Combined optical cable distribution cabinet

A combined type and wiring box technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of reduced water resistance and safety of the box, poor waterproof effect of the box, troublesome assembly process of the box, etc., to achieve cost saving and waterproof The effect is ideal and the effect of strengthening the firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

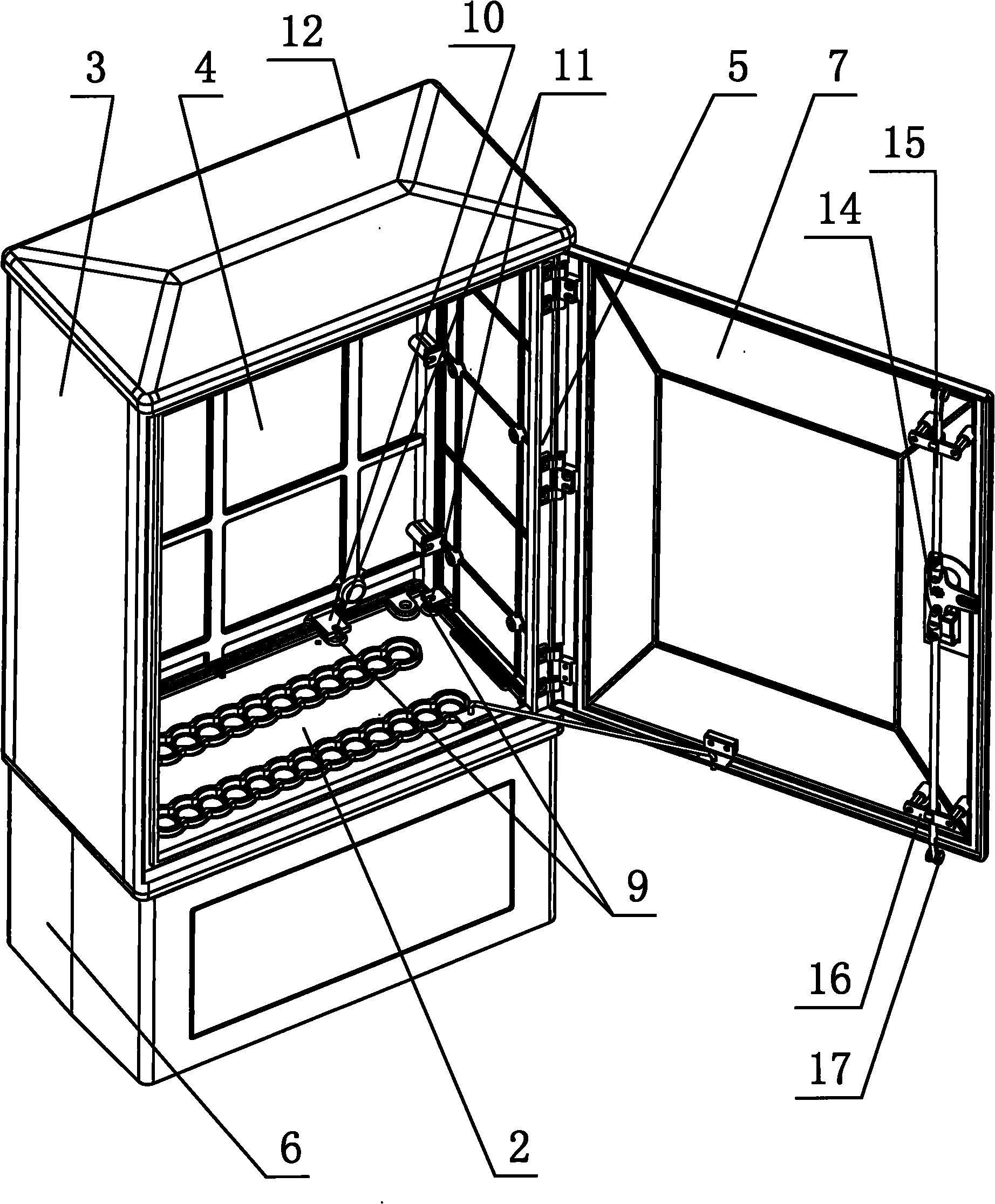

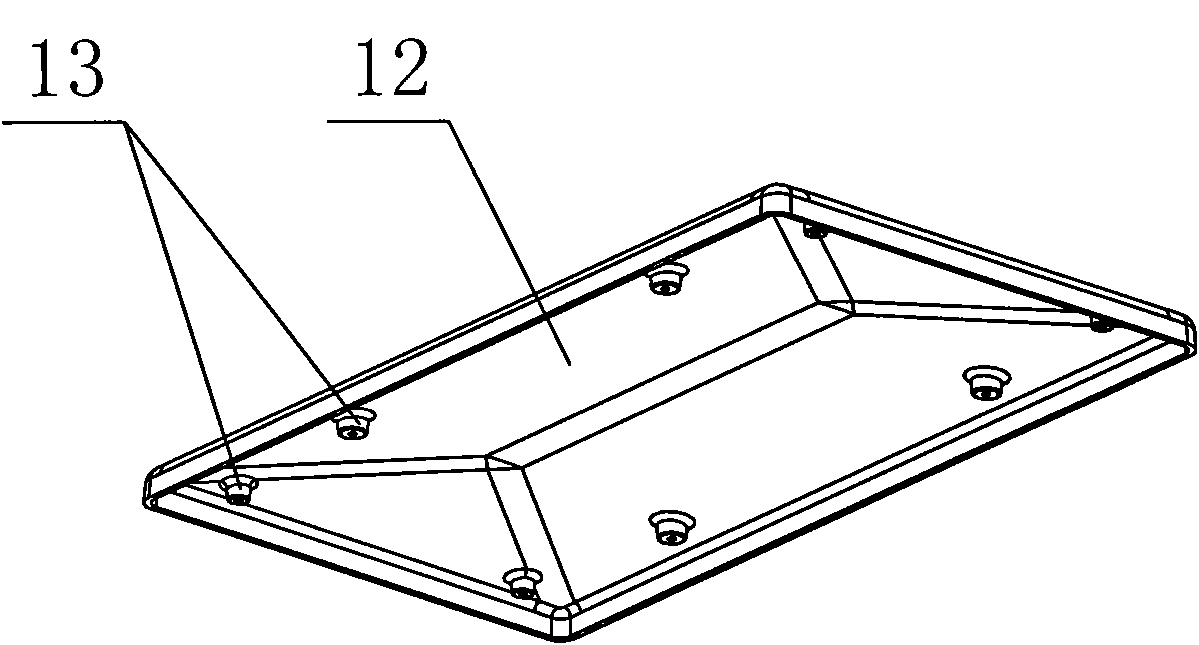

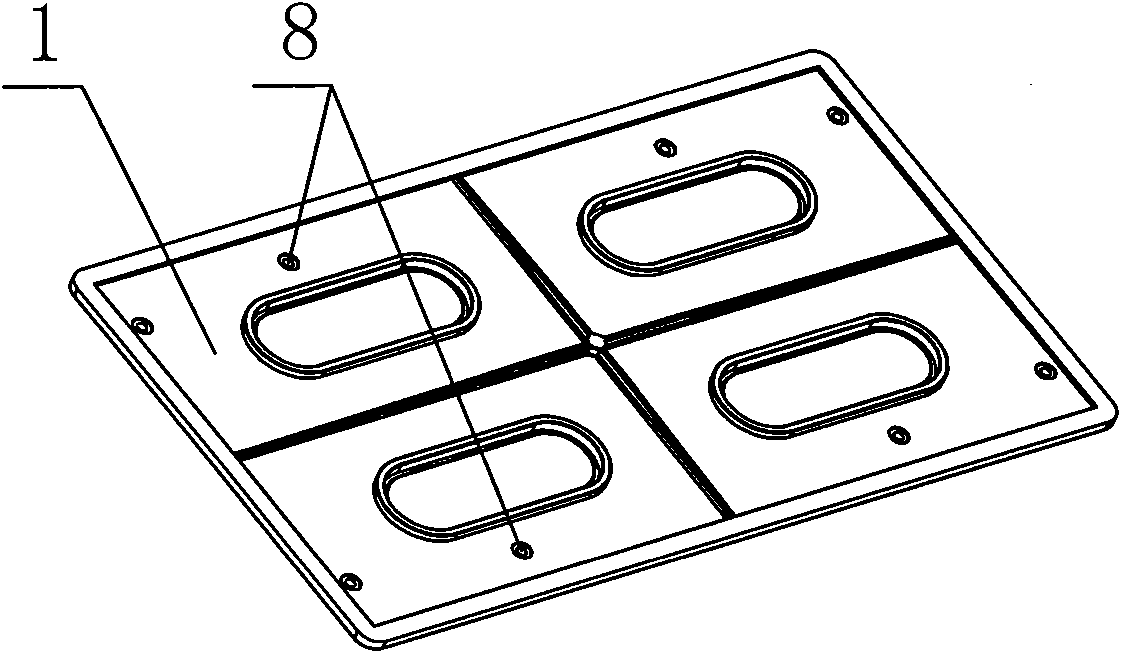

[0046] Such as figure 1 , figure 2 , image 3 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 As shown, the combined optical cable distribution box of the present invention includes an upper board 1, a lower board 2, left and right side boards 3, a rear board 4 and a door frame 5, and every two of the above six parts are adjacent and vertical Components are secured with complete sets of fasteners. A door 7 is hinged on the door frame 5, and a lock is provided between the door 7 and the door frame 5. Each set of fasteners includes a screw, a fixing seat 9 with a threaded hole 8 and a mounting seat 10 with a groove 11 corresponding to the threaded hole 8, and the screw passes through the groove 11 of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com