Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Eliminate backmixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric dewatering and desalting appliance for crude oil

InactiveCN1482212AReduce moisture contentEnhanced electrical coalescenceLiquid separation by electricityDewatering/demulsification with electric/magnetic meansElectricityOil water

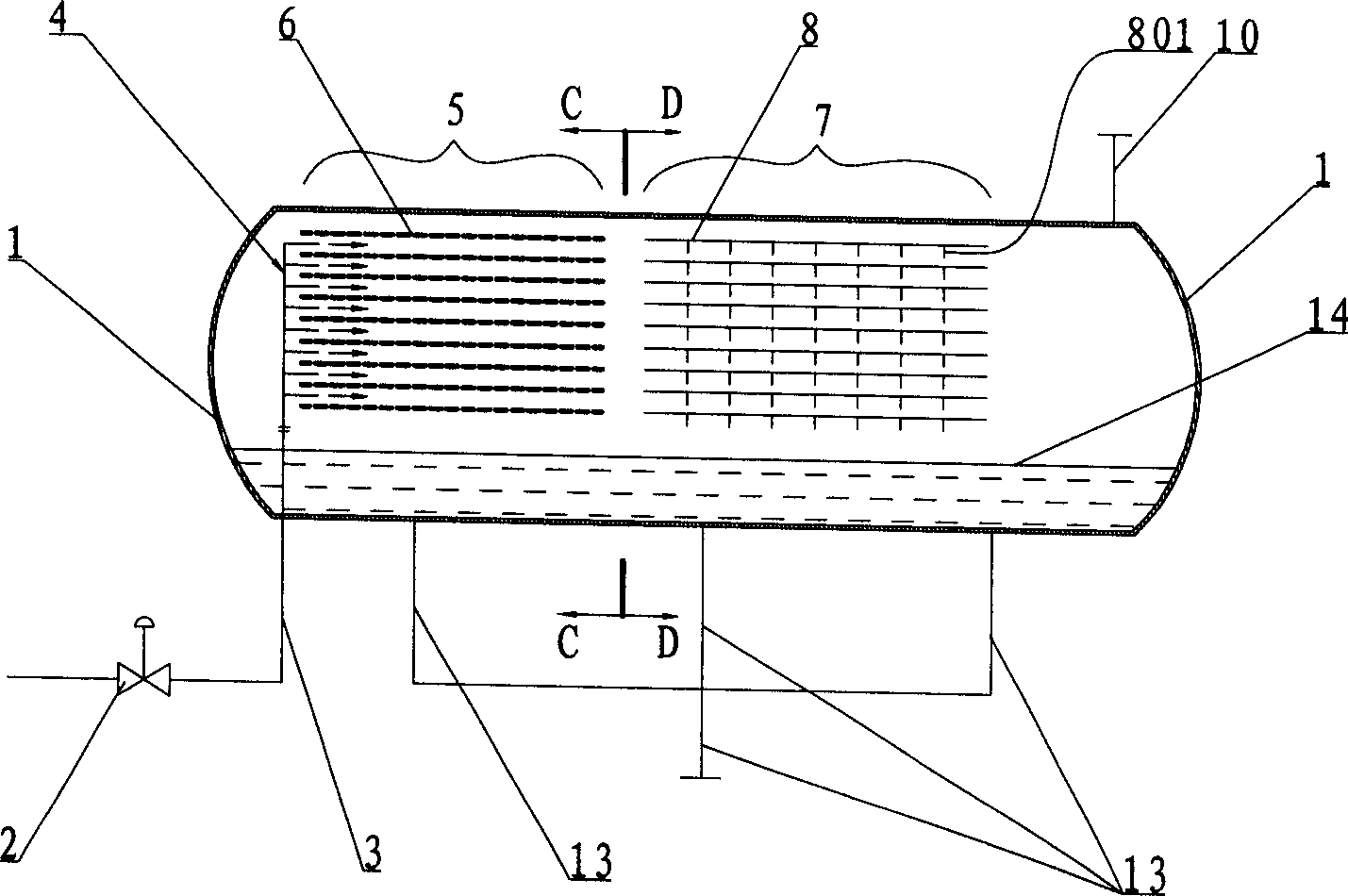

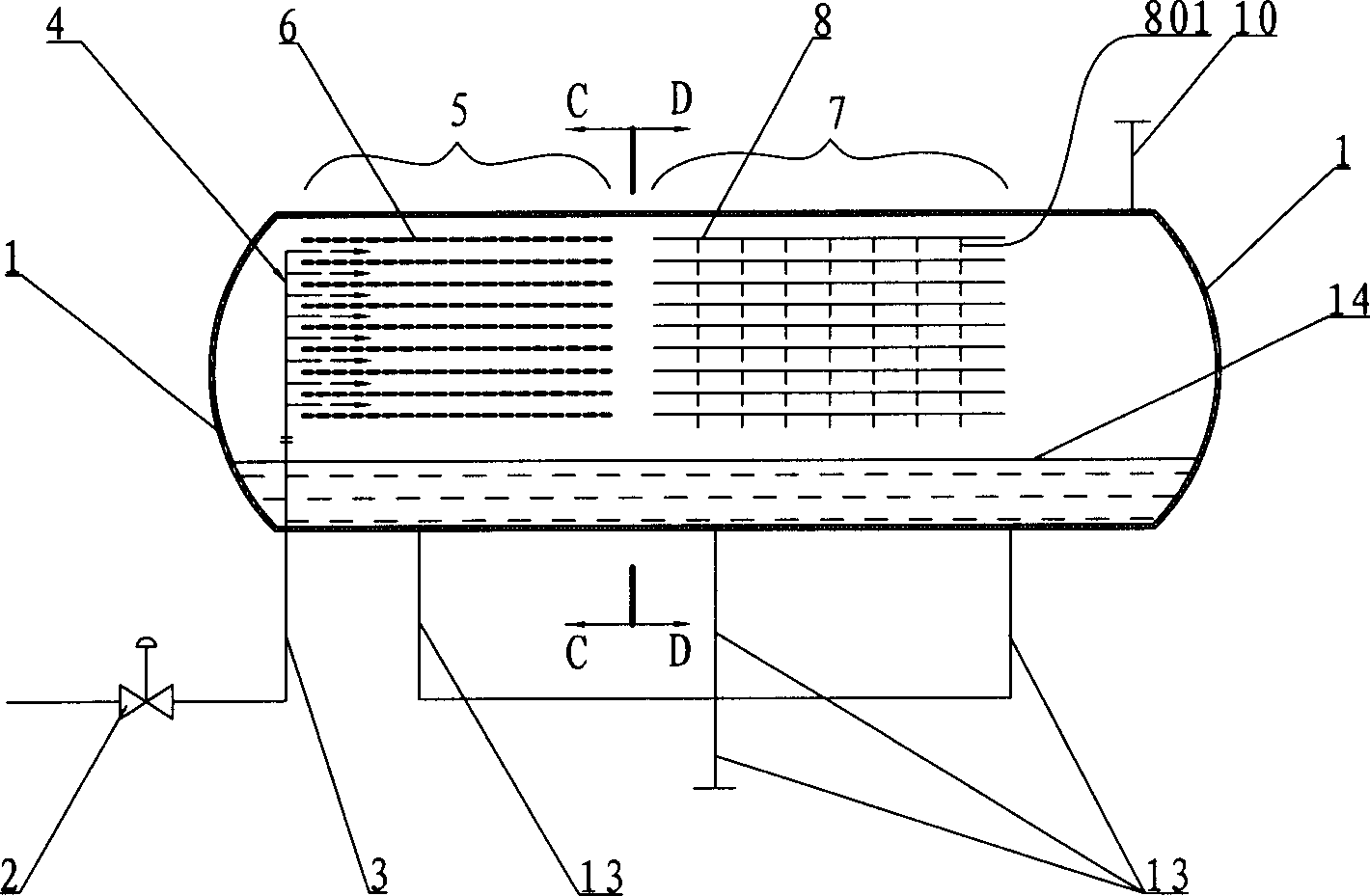

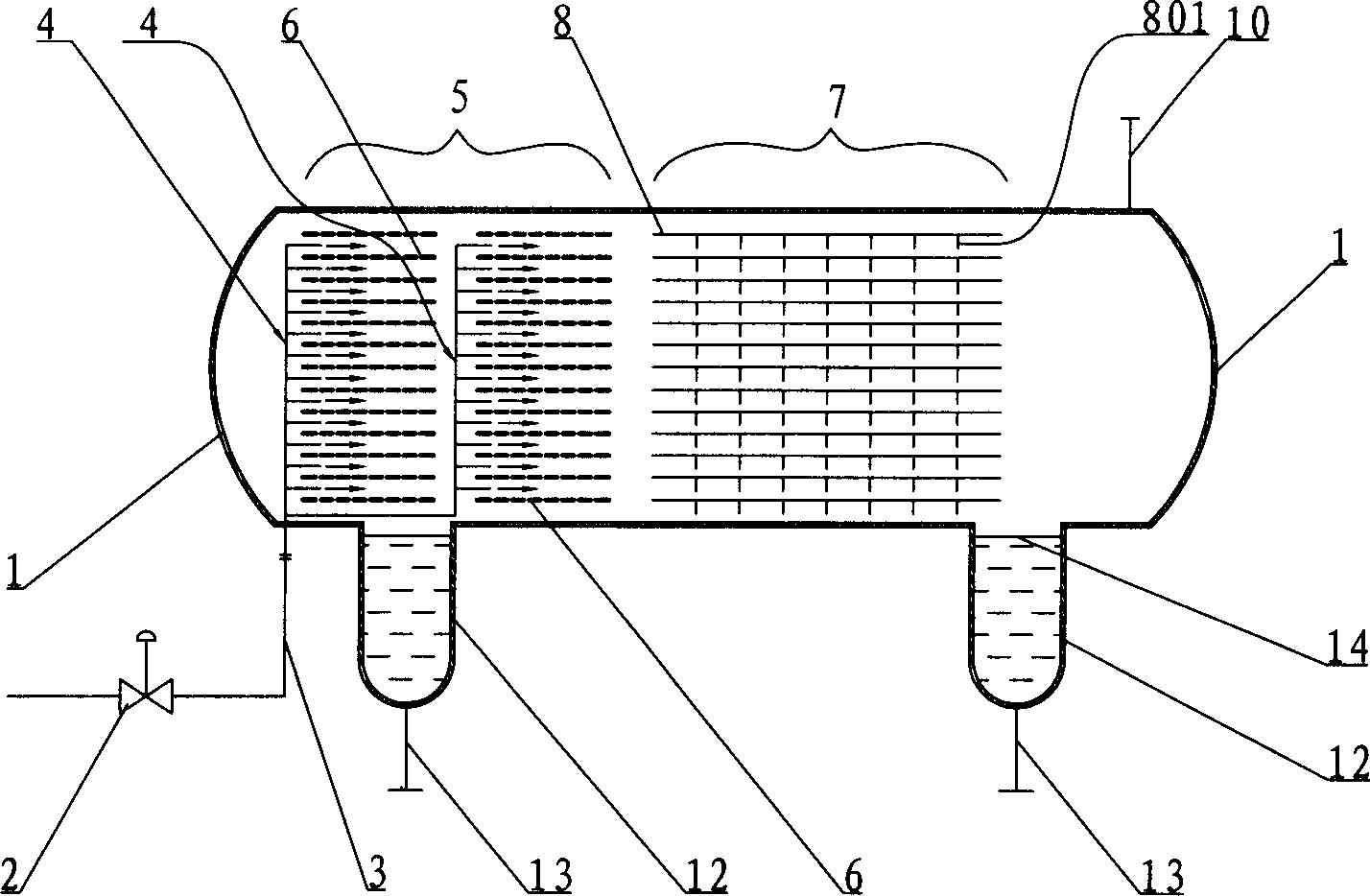

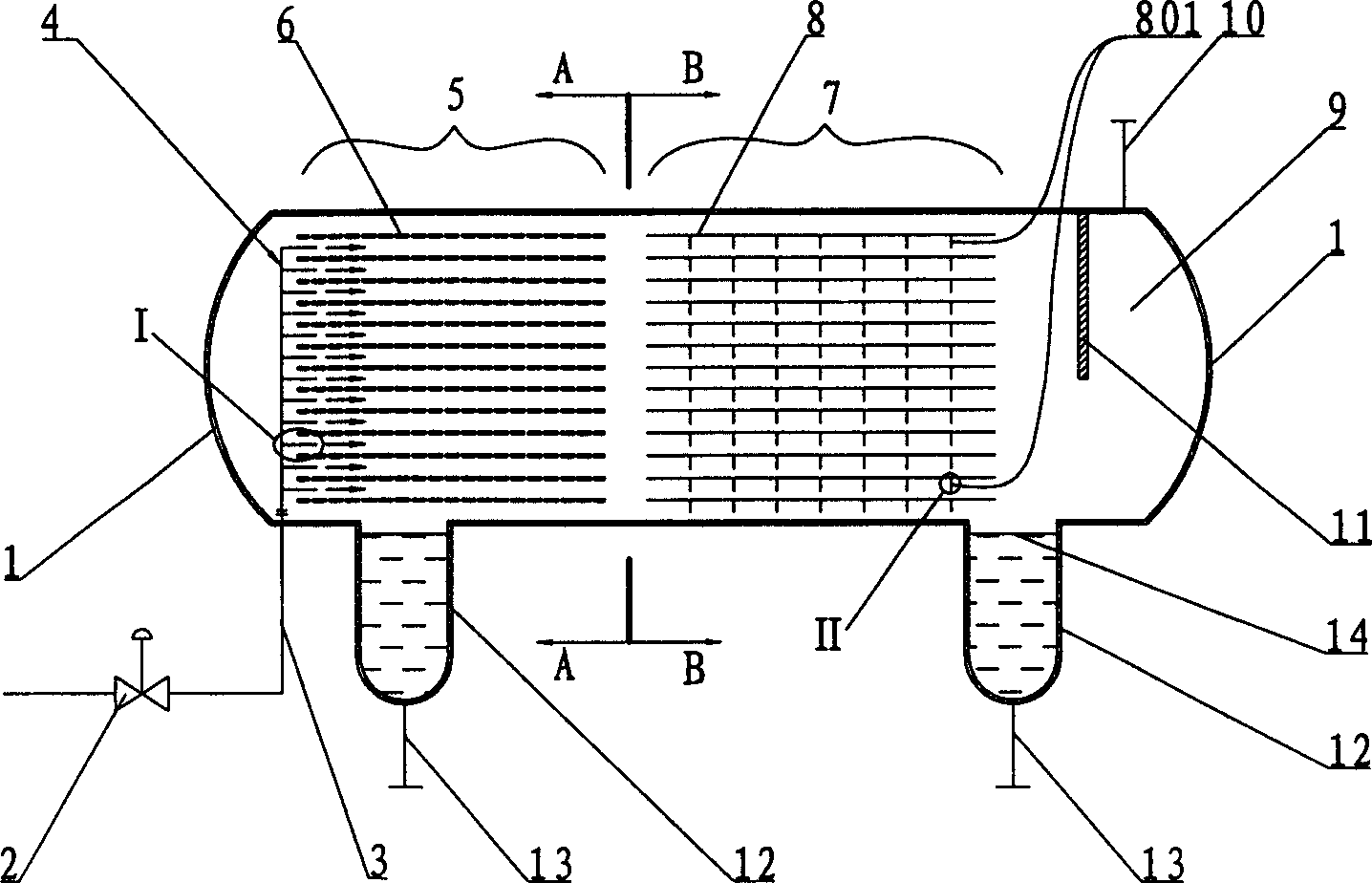

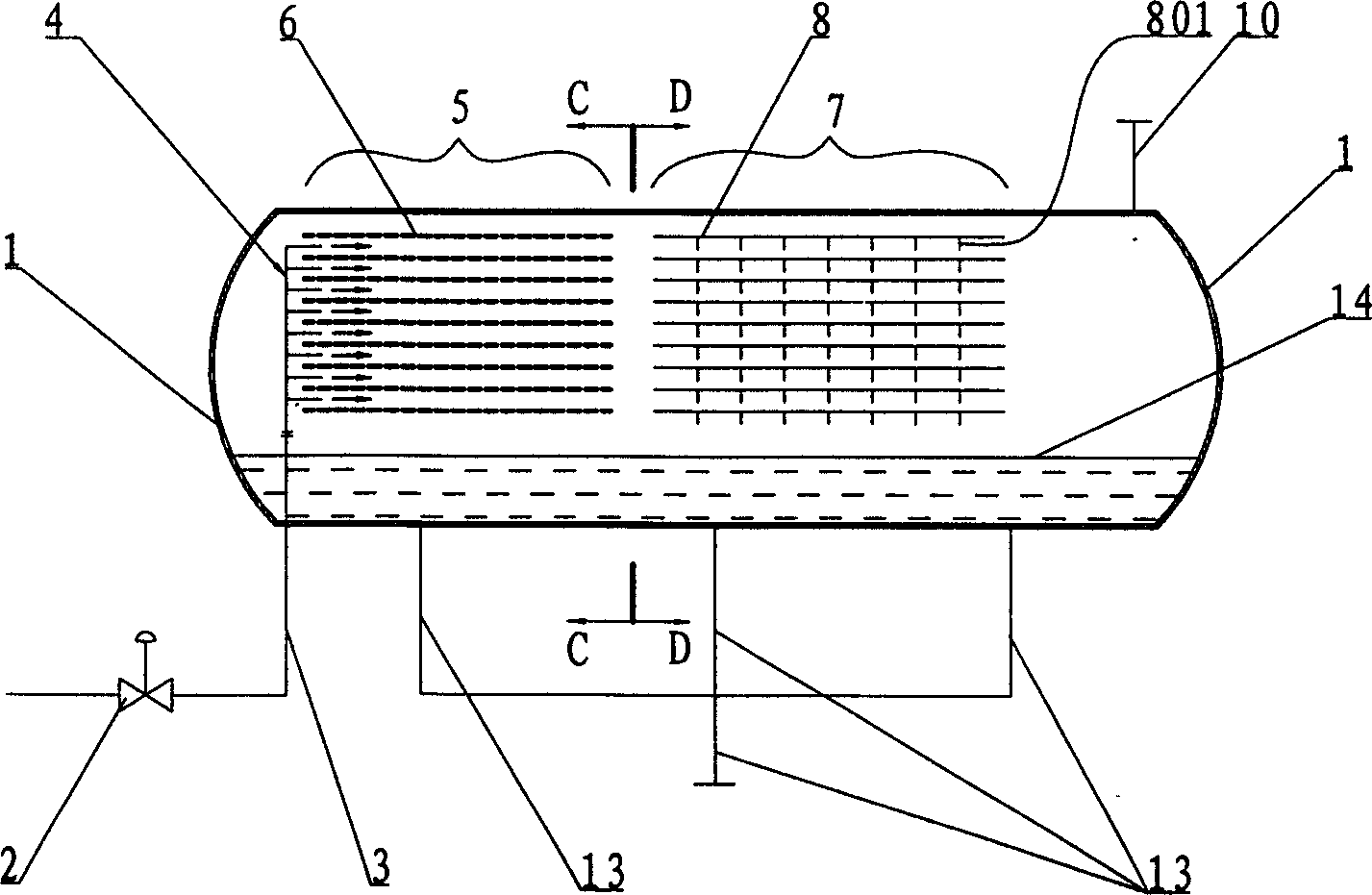

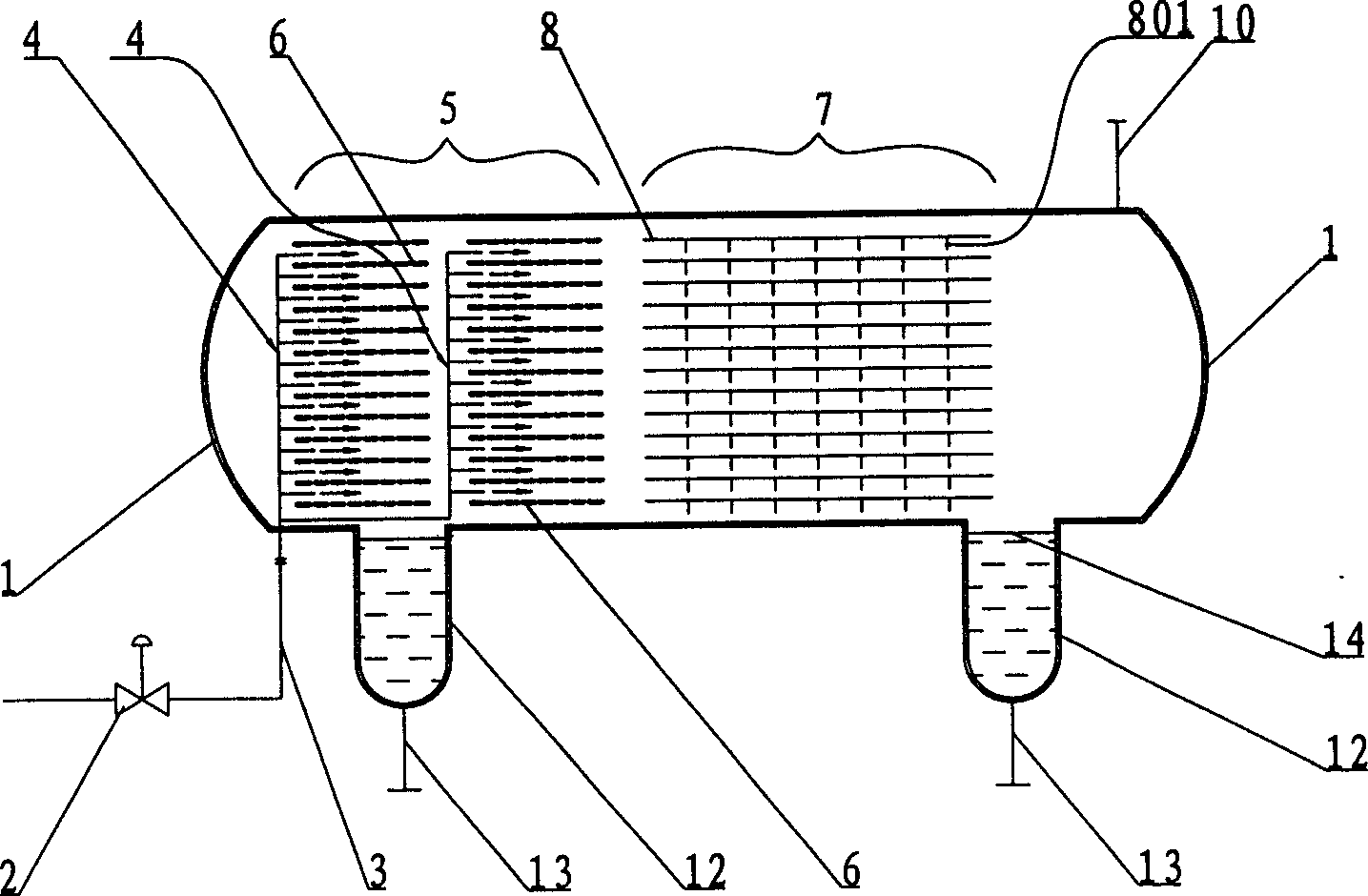

The electrical raw oil desalting and dewatering device for petrochemical industry features its direct material feeding in strong electric field and horizontal flow of raw oil. The electrical raw oildesalting and dewatering device of the present invention has material distributor and strong electric field coalescence area in tank axial direction and oil outlet pipe in the top of the raw oil purifying area, with the strong electric field coalescence area being provided with at least two layers of parallel electrode plates parallel to or perpendicular to the tank axis. The material distributor is provided with nozzles to spray mixed oil-water material into the strong electric field between two adjacent electrode plates. Between the strong electric field coalescence area and the purified raw oil outlet, deposit separating area may be set.

