Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Break the bottleneck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Data query method and system and storage medium

InactiveUS20150213134A1High cost of deploymentPoor service performanceWeb data indexingDigital data processing detailsData providerClient-side

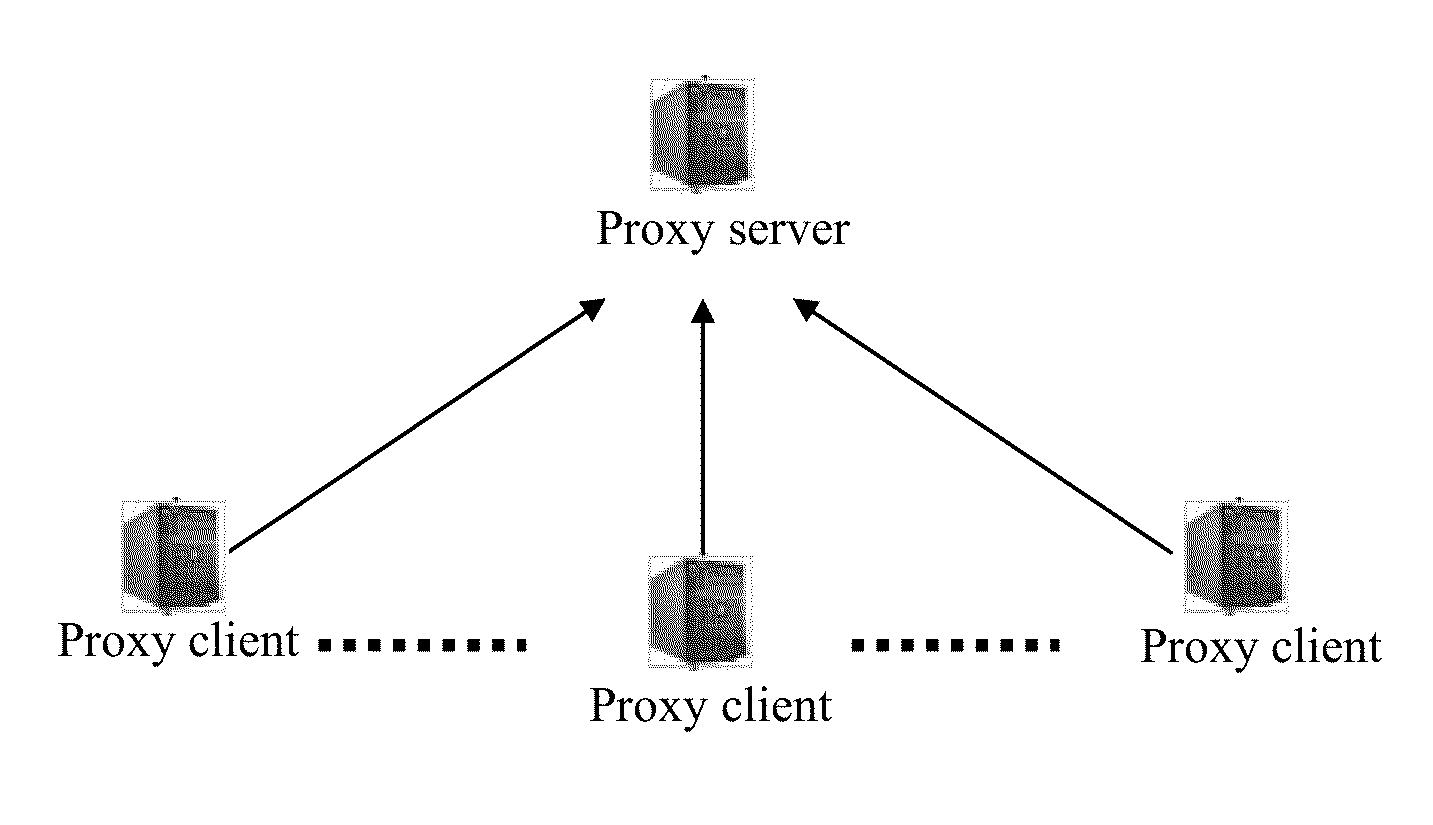

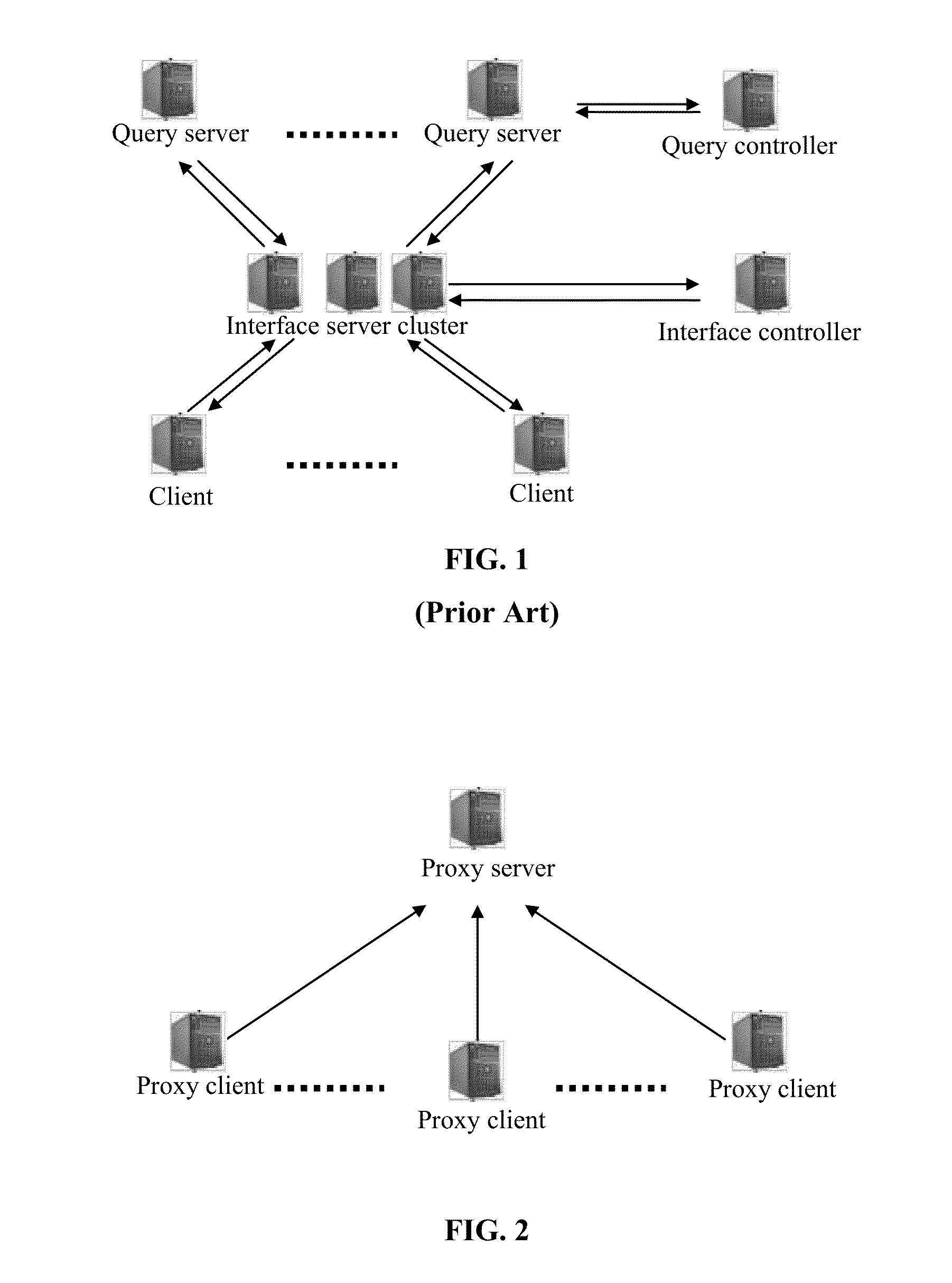

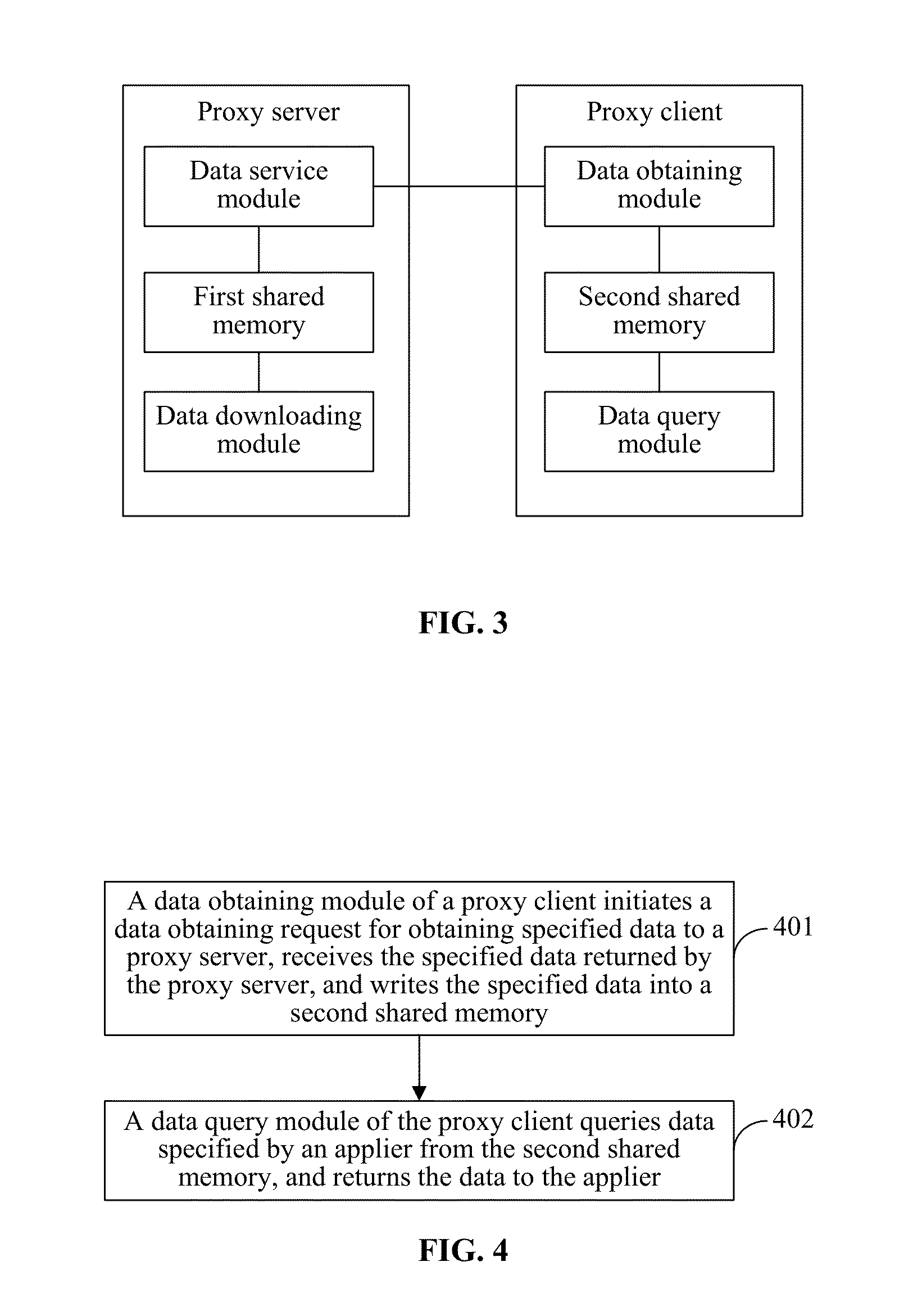

The present disclosure discloses a data query system, method, and storage medium. The data query system includes a proxy server and at least one proxy client. The proxy server is disposed on a server that serves as a data provider, and is configured to provide the proxy client with a data delivery service. The proxy client is disposed on a client that serves as a data user, and is configured to obtain data from the proxy server and save the data and provide a data query service. The proxy client thus includes a data obtaining module, a data query module, and a second shared memory. Accordingly, the present disclosure further discloses a data query method. The present disclosure has a simple structure, achieves fast data update, requires a low deployment cost, saves bandwidth resources, and achieves excellent service performance.

Owner:TENCENT TECH (SHENZHEN) CO LTD

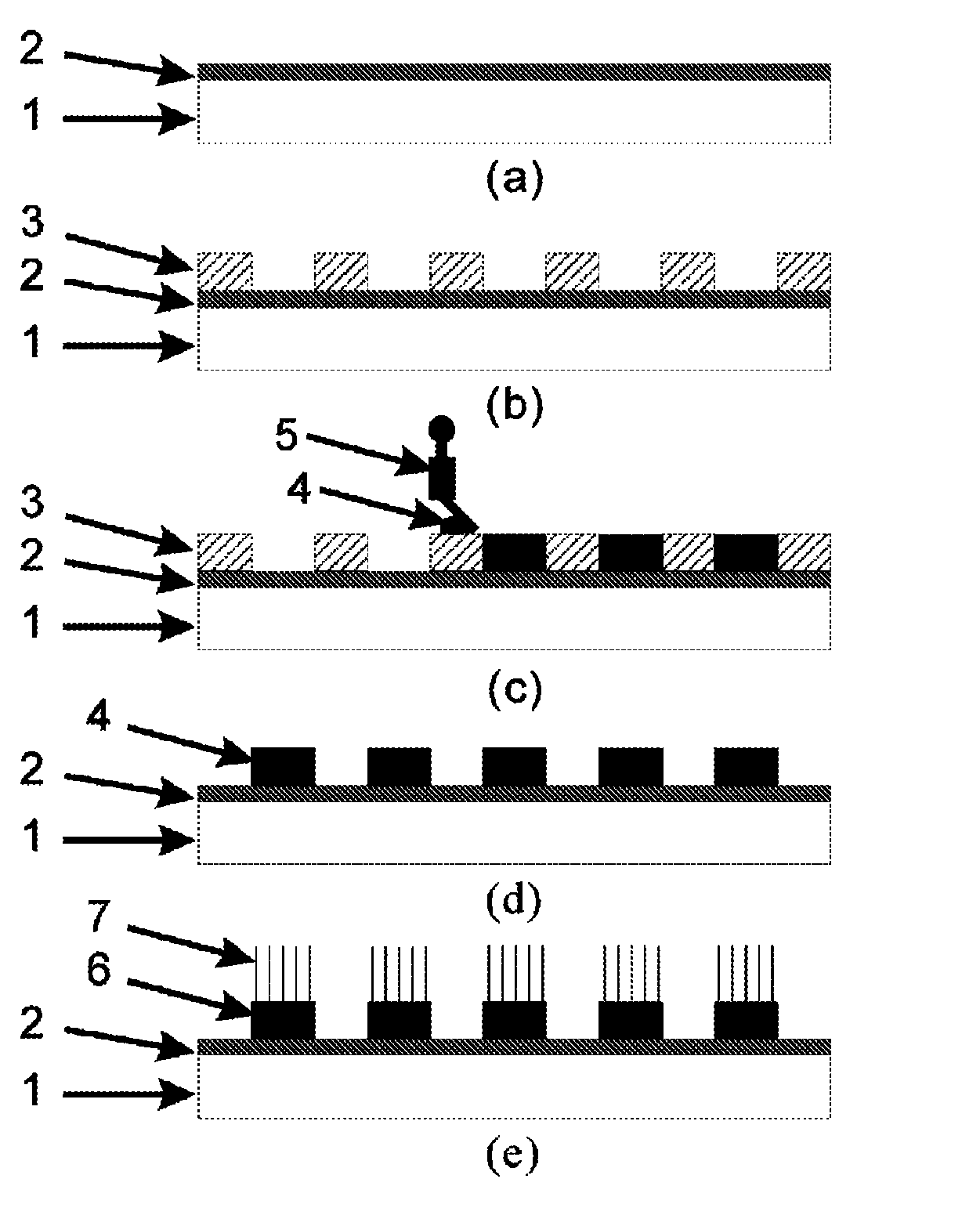

Method of growing single crystal Gallium Nitride on silicon substrate

InactiveUS7014710B2Break the bottleneckPolycrystalline material growthSemiconductor/solid-state device manufacturingManufacturing cost reductionEtching

