Dropping suspended wire retaining arm unit for heavy rod drawing machine

The technology of a large drawing machine and a wire take-up device is applied in the directions of transportation and packaging, thin material handling, and conveying filamentous materials. Achieve the effect of improving space utilization, avoiding security risks, and accurately and closely stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

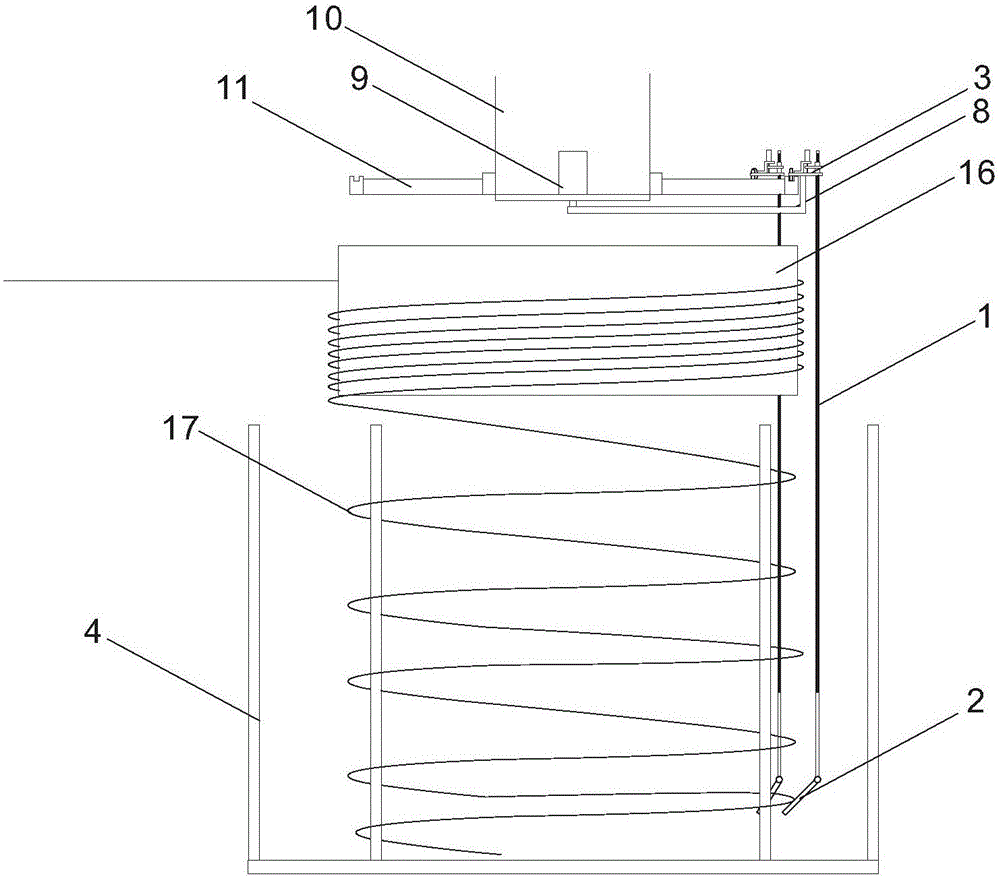

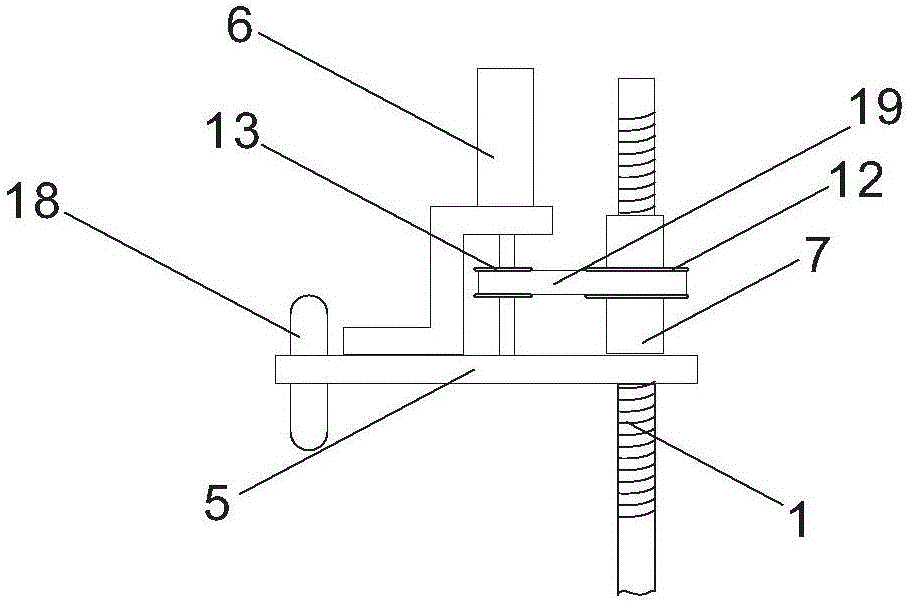

[0023] like figure 1 , figure 2As shown in the drawing, a large drawing machine hangs and falls the line stop arm device, which is located at the large drawing machine take-up device. The device includes a stop arm column 1, a stop bar 2 and two stop arm motion control modules 3, and the stop bar 2 is obliquely connected to the bottom end of the blocking arm column 1, and the blocking rod 2 forms an included angle of 135° with the blocking arm column 1. The stop arm post 1 is connected to the stop arm movement control