Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Avoid light absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

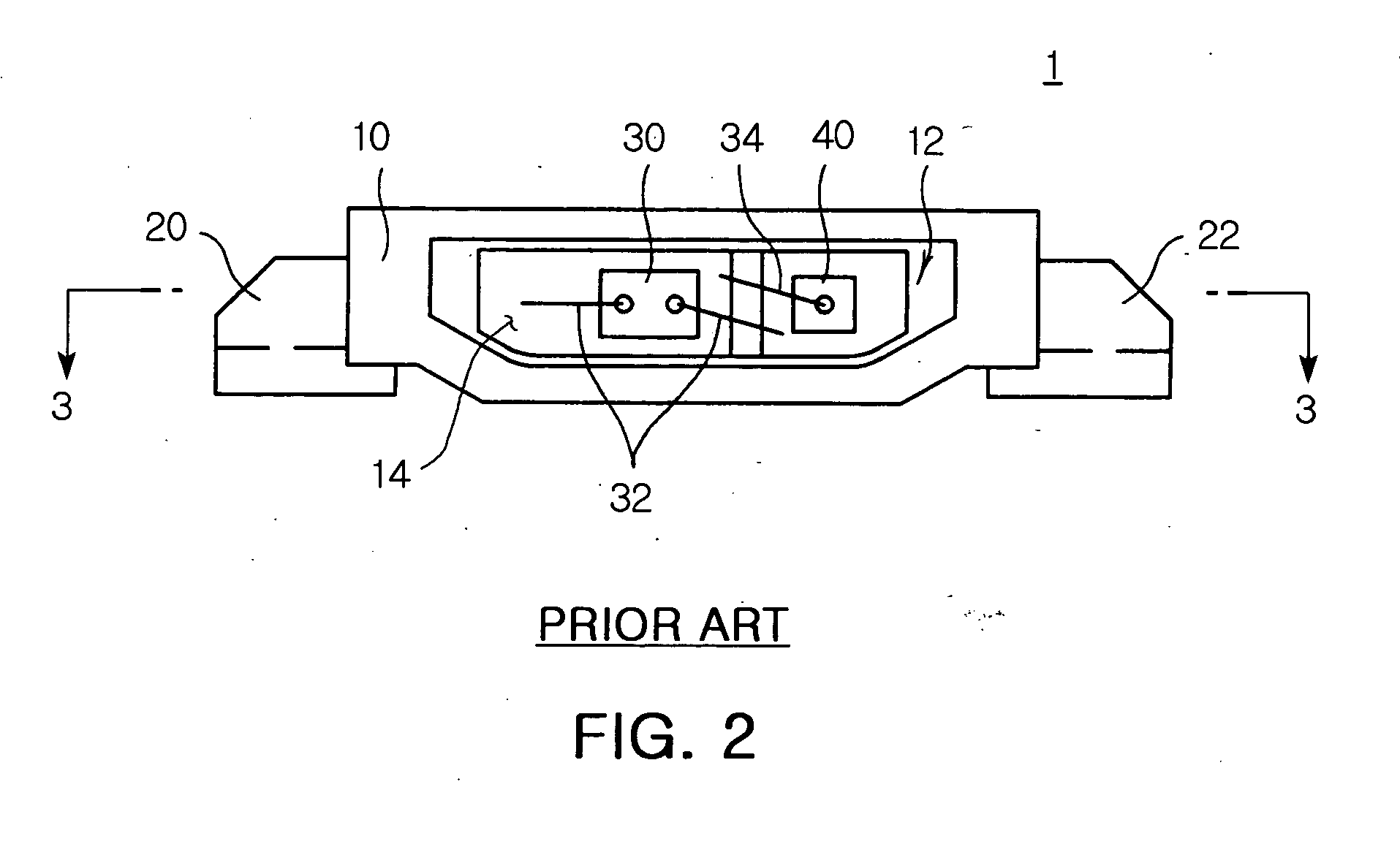

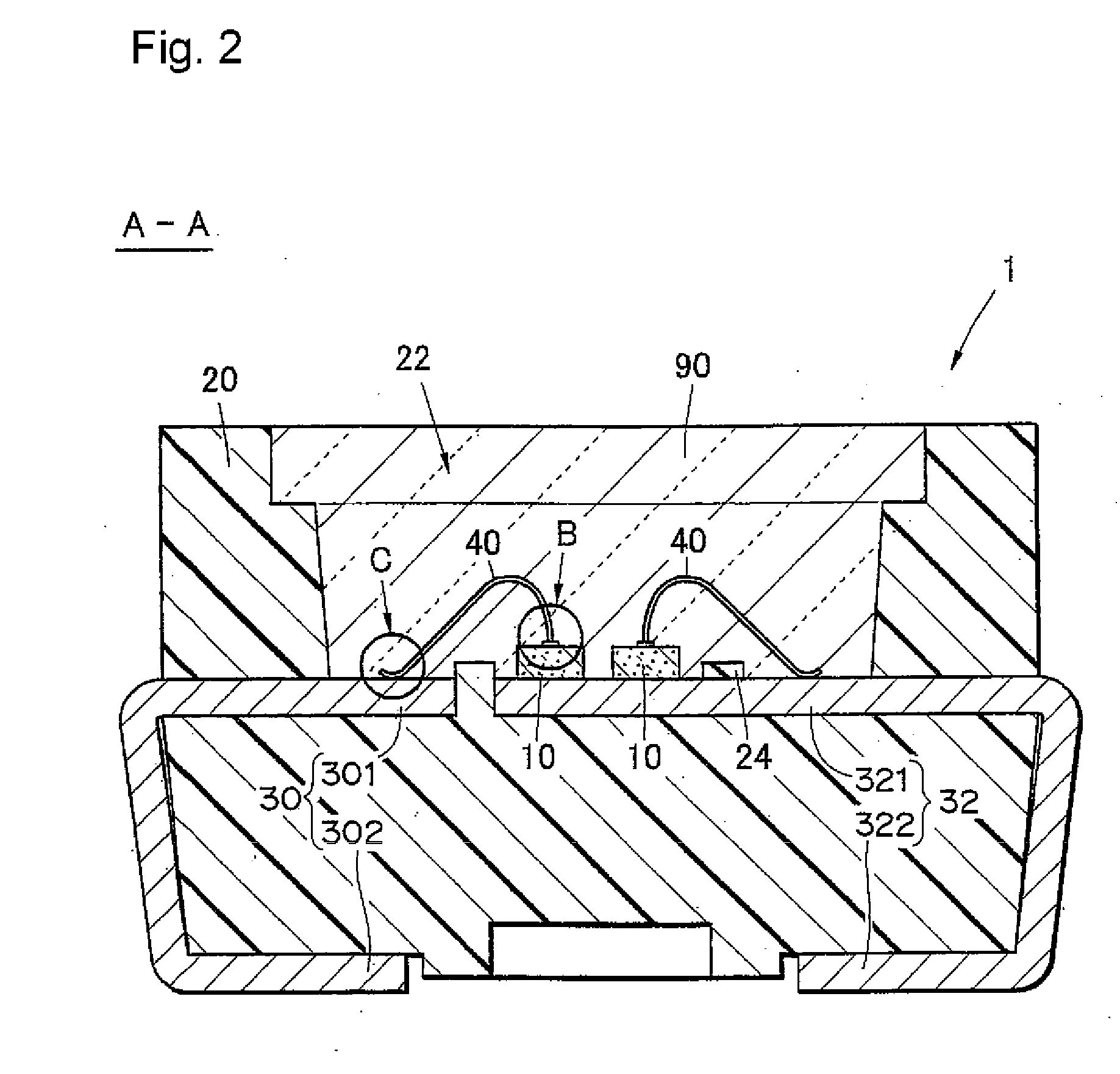

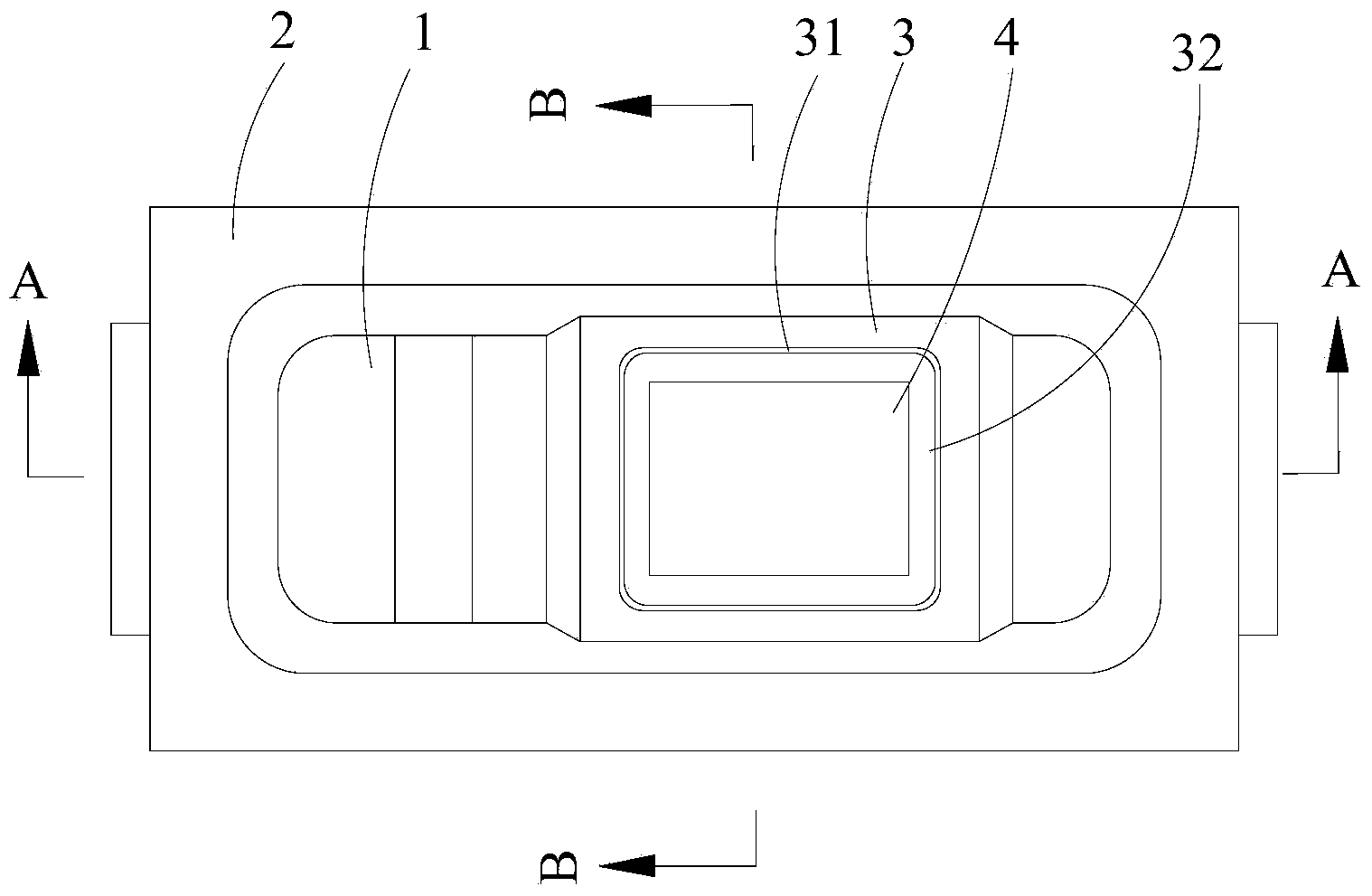

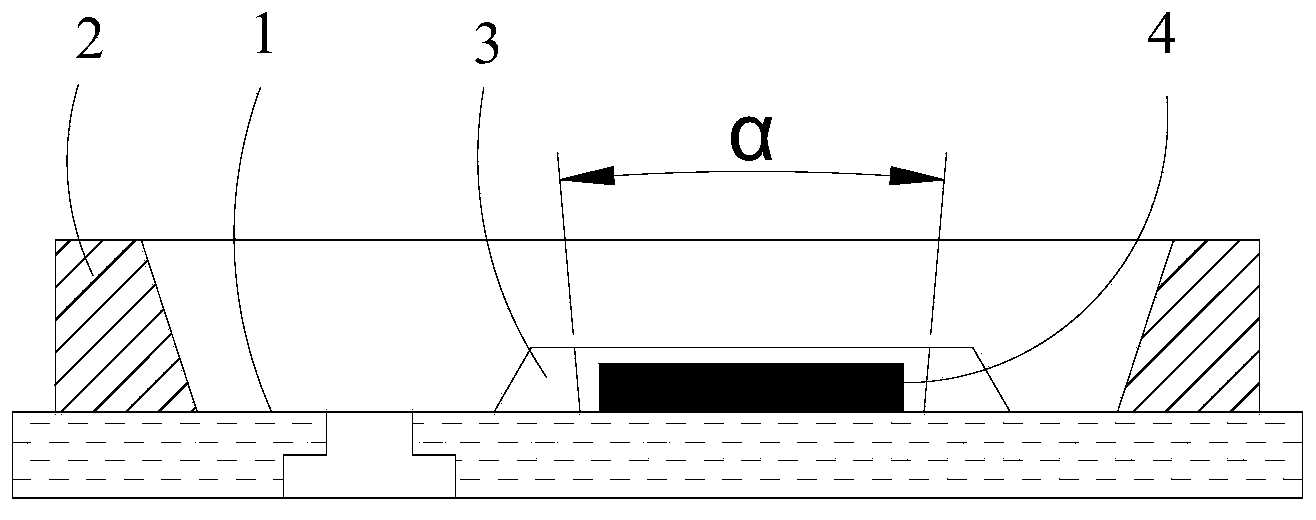

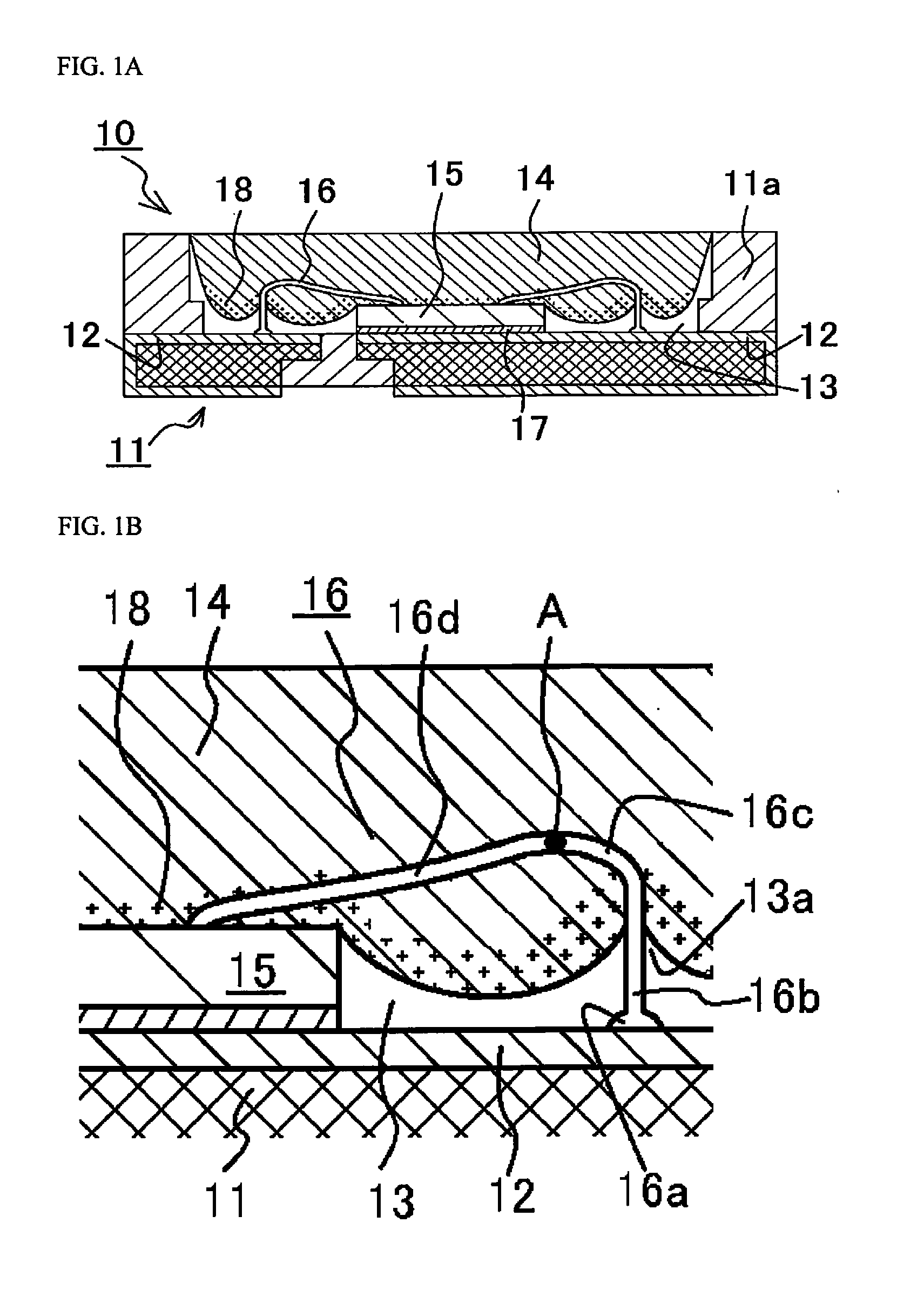

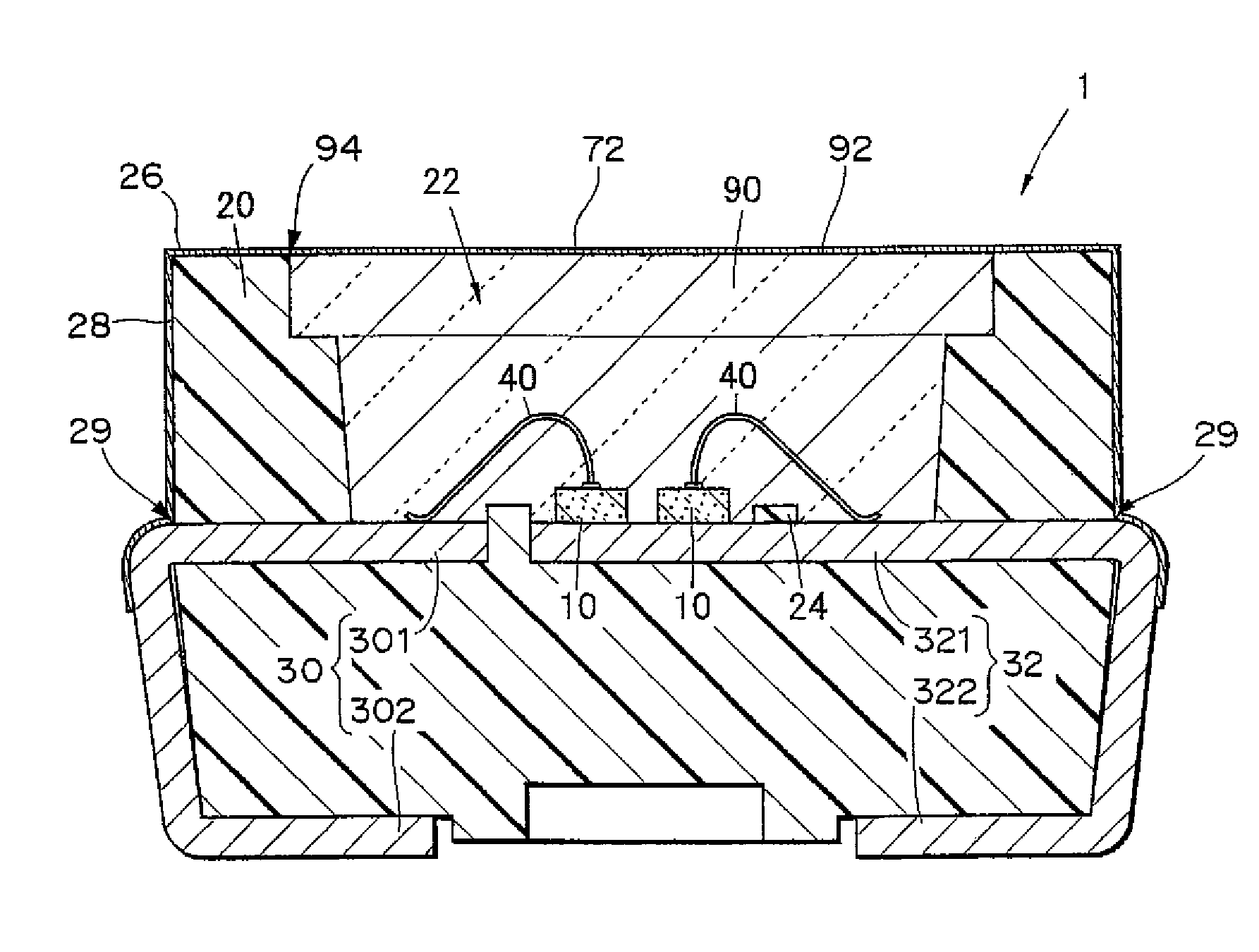

Side-view light emitting diode having protective device

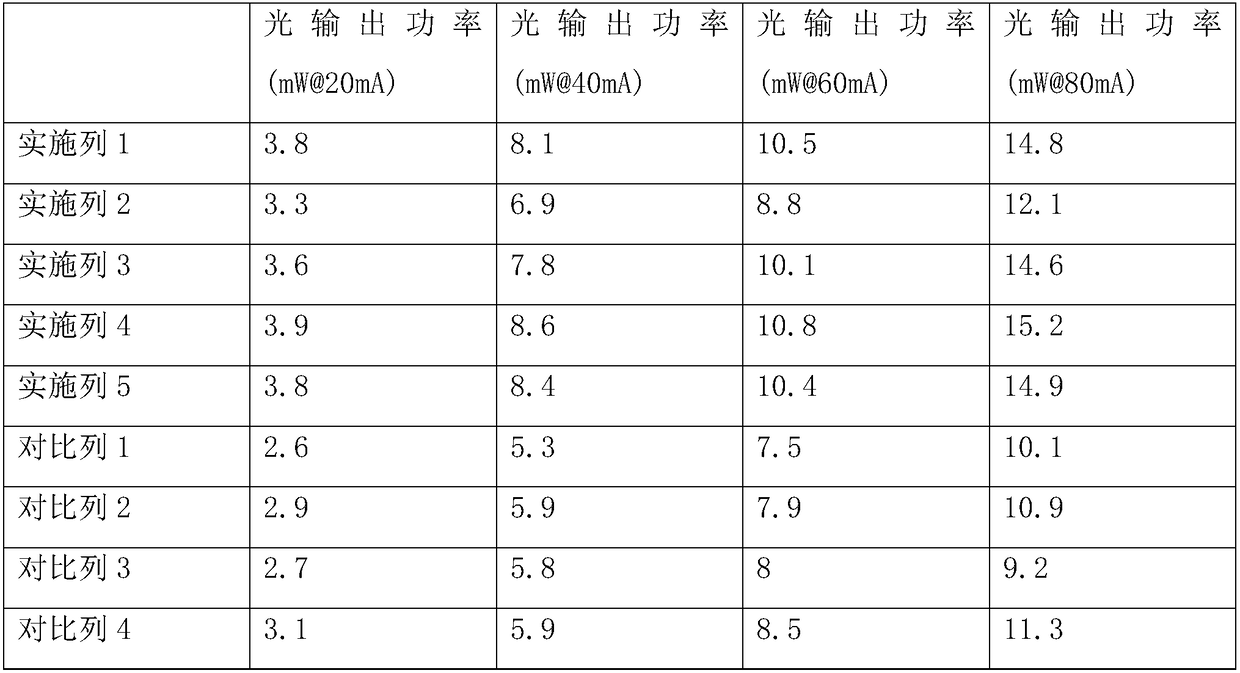

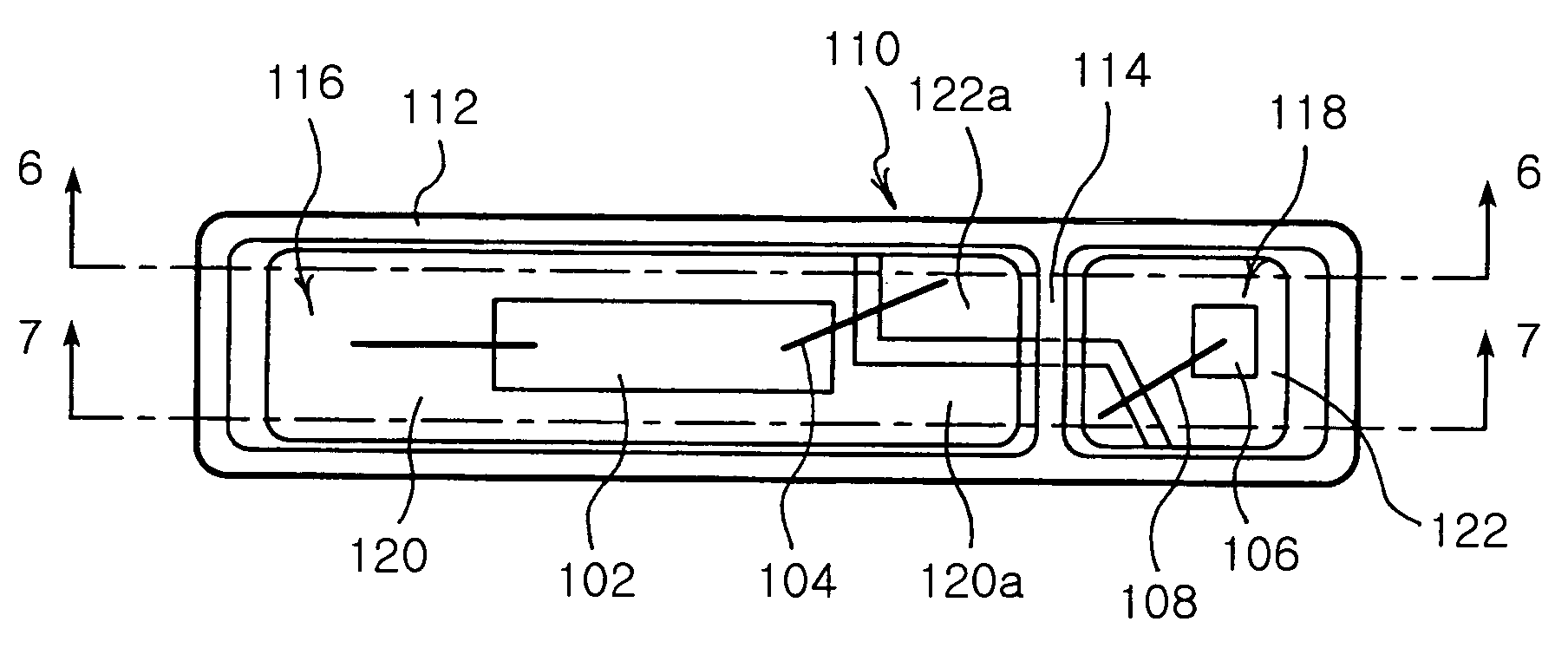

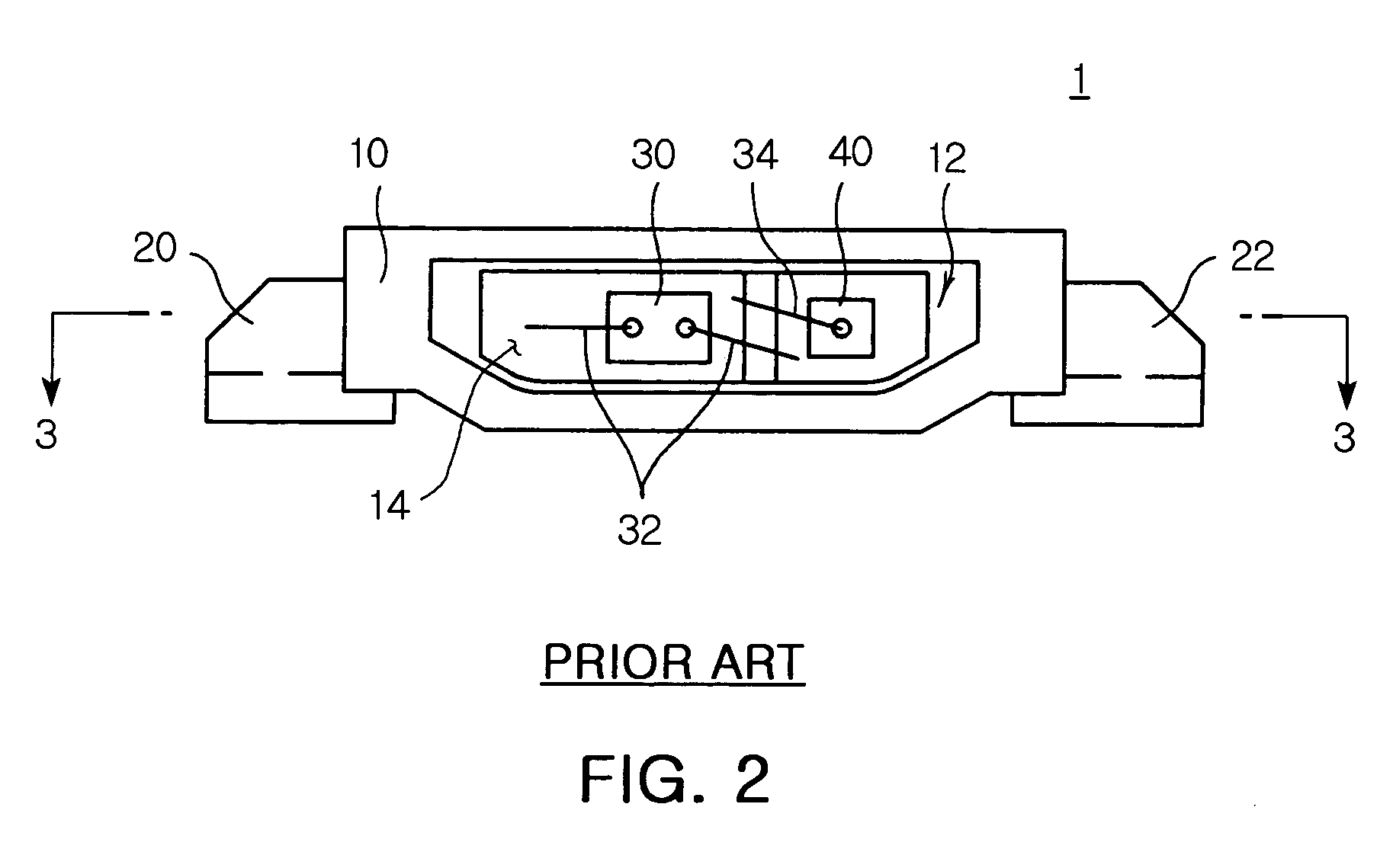

ActiveUS20070029564A1Avoid light absorptionPartly effectiveSolid-state devicesSemiconductor devicesEngineeringLead frame

In a side view LED, elongated first and second lead frames each have a finger extending therefrom. The finger of the first lead frame is disposed in parallel with that of the second lead frame. An LED chip and a protective device are mounted on mounting areas of the first and second lead frames, respectively and electrically connected to the first and second lead frames. A package body houses the first and second lead frames to form first and second opened areas. The first opened area is externally opened around the LED chip, the second opened area is externally opened around the protective device, and the partition wall is formed therebetween. First and second encapsulants are provided to the first and second opened areas, respectively to encapsulate the LED chip and protective device, respectively. At least the first encapsulant is transparent.