Owner:CHINA PETROCHEMICAL CORP +1

Electric desalting dewatering device for crude oil

InactiveCN1605615AReduce moisture contentEnhanced electrical coalescenceDewatering/demulsification with electric/magnetic meansElectricityPlanar electrode

The present invention is one electric raw oil desalting and dewatering apparatus for petrochemical industry. The present invention features the direct material feeding under strong electric field and the horizontal flow of raw oil. The electric raw oil desalting and dewatering apparatus has a tank with oil-water mixture inlet, axial strong electric field coagulation area with at least two layers of parallel planar electrode plates perpendicular to the axis of the tank, purified raw oil outlet with oil outlet pipe, material distributor inside the tank with nozzles to jet oil-water mixture into the strong electric fields between every two adjacent electrode plates, and depositing separation area set between the strong electric field coagulation area and the purified raw oil outlet.

Owner:CHINA PETROCHEMICAL CORP +1

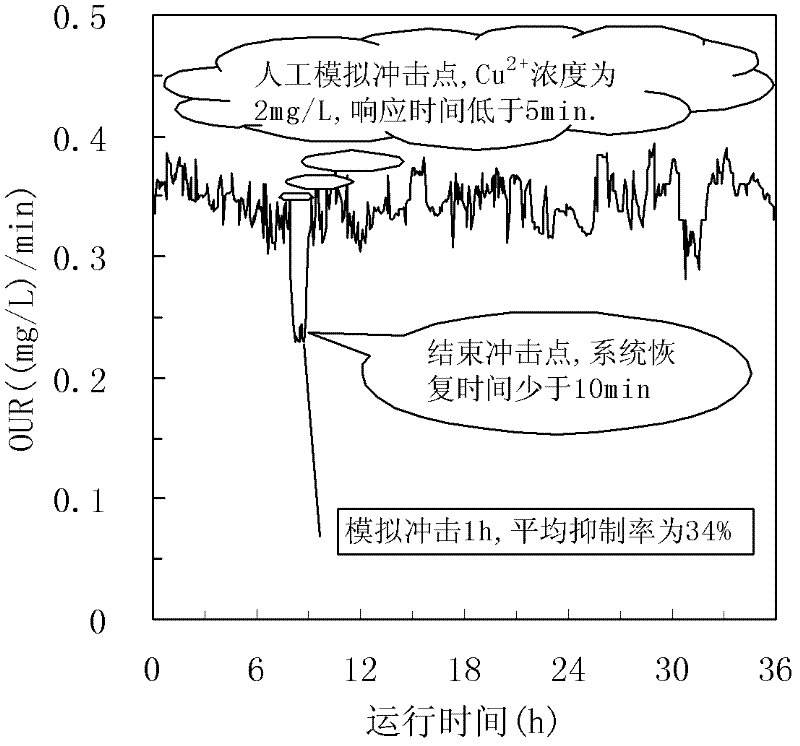

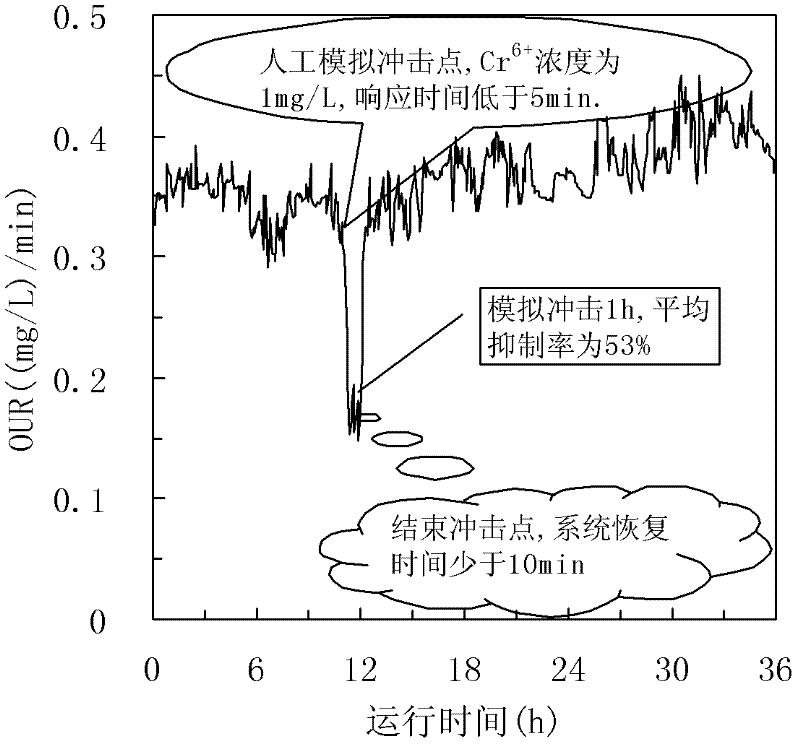

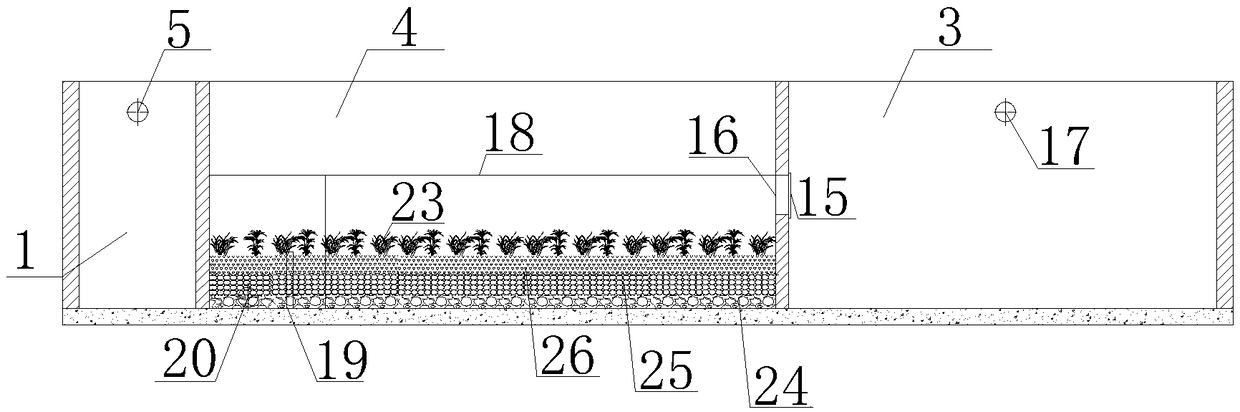

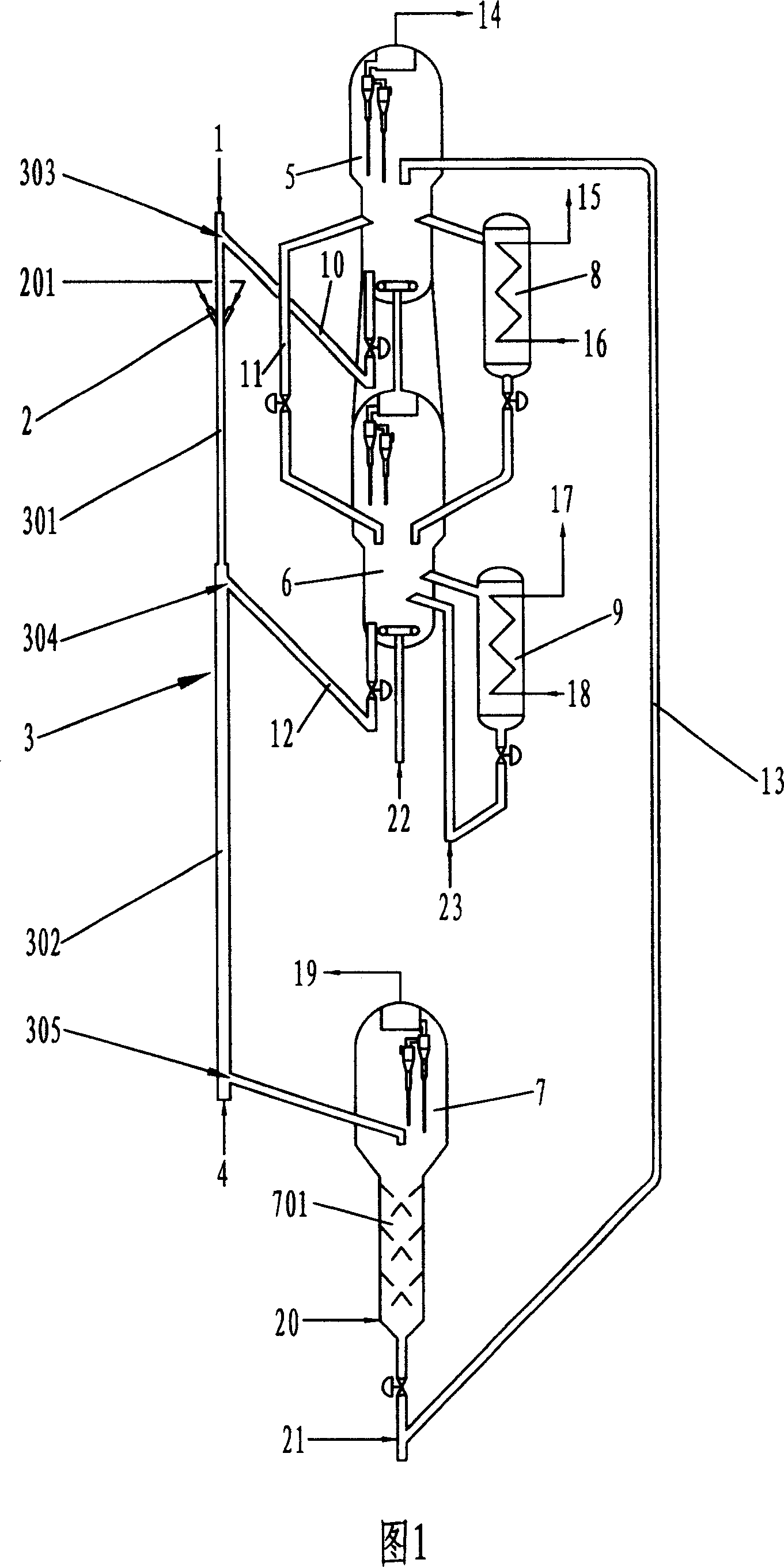

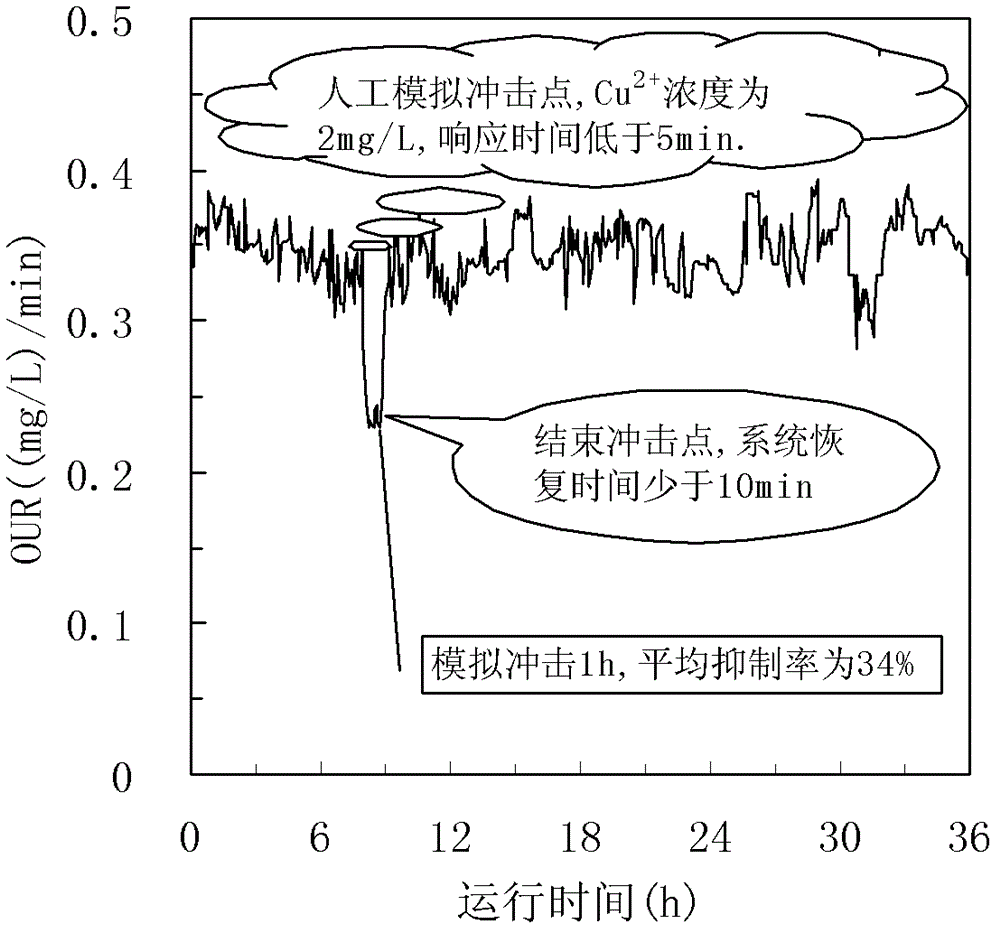

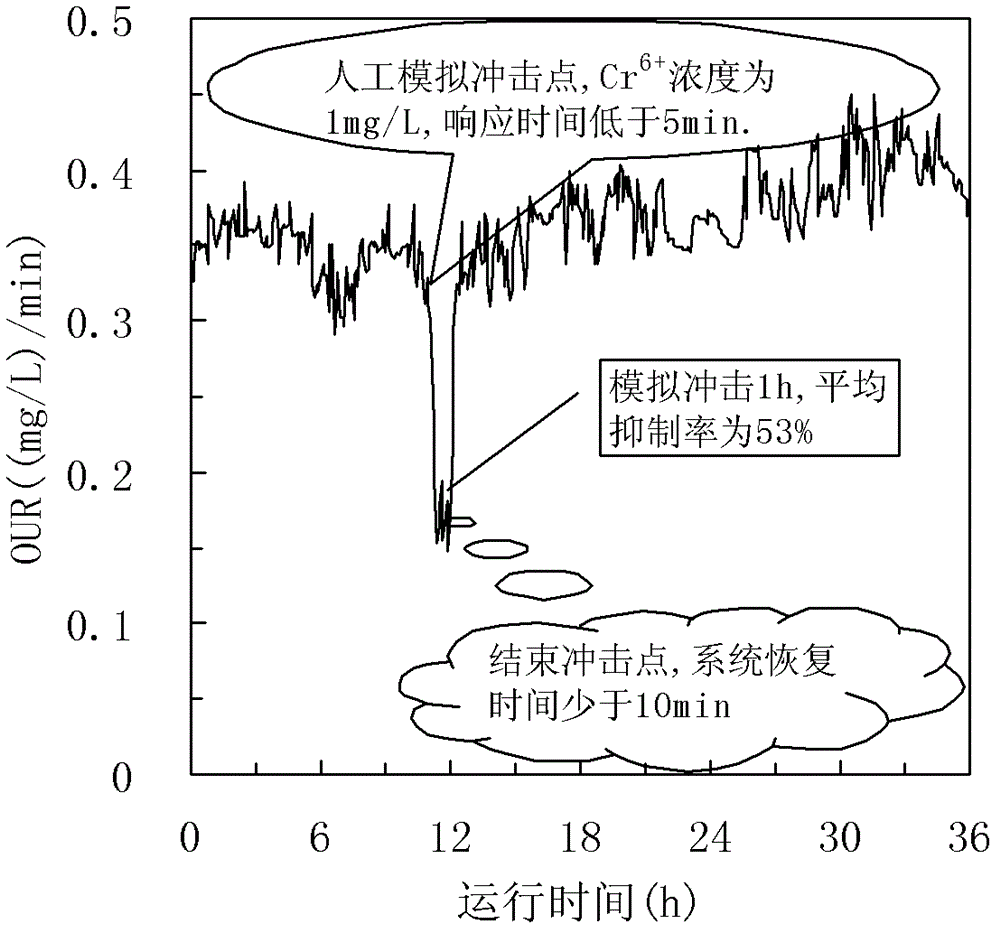

System and method for monitoring municipal saprobia inhibitive ability in real time based on oxygen uptake rate (OUR)