Owner:NAT CHENG KUNG UNIV

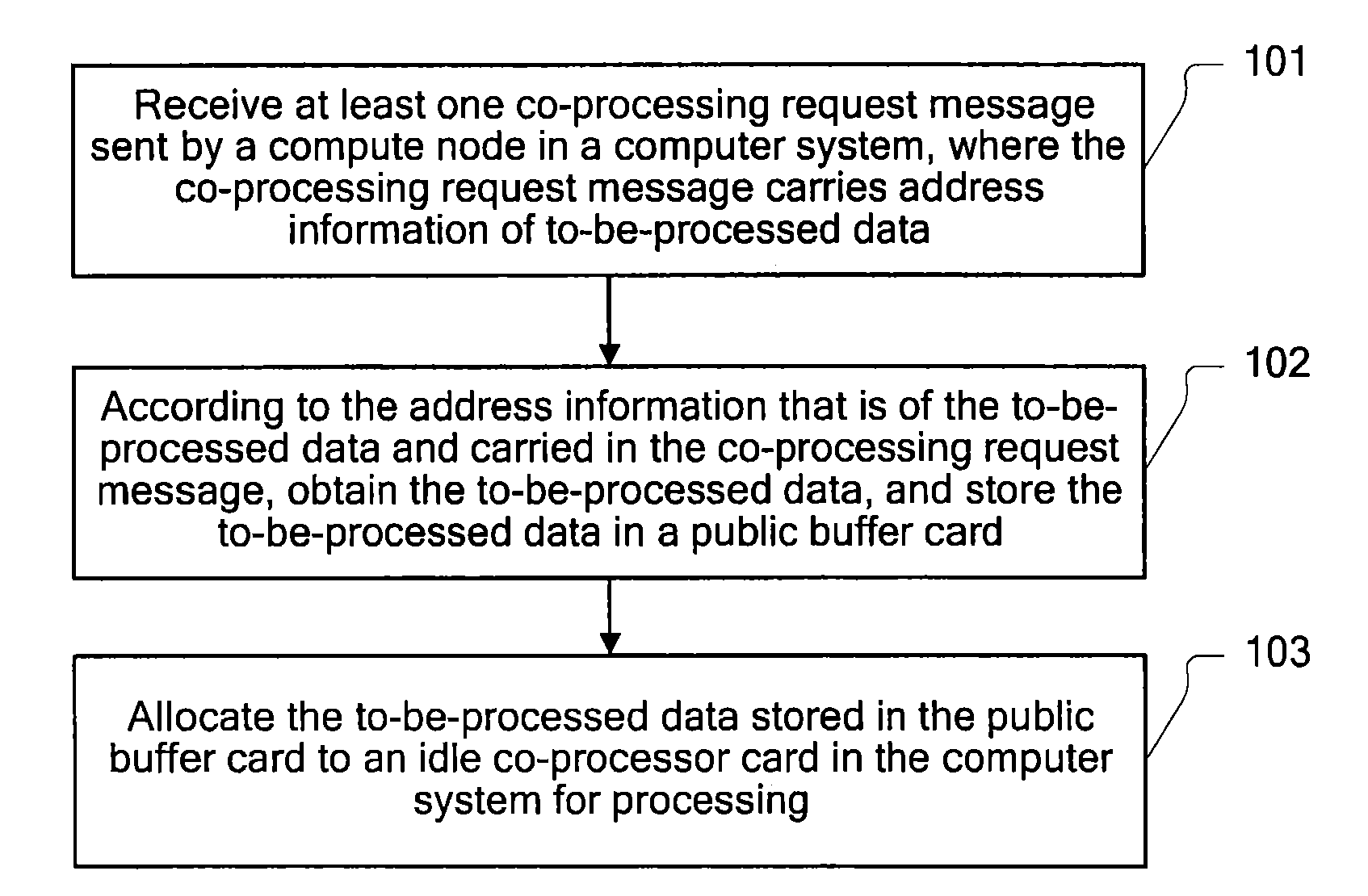

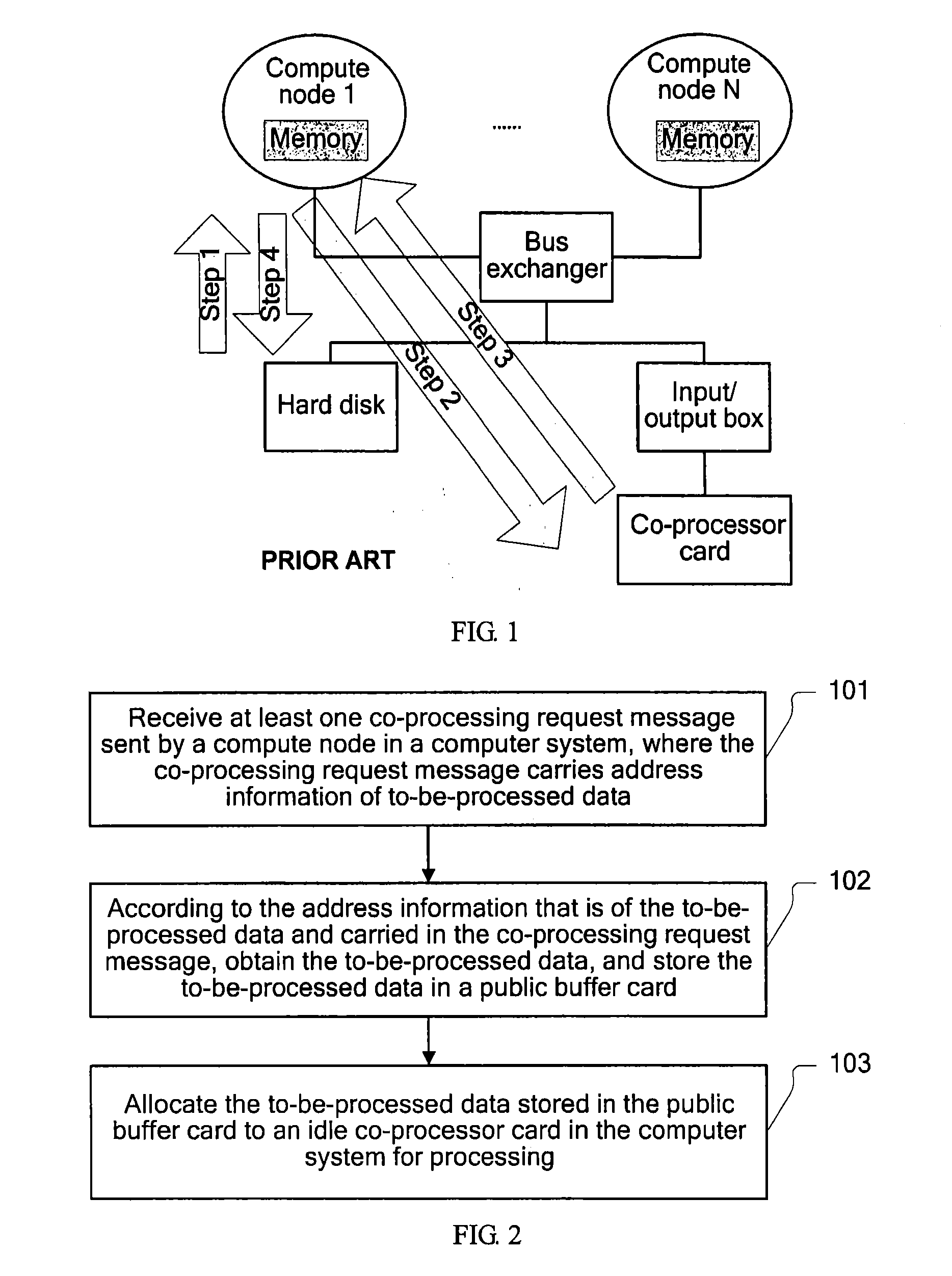

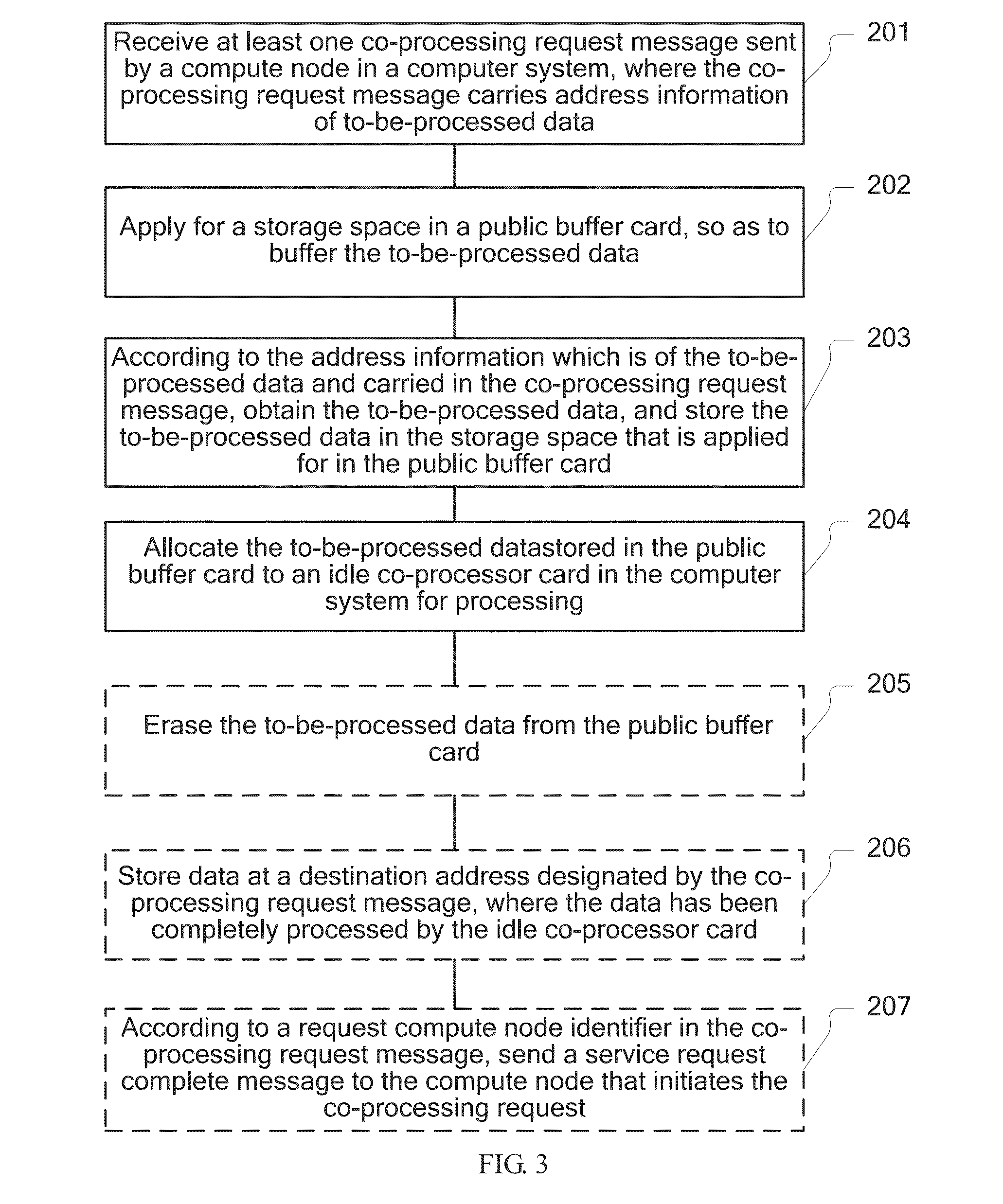

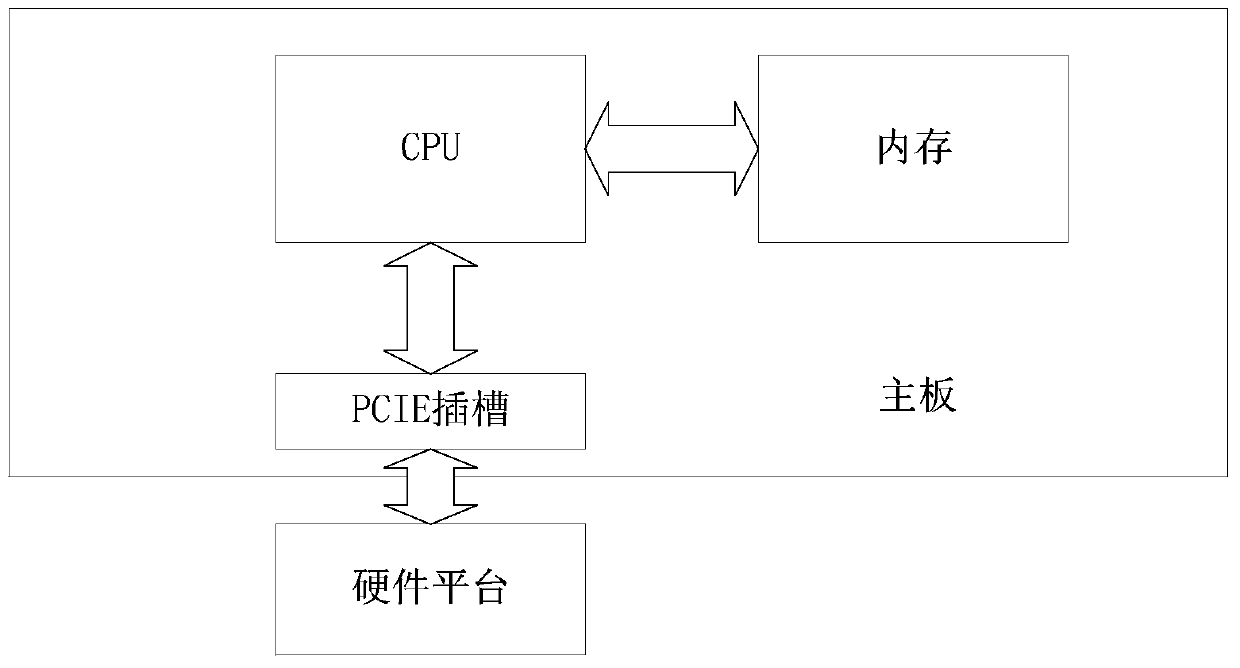

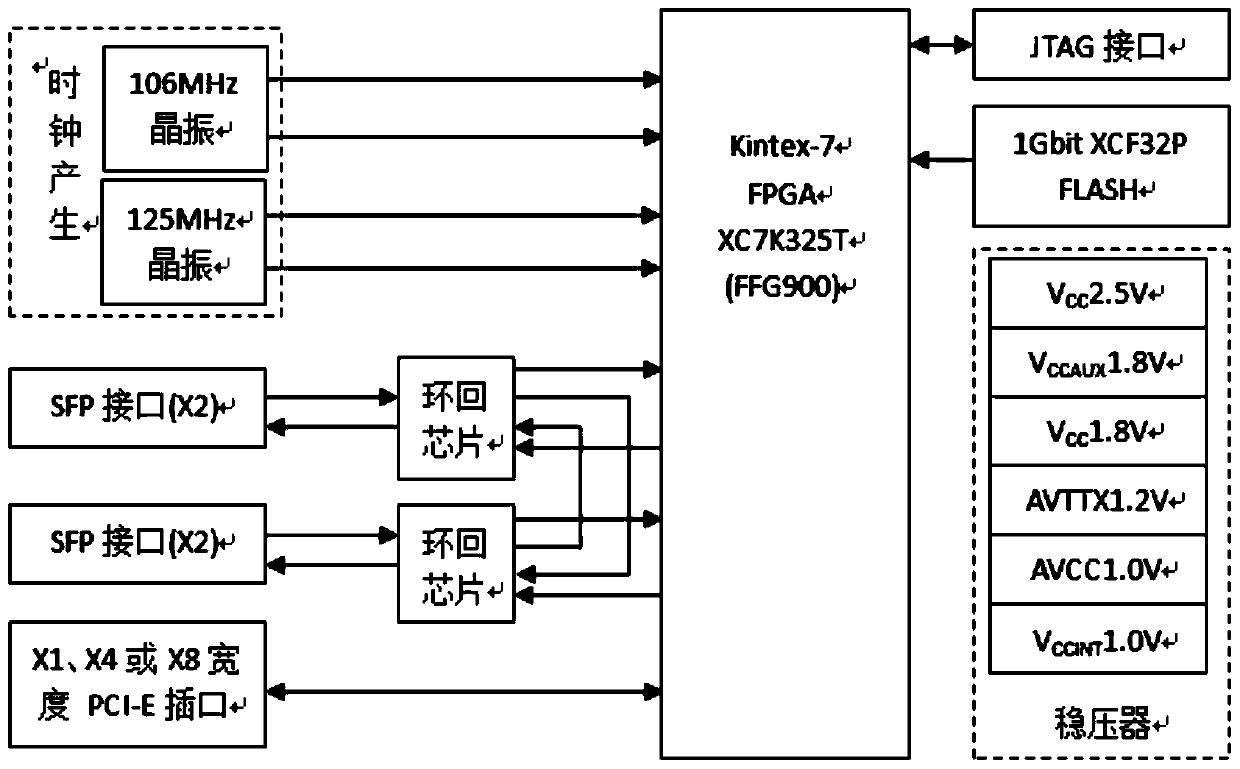

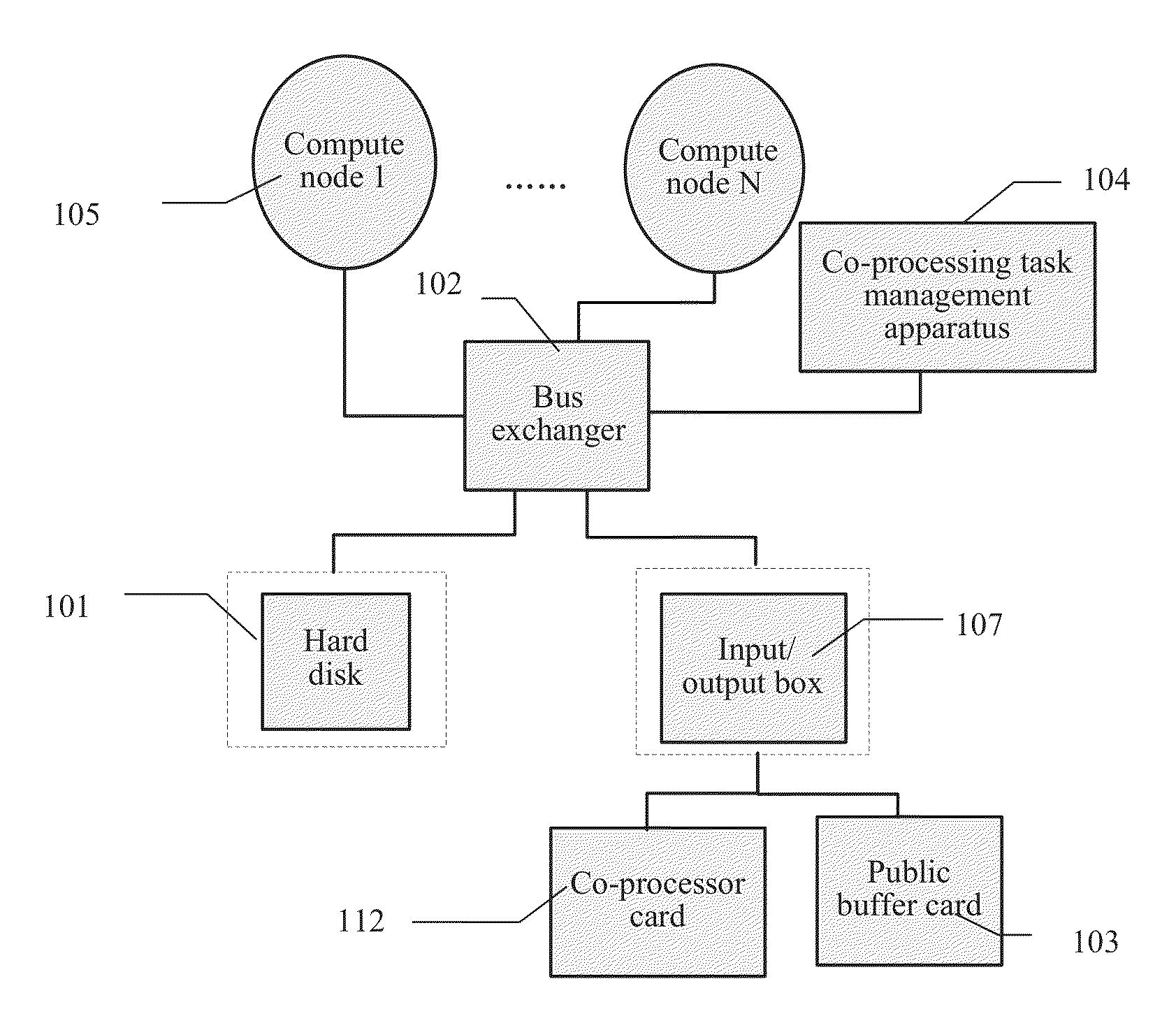

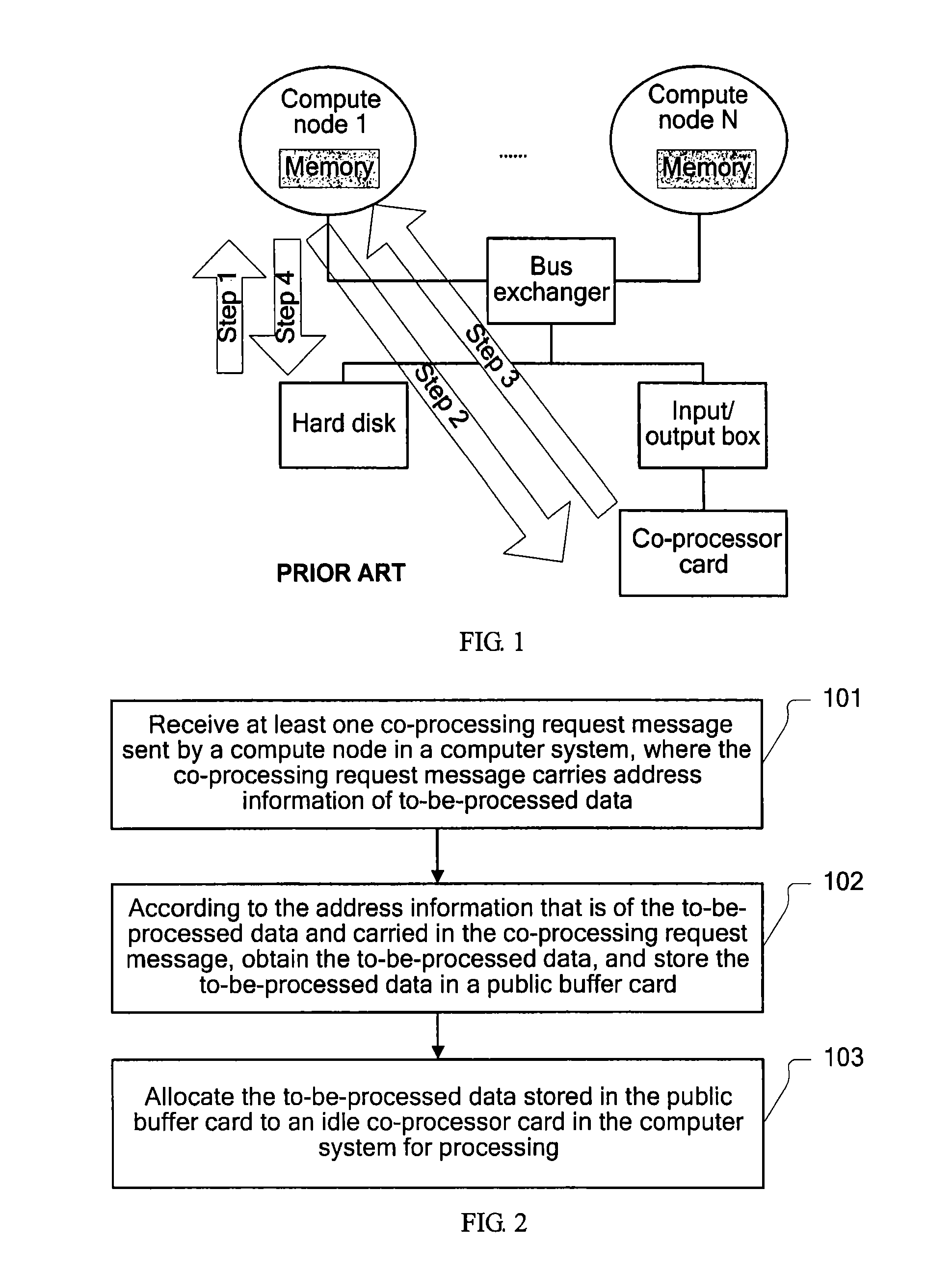

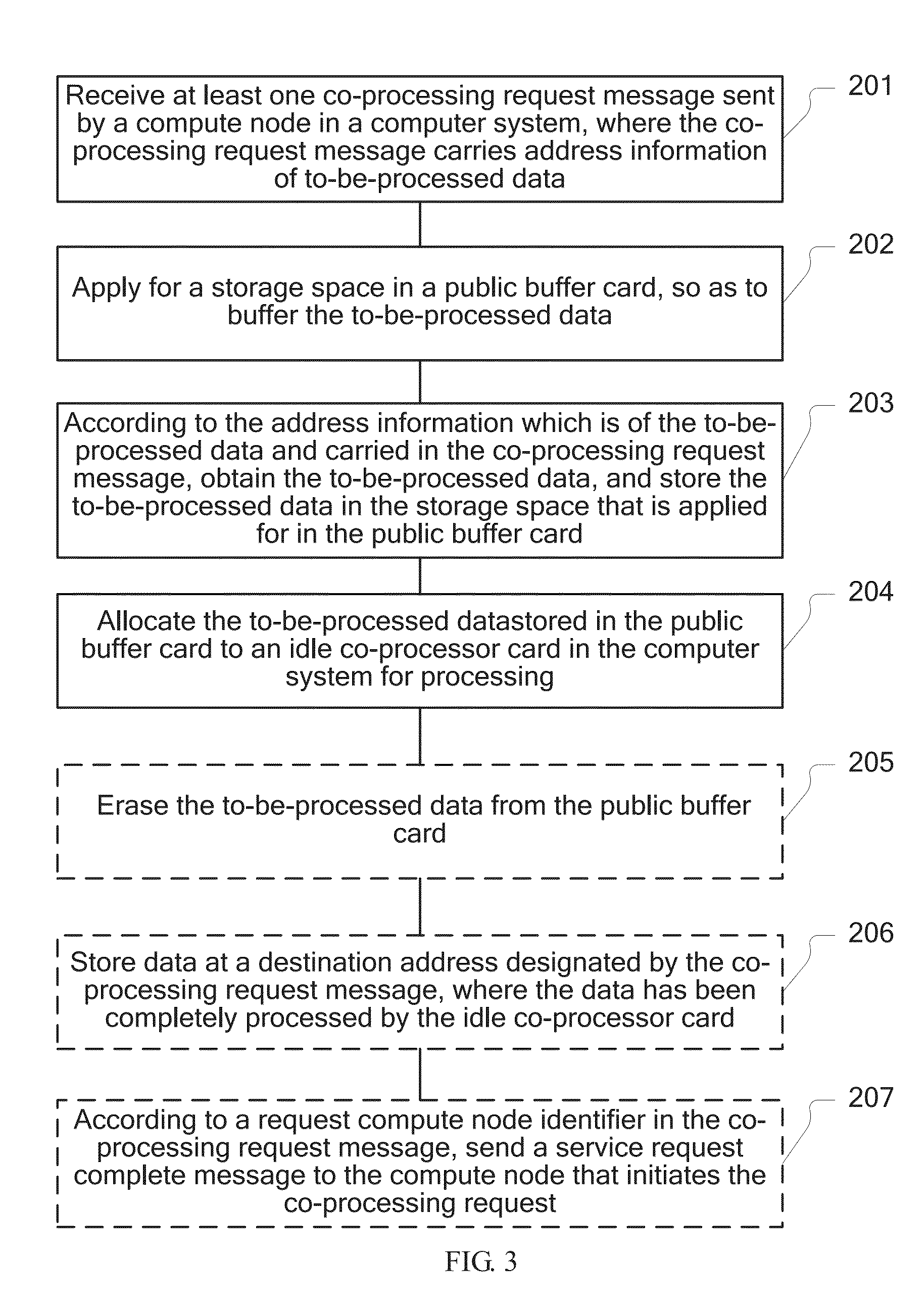

Co-processing acceleration method, apparatus, and system

ActiveUS20130151747A1Avoids overheadReduce memory overheadMultiple digital computer combinationsProgram controlData bufferCollaborative processing

An embodiment of the present invention discloses a co-processing acceleration method, including: receiving a co-processing request message which is sent by a compute node in a computer system and carries address information of to-be-processed data; according to the co-processing request message, obtaining the to-be-processed data, and storing the to-be-processed data in a public buffer card; and allocating the to-be-processed data stored in the public buffer card to an idle co-processor card in the computer system for processing. An added public buffer card is used as a public data buffer channel between a hard disk and each co-processor card of a computer system, and to-be-processed data does not need to be transferred by a memory of the compute node, which avoids overheads of the data in transmission through the memory of the compute node, and thereby breaks through a bottleneck of memory delay and bandwidth, and increases a co-processing speed.

Owner:HUAWEI TECH CO LTD

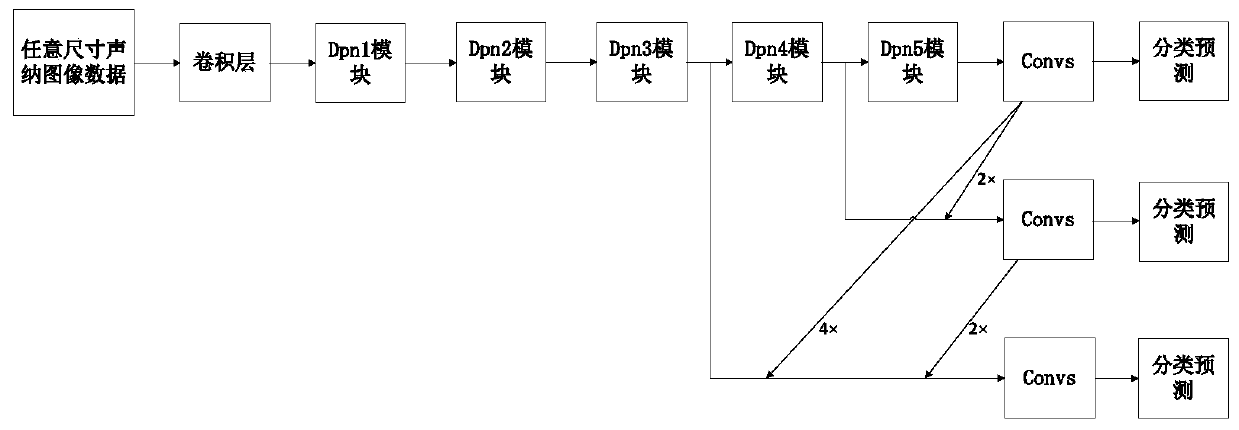

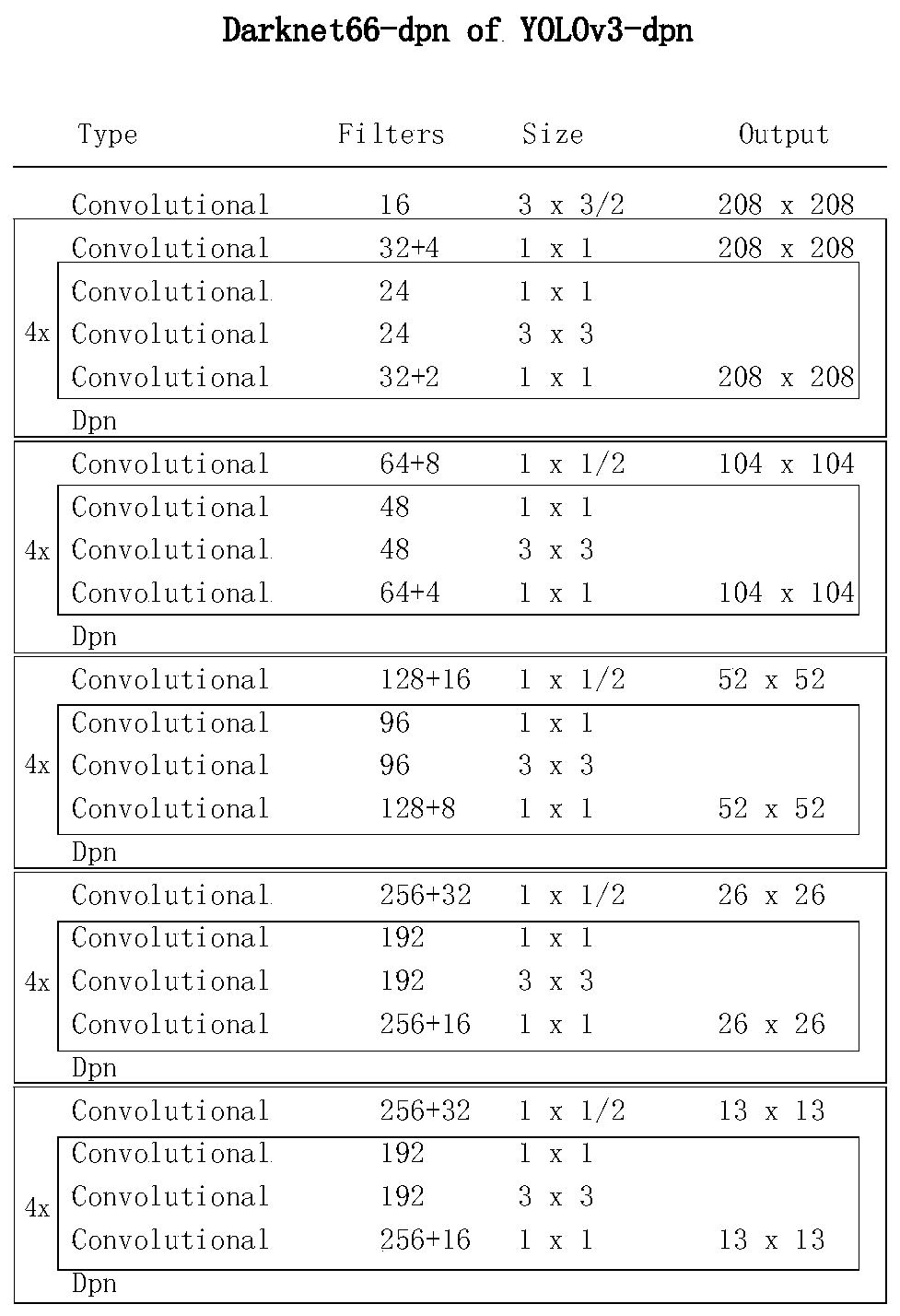

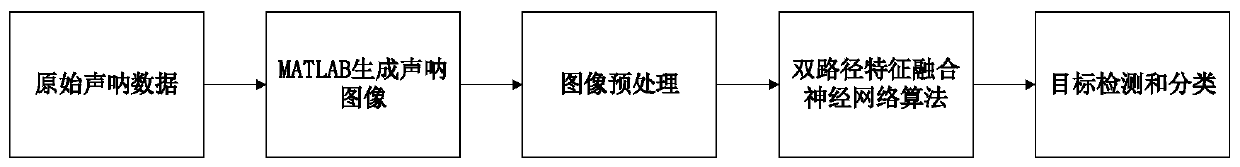

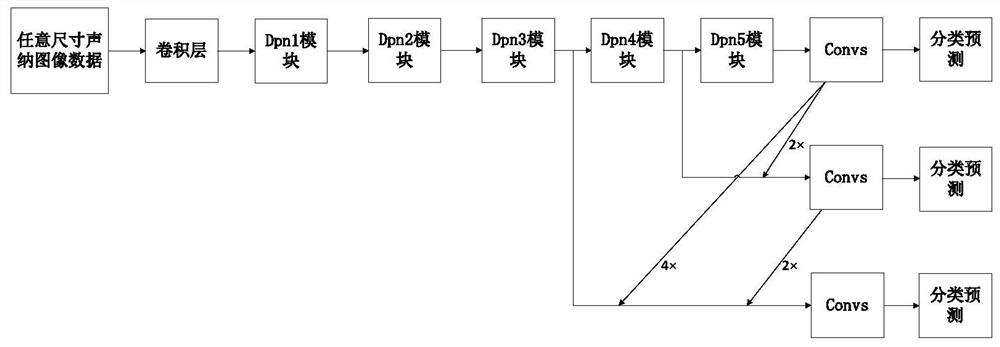

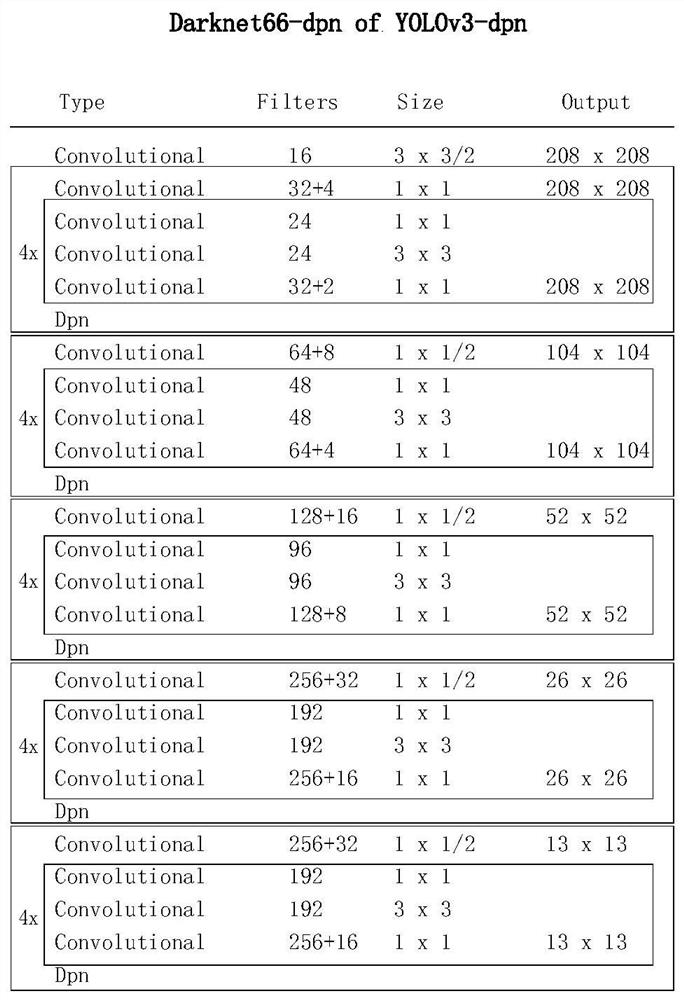

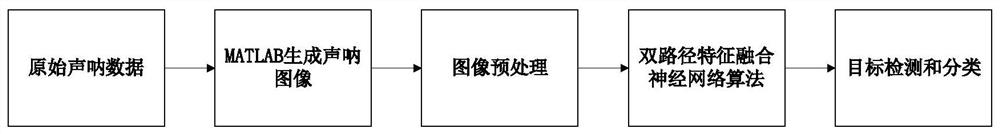

Robust sonar target detection method based on dual-path feature fusion network

ActiveCN110163108ADetection speedImprove the detection effectCharacter and pattern recognitionNeural architecturesImage segmentationDeep level

The invention discloses a robust sonar target detection method based on a dual-path feature fusion network. According to the traditional image processing method, an image segmentation method is used for distinguishing a background from a target; the method comprises the following steps of: 1, establishing a dual-path feature fusion network; and 2, training the dual-path feature fusion network obtained in the step 1; 3, performing sonar image generation and feature extraction; and 4, classifying and detecting the sonar image target frame by combining the default frame. According to the method,the deep learning technology is fused into target detection, the sonar image generated by the sonar data is input into the network model, feature extraction, target detection and target classificationare completed in the model at a time, and therefore the detection speed is greatly increased. According to the method, more deep features can be extracted, and target classification and regression are optimized fundamentally. According to the invention, multi-scale dense connection is adopted to fuse multi-level characteristics and improve the detection effect of medium and small targets.

