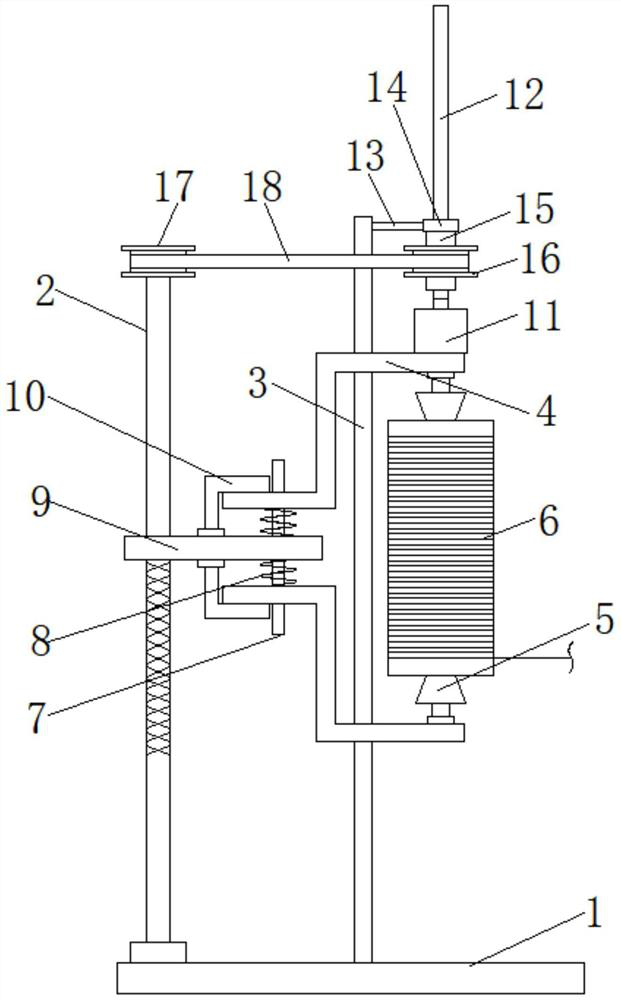

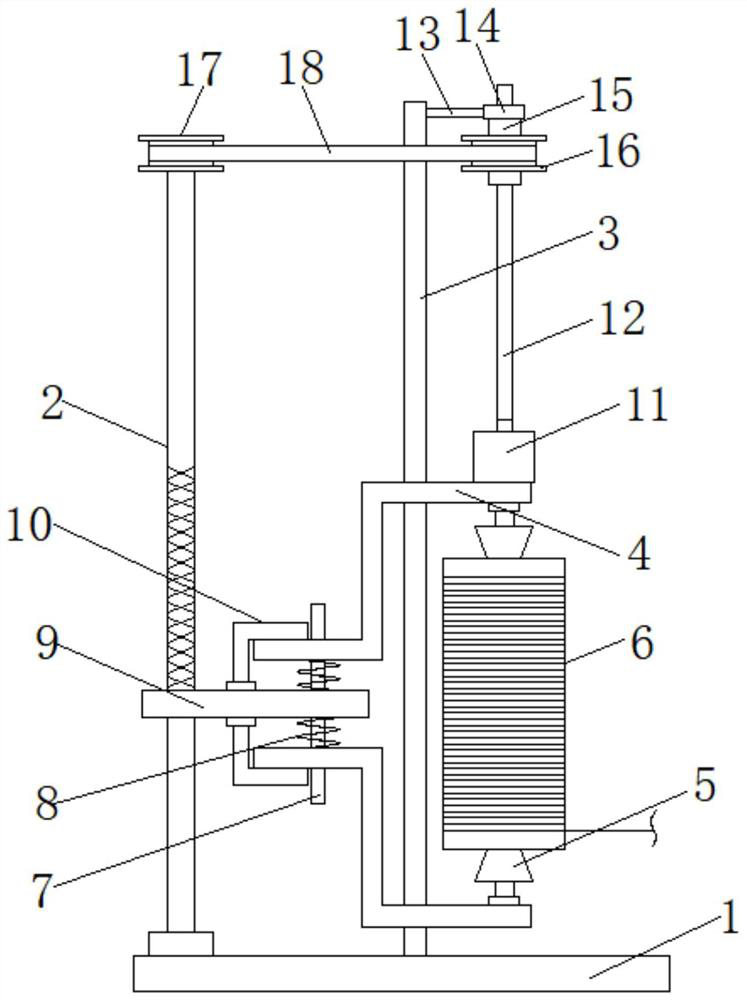

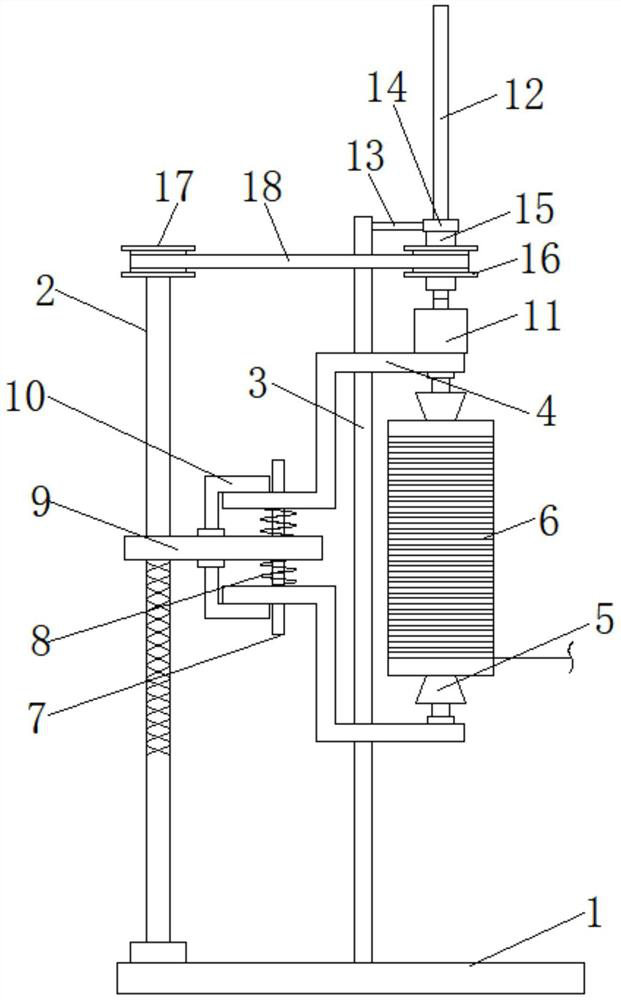

Chemical fiber yarn winding device

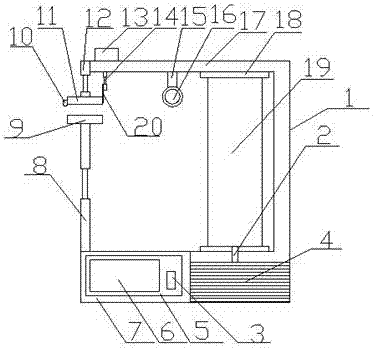

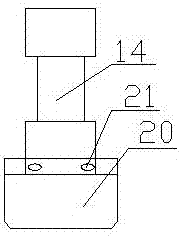

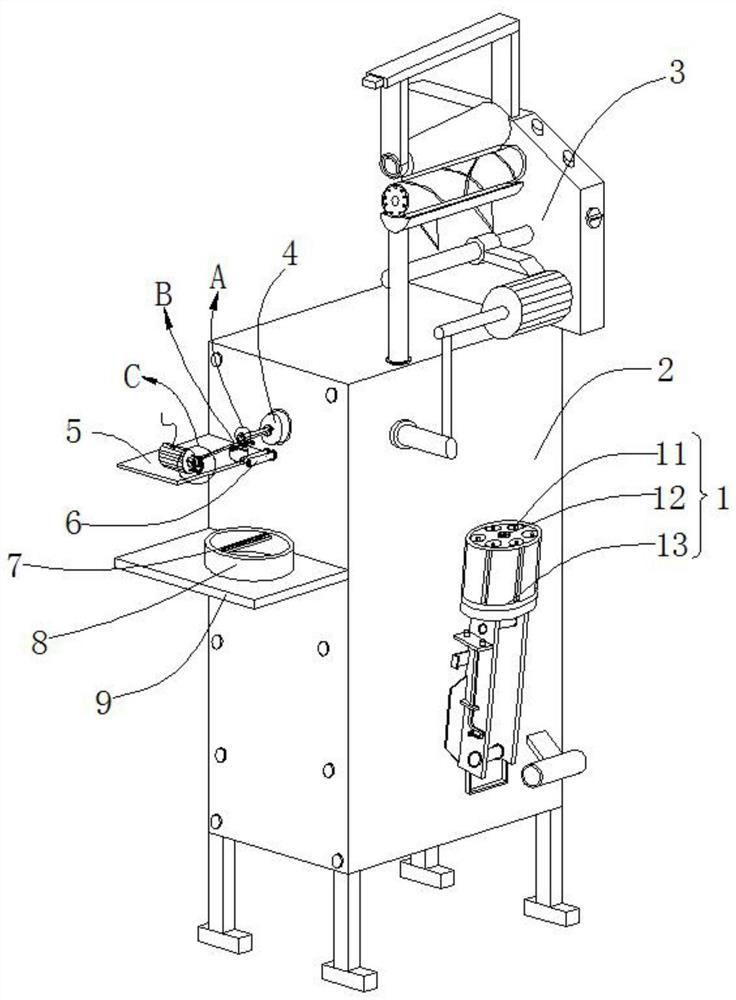

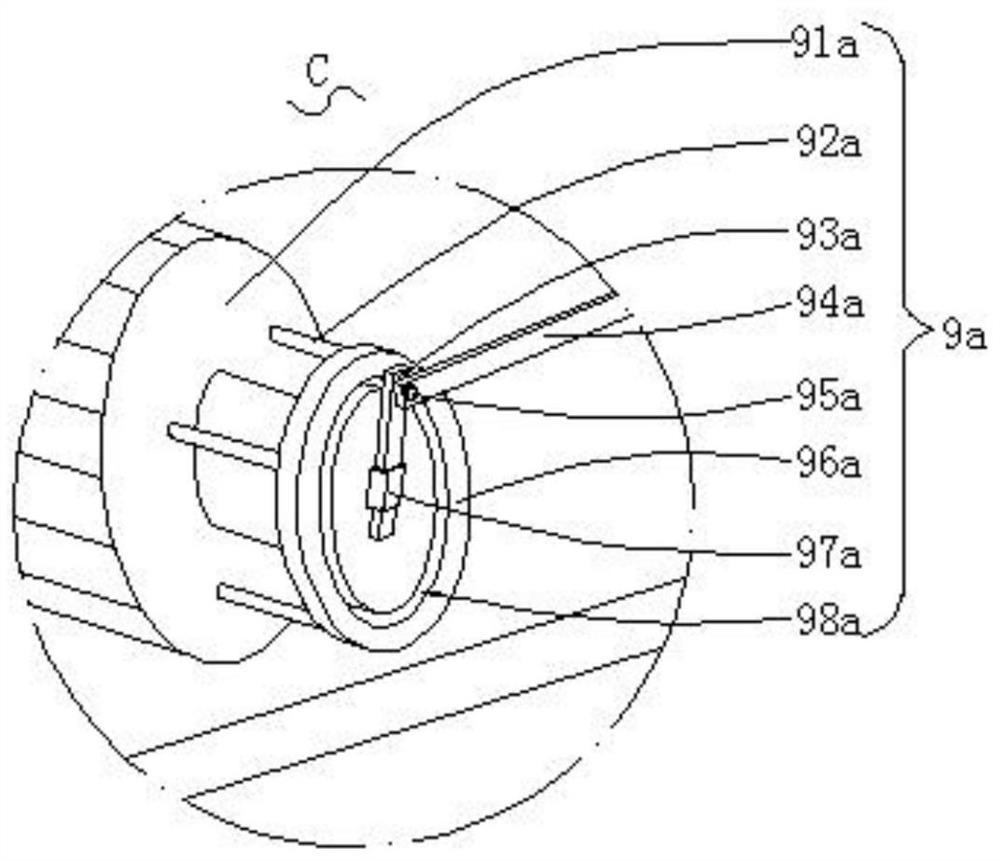

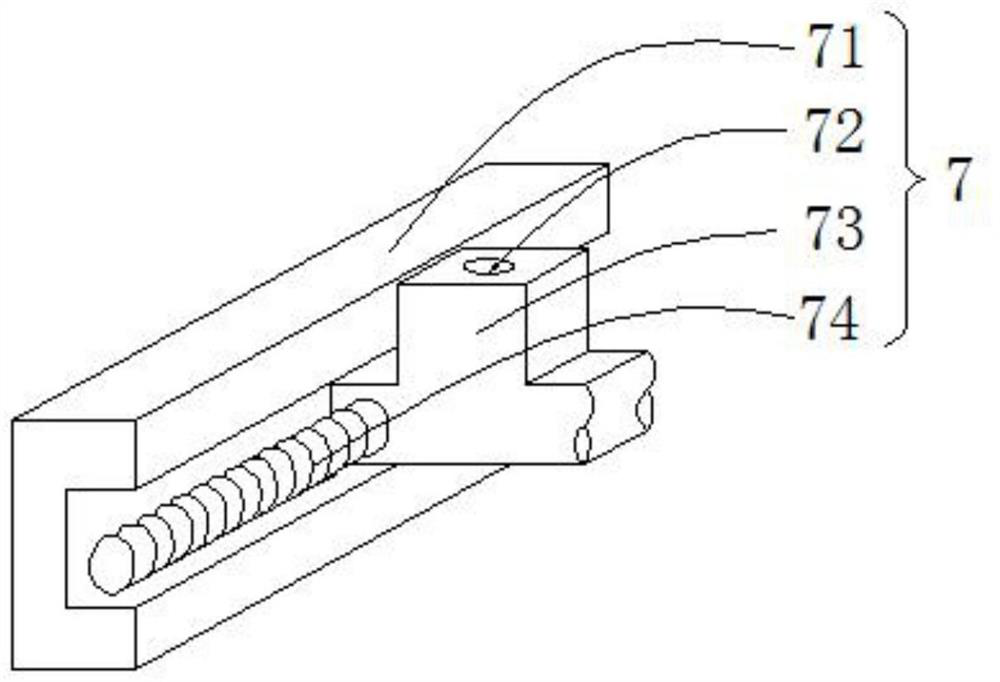

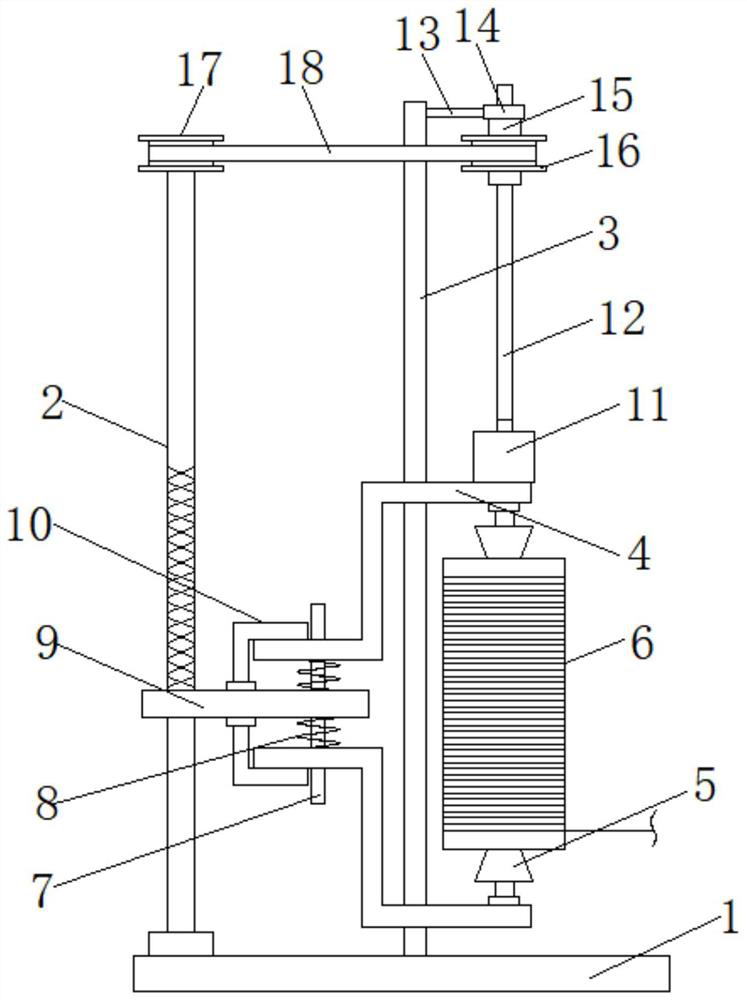

The invention belongs to the field of storage devices and particularly relates to a chemical fiber yarn winding device. Aiming at the problems of irregular and nonuniform winding of existing yarn winding devices, a scheme is proposed. According to the scheme, the chemical fiber yarn winding device comprises a workbench, supporting columns, a first support, a first driving device, a lead screw, a first lead screw nut, a first guide rod, a moving table, a lead frame, a second support, a rocking handle, a bidirectional lead screw, a second lead screw nut, a second guide rod, moving plates, a winding roller assembly and a second driving device; the first driving device is arranged on the first support and is in transmission connection with the lead screw; the first lead screw nut is connectedwith the lead screw and is connected with the moving table; a lead hole is formed in the lead frame, and the lead frame is arranged on the moving table; the moving plates are arranged on the second lead screw nut, and the top of the moving plates are provided with installation grooves; the winding roller assembly comprises a winding roller, limiting plates and a rotating shaft; and the second driving device is arranged on the moving plates. By means of the chemical fiber yarn winding device, yarn storage is more regular, ordered and uniform.

