Swirling-flow float valve tower plate

A float valve tray and float valve technology, which is applied in the fields of purification, rectification and absorption, can solve the problems that the float valve tray is easy to block, there is a liquid stagnation area, and the gas distribution is uneven, so as to improve the flux and efficiency , reduce the liquid surface gradient, reduce the effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

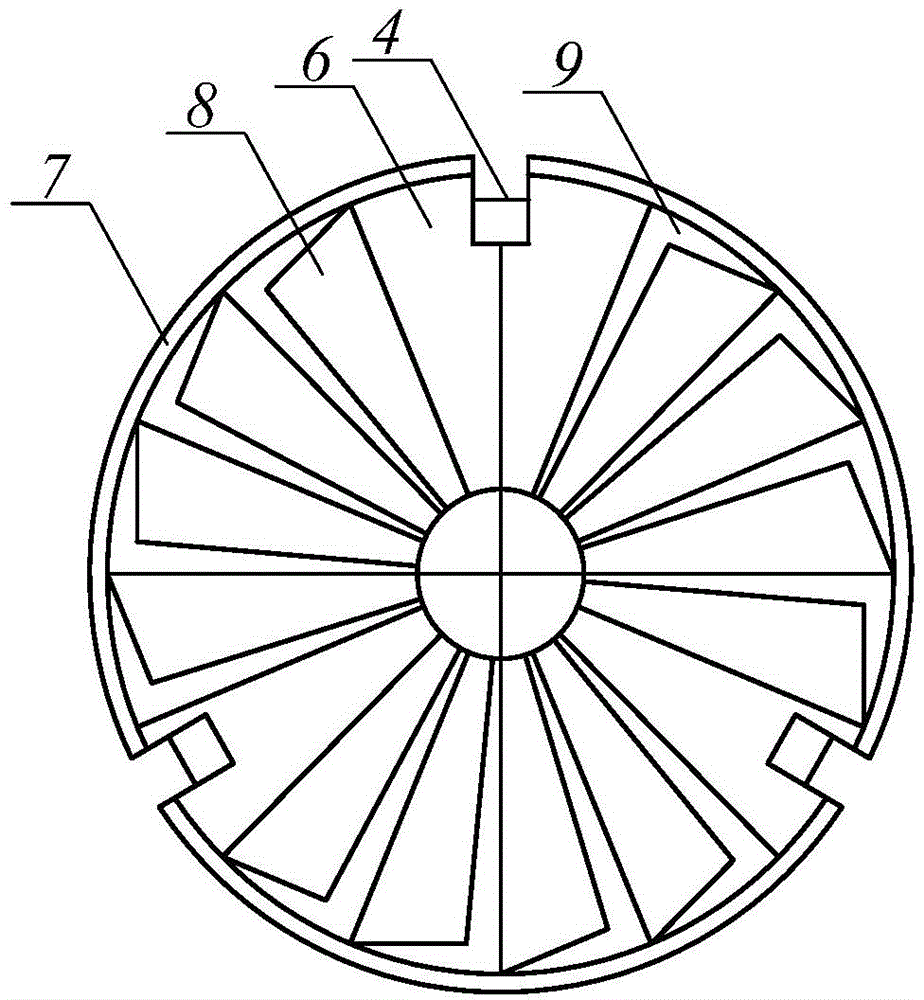

[0031] Such as Figure 1-3 As shown, the swirl valve tray of the present invention is made up of a tray (1), a swirl valve (2), and a valve hole (3); the tray (1) is punched with a valve hole (3) , the swirl float valve (2) is installed on the valve hole (3); the swirl sheet (7) is installed on the valve face (6) of the swirl float valve (2); there are valve legs (4) and The valve foot (5), the valve foot (5) is connected to the valve face (6) through the valve leg (4).

[0032] Composition of shift gas (vol%): CO 2 is 43.5, CO is 0.323, H 2 55.23, H 2 S is 0.188, HCN is 0.002, N 2 is 0.757; the temperature of the absorption tower is -40~-60°C, the pressure is 2.4MPa, and the gas-liquid ratio is 0.565m 3 (synthesis gas): 1kg (methanol)

[0033] For the swirl float valve, the number of swirl sheets on the valve surface (6) is 4 pieces; there is an included angle between the valve surface and the valve hole is α=30°; there are three valve legs under the valve surface, and ...

Embodiment 2

[0035] According to the conditions and steps described in Example 1, for the swirl valve tray, the number of swirl sheets on the valve surface (6) is 20; there is an included angle between the valve surface and the valve hole as α= 60°; there are three valve legs under the valve surface, and the height of the valve legs is h=40mm. The valve surface (6) is circular, the swirl sheet (8) and the valve hole (9) are fan-shaped, and the swirl float valve (2) is a floating type. The total sulfur of the purified syngas is less than lppm, CO 2 Less than 20ppm meets the technological requirements of the subsequent synthesis unit for the synthesis gas purification index.

Embodiment 3

[0037] According to the conditions and steps described in Example 1, for the swirl valve tray, the number of swirl sheets on the valve surface (6) is 12; there is an included angle between the valve surface and the valve hole as α= 45°; there are three valve legs under the valve surface, and the height of the valve legs is h=10mm. The valve surface (6) is circular, the swirl sheet (8) and the valve hole (9) are fan-shaped, and the swirl float valve (2) is fixed. The total sulfur of the purified syngas is less than lppm, CO 2 Less than 20ppm meets the technological requirements of the subsequent synthesis unit for the synthesis gas purification index.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com