Pretreatment method for improving mechanical property of wrought magnesium alloy

A wrought magnesium alloy and pretreatment technology, which is applied in the field of heat treatment to improve the mechanical properties of wrought magnesium alloys, can solve the problems of difficulty in realizing large-scale industrial production, poor safety, and complicated processes, and avoid inversion of strength and toughness. Effects of transportation and safe handling methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

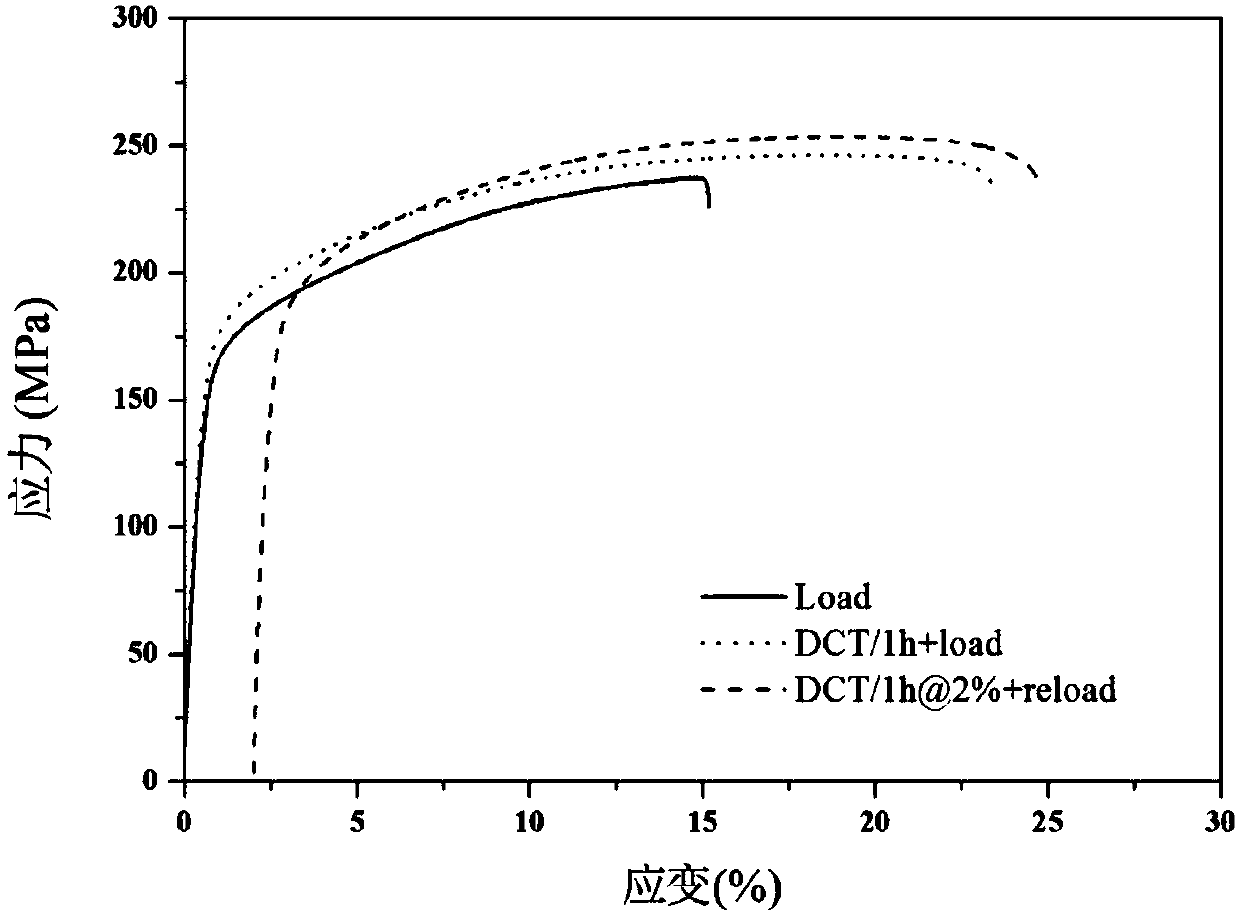

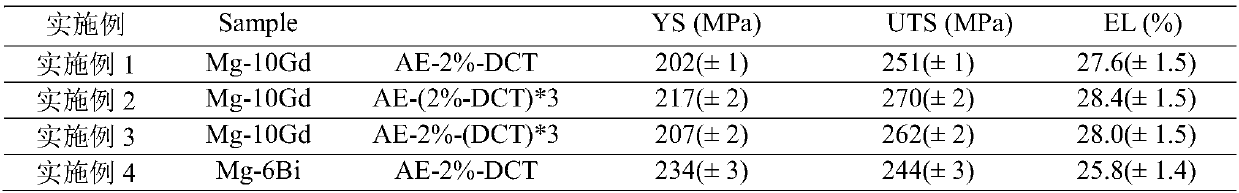

Embodiment 1

[0027] Select an ingot with a composition of Mg-10Gd (wt.%), and homogenize it, that is, place the ingot in a box-type heat treatment furnace, raise the temperature to 400°C with the furnace, keep it warm for 12h, and then place it in warm water at 35°C Quenching. Then preheat the homogenized ingot to 250°C, and extrude it into a rod with a diameter of 10mm at an extrusion speed of 0.1mm / s and an extrusion ratio of 25:1. The bar is processed into a tensile test bar, and then the above-mentioned tensile test bar is subjected to tensile pre-deformation treatment on a tensile testing machine, and the deformation amount is 2% (the deformation amount is length), and then unloaded. Finally, immerse the test bar directly in liquid nitrogen (-196°C) for cryogenic treatment for 1 hour. After the cryogenic treatment, take out the tensile test bar and place it in the air to return to room temperature naturally. Carry out tensile test (using GB / T 228.1-2010 metal material tensile test pa...