Owner:SAMSUNG ELECTRONICS CO LTD

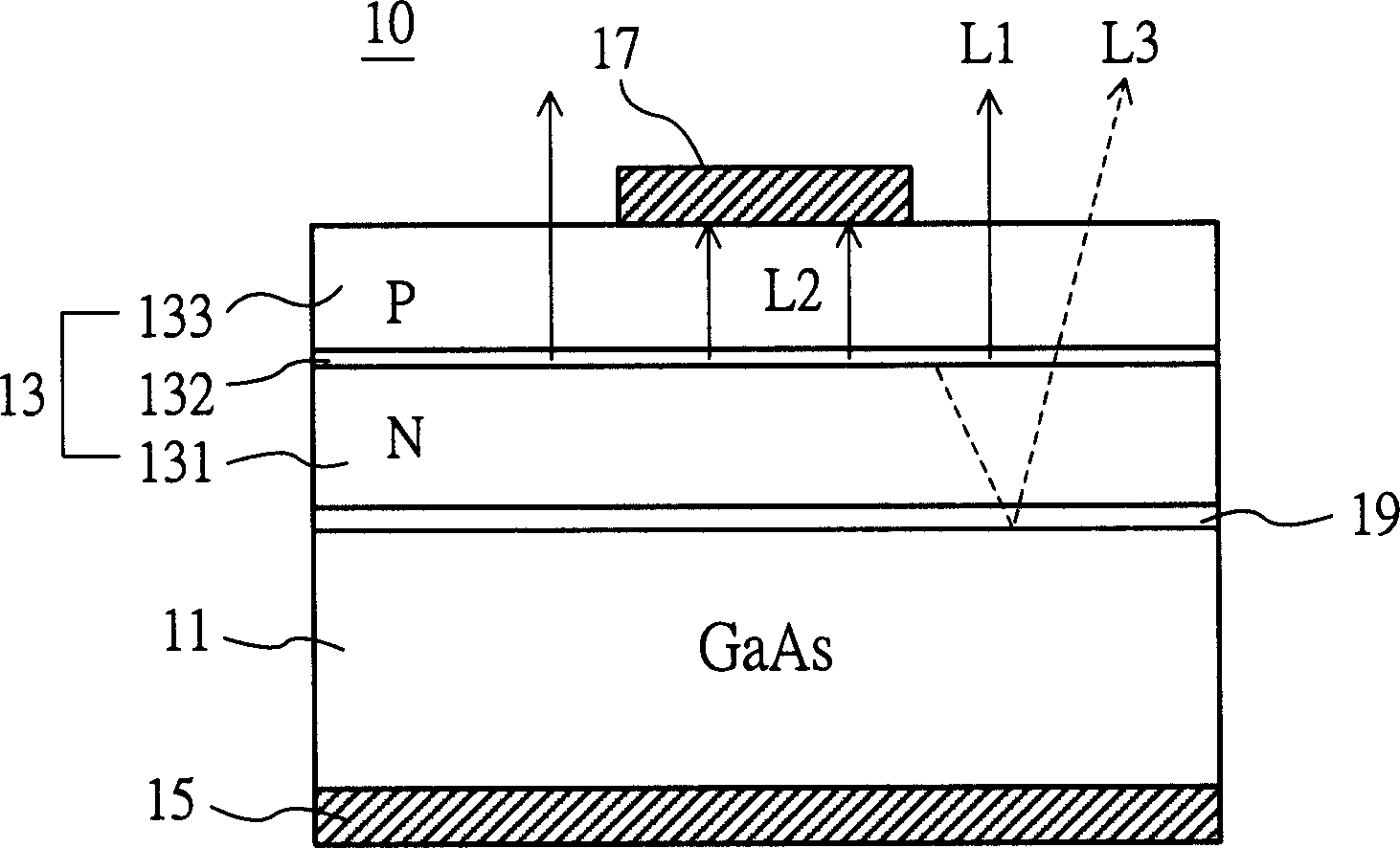

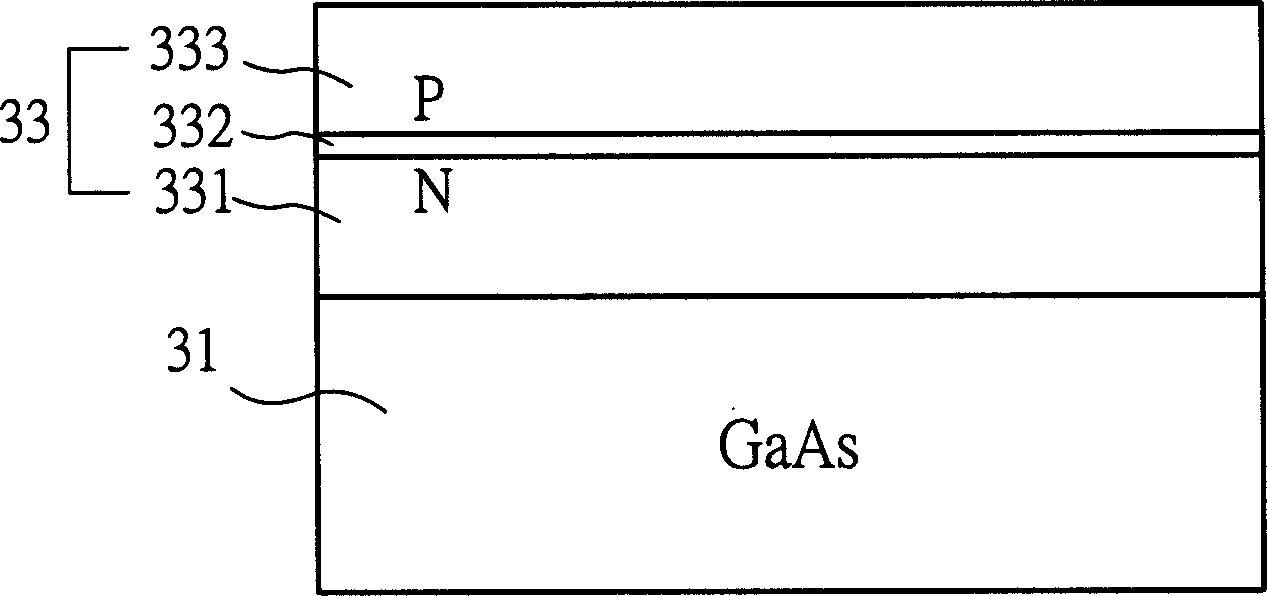

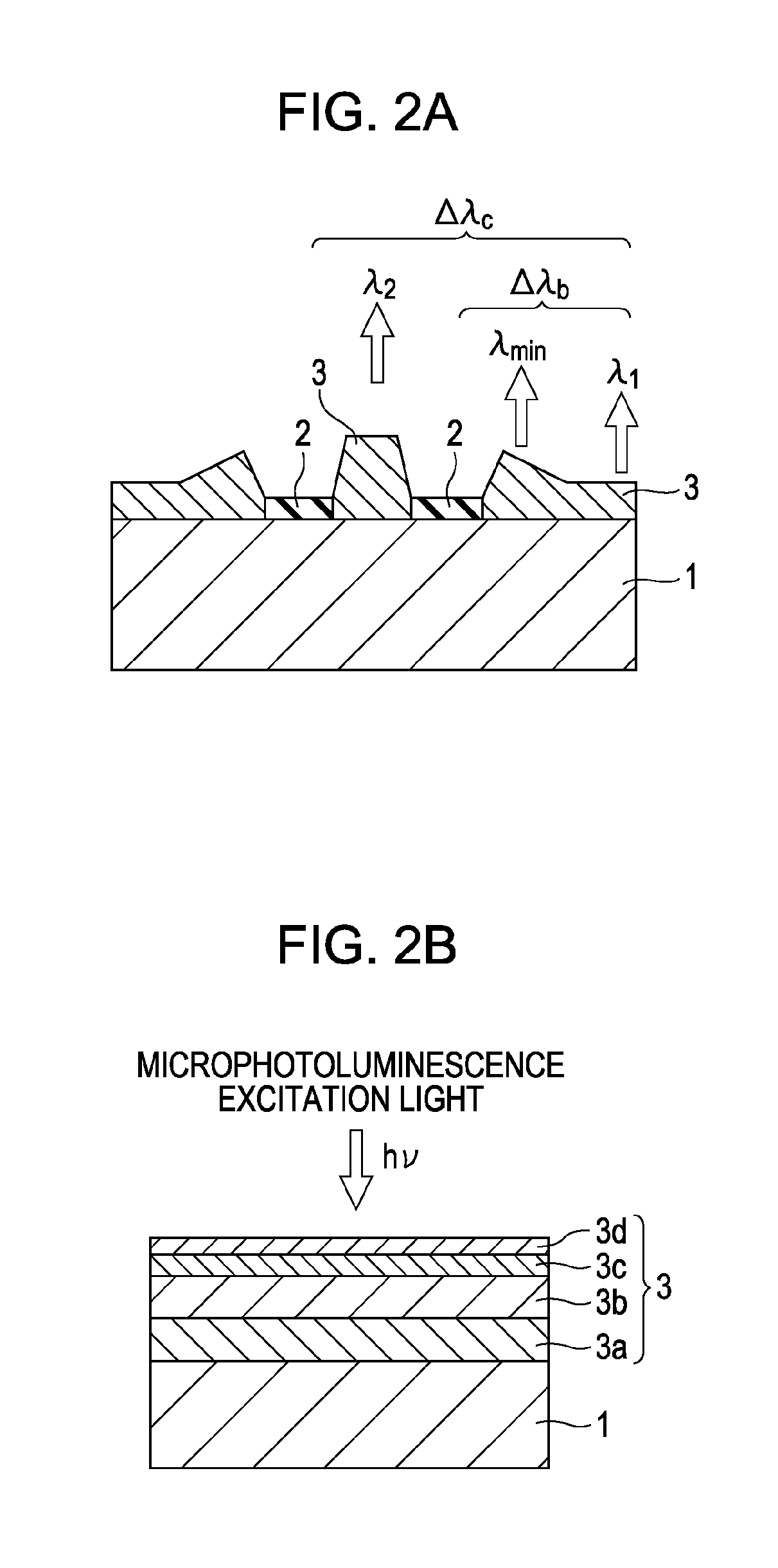

Light emitting device and method of manufacturing the same

ActiveUS20090026480A1Improve extraction efficiencyEffective lightingSemiconductor/solid-state device detailsSolid-state devicesLength waveLight emitting device

Provided is a light emitting device with high extraction efficiency, in which absorption of light by a conductive wire is prevented effectively. The light emitting device includes a conductive wire electrically connecting an electrode of a light emitting element and an electrically conductive member. The surface of the bonding portion of the conductive wire between the conductive wire and at least one of the electrode of the light emitting element and the electrically conductive member is covered with a metal film. The reflectivity of the metal film is higher than that of the conductive wire at the emission peak wavelength of the light emitting element.

Owner:NICHIA CORP

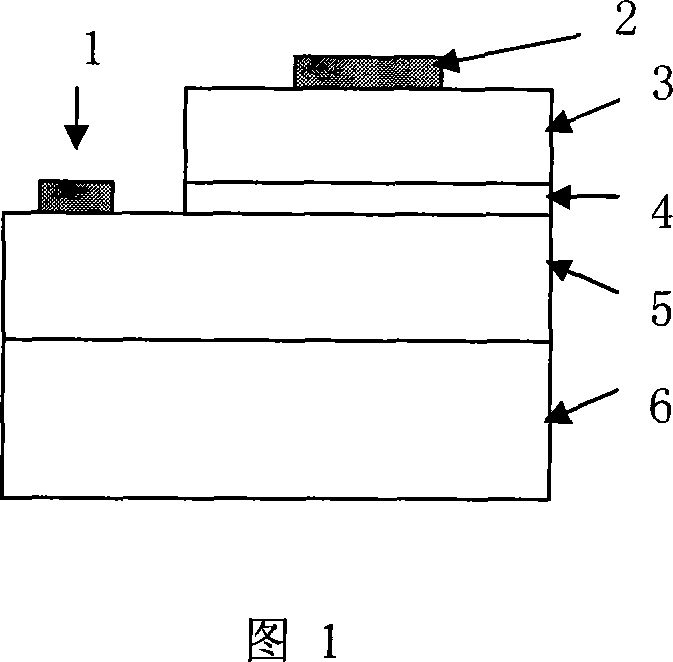

LED

InactiveCN1564333AUniform distribution of working current densityImprove efficiencySemiconductor devicesElectrical conductorEngineering

Quadreple epitaxial layer composed of first material layer, luminous layer and second material layer is formed on a semiconductor base plate. A euphotic base plate is fixed on surface of the second martial layer. With semiconductor base plate being removed, isolation groove and first extend groove are made under undersurface of first material to penetrate the first material layer and extend to part of volume of second material layer at least. First extend electrode is setup inside first extend groove. The first extend electrode is possible to connect with first electrode positioned at partial surface of the first material layer. Thus, the first electrode is located in nearly same level position to second electrode, which is on surface of other part of the first martial layer in order to carry out next processing easily. The invention increases luminescence are of PN interface, raises luminescence brightness and service life.