Owner:HANGZHOU DIANZI UNIV

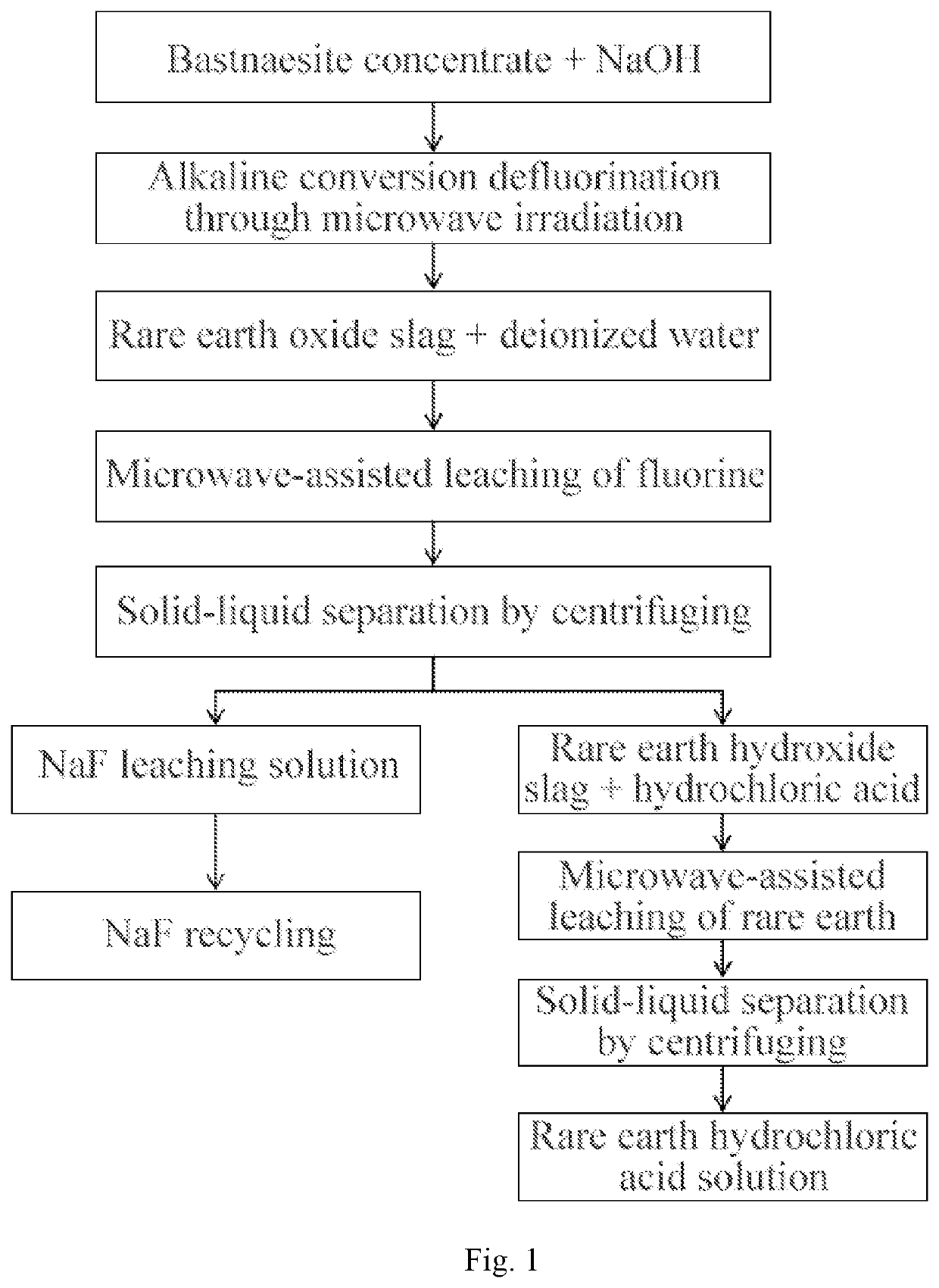

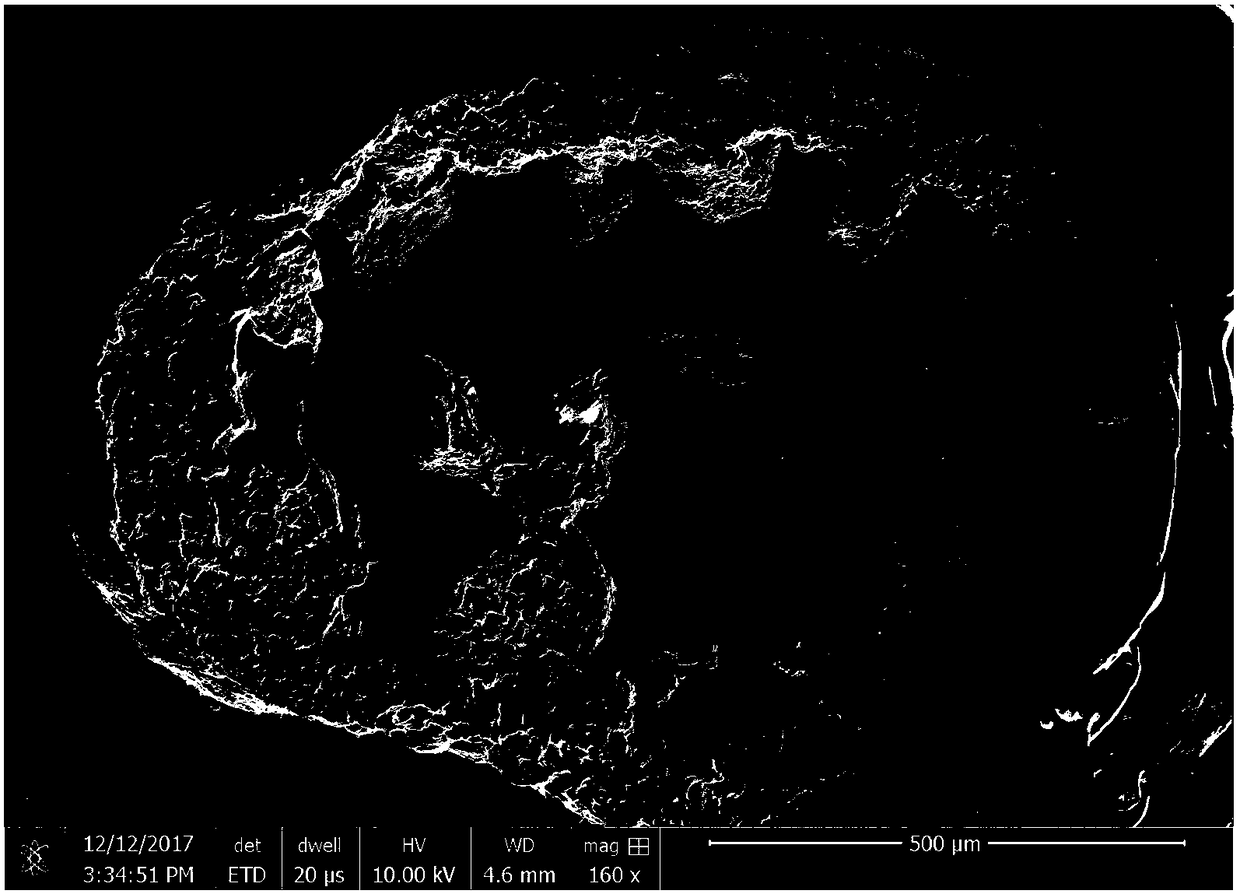

Microwave chemical method for totally extracting fluorine and rare earth from bastnaesite concentrate

PendingUS20210236956A1Short processReduce energy consumptionFluorineProcess efficiency improvementPregnant leach solutionPhysical chemistry

Disclosed is a microwave chemical method for totally extracting fluorine and rare earth from bastnaesite concentrate, including: alkaline conversion defluorination of bastnaesite through microwave irradiation, microwave-assisted leaching of fluorine, solid-liquid separation of leaching solution and microwave-assisted leaching of rare earth. The rare earth hydrochloric acid solution for leaching contains no fluorine ion, so that the fluorine interference of subsequent processes such as impurity removal can be completely avoided; the fluorine and the rare earth are leached with microwaves, which does not need the stirring, so that the automatic control is easy to implement; the fluorine and rare earth leaching speed is high, the leaching time is short and the complete leaching of fluorine and little residual alkali in the slag can be realized by two-time leaching; and no fluorine-containing waste water is discharged, and the total extraction of the rare earth can be realized by one-time leaching.

