Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about "Melt circulation arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

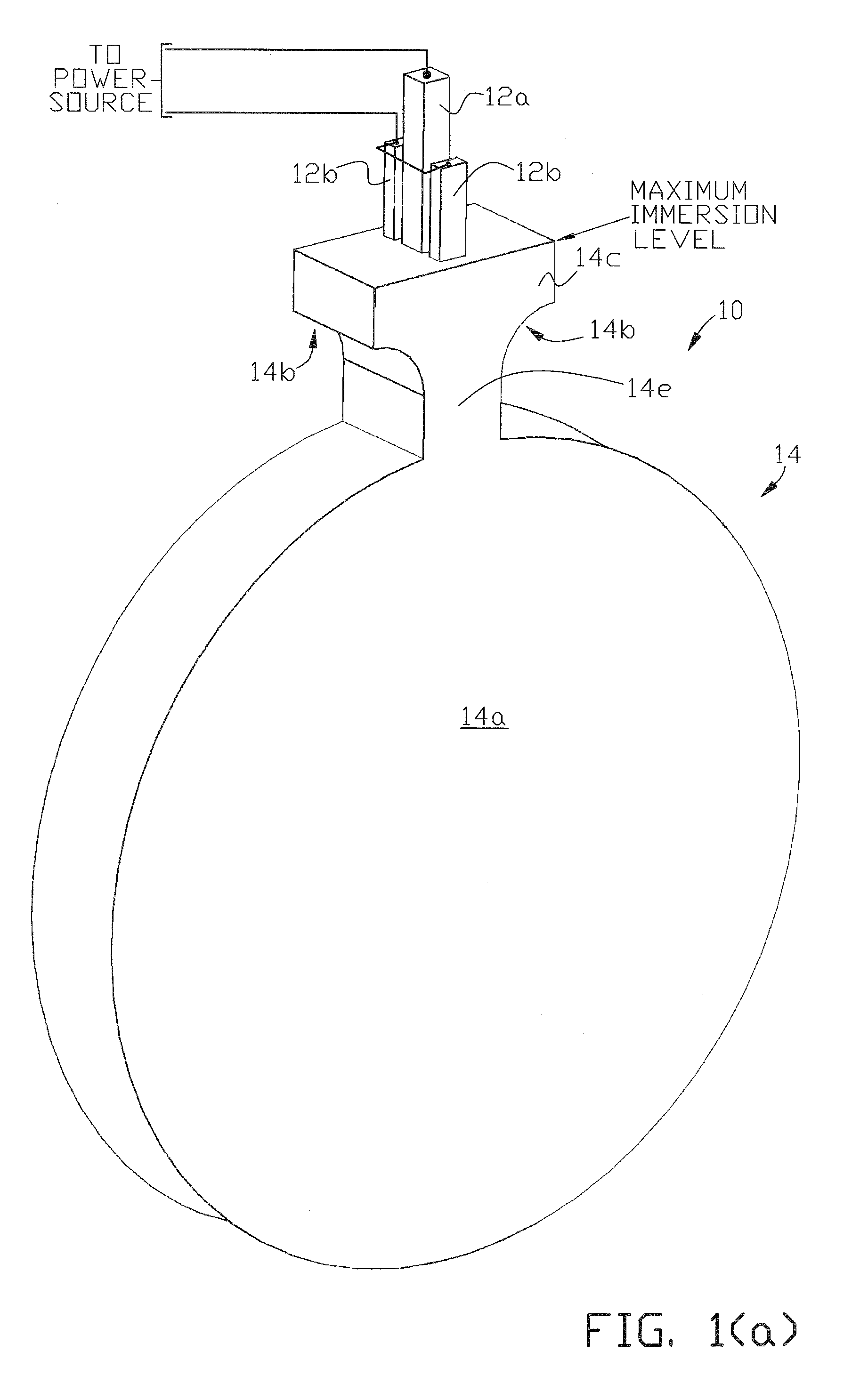

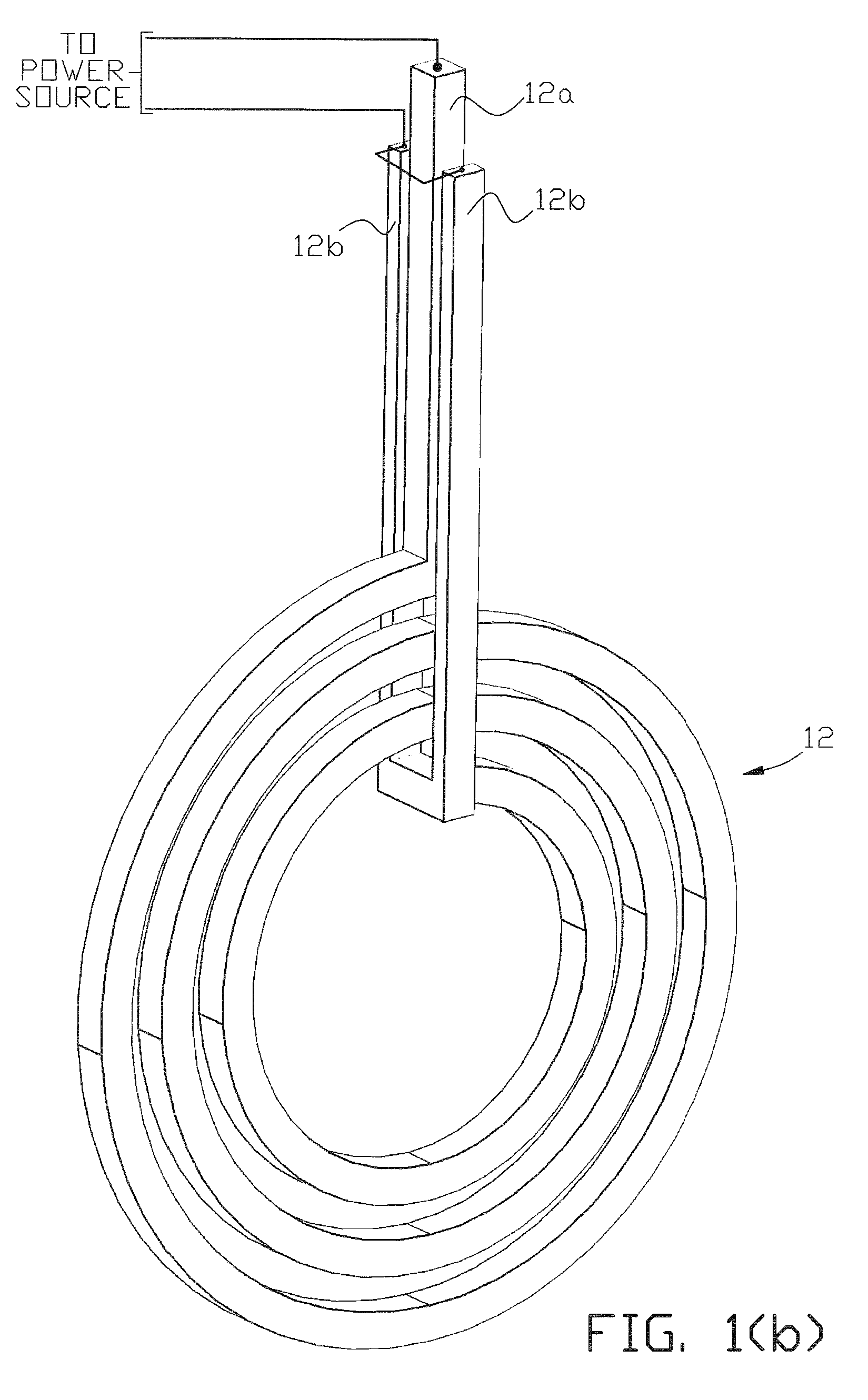

