A LED manufactured on the SiC substrate

A technology of light-emitting diodes and substrates, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of low LED efficiency and achieve the effects of increasing output power, reducing absorption, and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

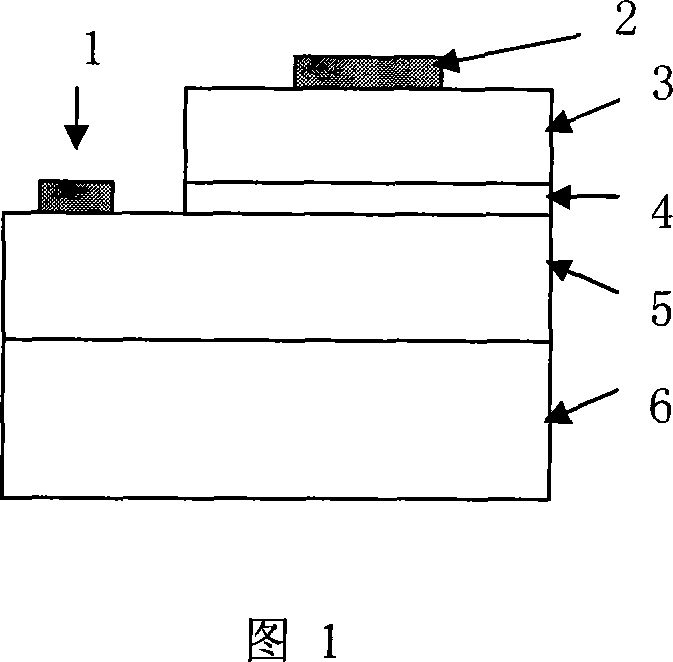

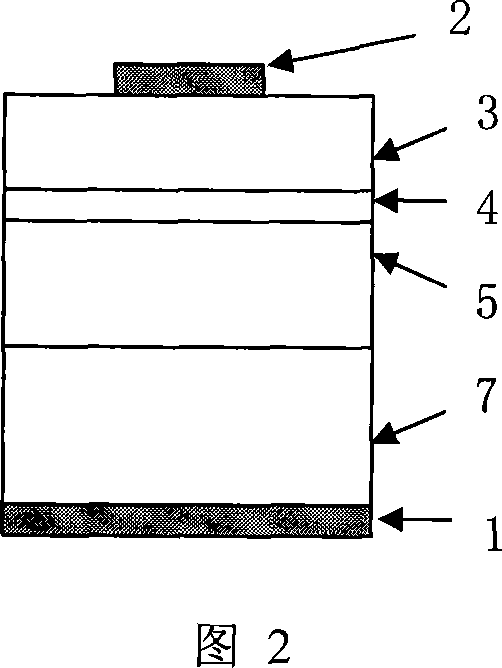

[0029] The structure of the light-emitting diode prepared on the SiC substrate of the present invention is shown in Figure 5, which includes a p-type AlInGaN layer 3, a light-emitting layer 4, an n-type AlInGaN layer 5 and a transparent SiC substrate 8 from top to bottom. The positive electrode 2 is provided on the n-type AlInGaN layer 3 , and the negative electrode 1 is provided on the n-type AlInGaN layer 5 . The substrate can be a transparent 6H-SiC single crystal wafer or a transparent 4H-SiC single crystal wafer, and the transparent SiC substrate 8 is colorless and transparent in the range of visible light. In order to reflect back the downwardly transmitted light, a metal reflective layer 9 is also provided on the bottom surface of the substrate 8 .

[0030] The conductive n-type 6H-SiC single crystal is green due to the presence of impurity ions. There is a strong absorption in the visible light band, as shown in the absorption spectrum of the 6H-SiC single crystal sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com