Owner:SICHUAN NORMAL UNIVERSITY

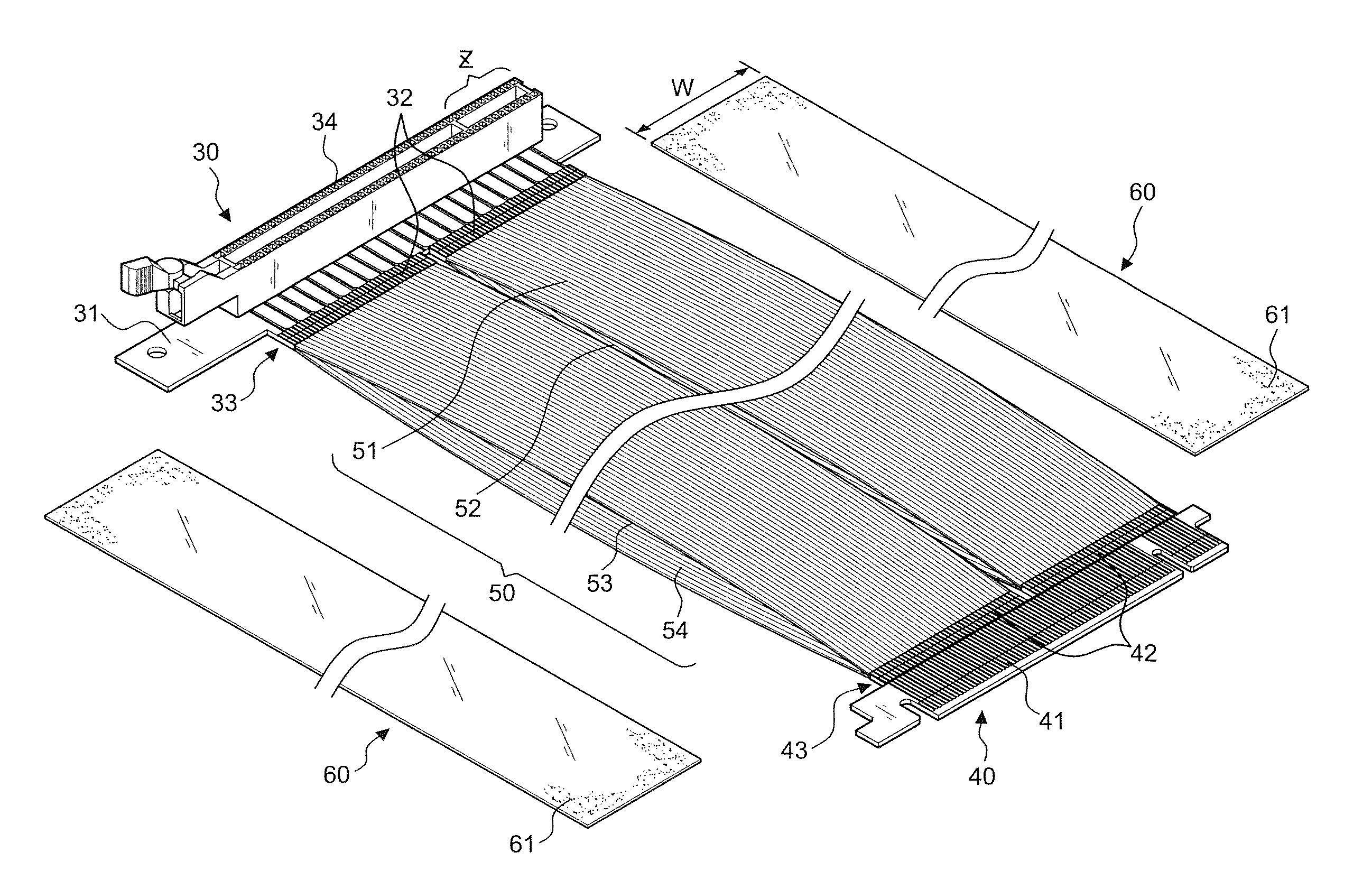

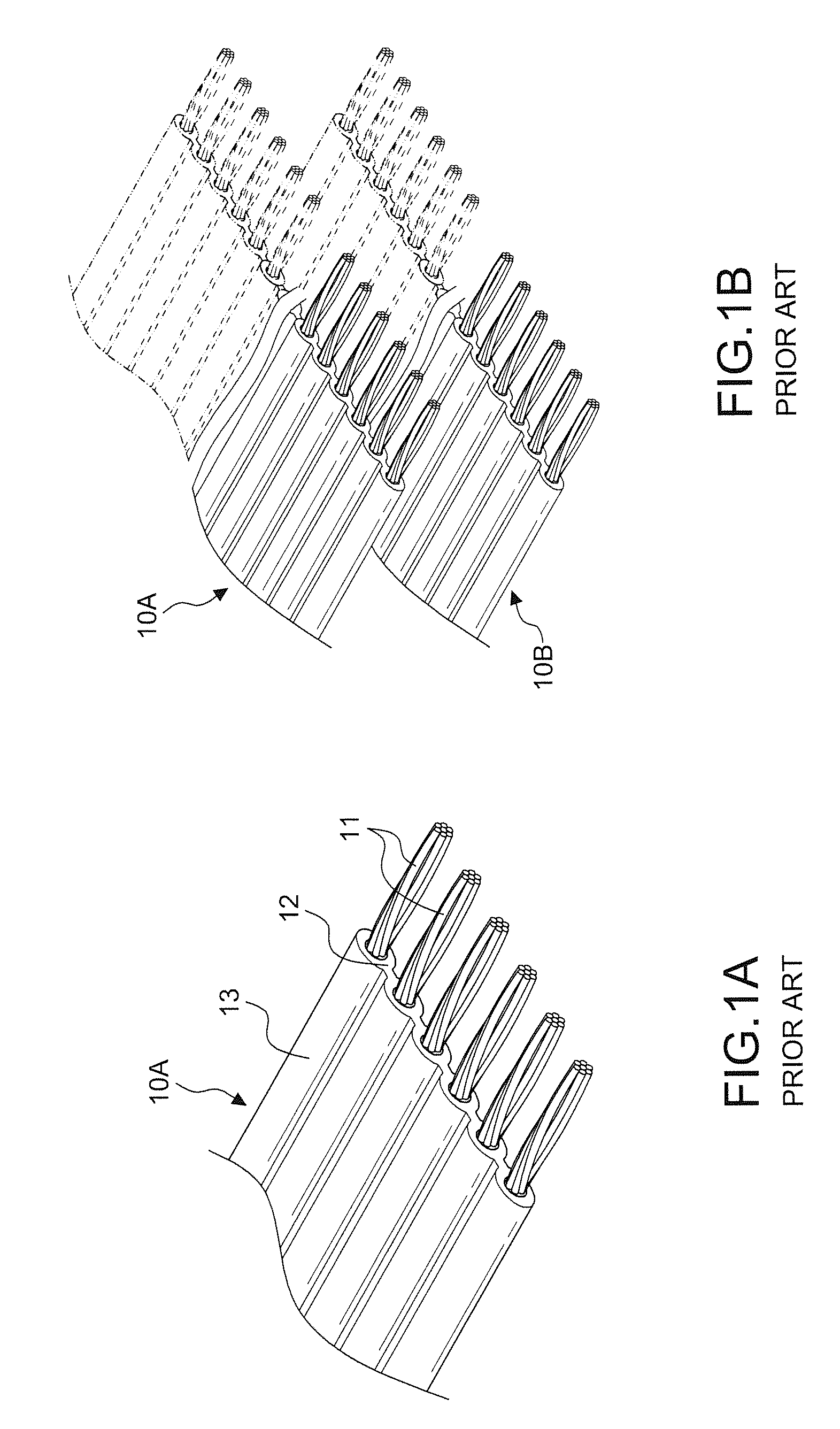

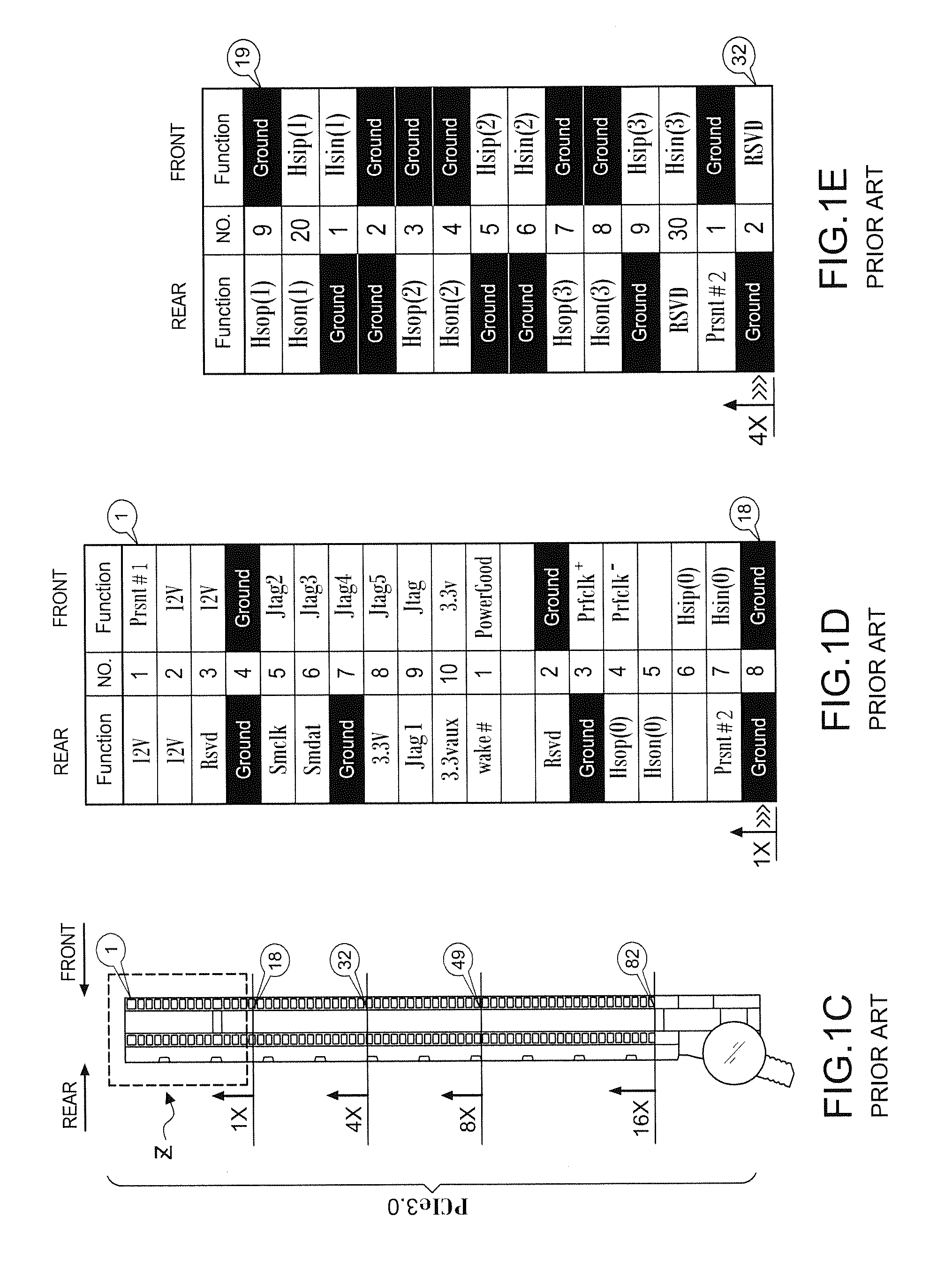

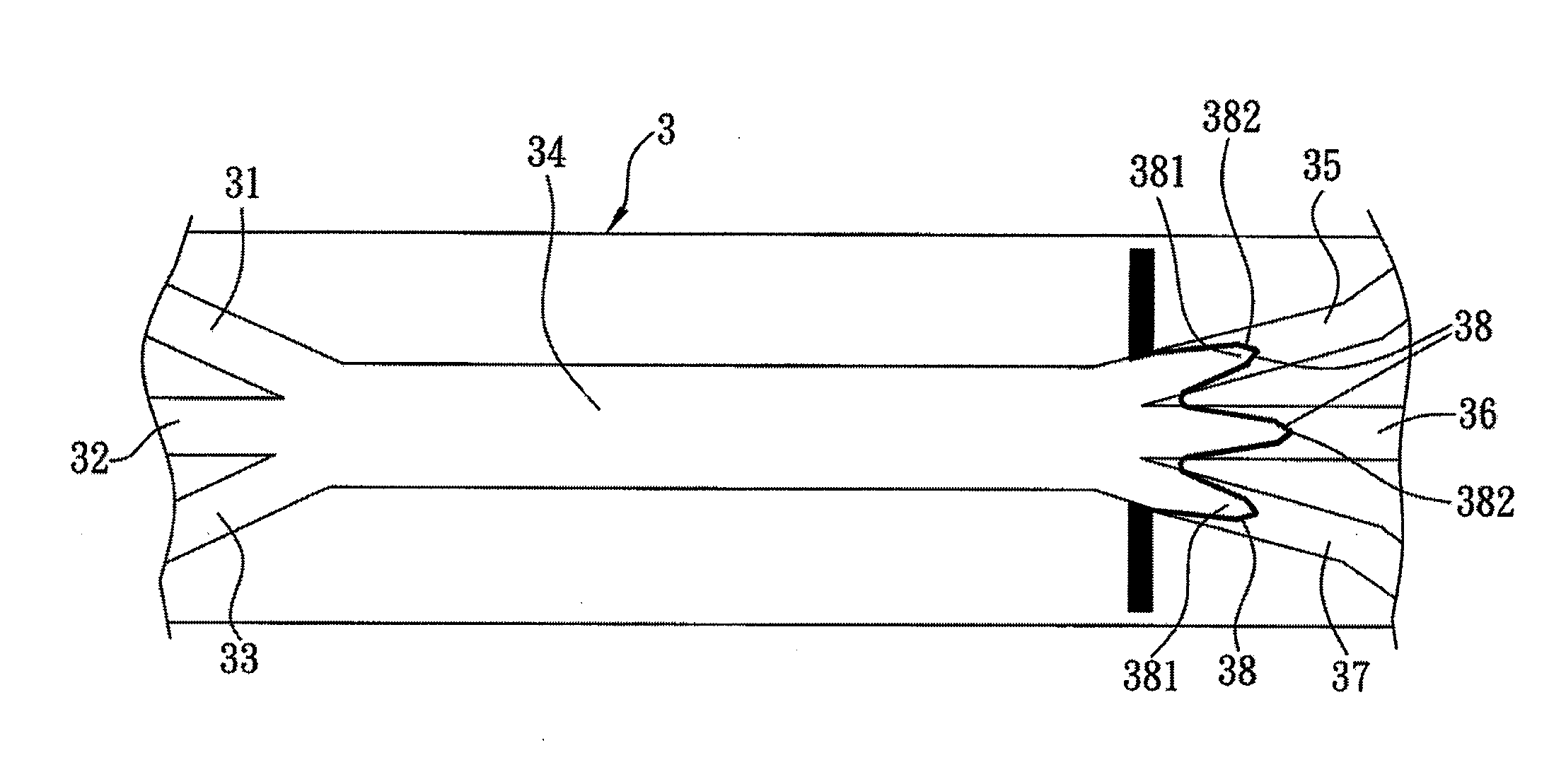

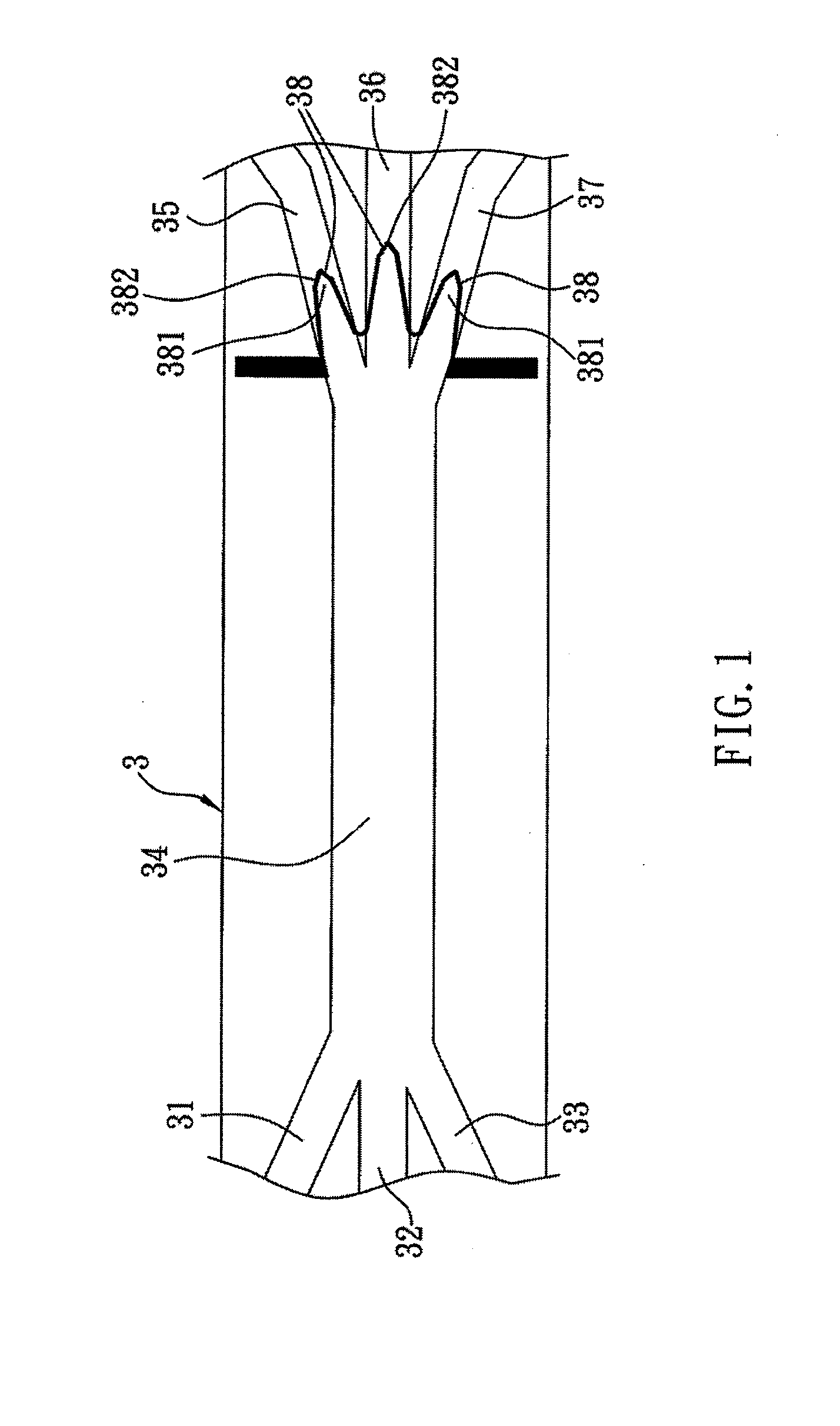

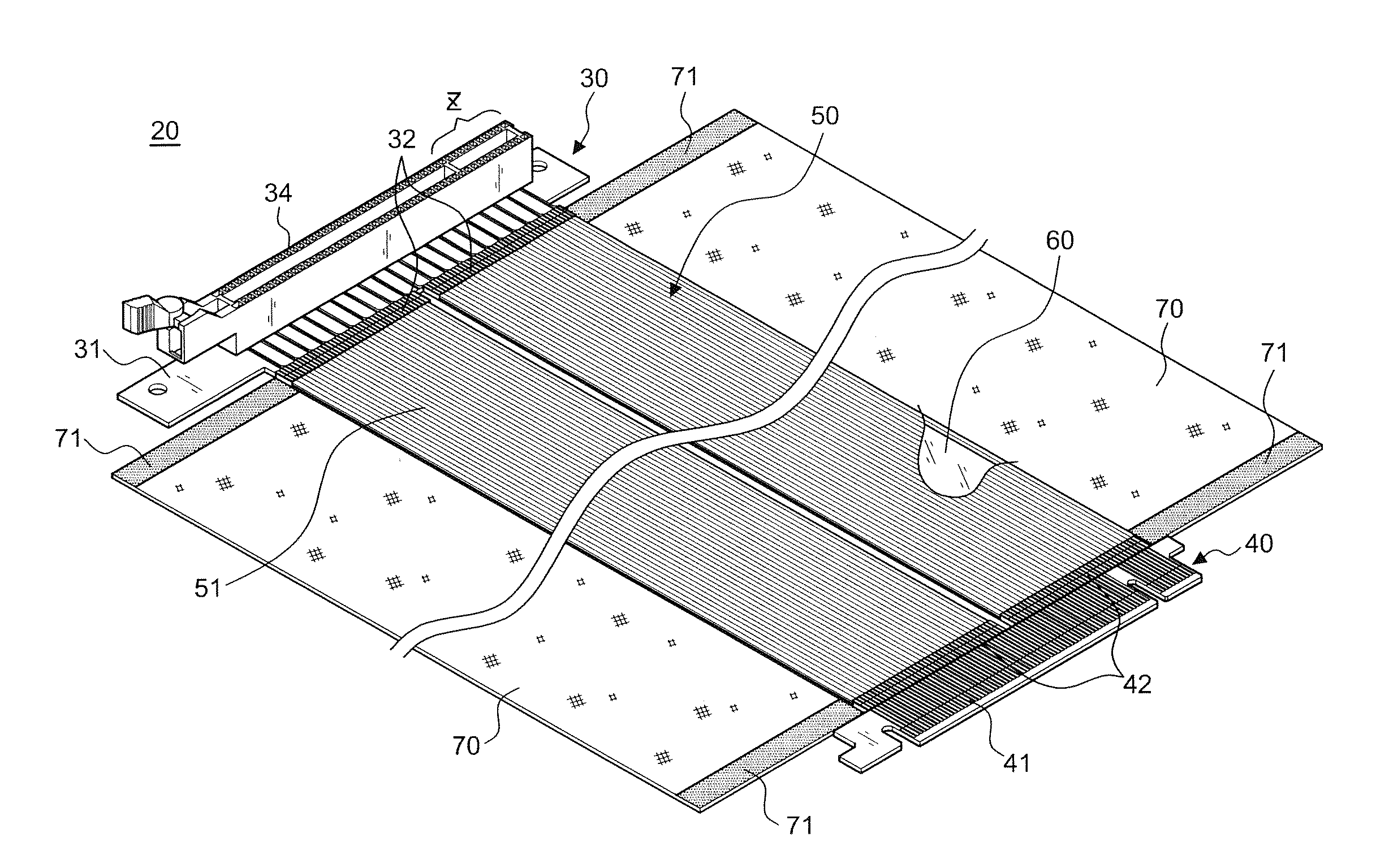

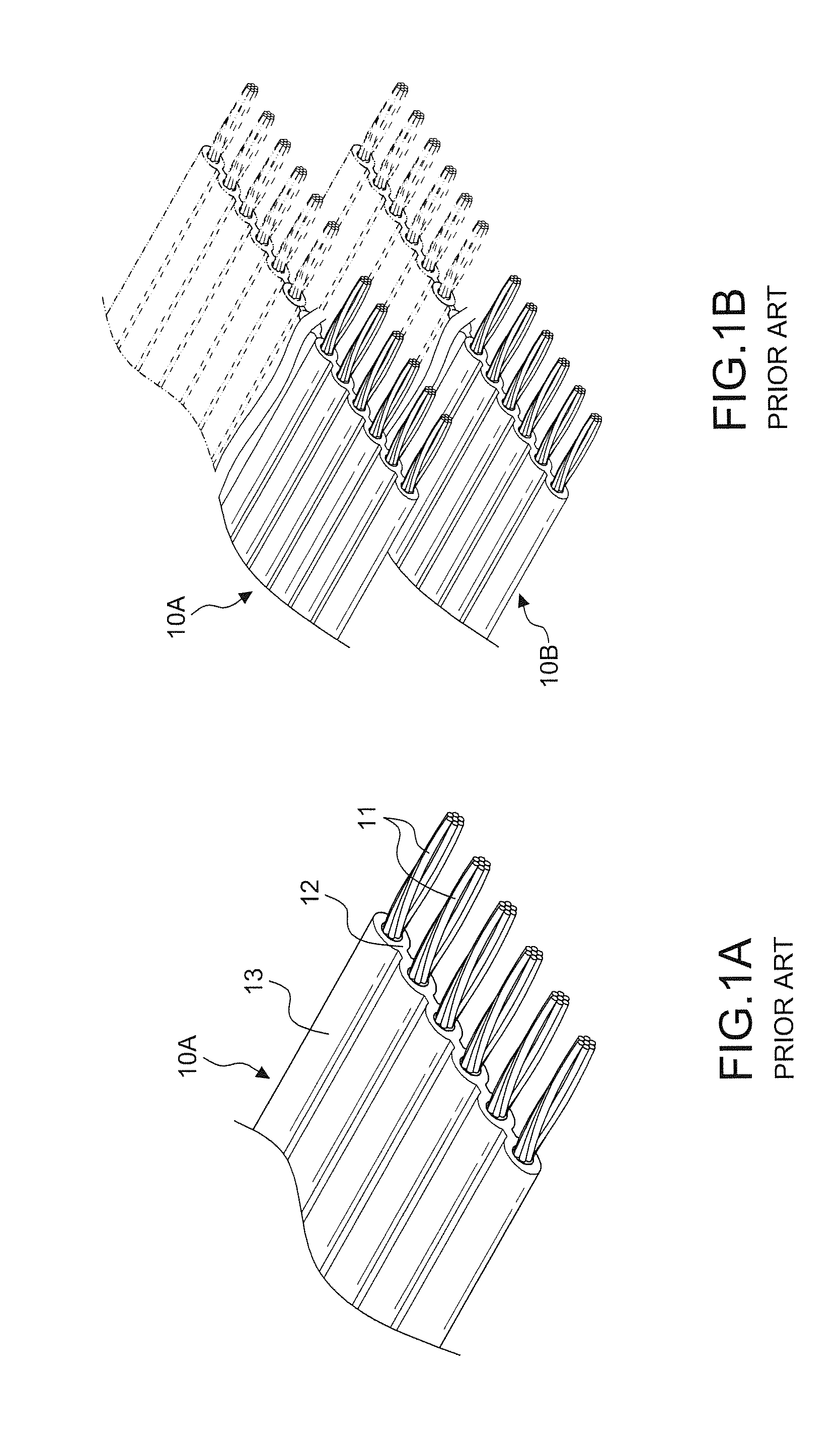

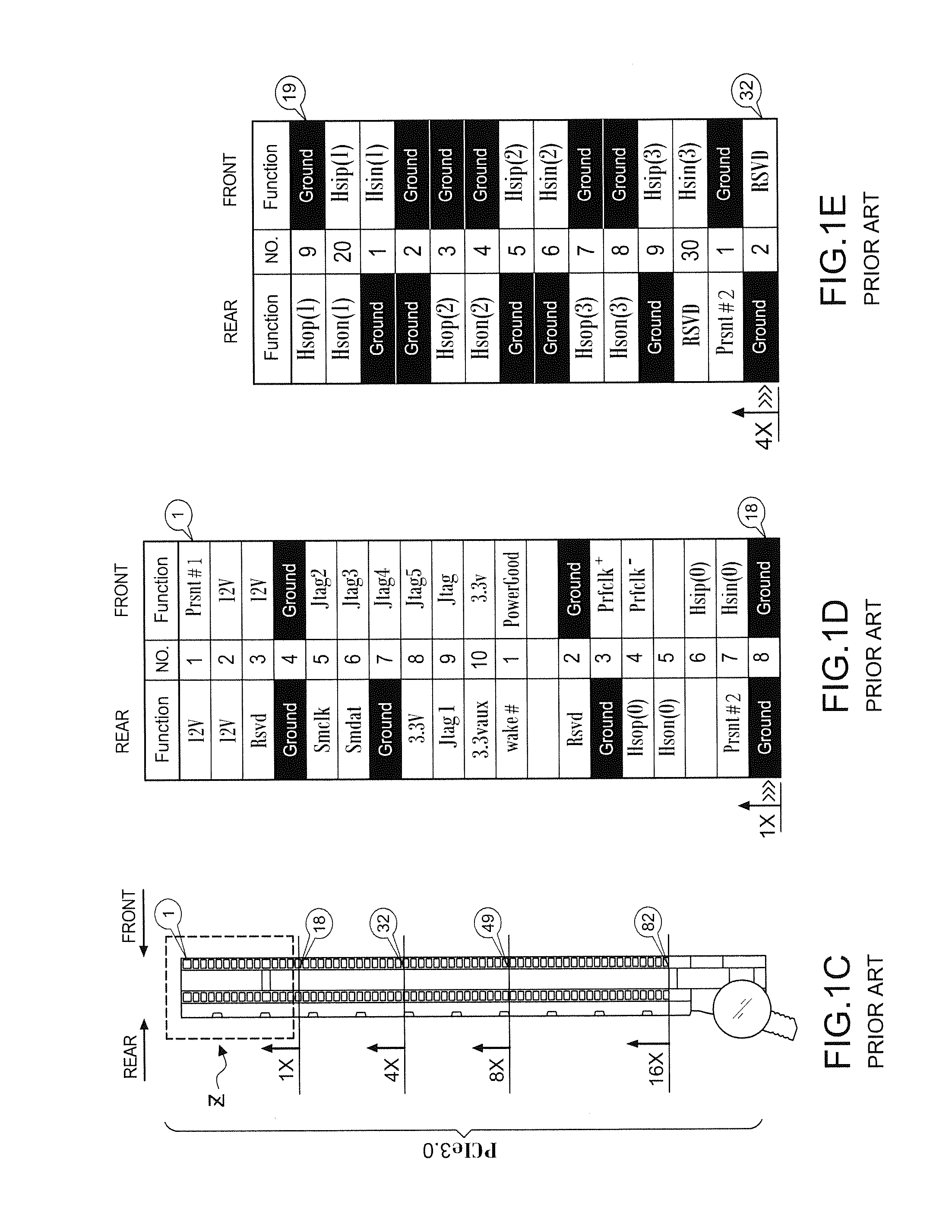

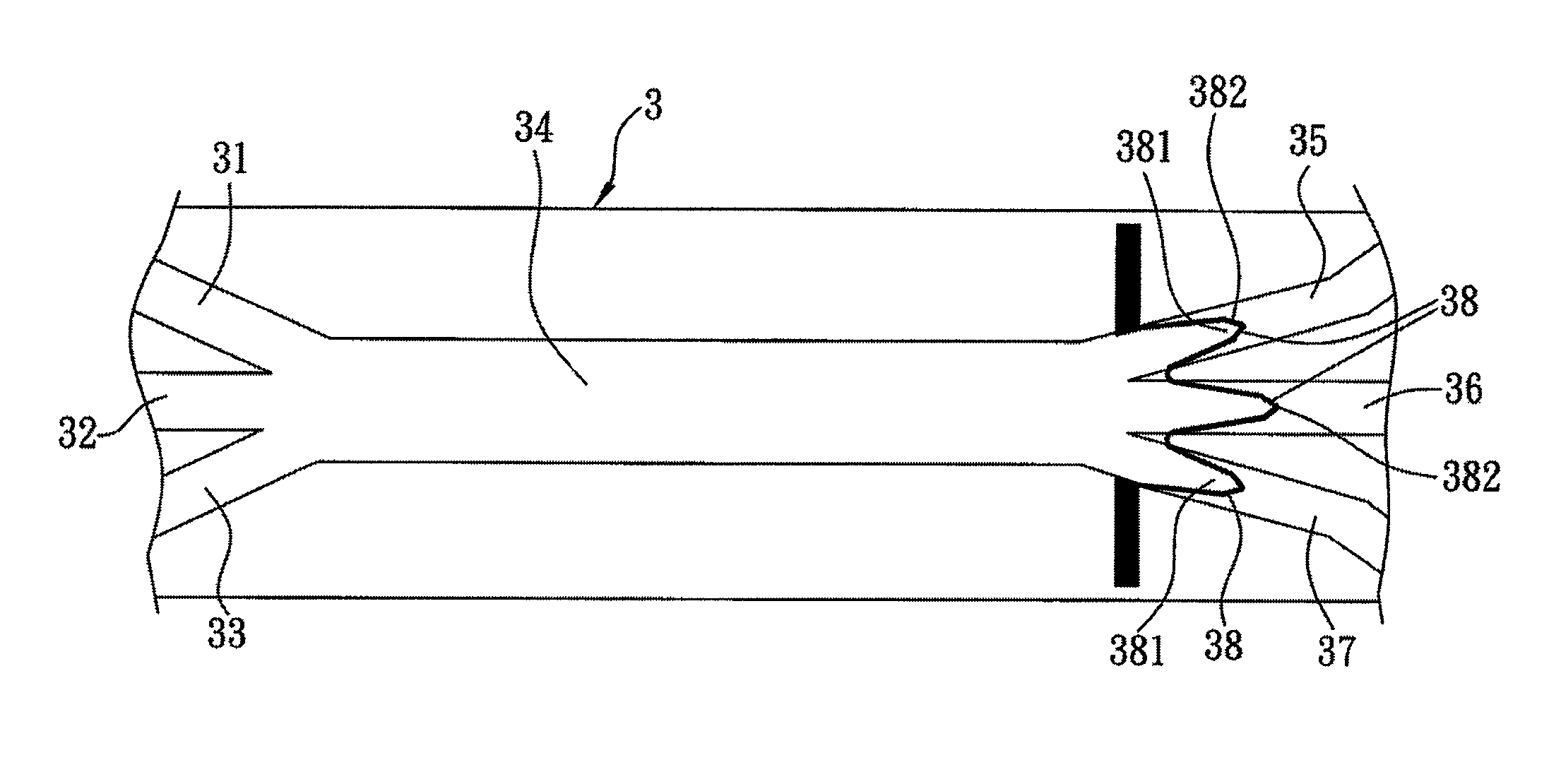

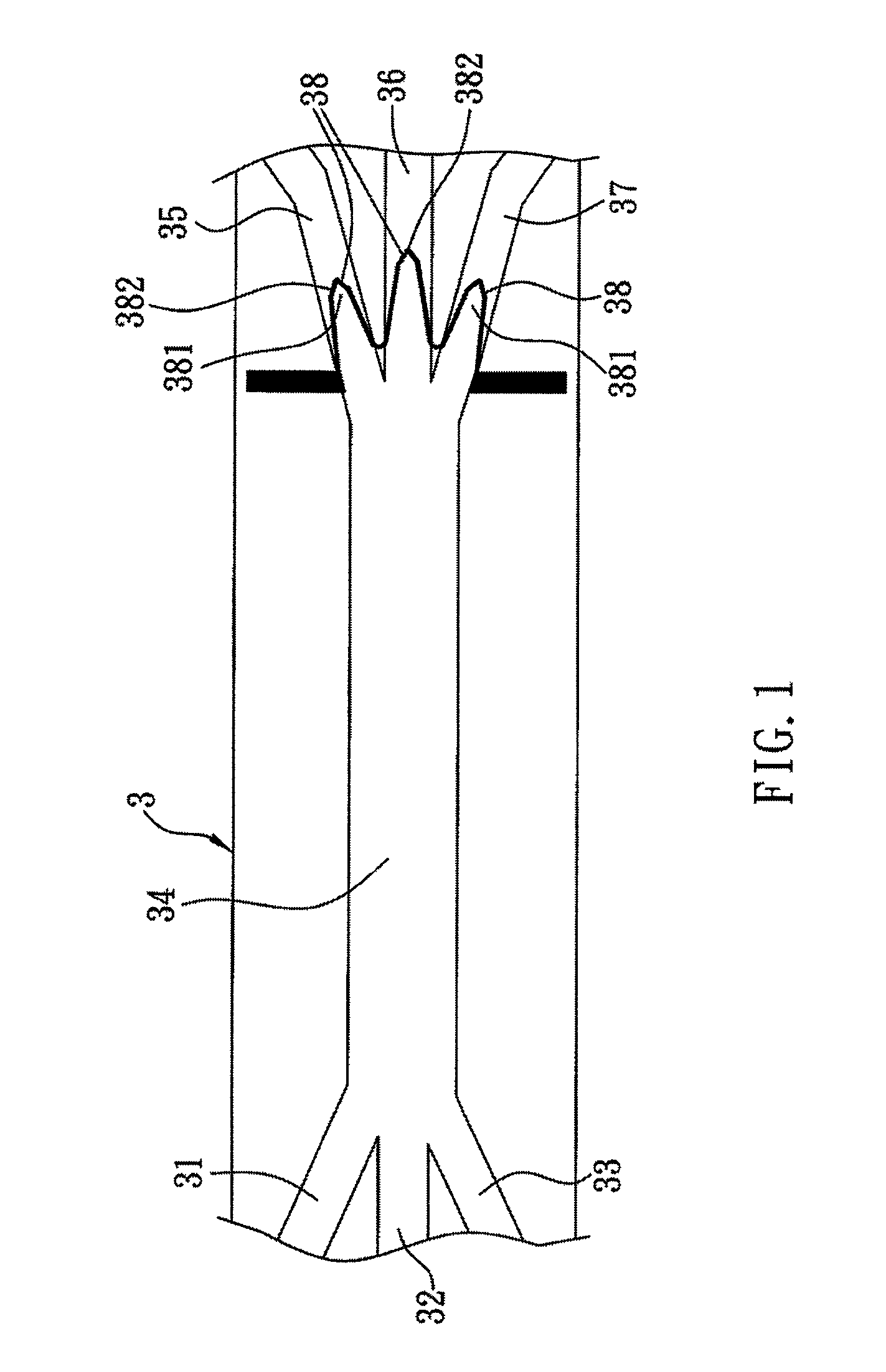

High-frequency signals double-layer flat cable adapter card

ActiveUS9215834B2Transmitting high frequency signalsWithout distortionMagnetic/electric field screeningElectrically conductive adhesive connectionsMetal foilMagnetic field effect

A high-frequency signal double-layer flat cable adapter card that is capable of eliminating transmission disorder of a double-layer cable caused by paralleling and overlap of high-frequency signals and a direct current power supply loop. The high-frequency double-layer flat cable adapter card comprises a first connecting end, a second connecting end and a flat cable group formed by at least two strips of flat cables. The first connecting end includes a first substrate and a connector. The second connecting end includes a second substrate. The flat cable group is in an upper-lower dual-layer structure and is connected between the first connecting end and the second connecting end. A conductive metal foil sheet is arranged between upper and lower dual layers of flat cables of the flat cable group. The width of the metal foil sheet must cover areas of the flat cable group adopted as a power supply loop to isolate the magnetic field effect of the areas of the upper and lower dual layers of flat cables adopted the power supply loop.

Owner:CHENG LIANG HO

Micro-nano active oxygen treatment method of sewage

ActiveCN102701456AEliminate subsequent contaminationTo achieve the purpose of purification and restorationTreatment with aerobic and anaerobic processesMicro nanoChemical oxygen demand

The invention discloses a micro-nano active oxygen treatment method of sewage, comprising the following steps: a, physically treating: settling the sewage to remove sand; b, separating: carrying out micro-nano bubble oxidization separation on the sewage, wherein the diameters of the bubbles are smaller than 50 microns; c, biologically treating: carrying out nitrification and denitrification reaction on the sewage which is subjected to the micro-nano bubble treatment and flows into a reaction pool with bionic biological carrier; and d, discharging: discharging under the conditions that the COD (chemical oxygen demand) of the sewage reaches 98%. The micro-nano active oxygen treatment method of the sewage thoroughly eliminates all organic pollution sources in the sewage and realizes the aim of purifying and reducing the sewage.

Owner:CHENGDU BRANCH TIBET GUOCE ENVIRONMENTAL PROTECTION TECH

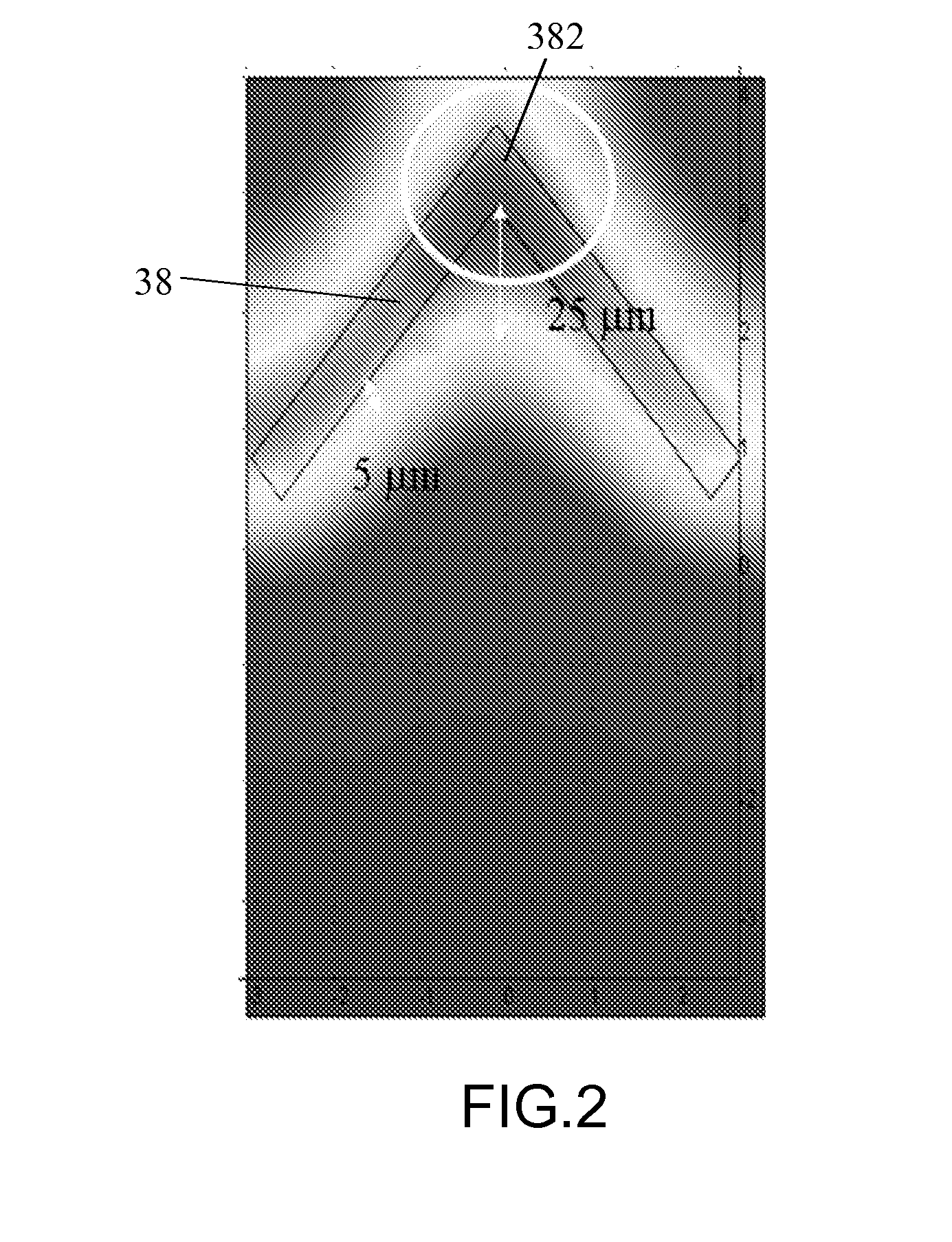

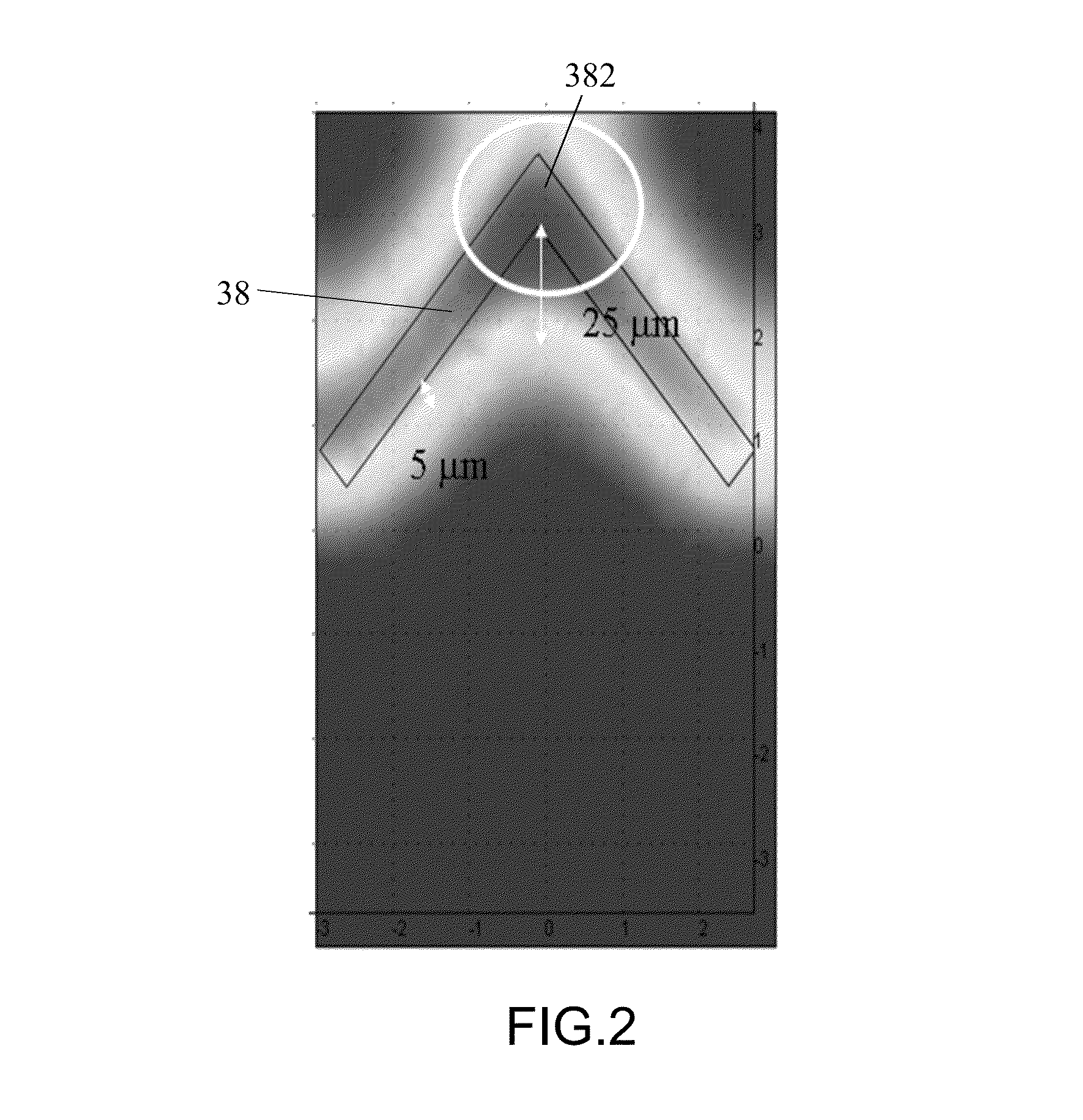

Microbial identification and manipulation of nanoscale biomolecules

InactiveUS20120292184A1Enhance electric fieldIncrease the electric field strengthDielectrophoresisElectrolysis componentsDielectrophoretic forceElectrophoresis

A method of microbial identification is disclosed. The method includes the steps of assembling dielectrophoretic particles modified with specific DNA probes on a surface thereof in a continuous fluid at a predetermined location in a microchannel to form a particle assembly by a negative dielectrophoretic force and a hydrodynamic force provided by the continuous fluid, narrowing gaps between the dielectrophoretic particles of the particle assembly to enhance the electric field in the gaps between the dielectrophoretic particles, injecting a fluid containing target DNAs of a target microbe into the microchannel at a predetermined flow rate to move the target DNAs toward the particle assembly and generating a positive dielectrophoretic force by the enhanced electric field to attract the target DNAs toward the dielectrophoretic particles of the particle assembly for hybridization with the DNA probes. The present invention also discloses a method of manipulation of nanoscale biomolecules.