Owner:OPTO TECH

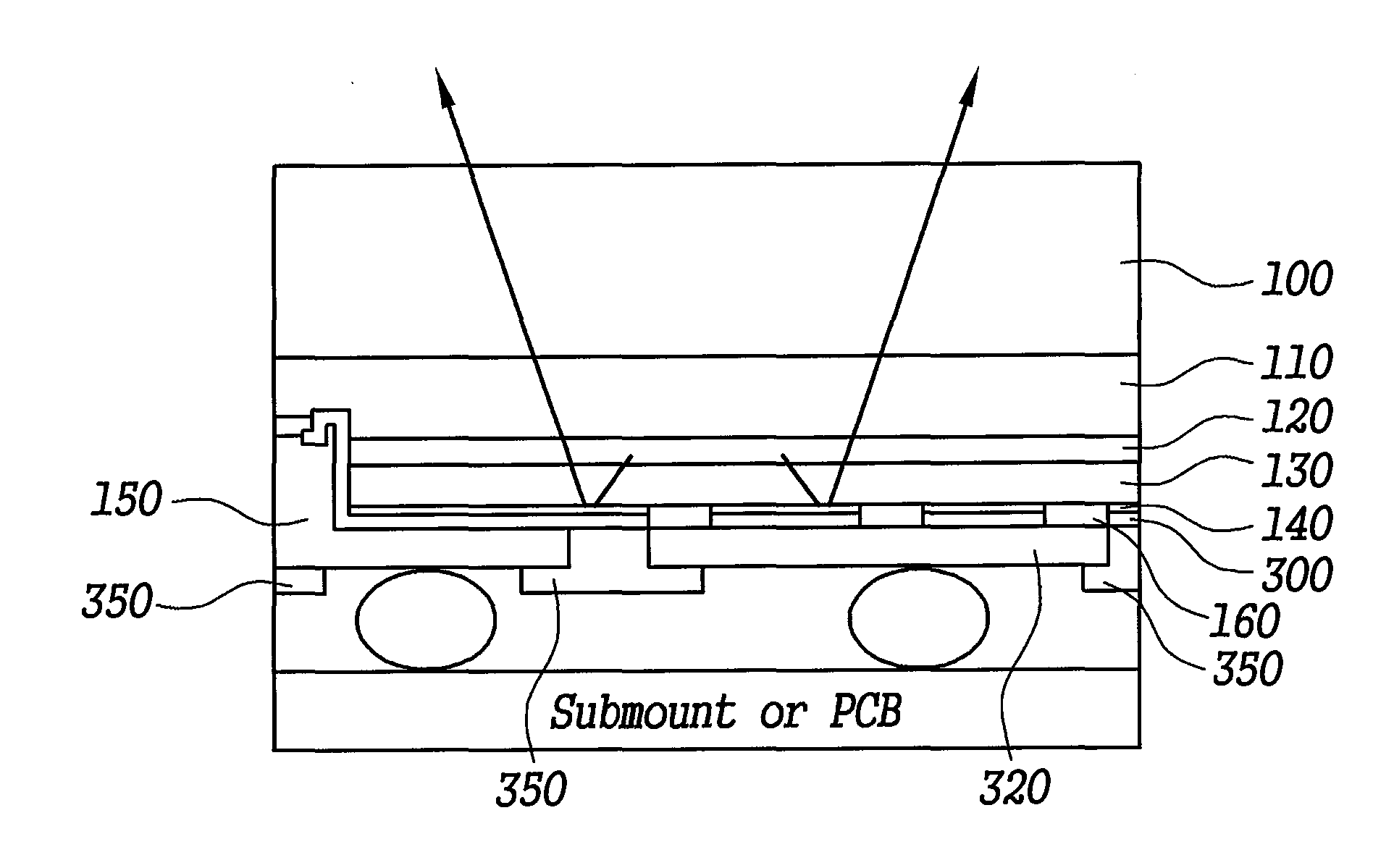

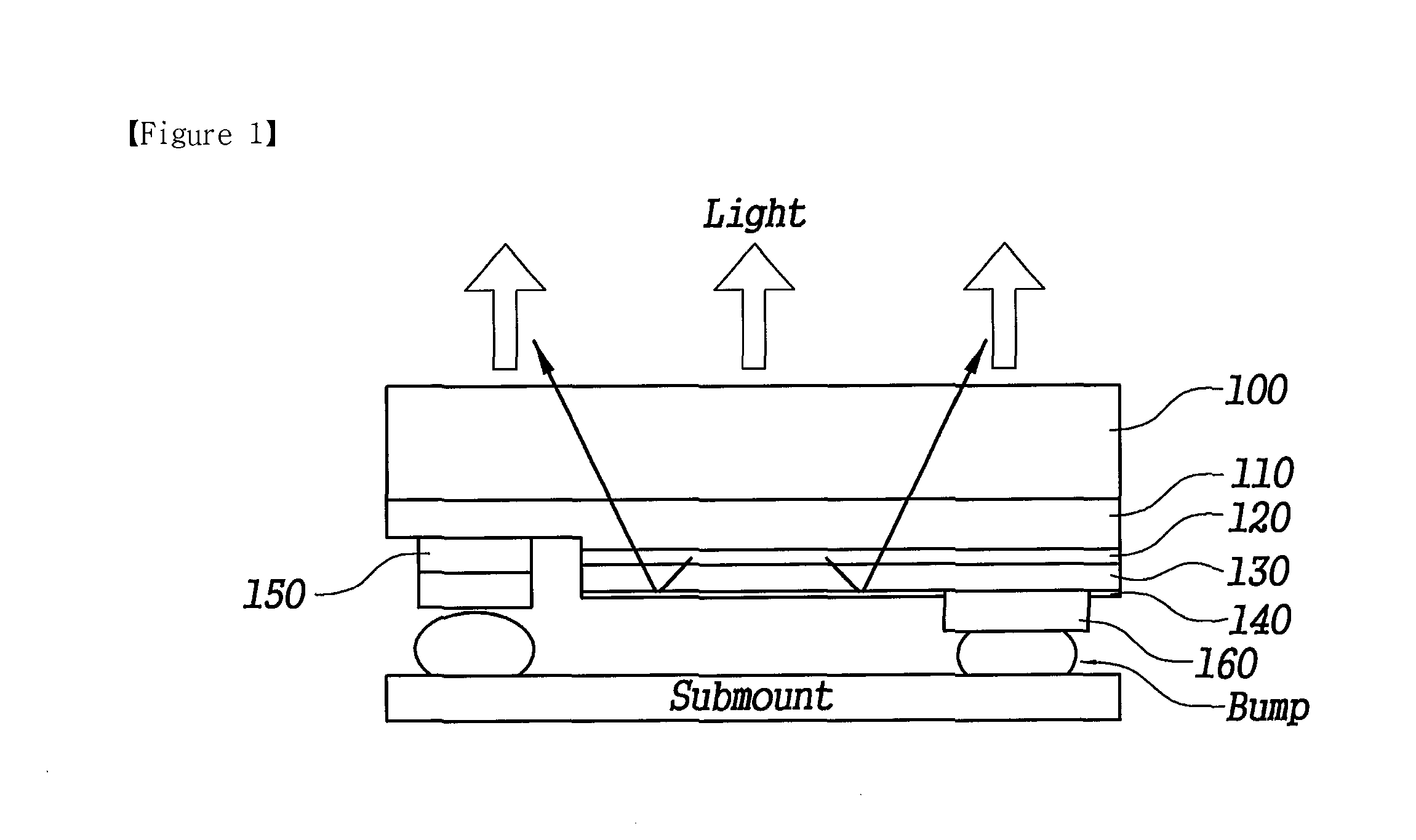

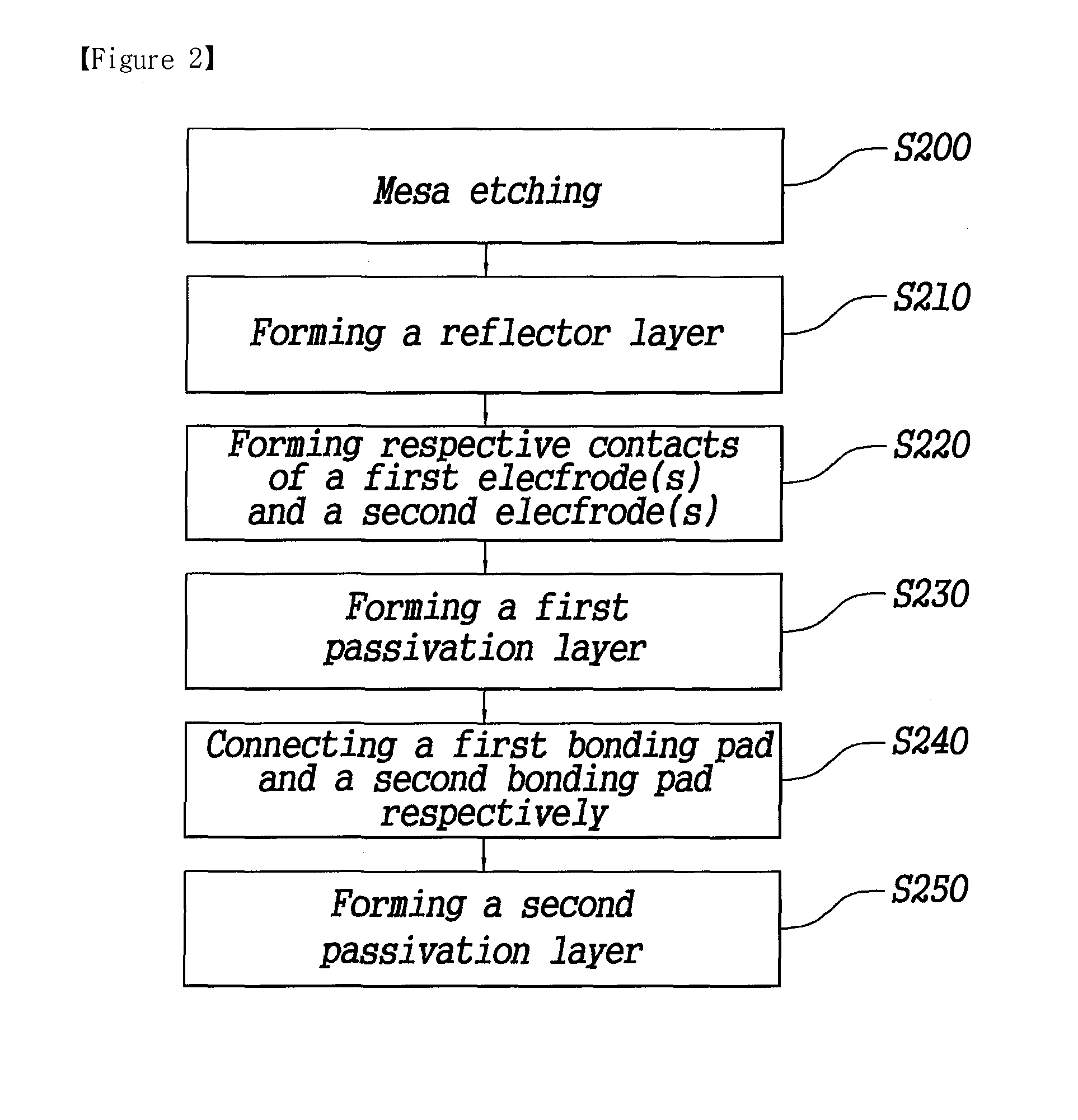

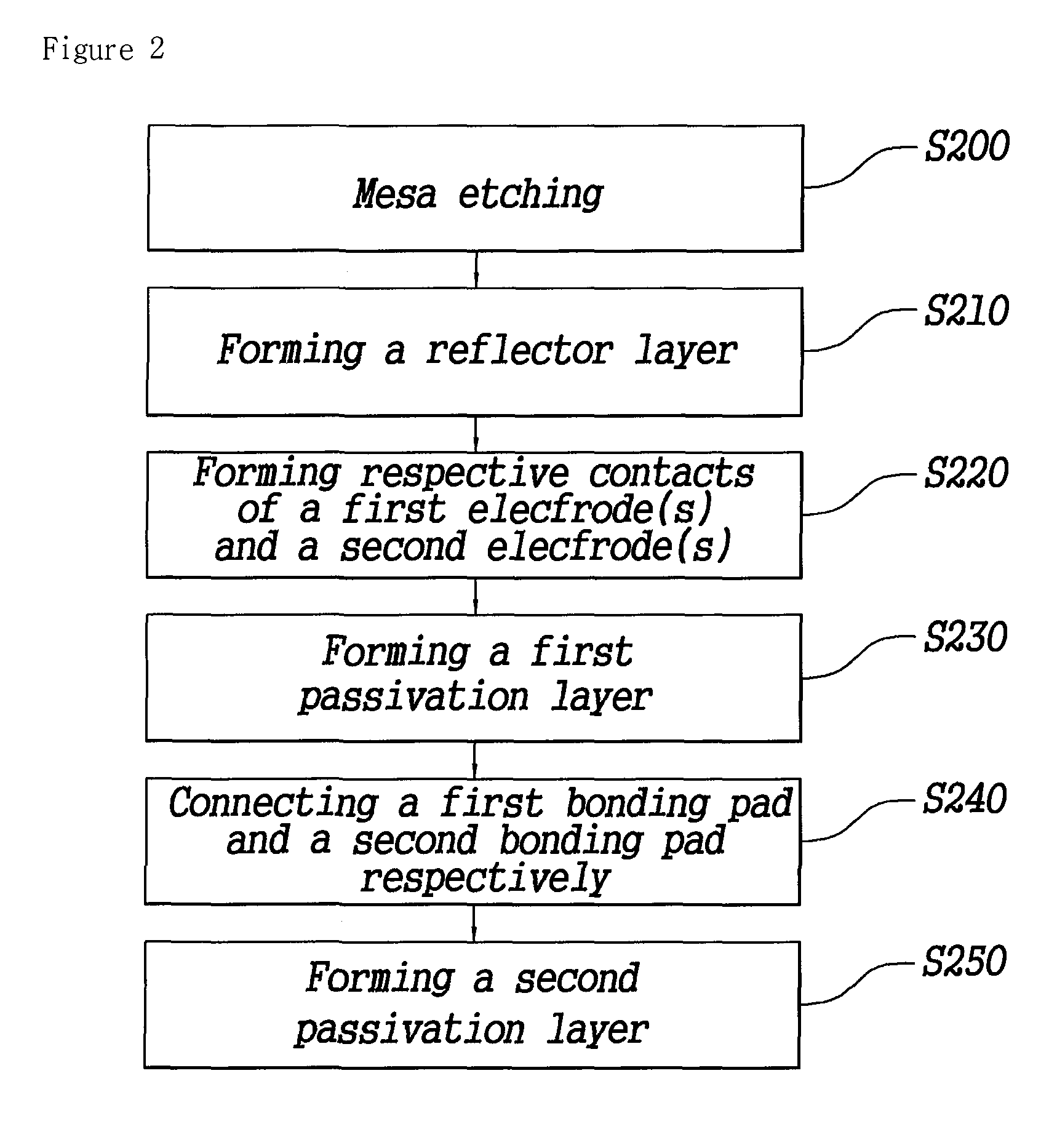

Light Emitting Diode With Metal Piles and Multi-Passivation Layers and Its Manufacturing Method

ActiveUS20110198635A1Reduce in quantityAvoid light absorptionSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorElectrode Contact

The present invention relates to a light emitting diode with metal piles and one or more passivation layers and a method for making the diode including a first steps of performing mesa etching respectively on a first semiconductor layer and a second semiconductor layer belonging to stacked layers formed on a substrate in sequence! a second step of forming a reflector layer on the mesa-etched upper and side face! a third step of contacting one or more first electrodes with the first semiconductor layer and one or more second electrodes through the reflector layer with the second semiconductor layer; a fourth step of forming a first passivation layer on the reflector layer and the contacted electrodes; and a fifth step of connecting the first electrodes to a first bonding pad through one or more first electrode lines, bring one ends of vertical extensions having the shape of a metal pile into contact with one or more second electrodes, and connecting the other ends of the vertical extensions to a second bonding pad through one or more second electrode lines. As effects of the present invention, the loss of light emitting area decreases and current diffusion efficiency increases.

Owner:KOREA PHOTONICS TECH INST

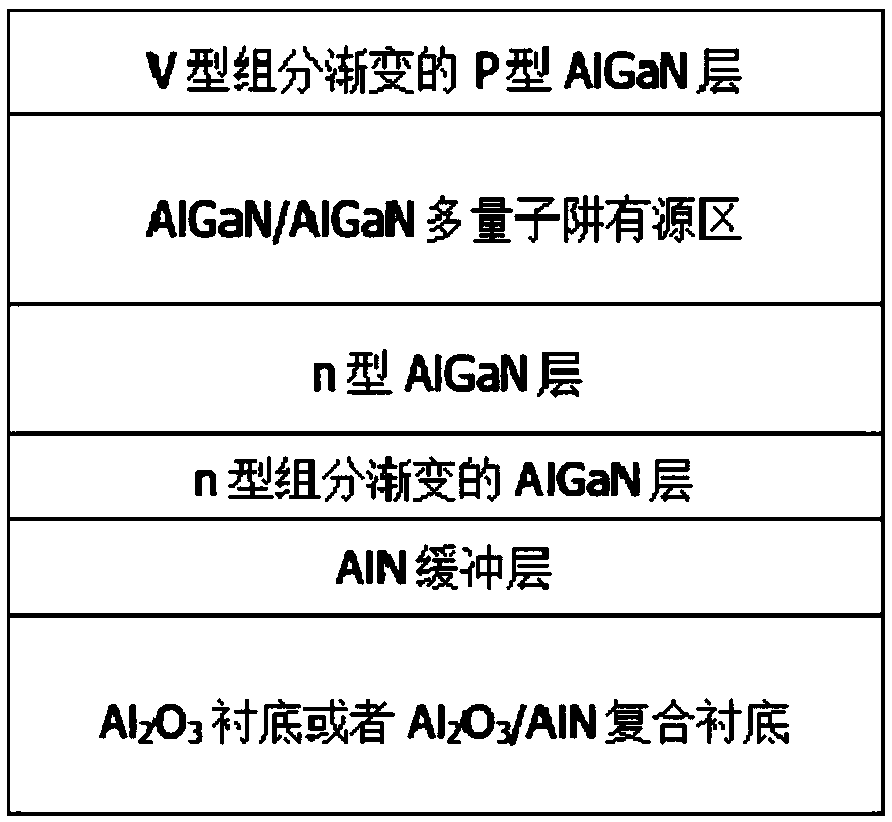

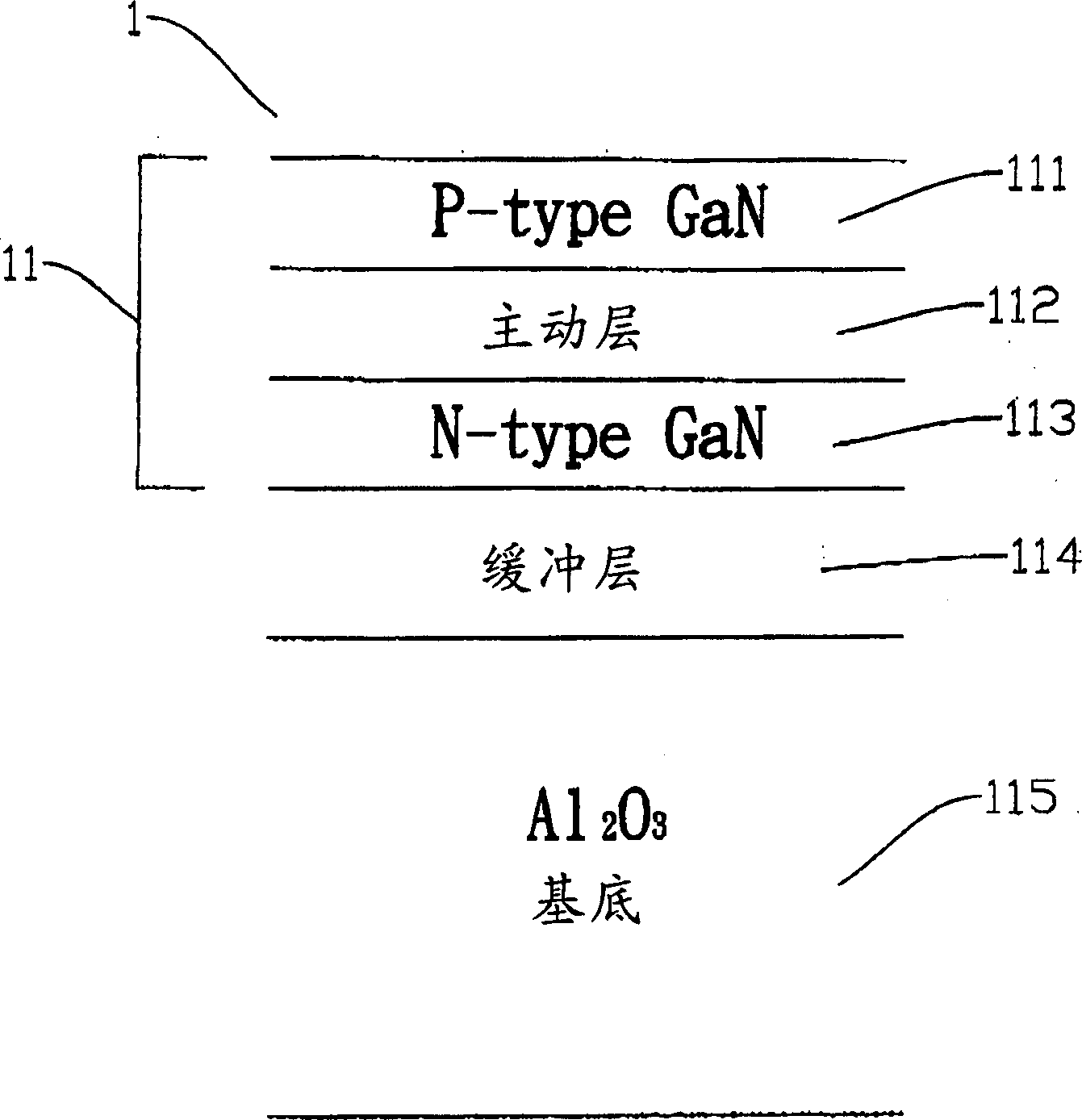

Preparation method of high-luminance V-shaped polarized doped deep ultraviolet LED

ActiveCN108365069AIncrease hole concentrationAvoid light absorptionSemiconductor devicesQuantum wellUltraviolet

The invention provides a preparation method of a high-luminance V-shaped polarized doped deep ultraviolet LED. The prepared deep ultraviolet LED structure comprises a substrate, an AlN buffer layer, astress relief layer, an N type AlGaN layer, an AlGaN / AlGaN multi-quantum-well active region and a P type AlGaN layer with V-shaped gradually changed Al components. By virtue of the P type AlGaN layerwith the V-shaped gradually changed Al components, the light emitting efficiency is improved; meanwhile, by adopting the V-shaped gradually changed structure to replace a P type AlGaN electron barrier layer, a P type AlGaN contact layer and a P type P-GaN layer, the light extracting efficiency is improved; and by virtue of the structure, the hole concentration of the P type layer is greatly improved, light absorption of the P type contact layer is avoided fundamentally, the manufacturing process is simple, and industrial production can be realized.

Owner:迪优未来科技(清远)有限公司

Side-view light emitting diode having protective device

ActiveUS7462871B2Avoid light absorptionPartly effectiveSolid-state devicesSemiconductor devicesLead frameSealant

In a side view LED, elongated first and second lead frames each have a finger extending therefrom. The finger of the first lead frame is disposed in parallel with that of the second lead frame. An LED chip and a protective device are mounted on mounting areas of the first and second lead frames, respectively and electrically connected to the first and second lead frames. A package body houses the first and second lead frames to form first and second opened areas. The first opened area is externally opened around the LED chip, the second opened area is externally opened around the protective device, and the partition wall is formed therebetween. First and second encapsulants are provided to the first and second opened areas, respectively to encapsulate the LED chip and protective device, respectively. At least the first encapsulant is transparent.