Owner:沛县谦和纺织有限公司

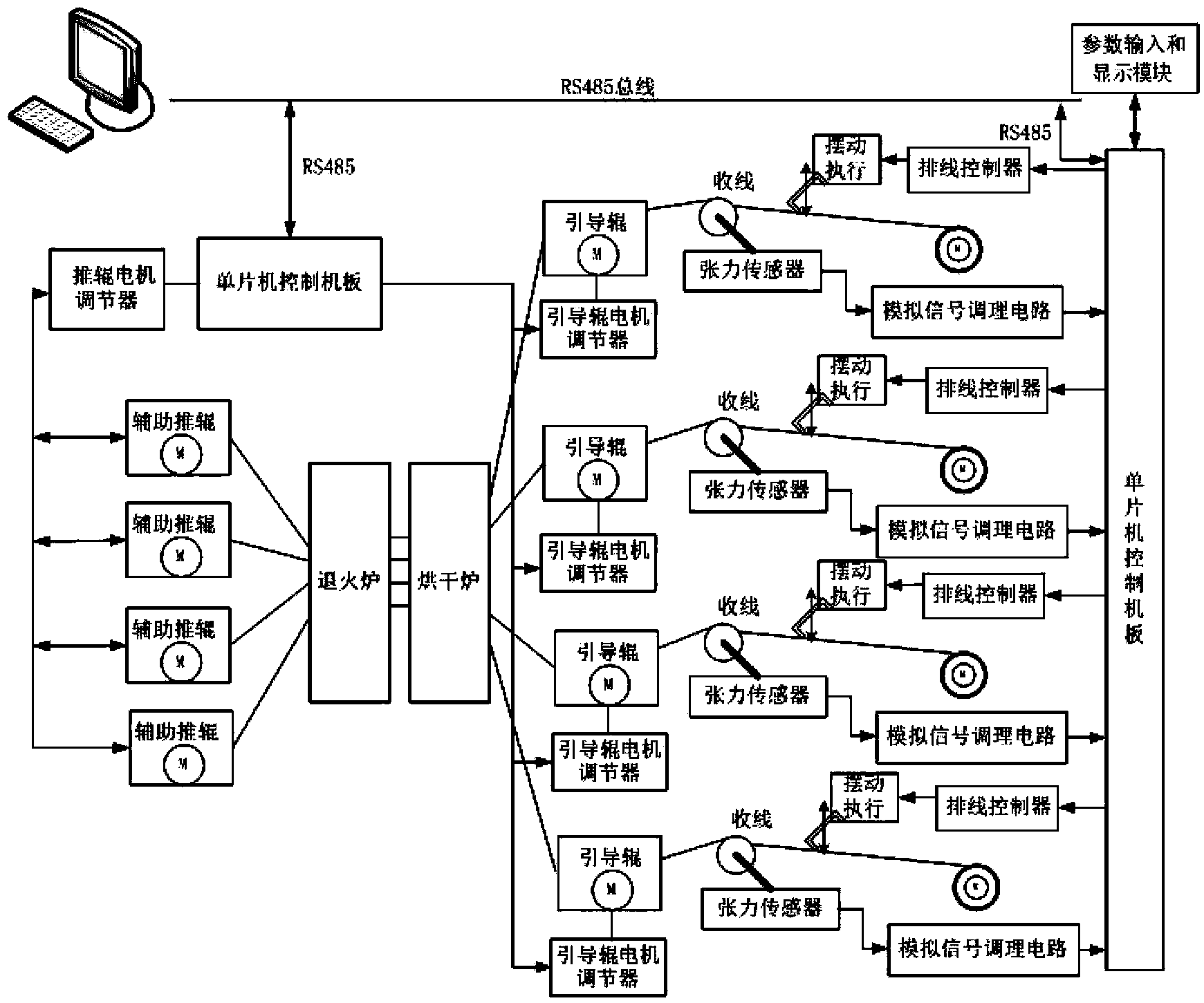

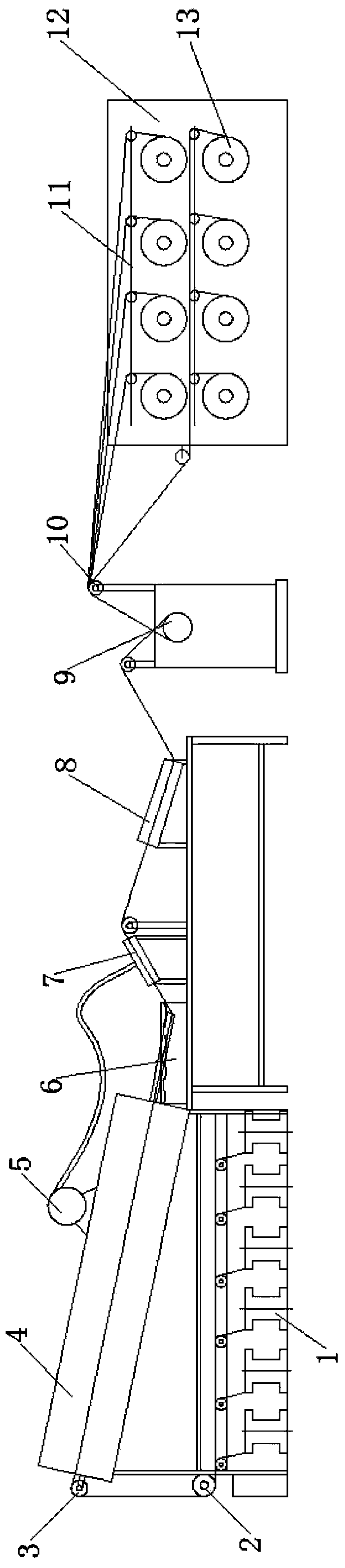

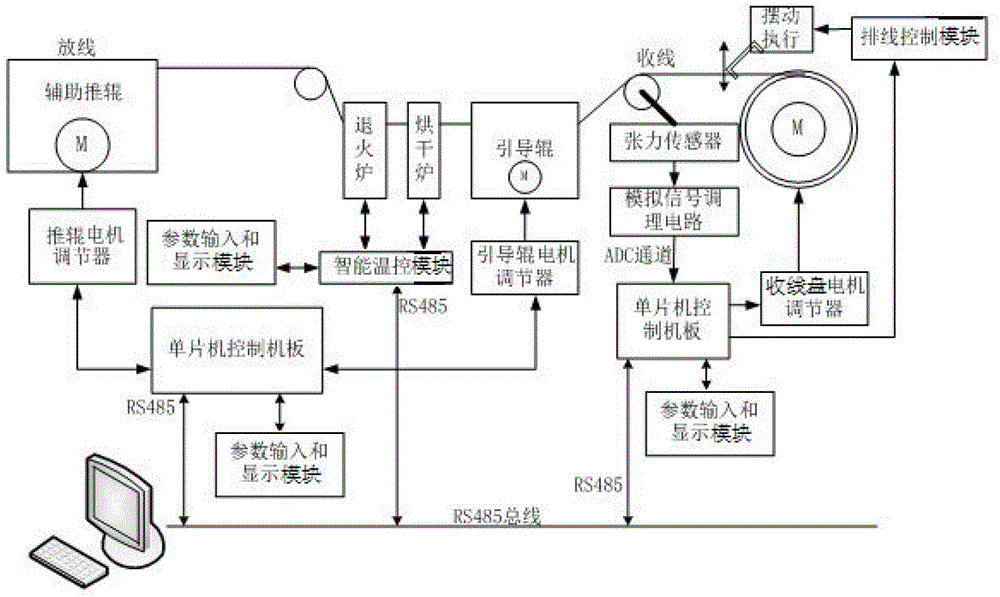

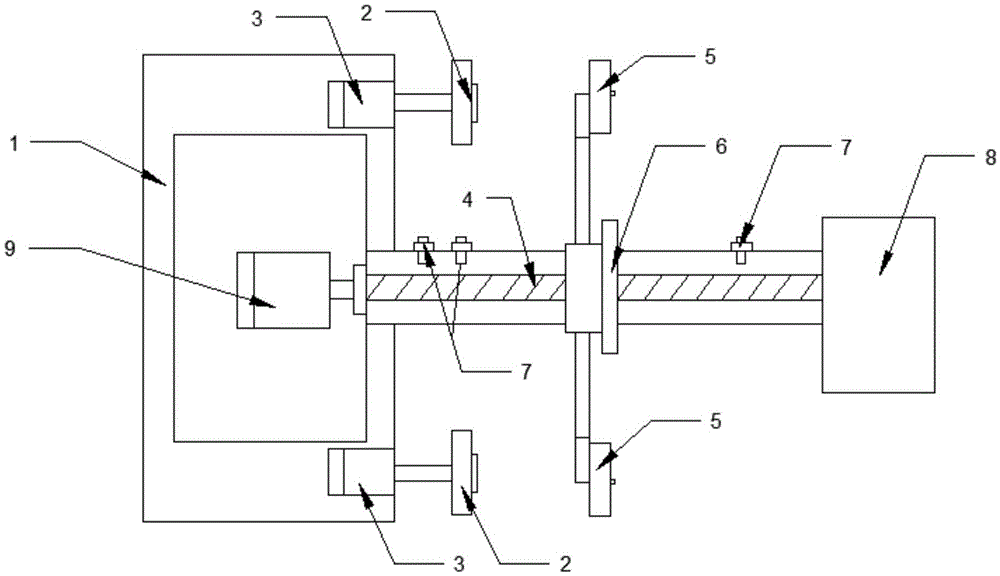

Intelligent control system and method of multi-specification tubular continuous annealing furnace

ActiveCN103436682AAvoid stretchingStable wire diameterFurnace typesHeat treatment process controlProduction lineContinuous annealing

The invention discloses an intelligent control system and an intelligent control method of a multi-specification tubular continuous annealing furnace, belonging to the technical field of intelligent control. Technical analysis and improvement are performed on the conventional continuous annealing furnace device; original single devices are rationally disassembled respectively; a plurality of groups of auxiliary push rollers, guide rollers, wire separation wheels and wire arrangement rods are additionally arranged on one set of equipment to form a continuous annealing production line capable of realizing simultaneous treatment and production of wires of multiple specifications; the annealing production line is intelligently controlled; temperature sensors are additionally arranged on the annealing furnace and a drying furnace to intelligently control the annealing and drying temperature. According to the system and the method, the annealing treatment on various wires of different specifications can be simultaneously completed on the same set of annealing equipment, and zero-tension annealing of the wires in the annealing furnace can be kept, so that the wires are prevented from being lengthened after being heated and softened, stable linear diameter is guaranteed, the equipment investment is reduced and the production cost is reduced; meanwhile, the automation degree is high, and remote monitoring and intelligent control can be realized.

Owner:江苏华旺新材料有限公司

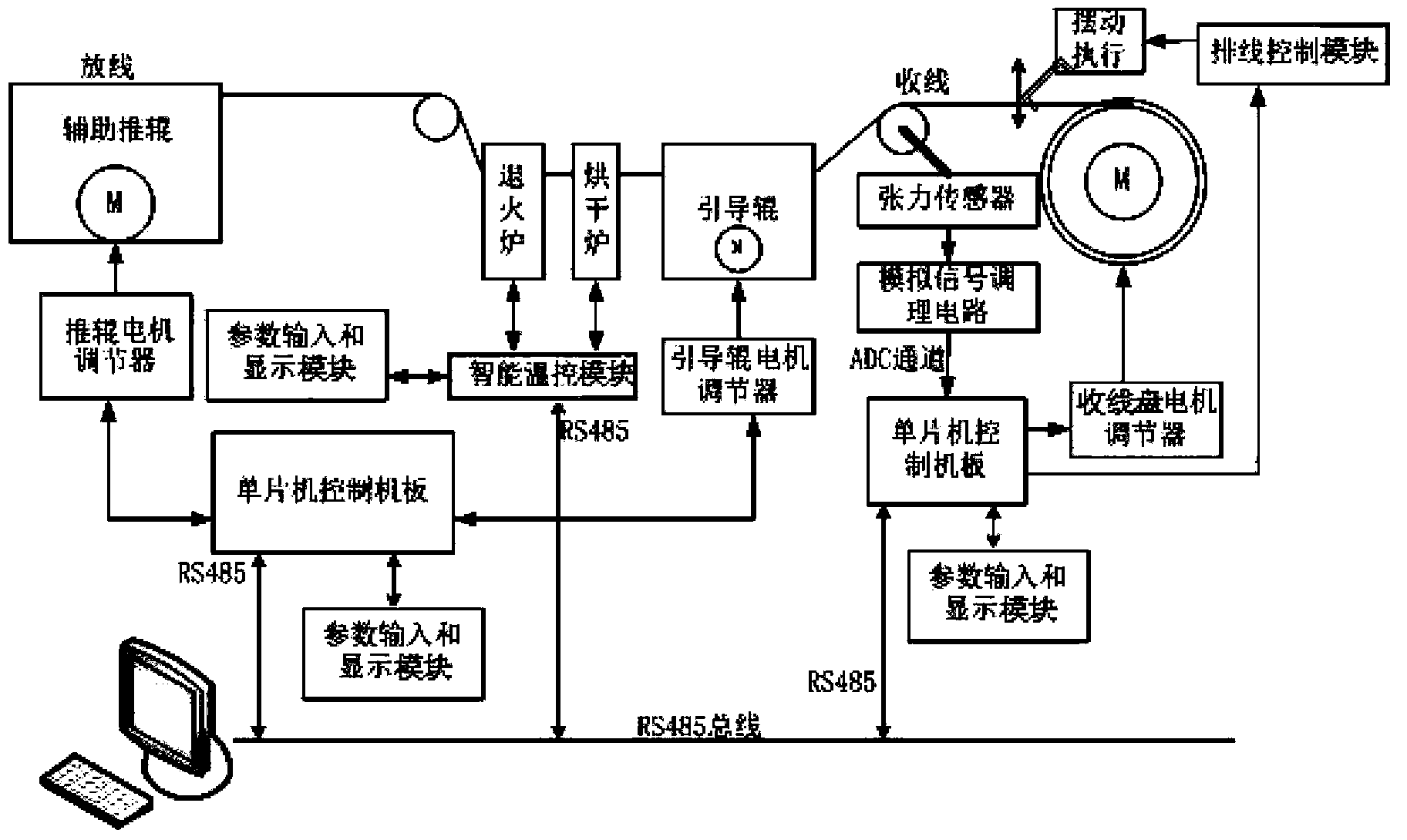

System and method for intelligently controlling tube continuous annealing furnaces

ActiveCN103436683AAvoid stretchingStable wire diameterFurnace typesHeat treatment process controlTemperature controlComputer module

The invention discloses a system and method for intelligently controlling tube continuous annealing furnaces, belonging to the technical field of intelligent control. The system disclosed by the invention is formed through carrying out a technical improvement on an existing annealing device, and respectively carries out intelligent control on an auxiliary push roller drive motor, a guide roller drive motor, a take-up reel drive motor and a winding displacement control module; a temperature sensor is respectively added on an annealing furnace and a drying furnace so as to intelligently control the annealing and drying temperatures; and the control processes are all implemented by parameter input, a display module or a computer, thereby achieving the purpose of remote monitoring and control. According to the invention, a situation that wires run in zero tension in the annealing furnace can be ensured, thereby avoiding that the wires are stretched after being softened by heating; the wires subjected to annealing can achieve an effect of constant-tension take-up, and the temperature control precision of the drying furnace and the annealing furnace is high, therefore, a situation that the wires running in the furnaces are always in an optimal recrystallization state is ensured, and the energy-saving effect is good; and the system and method disclosed by the invention are high in degree of automation, and realize remote monitoring and intelligent control.