Electric Induction Heating and Stirring of an Electrically Conductive Material in a Containment Vessel

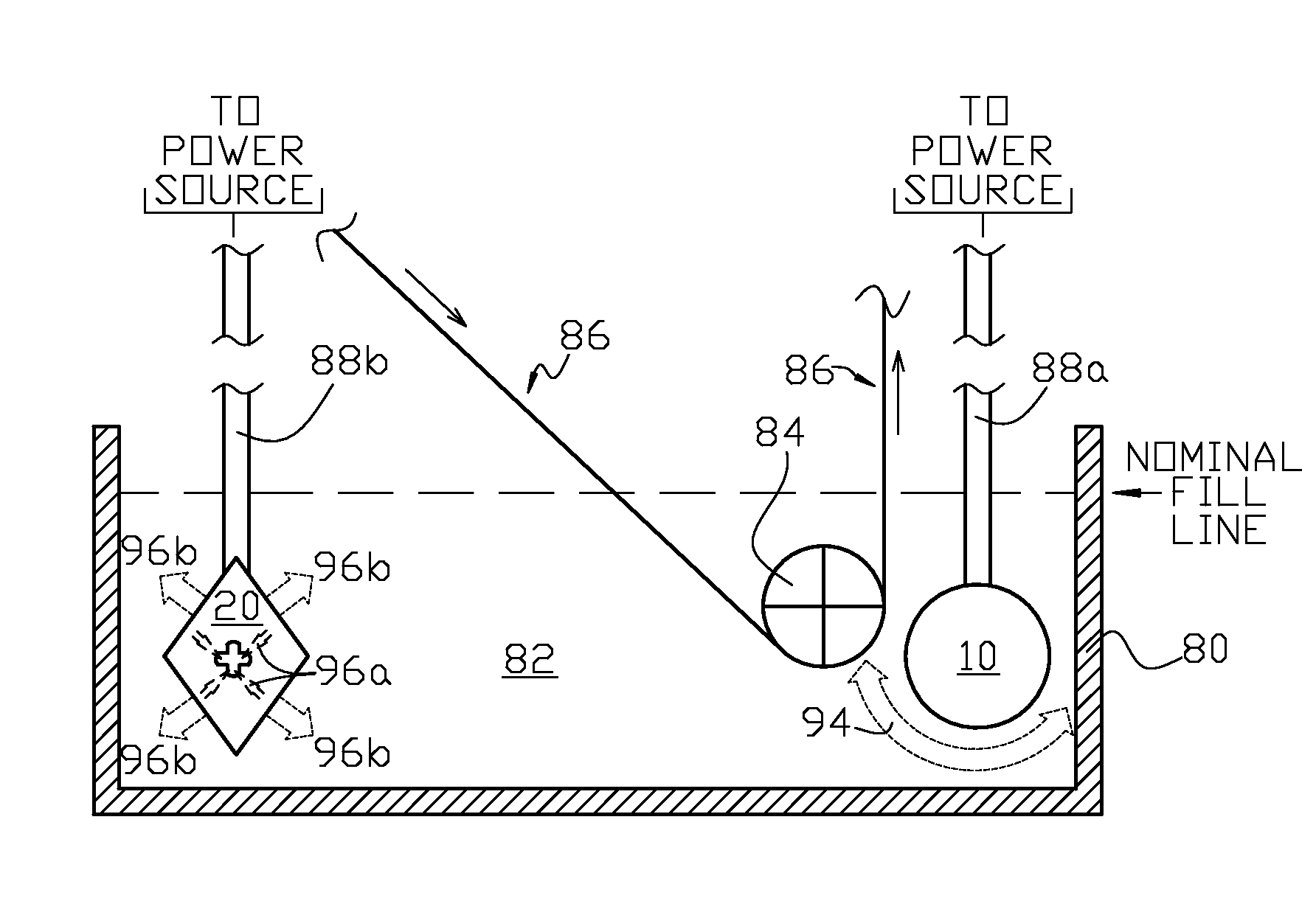

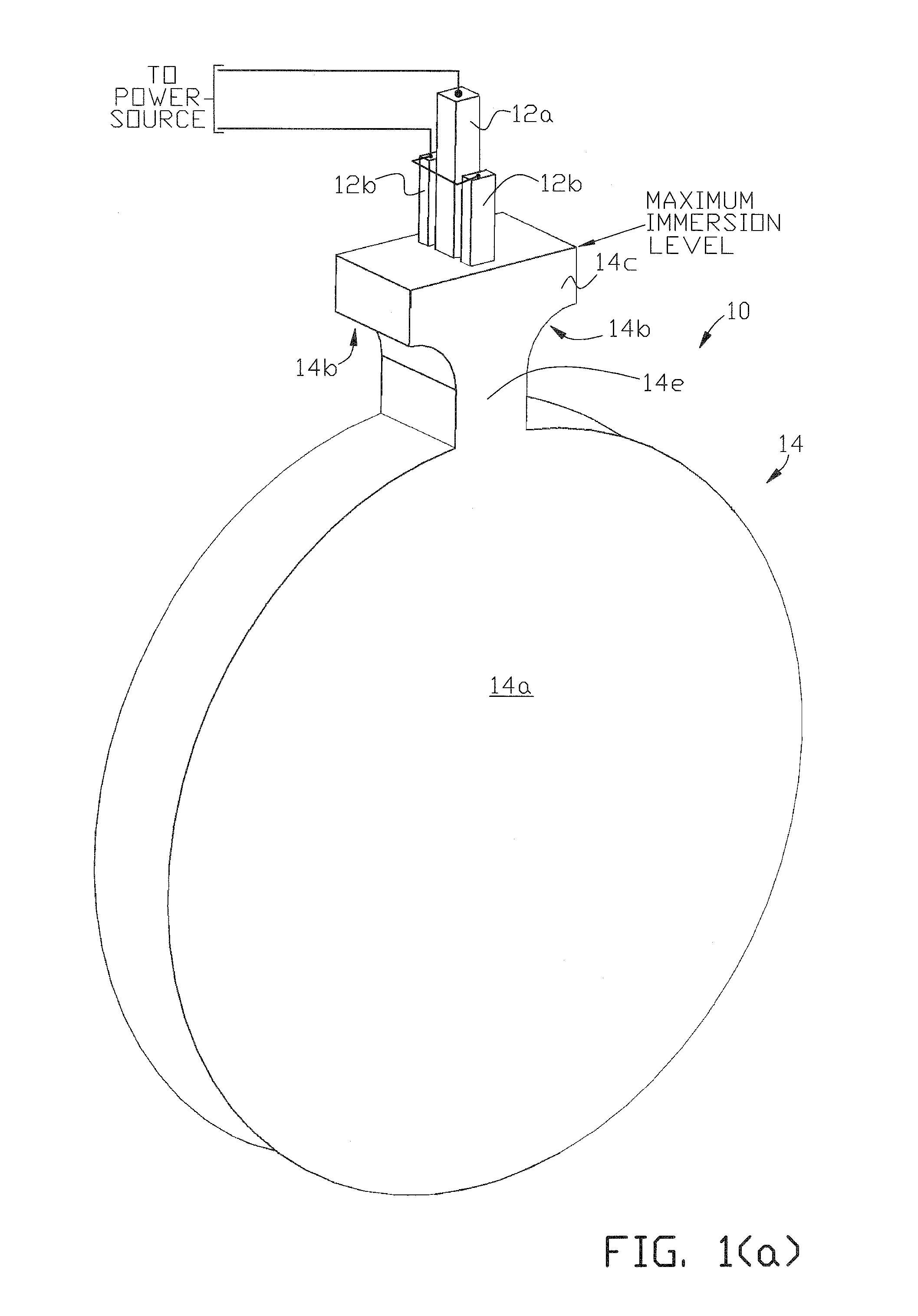

