High-clean stainless steel cable and treatment method thereof

A treatment method, stainless steel technology, applied in textiles, papermaking, textile cables, etc., can solve the problems of reducing the design tensile strength of a single steel wire, affecting the service life of the steel wire rope, and low tensile strength of the steel wire rope, and achieving good decontamination effect, High surface hardness and anti-rust ability, the effect of avoiding mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

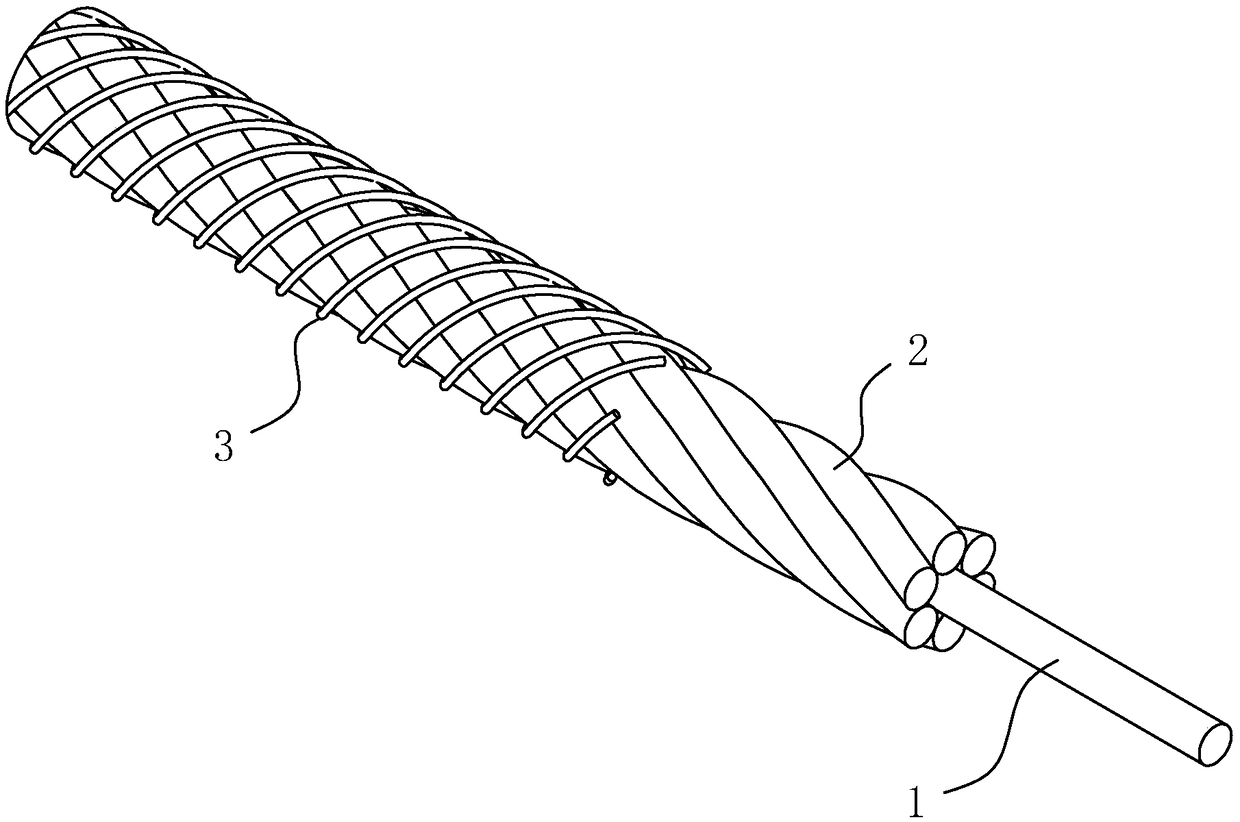

[0045] Embodiment one: a kind of high-clean stainless steel cable, such as figure 1 and figure 2 As shown, it includes a central steel wire 1 and a plurality of outer layer steel wires 2, and a plurality of outer layer steel wires 2 are helically twisted on the outside of the central steel wire 1, where there may be 6 outer layer steel wires 2, and the outer layer steel wires 2 and the central steel wire 1 form 6+1 structure. A protective steel wire strand 3 is wound and fixed outside a plurality of outer layer steel wires 2 , and the helical direction of the protective steel wire strand 3 is the same as or opposite to that of the outer layer steel wire 2 . The diameter d of the central steel wire 1 0 is 5.9mm, the diameter d of the outer steel wire 2 1 5.4mm, the diameter d of the protective steel wire strand 3 保 is 0.9mm.

