Control device of full-load supercritical water-cooled wall

A control device and water-cooled wall technology, applied in control systems, steam separation devices, components of steam boilers, etc., can solve the deviation of denitration device, the fatigue failure of water-cooled wall inner threaded pipes, and the inability to adapt to grid-connected, low-coal consumption, and deep peak regulation. need to wait

Inactive Publication Date: 2020-08-28

上海皖祥商务咨询有限公司

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Deep low-load and frequent load-changing operation modes seriously deteriorate the coal consumption index of comprehensive power supply, boiler water wall fatigue failure occurs from time to time, denitrification devices often deviate from the optimal working condition or even quit, and the quality of primary frequency regulation is often evaluated due to the decline, even due to the lowest load Safety and passive selection of start-stop peak shaving

In short, the current super (ultra)critical DC units cannot meet the needs of grid-connected low coal consumption and deep peak regulation

[0005] At present, the internal thread technology of the water wall, the orifice ring technology of the water wall, and the forced recirculation technology are adopted, so that the load adaptability has been lowered to a certain extent, and at the same time, the blockage of foreign matter in the orifice ring of the water wall and the fatigue of the internal thread pipe of the water wall are accompanied. failure, adding forced circulation pumps, etc., but they do not change the status quo of the subcritical operation of the lower-load water-cooled wall, which are essentially reformist methods

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0053] The present invention specifically proposes a full-load supercritical water-cooled wall control device and its principle for the first time, which requires secondary design in combination with the boundary conditions of specific units. There are no application examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A direct-current unit is the main power of coal electricity, a power supply coal consumption index of the direct-current unit is worsened due to peak regulation operation, metal fatigue failure occursfrom time to time, a denitration device deviates from the optimal working condition and even exits, primary frequency modulation quality is lowered and is checked frequently, and even start-stop peakregulation is selected passively due to lowest load safety. The invention deeply analyzes the functional basis of a water-cooled wall, and determines that the problem root is the subcritical workingcondition of the once-through boiler water-cooled wall, which is not changed in the existing improvement measures, so that a full-load supercritical water-cooled wall control device model is provided,a special throttling assembly composition and secondary design boundary conditions are formulated, the water-cooled wall and a superheater can be reliably isolated, a steam-water phase change position can be fixed, the coal-water deep correlation can be decoupled, a set of novel control strategy is provided, and the creativity provides a root treating scheme for the problem so as to fully adapt to the low-coal-consumption deep peak regulation requirement. A control device is specially applied to flexibility transformation of a supercritical once-through boiler or newly-built coal-electricityengineering design, and breaks through the limit bottleneck for coal-electricity deep regenerative transformation.

Description

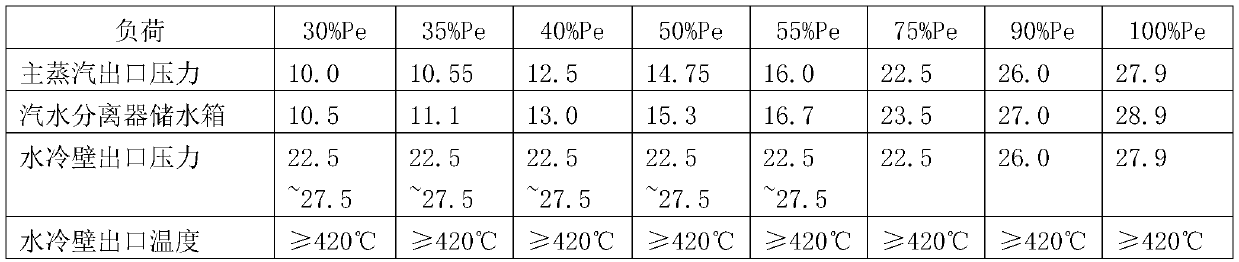

technical field [0001] The invention belongs to the field of thermal power generation, and in particular relates to a full-load supercritical water-cooled wall control device and its functional mechanism, which are mainly used in the transformation and new establishment of super (super) critical once-through boilers. Background technique [0002] The underlying logic of coal-fired power generation is the Carnot / Rankine cycle theory. In order to pursue higher thermal power conversion efficiency, the initial parameters of the steam entering the heat engine continue to increase. Drum boilers are no longer applicable, and once-through boilers are produced accordingly. The advantages of once-through boilers are less steel consumption, fast start-up speed, higher steam parameters, etc. With the use and promotion of super (super) critical once-through boilers, the power supply efficiency of units has generally improved, and the coal consumption of comprehensive power supply is basic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F22B35/12F22B37/26F22B37/44F23M5/08

CPCF22B35/12F22B37/26F22B37/446F23M5/08

Inventor 吴昊周福久

Owner 上海皖祥商务咨询有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com