Mesh belt type veneer drier

A drying machine and mesh belt technology, which is applied in the direction of drying solid materials, promoting the preliminary treatment of solid material drying, drying, etc., and can solve the problems of uneven drying and unsmooth feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

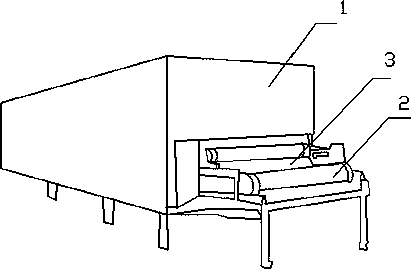

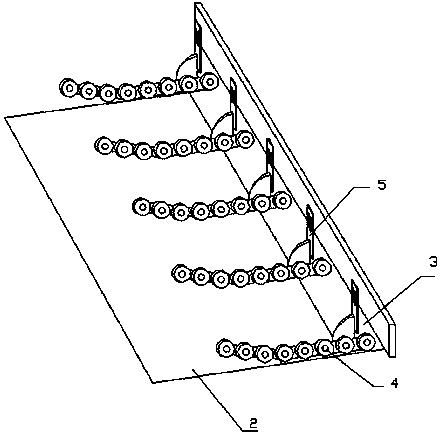

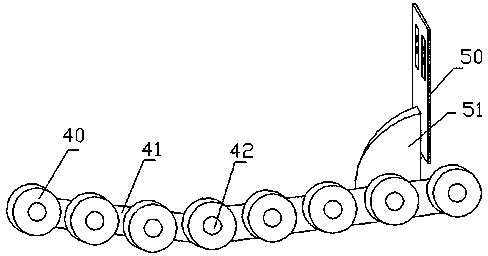

[0033] The present embodiment comprises mesh belt 2, sprocket wheel and drying chamber 1, and mesh belt 2 is driven by sprocket wheel, and drying chamber 1 is provided with feed inlet 3, and mesh belt 2 enters into drying chamber 1 from feed inlet 3, in drying A veneer leveling device is added at the feed port 3 of the chamber 1, and the veneer leveling device includes a plurality of leveling units 4 and a plurality of connecting pieces 5, one leveling unit 4 is connected to a connecting piece 5, and the leveling unit 4 passes through the connecting piece 5 Connected to the feed port 3 of the drying chamber 1, the flattening unit 4 includes a plurality of pinch rollers 40 and a pinch roller connector, and the plurality of pinch rollers 40 are connected together through the pinch roller connector.

[0034] The leveling units 4 are installed parallel to each other at equal intervals, and the installation height of the pressure rollers 40 of the leveling units 4 decreases graduall...

Embodiment 2

[0038] The present embodiment comprises mesh belt 2, sprocket wheel and drying chamber 1, and mesh belt 2 is driven by sprocket wheel, and drying chamber 1 is provided with feed inlet 3, and mesh belt 2 enters into drying chamber 1 from feed inlet 3, in drying A veneer leveling device is added at the feed port 3 of the chamber 1, and the veneer leveling device includes a plurality of leveling units 4 and a plurality of connecting pieces 5, one leveling unit 4 is connected to a connecting piece 5, and the leveling unit 4 passes through the connecting piece 5 Connected to the feed port 3 of the drying chamber 1, the flattening unit 4 includes a plurality of pinch rollers 40 and a pinch roller connector, and the plurality of pinch rollers 40 are connected together through the pinch roller connector.

[0039] The leveling units 4 are installed parallel to each other at equal intervals, and the installation height of the pressure rollers 40 of the leveling units 4 decreases graduall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com