ActiveCN102520016AGuaranteed to be airtightEliminate distracting factorsMaterial analysis by electric/magnetic meansSiphonProgrammable logic controller

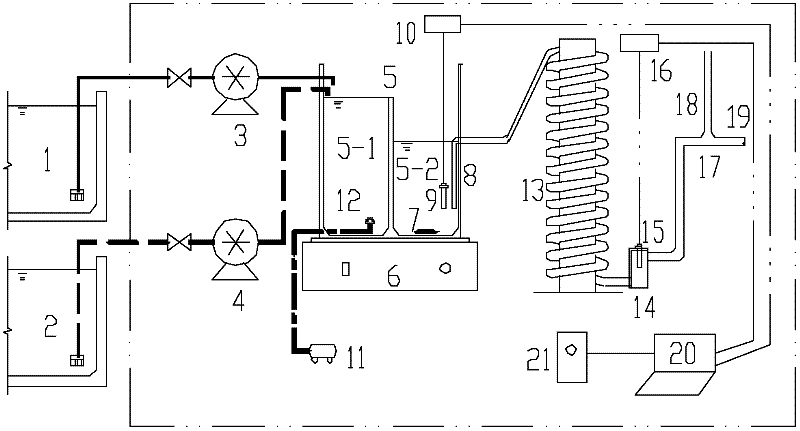

A system for monitoring municipal saprobia inhibitive ability in real time based on oxygen uptake rate (OUR) comprises an aeration siphon device communicated with a sewage supplying system and a sludge supplying system. The aeration siphon device is composed of an aeration groove and a siphon groove in adjoining mode, the wall of the aeration groove is higher than that of the siphon groove, the aeration groove is communicated with the sewage supplying system and the sludge supplying system, and the siphon groove is communicated with an inlet of a closed coiler flow-pushing type bioreactor through a siphon tube. A dissolved oxygen (DO) detection system detects DO values of the inlet and an outlet of the closed coiler flow-pushing type bioreactor, and the signal output end of the DO detection system is connected onto a programmable logic controller (PLC) control system which is connected with an alarm system. The core part of system for monitoring municipal saprobia inhibitive ability in real time adopts the closed coiler flow-pushing type bioreactor so as to monitor the DO value of the inlet and the DO of the outlet in real time, automatically calculate mutation condition of activated sludge OUR, determines OUR mutation rate with different inhibition degree through plenty of experiments, and judge inhibitable degree of the saprobia by comparing automatically calculated OUR mutation rate with a preset value.

Owner:TSINGHUA UNIV +1

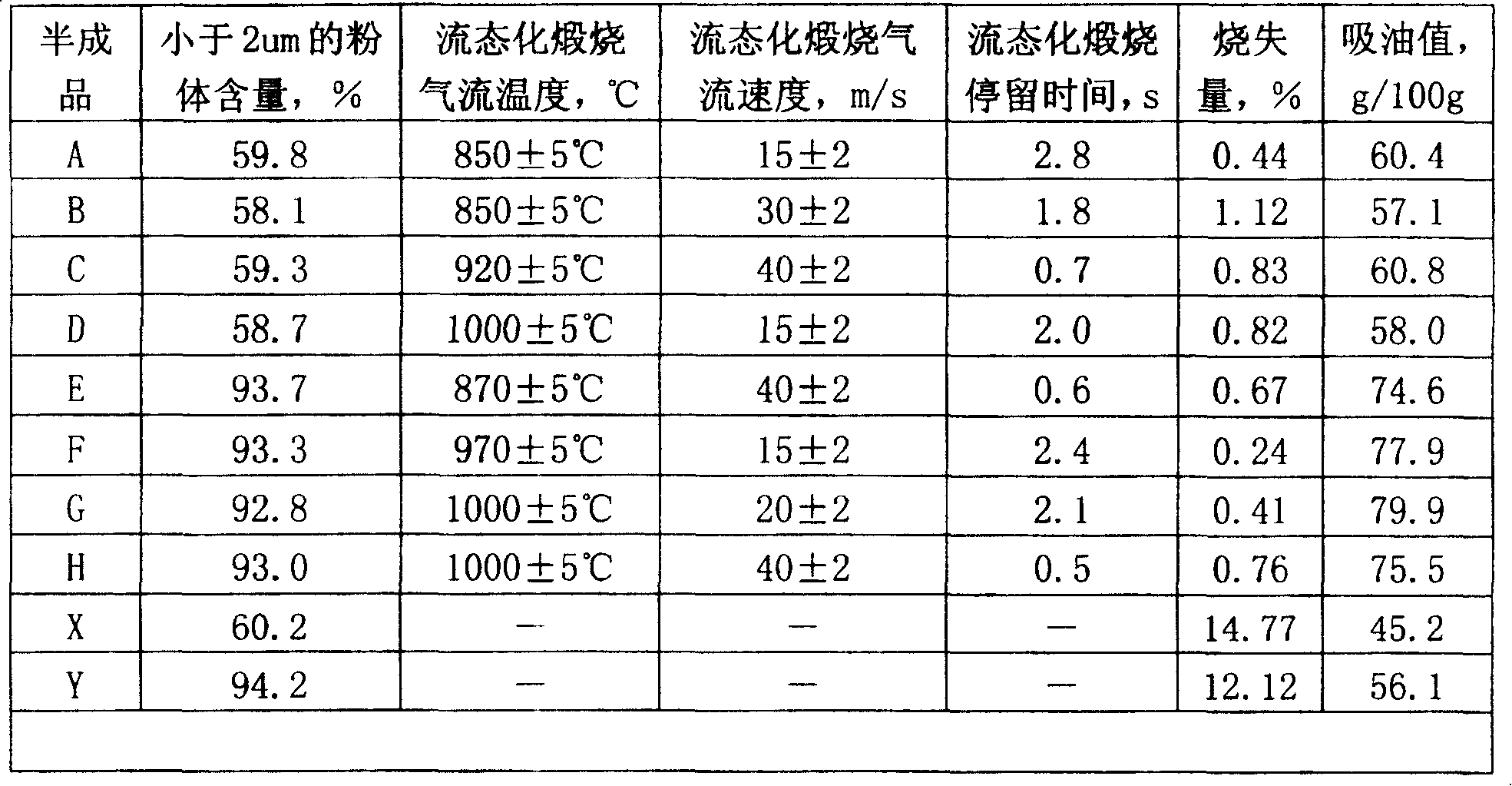

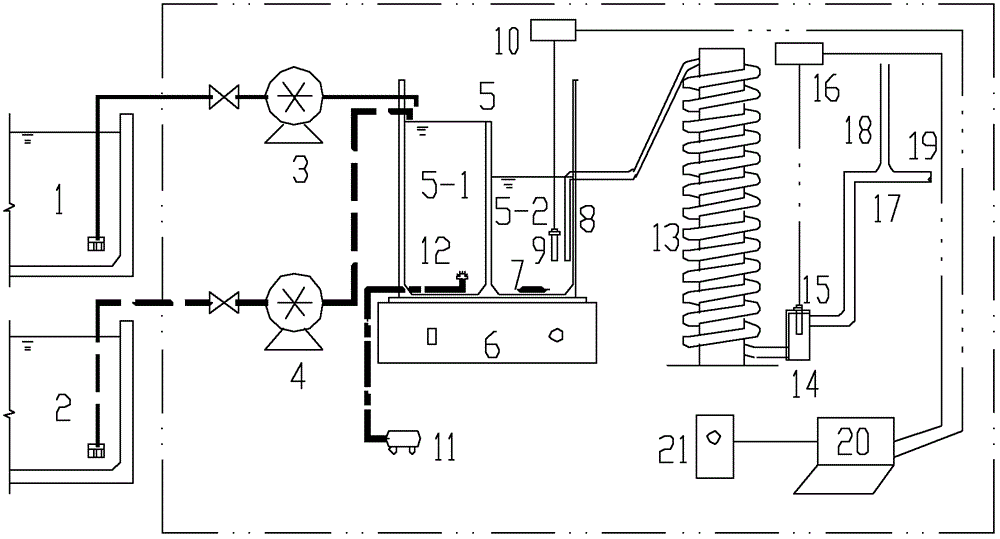

Technique of fluidized instant calcinations of kaolin in coal series

InactiveCN1915814AGood dispersionLarge gas-solid heat transfer areaPigmenting treatmentAluminium silicatesFlue gasEngineering

This invention relates to a fluid-state instantaneous calcining technique for calcining kaolin. The technique comprises a flue gas generating system, a loading system, a fluid-state calcining system, a gas-solid separating system and a post-calcining system. The material is loaded into the fluid-state calcining system by the loading system, where it is mixed with high-temperate flue gas flow generated by the flue gas generating system for instantaneous calcining. The calcined material is introduced into the gas-solid separating system, and the collected solid is then introduced to the post-calcining system for whitening treatment. The instantaneous calcining time is adjusted by the valve. The method can realize large-scale and continuous industrial manufacture, and can effectively reduce the time and energy consumption of post-calcining whitening treatment. The calcined kaolin product has improved oil-absorbency, hiding contrast rate and light extinction performance.

Owner:内蒙古蒙西高岭粉体股份有限公司

Tubular continuous method for preparing cyclopropanecarboxylic acid

InactiveCN101693660AIncrease production capacityHigh yieldOxygen-containing compound preparationOrganic compound preparationContinuous reactorAutomatic control

The invention discloses a tubular continuous method for preparing cyclopropanecarboxylic acid. In the method, gamma-butyrolactone used as a raw material reacts with thionyl chloride and alcohol to produce 4-chlorobutyrate; after the reaction liquid is processed in an acid gas removing way and an alcohol recycling way, the reaction liquid and liquid sodium alkoxide are synthesized to obtain cyclopropanecarboxylate in a tubular reactor; the rectified cyclopropanecarboxylate is firstly hydrolyzed in alkali liquor and then neutralized with acid to obtain crude cyclopropanecarboxylic acid; and the crude cyclopropanecarboxylic acid is rectified to obtain the pure cyclopropanecarboxylic acid. The synthetic technique of the cyclopropanecarboxylic acid adopts the tubular continuous reactor, thereby effectively reducing the equipment investment and enhancing the investment efficiency; the continuous reaction can conveniently realize automatic control, thereby ensuring the continuity and the stability of the production, saving the manual cost, realizing the safe production operation and enhancing the purity and the yield of the product; and the invention adopts a technique of adding solid caustic soda again in the second aqueous phase for recycling, thereby fully and comprehensively utilizing the resources, enhancing the yield for hydrolysis and greatly reducing the cost.