[0046] The wire composition of the central steel wire 1 and the outer steel wire 2 is 0.07-0.09%C, 0.7-0.9%Si, 1.0-1.3%Mn, 17.8-18.2%Cr, 9.0-9.5%Ni...

Embodiment 2

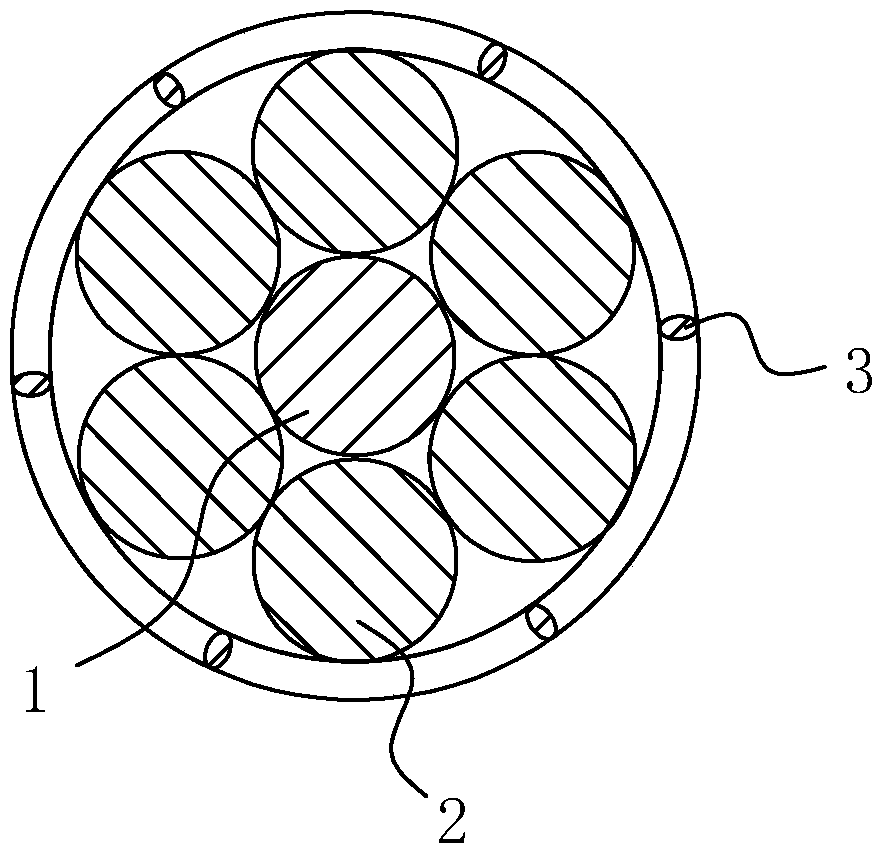

[0048] Embodiment two: a kind of high-clean stainless steel cable, such as image 3 and Figure 4 As shown, it includes a central steel wire 1 and a plurality of outer layer steel wires 2, and a plurality of outer layer steel wires 2 are helically twisted on the outside of the central steel wire 1, where there may be 6 outer layer steel wires 2, and the outer layer steel wires 2 and the central steel wire 1 form 6+1 structure. A reinforced steel wire strand 4 is arranged between the central steel wire 1 and two adjacent outer layer steel wires 2, the reinforced steel wire strand 4 is in line contact with the central steel wire 1 and the outer layer steel wire 2, and the reinforced steel wire strand 4 can be a plurality of strands as required. become. The diameter d of the central steel wire 1 0 is 5.9mm, the diameter d of the outer steel wire 2 1 5.4mm, the diameter d of reinforced steel wire strand 4 增 is 1.8mm. The reinforced steel wire strands 4 are helically twisted ...