Owner:江苏华旺新材料有限公司

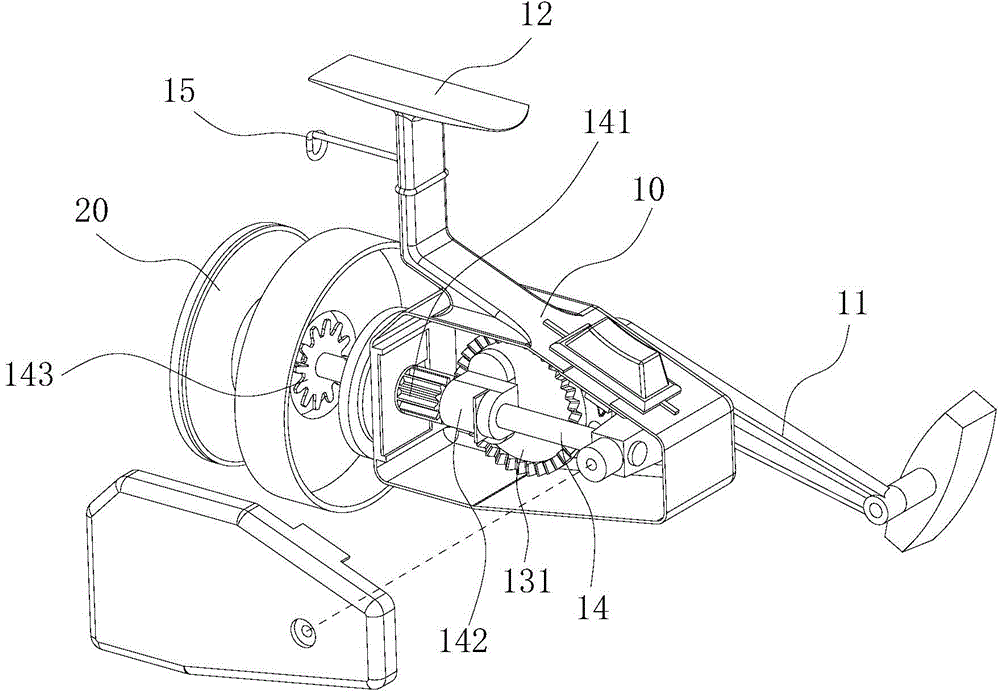

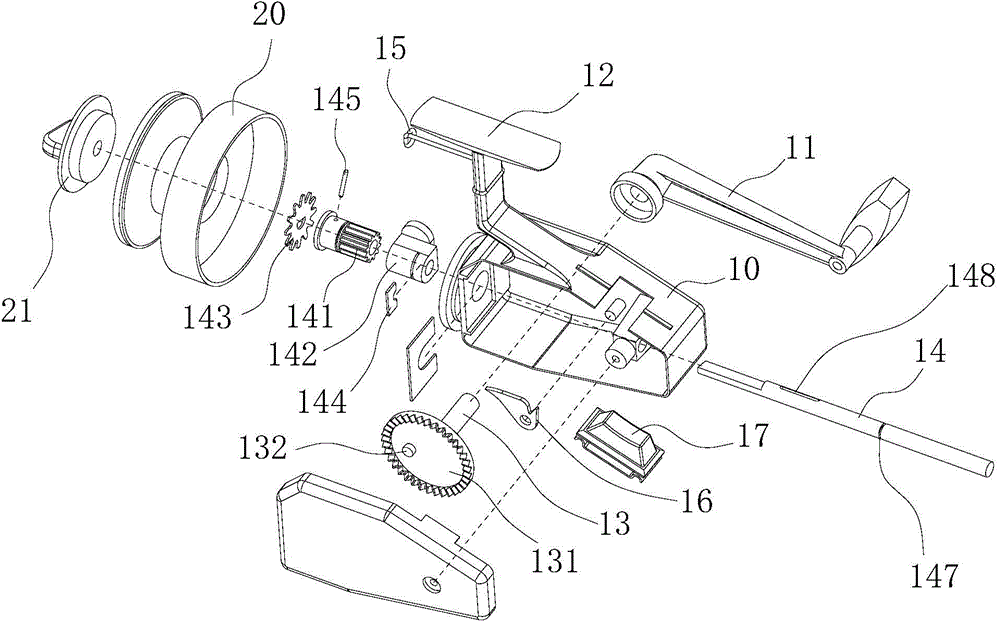

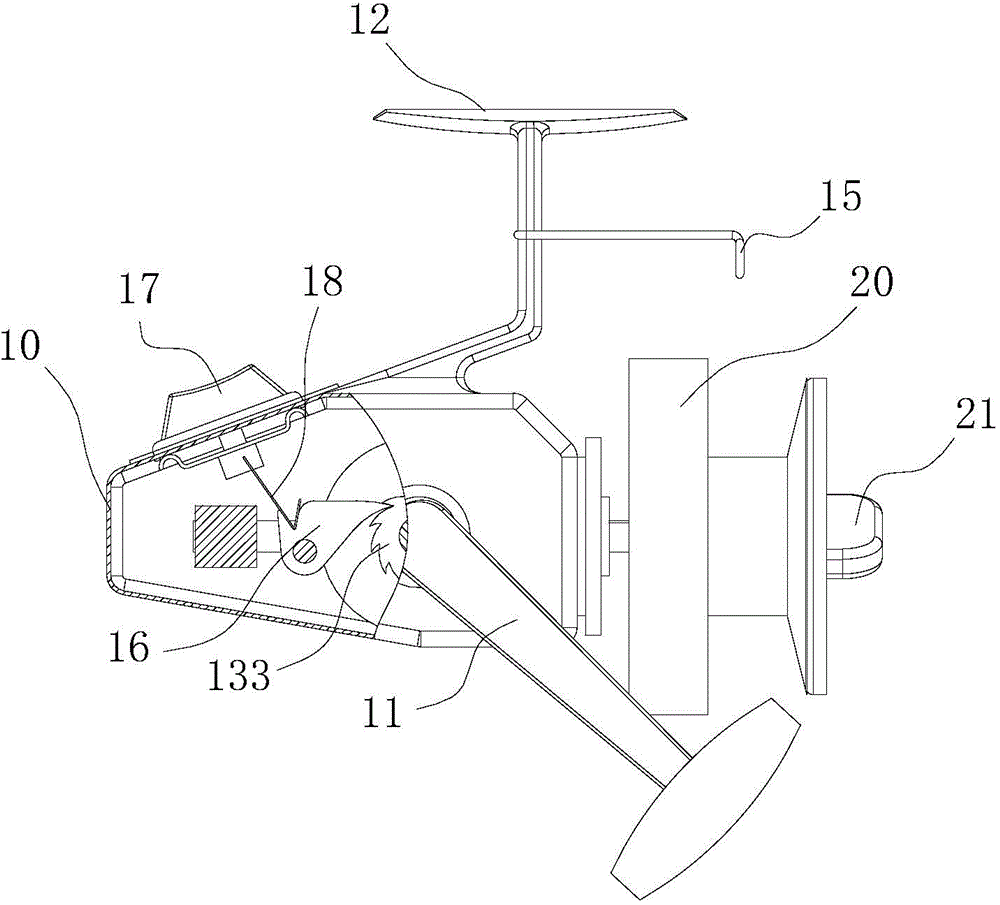

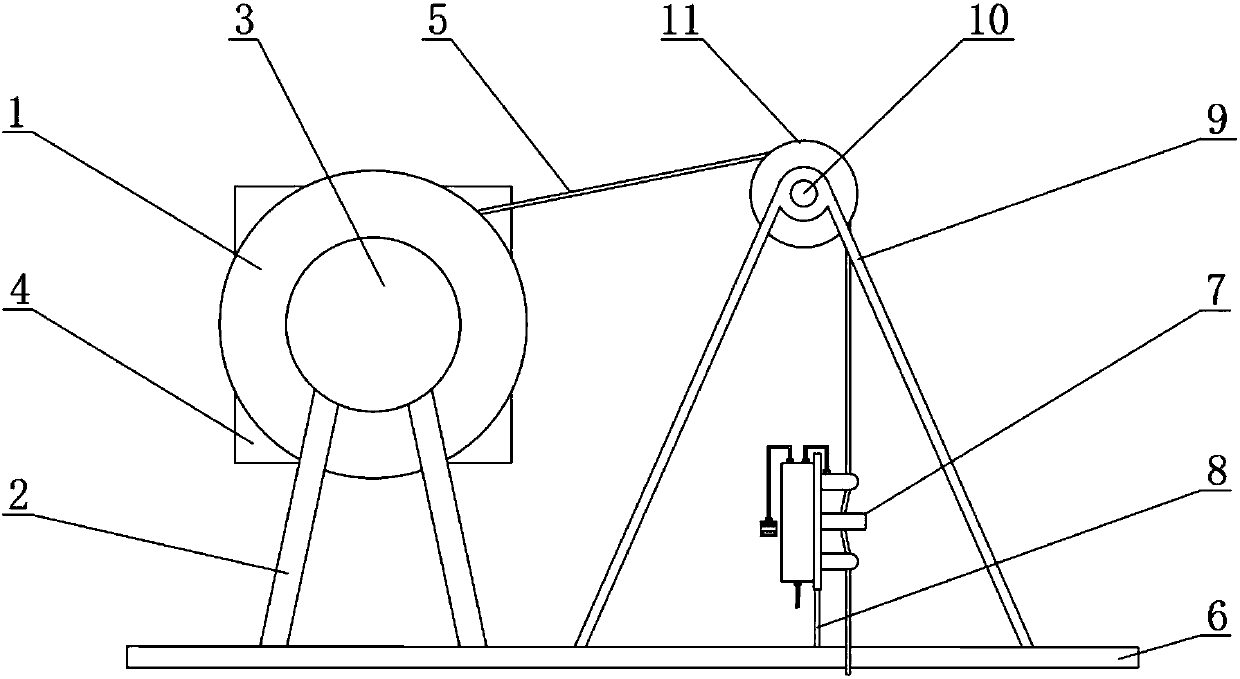

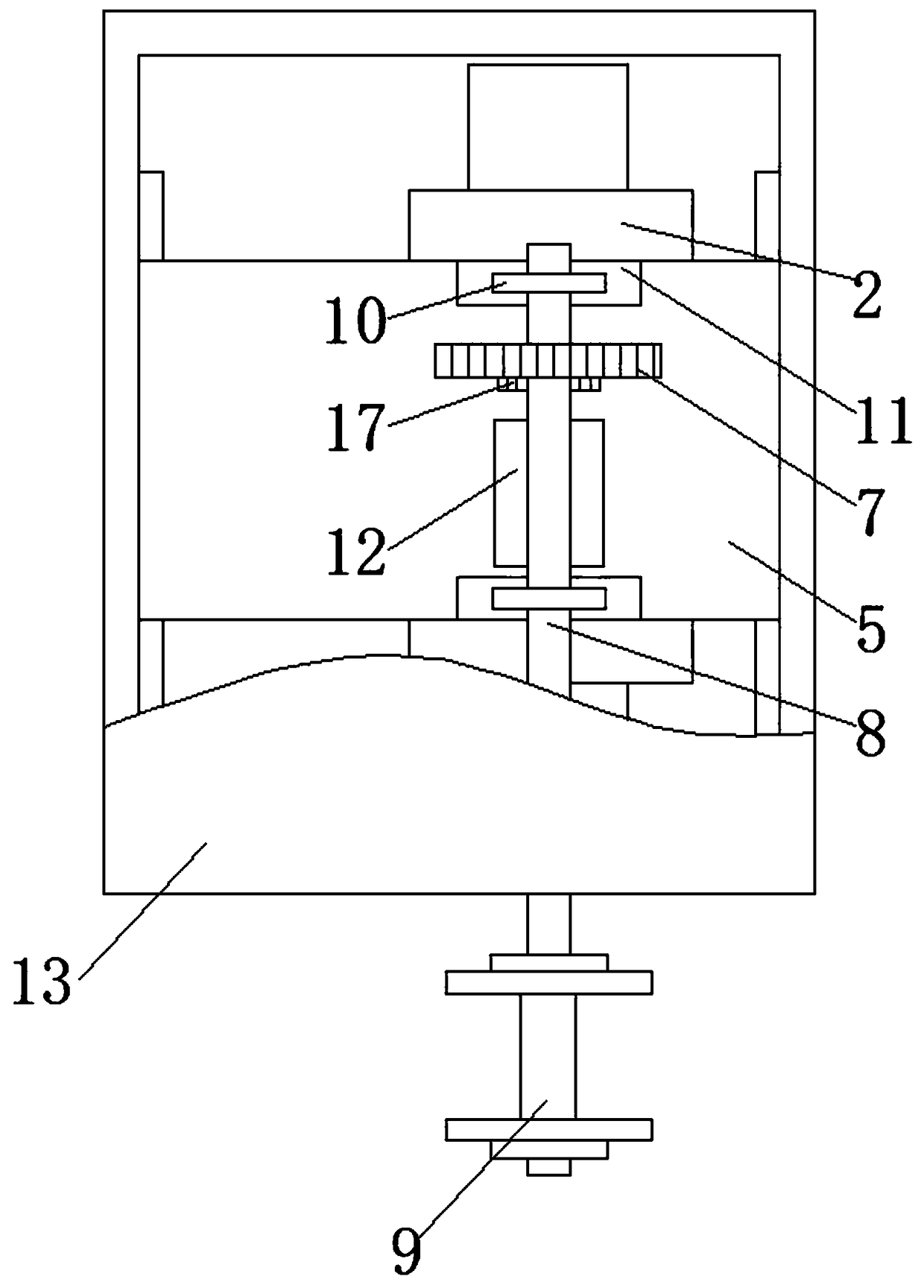

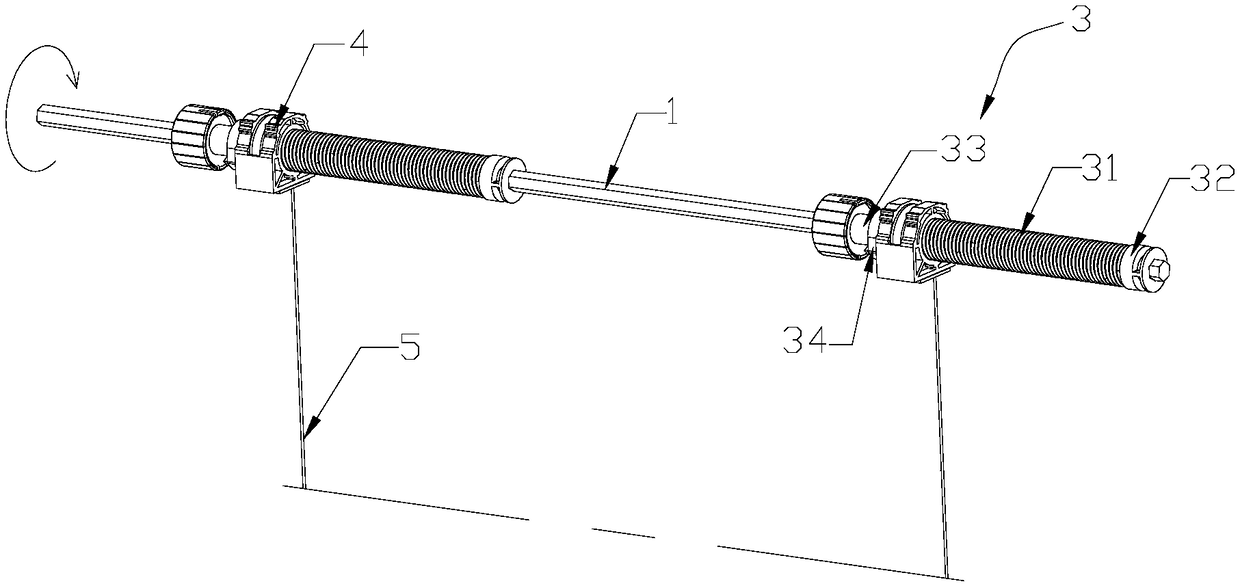

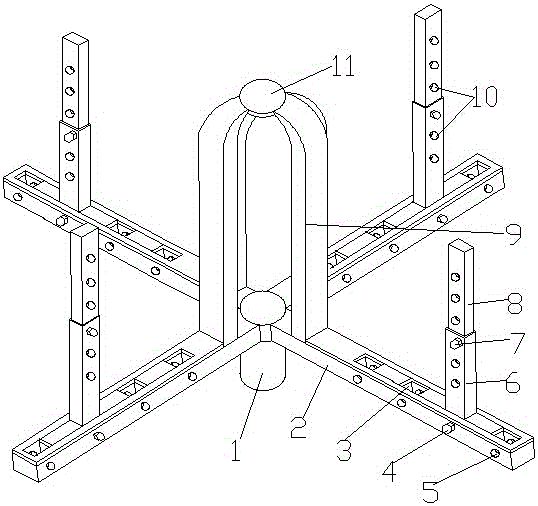

Fish line wheel

The invention belongs to fishing instruments, and particularly relates to a fish line wheel. The fish line wheel comprises a wheel seat and a line wheel body where a fish line is wound, wherein the line wheel body rotates in the peripheral direction and is arranged on the wheel seat in an axial sliding mode, the wheel seat is further provided with a connecting part, and the connecting part is used for connecting the wheel seat with a pole body of a fishing pole. The wheel seat is further provided with a driving handle, a first transmission mechanism, a second transmission mechanism and a guide ring, wherein the driving handle is rotationally arranged on the wheel seat and used for driving the line wheel body to move, the first transmission mechanism is used for transmitting rotation motions of the driving handle to the line wheel body, the second transmission mechanism is used for converting the rotation motions of the driving handle into linear reciprocating motions and then transmitting the linear reciprocating motions to the line wheel body, and the guide ring is fixed to the top end of a suspension rod arranged on the wheel seat and is suspended at the opening of an annular line winding groove of the line wheel body. Rotation and horizontal motions of the line wheel body are combined, the fishing line is distributed evenly in the line winding process, and the fishing line is not prone to being twisted itself due to guidance of the guide ring.