Owner:ZHEJIANG UNIV +1

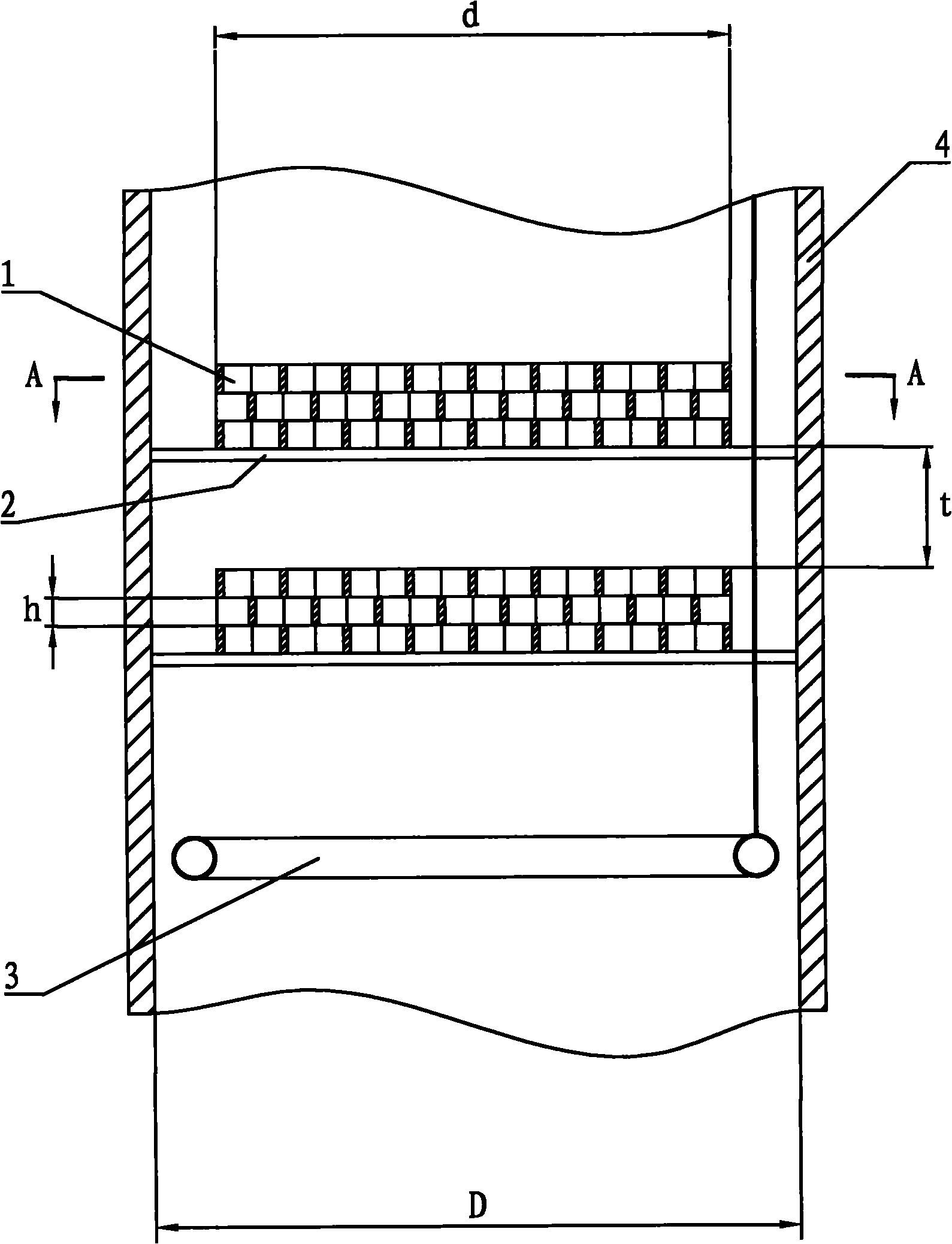

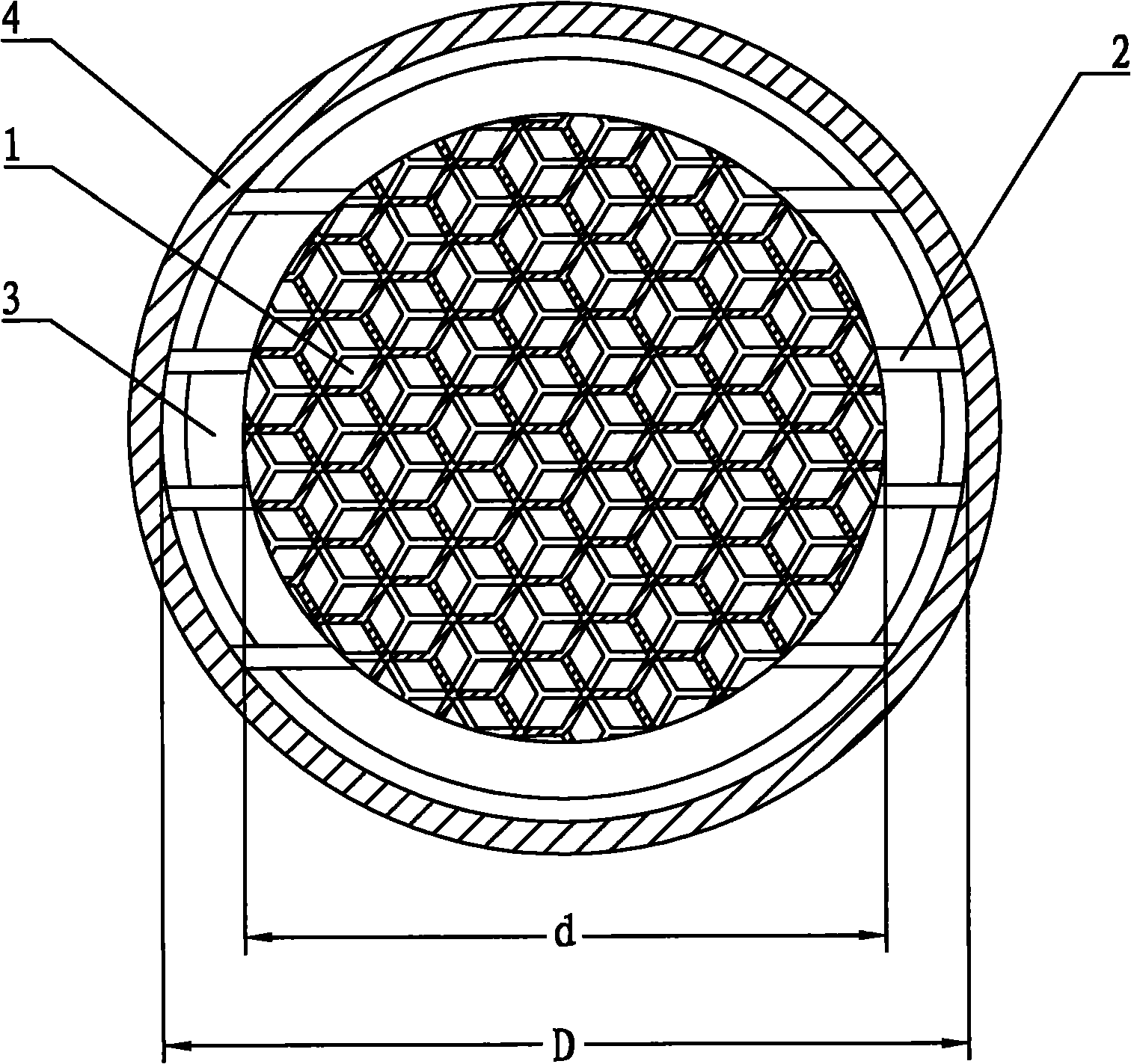

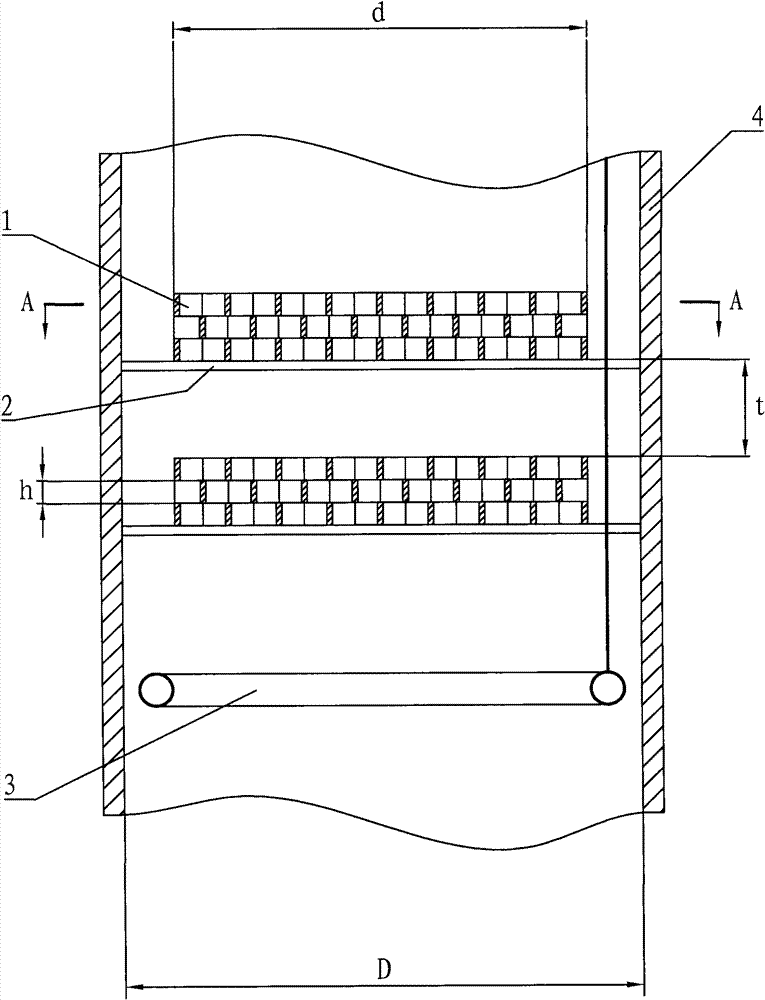

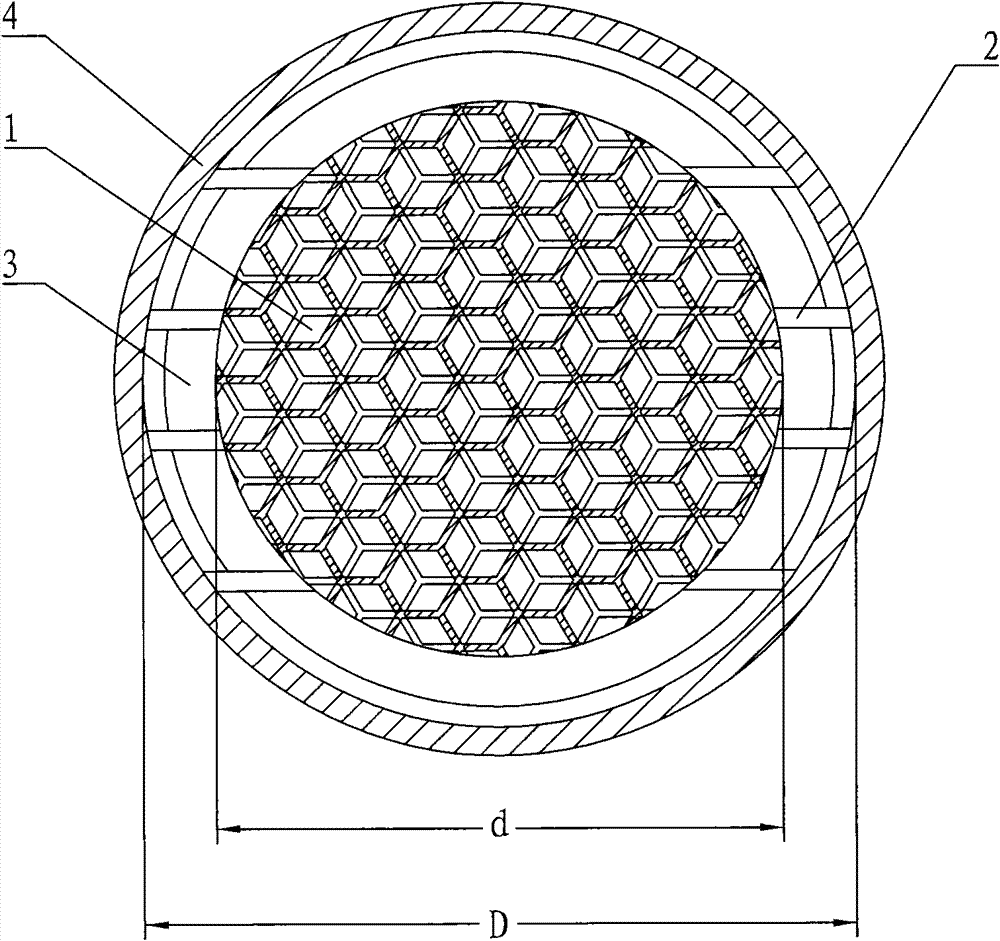

Gas-solid contact equipment for fluidized bed

ActiveCN101879432AImprove efficiencySimple structureCatalyst regeneration/reactivationChemical/physical/physico-chemical processesGas solidFluidized bed

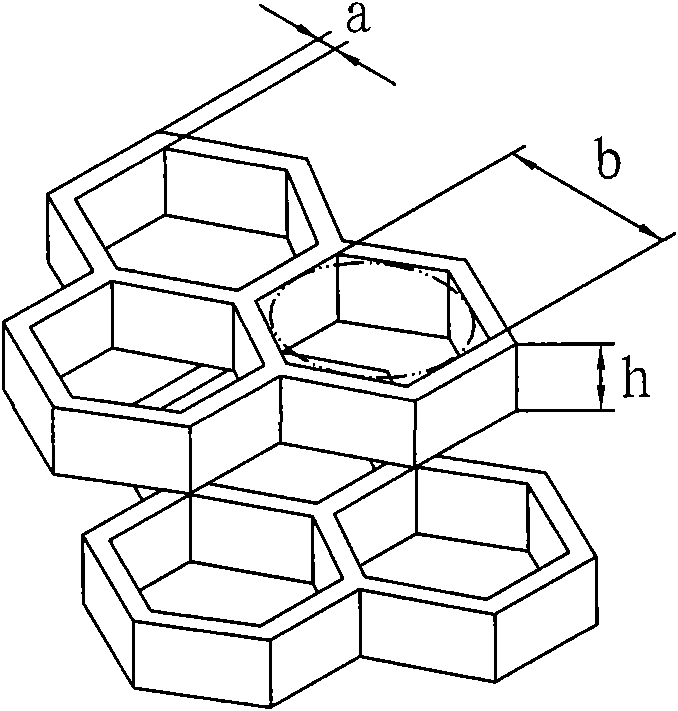

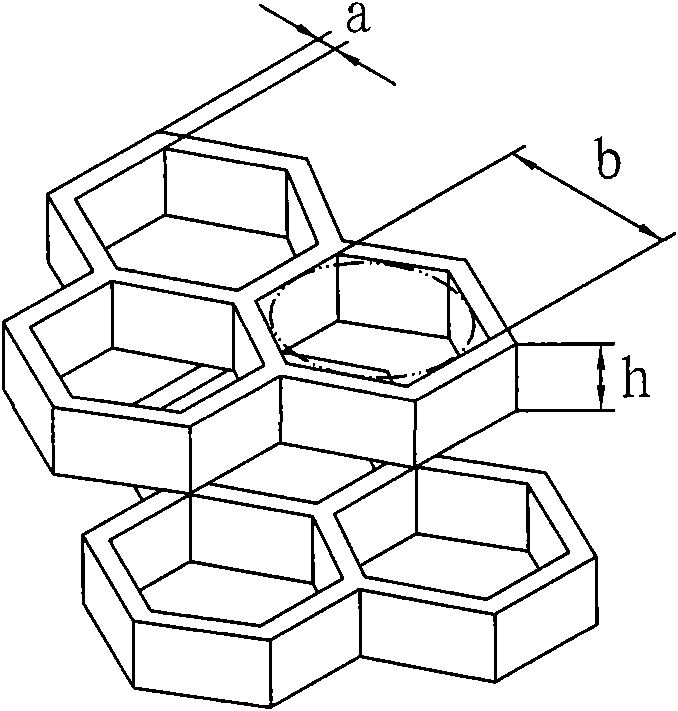

The invention discloses gas-solid contact equipment for a fluidized bed, which is used for catalytic conversion devices in petroleum refining, petrochemical industry and other industries so as to solve the problems of non-flowing region, local slugging of gas or local solid bridging and the like which are easy to generate respectively when the conventional contact equipment is provided with a corresponding tray-type inner component or a filler, and the problems that the inner component or filler is difficult to install, overhaul and maintain. The contact equipment is at least provided with two groups of fillers (1) along the axial direction of a cylinder body (4), and a space is reserved between the two groups of fillers; each group of filler consists of a plurality of filler layers which are overlapped along the vertical direction, each filler layer is provided with a vertical hexagonal channel formed by strip plates, and the cross section shape of the hexagonal channel is a regular hexagon shape; and in each group of filler, the hexagonal channels on two adjacent filler layers are alternately arranged. The equipment can be used as a stripper to strip oil gas, hydrocarbon or gas impurities carried in the catalyst, and also can be used as a regenerator to regenerate the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

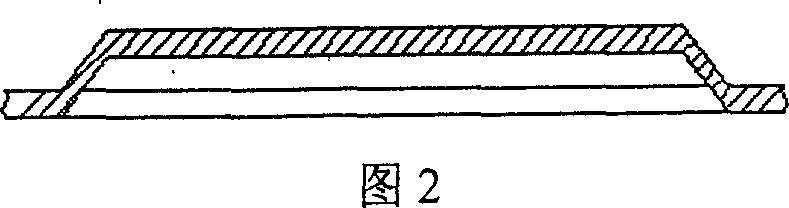

Electric desalting dewatering device for crude oil

InactiveCN1233793CReduce moisture contentEnhanced electrical coalescenceDewatering/demulsification with electric/magnetic meansElectricityPlanar electrode