Owner:SAMSUNG ELECTRONICS CO LTD

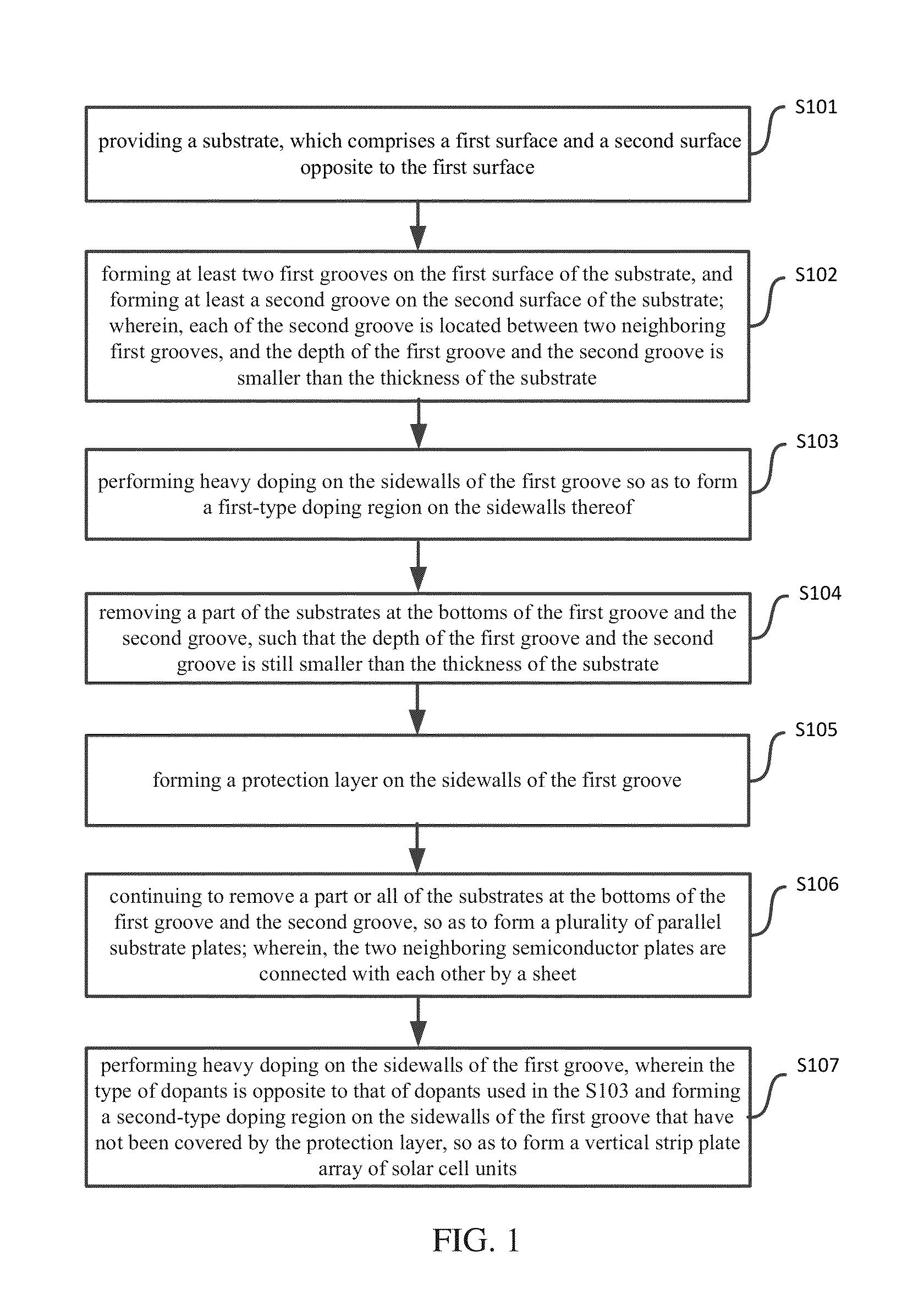

Method for cutting light emitting diode chip through deep etching

InactiveCN102881783AReduce homeworkAvoid chippingSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingLaser cutting

The invention provides a method for cutting a light emitting diode chip through deep etching. The method comprises the following steps: firstly, forming a light emitting element comprising a plurality of light emitting units on the surface of a semiconductor substrate; then fabricating a protecting layer with etching windows formed at the connections between each of the light emitting units; etching from each of the etching windows to form sliver channels; next, filling each of the sliver channels with insulation material and thinning the semiconductor substrate from back until exposing the insulation material; and finally making a back coating, removing the insulation material in each of the sliver channel, and expanding the film to obtain independent light emitting units. According to the invention, by adopting the method of forming the sliver channels through deep etching, the cut grooves are deep into the sapphire substrate, thus avoiding laser cutting processing step, avoiding the problem of light absorption caused by laser ablation, and increasing light outgoing efficiency; and the deep etching depth is equivalent to the final thickness of the chip, and separated chip grains can be obtained by removing the filled SiO2, thus reducing sliver operation, avoiding broken sides and broken corners in the slivers, and increasing the yield.

Owner:施科特光电材料(昆山)有限公司

Solar cell and photovoltaic module

PendingCN112201701AAvoid light absorptionRealize the effect of double-sided passivation contactPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention provides a solar cell and a photovoltaic module, and relates to the field of solar cells. The solar cell comprises: a semiconductor substrate, wherein the semiconductor substrate comprises a first surface and a second surface which are oppositely arranged; a first dielectric layer located on the first surface; a first N+ doped layer positioned on the surface of the first dielectric layer; a first passivation layer and / or a first anti-reflection layer located on the surface of the first N+ doped layer; a first electrode positioned on the surface of the first passivation layer and / or the first anti-reflection layer; a second dielectric layer located on the second surface; a first P+ doped layer positioned on the surface of the second dielectric layer; a second passivation layerand / or a second anti-reflection layer located on the surface of the first P+ doped layer; and a second electrode positioned on the surface of the second passivation layer and / or the second anti-reflection layer. According to the invention, the limitation that the passivation contact structure needs to be mutually balanced between transverse transmission and polycrystalline silicon film light absorption when applied to the front surface of the battery can be relieved, and the short-circuit current of the battery is improved while high open-circuit voltage is achieved.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

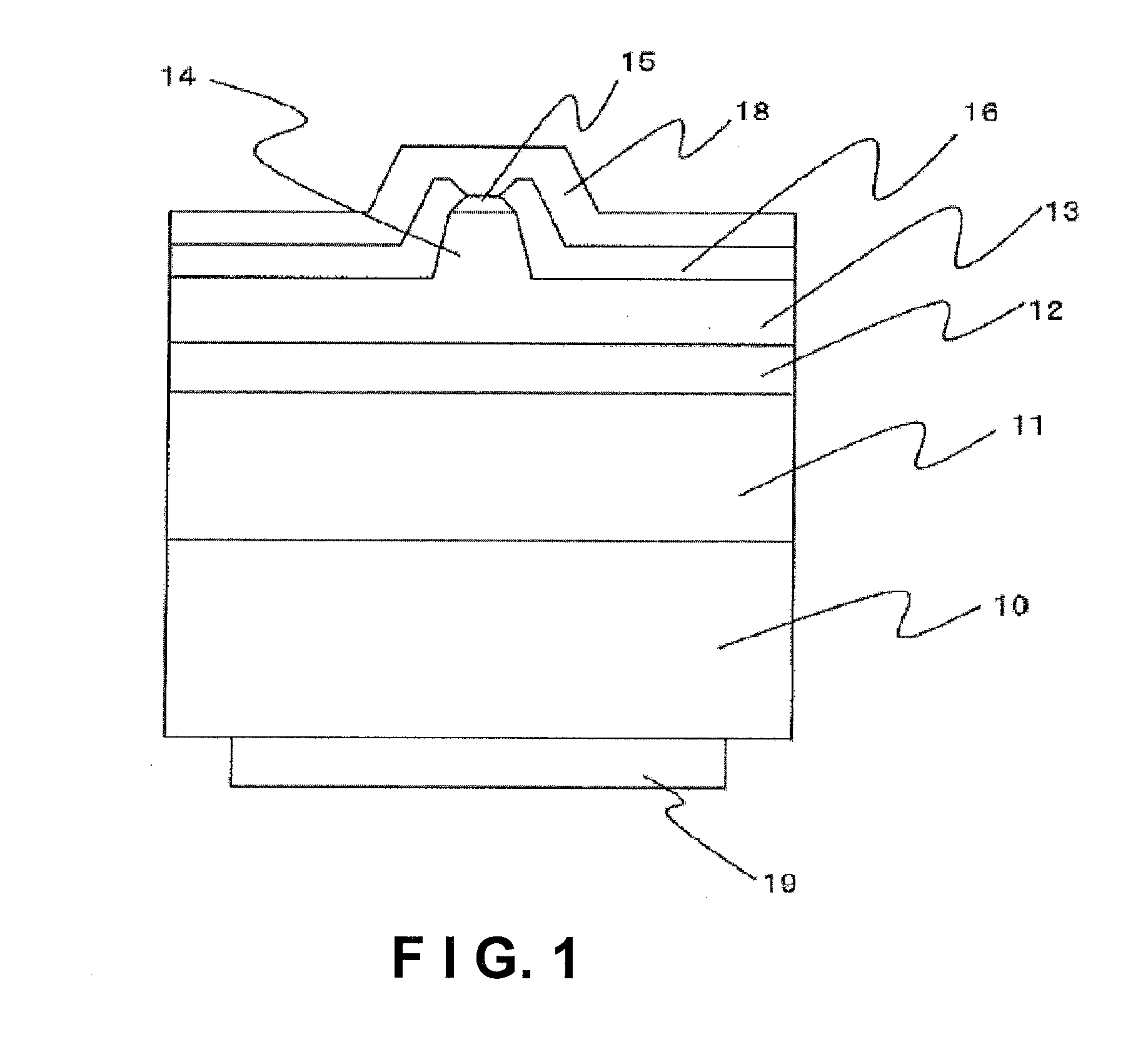

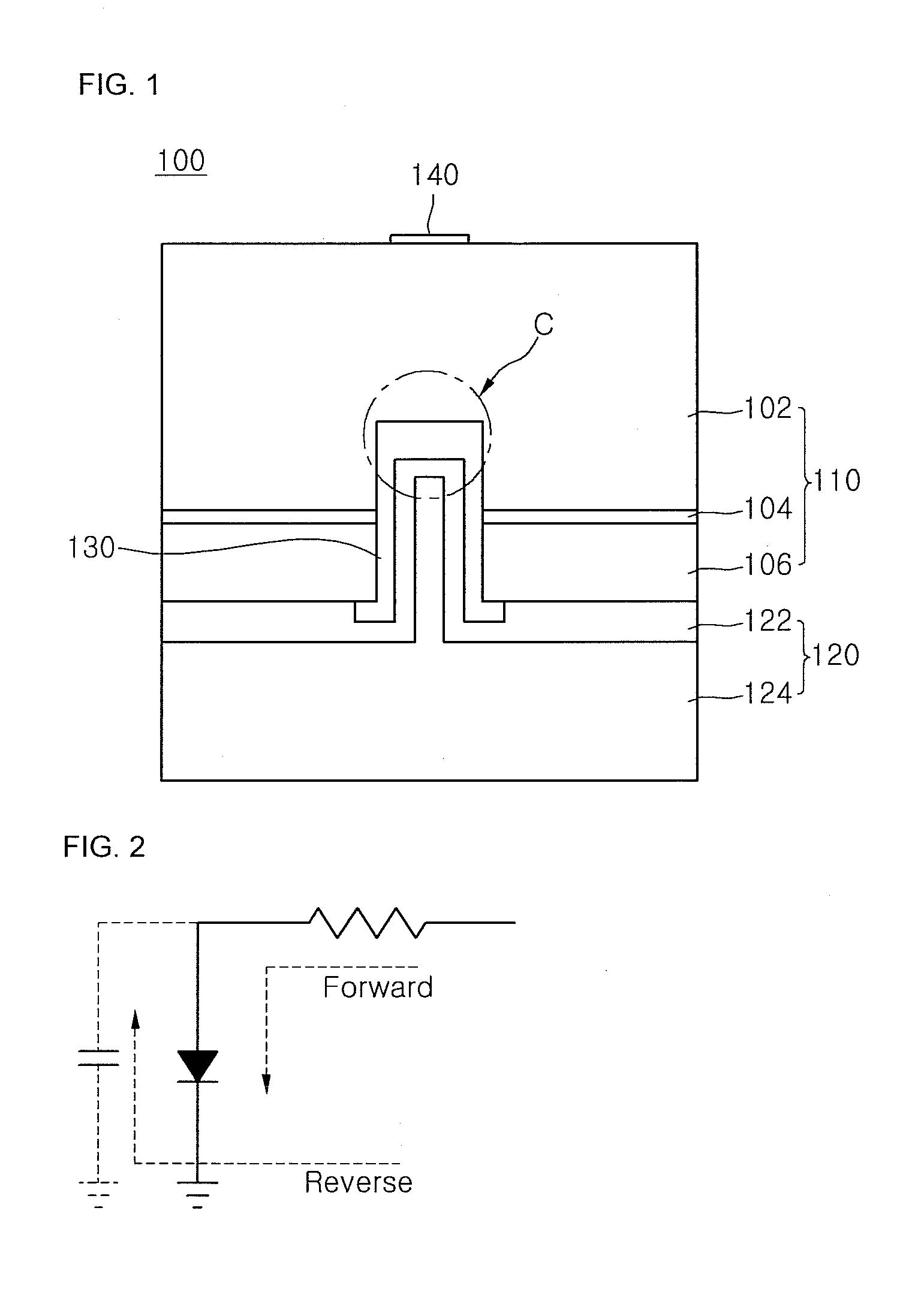

Semiconductor device and method of manufacturing semiconductor device

ActiveUS20100308445A1Improve reliabilityAvoid light absorptionOptical wave guidanceLaser detailsEngineeringRidge

A semiconductor device includes a semiconductor layer stacked on a substrate, a stripe-shaped ridge formed on a surface of the semiconductor layer, and electrode formed on an upper surface of the ridge and a protective film disposed on each side of the ridge. The electrode includes a flat portion having a flat surface substantially parallel to the upper surface of the ridge and sloped portions on both sides of the flat portion with each of the sloped portions having a sloped surface that is sloped with respect to the upper surface of the ridge. The protective film covers a region from a side surface of the ridge to the sloped surface of the sloped portion of the electrode.