Owner:管同海

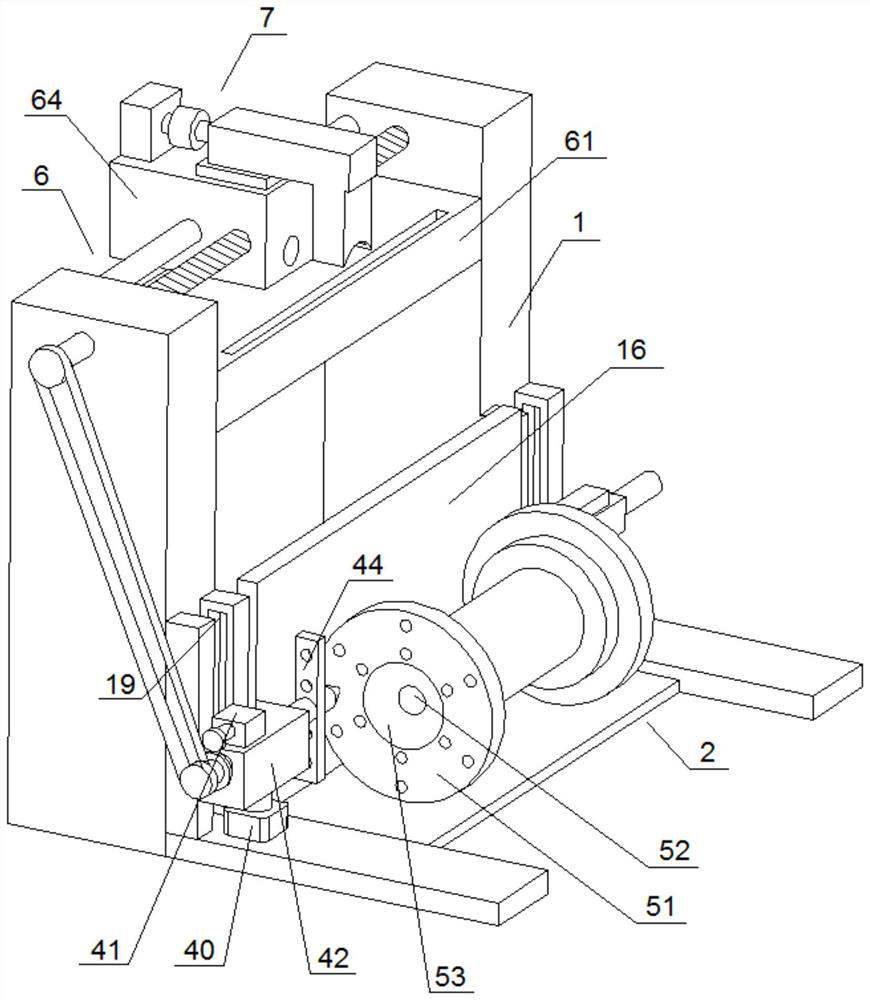

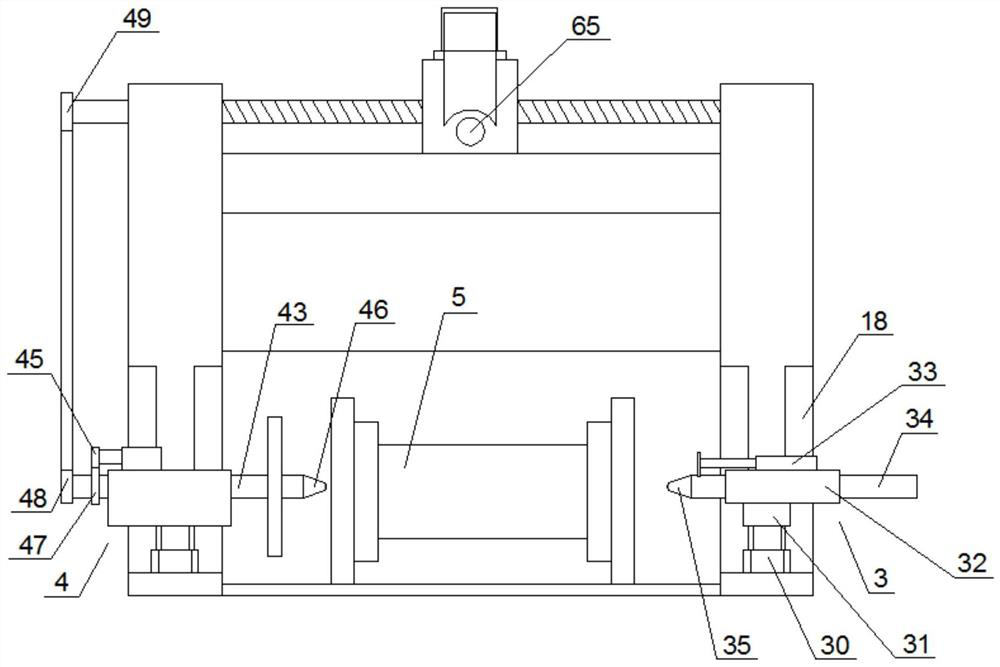

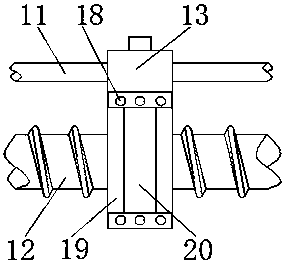

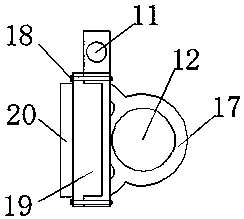

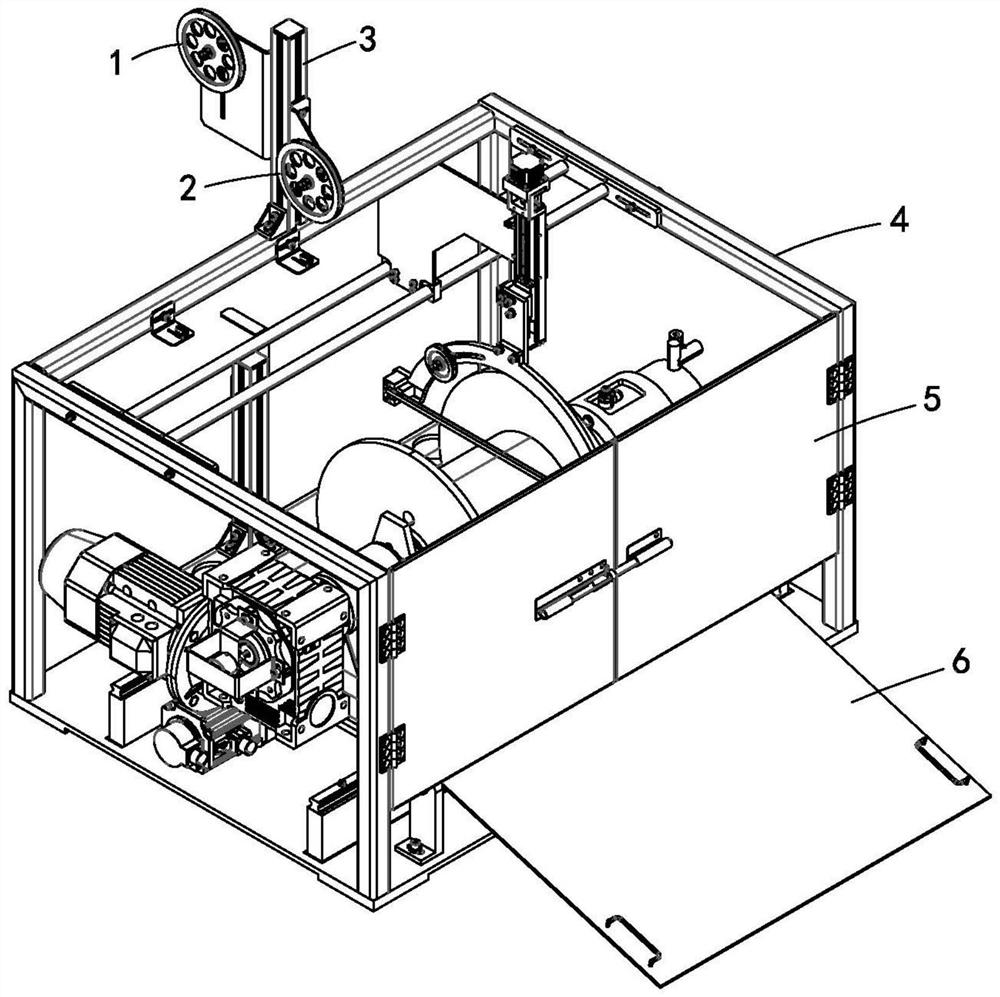

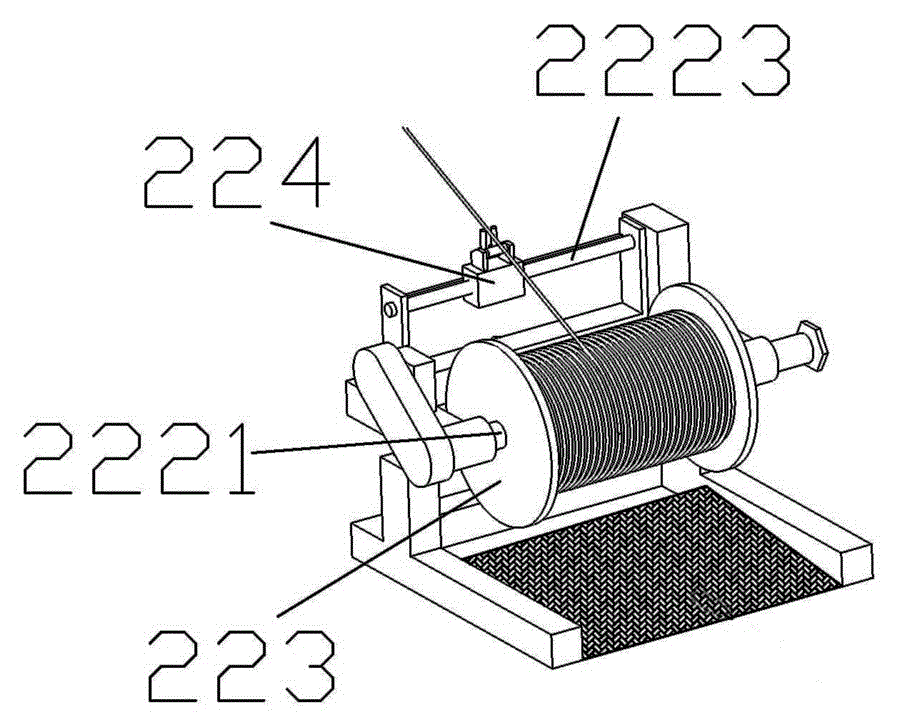

Butterfly-shaped leading-in optical cable automatic take-up system

ActiveCN112248049AQuick installationAvoid influenceFilament handlingMetal working apparatusControl systemWire cutting

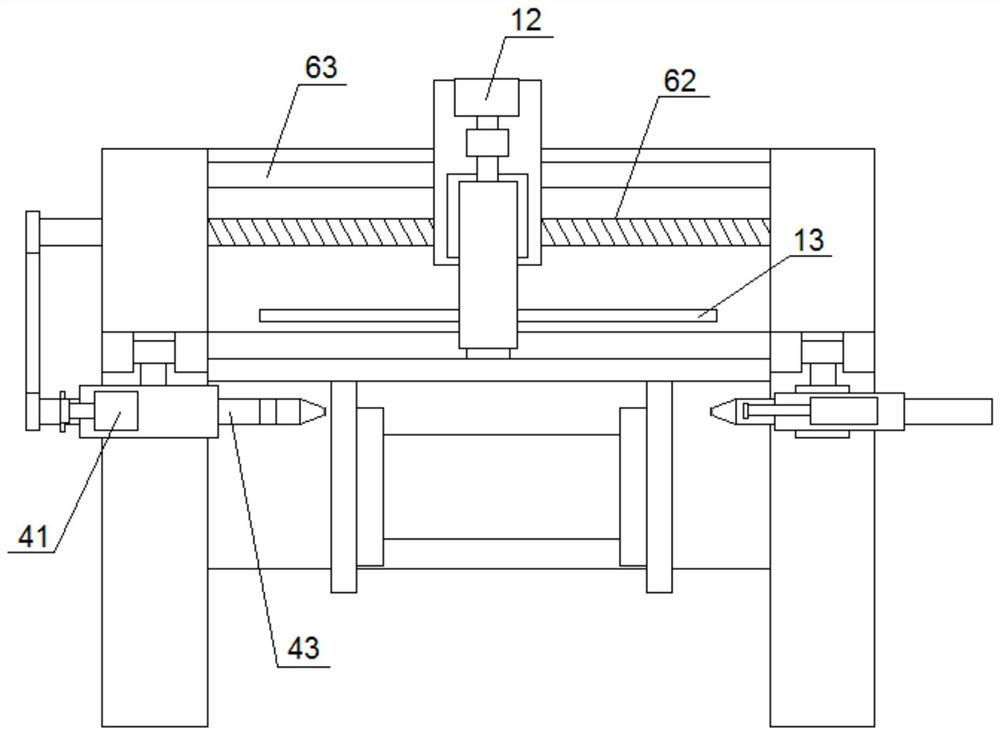

The invention discloses a butterfly-shaped leading-in optical cable automatic take-up system. The system comprises an automatic take-up device and a control system, wherein the automatic take-up device comprises a take-up frame, a horizontal moving frame, a positioning assembly, a driving assembly and a take-up reel, the take-up frame is provided with the horizontal moving frame, the take-up reelis arranged on the horizontal moving frame, the horizontal moving frame can horizontally move in the radial direction of the take-up reel, the positioning assembly and the driving assembly are both arranged on the take-up frame and located on the two sides of the take-up reel in the axis direction respectively, a cross beam is arranged at the top of the take-up frame and is parallel to the axis ofthe take-up reel, a moving wire passing device is arranged on the cross beam, and a wire cutting device is arranged at the top of the movable wire passing device. According to the system, the take-upreel can be automatically positioned, rapid installation is achieved, and the take-up device has the advantages of being high in automation degree, uniform in take-up, low in labor input cost and thelike.

Owner:SICHUAN TIANYI COMHEART TELECOM

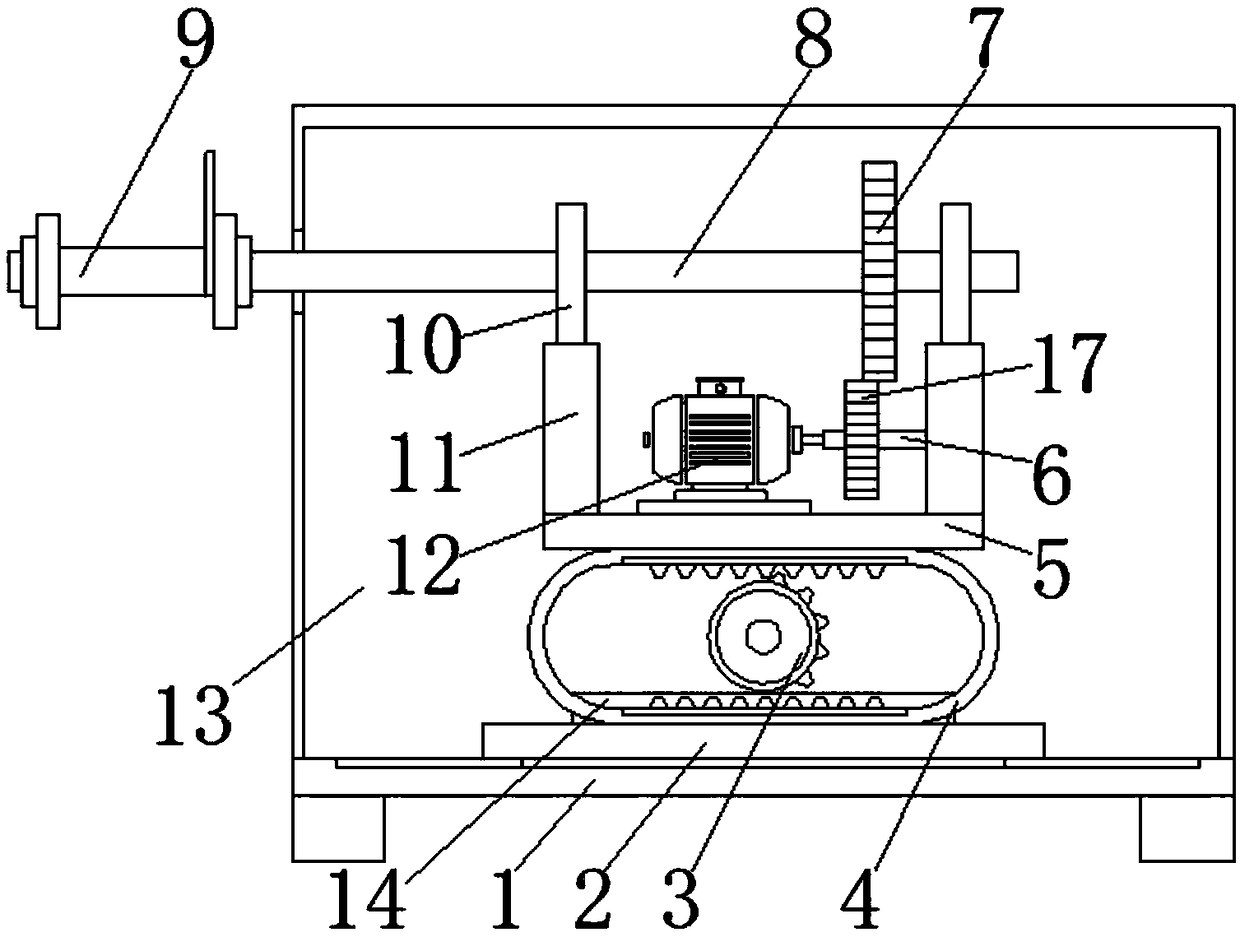

Safety winch for crane

InactiveCN107720582AExtended service lifeEnsure safetyWinding mechanismsPistonAutomotive engineering

The invention relates to the technical field of mechanical engineering, in particular to a safety winch for a crane, which includes a take-up wheel, a first fixing frame and a swing rod, a motor is provided at the front end of the take-up wheel, and a fixed rear end of the take-up wheel A brake device is connected, and the brake device includes a brake caliper body, a piston, a rubber ring, a friction block, an oil inlet pipe and a brake disc, and a brake caliper body is provided inside the brake device, and the brake caliper body is slidingly connected There is a piston, and the rubber ring is connected outside the piston. In the present invention, through the two brake caliper bodies, one is used as a normal brake and the other is used as an emergency brake. When the normal brake fails, the emergency brake is activated. It can not only ensure that the work efficiency is not affected, but also improve the safety of the working environment. This kind of design concept is novel, scientific in design, has huge economic benefits and broad market prospects, and is worth popularizing and using.