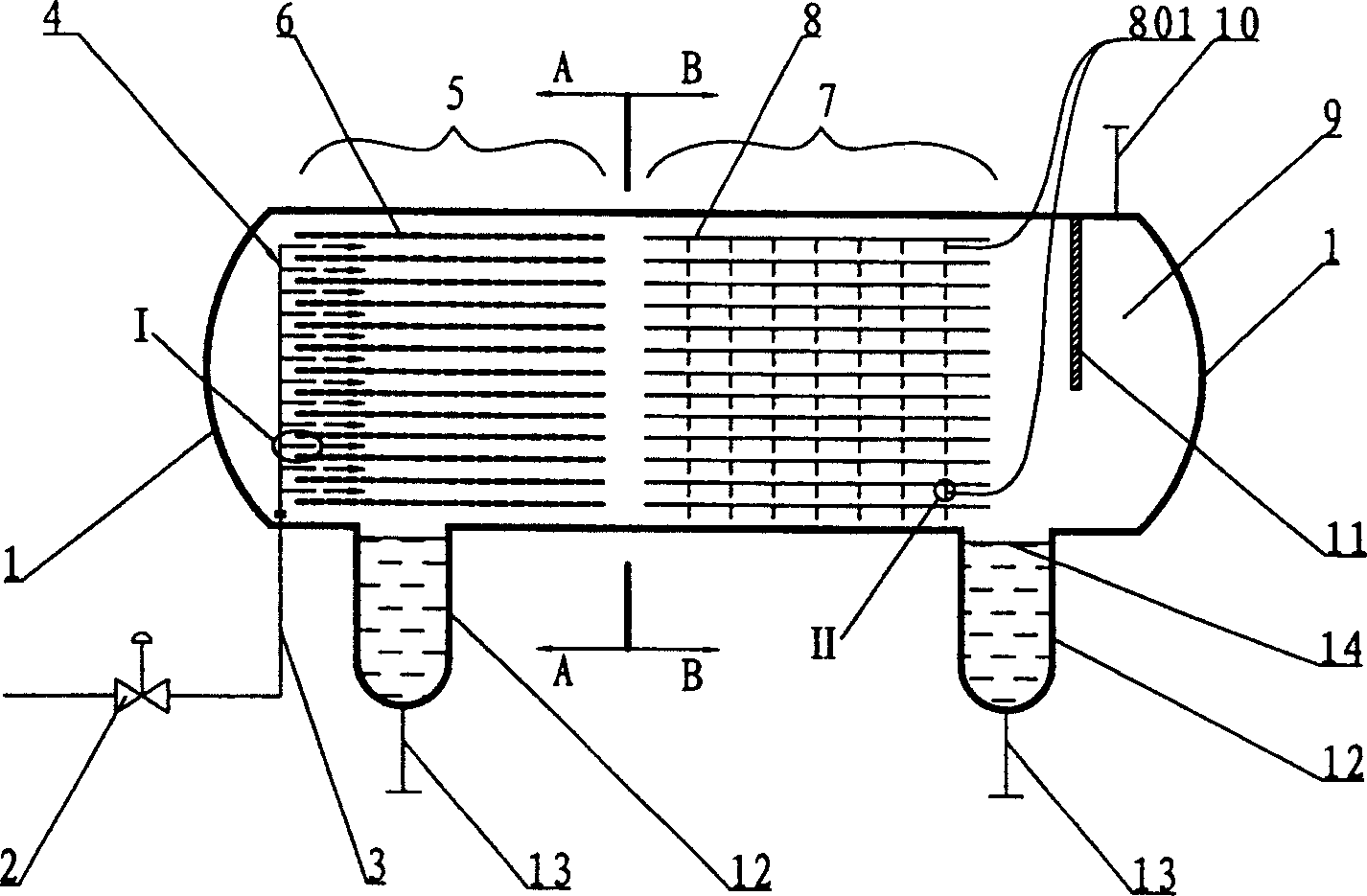

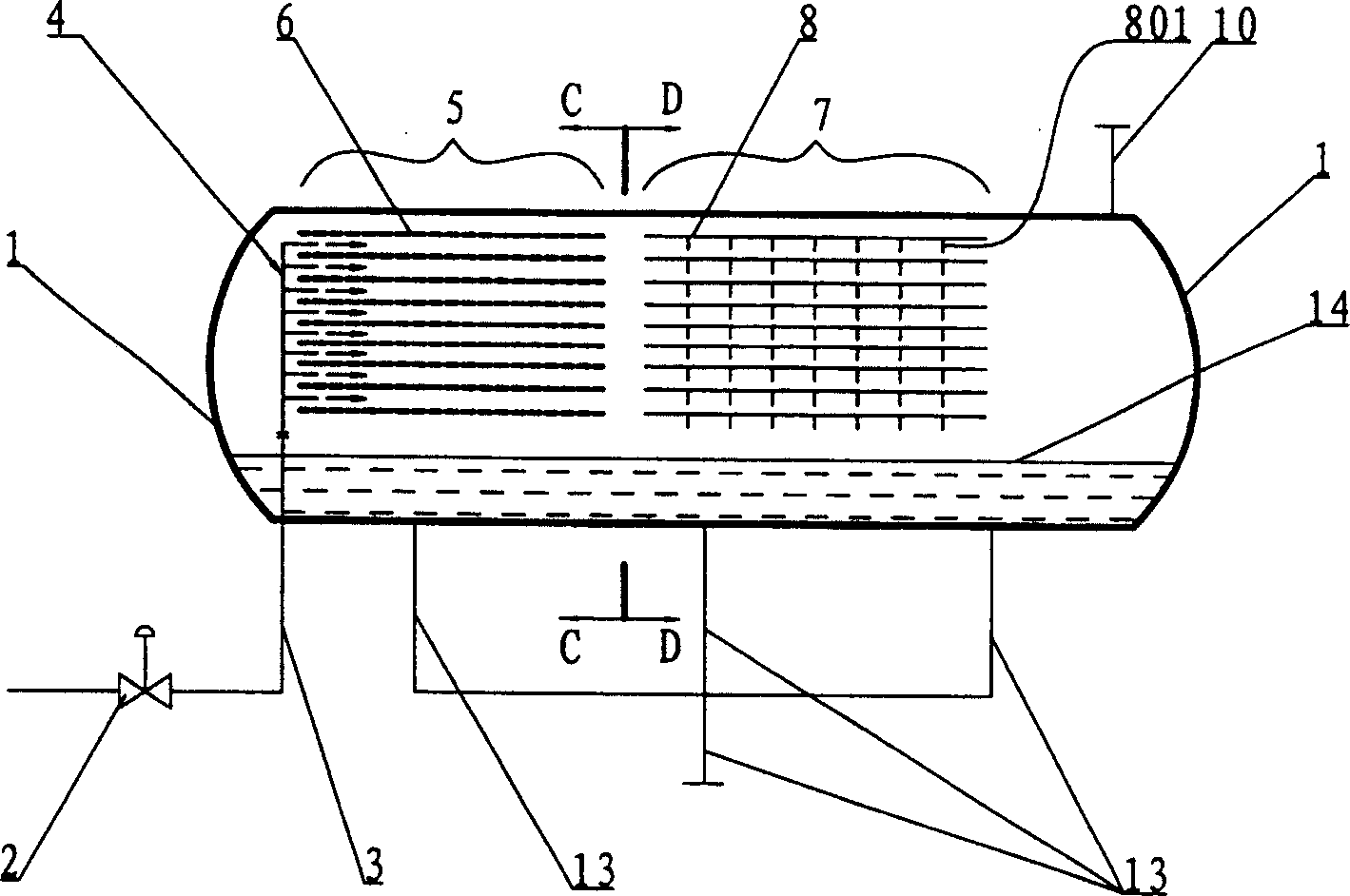

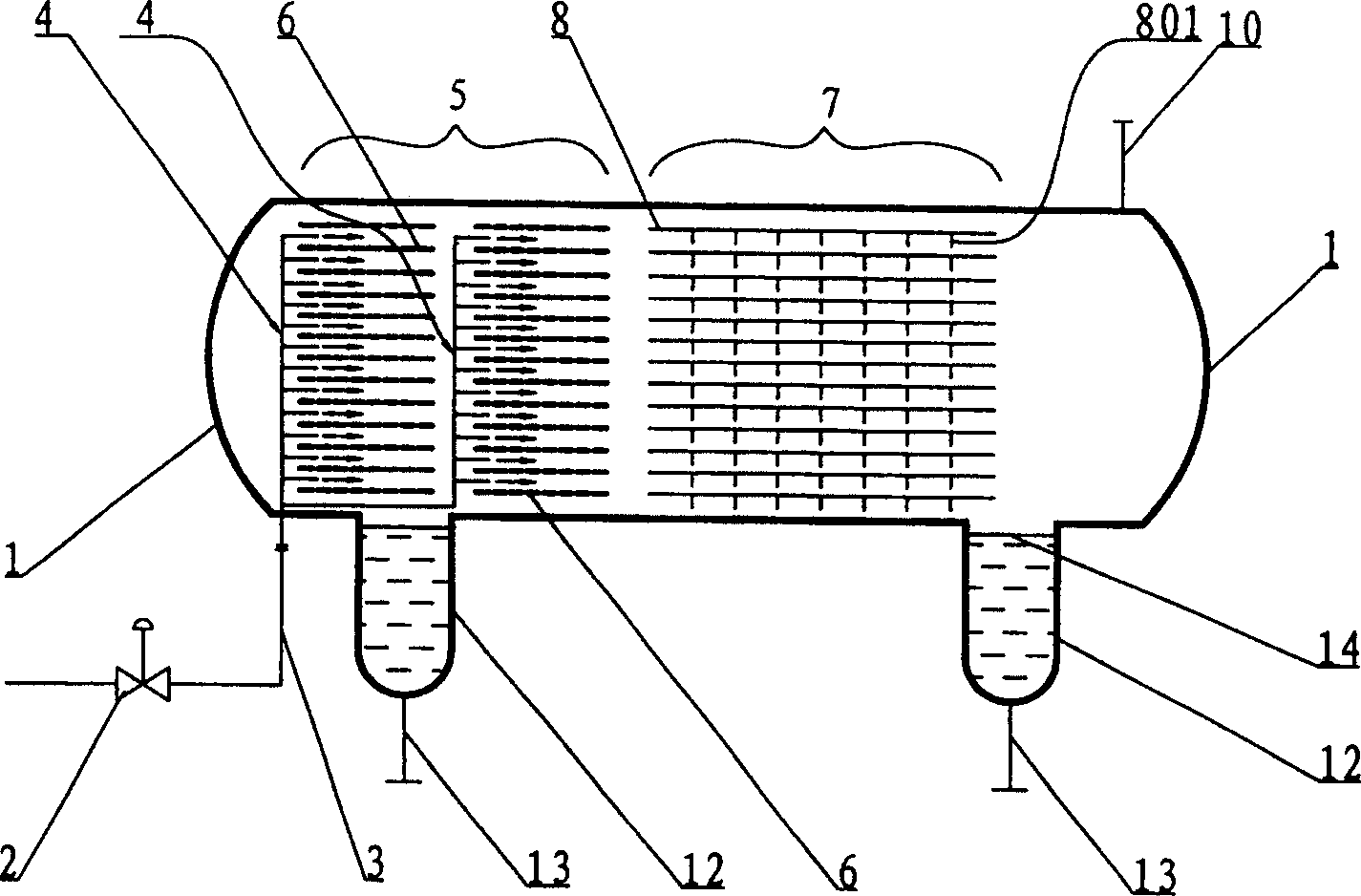

The invention discloses a crude oil electric desalination dehydrator used in the petrochemical industry, in order to solve the problems existing in the existing electric desalination dehydrator that adopt a weak electric field to feed materials, which weakens the electric coalescence in the strong electric field area and the crude oil moves from bottom to top Its main feature is that it can use strong electric field to directly feed and crude oil to flow horizontally during operation. In the electric desalination dehydrator of the present invention, a strong electric field coalescence zone (5) is provided along the axial direction of the tank body from the oil-water mixture inlet end of the tank body (1), and an oil outlet pipe (5) is provided on the top of the tank body purified crude oil outlet end ( 10), the strong electric field coalescence area is provided with at least two layers of planar electrode plates (6) perpendicular to the axis of the tank body, and the electrode plates of each layer are parallel to each other. A feed distributor (4) is arranged in the tank, and a spout is arranged on it, and the oil-water mixture is sprayed into the strong electric field between all adjacent two-layer electrode plates. A settling separation zone (7) can also be set between the strong electric field coalescence zone and the outlet end of the purified crude oil in the tank.

Owner:CHINA PETROCHEMICAL CORP +1

Electric dewatering and desalting appliance for crude oil

InactiveCN1208111CIncrease coalescence speedImprove coalescence performanceLiquid separation by electricityDewatering/demulsification with electric/magnetic meansElectricityPlanar electrode

The invention discloses a crude oil electric desalination dehydrator used in the petrochemical industry, in order to solve the problems existing in the existing electric desalination dehydrator that adopt a weak electric field to feed materials, which weakens the electric coalescence in the strong electric field area and the crude oil moves from bottom to top Its main feature is that it can use strong electric field to directly feed and crude oil to flow horizontally during operation. In the electric desalination dehydrator of the present invention, a feed distributor (4) and a strong electric field coalescence area (5) are sequentially arranged along the axial direction of the tank body from the oil-water mixture inlet end of the tank body (1), and the tank body is purified An oil outlet pipe (10) is provided on the top of the crude oil outlet, and at least two layers of planar electrode plates (6) parallel to the axial direction of the tank are provided in the strong electric field coalescence area, and the electrode plates of each layer are parallel to each other. The feed distributor is provided with a spout, which sprays the oil-water mixture into the strong electric field between all adjacent two-layer electrode plates. A settling separation zone (7) can also be set between the strong electric field coalescence zone and the outlet end of the purified crude oil in the tank.

