Columnar valve element

A valve core, columnar technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as unfavorable use, high precision and process requirements, and reduced sealing performance, to strengthen the sealing effect and improve the structure. Strength, the effect of enhancing sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

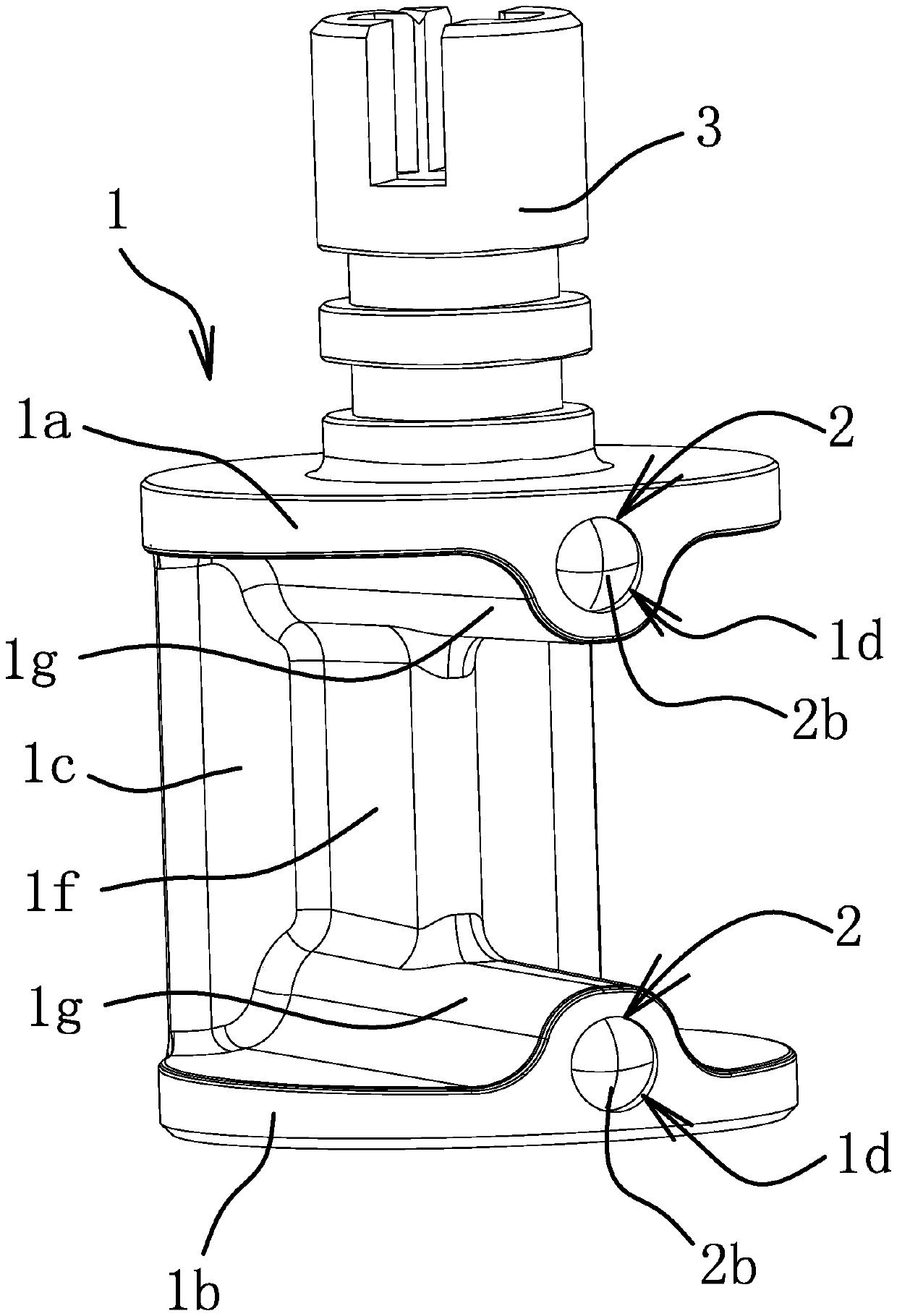

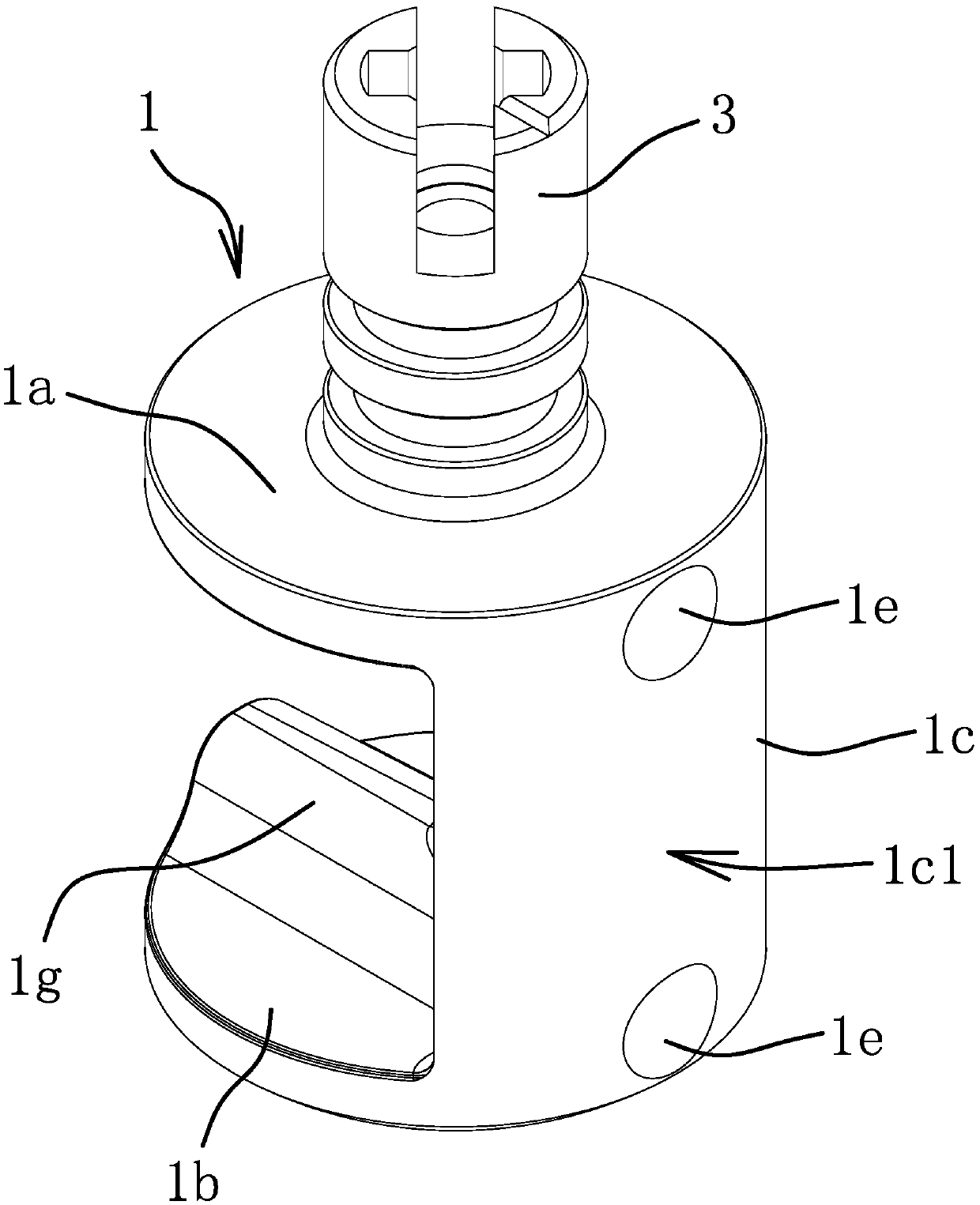

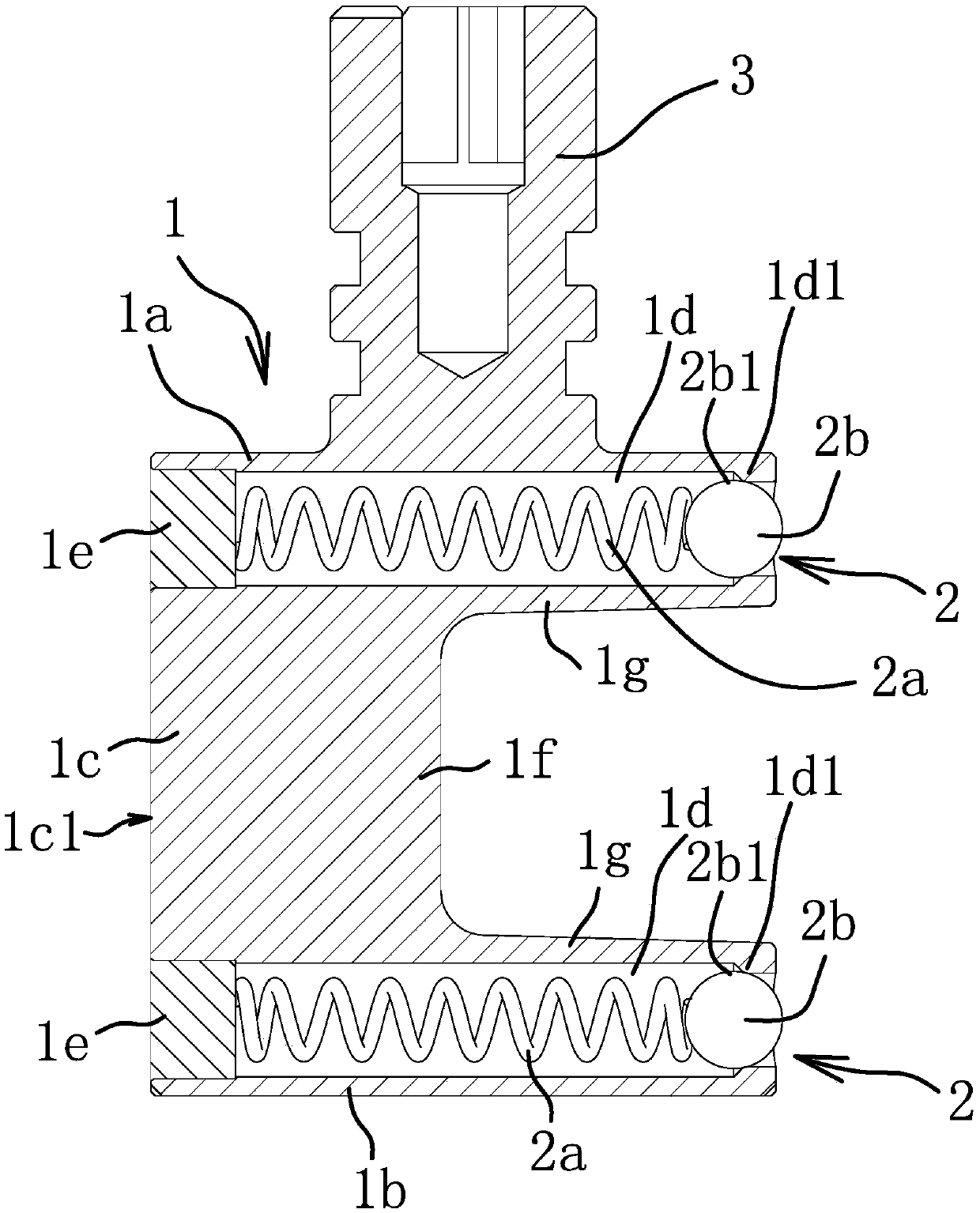

[0031] Such as Figure 1-Figure 3 As shown, a cylindrical valve core includes a body 1 and a core rod 3. The body 1 is in the shape of a "匚" and includes a circular top plate 1a, a circular bottom plate 1b, and a connection between the top plate 1a and the bottom plate 1b. Connection plate 1c. The side opposite to the connecting plate 1c on the top plate 1a and the