Owner:NAT CHENG KUNG UNIV

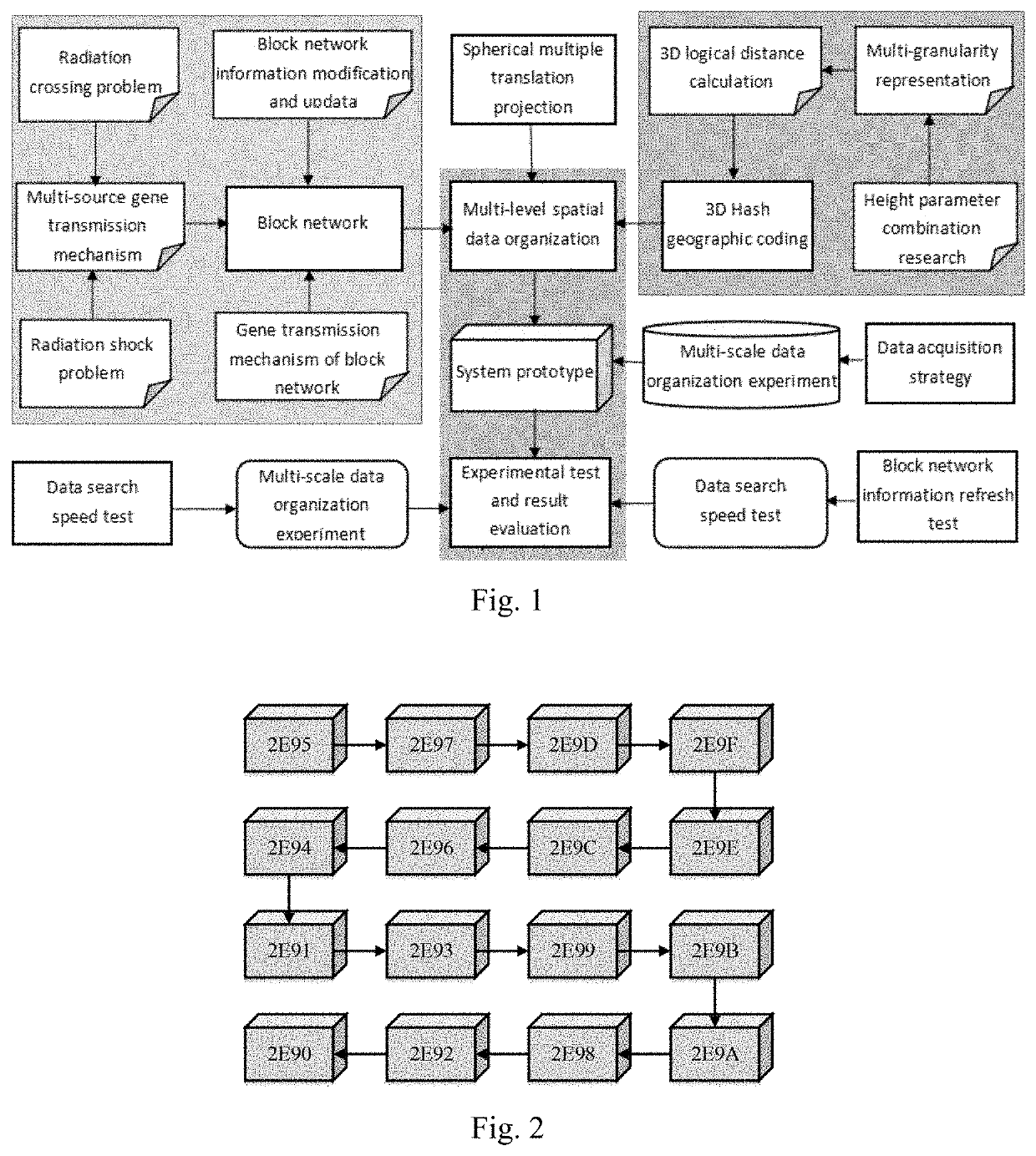

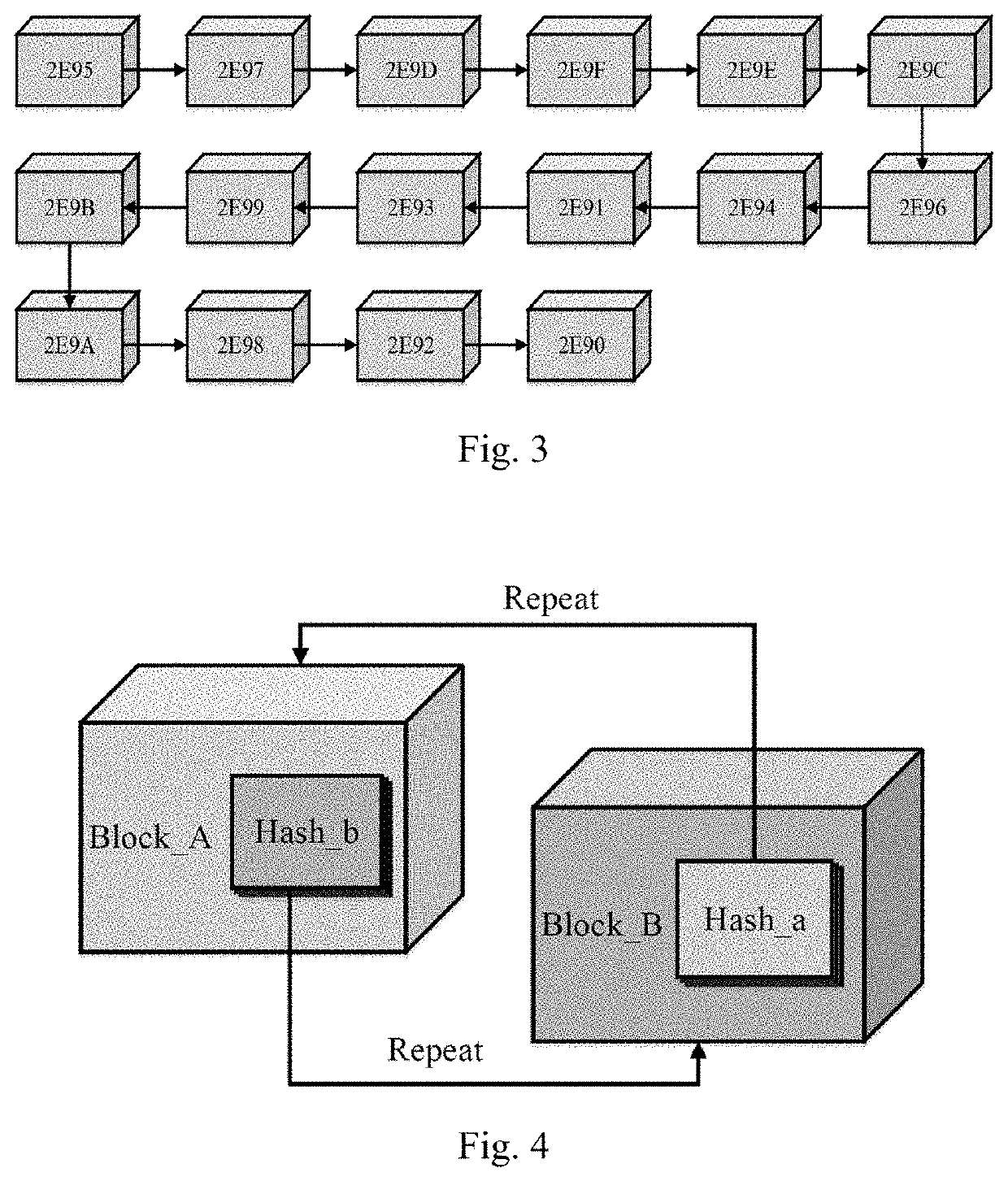

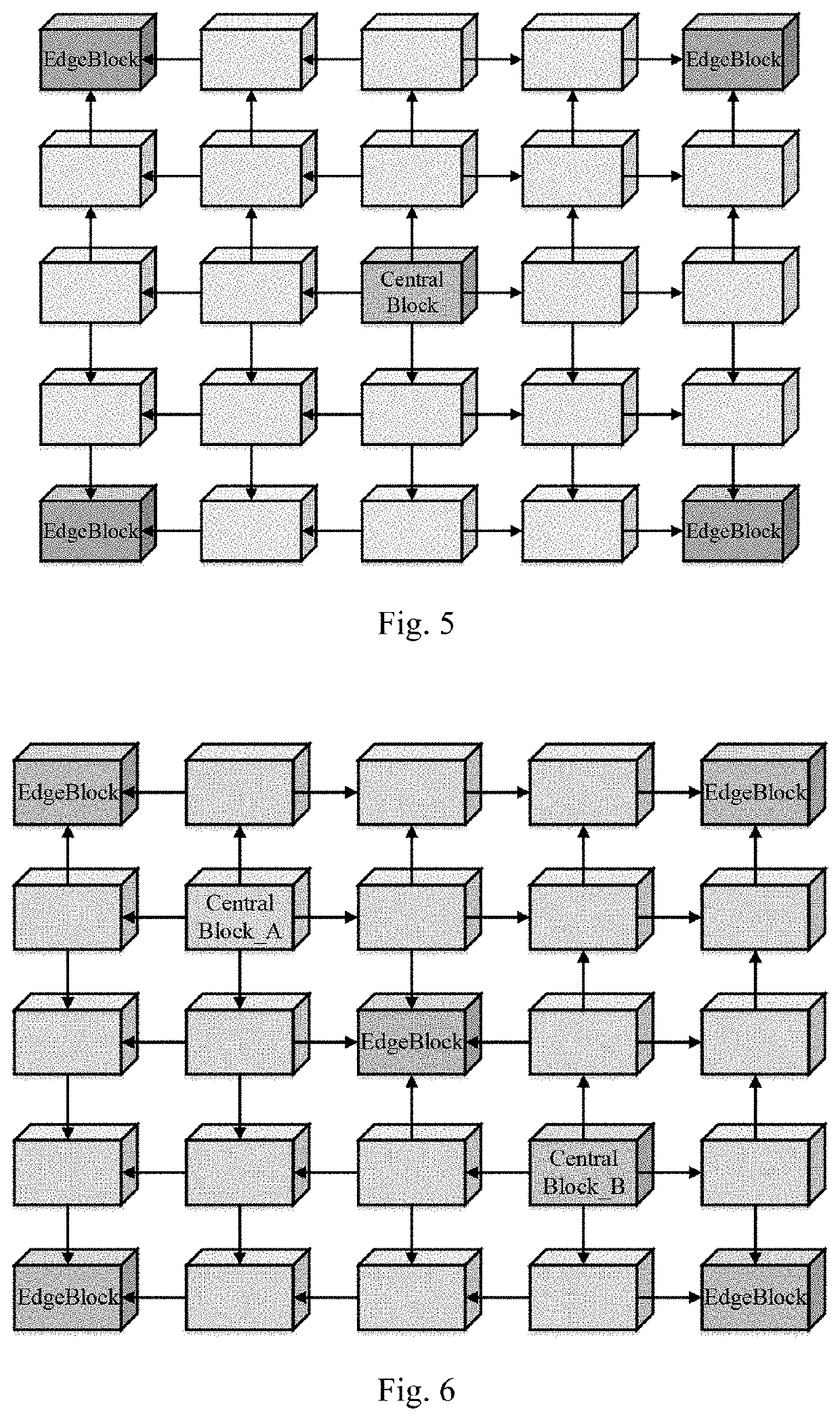

BlockNet security organization storage mapping method for spatial data

PendingUS20220121962A1Improve indexing speedIncrease spacingUser identity/authority verificationDatabase distribution/replicationAlgorithmEngineering

A BlockNet security organization storage mapping method for spatial data includes: first constructing a BlockNet gene propagation mechanism according to the characteristics of the BlockNet storage space data, and then designing multi-source gene propagation in a multi-space data center scenario mechanism. In the multi-source gene propagation mechanism, the propagation round control and the in / out-degree control mechanism are designed for the possible radiation crossover problems and radiation impact problems. A BlockNet information update plan is designed for data modification and update requirements in spatial data storage scenarios. In addition to realizing the unique primary key block coding of spatial data and accelerating the indexing speed, it also retains elevation information through multi-dimensional coding, expands the amount of information, improves the utilization efficiency of spatial data, and the security of data mapping and storage process is greatly improved.

Owner:QINGDAO UNIV

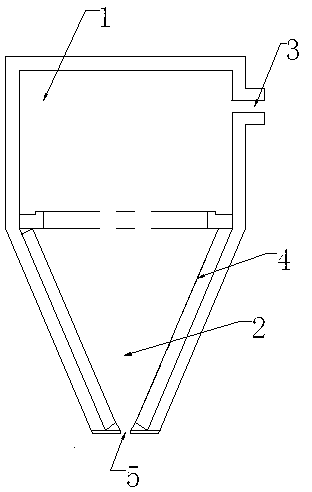

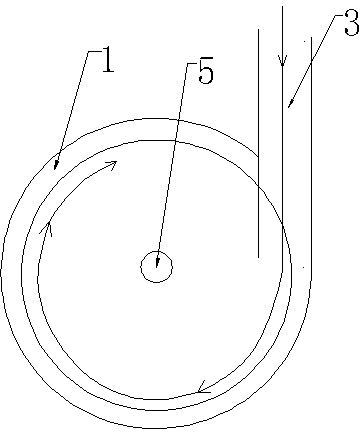

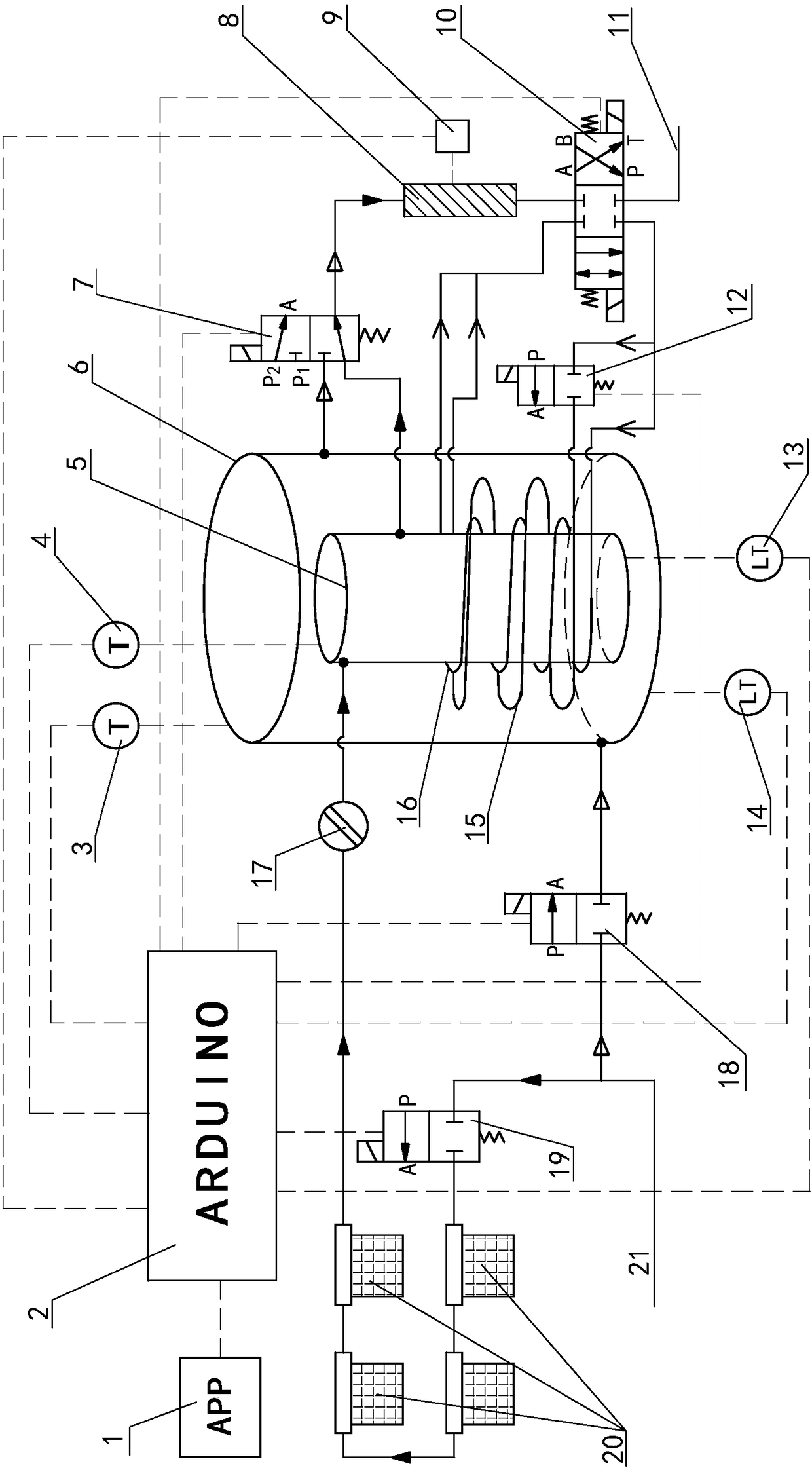

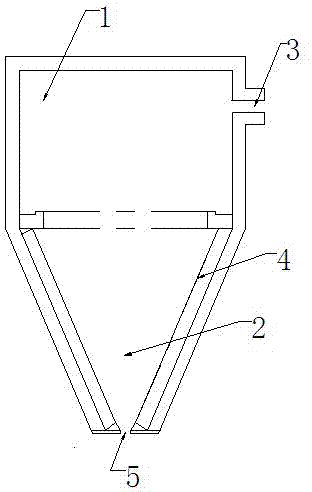

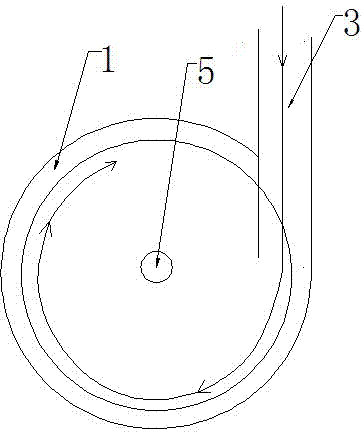

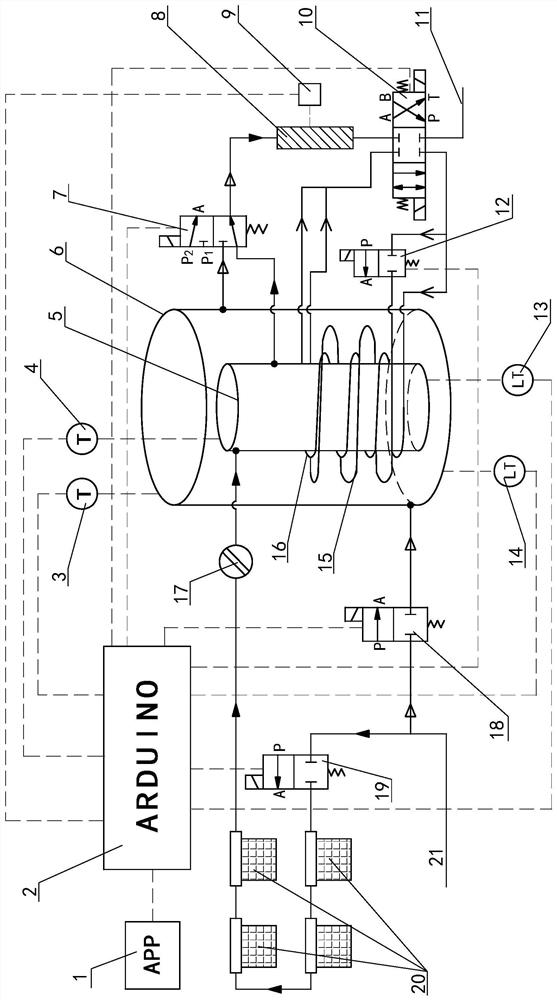

Intelligent water boiling control system

ActiveCN108387003ASave energyImprove utilization efficiencyFluid heatersMicrocontrollerSolenoid valve

The invention provides an intelligent water boiling control system. A tap water inlet end is connected with P ports of a second two-position two-way normally closed solenoid valve and a first two-position two-way normally closed solenoid valve. An A port of the first two-position two-way normally closed solenoid valve is connected with an inlet end of a solar thermal collector. An outlet end of the solar thermal collector is connected with an inlet of an inner-layer water storage tank. An outlet of the inner-layer water storage tank is connected with a P1 port of a two-position three-way solenoid valve. An A port of the second two-position two-way normally closed solenoid valve is connected with an inlet of an outer-layer water storage tank. An outlet of the outer-layer water storage tankis connected with a P2 port of the two-position three-way solenoid valve. A first-stage heat exchange pipeline and a second-stage heat exchange pipeline are arranged on the periphery of the inner-layer water storage tank. A single chip microcomputer controls the on-off states of the two-position three-way solenoid valve, a three-position four-way solenoid valve and a third two-position two-way normally closed solenoid valve to control the first-stage heat exchange pipeline, the second-stage heat exchange pipeline and a heating pipe, and three water temperatures are outputted to meet living needs. The intelligent water boiling control system has the advantages of green energy resource, intelligent control, convenience and quickness, and energy cycle.

Owner:SUZHOU SABO IND DESIGN

Intelligent water boiling device

ActiveCN108386993AUniform velocity distributionEliminate backmixingSolar heating energySolar heat collector for particular environmentWater savingWater storage tank

The invention discloses an intelligent water boiling device. A running water inlet end is connected with P ports of a second two-position two-way normally closed electromagnetic valve and a first two-position two-way normally closed electromagnetic valve; an A port of the first two-position two-way normally closed electromagnetic valve is connected with an inlet end of a solar heat collector; an outlet end of the solar heat collector is connected with an inlet of an inner layer water storage tank; an outlet of the inner layer water storage tank is connected with a P1 port of a two-position three-way electromagnetic valve; an A port of the second two-position two-way normally closed electromagnetic valve is connected with an inlet of an outer layer water storage tank; an outlet of the outerlayer water storage tank is connected with a P2 port of the two-position three-way electromagnetic valve; a heat exchange system is arranged at the outer periphery of the inner layer water storage tank; a single-chip microcomputer controls connection and disconnection of the two-position three-way electromagnetic valve, a three-position four-way electromagnetic valve and a third two-position two-way normally closed electromagnetic valve to control the heat exchange system and a heating pipe to output three water temperatures for different life demands; and the intelligent water boiling devicehas the advantages of green energy, intelligent control, convenient and quick energy circulation, excellent performances, prominent water saving effect and broad application prospect.

Owner:SUZHOU SABO IND DESIGN

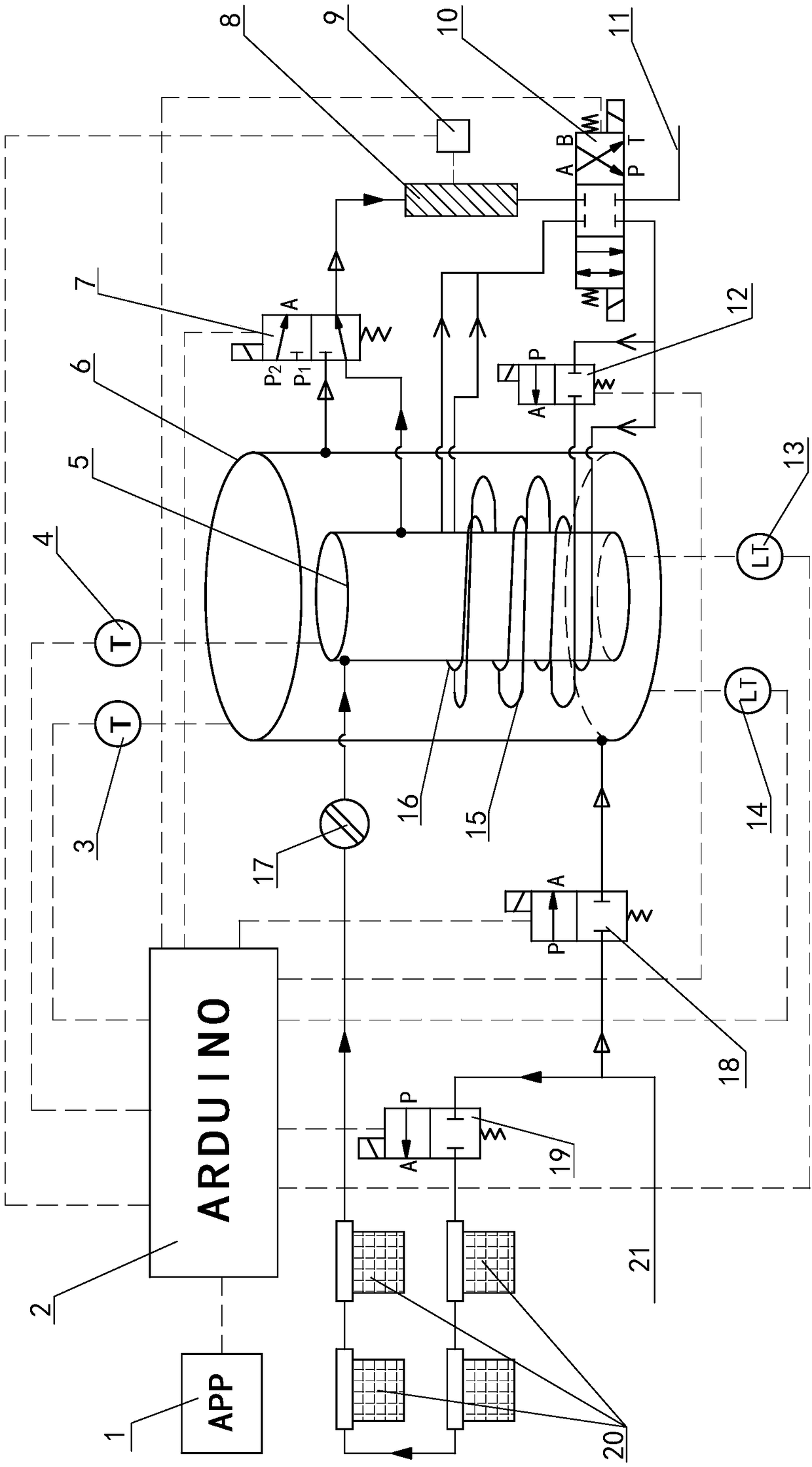

Control device of full-load supercritical water-cooled wall

InactiveCN111594817AMeet the requirements of peak shaving operation modeSmoothen the range of temperature difference around the perimeterSteam separation arrangementsBoiler controlProcess engineeringSuperheater

A direct-current unit is the main power of coal electricity, a power supply coal consumption index of the direct-current unit is worsened due to peak regulation operation, metal fatigue failure occursfrom time to time, a denitration device deviates from the optimal working condition and even exits, primary frequency modulation quality is lowered and is checked frequently, and even start-stop peakregulation is selected passively due to lowest load safety. The invention deeply analyzes the functional basis of a water-cooled wall, and determines that the problem root is the subcritical workingcondition of the once-through boiler water-cooled wall, which is not changed in the existing improvement measures, so that a full-load supercritical water-cooled wall control device model is provided,a special throttling assembly composition and secondary design boundary conditions are formulated, the water-cooled wall and a superheater can be reliably isolated, a steam-water phase change position can be fixed, the coal-water deep correlation can be decoupled, a set of novel control strategy is provided, and the creativity provides a root treating scheme for the problem so as to fully adapt to the low-coal-consumption deep peak regulation requirement. A control device is specially applied to flexibility transformation of a supercritical once-through boiler or newly-built coal-electricityengineering design, and breaks through the limit bottleneck for coal-electricity deep regenerative transformation.