Owner:WUXI AOTU AUTOMATION TECH CO LTD

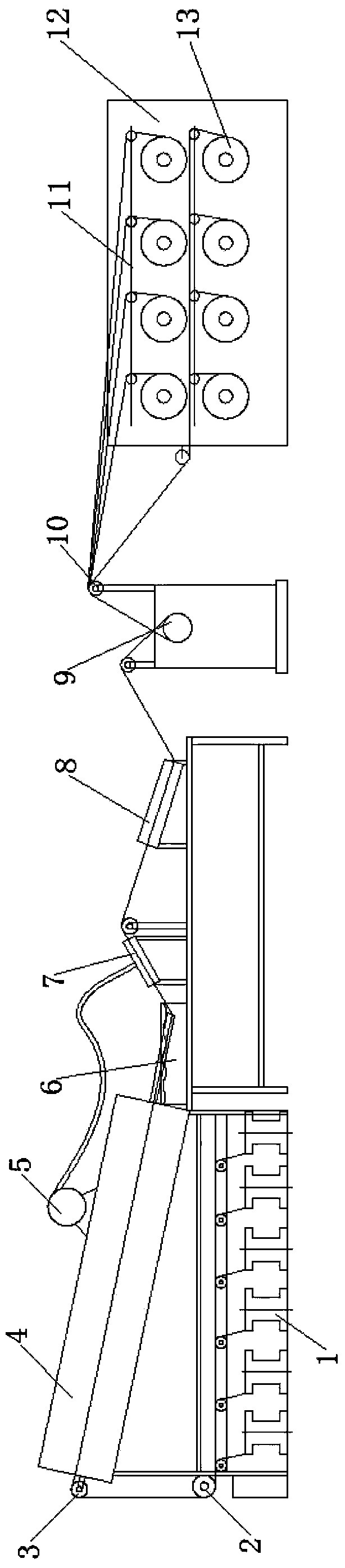

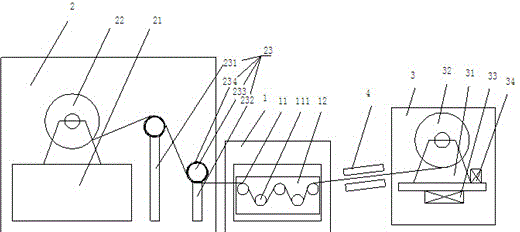

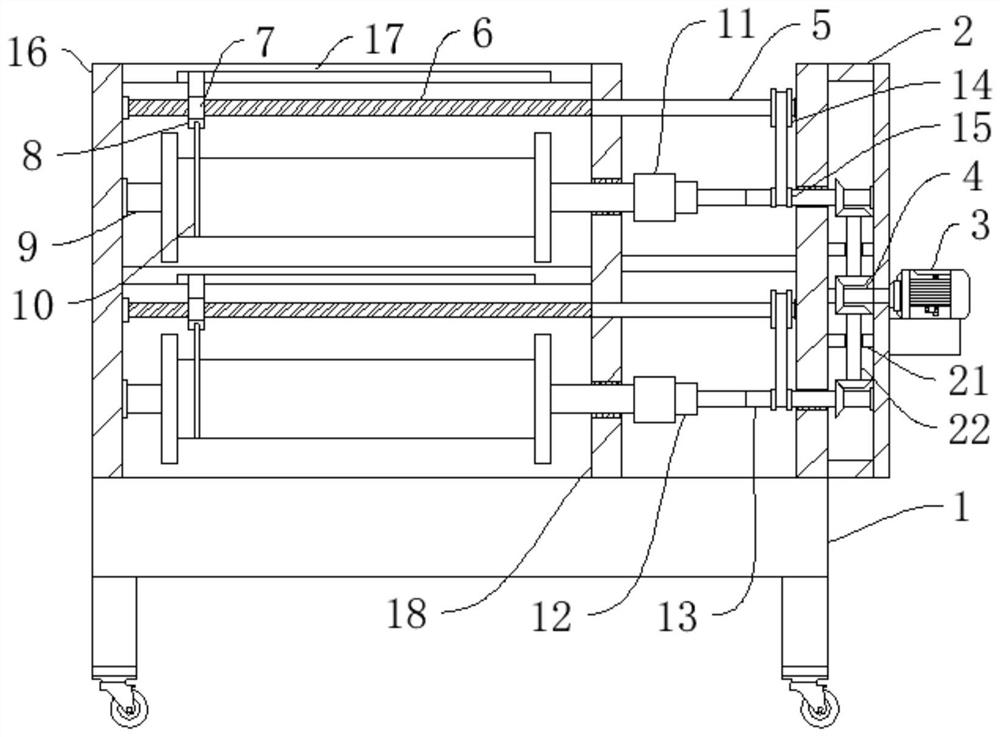

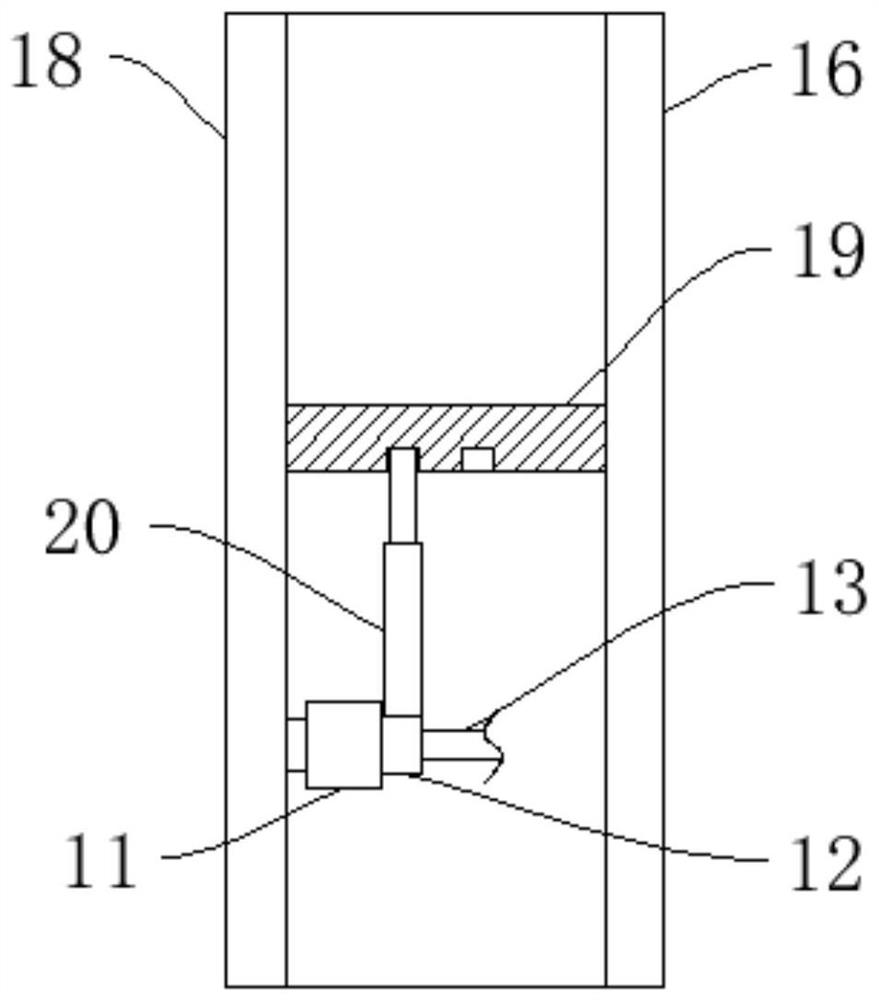

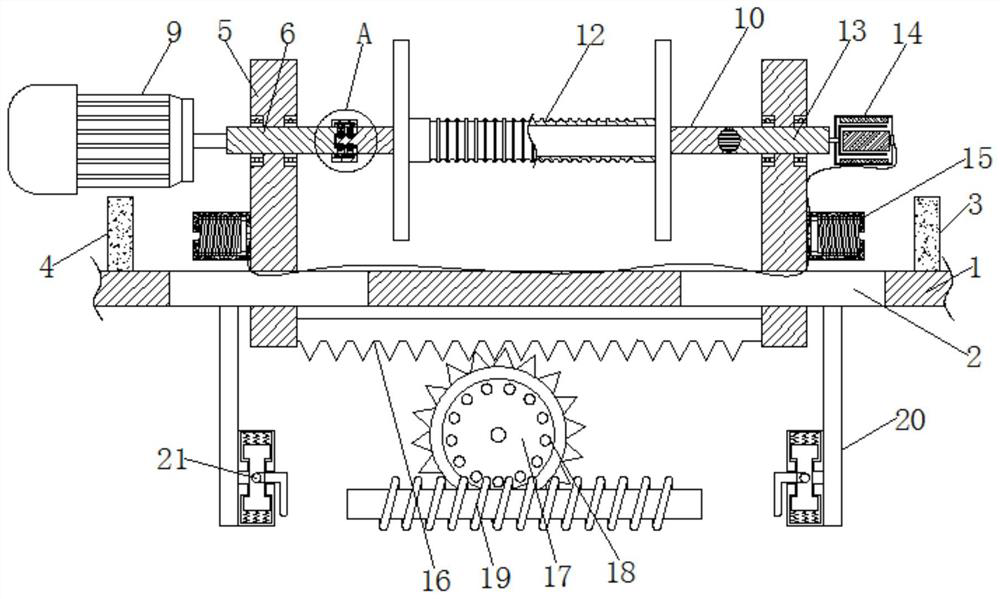

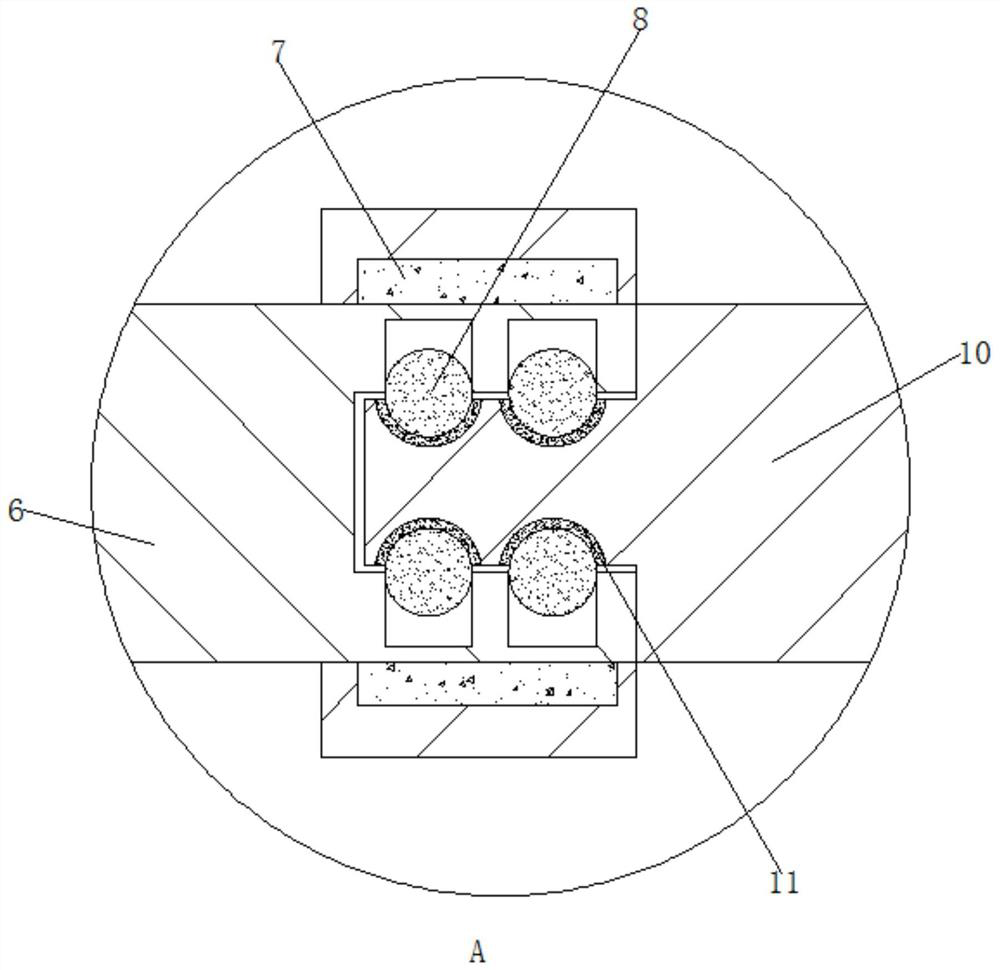

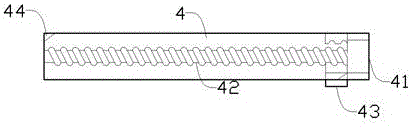

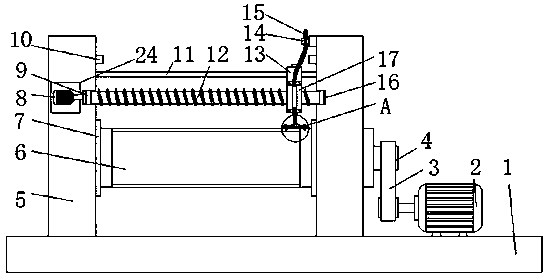

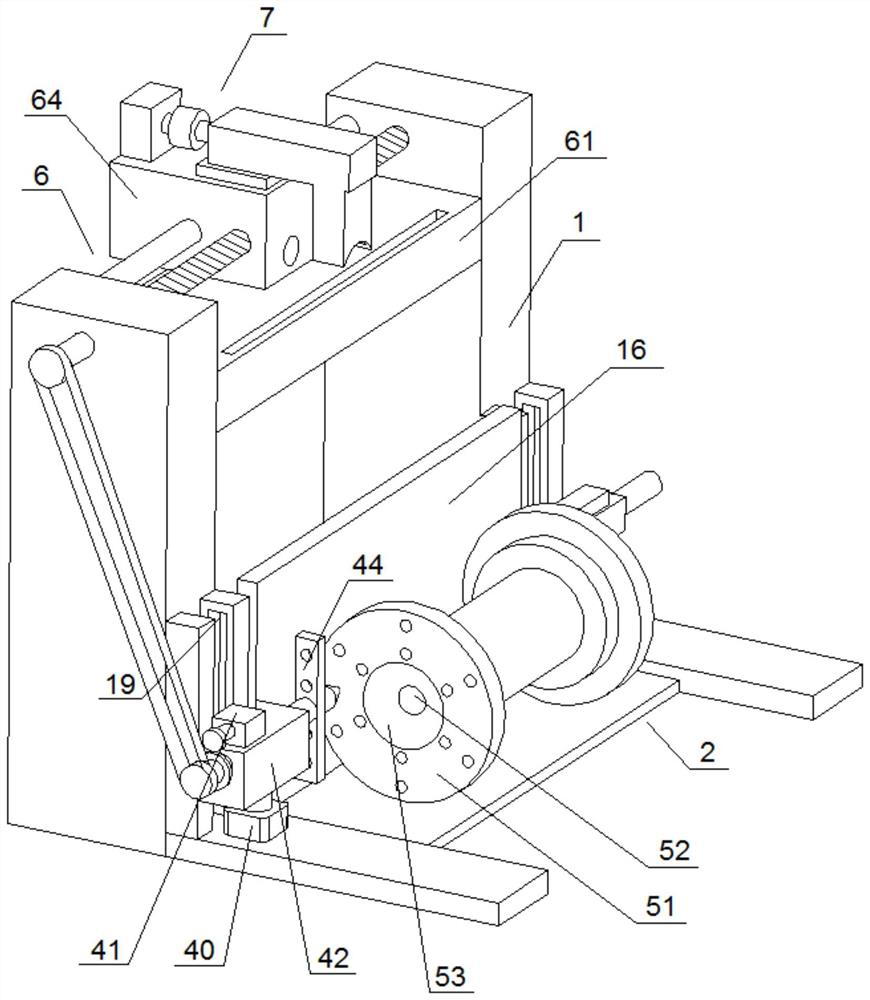

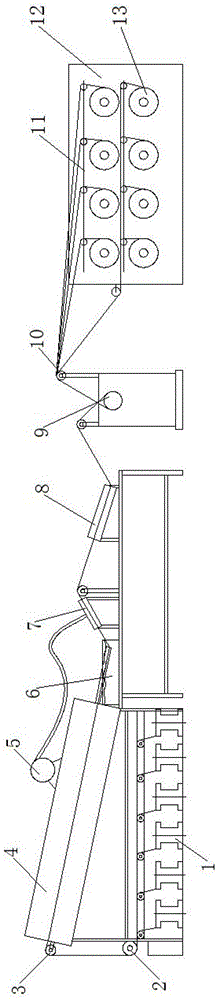

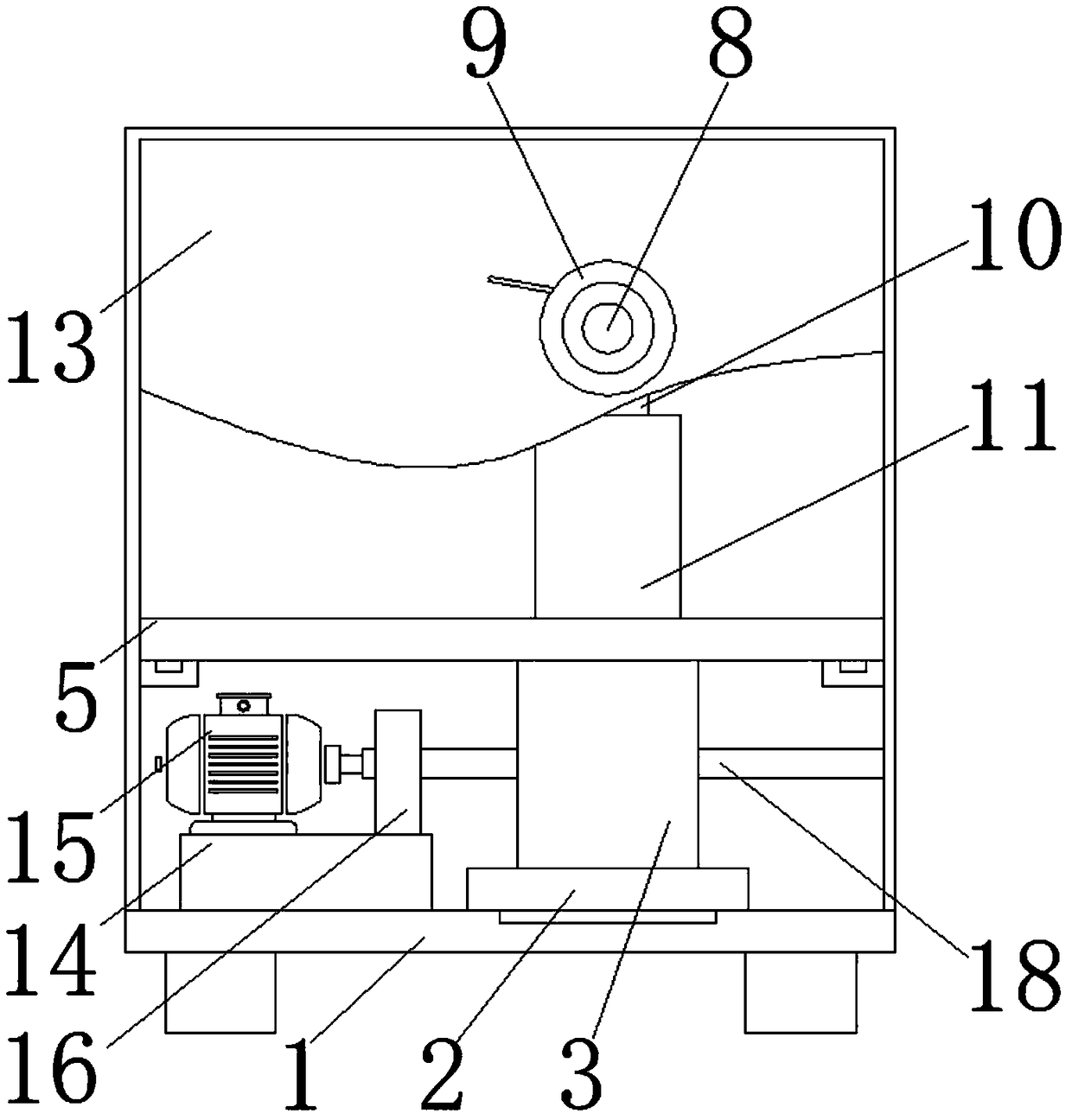

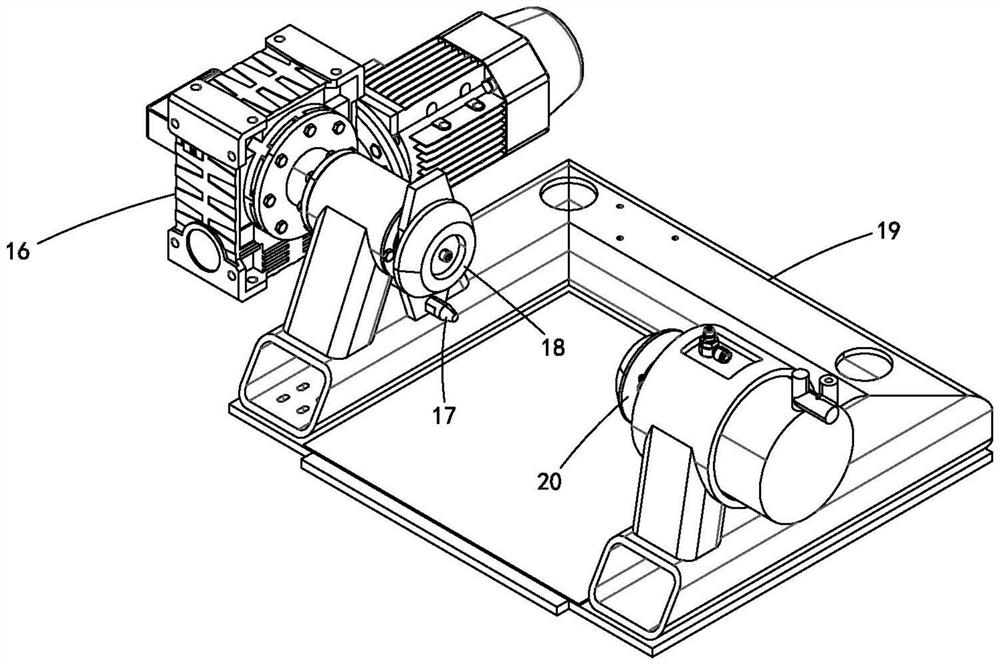

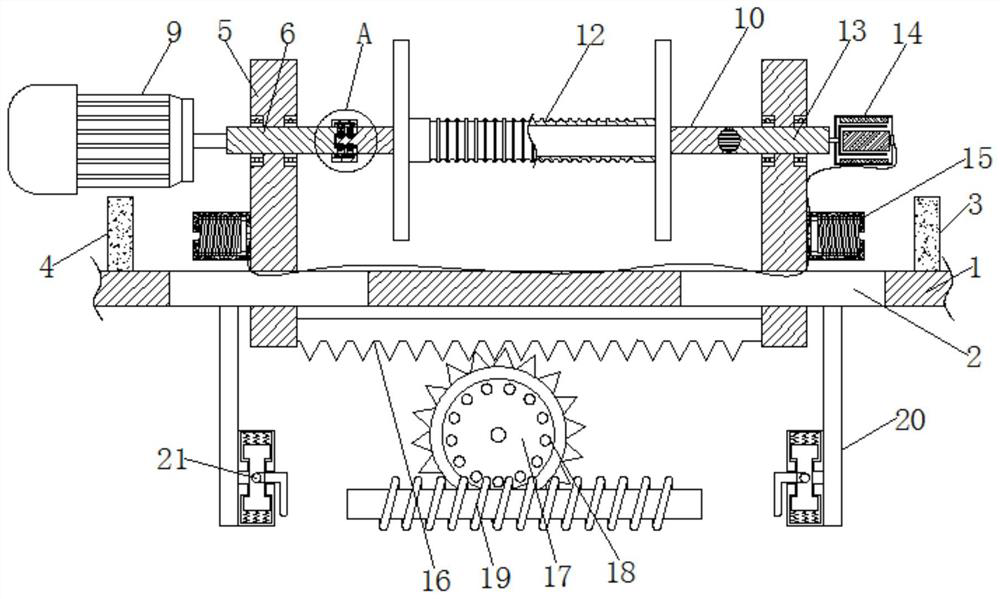

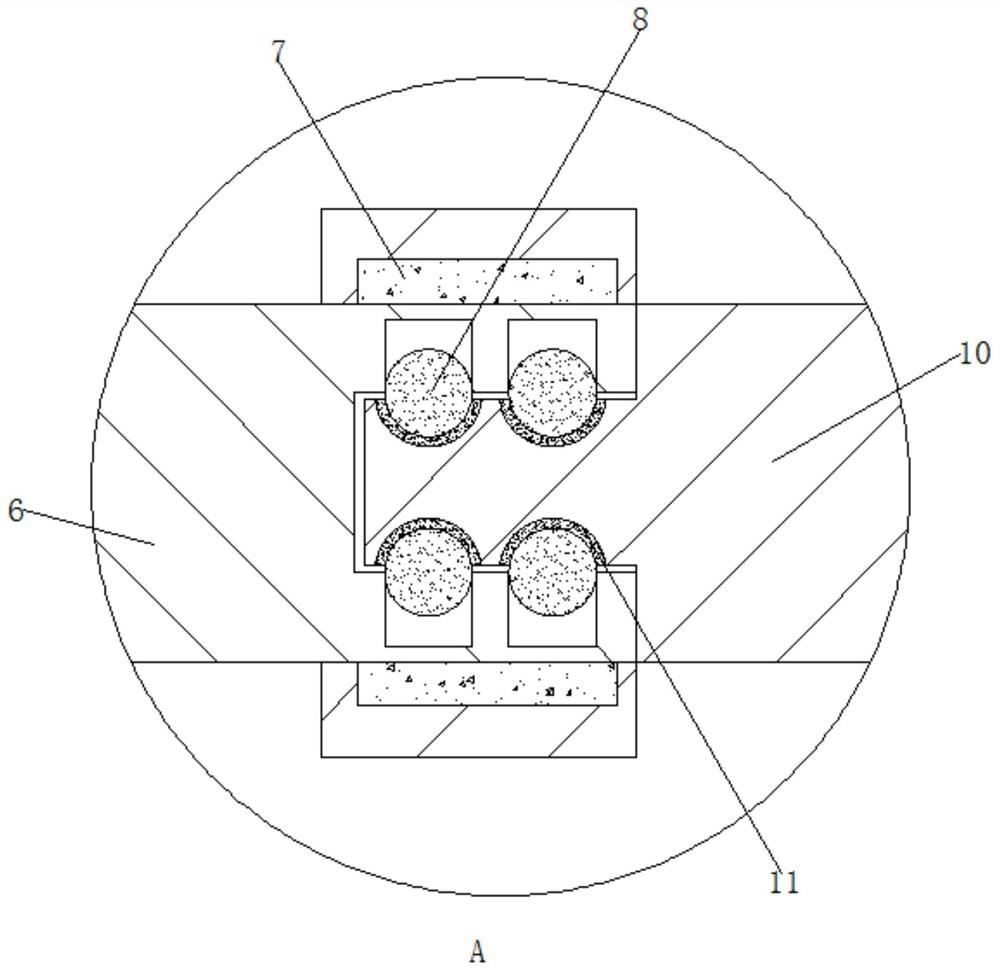

Wire drawing machine

InactiveCN105983590AImprove cleanlinessTake up evenlyExtrusion cleaning devicesMetal working apparatusEngineeringWater tanks

The invention relates to a wire drawing machine which includes a wire drawing apparatus. A wire releasing apparatus is arranged at one side of the wire drawing apparatus and a wire take-up apparatus is arranged at the other side. The wire releasing apparatus includes a wire releasing support and a wire releasing spindle fixedly mounted thereon. A wire arranging frame is arranged on the front end of the wire releasing support. A roller wheel group is arranged in the wire drawing apparatus. The wire take-up apparatus includes a wire take-up support which is provided with a wire take-up spindle. A driving apparatus is arranged on the bottom of the wire take-up support and is used for controlling the wire take-up spindle. The driving apparatus is connected to a counter. Through combination of the wire arranging frame and the roller wheel group, the wire take-up apparatus can take the wire up uniformly. The wire arranging frame is provided with the roller wheels and a hairbrush and a water tank is disposed in the wire take-up apparatus, so that the wire can be cleaned and counted and then can be dried by means of a drying machine. The wire drawing machine ensures the wire to be tidy and clean. The counter calculates the number of turns of the wire take-up spindle, and by which the number of taken-up wire by the wire take-up spindle can be determined, so that the machine is easy and convenient to use.

Owner:JIANGSU HAOJIA STAINLESS STEEL STANDARD PARTS

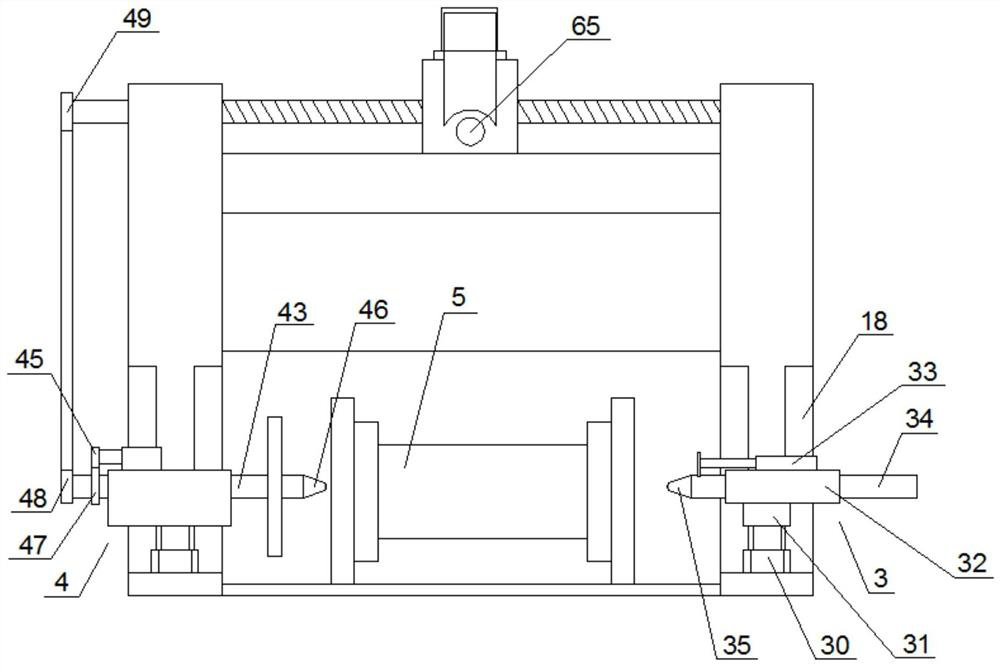

Cable take-up machine

The invention discloses a cable take-up machine, and relates to the technical field of cable production equipment. The technical problems that in a cable take-up machine in the prior art, cables are wound around a take-up reel unevenly, and the take-up effect is poor are solved. The cable take-up machine comprises a support, a cable guide wheel used for cable guide, a cable arrangement device used for cable arrangement and a take-up device used for take-up. The support comprises a first cross beam and a second cross beam. The cable guide wheel is arranged on the first cross beam. A cable arrangement wheel of the cable arrangement device is mounted on the second cross beam. The take-up device is mounted below the support. The cable take-up machine is mainly used for winding cables; due to the fact that the cable arrangement device is arranged, and a plurality of second fixing holes are formed in the straight line, passing through the circle center, on an eccentric wheel of the cable arrangement device, close and even take-up can be achieved, and the connecting position of a connecting shaft and the eccentric wheel can be selected according to needs; and thus, the left-right movement stroke of the cable arrangement wheel is adjusted so as to adapt to take-up work of take-up reels of different lengths.

Owner:TIANJIN LANGXING WIRE & CABLE

High-precision copper wire cutting and winding integrated device

InactiveCN107971435AAvoid continuing to take up the lineTake up evenlyMetal working apparatusCopper wireEngineering

The invention belongs to the technical field of copper wire cutting and winding, and discloses a high-precision copper wire cutting and winding integrated device. The high-precision copper wire cutting and winding integrated device comprises an integrated device body. The integrated device body comprises a supporting frame, an upper press plate, a lower press plate, a cutting knife and a take-up shaft. Fixed seats are mounted on the upper inner side and the lower inner side of the supporting frame. The take-up shaft is arranged between the two fixed seats and provided with a locating hole. A lower telescopic rod is arranged on one side of the lower end of the supporting frame. The lower press plate is mounted at the upper end of the lower telescopic rod. An upper telescopic rod is arrangedon one side of the upper end of the supporting frame. The upper press plate is mounted at the lower end of the upper telescopic rod. A copper wire detector is mounted on one side of the upper press plate and comprises a timer and a speed detector. According to the high-precision copper wire cutting and winding integrated device, due to the locating hole in the take-up shaft, copper wires can be fixed before take-up, and the situation that the copper wires are wound together disorderly in the copper wire cutting and winding process, and take-up and cutting of the red copper wires are inconvenient is avoided.

Owner:张玉英

Cable construction tightening device for high-voltage power grid

ActiveCN112467626ATake up evenlyImprove practicalityApparatus for overhead lines/cablesPower gridEngineering

The invention discloses a cable construction tightening device for a high-voltage power grid, and the device comprises a base; first supporting plates are fixedly connected to the left side and the right side of the upper end of the base, two pairs of clamping rods are rotatably connected to the sides, close to each other, of the first supporting plate and the second supporting plate on the left side, and a cable coil is fixedly connected between the two pairs of clamping rods; cables are wound around the two cable coils, and two threaded rods located on the rear sides of the two cable coils are rotationally connected between the first supporting plate and the second supporting plate on the left side. The whole device is simple in structure and convenient to operate, two cables can be tightened at the same time, one cable can also be tightened, cables of different thicknesses can be tightened, the practicability of the cable tightening device is greatly improved, and the cable tightening device is worthy of application and popularization.

Owner:国网河南省电力公司三门峡市陕州供电公司

Auxiliary device for winding computer network cables

The invention relates to the technical field of computer auxiliary equipment and discloses an auxiliary device for winding computer network cables. The auxiliary device comprises a base, wherein a sliding groove is formed in the surface of the base; a magnet I is arranged on the surface of the base; a magnet II is arranged on the surface of the base; support frames are arranged in the base; a rotating shaft is arranged in the support frames; and one end, away from the magnet II, of the rotating shaft is movably connected with a magnetic block. According to the auxiliary device for winding computer network cables, the magnet I and the magnet II cooperate with induction coils in use, the support frames cooperate with a rack in use, and a screw cooperates with current commutators in use; a cable winding shaft is capable of circularly moving left and right when winding the network cables, so that the network cables are wound more uniformly; the cable winding effect is improved; no manual coordination is needed; and the cable winding efficiency is improved.

Owner:湖南顺一鑫电子科技有限公司

Circulatory guide type automatic and uniform wire taking-up structure

Owner:SUZHOU PULINGDA AUTOMATION TECH CO LTD

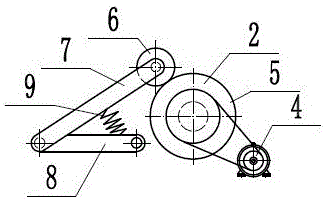

Wool yarn take-up device

InactiveCN105088432ASwing back and forthIt has the following advantages and effects: the take-up mechanism can swing back and forthContinuous wound-up machinesYarnEngineering