module 3 in a liftable manner, and the stop arm post 1 is located between the inner ring stop post and the outer ring stop post of a take-up iron frame 4 . The arm motion control module 3 is fixedly connected to a swing arm 8, the swing arm 8 is V-shaped, and the bottom point of the V-shape of the swing arm 8 is fixedly connected to the output end of the circular motion motor 9 of the first arm, and the V-shaped included angle is 60°, and the two arm movement ...

Embodiment 2

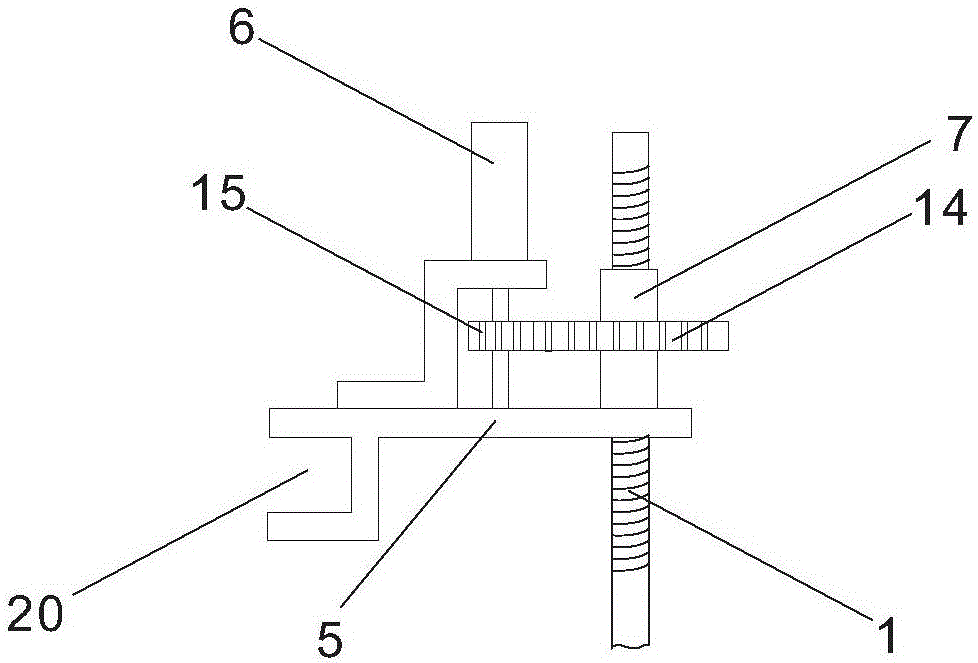

[0026] like image 3 As shown, a driven gear 14 is externally connected to the threaded cylinder 7, and the threaded cylinder 7 and the driven gear 14 are connected by a key. . The arm motion control module 3 is provided with a bayonet 20, which is adapted to the shape and size of the cross section of the support ring 11, the bayonet 20 is stuck on the outer ring of the support ring 11, and the inner wall of the bayonet 20 is embedded with balls. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com