Separation method of multi-component aromatic hydrocarbons

A separation method and multi-component technology, applied in the field of separation of multi-component aromatic hydrocarbon raw materials, can solve the problem that polyester PTA cannot meet market needs, save equipment cost and floor space, eliminate back-mixing, and simplify long processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

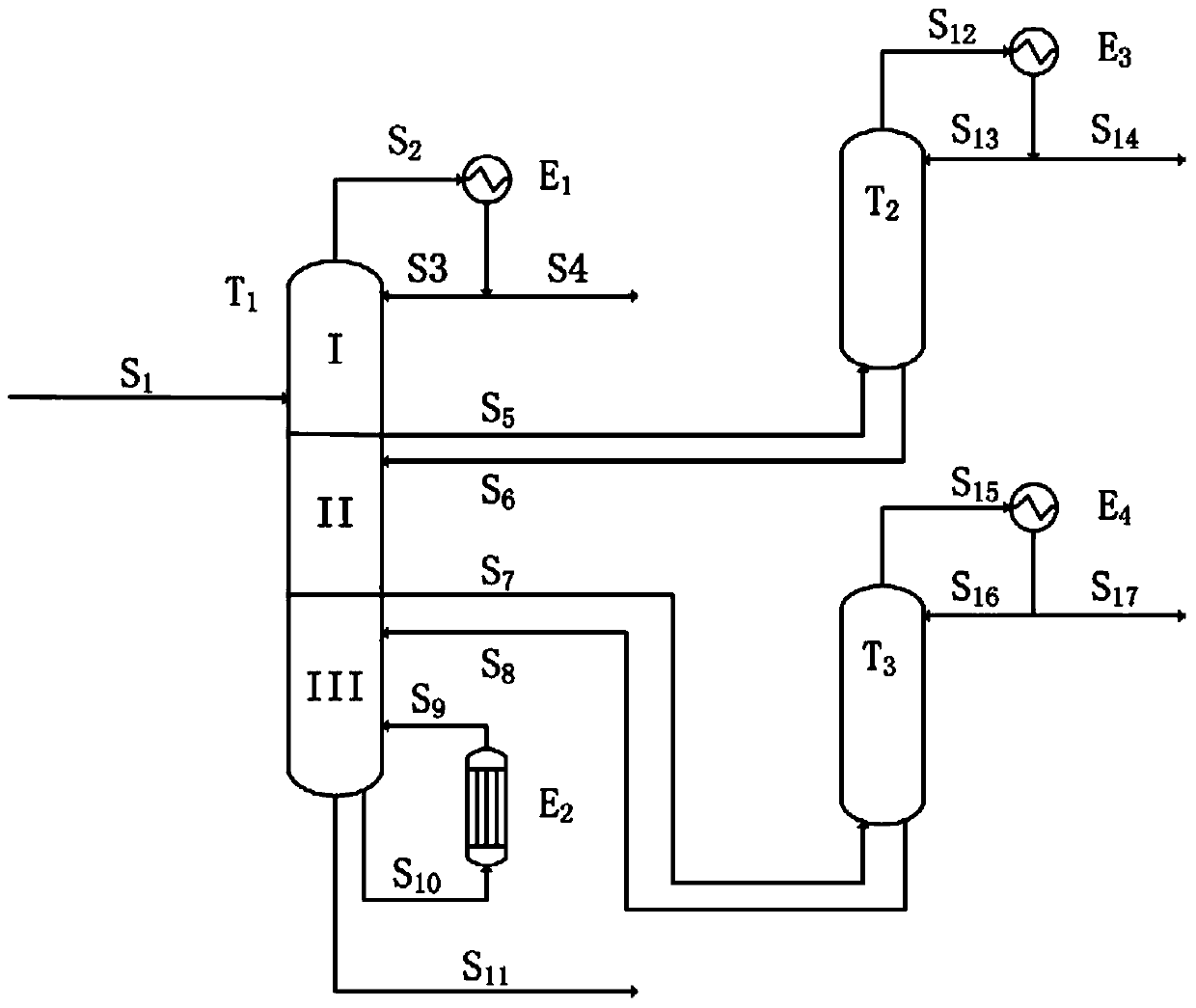

[0035] Combine below figure 1 Example 1 will be described.

[0036] Taking the separation of aromatics in the disproportionation unit as an example, the process flow is as follows figure 1 As shown, the raw material stream (S 1 ) flow rate is 1000kg / h, which contains 10% benzene, 35% toluene, 30% xylene, and 25% heavy aromatics. place. The number of theoretical plates of the first rectifying column is 100, the pressure at the top of the column is 150KPa, and the temperature at the top of the column is 89°C. The benzene component in the raw material is purified in the first rectifying tower I zone, and is extracted from the top of the tower to obtain the first product stream (S 4 ), wherein the benzene content is 0.999. The first sideline production stream (S 5 ) is the 60th theoretical plate, enters the bottom of the second rectifying tower, the stream temperature is 145°C, and the pressure is 180KPa. The number of theoretical plates of the second rectifying tower is 5,...

Embodiment 2

[0044] Combine below figure 1 Example 2 will be described.

[0045] Taking the separation of aromatics in the disproportionation unit as an example, the process flow is as follows figure 1 As shown, the raw material stream (S 1 ) flow rate is 800kg / h, which contains 10% benzene, 35% toluene, 30% xylene, and 25% heavy aromatics. place. The number of theoretical plates of the first rectifying column is 80, the pressure at the top of the column is 150KPa, and the temperature at the top of the column is 89°C. The benzene component in the raw material is purified in the first rectifying tower I zone, and is extracted from the top of the tower to obtain the first product stream (S 4 ), wherein the benzene content is 0.999. The first sideline production stream (S 5 ) is the 55th theoretical plate, enters the bottom of the second rectifying tower, the stream temperature is 149°C, and the pressure is 178KPa. The number of theoretical plates of the second rectifying tower is 15, ...

Embodiment 3

[0053] Combine below figure 1 Example 3 will be described.

[0054] Taking the separation of aromatics in the disproportionation unit as an example, the process flow is as follows figure 1 As shown, the raw material stream (S 1 ) flow rate is 1000kg / h, which contains 15% benzene, 30% toluene, 25% xylene, and 30% heavy aromatics. place. The number of theoretical plates of the first rectifying column is 80, the pressure at the top of the column is 150KPa, and the temperature at the top of the column is 89°C. The benzene component in the raw material is purified in the first rectifying tower I zone, and is extracted from the top of the tower to obtain the first product stream (S 4 ), wherein the benzene content is 0.999. The first sideline production stream (S 5 ) is the 50th theoretical plate, enters the bottom of the second rectifying tower, the stream temperature is 152°C, and the pressure is 175KPa. The number of theoretical plates of the second rectifying tower is 30,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com