Owner:上海皖祥商务咨询有限公司

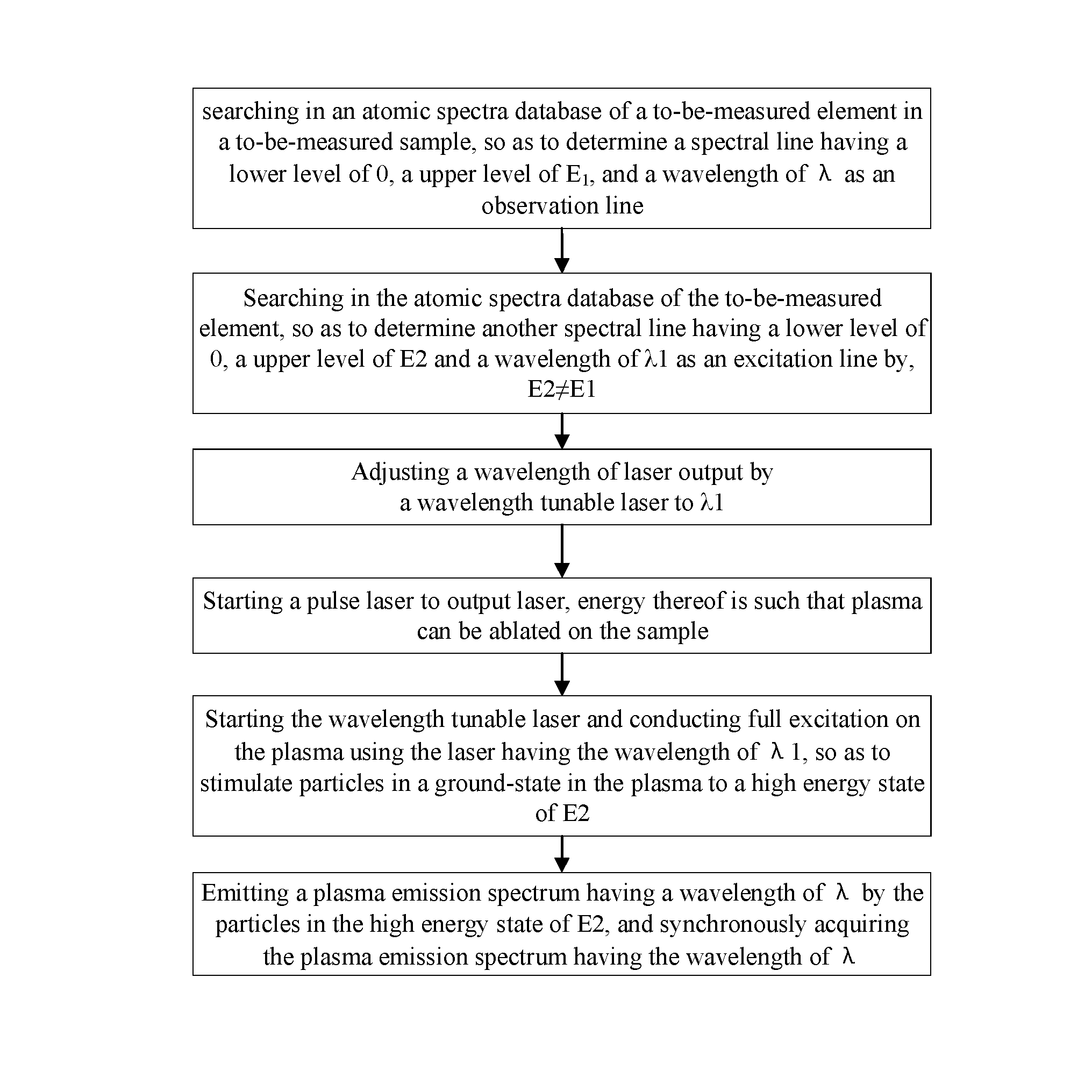

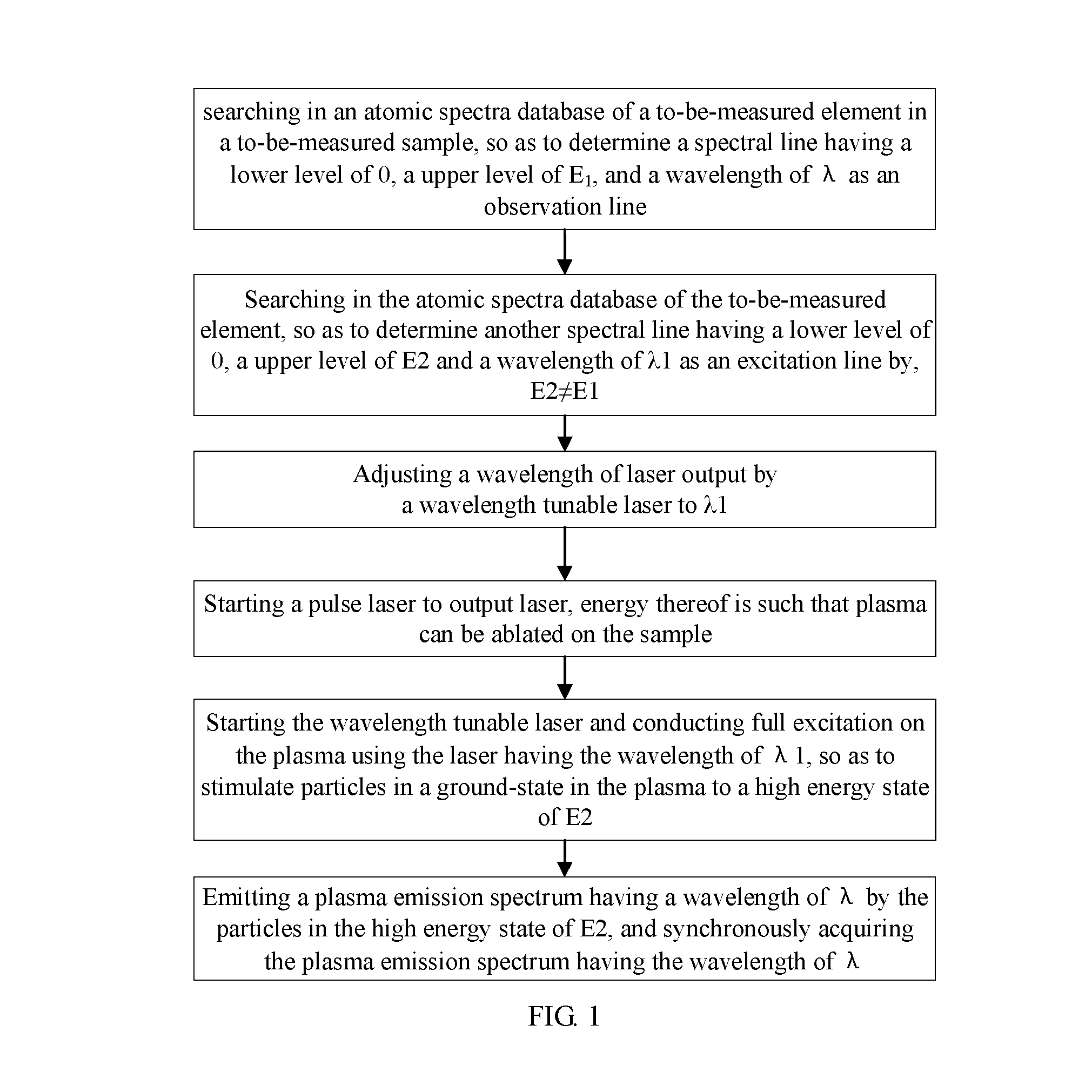

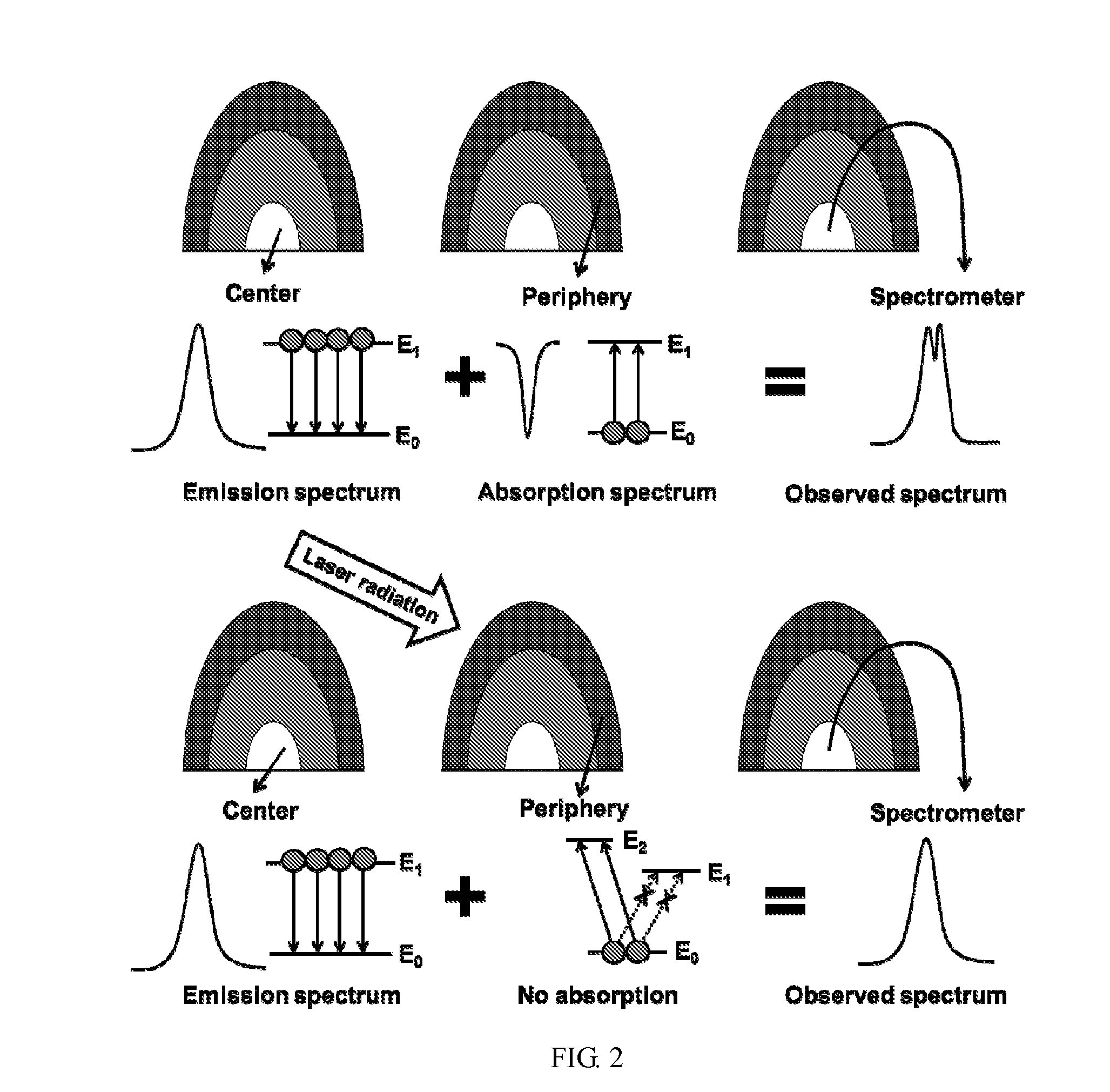

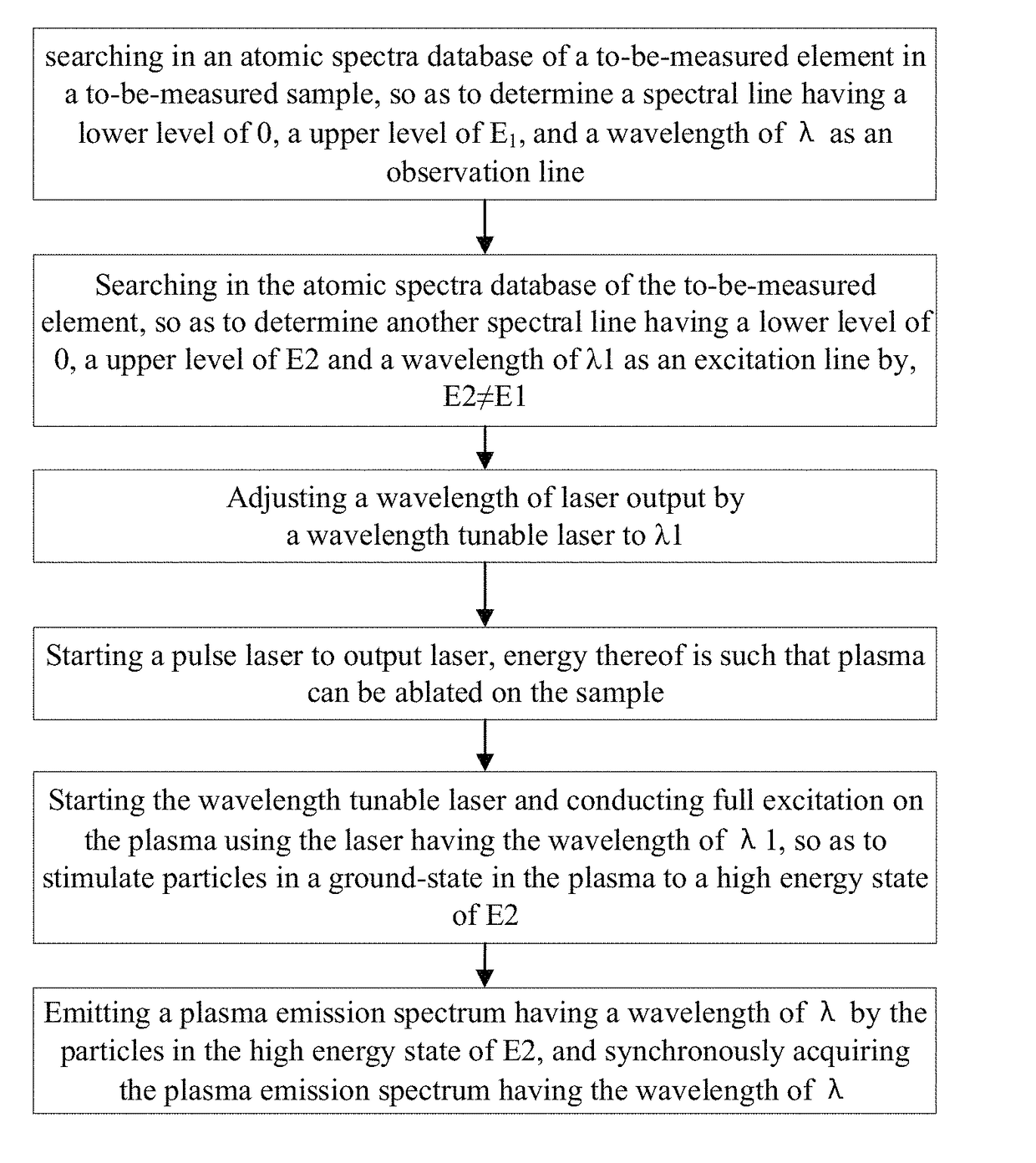

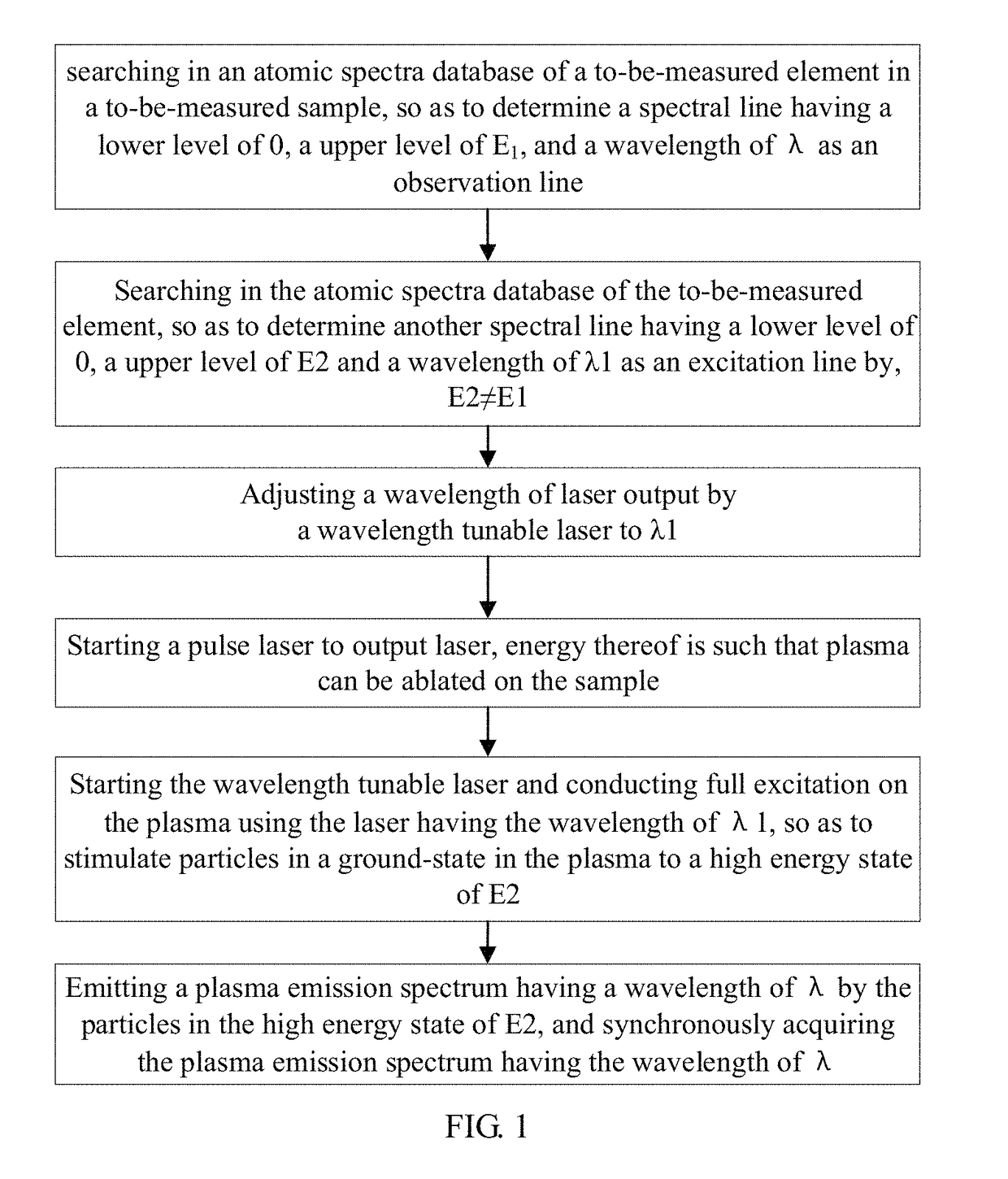

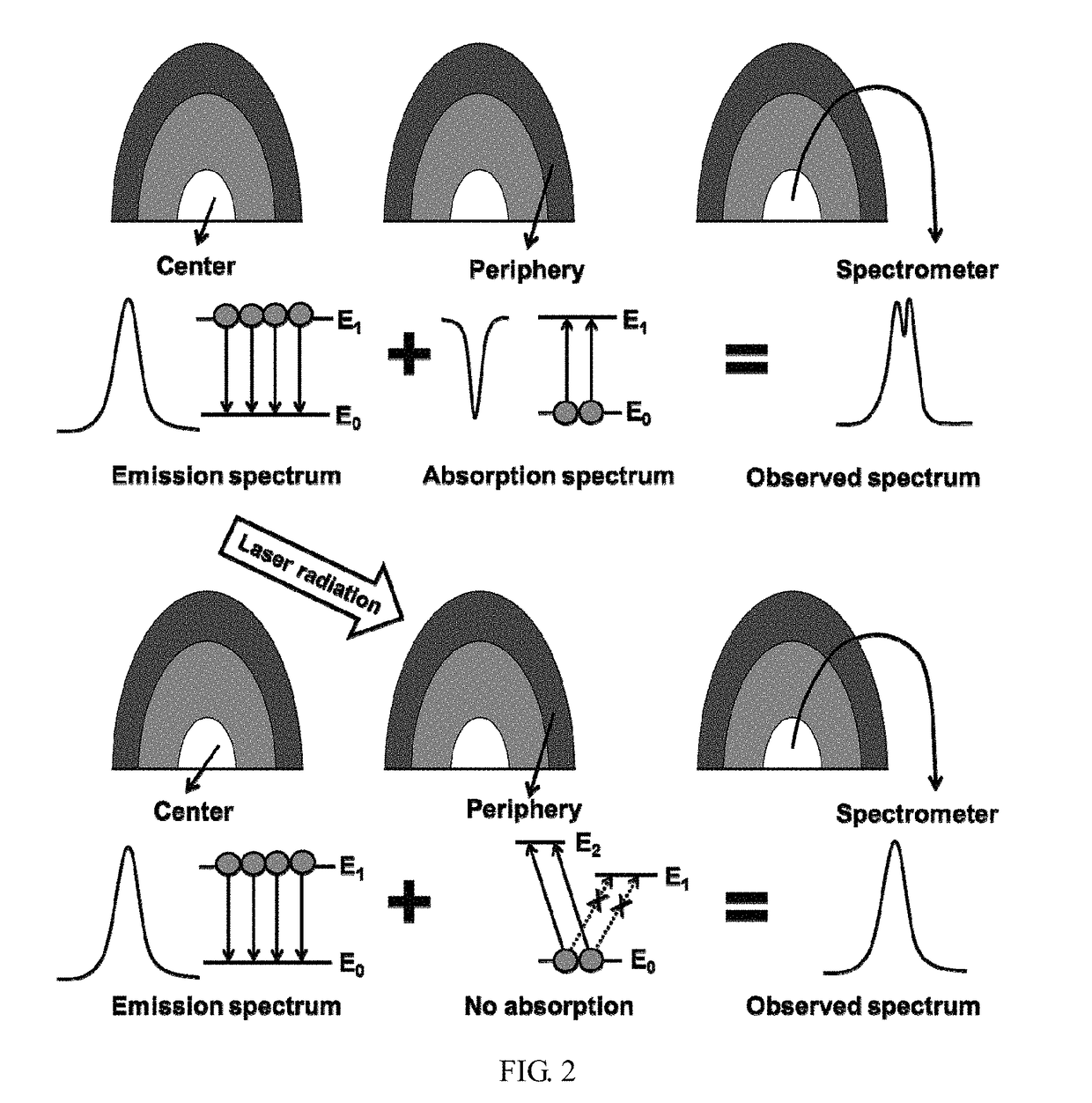

Method for inhibiting self-absorption effect in laser-induced breakdown spectroscopy

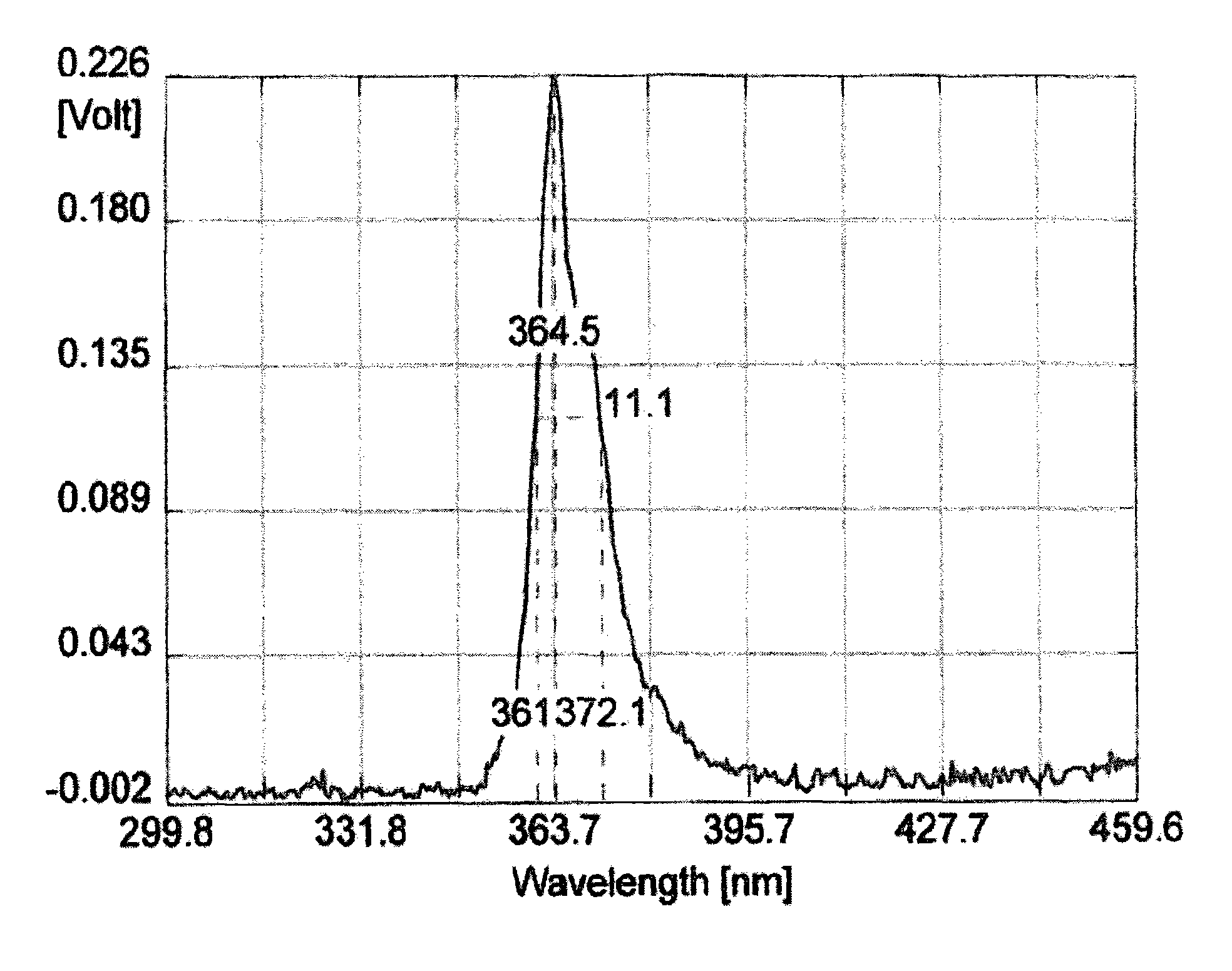

ActiveUS20170010215A1Inhibiting self-absorption effectEliminating self-absorption effectAnalysis by thermal excitationHigh energyLaser-induced breakdown spectroscopy

Provided is a method for inhibiting self-absorption effect of a LIBS, comprising ablating a to-be-measured sample via a pulse laser thereby generating plasma, and selectively stimulating the plasma using a wavelength-tunable laser beam enabling transition of particles in a ground-state in the plasma to high energy state as stimulated absorption, thereby improving a stimulated absorption transition efficiency of the particles in a ground-state, and preventing plasma spectrum from being influenced by self-absorption effect. The invention is capable of eliminating the self-absorption effect without introducing external interference, obtaining original characteristics of emission spectrum from the center of the plasma, and essentially inhibiting and finally eliminating the self-absorption effect of laser plasma by making use of intrinsic physical property of plasma.