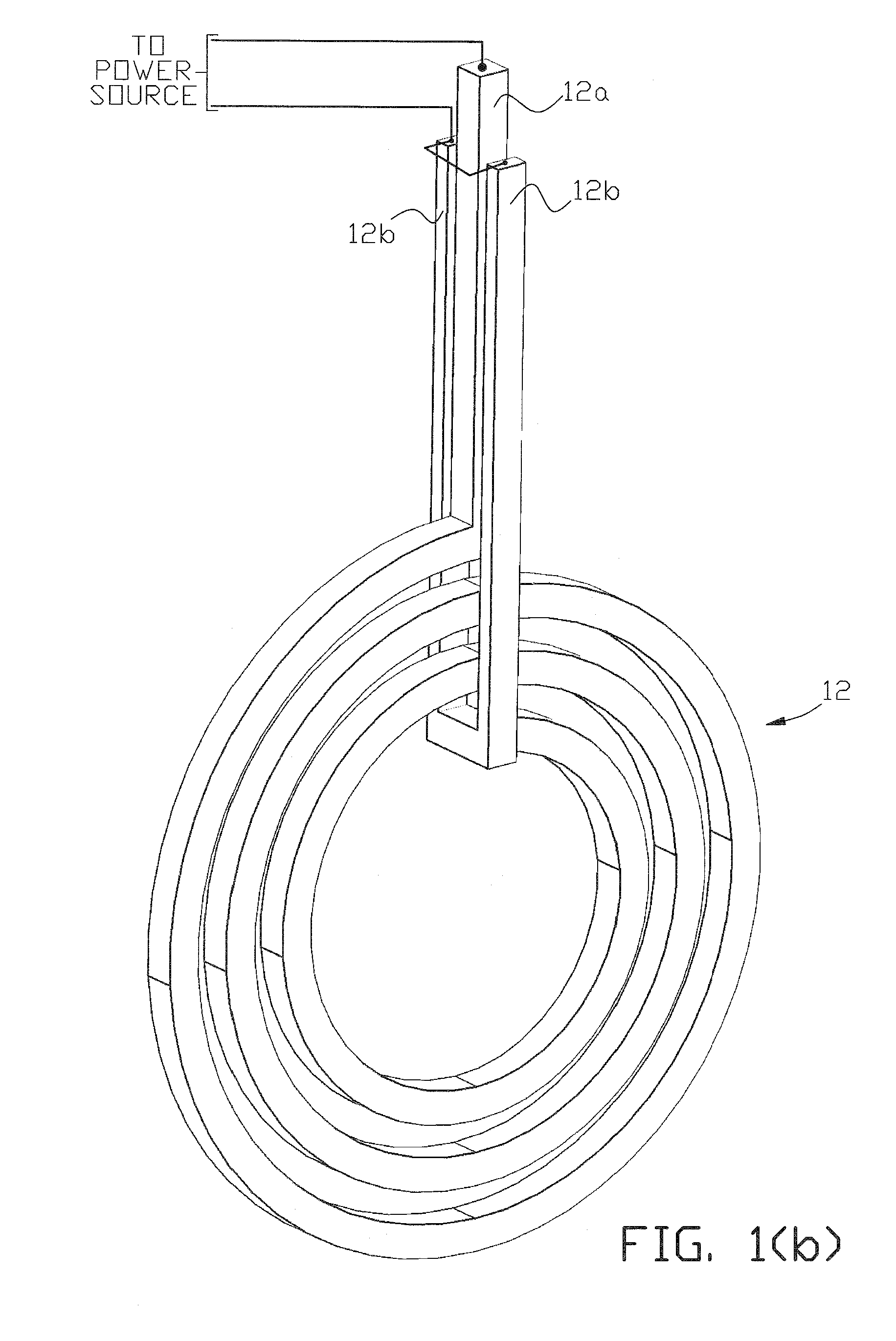

ActiveUS20110011750A1Furnaces without endless coreFrom normal