Owner:NICHIA CORP

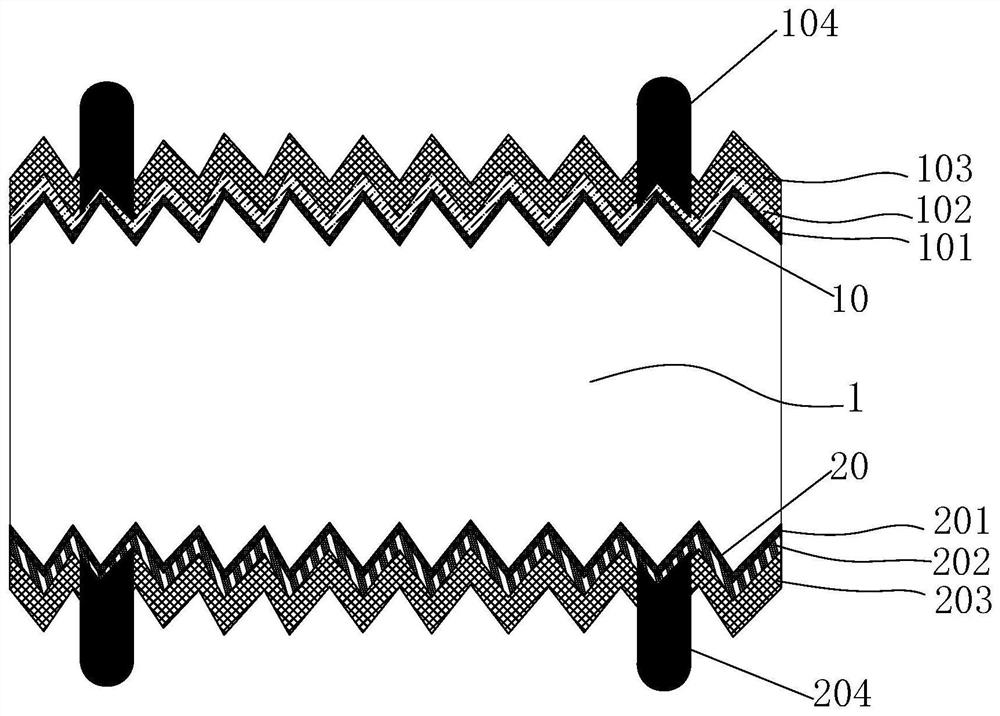

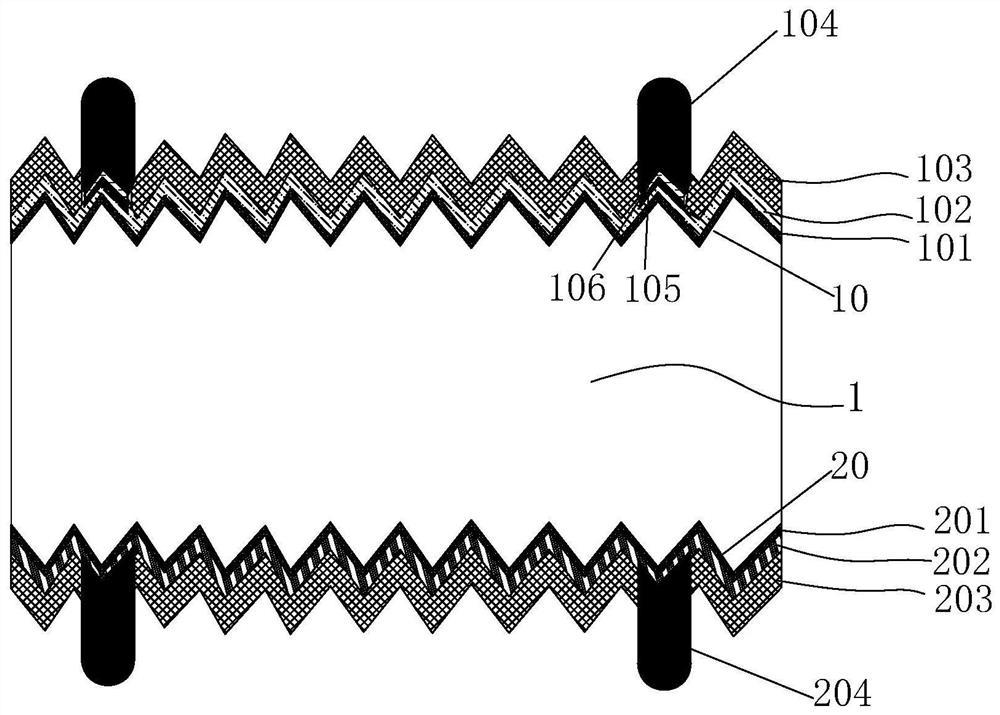

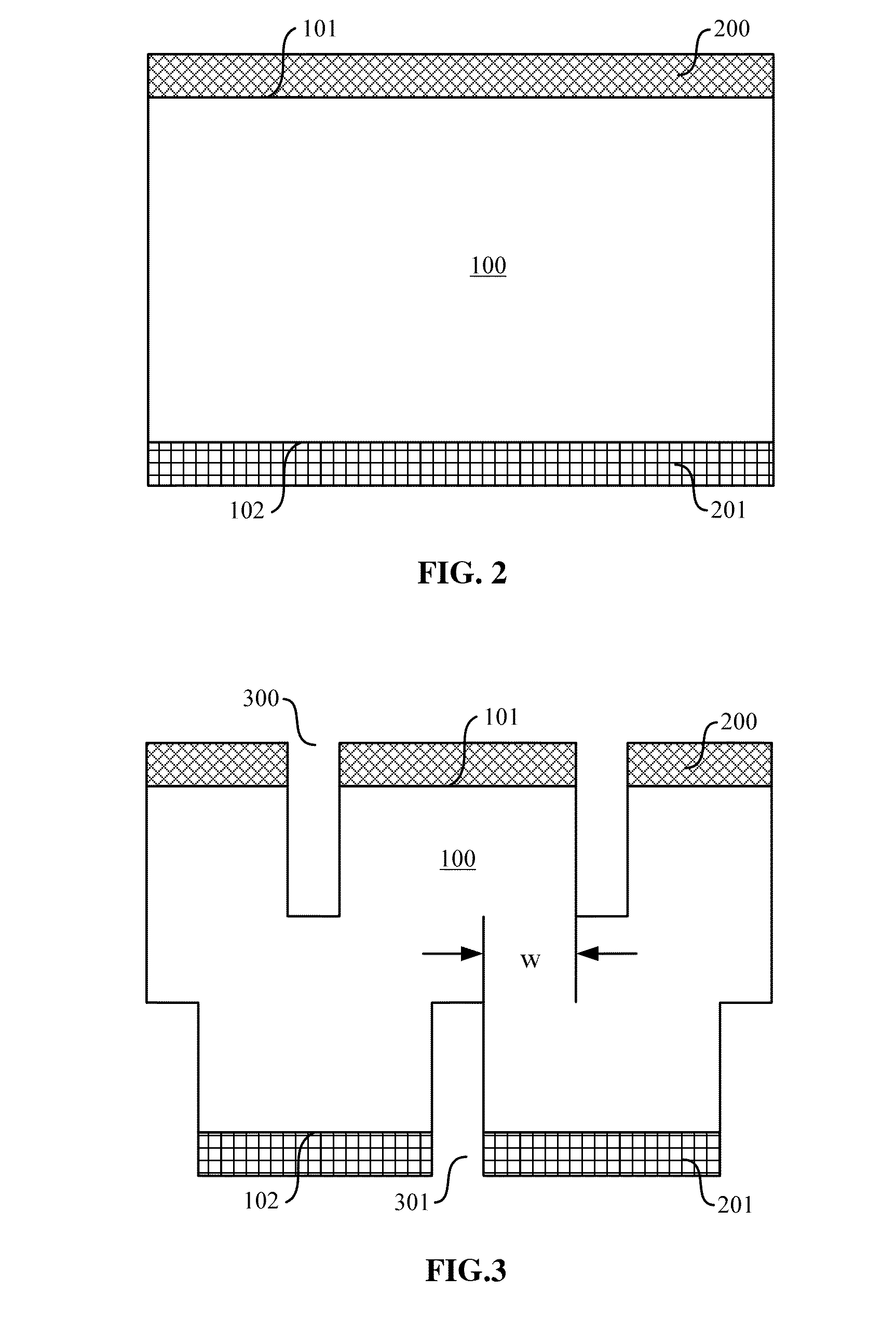

Solar cell unit and method for manufacturing the same

InactiveUS20140238461A1Efficient collectionIncrease currentFinal product manufacturePV power plantsEngineeringSolar cell

The present invention provides a solar cell unit, which comprises a semiconductor plate of first-type doping or second-type doping; wherein the semiconductor plate has a first surface and a second surface opposite to the first surface; the semiconductor plate comprises a first-type doping region and second-type doping region, both the first-type doping region and the second-type doping region are located on the first surface of the semiconductor plate; a first sheet is provided on the side surface of the semiconductor plate that is adjacent to the first-type doping region, and a second sheet is provided on the side surface of the semiconductor plate that is adjacent to the second type doping region.

Owner:LUO ZHIJIONG +2

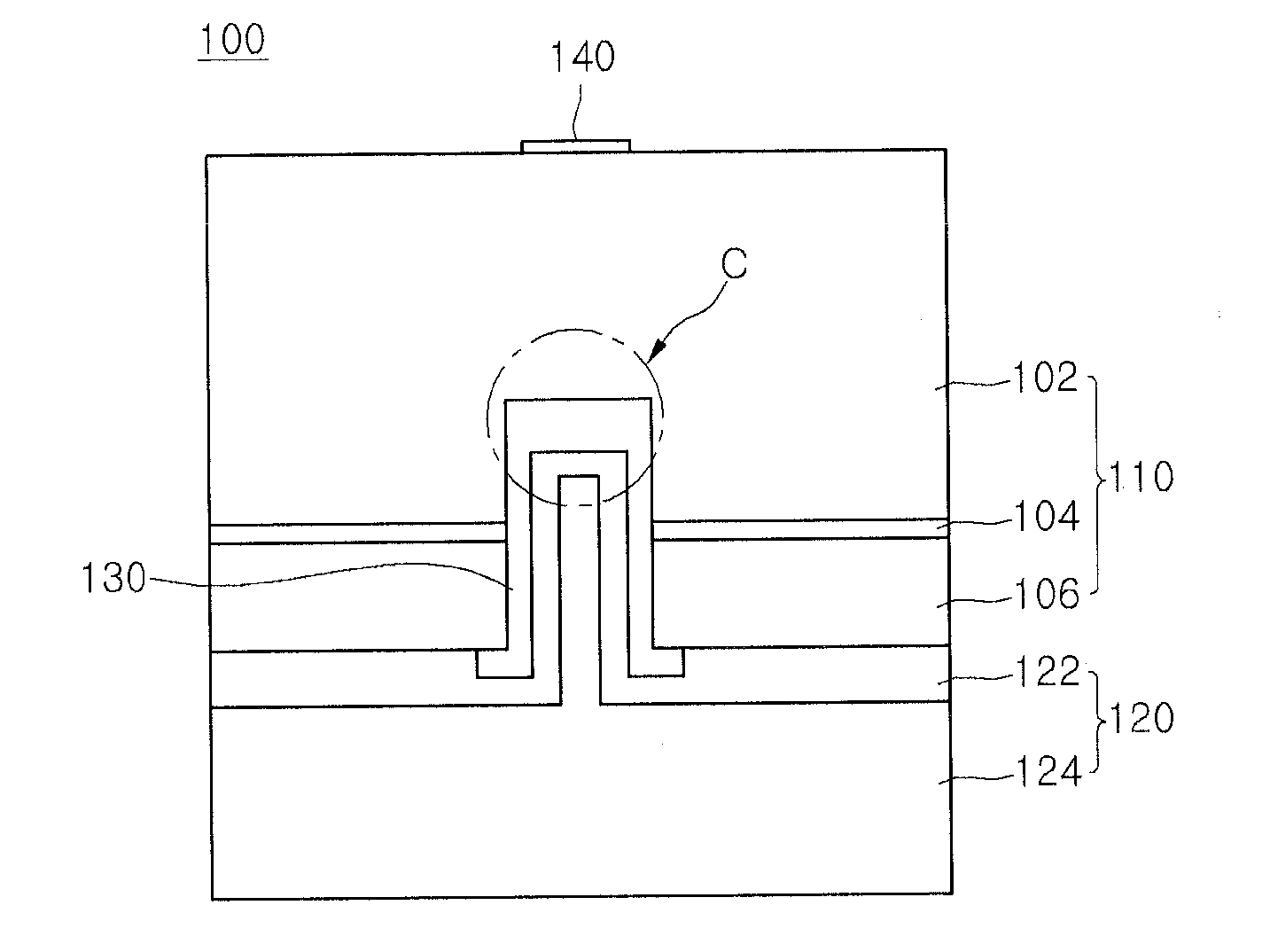

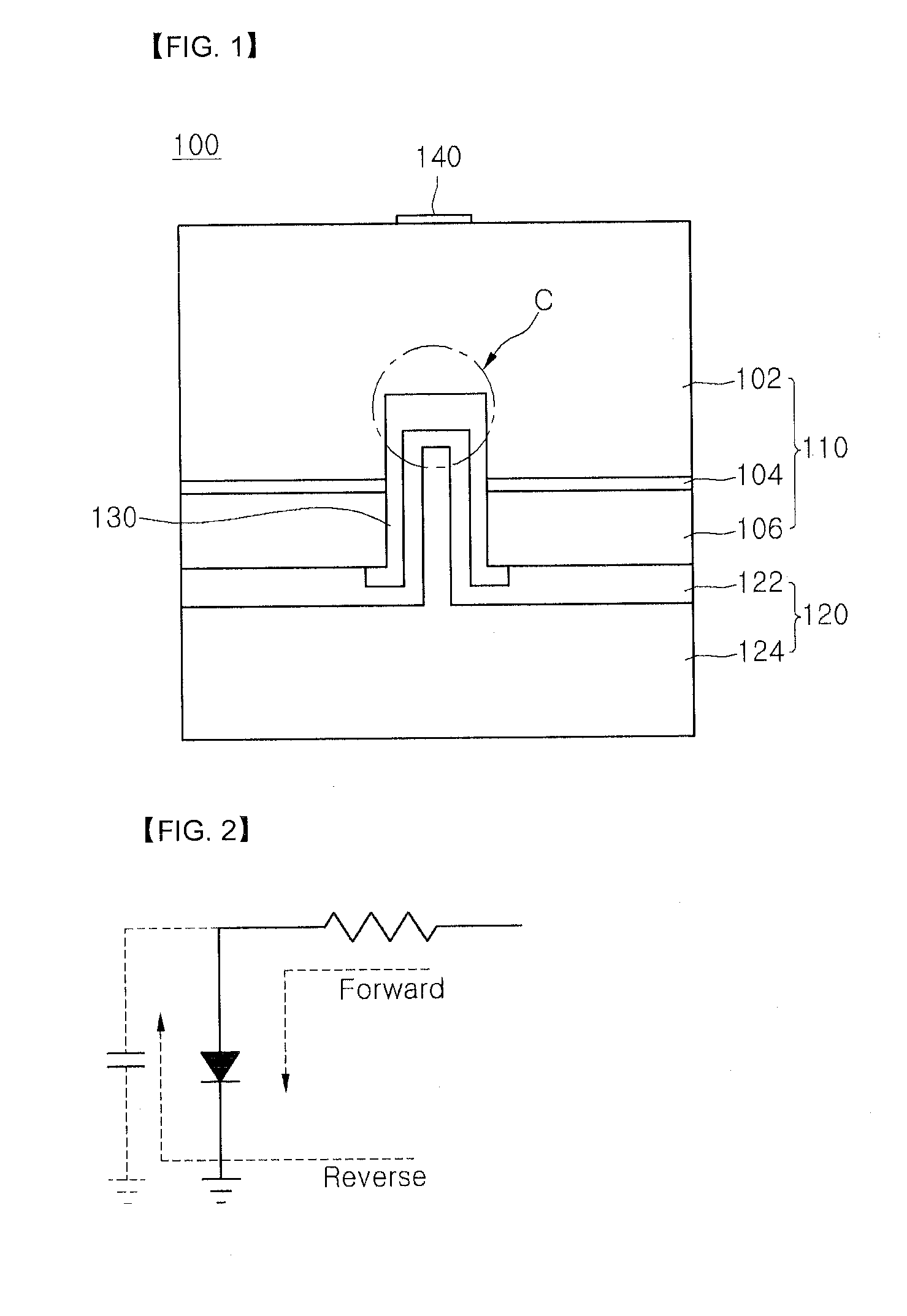

Light emitting device having a dielectric layer and a conductive layer in a cavity

InactiveUS20120086038A1Avoid damageAvoid light absorptionSolid-state devicesSemiconductor devicesLighting systemActive layer

Disclosed are a light emitting device, a light emitting device package, and a lighting system. The light emitting device includes a light emitting structure including a second conductive semiconductor layer, an active layer over the second conductive semiconductor layer, and a first conductive semiconductor layer over the active layer, a dielectric layer in a cavity defined by removing a portion of the light emitting structure, and a second electrode layer over the dielectric layer.

Owner:LG INNOTEK CO LTD

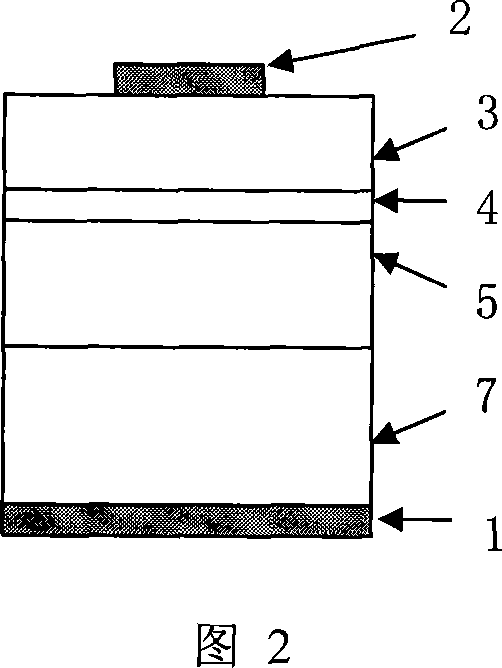

Semiconductor light emitting device and method for manufacturing the same

InactiveCN101226981AImprove heat transfer performanceIncrease contact areaSemiconductor devicesDielectric layerLight emitting device

The invention discloses a semiconductor light-emitting device, which comprises a substitution substrate and a semiconductor extension laminated layer which is orderly connected with the substitution substrate through a metal layer, wherein the semiconductor extension laminated layer at least comprises a buffer layer, an N type layer, a luminous layer and a P type layer from the upper to the lower, a conductor is arranged in the N type layer, one end of the N type layer extents to expose the buffer layer, and an N type electrode is arranged, and a dielectric layer is arranged between the other end of the conductor and the metal layer. The lower end of the substitution substrate is quipped with a P type electrode, and the conductor, the P type layer and the metal layer are separated. The device of the invention sends light from the side of the N type layer, a transparency electrode does not need to use on the side of sending the light, thereby being capable of effectively improving the output power of the semiconductor device, and also being capable of reducing the thermal resistance of a light emitting diode device. Further, the invention also discloses a method for preparing a semiconductor light emitting diode.