Embodiment 3

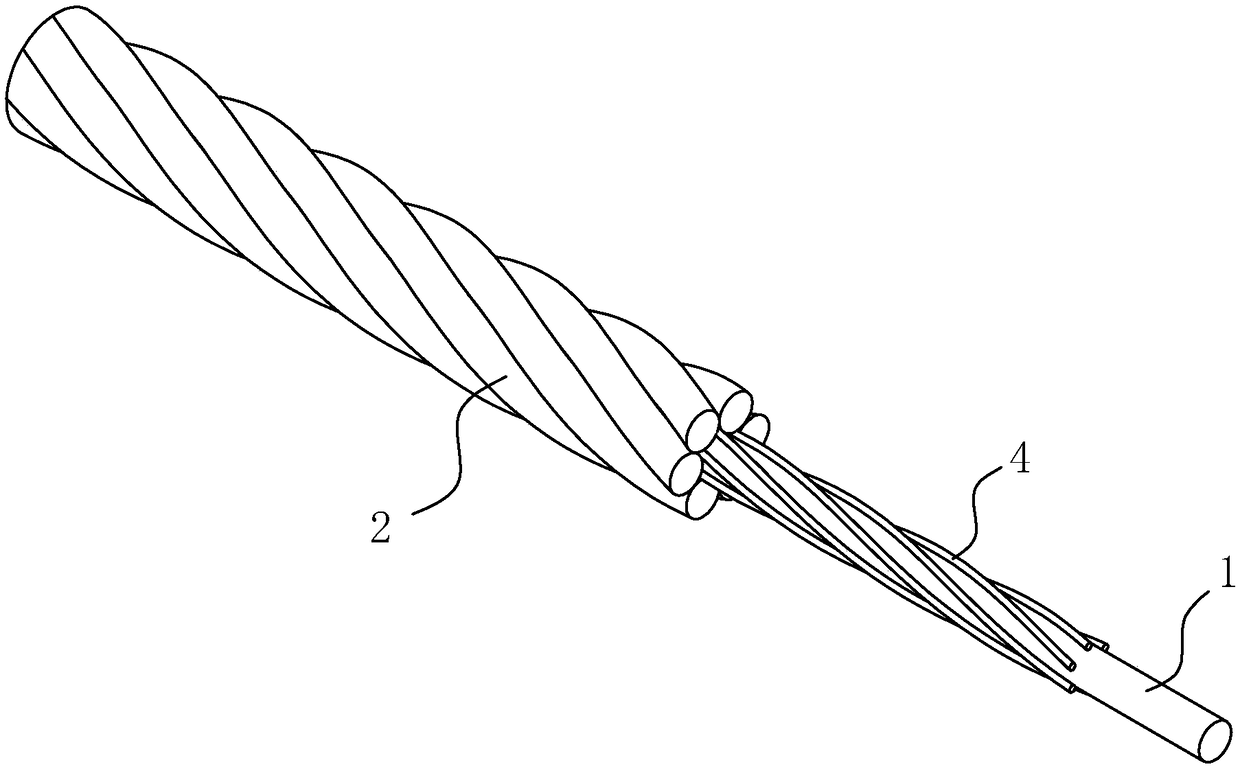

[0051] Embodiment three: a kind of high-clean stainless steel cable, such as Figure 5 As shown, the difference from Embodiment 1 is that a reinforced steel wire strand 4 is provided between the central steel wire 1 and two adjacent outer layer steel wires 2, and the reinforced steel wire strand 4 is in line contact with the central steel wire 1 and the outer layer steel wire 2 , the diameter d of the reinforced steel wire strand 4 增 is 1.8mm. The reinforced steel wire strands 4 are helically twisted together with the outer layer steel wires 2 on the outside of the central steel wire 1 . Compared with Embodiment 1, the advantage is that the reinforced steel wire strands 4 are filled between the central steel wire 1 and the outer layer steel wire 2, and the profile diameter of the entire steel cable does not change, and the reinforced steel wire strands 4 increase the overall strength of the steel cable. In the case of the steel wire strength level, the breaking force of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com