Embodiment 2

[0029] Select an ingot with a composition of Mg-10Gd (wt.%), and homogenize it, that is, place the ingot in a box-type heat treatment furnace, raise the temperature to 400°C with the furnace, keep it warm for 12h, and then place it in warm water at 35°C Quenching. Then preheat the homogenized ingot to 250°C, and extrude it into a rod with a diameter of 10mm at an extrusion speed of 0.1mm / s and an extrusion ratio of 25:1. The bar is processed into a tensile test bar, and then the above-mentioned tensile test bar is subjected to tensile pre-deformation treatment on a tensile testing machine, with a deformation amount of 2%, and then unloaded. Immerse the test bar directly in liquid nitrogen (-196°C) for cryogenic treatment for 1 hour. After the cryogenic treatment, take out the tensile test bar and place it in the air to return to room temperature naturally. Repeat again: the tensile pre-deformation treatment of the tensile test bar on the tensile testing machine—the deformatio...

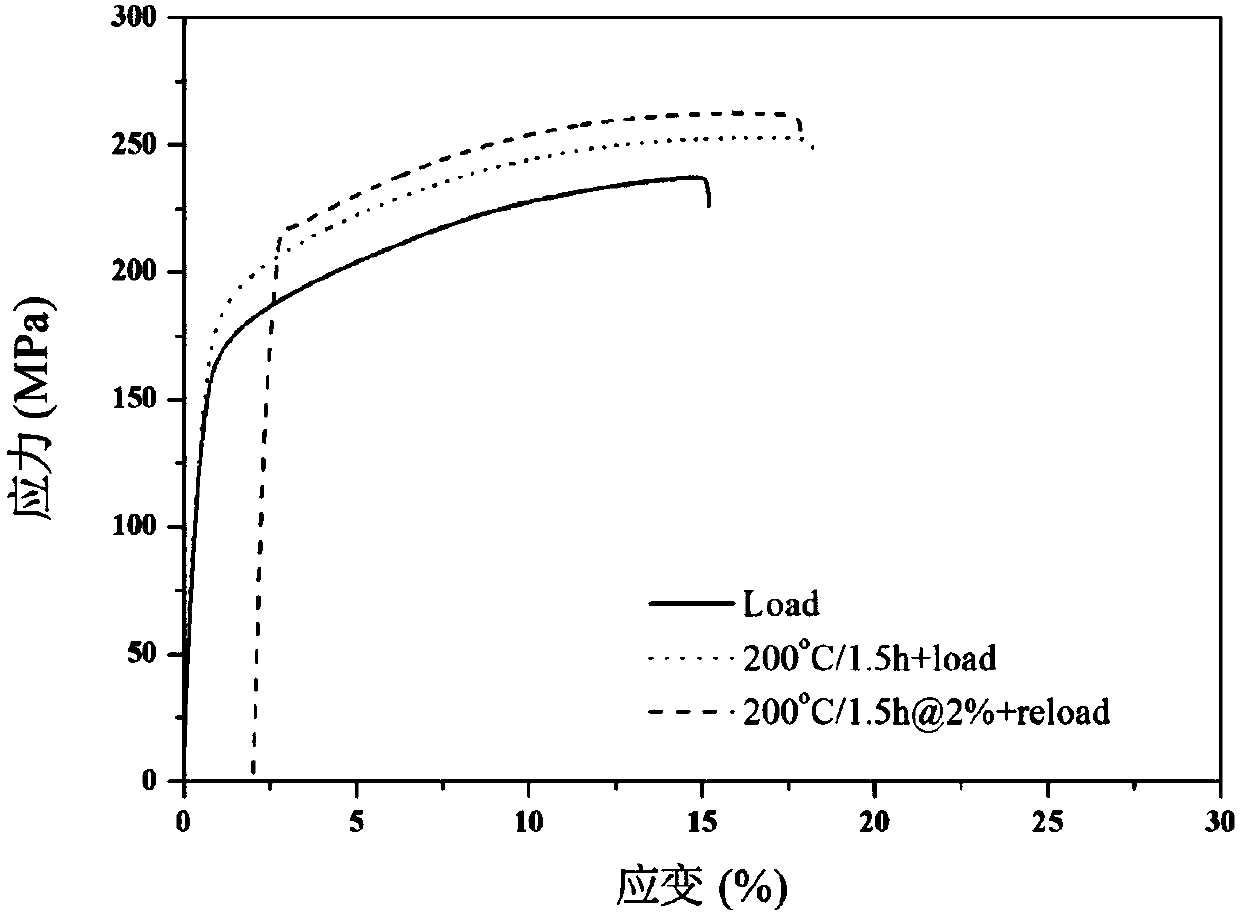

Embodiment 3

[0031]Select an ingot with a composition of Mg-10Gd (wt.%), and homogenize it, that is, place the ingot in a box-type heat treatment furnace, raise the temperature to 400°C with the furnace, keep it warm for 12h, and then place it in warm water at 35°C Quenching. Then preheat the homogenized ingot to 250°C, and extrude it into a rod with a diameter of 10mm at an extrusion speed of 0.1mm / s and an extrusion ratio of 25:1. The bar is processed into a tensile test bar, and then the above-mentioned tensile test bar is subjected to tensile pre-deformation treatment on a tensile testing machine, with a deformation amount of 2%, and then unloaded. Immerse the test bar directly in liquid nitrogen (-196°C) for cryogenic treatment for 1 hour. After the cryogenic treatment, take out the tensile test bar and place it in the air to return to room temperature naturally. Then repeat the submersion of the test rod in liquid nitrogen (-196°C) for 1h cryogenic treatment twice. Perform a tensil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com