Owner:SUN YAT SEN UNIV

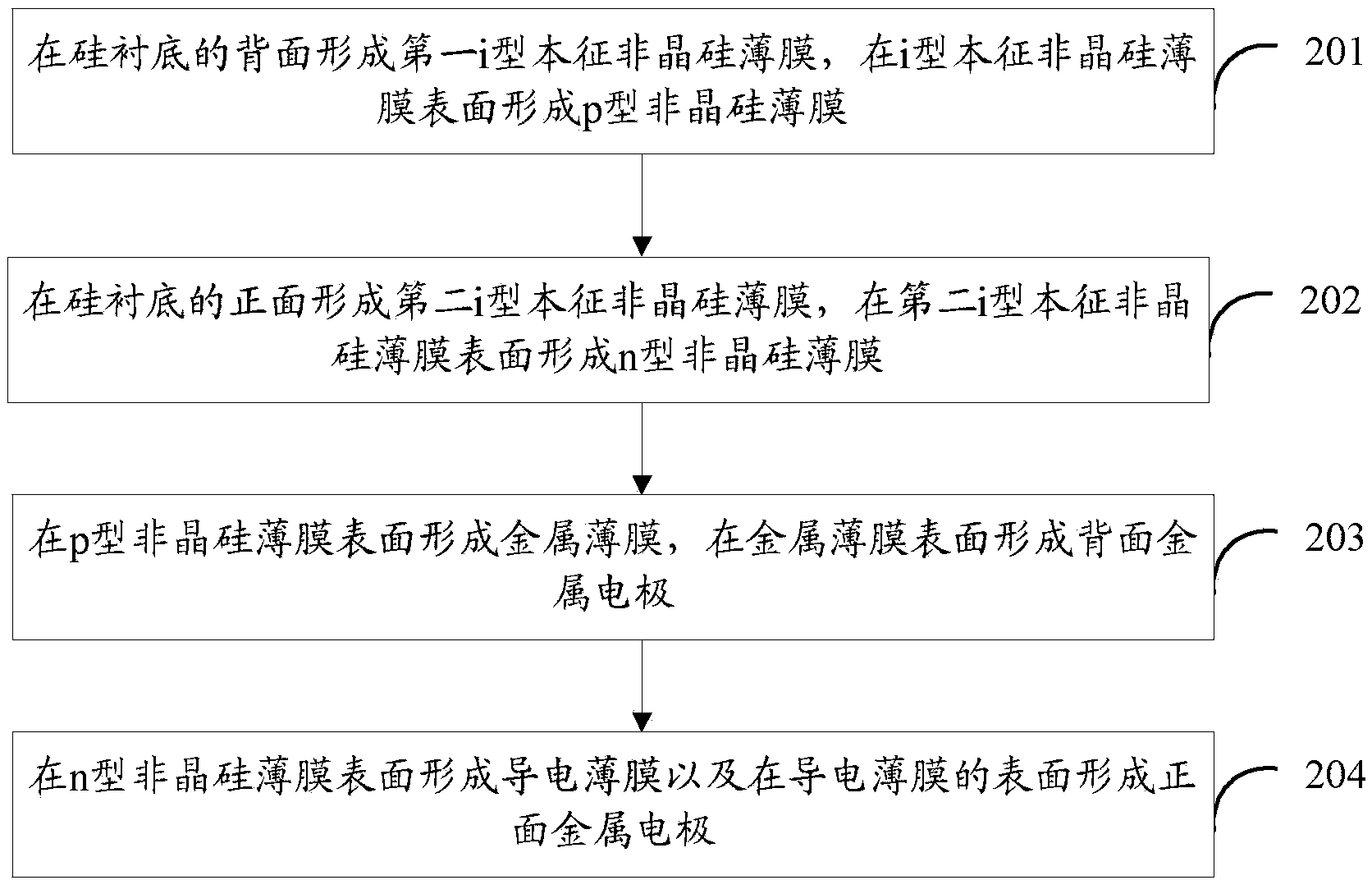

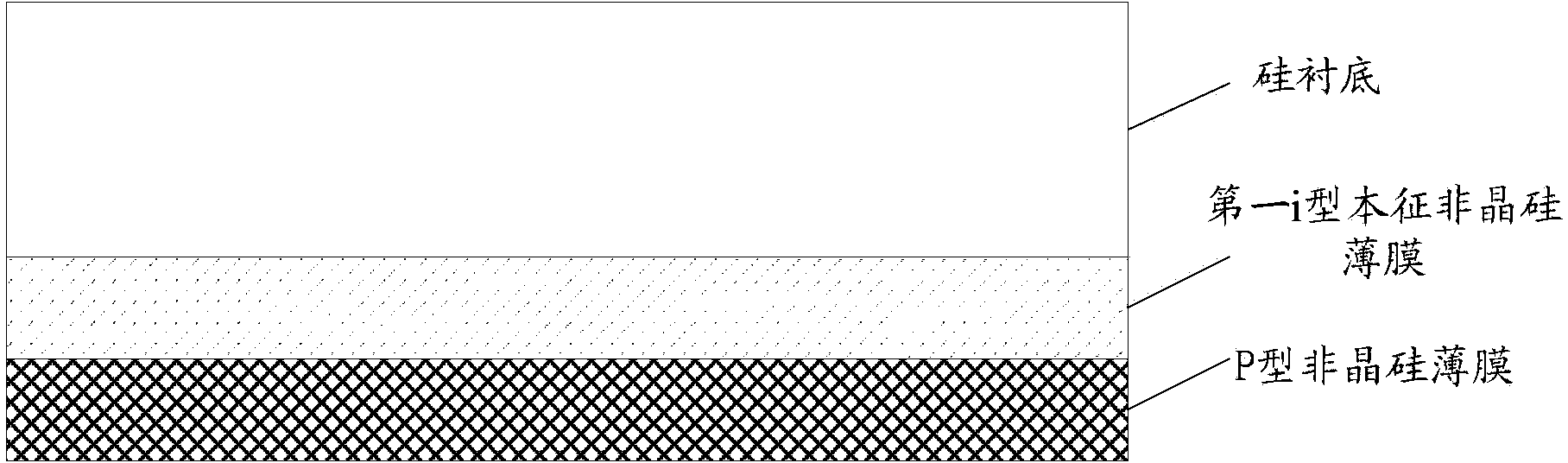

Heterojunction solar cell and manufacturing method thereof

ActiveCN104362193AImprove fill factorRestrict short-circuit currentFinal product manufacturePhotovoltaic energy generationHeterojunctionPower flow

The invention discloses a heterojunction solar cell and a manufacturing method thereof. A metal film is formed on the surface of a p-type amorphous silicon film on a backlight face, and a back metal electrode is formed on the surface of the metal film. Since work function of the metal film is higher than that of the p-type amorphous silicon film, or a metallic compound is formed on an interface to form a barrier layer or a tunneling layer on the interface, the metal film / p-type amorphous silicon interface is in ohmic contact and pretty low in interface resistance, and compared with a traditional P-type amorphous silicon / TCO (transparent conductive oxide)interface structure, the metal film / p-type amorphous silicon interface has the advantages that high contact resistance between a TCO and the p-type amorphous silicon film is avoided while fill factor of the cell can be increased beneficially. In addition, due to the fact that the solar cell is in an inversion structure, light absorption of the metal film is avoided, and accordingly restriction on short-circuit current of the cell due to light absorption of the metal film is avoided.

Owner:ENN SOLAR ENERGY

Preparation method of distributed Bragg reflector and vertical cavity surface emitting laser

InactiveCN110165550AAvoid warpingStress reliefLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserLattice mismatch

The invention relates to the technical field of semiconductor lasers, and particularly discloses a preparation method of a distributed Bragg reflector and a vertical cavity surface emitting laser. Themethod comprises the steps: providing a substrate; and alternately growing the first refractive index layer and the second refractive index layer of the distributed Bragg reflector on the substrate in turn, wherein the lattice constant of the substrate is located between the lattice constant of the first refractive index layer and the lattice constant of the second refractive index layer. The substrate having the lattice constant between the lattice constant of the first refractive index layer and the lattice constant of the second refractive index lay is used so that the stress of the firstrefractive index layer and the second refractive index layer grown on the substrate is enabled to cancel each other, i.e. the stress caused by lattice mismatch is eliminated by using the strain compensation mode so that the growth of the strain-free Bragg reflector is realized, and the problem of warping of the epitaxial wafer is avoided.

Owner:度亘核芯光电技术(苏州)有限公司

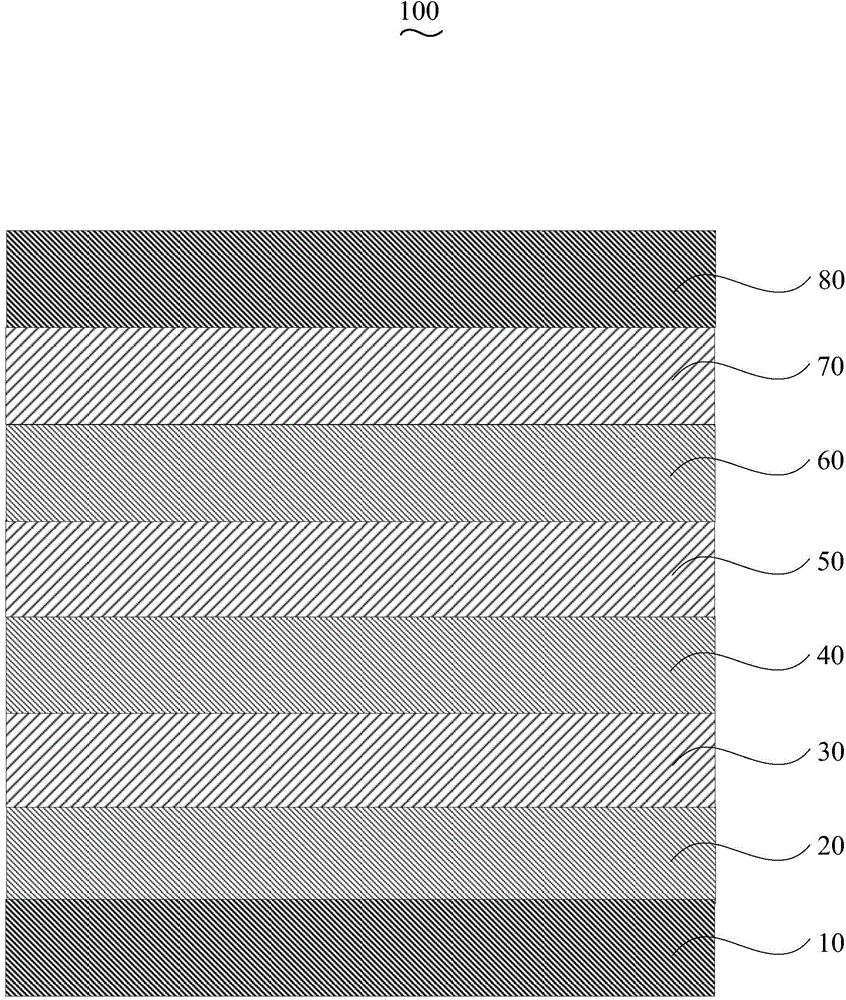

Light-emitting component

ActiveCN101752466AAvoid light absorptionAvoid shadesSemiconductor devicesOhmic contactOmni directional

The invention discloses a light-emitting component which at least comprises a light-emitting laminated layer, a first transparent conductive oxidation layer positioned under the light-emitting laminated layer, a transparent insulating layer positioned under the first transparent conductive oxidation layer, a second transparent conductive oxidation layer positioned under the transparent insulating layer, and a metallic reflection layer positioned under the second transparent conductive oxidation layer, wherein an omni-directional reflector (ODR) layer is formed by the metallic reflection layer and the second transparent conductive oxidation layer, and ohmic contact is formed between the first transparent conductive oxidation layer and the light-emitting laminated layer, so that the light-emitting efficiency of the light-emitting component can be improved.

Owner:EPISTAR CORP

Method for producing semiconductor laser, semiconductor laser, optical pickup, and optical disk drive

InactiveUS20100080107A1Suppressing waveguide lossAvoid light absorptionLaser detailsLaser optical resonator constructionOptical pickupIndium

A method for producing a semiconductor laser having an edge window structure includes the steps of forming masks of insulating films on a nitride-based III-V compound semiconductor substrate including first regions and second regions periodically arranged in parallel therebetween; and growing a nitride-based III-V compound semiconductor layer in a region not covered by the masks. The first region between each two adjacent second regions has two or more positions, symmetrical with respect to a center line thereof, where laser stripes are to be formed. The masks are formed on one or both sides of each of the positions where the laser stripes are to be formed at least near a position where edge window structures are to be formed such that the masks are symmetrical with respect to the center line. The nitride-based III-V compound semiconductor layer includes an active layer containing at least indium and gallium.

Owner:SONY CORP

Light-emitting assembly

The invention discloses a light-emitting assembly, at least comprising a light-emitting laminated layer, a first transparent conductive oxide layer located below the light-emitting laminated layer, a transparent insulation barrier layer located below the first transparent conductive oxide layer, a second transparent conductive oxide layer located below the transparent insulation barrier layer, and a metal reflection layer located below the second transparent conductive oxide layer, wherein the metal reflection layer and the second transparent conductive oxide layer form an omni-directional reflector (ODR), and ohm contact is formed by the first transparent conductive oxide layer and the light-emitting laminated layer so as to increase the light-emitting efficiency of the light-emitting assembly.

Owner:EPISTAR CORP

LED support and LED luminous body

ActiveCN103872218AImprove reliabilityImprove luminous efficiencySemiconductor devicesEngineeringBinding force

The invention is applicable to the field of illumination technologies and provides an LED support. The LED support comprises a metal substrate and a plastic reflection cup arranged on the metal substrate. A protruding box dam for installation of an LED chip is arranged in a region defined by the plastic reflection cup. The box dam and the plastic reflection cup are integrally formed. The depth of the box dam is one-third to three times the thickness of the LED chip. The opening angle of each set of opposite inner side faces of the box dam is smaller than 120 degrees. Because the plastic reflection cup and the box dam are integrally formed on the metal substrate, the procedures are reduced, the production efficiency is improved, the LED support is not prone to deformation and stripping, the binding force between the plastic reflection cup and the metal substrate is enhanced, and the reliability of the LED chip is improved; the depth of the box dam is designed to be one-third to three times the thickness of the LED chip, and the opening angle of each set of opposite inner side faces of the box dam is limited below 120 degrees, so the side faces are prevented from absorbing light, the normal light emergence of the obverse sides is guaranteed, and the luminous efficiency is improved.

Owner:SHENZHEN REFOND OPTOELECTRONICS

Light emitting device and light emitting device package

InactiveUS20110095320A1Avoid damageAvoid light absorptionSolid-state devicesSemiconductor devicesLighting systemActive layer

Disclosed are a light emitting device, a light emitting device package, and a lighting system. The light emitting device includes a light emitting structure including a second conductive semiconductor layer, an active layer over the second conductive semiconductor layer, and a first conductive semiconductor layer over the active layer dielectric layer in a cavity defined by removing a portion of the light emitting structure, and a second electrode layer over the dielectric layer.

Owner:LG INNOTEK CO LTD

Light emitting device

ActiveUS20150092414A1Simple configurationEfficient extractionElectric circuit arrangementsSolid-state devicesLight emitting deviceMetal

A light emitting device of the invention includes a substrate having a metal on a surface thereof; a light emitting element installed on the surface of the substrate; a wire that connects the light emitting element and the metal; and a light reflecting member that covers the metal, the wire having a first bonding ball that is disposed on a surface of the metal, and an extension that extends above the first bonding ball, and the light reflecting member having a protrusion over the first bonding ball.

Owner:NICHIA CORP

A LED manufactured on the SiC substrate

InactiveCN101060150AImprove luminous efficiencyReduce absorptionSemiconductor devicesSic substrateCharge carrier

The provided LED prepared on SiC substrate comprises: from top to bottom, a p-type AlInGaN layer with an anode, a luminous layer, a n-type AlInGaN layer with a cathode, and the clear transparent SiC monocrystal substrate with background carrier concentration less than 1X1016 / cm3 and resistivity over 103Omega. cm. this invention improves LED luminous efficiency, and fit to prepare heavy-power device.

Owner:SHANDONG UNIV

Light-emitting diode structure

InactiveCN1489223AImprove luminous efficiencyProcess Efficiency ImprovementLaser detailsSemiconductor lasersVaporizationBoron

The invention relates to structure of LED. Most of Si substrate with Miller indices as 100 is removed by using photo-resistetching. Meanwhile, part of Boron monophosphide layer near crystal lattice of Si substrate is removed by using photo-resistetching. Micro removing is carried out for LED by photo etching or a micro-lens is made at exacatin of removed structure for focusing light. A reflecting minor with multilayer films is formed above LED through procedure of coating by vaporization or epitaxy process in order to reflect emitting light. Thus, the LED with structure of backside emitting is made: preventing light absorption by Si substrate; reflecting minor with multilayer films and micro-lens reflect and focus light emitted by LED so as to raise luminous efficiency.