Owner:CHINA PETROCHEMICAL CORP +1

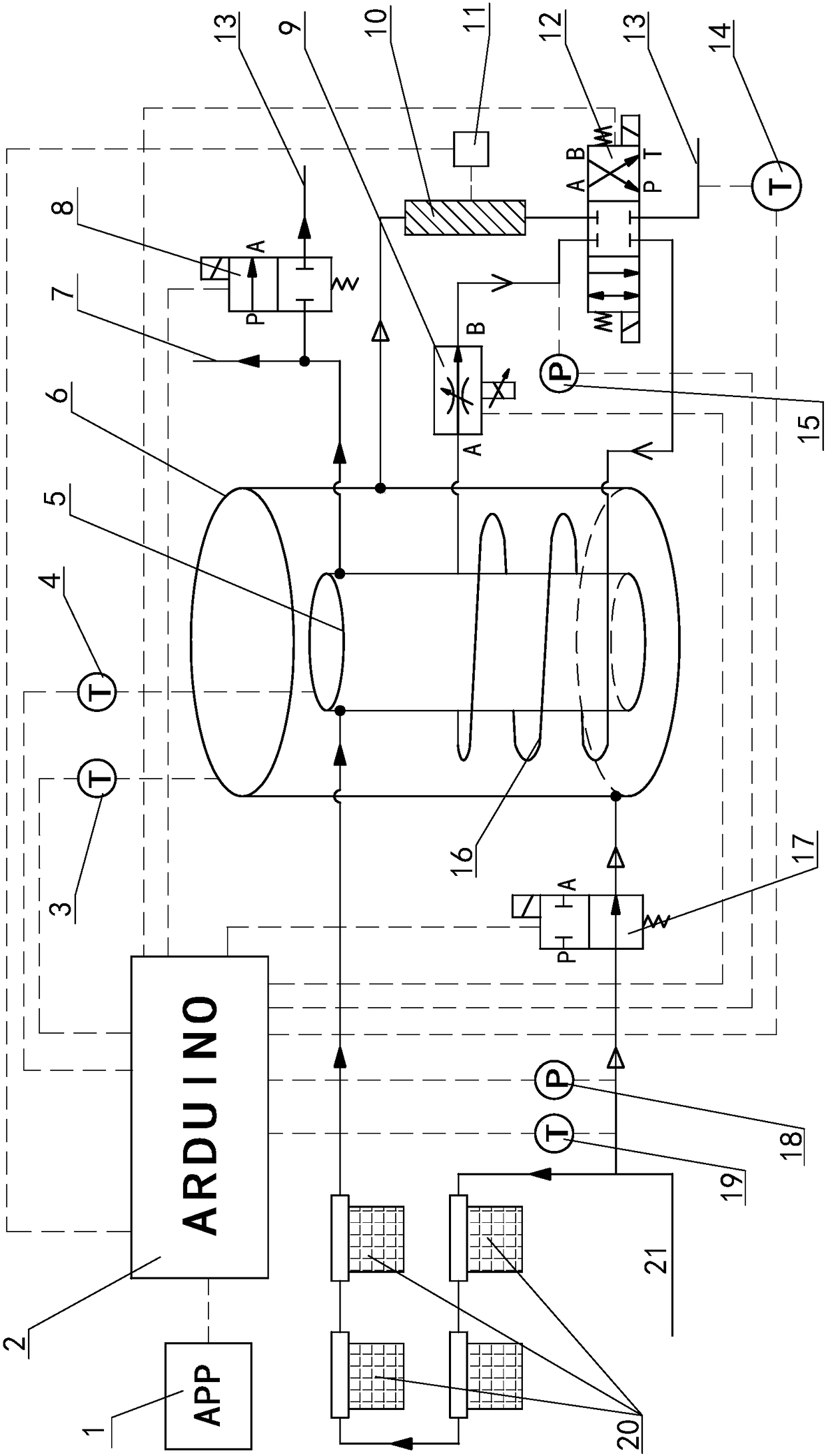

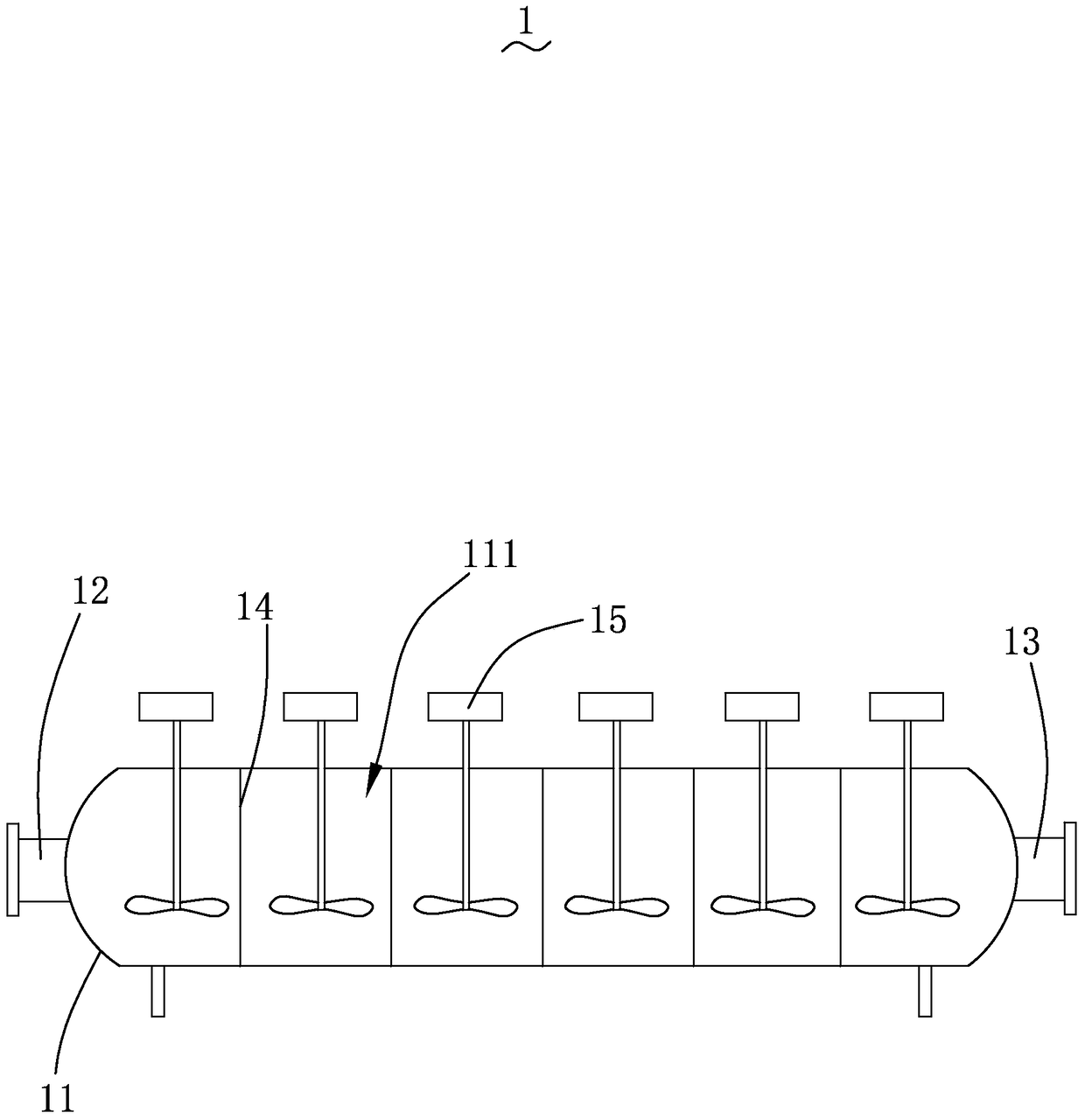

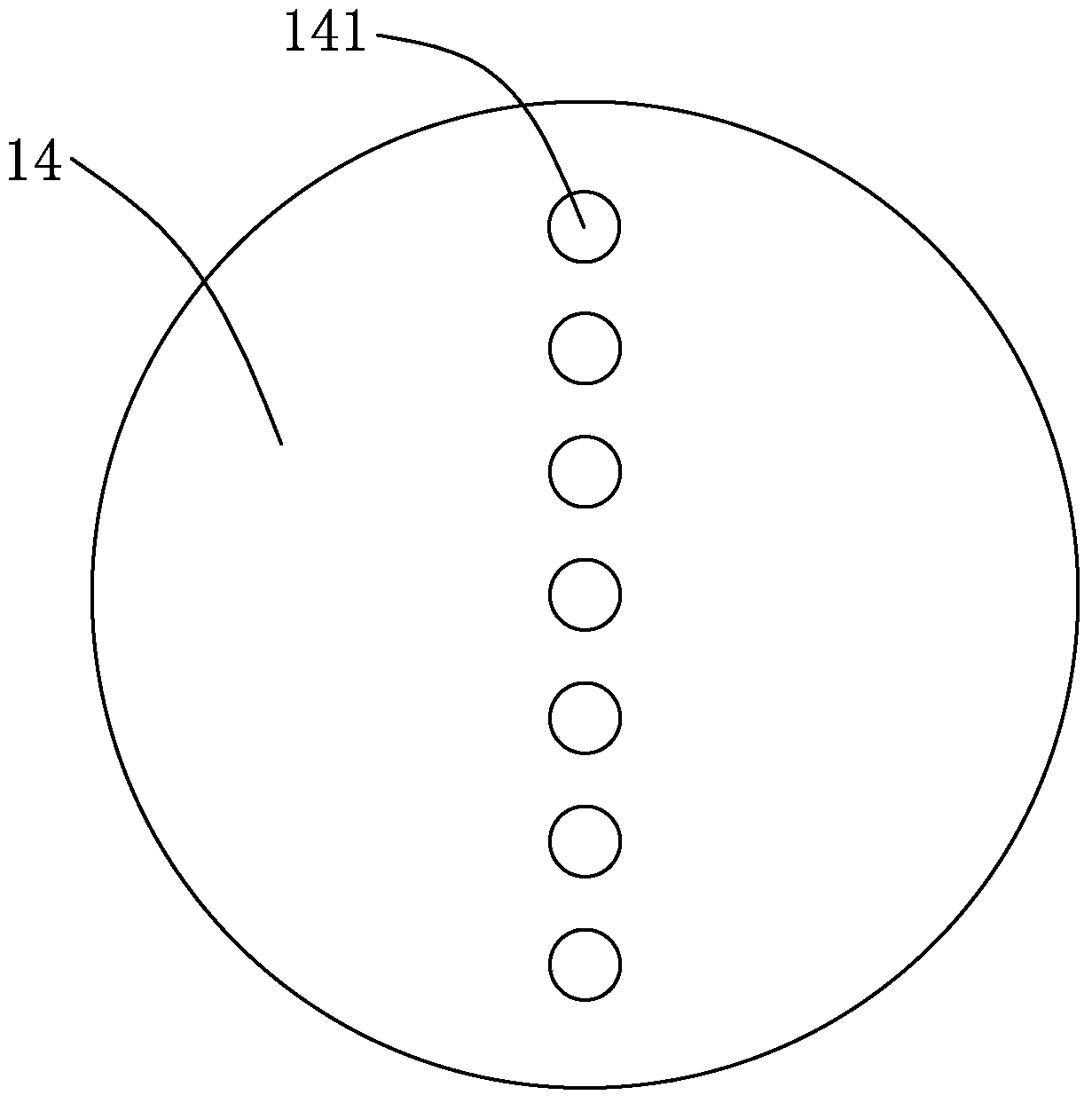

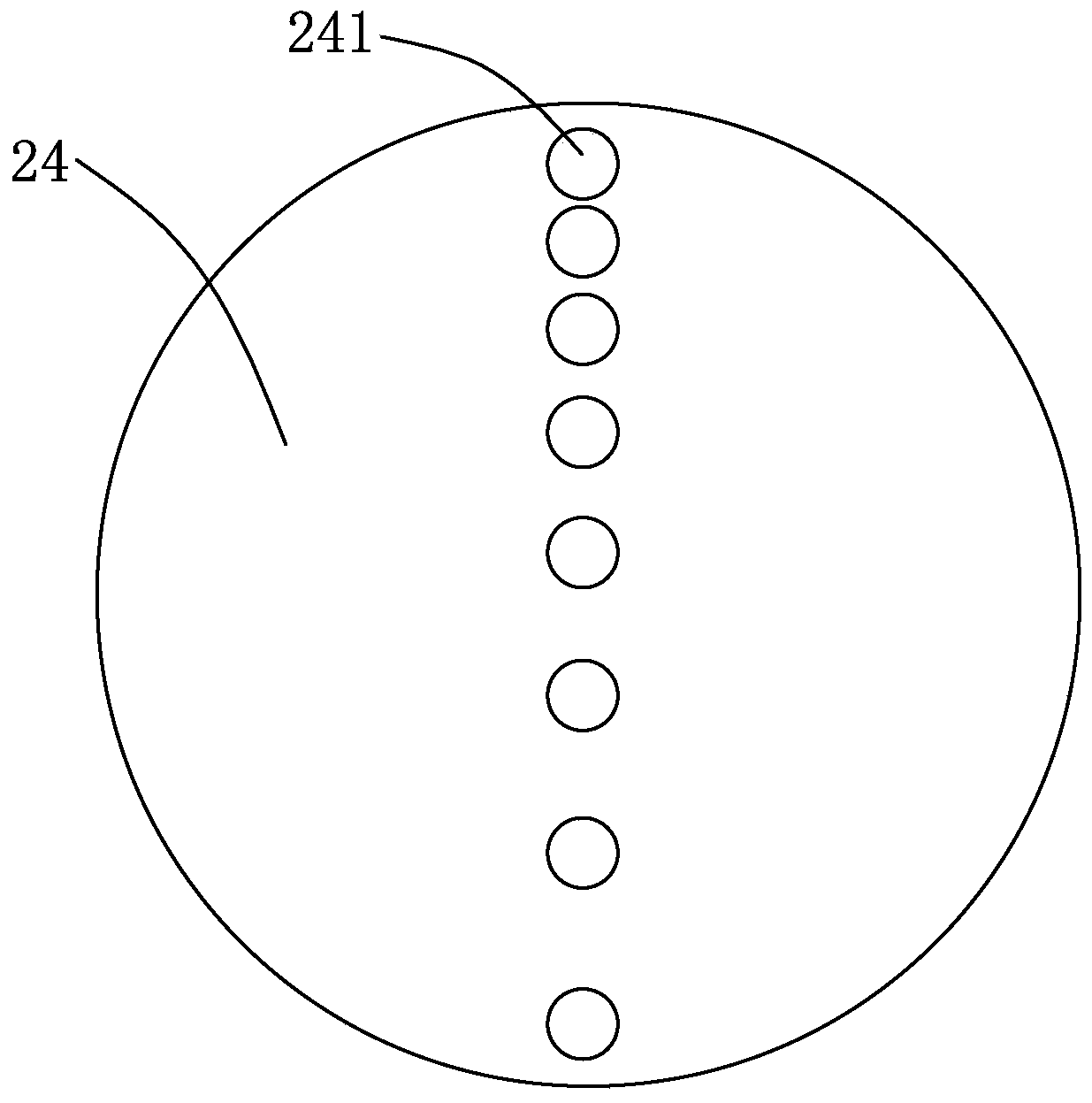

Intelligent water boiling device

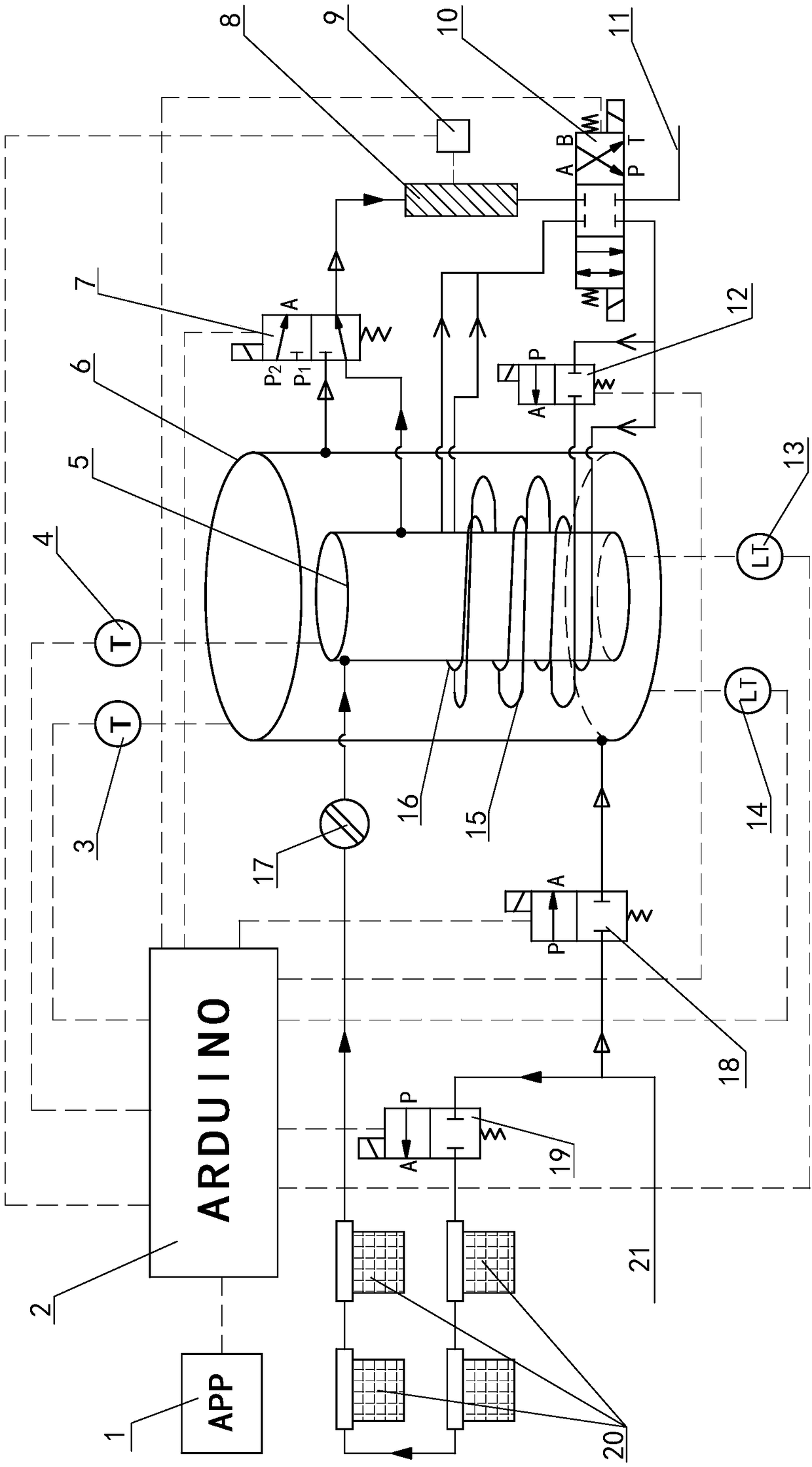

ActiveCN108386993AUniform velocity distributionEliminate backmixingSolar heating energySolar heat collector for particular environmentWater savingWater storage tank

The invention discloses an intelligent water boiling device. A running water inlet end is connected with P ports of a second two-position two-way normally closed electromagnetic valve and a first two-position two-way normally closed electromagnetic valve; an A port of the first two-position two-way normally closed electromagnetic valve is connected with an inlet end of a solar heat collector; an outlet end of the solar heat collector is connected with an inlet of an inner layer water storage tank; an outlet of the inner layer water storage tank is connected with a P1 port of a two-position three-way electromagnetic valve; an A port of the second two-position two-way normally closed electromagnetic valve is connected with an inlet of an outer layer water storage tank; an outlet of the outerlayer water storage tank is connected with a P2 port of the two-position three-way electromagnetic valve; a heat exchange system is arranged at the outer periphery of the inner layer water storage tank; a single-chip microcomputer controls connection and disconnection of the two-position three-way electromagnetic valve, a three-position four-way electromagnetic valve and a third two-position two-way normally closed electromagnetic valve to control the heat exchange system and a heating pipe to output three water temperatures for different life demands; and the intelligent water boiling devicehas the advantages of green energy, intelligent control, convenient and quick energy circulation, excellent performances, prominent water saving effect and broad application prospect.

Owner:SUZHOU SABO IND DESIGN

Technique of fluidized instant calcinations of kaolin in coal series

InactiveCN100431957CGood dispersionLarge gas-solid heat transfer areaPigmenting treatmentAluminium silicatesFlue gasEngineering

This invention relates to a fluid-state instantaneous calcining technique for calcining kaolin. The technique comprises a flue gas generating system, a loading system, a fluid-state calcining system, a gas-solid separating system and a post-calcining system. The material is loaded into the fluid-state calcining system by the loading system, where it is mixed with high-temperate flue gas flow generated by the flue gas generating system for instantaneous calcining. The calcined material is introduced into the gas-solid separating system, and the collected solid is then introduced to the post-calcining system for whitening treatment. The instantaneous calcining time is adjusted by the valve. The method can realize large-scale and continuous industrial manufacture, and can effectively reduce the time and energy consumption of post-calcining whitening treatment. The calcined kaolin product has improved oil-absorbency, hiding contrast rate and light extinction performance.

Owner:内蒙古蒙西高岭粉体股份有限公司

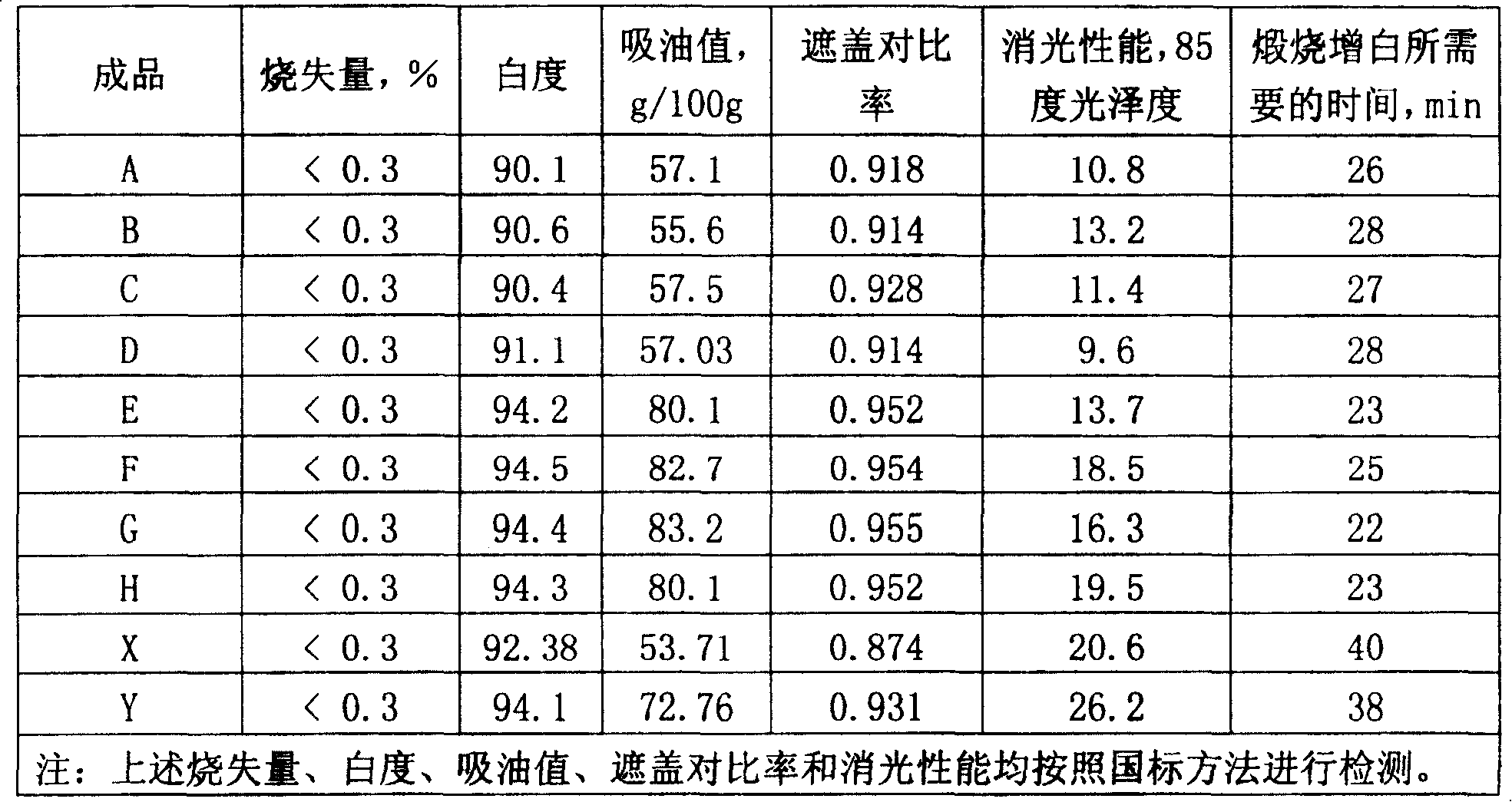

Swirling-flow float valve tower plate

InactiveCN105582687AImprove throughputImprove efficiencyFractional distillationUnit operationEngineering

The invention relates to an internal component of oil-refining and chemical equipment, specifically to a swirling-flow float valve tower plate. The swirling-flow float valve tower plate comprises a valve face, a swirling-flow hole, a supporting angle, valve legs, valve feet, a tower plate and a gas guiding hole. According to the invention, gas enters the tower plate from the valve hole and is firstly dispersed by the valve hole, wherein part of the gas ejects from the swirling-flow hole arranged on the valve face and forms small-size gas bubbles after contacting with liquid; since the action of a swirling-flow field strengthens mass transfer between gas and liquid phases above the valve face, treatment capacity of the tower is greatly improved; meanwhile, the swirling-flow float valve tower plate has the advantages of self-cleaning capacity, small gradient of a liquid level on the tower plate, uniform distribution of the gas, no liquid-stagnation zone, high efficiency of the tower plate, large treatment capacity, etc., and can be extensively applied in unit operations like mass transfer and heat transfer of gas-liquid two phases and gas-liquid-solid three phases like gas purification, rectification, absorption and dust-removal.

Owner:CHINA PETROLEUM & CHEM CORP +1

Intelligent boiled water control method with boiled water heat energy recycling function

ActiveCN108344191AEliminate backmixingReduce dead zoneSolar heating energySolar heat collector controllersSolar thermal collectorWater storage tank

The invention discloses an intelligent boiled water control method with the boiled water heat energy recycling function. According to the intelligent boiled water control method, intelligent boiled water control can be realized through an intelligent boiled water control device with the boiled water heat energy recycling function, a tap water inlet end is connected to a P port of a second two-position two-way normally-closed electromagnetic valve and a P port of a first two-position two-way normally-closed electromagnetic valve, an A port of the first two-position two-way normally-closed electromagnetic valve is connected to the inlet end of solar thermal collectors, the outlet end of the solar thermal collectors is connected to an inlet of an inner-layer water storage tank, an outlet of the inner-layer water storage tank is connected to a P1 port of a two-position three-way electromagnetic valve, an A port of the second two-position two-way normally-closed electromagnetic valve is connected to an inlet of an outer-layer water storage tank, an outlet of the outer-layer water storage tank is connected to a P2 port of the two-position three-way electromagnetic valve, and a heat exchange pipeline is arranged on the periphery of the inner-layer water storage tank. The intelligent boiled water control method has the advantages that the flow rate is controlled by an electromagnetic flow valve, water with multiple water temperatures can be output to meet the requirements of domestic water, a temperature sensor is arranged at the water outlet end to monitor the temperature of the water outlet end in real time, and therefore the boiled water heat energy can be recycled, and energy conservation can be matched with the flow rate.

Owner:SUZHOU SABO IND DESIGN

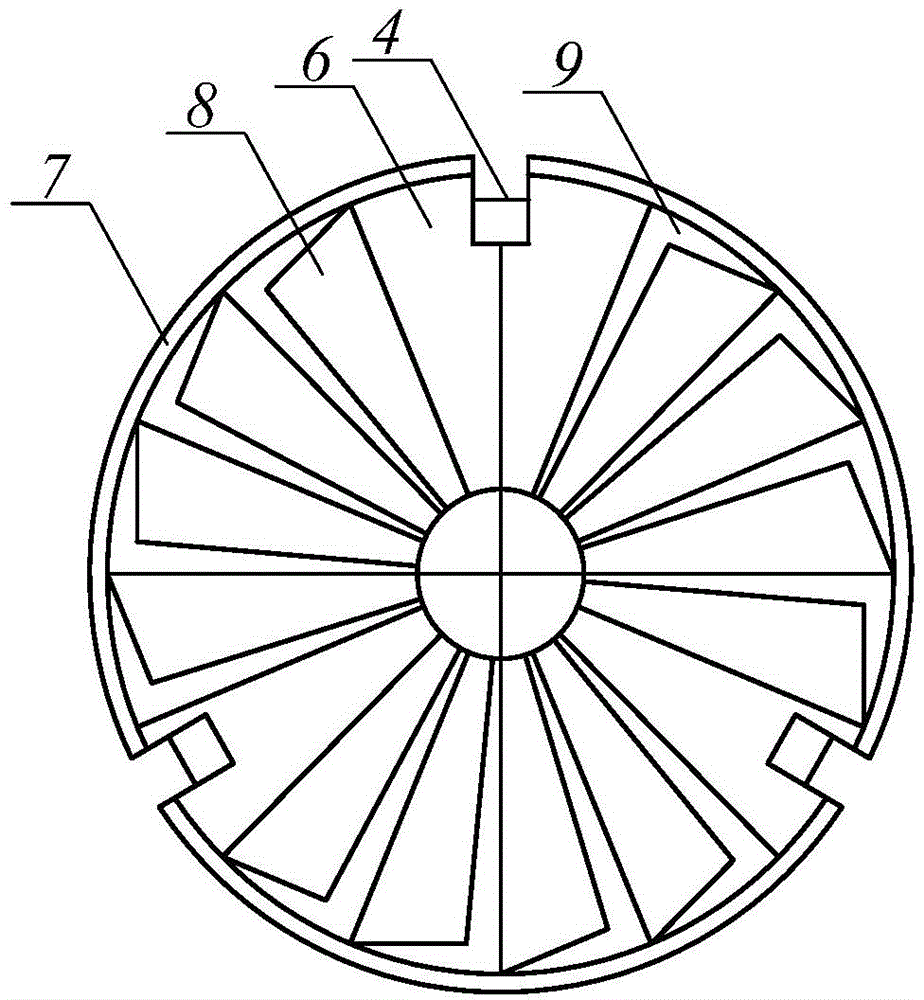

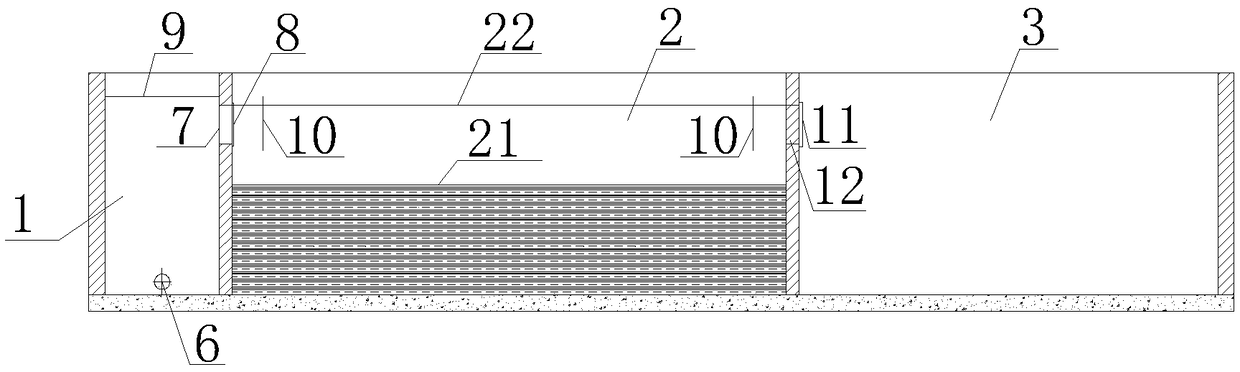

Water source protecting area highway runoff collecting and emergency purifying system

PendingCN109371776ASimple structureEasy maintenanceSewerage structuresPaving gutters/kerbsActivated carbonWater source

The invention relates to the technical field of environmental protection and water purification, in particular to a water source protecting area highway runoff collecting and emergency purifying system. The system comprises a flow distribution pool, a physical adsorption pool, an emergency storage pool and a grass planting ecological pool. The flow distribution pool, the physical adsorption pool,the emergency storage pool and the grass planting ecological pool sequentially communicate in series. The flow distribution pool communicates with a road surface runoff water input pipe, a later-period runoff water output pipe, a flow distribution pool water output pipe and a flow distribution pool check valve, and a rapid starting and closing valve is arranged in the flow distribution pool. The physical adsorption pool communicates with a physical adsorption pool water output pipe, and multiple layers of activated carbon plates are arranged in the physical adsorption pool. The emergency storage pool communicates with an emergency storage pool water output pipe and an emergency water input pipe, and a valve well and a bidirectional emptying valve are arranged in the emergency storage pool.The grass planting ecological pool communicates with a grass planting ecological pool water output pipe, a flow guide wall and a fine stone baffle are arranged in the grass planting ecological pool,and aquatic ecological plants are planted on the bottom of the pool.

