Semiconductor processing apparatus

A processing device and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high equipment cost and complicated methods, and achieve the effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

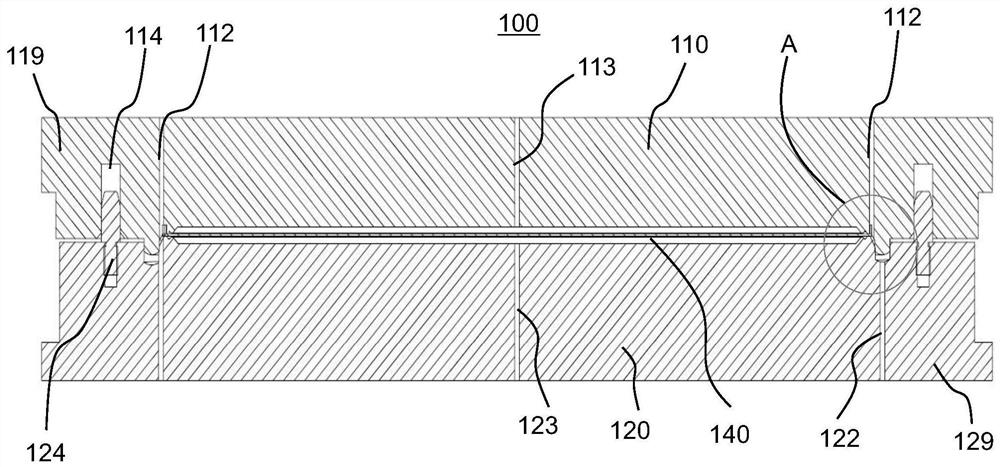

[0026] Please refer to Figure 2a to Figure 3b , which shows a schematic structural diagram of the semiconductor processing device 100 provided in the first embodiment of the present invention, wherein: Figure 2a It is a schematic cross-sectional view of the semiconductor processing device in the first embodiment of the present invention; Figure 2b for Figure 2a The enlarged schematic diagram of circle A in ; Figure 3a for Figure 2a A bottom view of the first chamber portion of the semiconductor processing apparatus in Figure 3b for Figure 2a A top view of the second chamber section of the semiconductor processing apparatus in .

[0027] Please refer to Figure 2a to Figure 3b , the semiconductor processing apparatus 100 includes a first chamber part 110 and a second chamber part 120 . The first chamber portion 110 includes a first chamber plate 119 and a flange 118 extending from a periphery of the first chamber plate 119 . The second chamber portion 120 includ...

no. 2 example

[0047] Please refer to Figure 4 to Figure 6b , which shows a schematic structural diagram of the semiconductor processing device 200 provided in the second embodiment of the present invention, wherein: Figure 4 It is a schematic cross-sectional view of the semiconductor processing device in the first embodiment of the present invention; Figure 5 for Figure 4 The enlarged schematic diagram of circle B in ; Figure 6a for Figure 4 A bottom view of the first chamber portion of the semiconductor processing apparatus in Figure 6b for Figure 4 A top view of the second chamber section of the semiconductor processing apparatus in .

[0048] The structure of the semiconductor processing device 200 in the second embodiment is mostly the same as that of the semiconductor processing device 100 in the first embodiment, so the same parts are marked with the same marks, and the difference between the two is mainly: semiconductor processing There are some differences in the struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com