Owner:HUAZHONG UNIV OF SCI & TECH

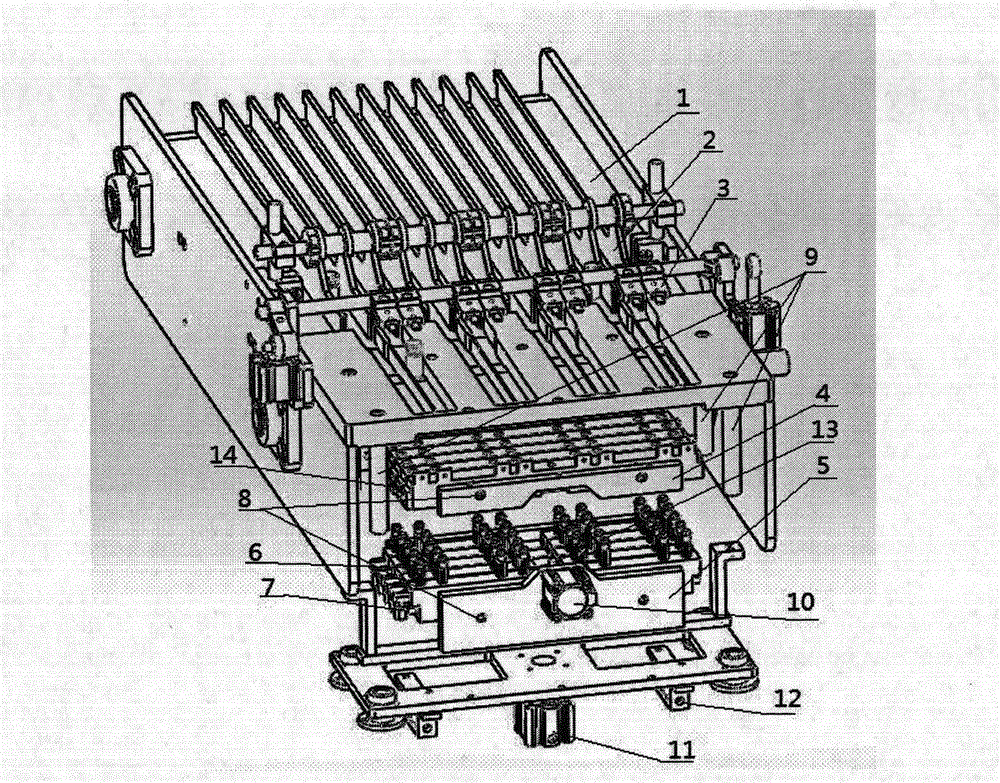

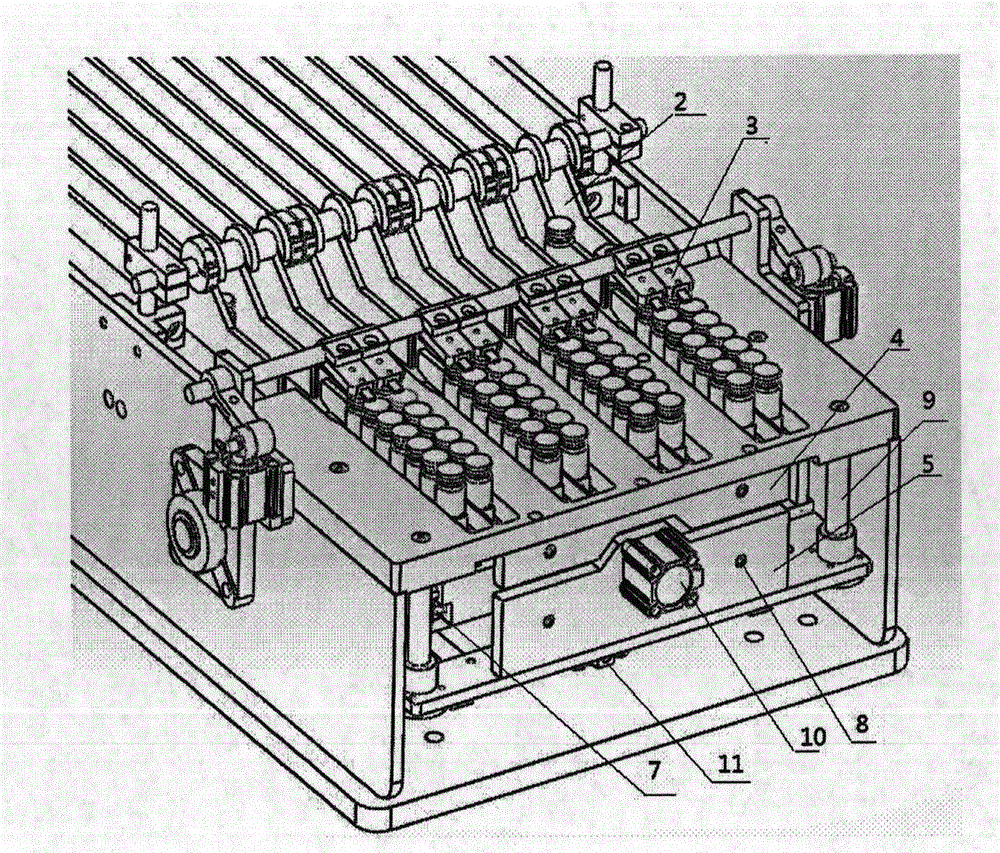

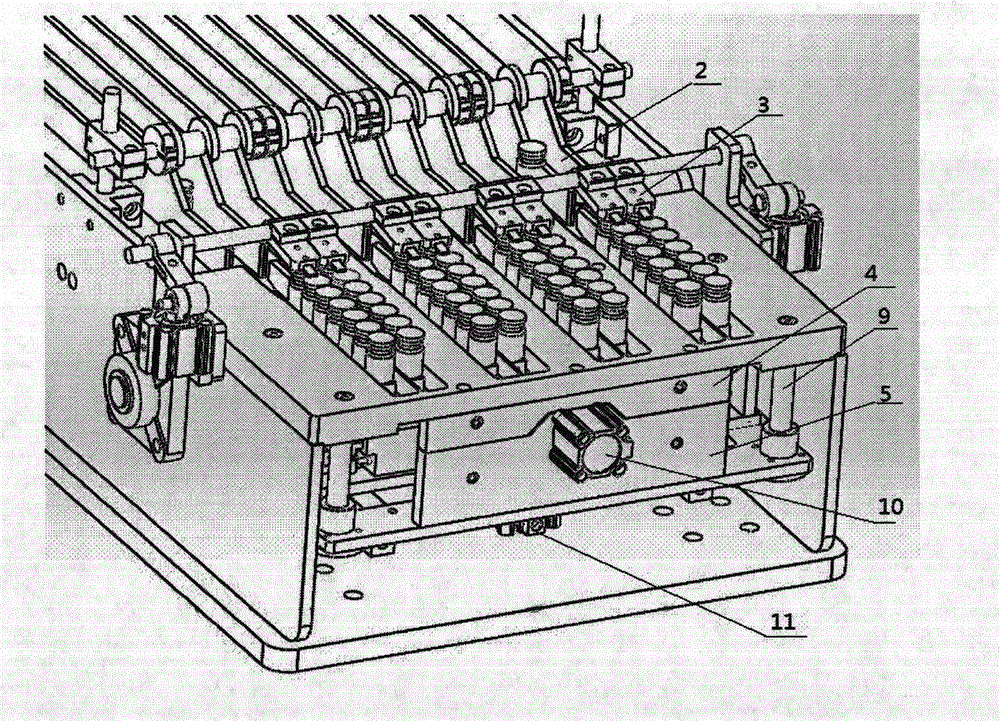

Spacing mechanism for novel penicillin bottle feeder

The invention discloses a novel feeder. The bottle feeder comprises a bottle feeding conveyor belt, longitudinal partition boards, a bottle pressing mechanism, a plurality of rows of transverse spacing mechanisms and a bottle suction mechanical arm assembly. The transverse spacing mechanisms are located at the tail ends of the bottle feeding conveyor belt and is an independent mechanism which is arranged under a suction cup mechanical arm. Compared with feeders in the prior art, the bottle feeder has the following advantages that under the action of suction heads, there is no need to worry that bottles can move without being limited at a high speed during spacing; the spacing distance is controlled through buckles; bottle feeder is very accurate in spacing, is free from the influence of spacing of intervals of large sizes, is high in speed and modularized in spacing mechanism, the mechanical arm has a single action and is not responsible for bottle insertion and spacing actions; maintenance is single, a plurality of rows of bottles can be spaced simultaneously; on one hand, the occupied area of automation equipment is reduced, and on the other hand, as a result of modularization of the spacing mechanisms, the stability of the machine is improved, the overall speed of the automation equipment is increased, and the bottleneck constraint of the speed of penicillin bottle equipment in the industry is broken.

Owner:罗勇

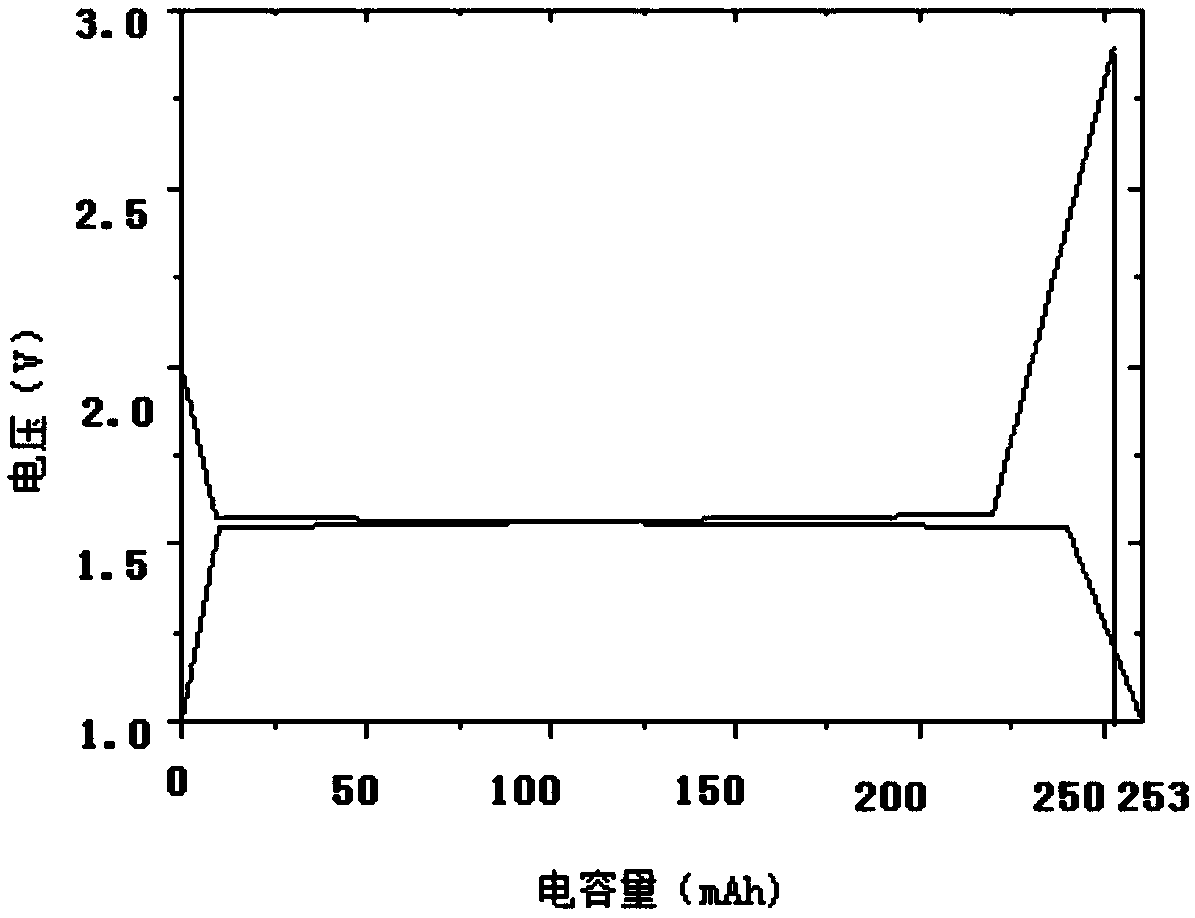

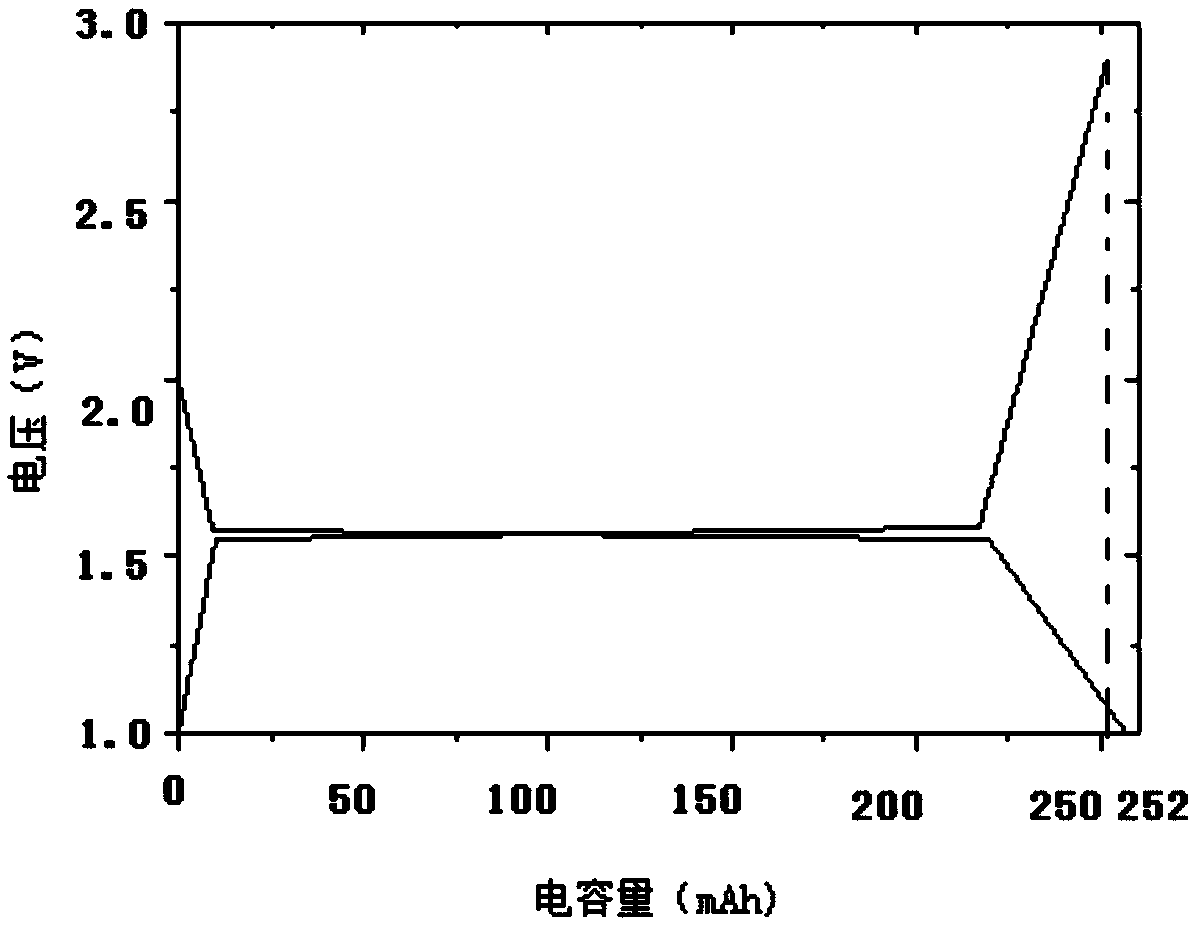

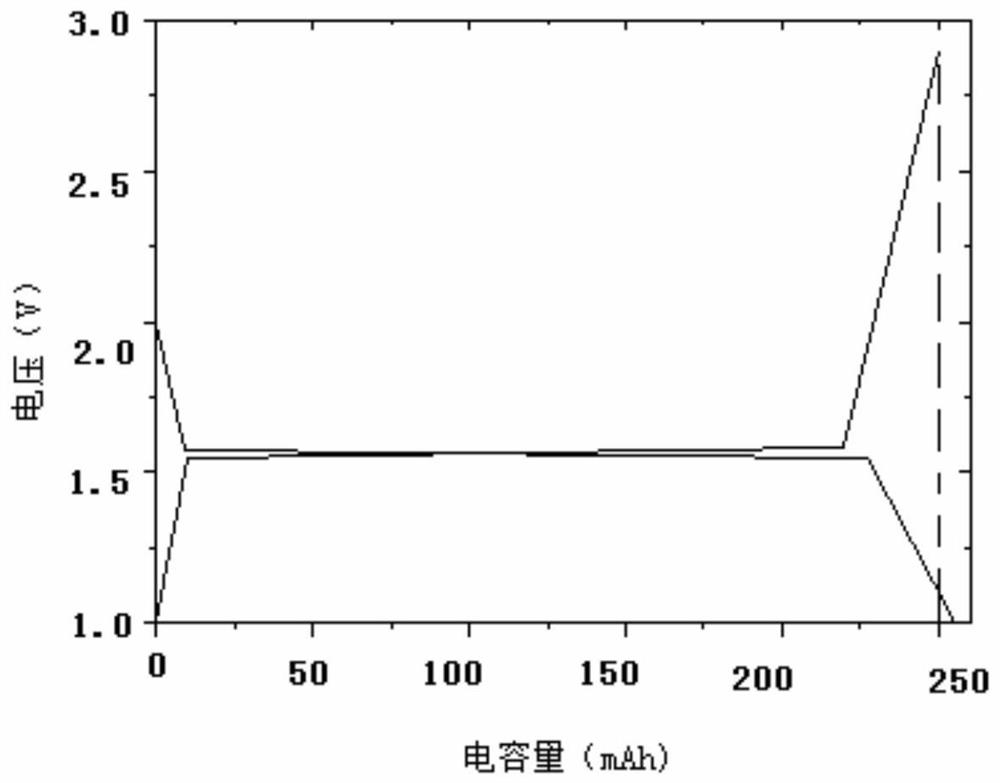

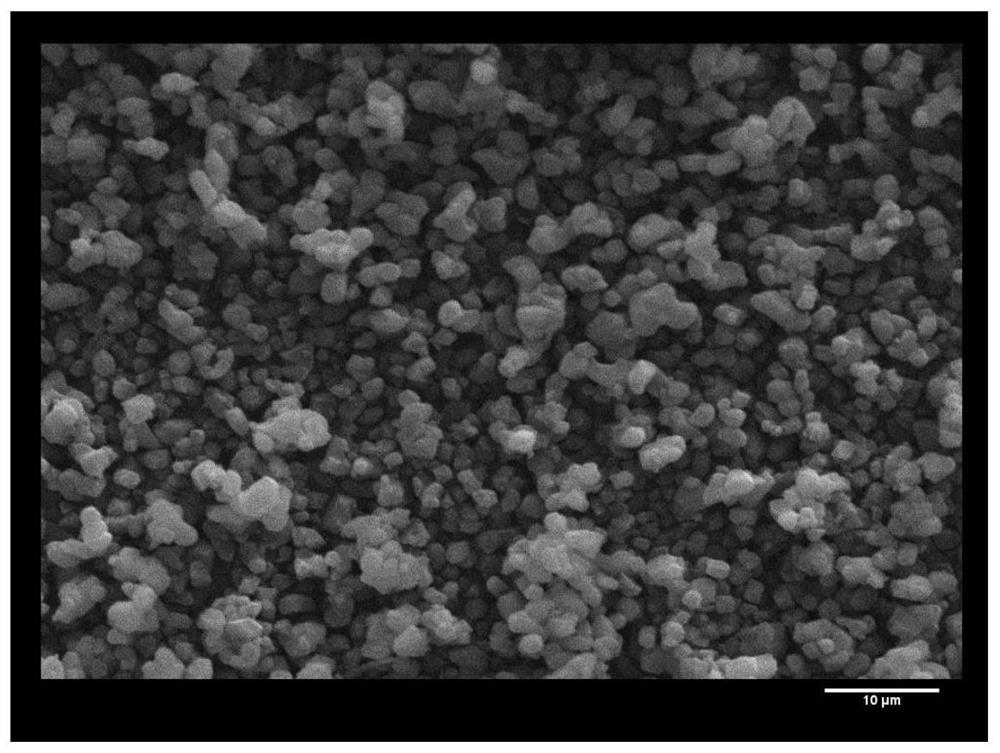

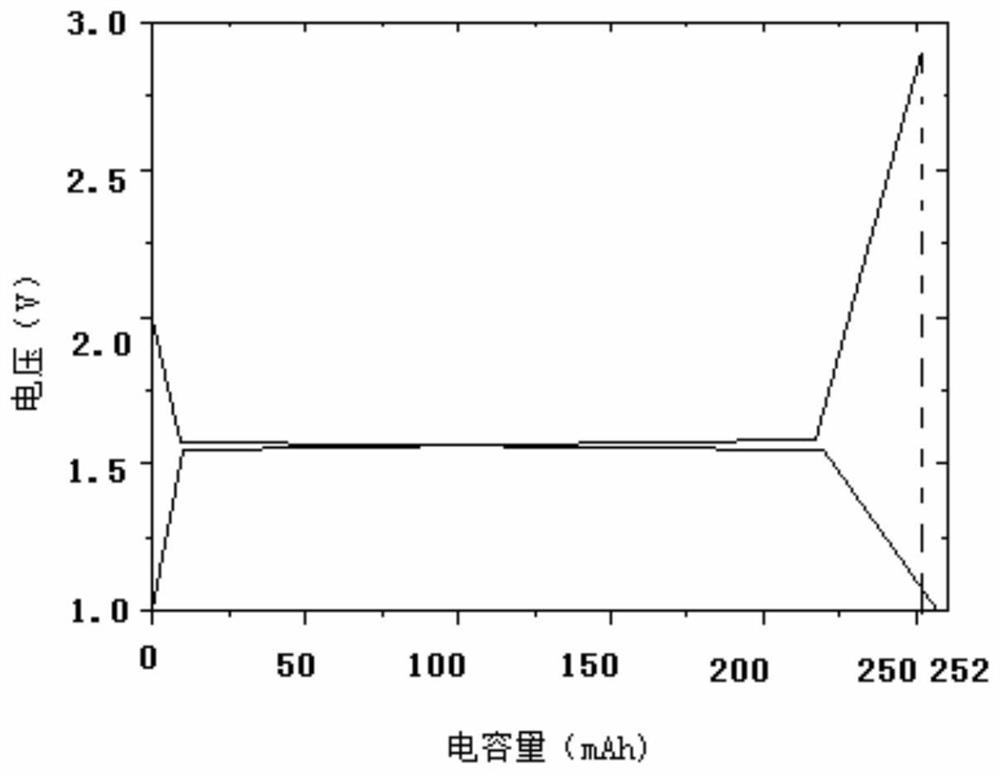

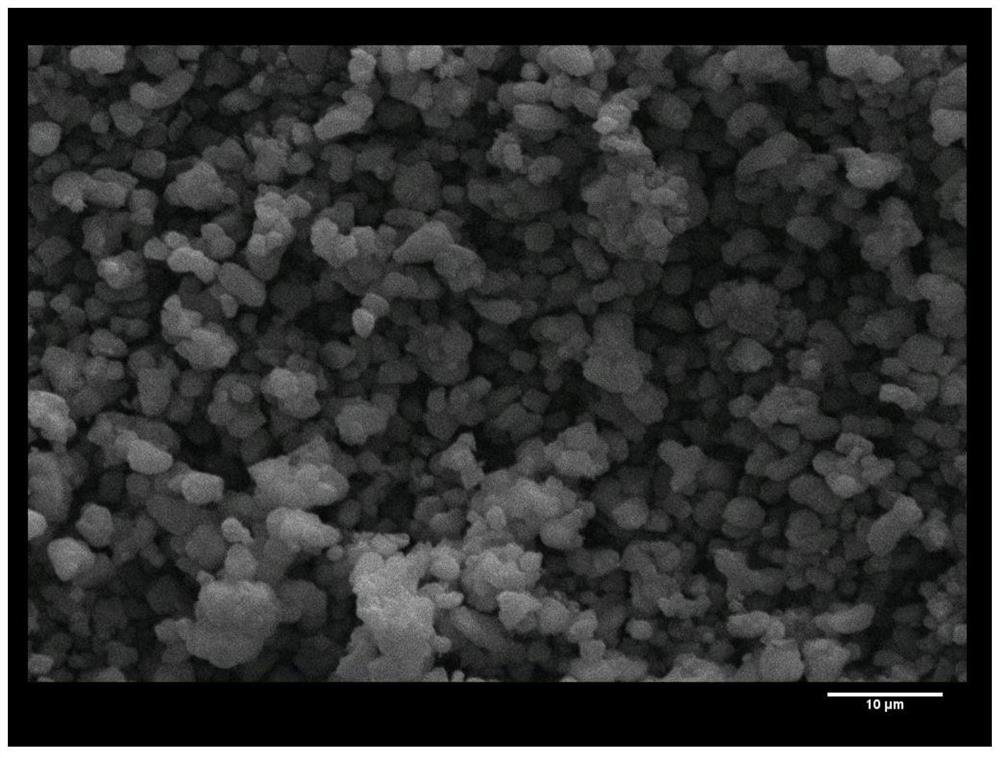

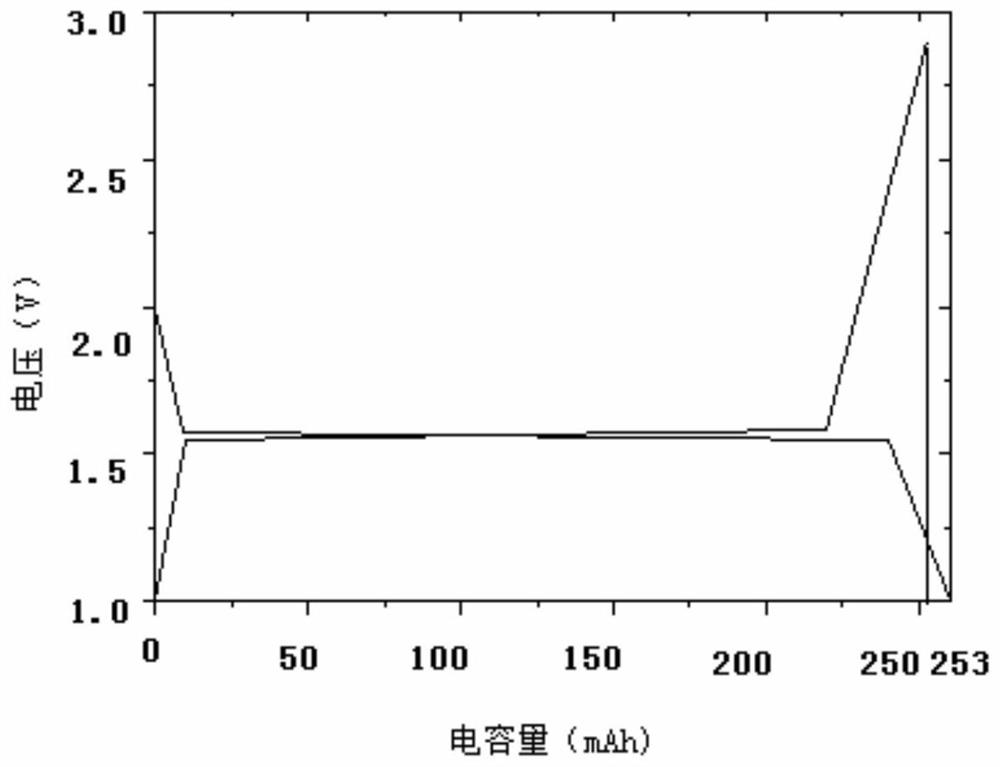

A method for improve that capacity of 1.55 V nanometer lithium titanate battery

The invention discloses a method for improving nanometer 1.55 V lithium titanate battery, Butyl titanate is dissolve by adding wat and polyvinyl alcohol PVA into butyl titanate, The precursor was prepared by homogeneous hydrothermal reaction with aqueous solution of lithium hydroxide and terbium nitrate Tb (NO_3) _ 3. The precursor was calcined to obtain Li_ (0.99) Tb_ (0.01) Li_ (1 / 3) Ti_ (5 / 3) O_ (4) powders. The capacity of the 1.55 V battery of the lithium titanate synthesized by the present invention was 253 mAh / g.