Owner:NANCHANG UNIV

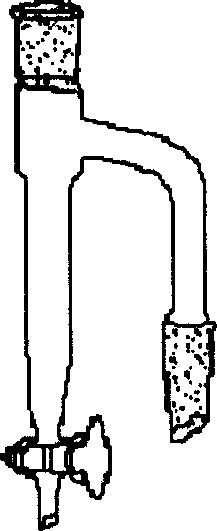

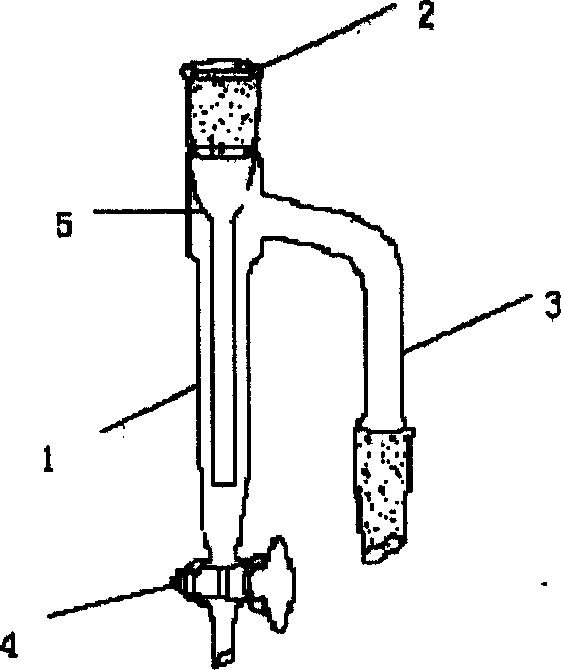

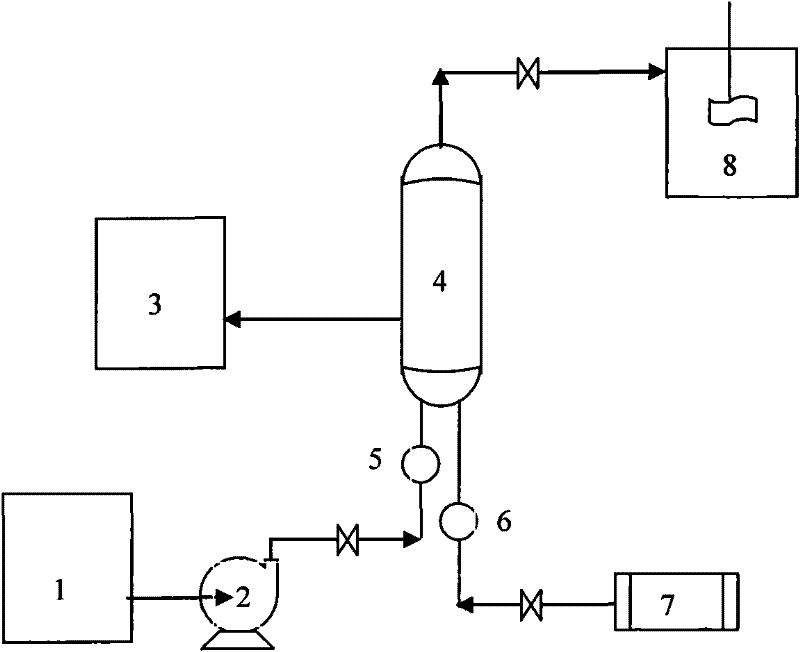

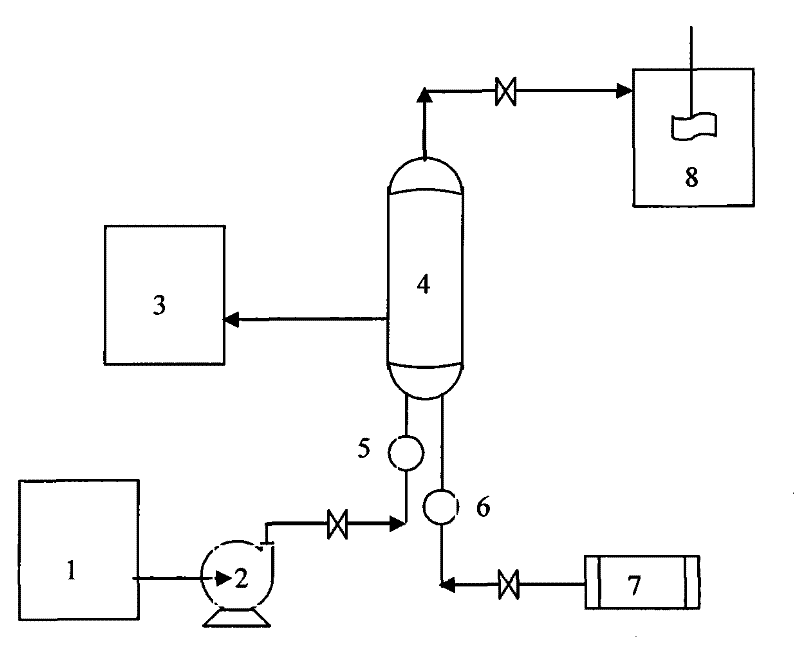

Continuous water separation device

InactiveCN1879968AEliminate backmixingDwell time eliminationLaboratory glasswaresEngineeringPressure balance

The invention relates to a continuous water separator, which comprises: a liquid inlet (2), a container (1), an overflow tube (3), and an outlet valve (4), wherein the liquid inlet (2) and outlet valve (4) are independently on the top and bottom of container (1); the overflow tube (3) is at the upper part of container (1); the liquid inlet (2) is mounted with liquid tube (5) inserted into the lower part of container (1); the upper part of liquid tube (5) has one pressure balance hole (6). The invention can eliminate reflux, prolong the separate time, and improve the separate efficiency. And the invention has simple structure and lower cost.

Owner:NANJING UNIV

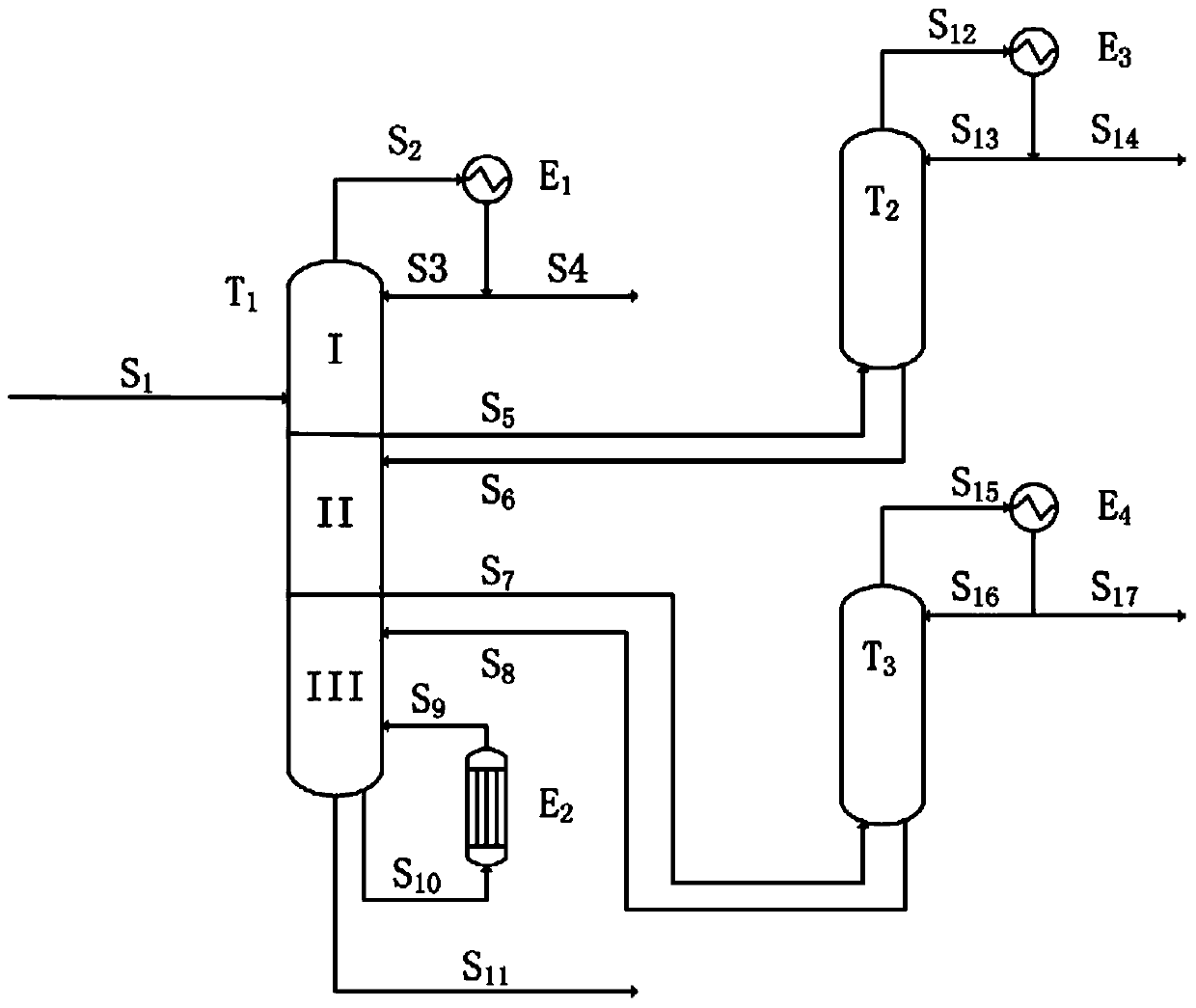

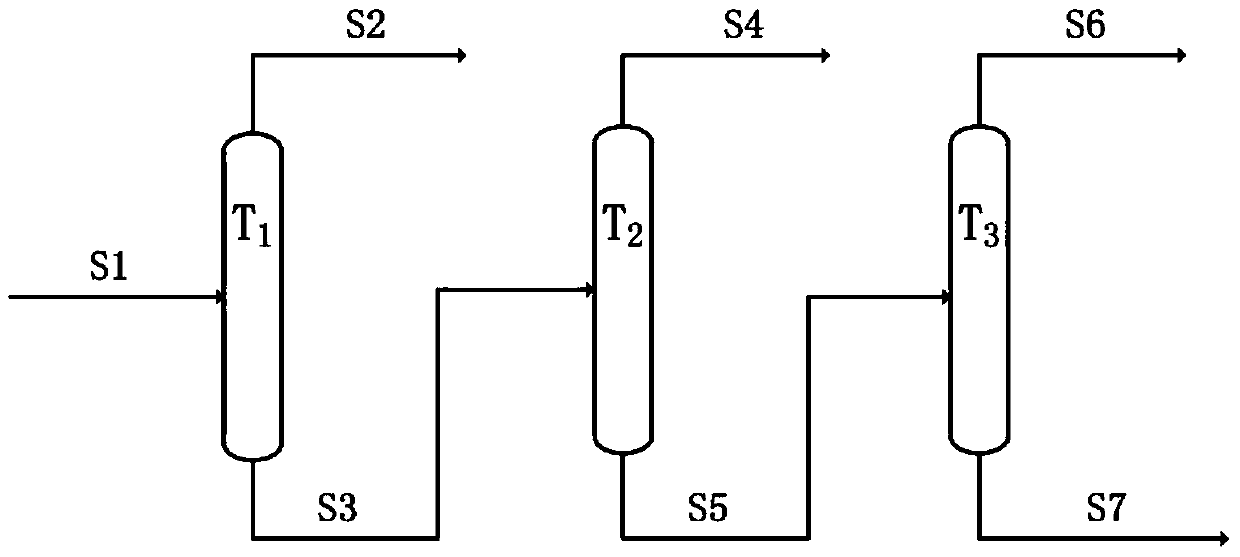

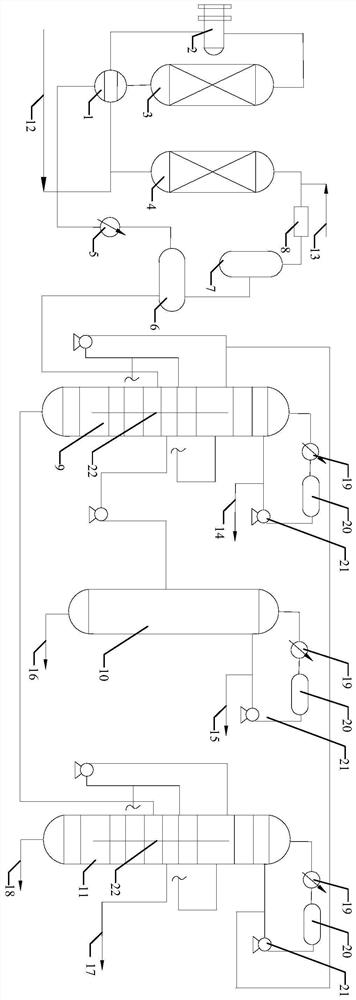

Separation method of multi-component aromatic hydrocarbons

ActiveCN106478338BReduce in quantityImprove utilization efficiencyDistillation purification/separationGas phaseReboiler

The invention relates to a benzene-toluene-xylene-heavy aromatics separating method. The method is characterized in that multiple components of benzene, toluene, xylene, C9 and heavy aromatics are introduced into a first rectifying tower, the rectifying tower kettle is heated, and a first product benzene is extracted from the top of the tower. Two gas phase material flows extracted from different positions at intermediate section of the first rectifying tower are respectively introduced into the bottom of a second rectifying tower and a third rectifying tower which have no arrangement of a reboiler, a second product toluene and a third product xylene are respectively extracted from the top of the tower, the liquid phase material flow at the bottom of the second rectifying tower and the third rectifying tower enables backflow into the first rectifying tower, and a fourth product heavy aromatics extracted from the bottom of the first rectifying tower. Compared with a traditional sequence separating technology, The method has the advantages of low investment and low energy consumption, and can be used for industrial separation of benzene-toluene-xylene-heavy aromatics.

Owner:CHINA PETROLEUM & CHEM CORP +1

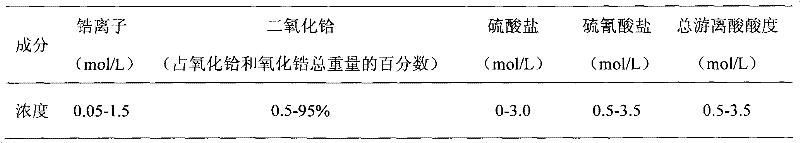

Method for separating zirconium from hafnium by using elution extraction method

ActiveCN102021335BHigh separation factorReduce consumptionProcess efficiency improvementLiquid waterSeparation coefficient

The invention discloses a method for separating zirconium from hafnium by using an elution extraction method, belonging to the technical field of zirconium and hafnium separation. The method comprises the following steps of: preparing liquid MIBK (Methyl Iso Butyl Ketone) into MIBK elution extraction resin; extracting hafnium with an extraction agent of MIBK; reserving hafnium in a material liquid water phase and precipitating water ammonia water; eluting the elution extraction resin with hydrochloric acid and desorbing the elution extraction resin with sulfuric acid solution to obtain a solution containing hafnium; precipitating with ammonia water; and respectively washing and roasting the precipitation to obtain zirconium oxide and hafnium oxide in atomic energy level. The process method has the advantages of less mass transfer, high extraction capacity, large zirconium and hafnium separation coefficient, simple process flow and less investment and is easy for operation; two qualified products can be obtained by one-time extraction; the equipment has high yield and the consumption of chemical materials is low. According to the invention, the concentration of the used thiocyanic acid is lower than that used by a liquid-liquid solvent extraction method; the equipment is easy to close; and the pollution of H2S, HCN and methyl mercaptan generated by decomposing the volatilized MIMK and HSCN to the environment can be greatly reduced.

Owner:有研资源环境技术研究院(北京)有限公司

Method for preparing m-dichlorobenzene by adopting microreactor

PendingCN112174772AEliminate backmixingHigh selectivityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsAcid catalyzedSulfonic acid

The invention discloses a method for preparing m-dichlorobenzene from o-dichlorobenzene in a microreactor by using a solid acid catalyst, the solid acid catalyst is a catalyst with sulfonate radicalsimmobilized on a carrier, and the carrier is fumed silica or mesoporous silica. The method is continuous in reaction, high in m-dichlorobenzene selectivity and easy in quality control.

Owner:江苏方圆芳纶研究院有限公司

Tubular continuous method for preparing cyclopropanecarboxylic acid

InactiveCN101693660BIncrease production capacityHigh yieldOxygen-containing compound preparationOrganic compound preparationContinuous reactorAutomatic control

Owner:ZHEJIANG UNIV +1

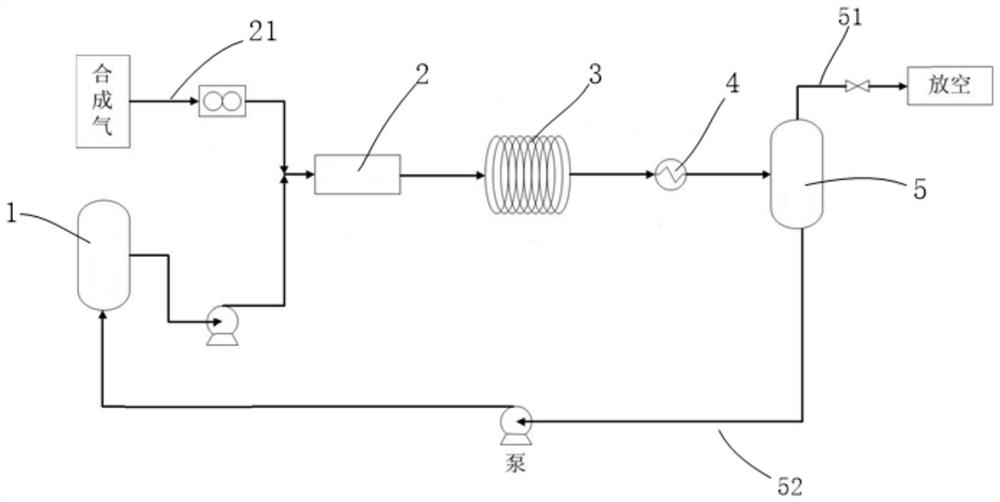

Method for synthesizing isononanal by using microchannel reaction device

PendingCN114100541AShort reaction timeImprove reaction efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsChemical/physical/physico-chemical microreactorsFluid phasePtru catalyst

The invention discloses a method for synthesizing isononanal by a microchannel reaction device, which belongs to the technical field of organic chemical industry, and comprises the following steps: preparing a rhodium catalyst, an organic phosphine ligand and diisobutylene mixture into a raw material solution; the synthesis gas and the raw material liquid are pumped into the micro-channel mixer at the same time to be prepared into mixed liquid. Feeding the mixed solution into a micro-channel reactor for reaction to obtain a crude product, cooling the crude product by a cooler, feeding the crude product into a separation tank, emptying a gas phase, conveying a liquid phase to a liquid phase tank through a liquid phase pump for circular reaction, and obtaining a product after target reaction retention time is reached. According to the invention, the micro-channel reactor is adopted to synthesize isononanal, and the liquid-phase circulating system is adopted to reduce the large gas-liquid ratio required by isononanal synthesis to 20: 1 or below, so that the gas-liquid mixing effect is ensured, the reaction system is stable, the preparation time is shortened, and the production cost is reduced. In addition, proper types and proportions of the rhodium catalyst, the organic phosphine ligand and the diisobutylene mixture are matched and selected, so that the conversion rate reaches 90% or above, and the selectivity of isononanal reaches 90% or above.

