LED

A technology of light-emitting diodes and diodes, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of not being in the same horizontal position, loss of luminous area, and lower production qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

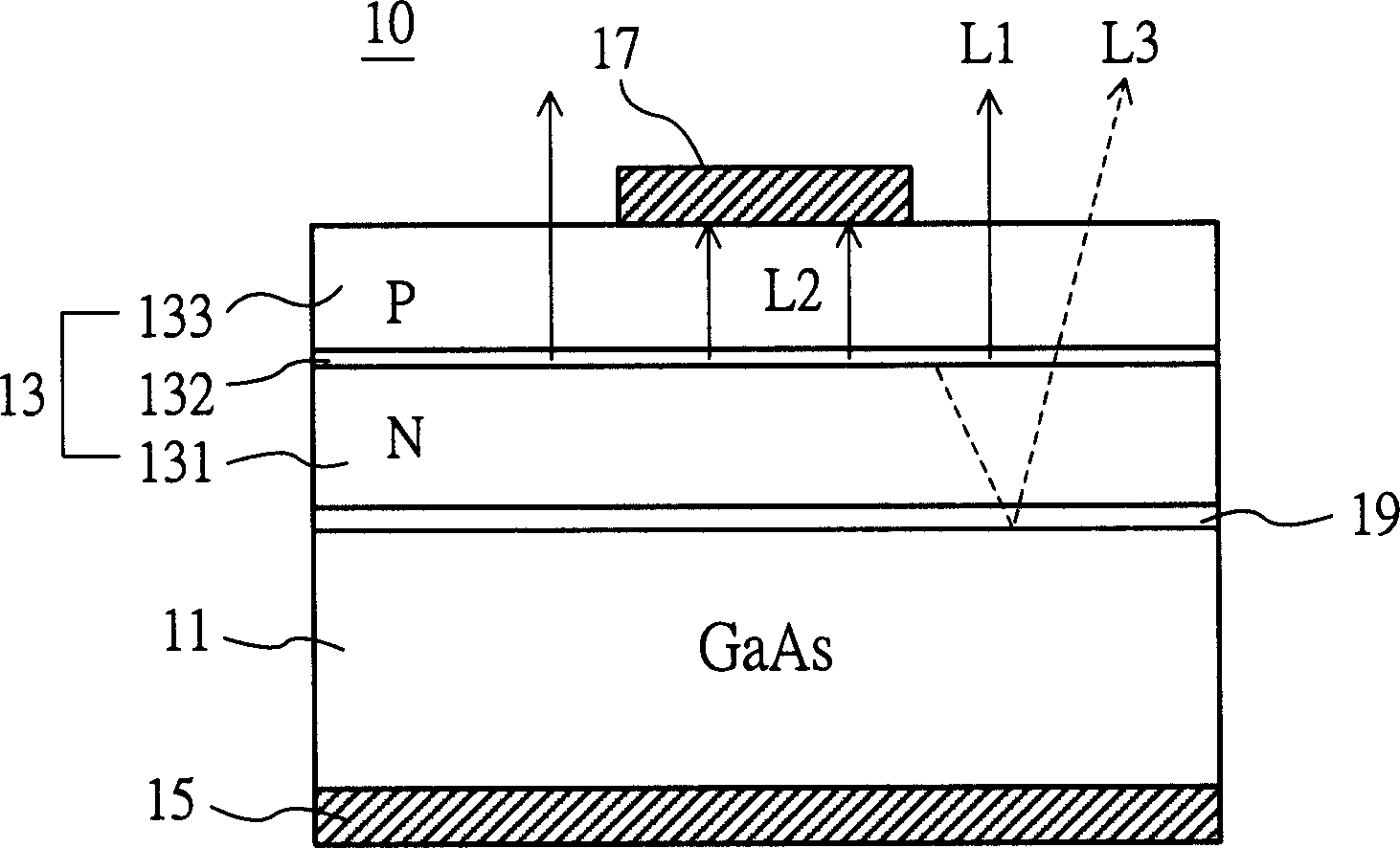

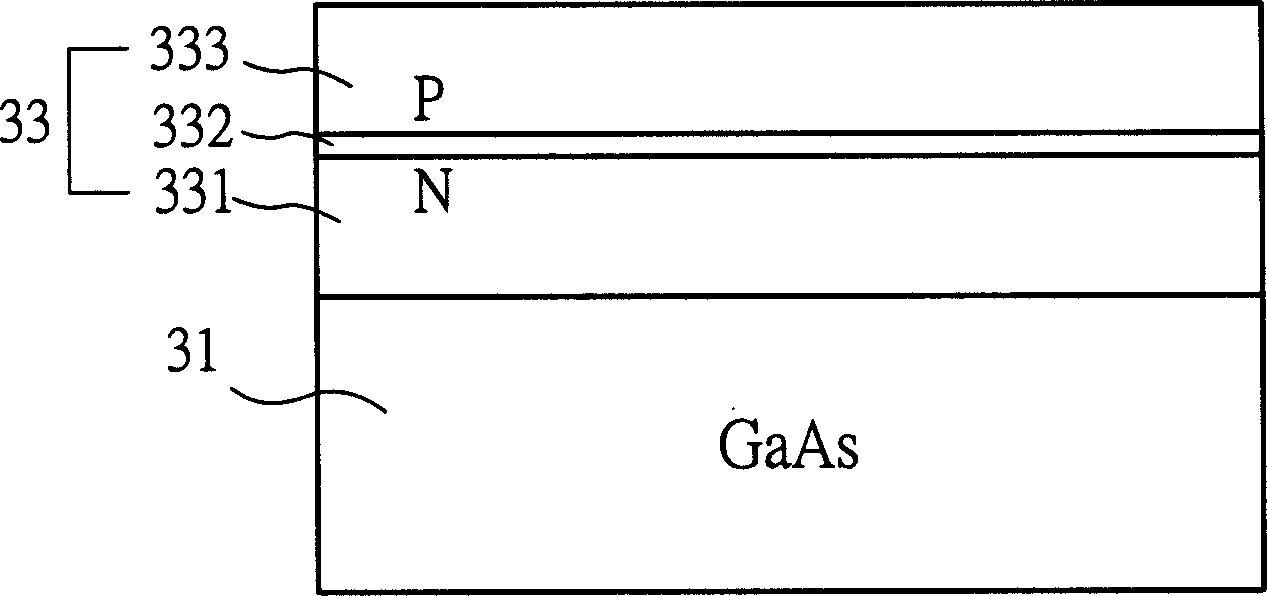

[0071] see Figure 3A to Figure 3C , are respectively the structural cross-sectional views of a preferred embodiment of the light-emitting diode of the present invention in each manufacturing step; as shown in the figure, the manufacturing of the present invention mainly includes the following steps:

[0072] First, a semiconductor substrate 31 is provided, such as a GaAs substrate (light-absorbing substrate), and a first material layer 331 (such as an N-type or P-type cladding layer), a light-emitting layer 332 and a second material layer are sequentially grown on the upper surface of the GaAs substrate 31. The material layer 333 (such as a P-type or N-type cladding layer), so as to form a quaternary epitaxial layer 33, as shown in FIG. 3A.

[0073] Wherein, the light-emitting layer 332 can be a PN interface, and can be optionally made of a ternary or quaternary compound, such as aluminum gallium arsenide (AlGaAs), aluminum gallium indium phosphide (AlGaInP) or aluminum galli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com