Air distribution system for SCR plate-type catalyst continuous calcining furnace

A catalyst and calciner technology, applied in the field of kiln auxiliary facilities, can solve problems such as burning of catalyst plates, large amount of hot air, affecting product quality, etc., and achieve the effect of improving activity and ensuring calcining quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

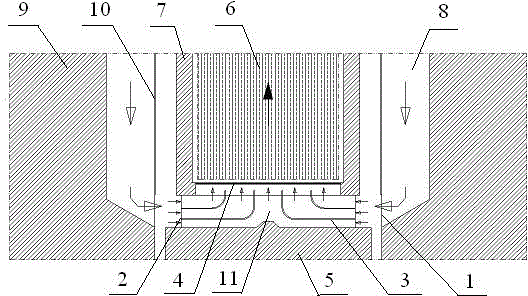

[0011] Such as figure 1 As shown, the trolley air distribution device for SCR plate catalyst continuous vertical calciner is a product that forms a circulating air cavity 8 between the sides and top of the calciner 9 furnace and the inner wall to form a circulating air chamber 8 and is arranged on the trolley 5 The airtight hot air circulation duct formed by the catalyst product 6 in the loading box 7 is provided with a sieve plate 4 for placing the catalyst product 6 at the bottom of the product loading box 7, and an air inlet channel is set between the sieve plate 4 and the trolley 5 11. Both sides of the air inlet duct 11 are equipped with upper and lower two air distribution plates 3 to divide it into three branch air ducts, so that the circulating hot air can evenly enter the gaps in each section of the catalyst product 6, and the air inlets on both sides of the air inlet duct 11 2 communicates with the air outlet 1 provided at the lower part of the circulating air duct 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com