Gas protection device for front side of titanium alloy material weld joint

A gas shielding device, the technology of the front of the welding seam, which is applied to the device for supplying/removing shielding gas, welding equipment, welding accessories, etc., can solve the problems of poor reliability, short protection distance, unstable manual operation, etc., to reduce welding Effects of deformation, protection of the weld surface, flexibility and scalability benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

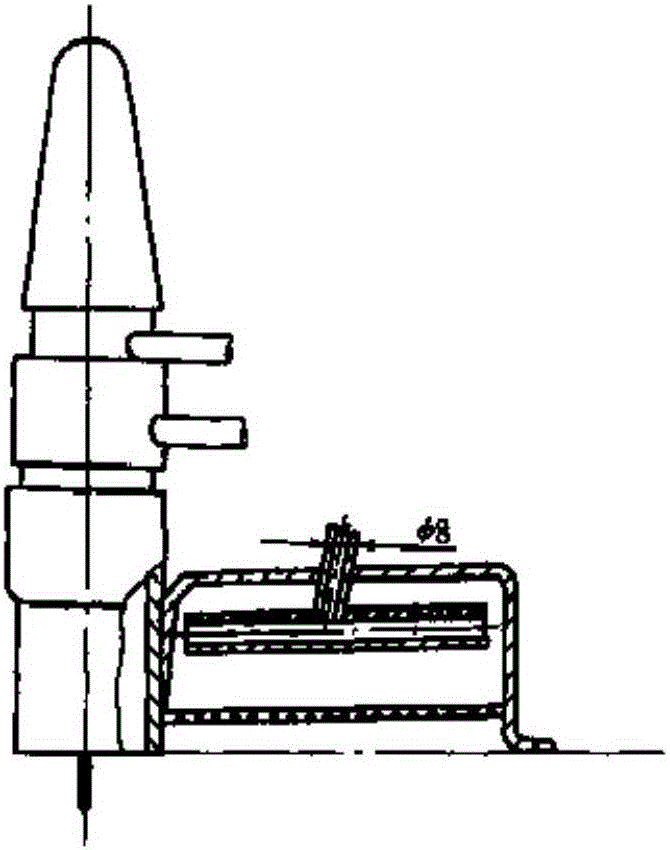

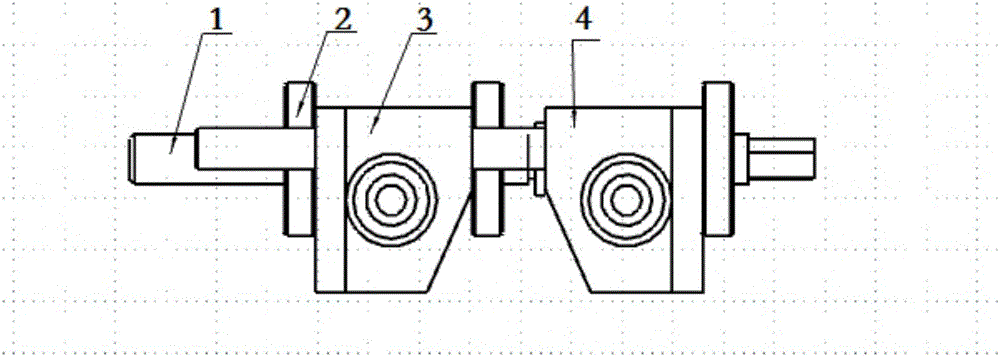

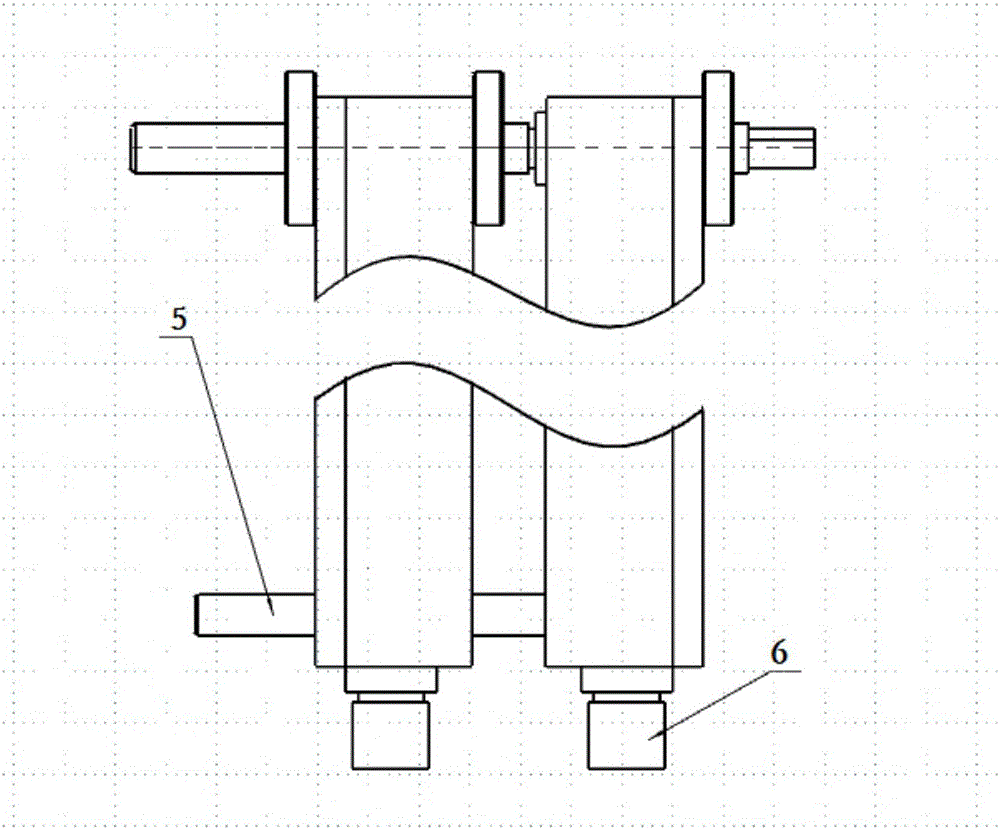

[0024] The invention provides a front gas protection device for a titanium alloy material welding seam, such as figure 2 and image 3 As shown, it includes connecting screw 1 and two ventilation sliders; the two ventilation sliders are respectively ventilation slider I3 and ventilation slider II4.

[0025] The two ventilation sliders are connected through a screw 1, and the distance between the two ventilation sliders is adjusted through a nut 2 matched with the screw 1, so as to achieve the best gas protection effect.

[0026] The ventilation slider is provided with an air inlet 6, and an air inlet channel 9 is processed along the air inlet 6 to the inside of the ventilation slider. The opposite surfaces of the two ventilation sliders are processed with more than one group of ventilation hole groups, and each group is connected to the ventilation blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com