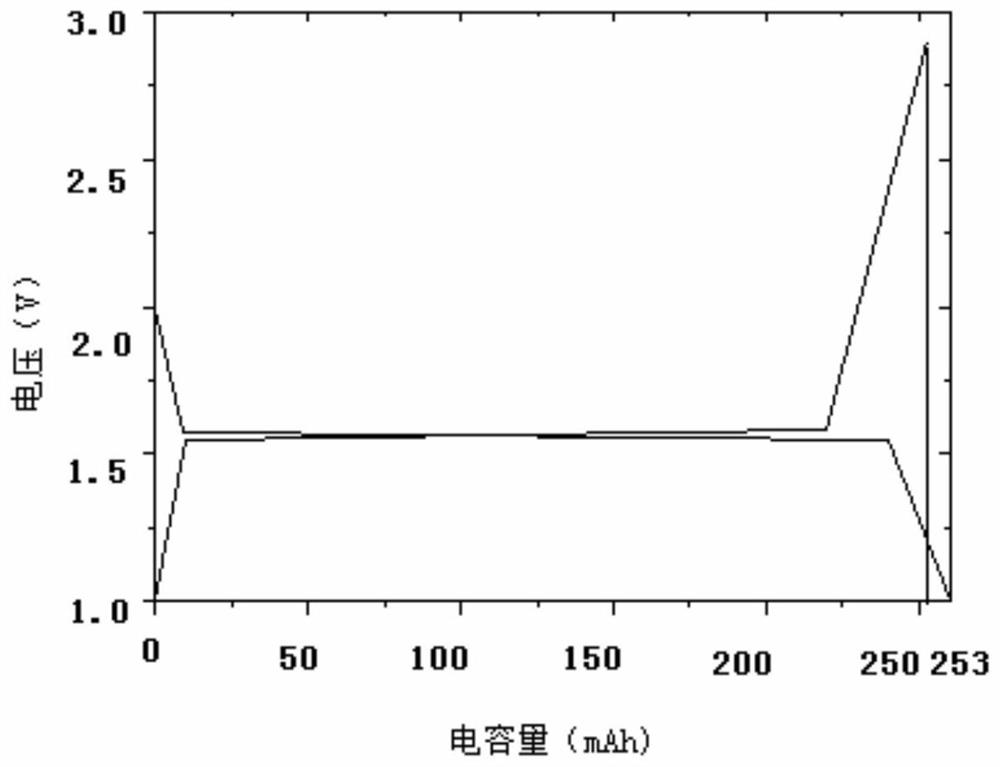

A method for improving the capacity of 1.55v nano lithium titanate battery

A technology of lithium titanate and battery capacity, applied in the field of increasing the capacity of 1.55V nano-lithium titanate single battery, can solve the problems of loss of battery performance, unsafe silicon material, reduction of battery cycle times, etc. bottleneck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

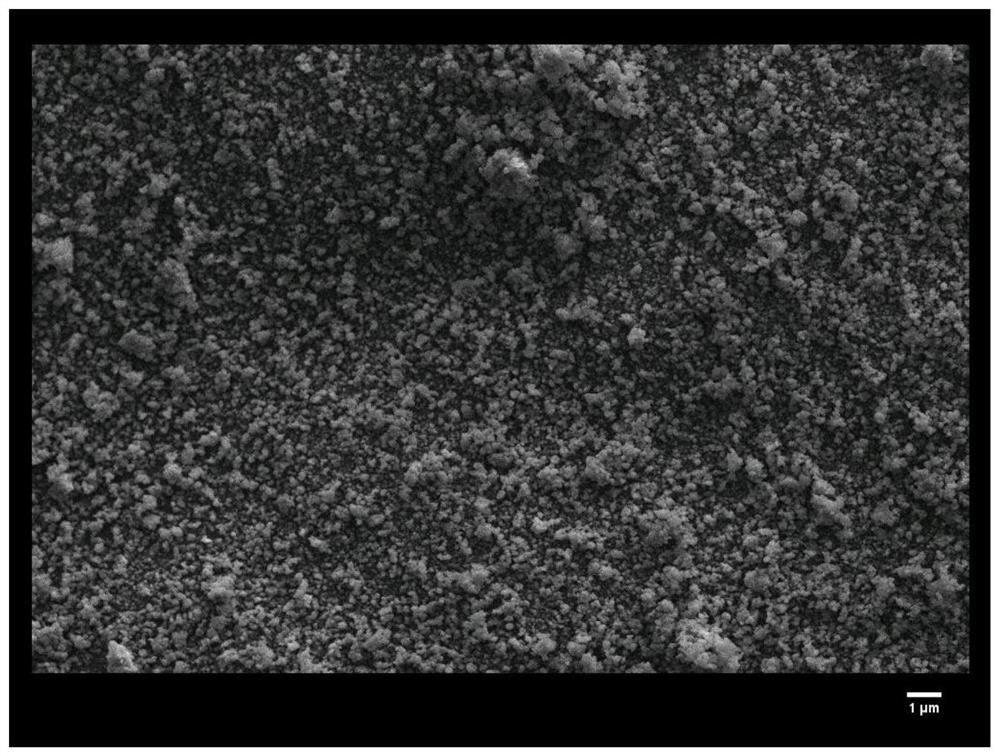

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] A method for improving the capacity of a 1.55V nano-lithium titanate battery, the specific steps are:

[0025] Step 1: Prepare raw materials

[0026] Weigh and weigh butyl titanate C 16 h 36 o 4 Ti, polyvinyl alcohol PVA, lithium hydroxide LiOH and terbium nitrate Tb (NO 3 ) 3 Four raw materials, the molar ratio of elements lithium, titanium and terbium is required to meet 1.666:1.323:0.01, and the weight of PVA is 5-10% of the total weight of the three raw materials of butyl titanate, lithium hydroxide and terbium nitrate;

[0027] Step 2: Precursor Synthesis

[0028] In butyl titanate C 16 h 36 o 4 Add water and polyvinyl alcohol PVA to Ti to dissolve butyl titanate, then add lithium hydroxide LiOH and terbium nitrate (NO 3 ) 3 After the aqueous solution is mixed evenly, add it to the autoclave, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com