Owner:SHANDONG UNIV OF SCI & TECH

Robust sonar target detection method based on dual-path feature fusion network

ActiveCN110163108BDetection speedImprove efficiencyCharacter and pattern recognitionNeural architecturesImaging processingImage segmentation

The invention discloses a robust sonar target detection method based on a dual-path feature fusion network. The traditional image processing method uses the method of image segmentation to distinguish the background from the target; the present invention is as follows: 1. Build a dual-path feature fusion network. 2. Train the dual-path feature fusion network obtained in step 1. 3. Sonar image generation and feature extraction. Fourth, classify and detect the target frame of the sonar image in combination with the default frame. The present invention integrates deep learning technology into target detection, inputs sonar images generated by sonar data into a network model, and completes feature extraction, target detection, and target classification in the model at one time, thereby greatly improving the detection speed. The present invention can extract more deep-level features, and fundamentally optimizes target classification and regression. The present invention adopts multi-scale dense connection to fuse multi-level features and improve the detection effect of small and medium targets.

Owner:HANGZHOU DIANZI UNIV

High-frequency signals double-layer flat cable adapter card

ActiveUS20150136469A1Minimize high-frequency signal lossImprove transfer rateMagnetic/electric field screeningElectrically conductive adhesive connectionsMetal foilMagnetic field effect

A high-frequency signal double-layer flat cable adapter card that is capable of eliminating transmission disorder of a double-layer cable caused by paralleling and overlap of high-frequency signals and a direct current power supply loop. The high-frequency double-layer flat cable adapter card comprises a first connecting end, a second connecting end and a flat cable group formed by at least two strips of flat cables. The first connecting end includes a first substrate and a connector. The second connecting end includes a second substrate. The flat cable group is in an upper-lower dual-layer structure and is connected between the first connecting end and the second connecting end. A conductive metal foil sheet is arranged between upper and lower dual layers of flat cables of the flat cable group. The width of the metal foil sheet must cover areas of the flat cable group adopted as a power supply loop to isolate the magnetic field effect of the areas of the upper and lower dual layers of flat cables adopted the power supply loop.

Owner:CHENG LIANG HO

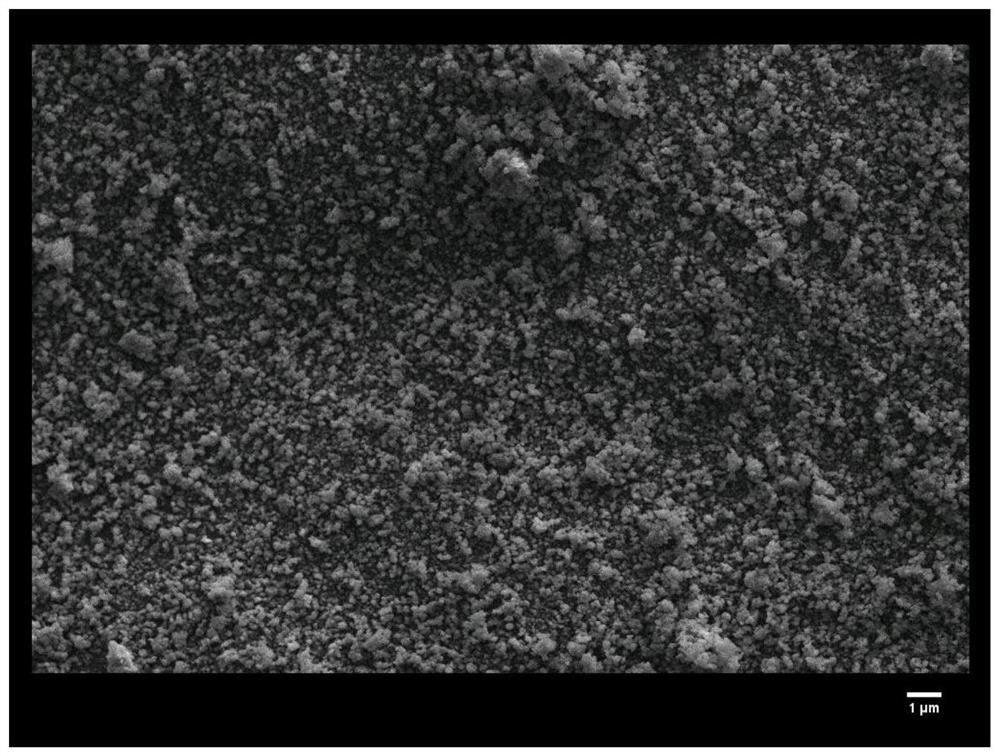

A method for improving that capacity of 1.55 V carbon coated lithium titanate battery

ActiveCN109244387ABreak the bottleneckCell electrodesSecondary cellsArgon atmosphereLithium hydroxide

A method for improving that capacity of 1.55 V carbon coated lithium titanate battery comprise grinding and uniformly mixing a certain proportion of lithium hydroxide, titanium oxide, terbium oxide and glucose, and performing calcining in a high-temperature furnace under an argon atmosphere for 5-10 hours, wherein the calcination temperature is 700-900 DEG C, performing naturally cooling, pulverizing, and sieving to obtain a C-coated LiTb0. 99Tb0. 01Li1 / 3Ti5 / 3O4. A 1.55 V battery of lithium titanate synthesize by hydrothermal reaction of that present invention has a capacity of 252 mAh / g.

Owner:SHANDONG UNIV OF SCI & TECH

Micro-nano active oxygen treatment method of sewage

ActiveCN102701456BEliminate subsequent contaminationTo achieve the purpose of purification and restorationTreatment with aerobic and anaerobic processesMicro nanoChemical oxygen demand

The invention discloses a micro-nano active oxygen treatment method of sewage, comprising the following steps: a, physically treating: settling the sewage to remove sand; b, separating: carrying out micro-nano bubble oxidization separation on the sewage, wherein the diameters of the bubbles are smaller than 50 microns; c, biologically treating: carrying out nitrification and denitrification reaction on the sewage which is subjected to the micro-nano bubble treatment and flows into a reaction pool with bionic biological carrier; and d, discharging: discharging under the conditions that the COD (chemical oxygen demand) of the sewage reaches 98%. The micro-nano active oxygen treatment method of the sewage thoroughly eliminates all organic pollution sources in the sewage and realizes the aim of purifying and reducing the sewage.

Owner:CHENGDU BRANCH TIBET GUOCE ENVIRONMENTAL PROTECTION TECH

Preparation method of polyolefin nanometer composite material

The invention discloses a preparation method of a polyolefin nanometer composite material. The method is characterized by comprising the following steps that 1, polyolefin particles are supplied; 2, after a precursor of an inorganic nanofiller and a solvent are mixed, the mixture is added into polyolefin particles to be dipped, and a mixed solution is obtained; 3, after the mixed solution is frozen, vacuum drying is performed, refrigerating and drying are performed again circularly for 5-20 times, and dried particles are obtained; 4, a hydrochloric acid / ethanol solution is steamed into the dried particles in a steam mode, and particles fumigated by steam are obtained; 5, the particles fumigated by steam are washed with water 1-5 times, and sufficient drying is performed to obtain solid particles; 6, the solid particles are stirred at the temperature of 120-260 DEG C and the speed of 10-300 rpm for 1-60 min, and forming is performed to obtain the polyolefin nanometer composite material.When the addition amount of the nanofiller is larger than 10% and smaller than 30%, the polyolefin nanometer composite material with the uniform nanofiller dispersion and excellent mechanical property can still be obtained.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

An intelligent boiling water control system

ActiveCN108387003BSave energyImprove utilization efficiencyFluid heatersWater storage tankSolenoid valve

The invention provides an intelligent water boiling control system. A tap water inlet end is connected with P ports of a second two-position two-way normally closed solenoid valve and a first two-position two-way normally closed solenoid valve. An A port of the first two-position two-way normally closed solenoid valve is connected with an inlet end of a solar thermal collector. An outlet end of the solar thermal collector is connected with an inlet of an inner-layer water storage tank. An outlet of the inner-layer water storage tank is connected with a P1 port of a two-position three-way solenoid valve. An A port of the second two-position two-way normally closed solenoid valve is connected with an inlet of an outer-layer water storage tank. An outlet of the outer-layer water storage tankis connected with a P2 port of the two-position three-way solenoid valve. A first-stage heat exchange pipeline and a second-stage heat exchange pipeline are arranged on the periphery of the inner-layer water storage tank. A single chip microcomputer controls the on-off states of the two-position three-way solenoid valve, a three-position four-way solenoid valve and a third two-position two-way normally closed solenoid valve to control the first-stage heat exchange pipeline, the second-stage heat exchange pipeline and a heating pipe, and three water temperatures are outputted to meet living needs. The intelligent water boiling control system has the advantages of green energy resource, intelligent control, convenience and quickness, and energy cycle.

Owner:SUZHOU SABO IND DESIGN

A hydrothermal reaction method to improve the capacity of 1.55v lithium titanate battery

ActiveCN109264773BBreak the bottleneckAlkali titanatesCell electrodesLithium hydroxidePhysical chemistry

The invention discloses a hydrothermal reaction method for increasing the capacity of a 1.55V lithium titanate battery, which comprises lithium hydroxide LiOH and thulium nitrate Tm(NO) 3 aqueous solution, and butyl titanate C 16 h 36 o 4 The organic solution of Ti is mixed according to the proportion and then hydrothermally reacted to obtain the precursor: then the precursor is calcined to obtain the molecular formula Li 0.99 T m 0.01 Li 1 / 3 Ti 5 / 3 o 4 lithium titanate powder. In the present invention, thulium nitrate is added to butyl titanate and lithium hydroxide, and by designing the ratio of the three raw materials, the capacity of the lithium titanate 1.55V battery synthesized by hydrothermal reaction is 250mAh / g.

Owner:SHANDONG UNIV OF SCI & TECH

A method for improving the capacity of 1.55v carbon-coated lithium titanate battery

ActiveCN109244387BBreak the bottleneckCell electrodesSecondary cellsLithium hydroxideArgon atmosphere

The invention discloses a method for improving the capacity of a 1.55V carbon-coated lithium titanate battery, which is a high-temperature furnace under an argon atmosphere after grinding and mixing a certain proportion of lithium hydroxide, titanium oxide, terbium oxide and glucose uniformly. Calcination in middle temperature for 5-10 hours, the calcination temperature is 700-900°C, after natural cooling, pulverize and sieve to obtain lithium titanate negative electrode material Li coated with C 0.99 Tb 0.01 Li 1 / 3 Ti 5 / 3 o 4 . The capacity of the 1.55V lithium titanate battery synthesized by the hydrothermal reaction of the present invention is 252mAh / g.

Owner:SHANDONG UNIV OF SCI & TECH

Method for inhibiting self-absorption effect in laser-induced breakdown spectroscopy

ActiveUS9810634B2Inhibition effectEliminate the effects ofSpectrum investigationAnalysis by thermal excitationHigh energyLaser-induced breakdown spectroscopy

Provided is a method for inhibiting self-absorption effect of a LIBS, comprising ablating a to-be-measured sample via a pulse laser thereby generating plasma, and selectively stimulating the plasma using a wavelength-tunable laser beam enabling transition of particles in a ground-state in the plasma to high energy state as stimulated absorption, thereby improving a stimulated absorption transition efficiency of the particles in a ground-state, and preventing plasma spectrum from being influenced by self-absorption effect. The invention is capable of eliminating the self-absorption effect without introducing external interference, obtaining original characteristics of emission spectrum from the center of the plasma, and essentially inhibiting and finally eliminating the self-absorption effect of laser plasma by making use of intrinsic physical property of plasma.

Owner:HUAZHONG UNIV OF SCI & TECH

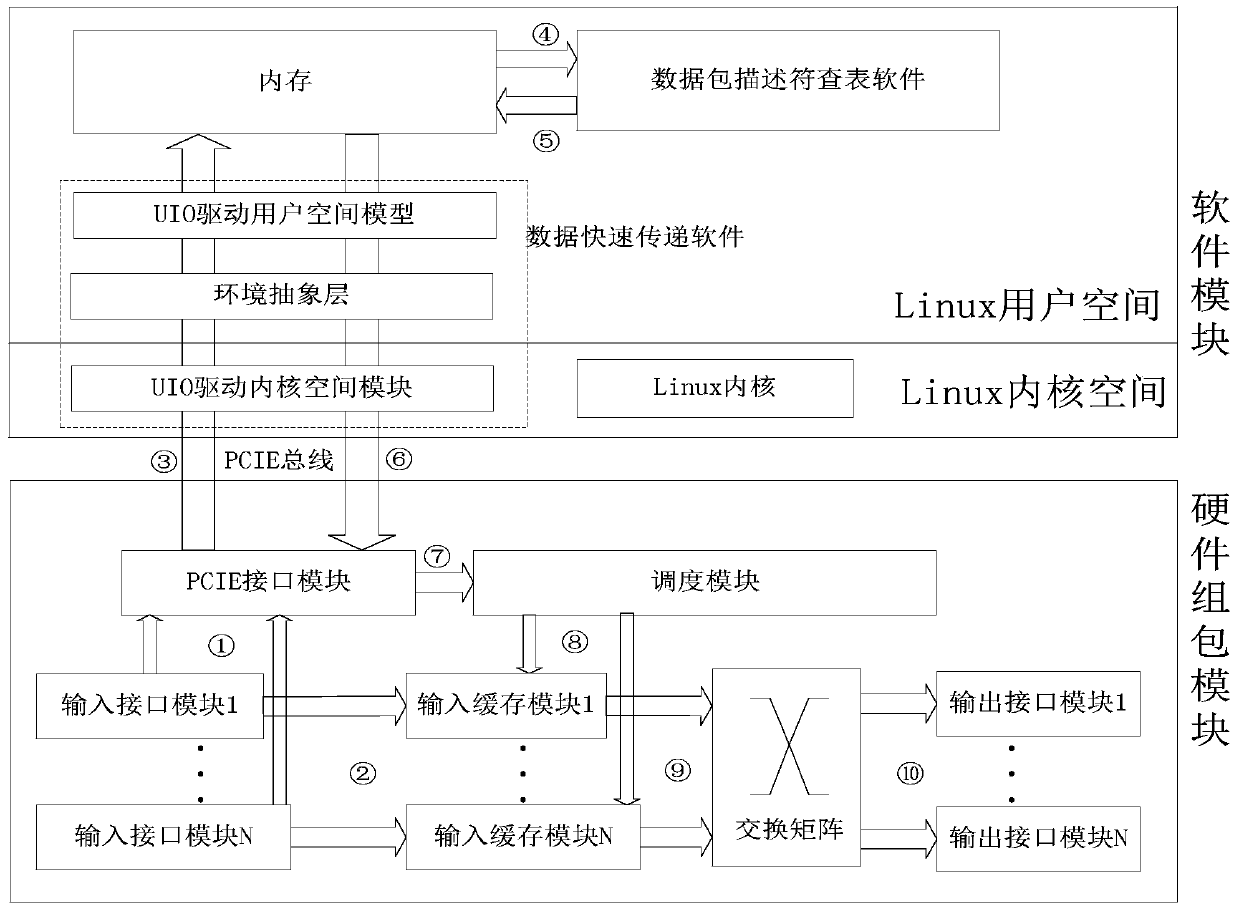

A Data Packet Forwarding Method Based on Software Lookup Table

InactiveCN105099957BLow costHigh-speed packet capabilityData switching networksWire speedSoftware switch

The invention relates to a data packet forwarding method based on software look-up table. The method is based on Intel DPDK, and realizes the data packet forwarding function in the switch by using hardware to extract data packet headers, fast data transfer software to efficiently transfer data in batches, and software to look up tables flexibly. The table lookup algorithm combines the cuckoo hash table with the open address method to store enough entries and improve the table lookup speed. The network equipment has the following characteristics at the same time: multi-port wire-speed forwarding, flexible large-capacity table lookup, and low cost. It combines the high-speed grouping capability of hardware, the large-scale data packet processing and forwarding capability of fast data transfer software, and the high-speed and flexible search capability of software. Compared with traditional hardware switches, it has better scalability and programmable features; compared with traditional software switches, it can provide greater throughput and lower delay.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A method for improving the capacity of 1.55v nano lithium titanate battery

ActiveCN109216801BBreak the bottleneckSecondary cells charging/dischargingPolyvinyl alcoholLithium hydroxide

The invention discloses a method for improving a nanometerized 1.55V lithium titanate battery. It is to add water and polyvinyl alcohol PVA to dissolve butyl titanate in butyl titanate, and mix lithium hydroxide and terbium nitrate Tb(NO 3 ) 3 The aqueous solution is mixed uniformly in a certain proportion and hydrothermally reacted to obtain the precursor: then the precursor is calcined to obtain the molecular formula Li 0.99 Tb 0.01 Li 1 / 3 Ti 5 / 3 o 4 lithium titanate powder. The capacity of the 1.55V battery utilizing the lithium titanate synthesized by the present invention is 253mAh / g.

Owner:SHANDONG UNIV OF SCI & TECH

Microbial identification and manipulation of nanoscale biomolecules

InactiveUS8808518B2Rapid and highly sensitive and highly specific methodEnhance the electric fieldDielectrophoresisElectrostatic separatorsMicroorganismDielectrophoretic force

A method of microbial identification is disclosed. The method includes the steps of assembling dielectrophoretic particles modified with specific DNA probes on a surface thereof in a continuous fluid at a predetermined location in a microchannel to form a particle assembly by a negative dielectrophoretic force and a hydrodynamic force provided by the continuous fluid, narrowing gaps between the dielectrophoretic particles of the particle assembly to enhance the electric field in the gaps between the dielectrophoretic particles, injecting a fluid containing target DNAs of a target microbe into the microchannel at a predetermined flow rate to move the target DNAs toward the particle assembly and generating a positive dielectrophoretic force by the enhanced electric field to attract the target DNAs toward the dielectrophoretic particles of the particle assembly for hybridization with the DNA probes. The present invention also discloses a method of manipulation of nanoscale biomolecules.

Owner:NAT CHENG KUNG UNIV

Intelligent water boiling device

ActiveCN108386993BSave energyReduce pollutionSolar heating energySolar heat collector for particular environmentMicrocontrollerWater storage tank

Owner:SUZHOU SABO IND DESIGN

Co-processing acceleration method, apparatus, and system

ActiveUS8478926B1Reduce memory overheadIncrease co-processing speedMultiple digital computer combinationsProgram controlComputerized systemData storing

Owner:HUAWEI TECH CO LTD

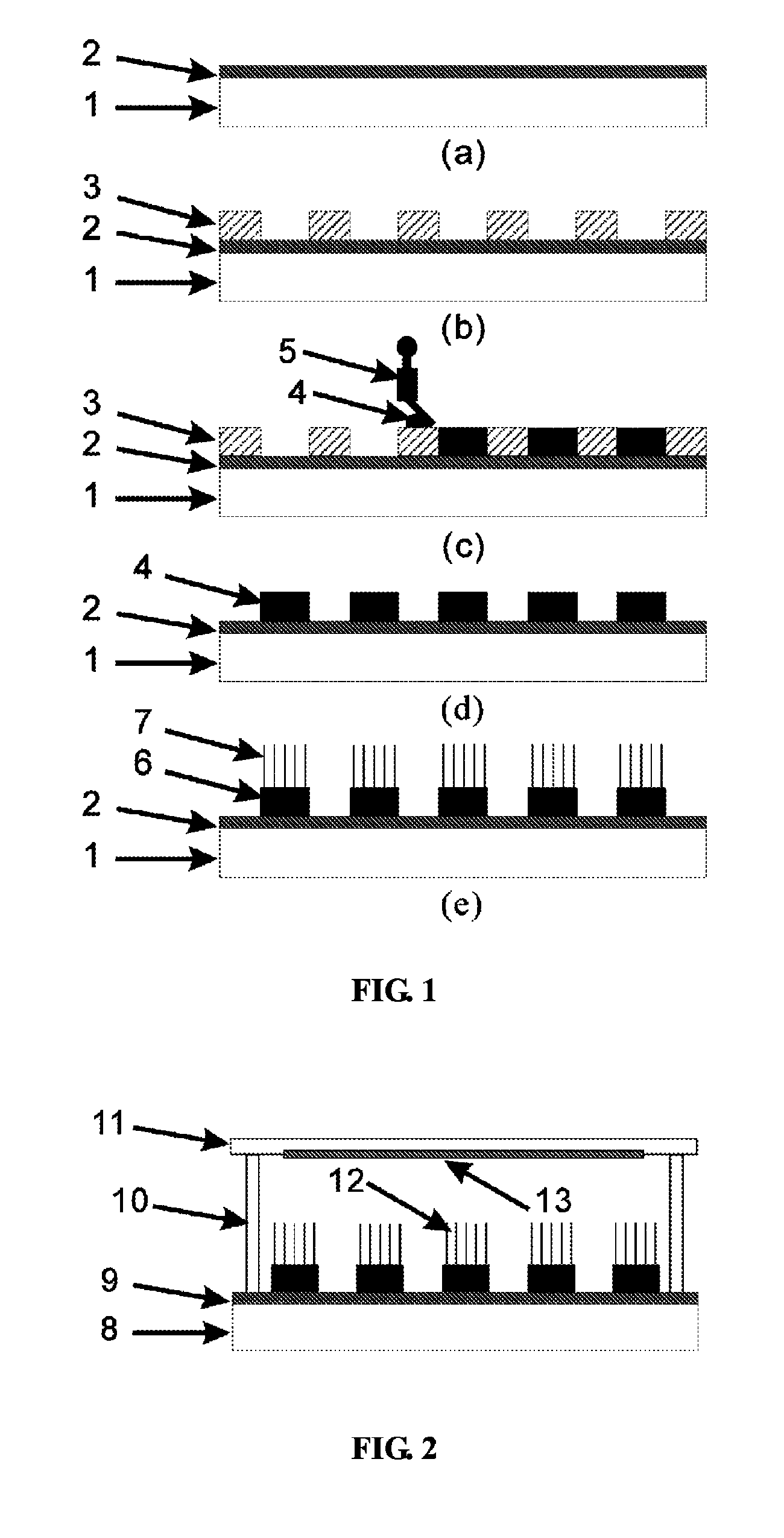

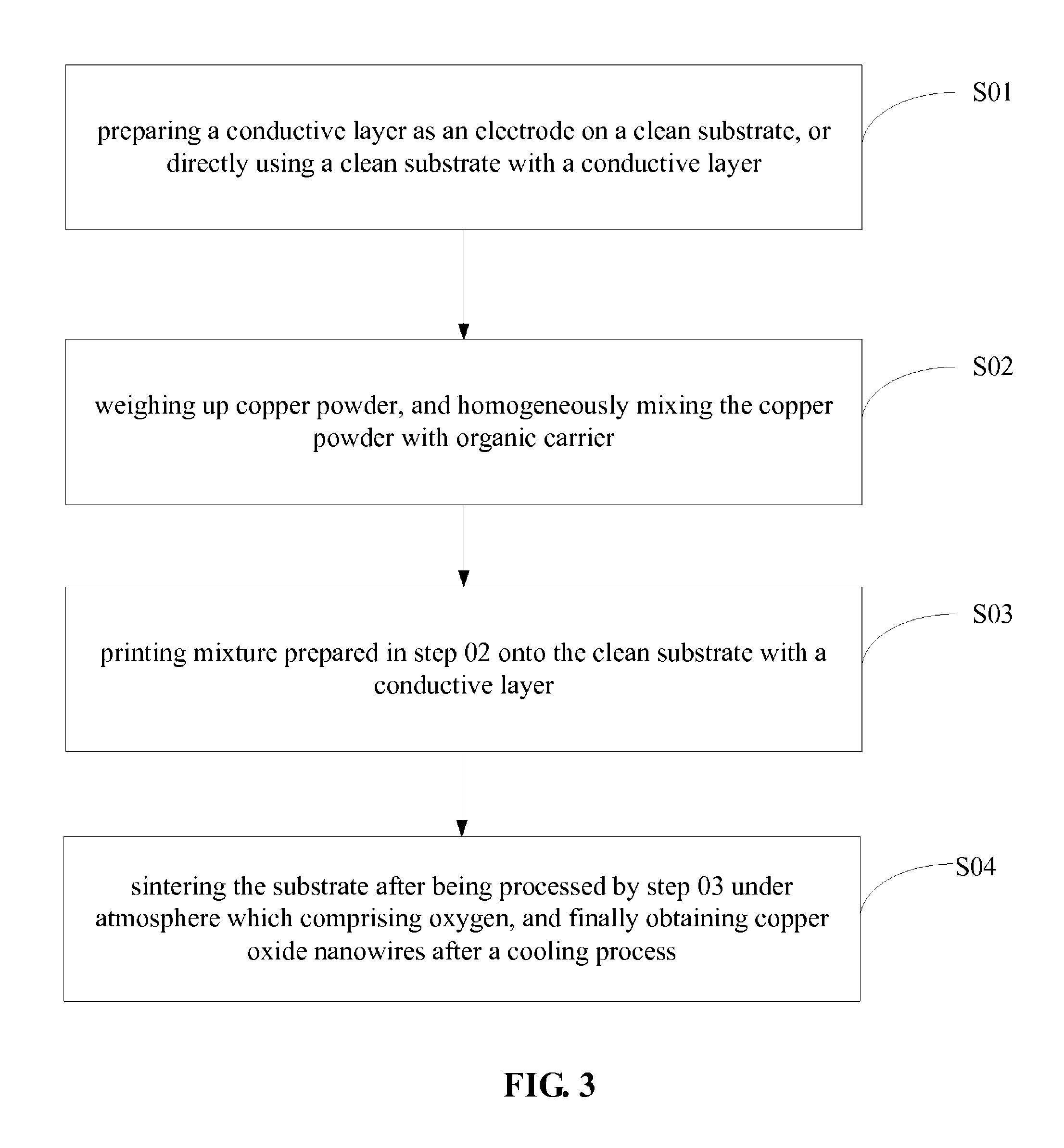

Preparation method for copper oxide nanowires

ActiveUS8852675B2Easy to prepareLow costMaterial nanotechnologyPretreated surfacesField emission deviceNanowire

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com