Owner:VTERA TECH

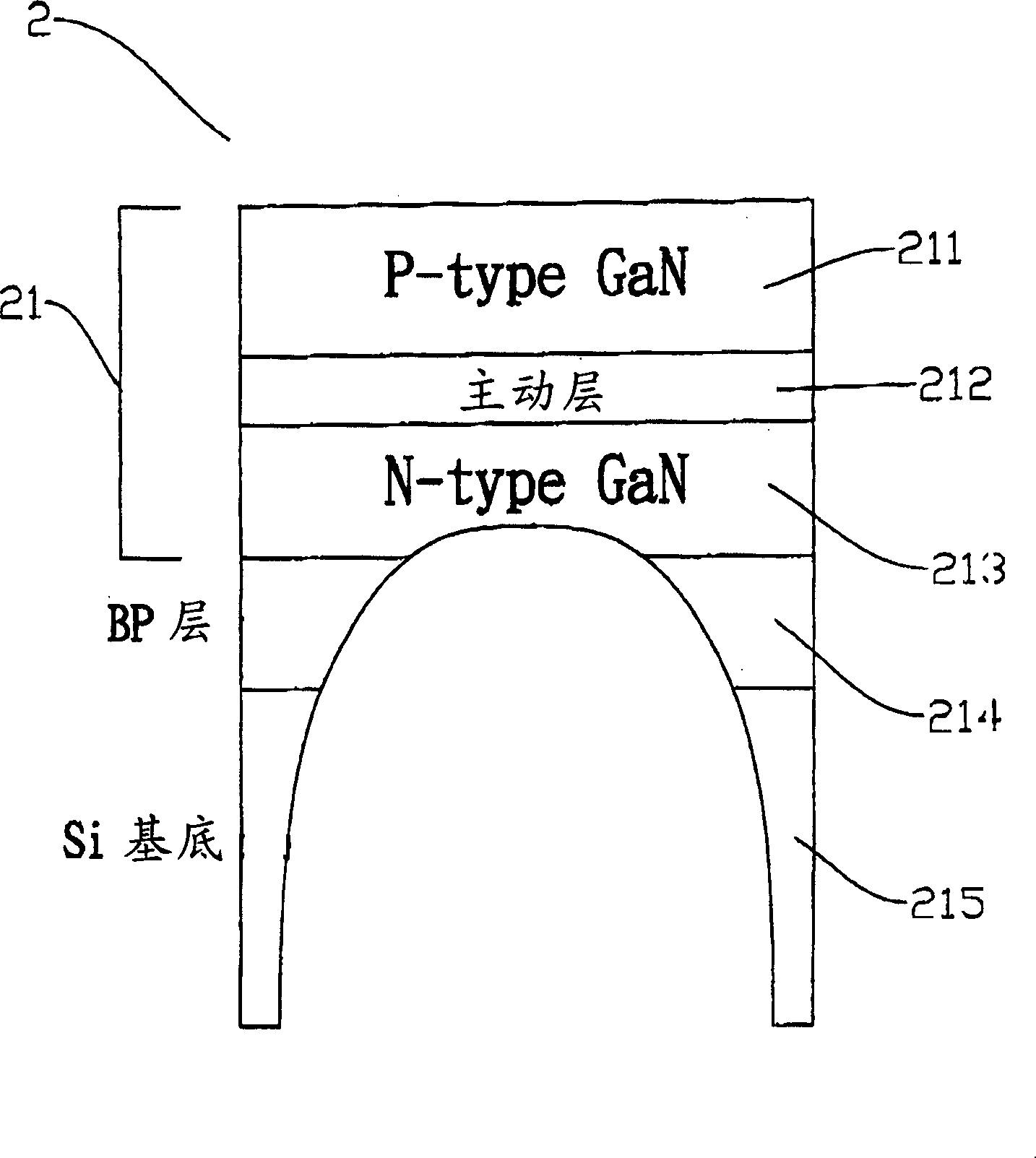

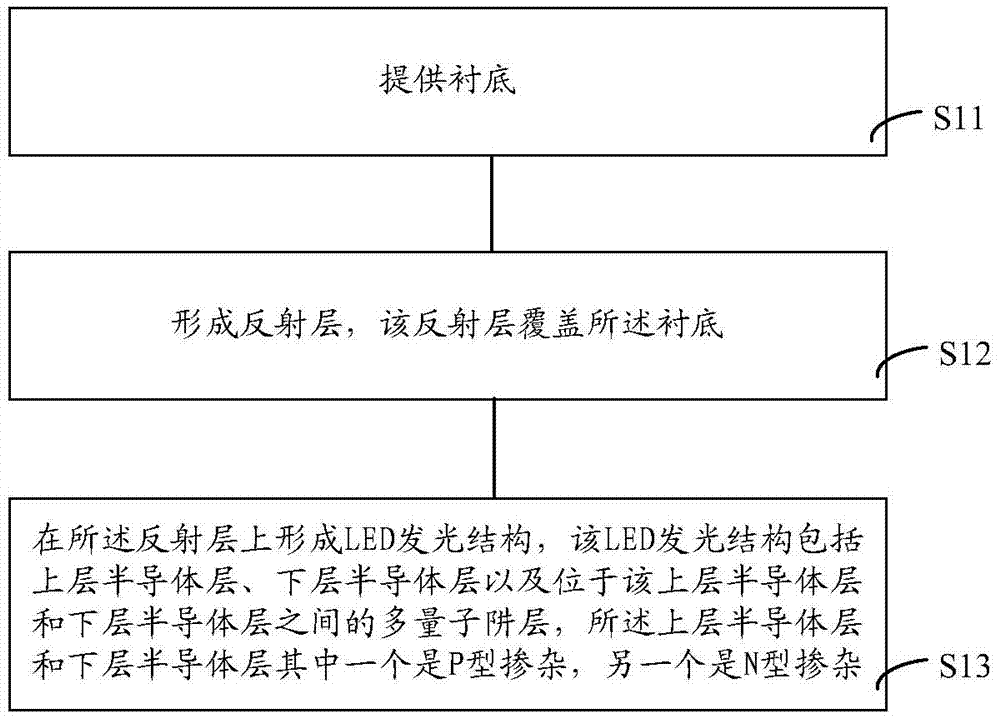

LED (light emitting diode) structure and manufacturing method thereof

InactiveCN103682006AAvoid light absorptionReduce manufacturing costSemiconductor devicesManufacturing cost reductionPolymer light emitting diodes

The invention provides an LED (light emitting diode) structure and a manufacturing method thereof. The LED structure comprises a substrate, a reflecting layer and an LED luminescent structure, wherein the reflecting layer covers the substrate; the LED luminescent structure is arranged on the reflecting layer, the LED luminescent structure comprises an upper semiconductor layer, a lower semiconductor layer and a multiple-quantum-well layer which is arranged between the upper semiconductor layer and the lower semiconductor layer, one of the upper semiconductor layer and the lower semiconductor layer is P-type doped and the other one is N-type doped. By adopting the LED structure, the light absorption problem can be overcome without transferring or schematizing the substrate, so that the manufacturing cost is reduced; moreover, the growth time for adopting the MOCVD (metal organic chemical vapor deposition) to form the LED luminescent structure can be reduced.

Owner:HANGZHOU SILAN AZURE

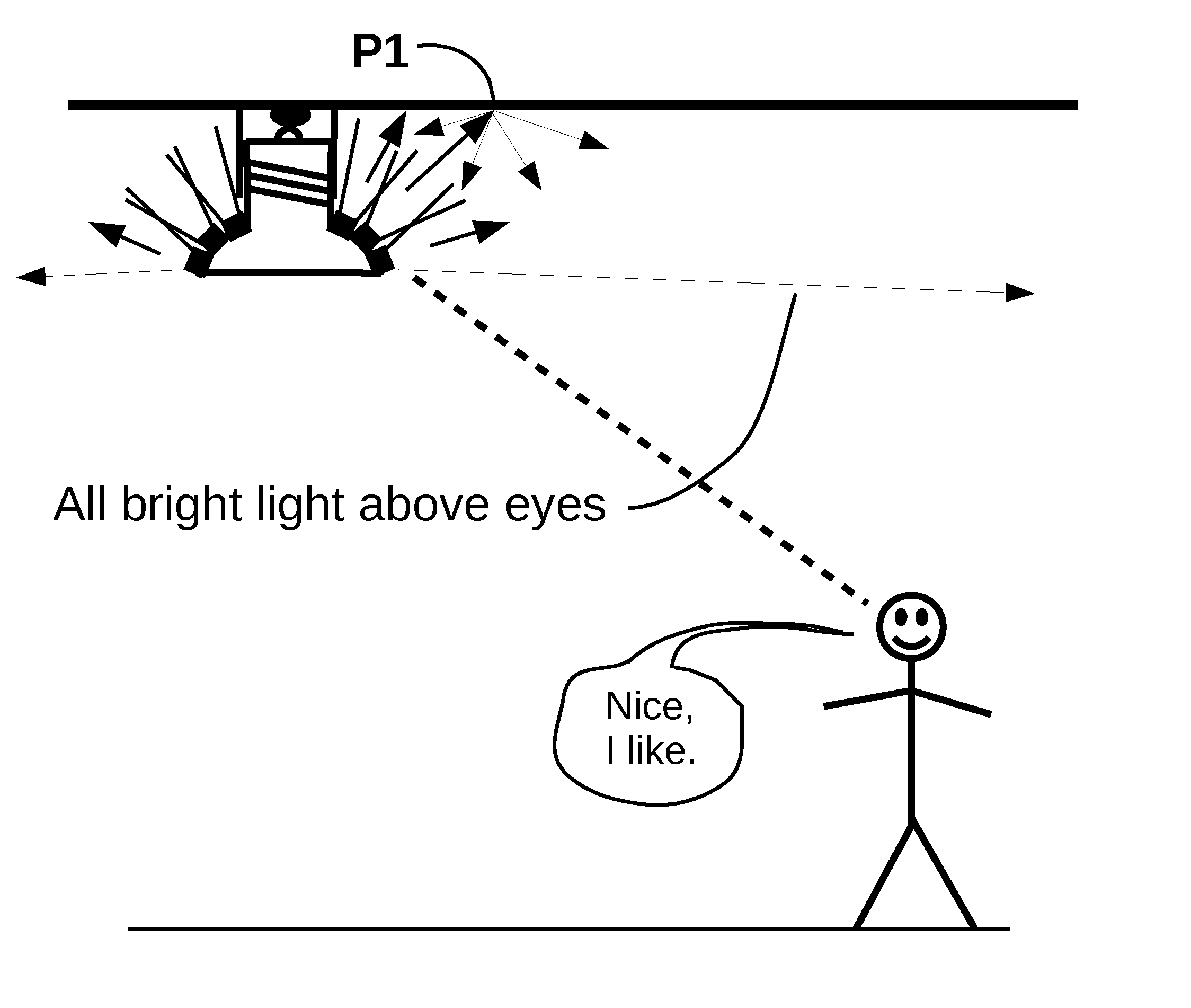

Method and means to evenly distribute ambient illumination and to avoid bright LED beam directly into human eyes

InactiveUS20170030552A1Reduce energy efficiencyAbsorption of lightElectrical apparatusElectroluminescent light sourcesLight energyEffect light

An energy-saving LED-based device with improved support structure for high-brightness LED chips for room illumination. The improved support structure positions the LED chips in such a way that the light is emitted towards the ceiling, the floor, or any other surface, along such a path that human eyes are unlikely to cross the light path. Because the bright light is kept away from people's eyes, there is no need for shades, which absorbs some of the light produced. Two of the most common shades are the light breakers surrounding the standing lamps in residential spaces and the light breakers around the lights near the ceiling that are part of the indirect lighting. Dispensing with the shades increases the overall energy efficiency because the light energy absorption by the shade is obviated. The illumination created by such improved LED arrangement is also more pleasing to humans because it creates less shadows.

Owner:MONTEIRO SERGIO LARA PEREIRA

LED (Light-Emitting Diode) plane light source and method for increasing light guiding efficiency thereof

InactiveCN102080777AReduce usageImprove incident efficiencyPoint-like light sourceElectric lightingLight sensingLight guide

The invention relates to an LED (Light-Emitting Diode) plane light source and a method for increasing the light guiding efficiency thereof, belonging to the technical field of light sensing engineering application. The LED plane light source is characterized in that a light reflection layer is arranged between the side of a light guiding plate and a PCB (Printed Circuit Board), a light outlet is prearranged at a position on the light reflection layer corresponding to LED light sources, and the PCB, the light reflection layer and the light guiding plate clings to each other in sequence; and the LED light sources respectively arranged at two opposite sides of the light guiding plate are arranged in ways of mutual cross and ectopic complementation. One side of each of the LED light sources is additionally provided with the light reflection layer on which the light outlet is prearranged, thus the light reflection at the side of the light guiding plate is avoided, light emitted by an LED is directly led out through the light outlet by the light guiding plate, and the light incidence efficiency is increased; the LED light sources are arranged in ways of mutual cross and ectopic complementation, thus, the condition that the LED absorbs the light from the opposite LED per se is avoided, and the light guiding efficiency is increased; and on the basis of ensuring same brightness, the consumption of the LEDs can be reduced and the lost can be lowered.

Owner:PUHUAN OPTOELECTRONICS TECH SHANGHAI

Light emitting device and method of manufacturing the same

ActiveUS7956469B2Improve extraction efficiencyEffective lightingSemiconductor/solid-state device detailsSolid-state devicesLength waveLight emitting device

Provided is a light emitting device with high extraction efficiency, in which absorption of light by a conductive wire is prevented effectively. The light emitting device includes a conductive wire electrically connecting an electrode of a light emitting element and an electrically conductive member. The surface of the bonding portion of the conductive wire between the conductive wire and at least one of the electrode of the light emitting element and the electrically conductive member is covered with a metal film. The reflectivity of the metal film is higher than that of the conductive wire at the emission peak wavelength of the light emitting element.

Owner:NICHIA CORP

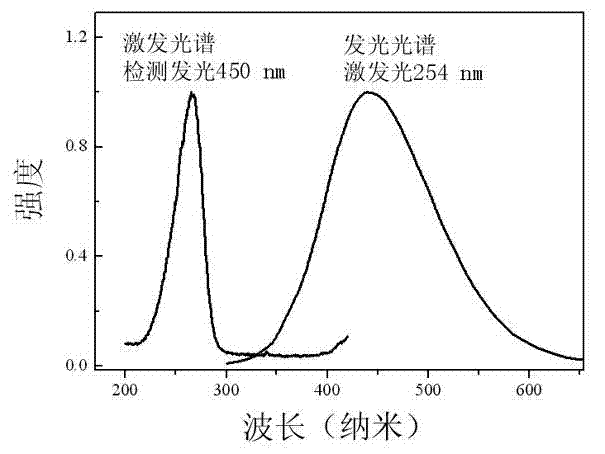

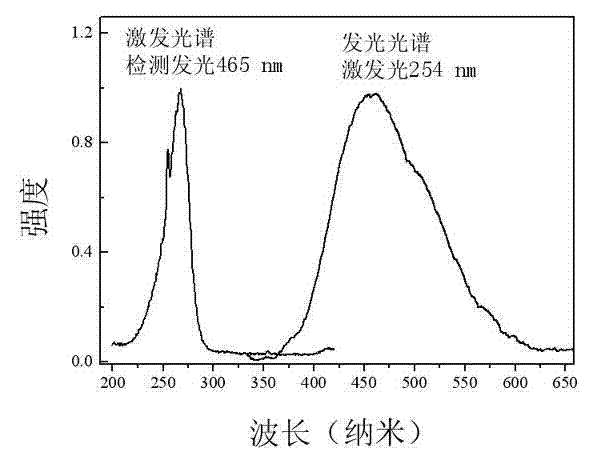

Rare earth niobium tantalate fluorescent powder with adjustable luminous chroma, preparation method and application thereof

ActiveCN102585818AHigh crystallinityImprove lighting qualityLuminescent compositionsAir atmospherePhotoluminescence

The invention relates to rare earth niobium tantalate fluorescent powder with adjustable luminous chroma, a preparation method and application of the rare earth niobium tantalate fluorescent powder. The fluorescent powder is niobate and tantalate which are activated by Eu3+, and the molecular formula of the fluorescent powder is R(1-z)EuzCaM3O10, wherein M is at least one of Nb and Ta, R is at least one of La3+, Sm3+, Gd3+, Lu3+ and Y3+, z is the molar percentage of Eu3+ doping amount, and z is greater than 0.0001 and less or equal to 1.0. The preparation method comprises the following steps of: weighing raw materials according to the proportion; porphyrizing and uniformly mixing the raw materials, and pre-sintering at a temperature of 300-1,000 DEG C; cooling, taking out the mixture and grinding; and calcining in an air atmosphere at a temperature of 1,200-1,500 DEG C. Along with the increase of the molar percentage of Eu3+ doping amount, the chroma of the fluorescent powder can be changed from blue green to white and then red. The fluorescent powder can be applied to various illumination display and photoluminescence chroma adjustment taking ultraviolet light or near-ultraviolet light as an excitation source.

Owner:扬州科丰高新产业投资开发集团有限公司

White light LED wafer packaging structure and packaging method

InactiveCN105428502ASolve the spot problemAvoid light absorptionSolid-state devicesSemiconductor devicesLight spotSilica gel

The invention discloses a white light LED wafer packaging structure. The white light LED wafer packaging structure comprises a substrate, at least a white light LED wafer, a white silica gel layer and a transparent silica gel layer, wherein the white light LED wafer is fixed on the substrate; the white silica gel layer is arranged on the side face of the white light LED wafer; the white light LED wafer is connected with the substrate through a gold thread; and the white light LED wafer and the white silica gel layer are coated with the transparent silica gel layer. The invention also discloses a white light LED packaging method. The invention adopts the white light wafer with a perpendicular structure, so that the light spot problem of the light source is effectively solved; the substrate of the wafer is coated with the white silica gel layer, so that the light-absorbing phenomenon of the substrate material is effectively avoided; and meanwhile, the light loss in a secondary reflection process is reduced, so that the light out-coupling efficiency of the product is improved, and the luminance of the whole device is improved.

Owner:JIANGSU WENRUN OPTOELECTRONICS

Semi-reflecting and semi-transmitting glass and preparation method thereof

ActiveCN104527165AHardness advantageHas semi-reflective and semi-transparent propertiesLaminationLamination apparatusRefractive indexPost-Procedure

The invention discloses semi-reflecting and semi-transmitting glass with the advantages of high hardness, acid and alkali corrosion resistance, alkali liquor ultrasound resistance, scratch resistance and high post-procedure machinability. The reflectivity of the semi-reflecting and semi-transmitting glass refers to any reflectivity in a range from 18 percent to 75 percent. The semi-reflecting and semi-transmitting glass comprises a glass substrate, a first low-refractive index layer, a first high-refractive index layer, a second low-refractive index layer, a second high-refractive index layer, a third low-refractive index layer, a third high-refractive index layer and a fourth high-hardness refractive index layer which are sequentially laminated with one another, wherein the first low-refractive index layer is made of SiO2; the first high-refractive index layer is made of Nb2O5; the second low-refractive index layer is made of SiO2; the second high-refractive index layer is made of Nb2O5; and the third low-refractive index layer is made of SiO2. The hardness of the semi-reflecting and semi-transmitting glass can be 7H, and the semi-reflecting and semi-transmitting glass has the advantages of acid and alkali corrosion resistance, alkali liquor ultrasound resistance, scratch resistance and high post-procedure machinability. The invention also discloses a method for preparing the semi-reflecting and semi-transmitting glass.

Owner:YICHANG NANBO DISPLAY

Light emitting diode with metal piles and multi-passivation layers and its manufacturing method

ActiveUS8847267B2Reduce in quantityAvoid light absorptionSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorOptoelectronics

The present invention relates to a light emitting diode with metal piles and one or more passivation layers and a method for making the diode including a first steps of performing mesa etching respectively on a first semiconductor layer and a second semiconductor layer belonging to stacked layers formed on a substrate in sequence! a second step of forming a reflector layer on the mesa-etched upper and side face! a third step of contacting one or more first electrodes with the first semiconductor layer and one or more second electrodes through the reflector layer with the second semiconductor layer; a fourth step of forming a first passivation layer on the reflector layer and the contacted electrodes; and a fifth step of connecting the first electrodes to a first bonding pad through one or more first electrode lines, bring one ends of vertical extensions having the shape of a metal pile into contact with one or more second electrodes, and connecting the other ends of the vertical extensions to a second bonding pad through one or more second electrode lines. As effects of the present invention, the loss of light emitting area decreases and current diffusion efficiency increases.

Owner:KOREA PHOTONICS TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com