The invention provides a wool yarn take-up device and belongs to the technical field of textile machinery. The wool yarn take-up device comprises a take-up mechanism and a swing mechanism. A guide roll of the take-up mechanism is arranged on a rack in a rotating mode. Yarn guide grooves are formed in the guide roll at equal intervals. A yarn take-up support is arranged on the rack in front-rear sliding mode. One end of a bearing support is fixed to the yarn take-up support. The other end of the bearing support is hinged to the lower end of a take-up roll support. A take-up roll is arranged at the upper end of the take-up roll support in a rotating mode and is tightly attached to the guide roll under the action of a pressure spring. A first belt wheel of a drive mechanism is concentrically arranged on one side of the guide roll. The first belt wheel and a second belt wheel are connected through a drive belt. The second belt wheel is coaxially connected with a drive motor. One end of a connection rod of the swing mechanism is hinged to one end of the yarn take-up support. The other end of the connection rod is hinged to one end of a crank. The other end of the crank is connected with a swing motor. The wool yarn take-up device is uniform in take-up, good in effect, simple in structure and low in cost.

Owner:NANTONG DOUBLE GREAT TEXTILE

Copper wire winding device

The invention discloses a copper wire take-up device, which comprises a guide rail, a rotating shaft, a fixed shaft, a guide rail, an oil storage tank, an oil dripping pipe, a recovery pipe, a motor, and a weighing device. The guide rail is arranged above the rotating shaft, and the rotating shaft is arranged On the fixed shaft, the fixed shaft is set on the weighing device, the recovery pipe is set on the rotating shaft, the wire groove is set on the guide rail, the oil storage tank is set on one side of the wire groove, and the oil drip tube is set Above the wire groove, the motor is arranged on the rotating shaft. The invention has simple and reasonable structure and is convenient to use.

Owner:ANHUI JIEAO ELECTRIC CO LTD

Winding machine for textile

The invention relates to the textile field, in particular to a textile bobbin winder. The textile bobbin winder comprises a paying-off mechanism, a shell, a machine body, a first motor, a first supporting plate, two limiting columns, a sliding mechanism, a yarn box, a second supporting plate, a drive mechanism, a taking-up mechanism and a yarn pushing mechanism. The sizes of fixing columns which are in a prism shape in the paying-off mechanism are equal to that of a clamping column of the taking-up mechanism, it is achieved that a bobbin can be directly clamped to the surface of the fixing column, the practicability is high, and labor is saved. The drive mechanism cooperates with the yarn pushing mechanism to swing a yarn harness needing winding between the two limiting columns, it is avoided that the yarn harness is taken up at one position of the surface of the bobbin, and therefore taking-up is more uniform. The inner portion of the yarn box is fixedly connected with a sliding frame. A reversed-T-shaped swing block is connected into the sliding frame in a sliding manner. A yarn harness to be wound is inserted into a yarn hole in the swinging block. A spring is arranged between the swinging block and the sliding frame. In cooperation with swinging of the yarn pushing mechanism, the yarn harness is prevented from being snapped.

Owner:嘉兴市鑫锋纺织股份有限公司

Aluminum alloy wire rod coiling device

The invention relates to the technical field of aluminum alloy wire rods, and discloses an aluminum alloy wire rod coiling device. The aluminum alloy wire rod coiling device comprises a base, stands are fixedly connected to the two sides of the upper surface of the base, a roller base is fixedly connected to the lower middle side of the portion between the stands, a first motor is fixedly installed on the right side of the upper surface of the base, a belt wheel is fixedly installed on the first motor, and a roller corresponding to the roller base is rotationally connected to the first motor through a belt. According to the aluminum alloy wire rod coiling device, an upper table plate and a lower table plate are matched to fix alloy wires to the roller, when the roller rotates, a rolling shaft lead screw drives a lead screw sleeve to leftwards move at constant speed, when the lead screw sleeve reaches the position of a sensor, a second motor reversely rotates to drive the lead screw sleeve to move rightwards, then the alloy wires can be evenly distributed on the surface of the roller, the structure achieves the advantage of even wire winding, and the alloy wires can beeffectively prevented from being extruded in the roller together.

Owner:湖州大本营科技有限公司

A Butterfly-shaped Lead-In Optical Cable Automatic Take-Up System

ActiveCN112248049BQuick installationRapid positioningFilament handlingMetal working apparatusControl systemMechanical engineering

The invention discloses an automatic wire take-up system for a butterfly-shaped lead-in optical cable, comprising an automatic wire take-up device and a control system. The automatic wire take-up device includes a wire take-up frame, a horizontal moving frame, a positioning assembly, a drive assembly and a wire take-up reel. There is a horizontal moving frame on the upper, and the wire take-up reel is arranged on the horizontal moving frame, and the horizontal moving frame can move horizontally along the radial direction of the wire take-up reel. The components are respectively located on both sides of the axis of the take-up reel. The top of the take-up frame is provided with a cross beam, the cross beam is arranged in parallel with the axis of the take-up reel, the cross beam is provided with a moving wire device, and the top of the moving wire device is provided with a tangent device . It can automatically position the take-up reel, realize fast installation, and has the advantages of high automation, uniform take-up and low labor input cost.

Owner:SICHUAN TIANYI COMHEART TELECOM

System and method for intelligently controlling tube continuous annealing furnaces

ActiveCN103436683BAvoid stretchingStable wire diameterFurnace typesHeat treatment process controlTemperature controlComputer module

Owner:江苏华旺新材料有限公司

Safety line uncoiling device for safety line security papers

InactiveCN108773735AReach the function of uncoiling safety lineSolve the problem of uneven unwinding and windingFilament handlingEngineeringSlide plate

The invention discloses a safety line uncoiling device for safety line security papers. The device comprises a base plate; the top of the base plate is connected with a slide plate in a sliding mode;the top of the slide plate is fixedly connected with a gear frame; the top of the gear frame is fixedly connected with a mounting plate; two bases are fixedly connected to the top of the mounting plate; the tops of the two bases are fixedly connected with first bearing bases; the two first bearing bases are rotationally connected with a main shaft; a third gear fixedly sleeves the outer wall of the main shaft; a first motor is fixedly mounted at the top of the mounting plate between the two bases; a first gear shaft fixedly sleeves an output shaft of the first motor; a first gear fixedly sleeves the outer wall of the first gear shaft; and the third gear is engaged with the first gear. The device is high in practicability and convenient to use, and solves the problem of nonuniform uncoilingand line collection in a traditional safety line uncoiling device for the safety line security papers.

Owner:芜湖韩大防伪科技有限公司

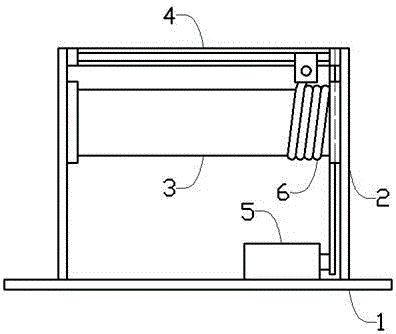

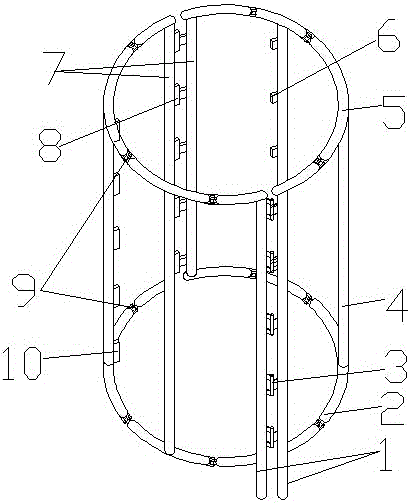

Electric curtain system

PendingCN109322605ATake up evenlyPrevent thread churningDoor/window protective devicesEngineeringScrew thread

The invention discloses an electric curtain system which comprises a rotating shaft, a power device is connected with the rotating shaft, a plurality of screw rods arranged at intervals are arranged on the rotating shaft, pulling ropes are arranged on the screw rods, and one ends of the pull ropes are fixed by the screw rods. The rotation of the screw rods drives the pull ropes to be raised or lowered, fixed limiting seats are connected with the screw rods in a threaded mode, and the screw pitch of the screw rods is not less than the diameter of the pull ropes. The electric curtain system drives the screw rods to move evenly in the limiting seats by the power device driving the rotating shaft to rotate, the pull ropes are raised or lowered evenly with the screw rods, so that the uniform winding of the curtain system is realized, and the situation that when the pull ropes are raised or lowered, the pull ropes are overlapped on the screw rods and wire agitating is prevented. The electriccurtain system is used in the field of curtain system.