Owner:上海簇睿低碳能源技术有限公司

Float valve fixing column plate

Owner:NANJING UNIV

Boiling water control method capable of utilizing solar auxiliary heating and recycling heat energy

ActiveCN108195074AFit for drinkingReal-time monitoring of energy-saving effectsFluid heatersSolar heating energyThermal energyWater quality

The invention discloses a boiling water control method capable of utilizing solar auxiliary heating and recycling heat energy. A boiling water control device utilizing solar auxiliary heating and witha function of boiling water heat energy recycling is adopted for implementing boiling water control, solar heat collectors mounted on the top layer of a campus building are utilized for being combined with a heat exchange pipeline, an inner layer closed water storage box, an outer layer closed water storage box and an intelligent terminal, and multiple kinds of water are output so as to meet thedomestic water requirements of students; a temperature sensor is arranged at a water outlet end so as to monitor the temperature of the water outlet end in real time, boiling water heat energy recycling is achieved, and then energy saving and flow matching are achieved; meanwhile, pressure sensors are arranged to monitor pressure in real time, and reference bases are provided for subsequent equipment maintenance; the advantages of environment protection, energy saving, high efficiency, convenience, rapidness and energy circulation are achieved; the performance is excellent; the water saving effect is remarkable; and the application prospects are wide.

Owner:SUZHOU SABO IND DESIGN

Down pipe type catalytic cracking method and apparatus

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

System and method for monitoring municipal saprobia inhibitive ability in real time based on oxygen uptake rate (OUR)

ActiveCN102520016BGuaranteed to be airtightEliminate distracting factorsMaterial analysis by electric/magnetic meansSiphonProgrammable logic controller

Owner:TSINGHUA UNIV +1

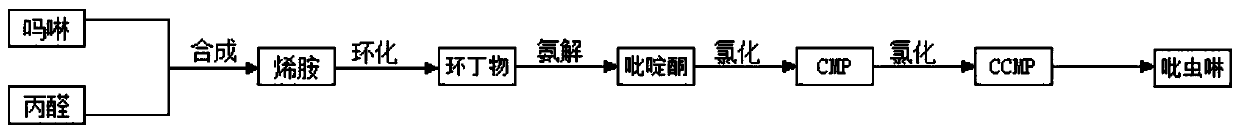

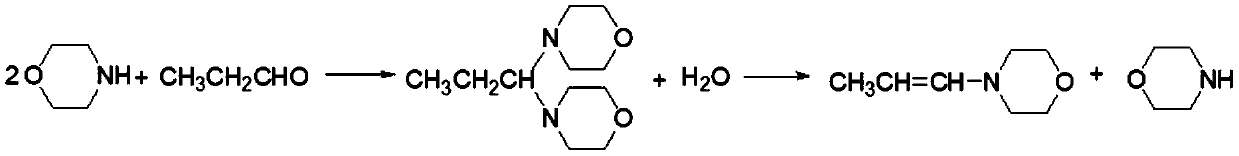

Method for synthesizing imidacloprid intermediate morpholinyl propylene by micro-channel reactor

The invention discloses a method for synthesizing enamine by adopting a micro-channel reactor. The method comprises the following steps: simultaneously pumping morpholine and n-propionaldehyde into the micro-channel reactor according to a molar ratio of (2.0-10.0): 1, and reacting at a certain reaction temperature under a certain reaction pressure for a certain reaction time; and then carrying outheat preservation, negative-pressure dehydration and negative-pressure rectification to obtain an enamine finished product. The invention also provides a production method of imidacloprid. The production method comprises the following steps: cyclizing enamine to prepare a cyclobutyl compound, and carrying out ammonolysis on the cyclobutyl compound to prepare pyridone; carrying out chlorine addition and phosgene chlorination on pyridone to prepare 2-chloro-5-methylpyridine; carrying out chlorination on the 2-chloro-5-methylpyridine by using chlorine gas to synthesize 2-chloro-5-chloromethylpyridine; and synthesizing imidacloprid from a 1, 2-chloro-5-chloromethylpyridine / N, N-dimethylformamide solution and imidazolidine.

Owner:JIANGSU YANGNONG CHEM GROUP +3

Method and device for separating surfactant from dilute solution

InactiveCN101716464BReduce pollutionExtended service lifeSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisConcentration polarizationCoupling

The invention discloses a method and a device for separating surfactant from dilute solution. A raw material tank filled with dilute solution containing surfactant is connected from the bottom of a vertically arranged tubular membrane module via a solution pump, a first valve and a liquid flowmeter; a compressor is also connected from the bottom of the vertically arranged tubular membrane module via a second valve and a gas flowmeter; the top part of the vertically arranged tubular membrane module is connected to a foam collecting groove via a third valve; the middle part of the vertically arranged tubular membrane module is connected with a liquid storage tank. The adoption of the membrane and foam separation inner coupling method can reduce the concentration polarization of the membranesurface effectively, reduce membrane pollution, prolong the service life of the membrane, and simultaneously can eliminate back mixing phenomenon in the membrane and foam separation process, improve mass transfer rate of membrane and foam separation, and achieve separation efficiency. The rejection of the surfactant is 64.9% to 99.9%, thus saving more energy.

Owner:ZHEJIANG UNIV

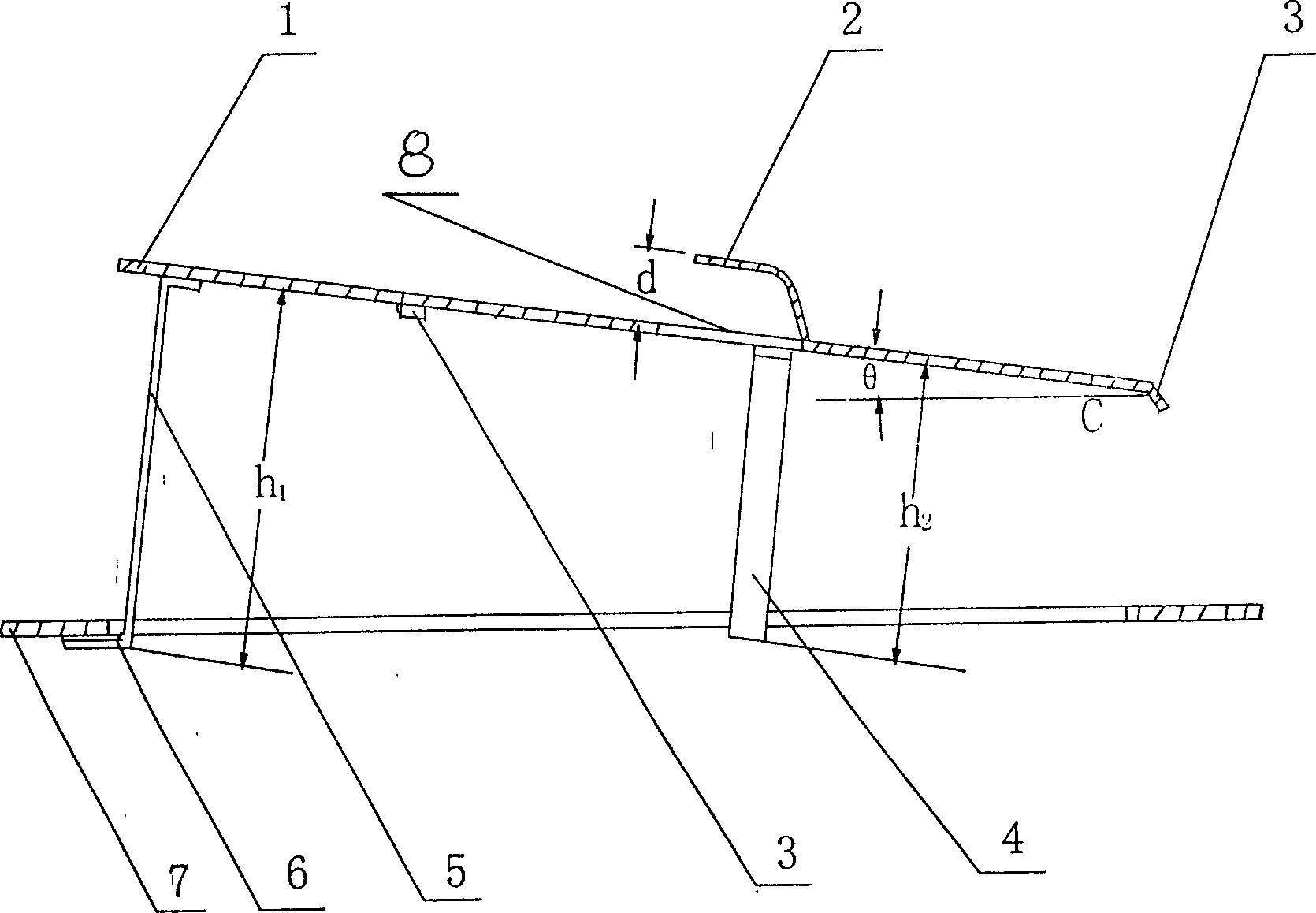

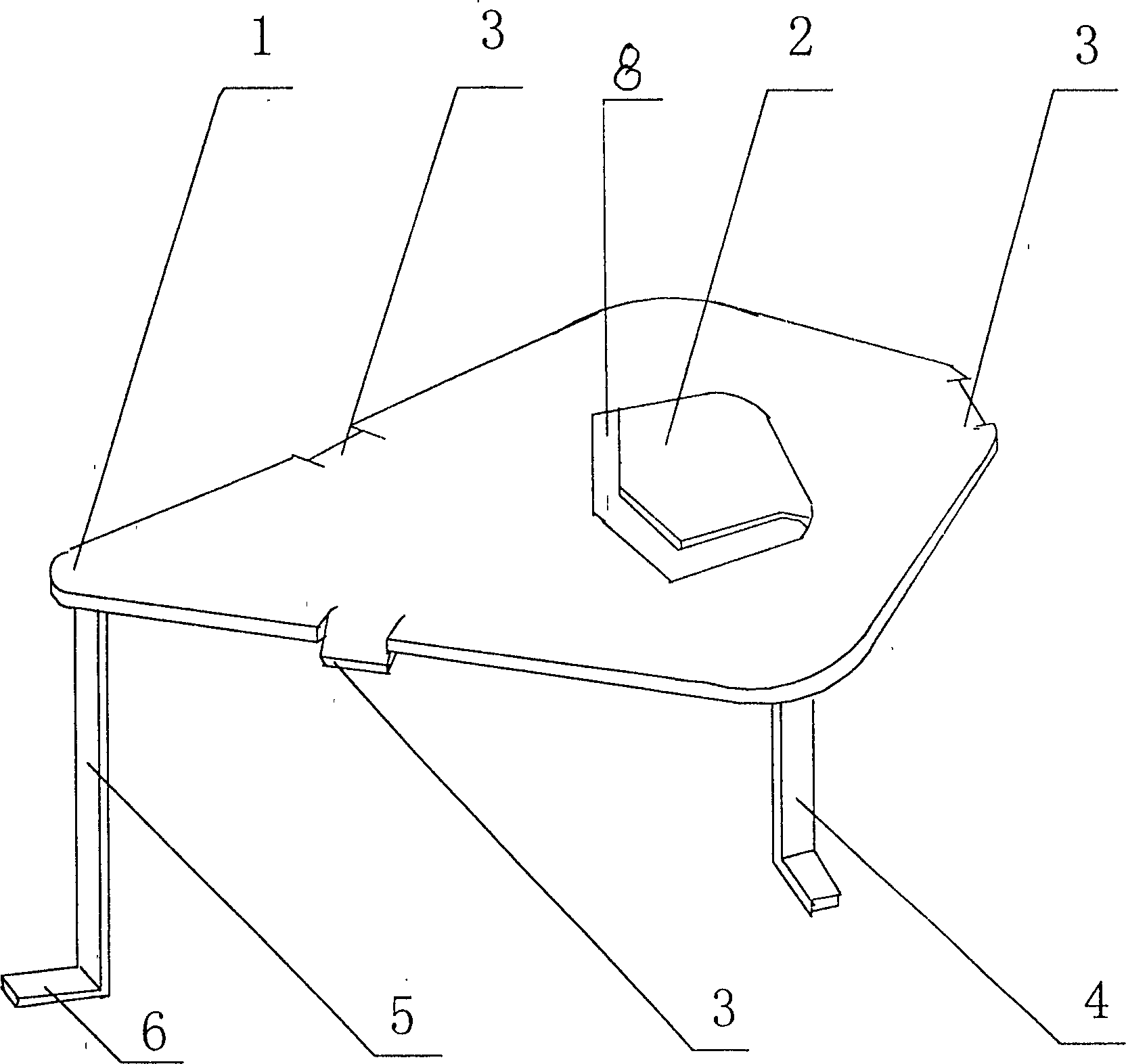

Guide float valve tray

InactiveCN1155430CReduce resistanceLittle reverse propulsionFractional distillationFloat ValueLeg length

The present invention relates to a guide float valve plate which comprises a guide float valve which is a symmetrical quadrangular guide float valve, its valve cover is a quadrangular from with symmetrical diagonal liens, the included angle of long edges is directed against overflow weir, under the valve cover more than three valve legs are mouthed, front valve leg length is longer than rear valve leg length, so that when the float value is completely opened, between valve cover and valve hole plate an included angle toward overflow weir is opened, said included angle is 2-10 deg, and on the valve cover can be mounted the guide hole and guide plate. Said invention can effectively reduce liquid level gradient on the plate, raise plate flux, raise mass transfer efficiency and reduce resistance of plate.

Owner:NANJING UNIV

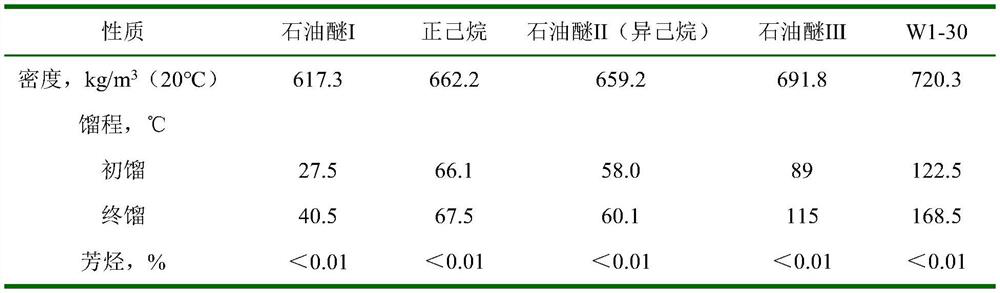

Fine processing method of crude hexane

ActiveCN112403013AGood activity at low temperatureImprove stabilityTreatment with hydrotreatment processesFractional distillationPtru catalystUnsaturated hydrocarbon

The invention relates to a fine processing method of crude hexane, which comprises the following steps of: fully mixing the raw material crude hexane with hydrogen, carrying out heat exchange with thereaction product, heating to 130-190 DEG C by a heat exchanger, introducing the mixture into a catalyst-loaded hydrogenation reactor, and carrying out hydrofining reaction under the action of a hydrofining catalyst to remove aromatic hydrocarbons and unsaturated hydrocarbons in the raw material; carrying out gas-liquid separation on a product after reaction through a low-pressure separator, and then feeding the product into a fractionation system for fine cutting; enabling the reaction product to firstly enter a first partition plate tower of the fractionation system to be separated, discharging a petroleum ether I product from the tower top, discharging mixed C6 from the side line, and then enabling the mixed C6 to enter an n-hexane removal tower to be further cut to obtain petroleum ether II and n-hexane products; and conveying a tower bottom product of the first partition plate tower to a second partition plate tower to be separated to obtain petroleum ether III and W1-30 products.The method has the advantages that a high-quality hexane product can be obtained, the byproduct utilization rate is increased, and the economic benefit is improved.

Owner:洛阳金达石化有限责任公司

Gas-solid contact equipment for fluidized bed

ActiveCN101879432BImprove efficiencySimple structureCatalyst regeneration/reactivationChemical/physical/physico-chemical processesGas solidFluidized bed

The invention discloses gas-solid contact equipment for a fluidized bed, which is used for catalytic conversion devices in petroleum refining, petrochemical industry and other industries so as to solve the problems of non-flowing region, local slugging of gas or local solid bridging and the like which are easy to generate respectively when the conventional contact equipment is provided with a corresponding tray-type inner component or a filler, and the problems that the inner component or filler is difficult to install, overhaul and maintain. The contact equipment is at least provided with two groups of fillers (1) along the axial direction of a cylinder body (4), and a space is reserved between the two groups of fillers; each group of filler consists of a plurality of filler layers whichare overlapped along the vertical direction, each filler layer is provided with a vertical hexagonal channel formed by strip plates, and the cross section shape of the hexagonal channel is a regular hexagon shape; and in each group of filler, the hexagonal channels on two adjacent filler layers are alternately arranged. The equipment can be used as a stripper to strip oil gas, hydrocarbon or gas impurities carried in the catalyst, and also can be used as a regenerator to regenerate the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing m-dichlorobenzene by adopting microreactor

InactiveCN112142554AHigh selectivityIncrease contentOrganic-compounds/hydrides/coordination-complexes catalystsChemical/physical/physico-chemical microreactorsPtru catalystM-dichlorobenzene

The invention discloses a method for preparing m-dichlorobenzene from p-dichlorobenzene in a microreactor by using a solid acid catalyst, wherein the solid acid catalyst is a catalyst in which sulfonate radicals are immobilized on a carrier, and the carrier is fumed silica or mesoporous silica. The method is continuous in reaction, high in m-dichlorobenzene selectivity and easy in quality control.

Owner:江苏方圆芳纶研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com