bottom plate 1b is provided with a pressing assembly 2, and the pressing assembly 2 includes a pressing head 2b, and the pressing head 2b on the top plate 1a protrudes from the side of the top plate 1a in an elastic manner On the surface, the pressing head 2b on the bottom plate 1b protrudes from the side surface of the bottom plate 1b in an elastic manner. The core rod 3 is integrally connected or separately fixed on the top plate 1a, and a communication port is formed between the top plate 1a and the bottom plate 1b. The cross section of the connecting plate 1c is convex arched, the two sides of the connecting p...

Embodiment 2

[0035] The main structure of the spool is the same as that of the first embodiment, and the structure of the pressing assembly 2 is different from that of the first embodiment. The pressing assembly 2 includes an elastic sheet, which is in the shape of a "J" or U. The installation hole 1d is a blind hole, the open end of the elastic sheet is fixed in the installation hole 1d, and the closed end of the elastic sheet extends out of the installation hole 1d. In this embodiment, the closed end of the elastic sheet is the pressing head 1b. When the valve core is inserted into the valve body 4, the outer end surface of the pressing head 2b is against the cavity wall surface of the inner cavity of the valve body 4, and the elastic sheet is elastically deformed and the resulting force acts on the body 1, so that the sealing surface 1c1 abuts against the wall surface of the inner cavity of the valve body 4 to form a seal, and under the action of the pressing component 2, the sealing eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com