Owner:GUANGDONG RAEX INTELLIGENT TECH CO LTD

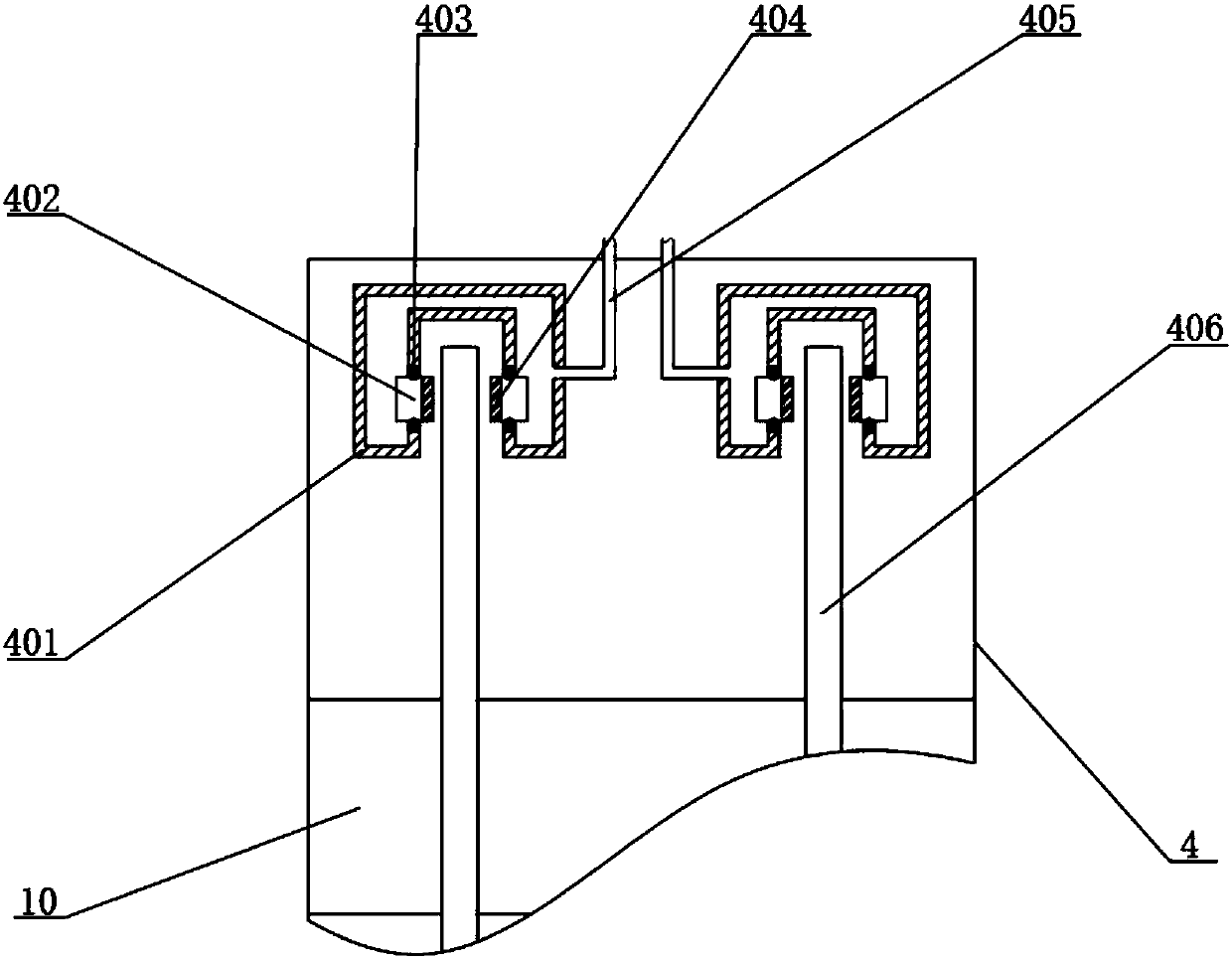

An adjustable opening and closing reinforcement device for a copper wire take-up reel

The invention discloses an adjustable opening / closing reinforcing device for a copper cable reeling disc and belongs to the field of mechanical processing equipment. The device comprises a reeling roller, a bottom round rod, a top round rod, two rotary fixing rods and two connecting rods, wherein the bottom round rod and the top round rod are fixedly connected through the reeling roller and are concentric circles; rotating pairs are arranged on both the top round rod and the bottom round rod; two end openings are formed in the bottom round rod and the top round rod along a diameter line; the rotary fixing rods are fixed at one end openings; the connecting rods are fixed at the other end openings; the two rotary fixing rods are connected through a hinge; the two connecting rods are connected through a locking buckle; the locking buckle comprises a movable part and a fixed part. A large number of cables can be reeled by the device at one time; the phenomena that the cables are unbound and are in a mess when the cables are reeled in a large number are avoided; the reeling effect on the copper cables with relatively high unit weight, relatively high product elongation percentage and relatively low tensile property is particularly better; uniform cable reeling is guaranteed; the cables are guaranteed not to be stretched.

Owner:WUHU CHANGRUN SPECIAL COPPER

Fixed wire coil take-up device

PendingCN114057017ATake up evenlyPrevent lateral movementFilament handlingEngineeringElectrical and Electronics engineering

The invention discloses a fixed wire coil take-up device in the field of automation equipment. The fixed wire coil take-up device comprises a frame, wherein a first guide part is fixed on one frame at the top part of the frame, a second guide part is fixed between adjacent frames at the two ends of the frame where the first guide part is located, the first guide part and the second guide part are located on the same straight line, a take-up device is arranged below the second guide part, a displacement device is connected below the take-up device, a door plate is arranged on the side face, opposite to the side face where the first guide part is located, of the frame, and a movable discharging plate is arranged below the door plate. The fixed wire coil take-up device can automatically clamp a feeding disc so that the feeding disc is suspended, and the problem that manual feeding is difficult is solved; a plurality of guide parts are used for guiding and preventing a wire belt from moving transversely; and the take-up device capable of automatically displacing can enable the material disc to take up more uniformly in the take-up process.

Owner:江苏泰力松新材料有限公司

High-performance low-zinc brass alloy wire coiling device for electronic communication

The invention discloses a high-performance low-zinc brass alloy wire coiling device for electronic communication. The high-performance low-zinc brass alloy wire coiling device has the technical schemekey points that a control cabinet is included, supporting columns are fixedly connected to the left side and the right side of the upper surface of the control cabinet, a wire coiling shaft is mounted between the two supporting columns, the two ends of the wire coiling shaft are rotationally connected with the inner side faces of the two supporting columns through bearings, and the wire coiling shaft is provided with a fixing hole; a guiding rod is located below the wire coiling shaft, and the two ends of the guiding rod are fixedly connected to the inner side faces of the supporting columns;the guiding rod is slidably connected with a guiding block in a sleeved mode, the outer side face of the guiding block is coaxially and rotationally connected with a pulley, and the outer side face of the pulley is provided with a groove; and a cylinder sleeve of a hydraulic cylinder is fixedly connected to the inner side faces of the supporting columns, and the output end of the hydraulic cylinder is fixedly connected to the end face of the guiding block. The high-performance low-zinc brass alloy wire coiling device facilitates fixing of a brass alloy wire, can limit and change a wire coiling direction of the brass alloy wire, and facilitates even wire coiling of the brass alloy wire.

Owner:WUHU CHUJIANG ALLOY COPPER

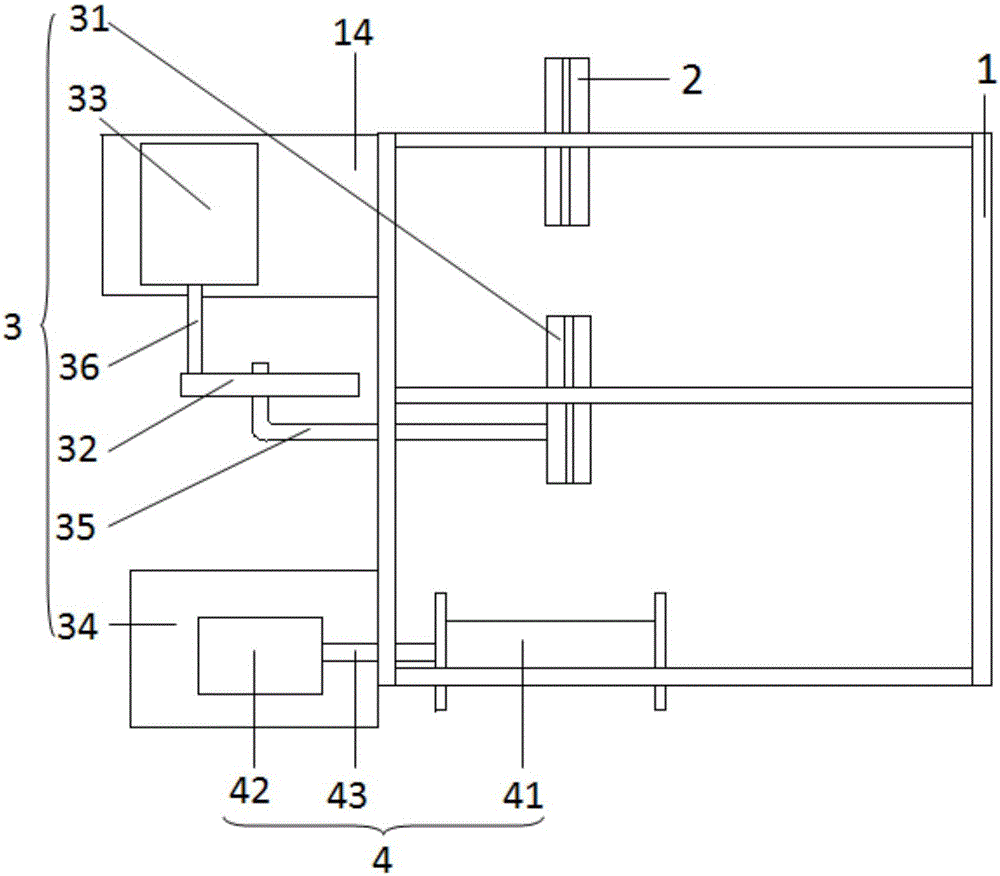

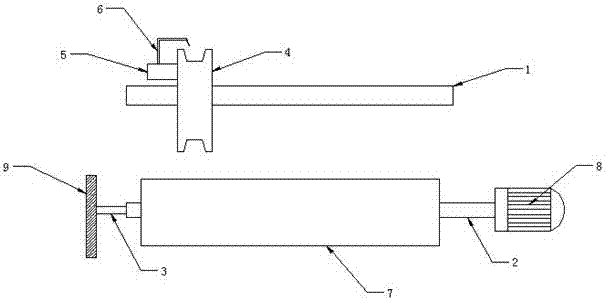

A wire stretching and winding device

ActiveCN105060007BTake up evenlyMake full use of spaceFilament handlingEngineeringMechanical engineering

Owner:ANJI TENGFEI ELECTRONICS

Blend fiber functional embroidery thread and processing device thereof

The invention discloses a blend fiber functional embroidery thread and a processing device thereof, relates to the technical field of embroidery thread processing, and provides the following scheme aiming at solving the problems that the crease resistance and the water absorption capacity of an existing embroidery thread are poorer due to solid winding of silk threads, and uniform winding is inconvenient during production. The processing device comprises a fixed plate, a reciprocating lead screw is rotationally connected to the top of the fixed plate, a guide rod fixedly connected with the fixed plate is arranged at the right side of the reciprocating lead screw, the guide rod is movably sleeved with a clamping mechanism in threaded connection with the reciprocating lead screw in a sleevedmanner, and a driving take-up mechanism is arranged above the clamping mechanism. The processing device not only facilitates uniform take-up of the embroidery thread during production, but also enables the embroidery thread to have good crease resistance and water absorption effects, and the practicability of the embroidery thread is improved.

Owner:浙江三和线业科技股份有限公司

A blended fiber functional embroidery thread and its processing device

The invention discloses a blended fiber functional embroidery thread and a processing device thereof, and relates to the technical field of embroidery thread processing, aiming at the solid winding of the existing embroidery thread, resulting in poor wrinkle resistance and water absorption capacity, and inconvenient and uniform production. For the problem of winding, the following scheme is now proposed, including the fixed plate, the top of the fixed plate is rotatably connected with a reciprocating screw rod, and the right side of the reciprocating screw rod is provided with a guide rod fixedly connected with the fixed plate, and the guide rod The outer movable sleeve is provided with a clamping mechanism which is threadedly connected with the reciprocating screw rod, and a drive take-up mechanism is provided above the clamping mechanism. The invention not only facilitates uniform winding up of the embroidery thread during production, but also has good anti-wrinkle and water-absorbing effects on the embroidery thread itself, thereby improving the practicability of the embroidery thread.

Owner:浙江三和线业科技股份有限公司

A computer network cable take-up auxiliary device

ActiveCN111847105BTake up evenlyImprove the take-up effectFilament handlingComputer-aidedControl theory

The present invention involves the technology field of computer auxiliary equipment, and has disclosed a computer -based network cable closing auxiliary device, including the base, which is opened on the surface of the base.Set up with a magnet two, the internal setting of the base is set with a bracket, the internal setting of the bracket is set with a rotor shaft, which is connected to a magnetic block from one end of the one -end of the rotating shaft.The coordination of the shaft and the branches, from the combination of the axis shaft and the induction magnet, the combination of the magnetic one and the magnet two and the inductive coil, the combination of brackets and racksWhen the wire shaft is closed on the network cable, it can be moved left and right to make the closing line of the network cable more uniform, which improves the line collection effect. No manual cooperation is required to improve the line efficiency.

