Preparation method of polyolefin nanometer composite material

A nano-composite material and polyolefin technology, applied in the field of preparation of polyolefin nano-composite materials, can solve the problems of low preparation efficiency, large amount of ash, restricting the performance of materials, etc., and achieve the effect of uniform dispersion of nano-fillers and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of polyolefin nanocomposite material, comprises the steps:

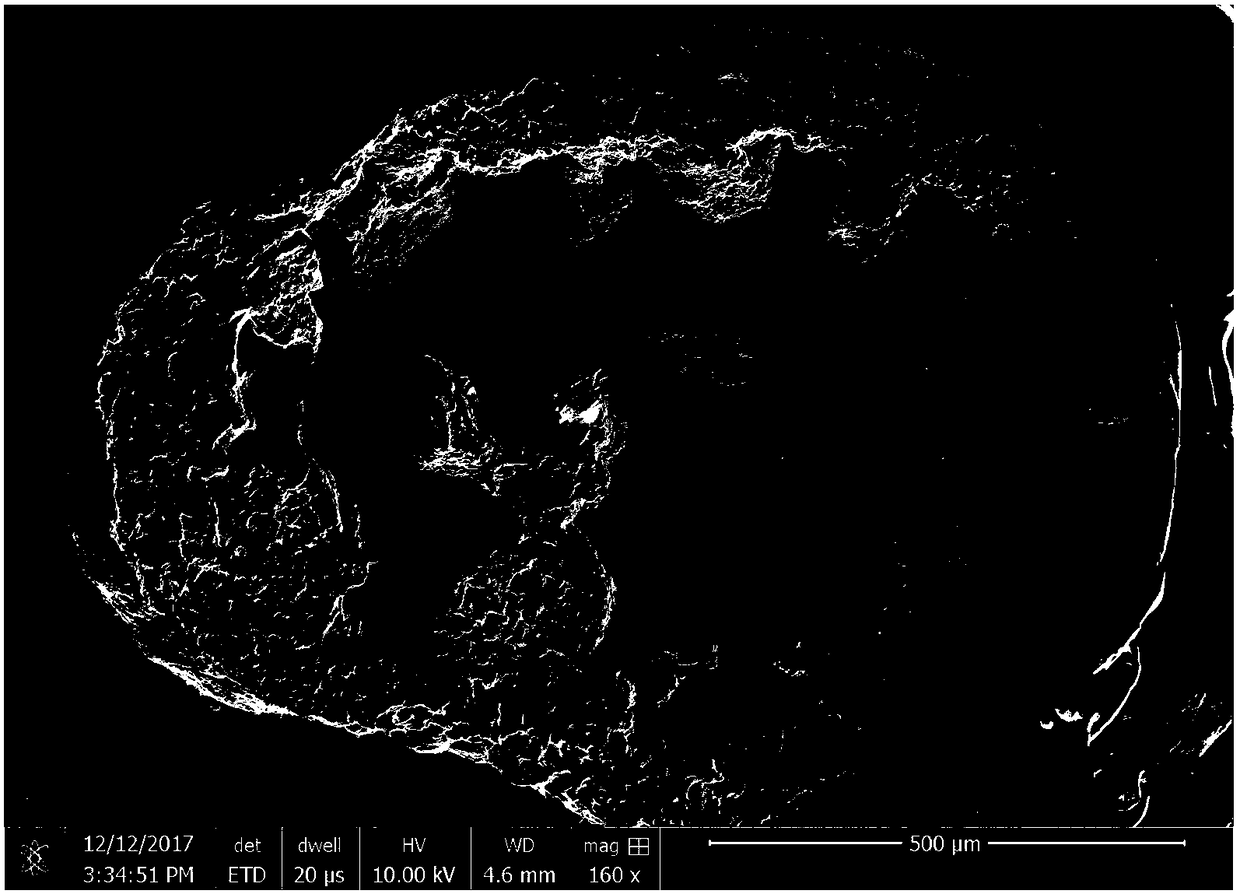

[0027] (1) Provide 10g of polyethylene particles with a pore volume of 1.5mL / g, and the porous structure inside the primary particles is as follows: figure 1 Shown; (2) 7.125g TiCl 4 After mixing with 10mL of toluene, add polyethylene particles in step (1) and impregnate for 108h to obtain TiCl 4 / mixed solution of polyethylene particles / toluene; (3) TiCl 4 The mixed solution of polyethylene particles / toluene was frozen with liquid nitrogen, and then vacuum-dried. After the mixed solution was thawed, it was frozen again with liquid nitrogen and dried slowly, and the dried particles were obtained in a cycle of 20 times; (4) 100mL concentration The hydrochloric acid / ethanol solution that is 2mol / L steams in the dry granule gained in the step (3) in the form of steam, and steam enters speed 0.1mL / min, obtains the granule after steam fumigation; (5) the granule after steam fumigation Wash...

Embodiment 2

[0029] The preparation method of polyolefin nanocomposite material, comprises the steps:

[0030] (1) Provide 10g of polyethylene particles with a pore volume of 1.5mL / g, and the porous structure inside the primary particles is as follows: figure 1 Shown; (2) 2.375g TiCl 4 After mixing with 5mL of toluene, add polyethylene particles in step (1) and impregnate for 24h to obtain TiCl 4 / mixed solution of polyethylene particles / toluene; (3) TiCl 4 The mixed solution of polyethylene particles / toluene was frozen with liquid nitrogen, and then vacuum-dried. After the mixed solution was thawed, it was frozen again with liquid nitrogen and dried slowly, and the dried particles were obtained in a cycle of 5 times; (4) 100mL concentration The hydrochloric acid / ethanol solution that is 0.1mol / L is steamed in the dry particle gained in the step (3) in the form of steam, and steam enters speed 0.1mL / min, obtains the particle after steam fumigation; (5) the particle after steam fumigation...

Embodiment 3

[0032] The preparation method of polyolefin nanocomposite material, comprises the steps:

[0033] (1) 10 g of polypropylene particles with a pore volume of 0.01 mL / g are provided; (2) 4.0 g of TiCl 3 After mixing with 0.1mL tetrahydrofuran, add polypropylene particles in step (1) and impregnate for 76h to obtain TiCl 3 / The mixed solution of polypropylene particles / tetrahydrofuran; (3) TiCl 3The mixed solution of polypropylene particles / tetrahydrofuran was frozen with liquid nitrogen, and then vacuum-dried. After the mixed solution was thawed, it was frozen again with liquid nitrogen and dried slowly. The cycle was 7 times to obtain dry particles; (4) 10 mL concentration The hydrochloric acid / ethanol solution that is 20mol / L steams in the dry granule gained in the step (3) in the form of steam, and steam enters speed 10mL / min, obtains the granule after steam fumigation; (5) the granule after steam fumigation is water Washing 3 times, fully drying, to obtain solid particles; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com