Owner:湖南顺一鑫电子科技有限公司

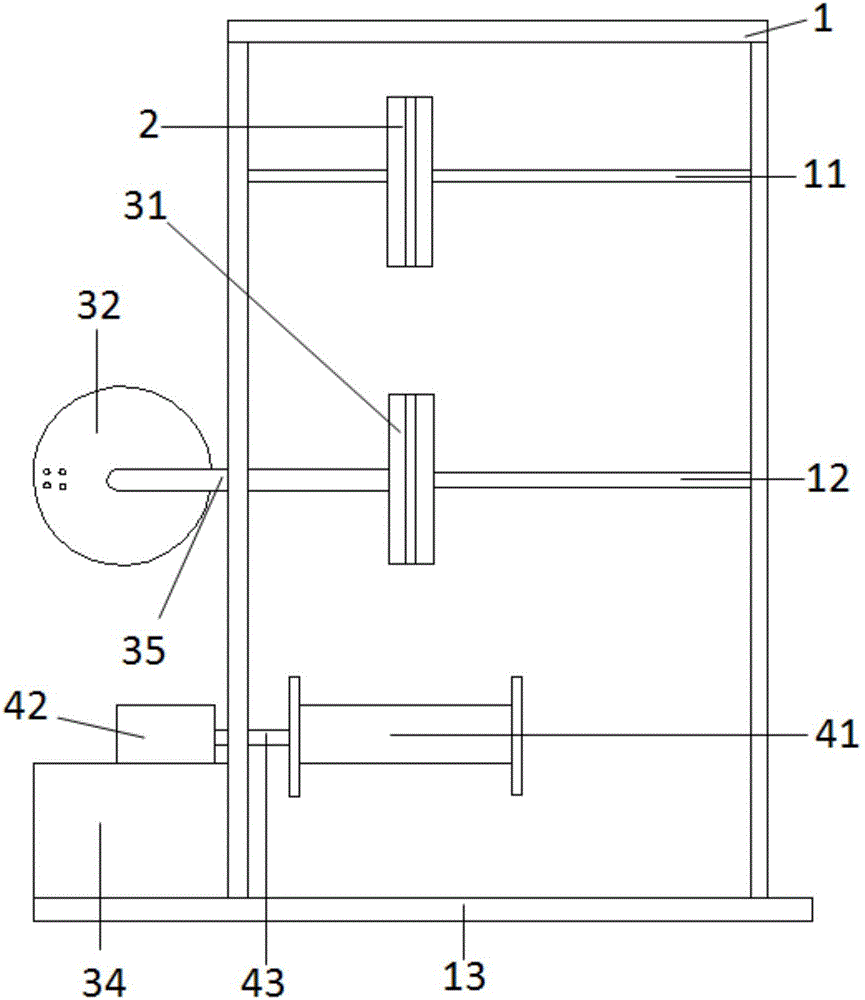

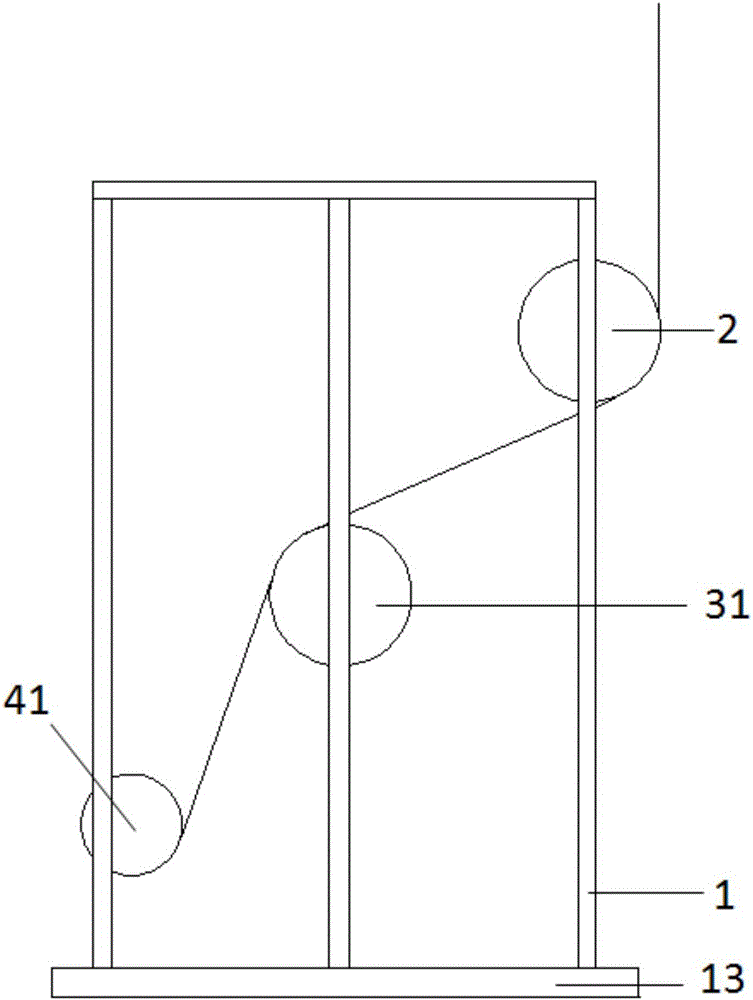

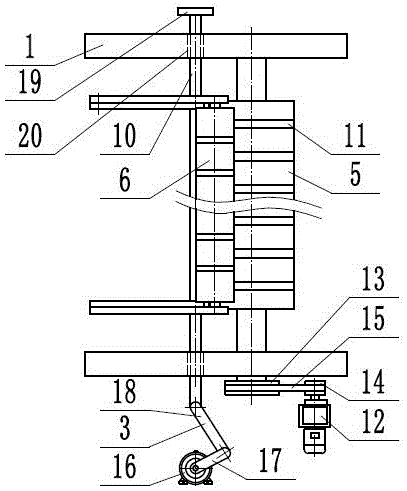

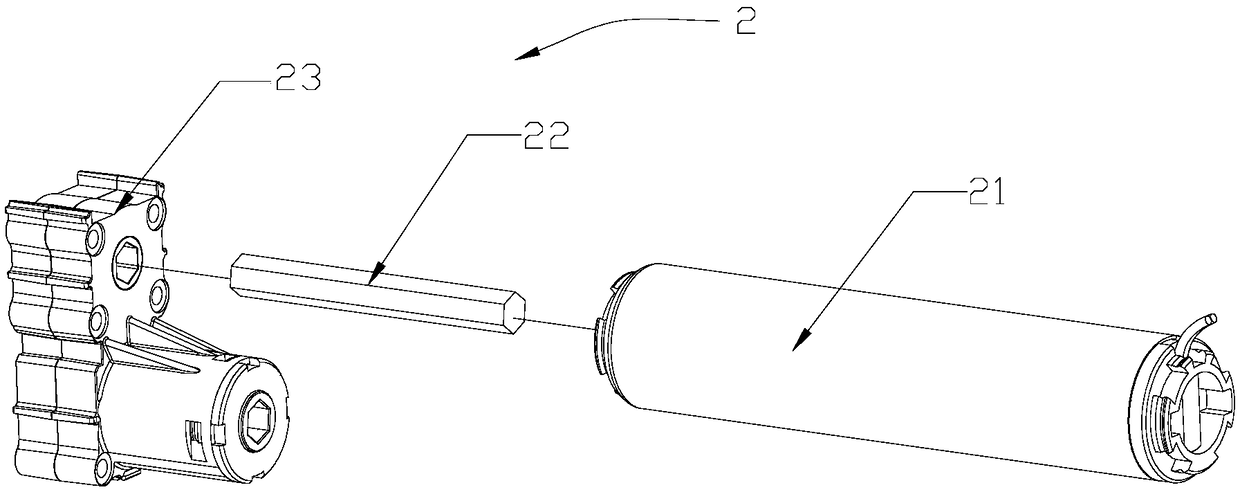

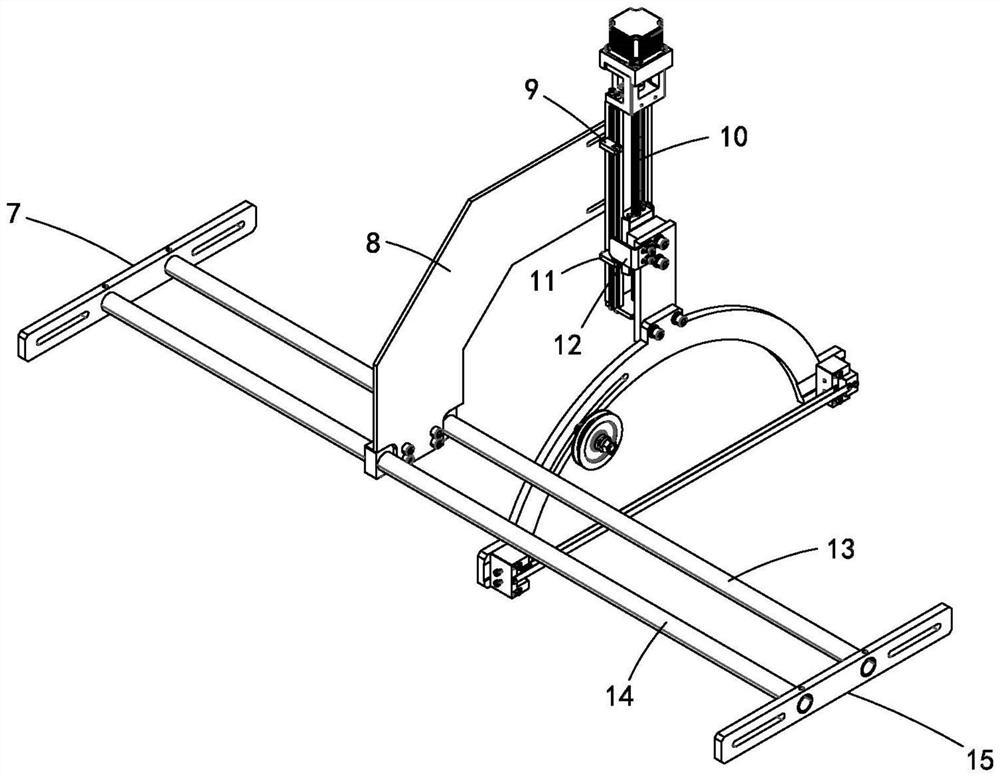

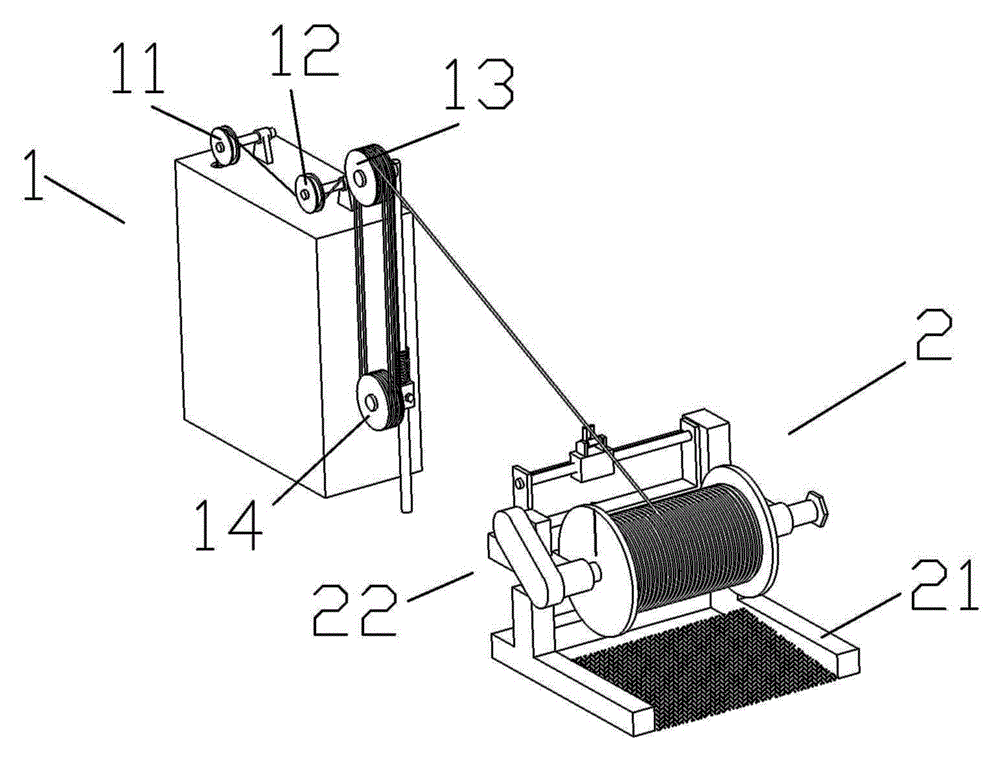

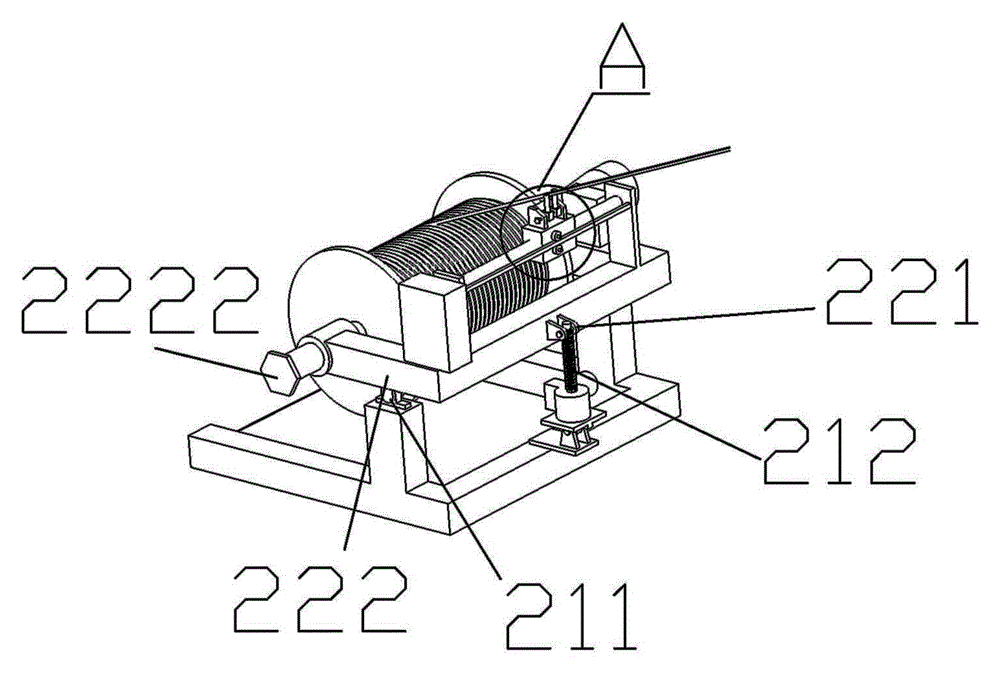

Electric wire stretching and winding device

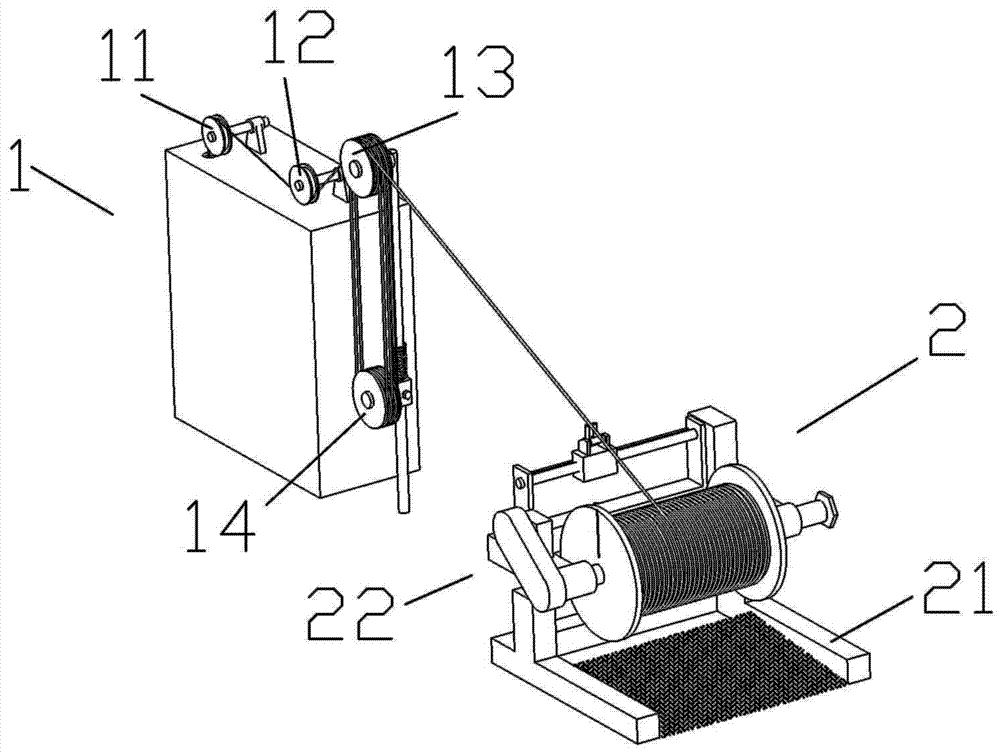

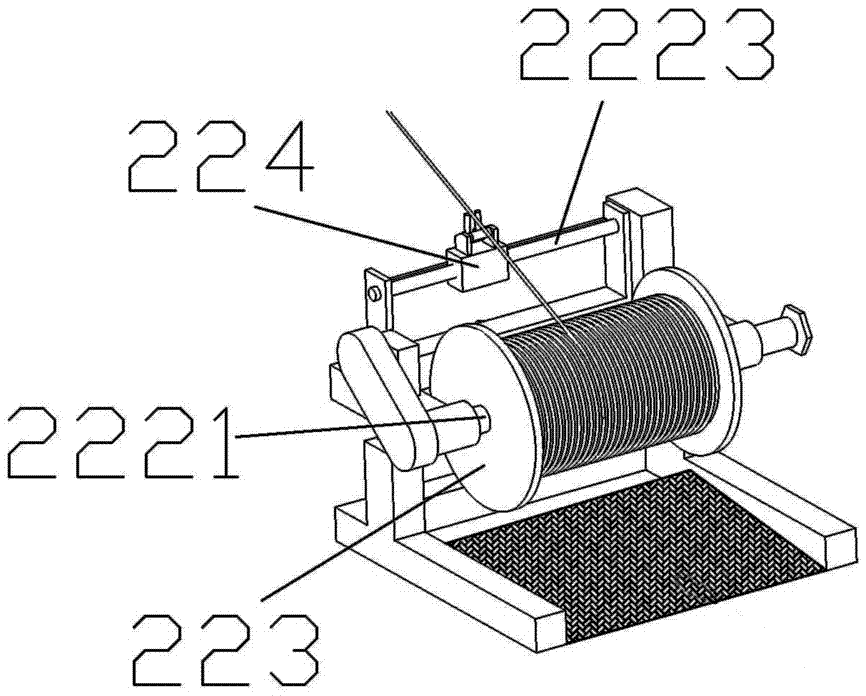

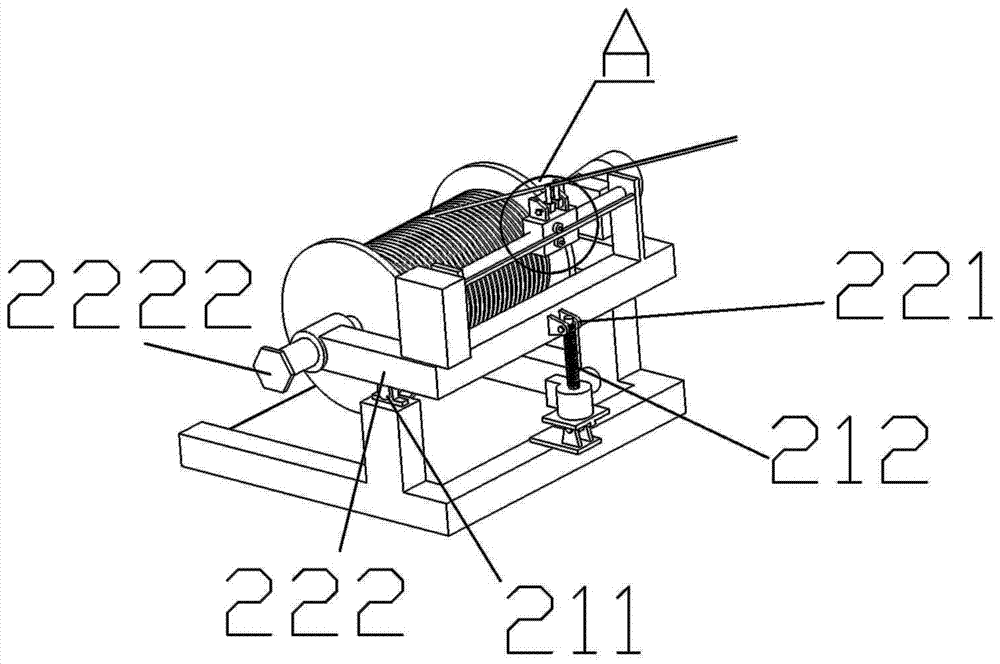

The invention relates to an electric wire stretching and winding device and belongs to the technical field of cable processing. The electric wire stretching and winding device comprises an electric wire stretching device (1) and an electric wire winding machine (2) connected to the rear portion of the electric wire stretching device (1). The electric wire winding machine (2) comprises a base (21) and a winding part (22) located on the base (21). First shaft structures (211) are arranged on the two sides of the base (21) and connected with the winding part (22). The winding part (22) can rotate around the first shaft structures (211). A connection rod (212) which can be driven by a motor to move in the vertical direction is further arranged at the rear end of the base (21). The connection rod (212) is connected with a second shaft structure (221) located at the rear end of the winding part (22). The electric wire stretching and winding device has the advantages that electric wires are evenly wound, the space of a winding drum can be fully utilized, and residual stress on the surfaces of the electric wires is eliminated.

Owner:ANJI TENGFEI ELECTRONICS

A vertical adjustable take-up reel

ActiveCN104464953BImprove adjustabilityAvoid being stretched or even brokenFilament handlingCable/conductor manufactureScrew threadMachining

The invention discloses a vertical adjustable wire take-up reel, which belongs to the field of mechanical processing equipment. It includes a rotating shaft and a take-up chassis. The take-up chassis includes a limit roller and a take-up roller, and there are 3-6, all fixed on the top of the rotating shaft. The limit roller includes a roller sleeve and a roller rod, and the roller sleeve is covered with a roller. rod, and the same side is provided with a second threaded hole, and is fixed by a second screw; the upper end surface of the take-up chassis is fixed with a take-up roller and a groove, and a roller sleeve is arranged in the groove, and passes through the groove on the side of the take-up chassis. The groove is provided with a first threaded hole, and when the roller sleeve is placed in the groove, a threaded hole is also provided at the corresponding position of the first threaded hole, and is fixed by the first screw. The present invention realizes the adjustability of the distance between the take-up roller and the limit roller and the overall height of the limit roller through the limit roller provided on the upper end surface of the take-up chassis, so it can be used for coils of different sizes and heights. The winding is realized, and the limit roller can also avoid the phenomenon that the cable will not be unbound and messy in the horizontal direction when a large amount of winding is performed.

Owner:WUHU CHANGRUN SPECIAL COPPER

Take-up device

InactiveCN105417269ASimple structureWith two-way take-up functionFilament handlingEngineeringMachining

The invention provides a take-up device. The take-up device comprises a machine base, take-up rollers, wind-up motors, a lead screw, first guiding wheels, a second guiding wheel, sensors, a control box and a lead screw motor. According to the take-up device, the structure is simple, the device has the bidirectional take-up function, the take-up operation in machining of two devices can be completed, the take-up efficiency is high, automatic adjustment control can be achieved, and take-up is uniform.

Owner:TIANJIN OLYNNOK TELECOMM SCI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com