temperature solutionsRefractoryElectrically conductive

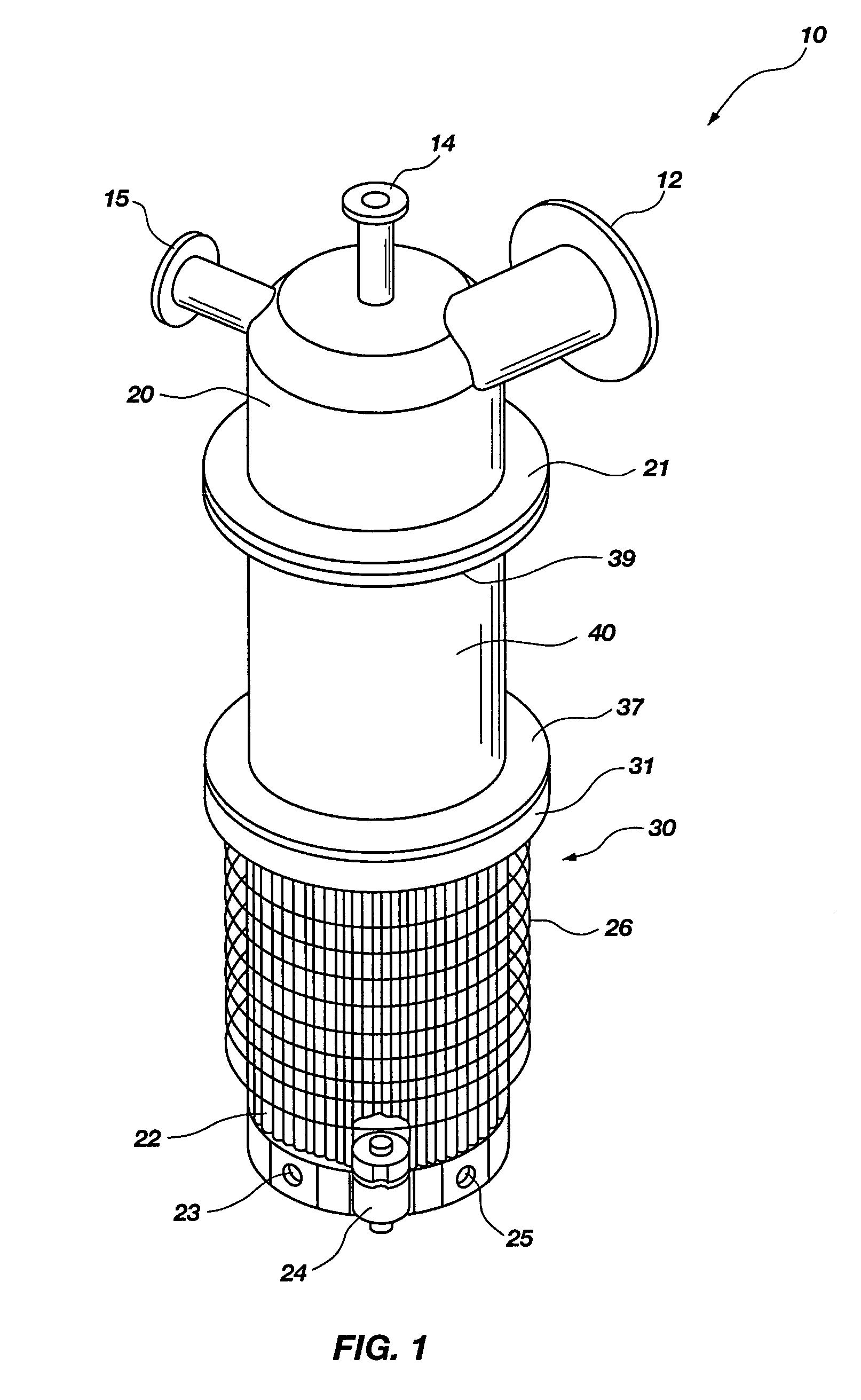

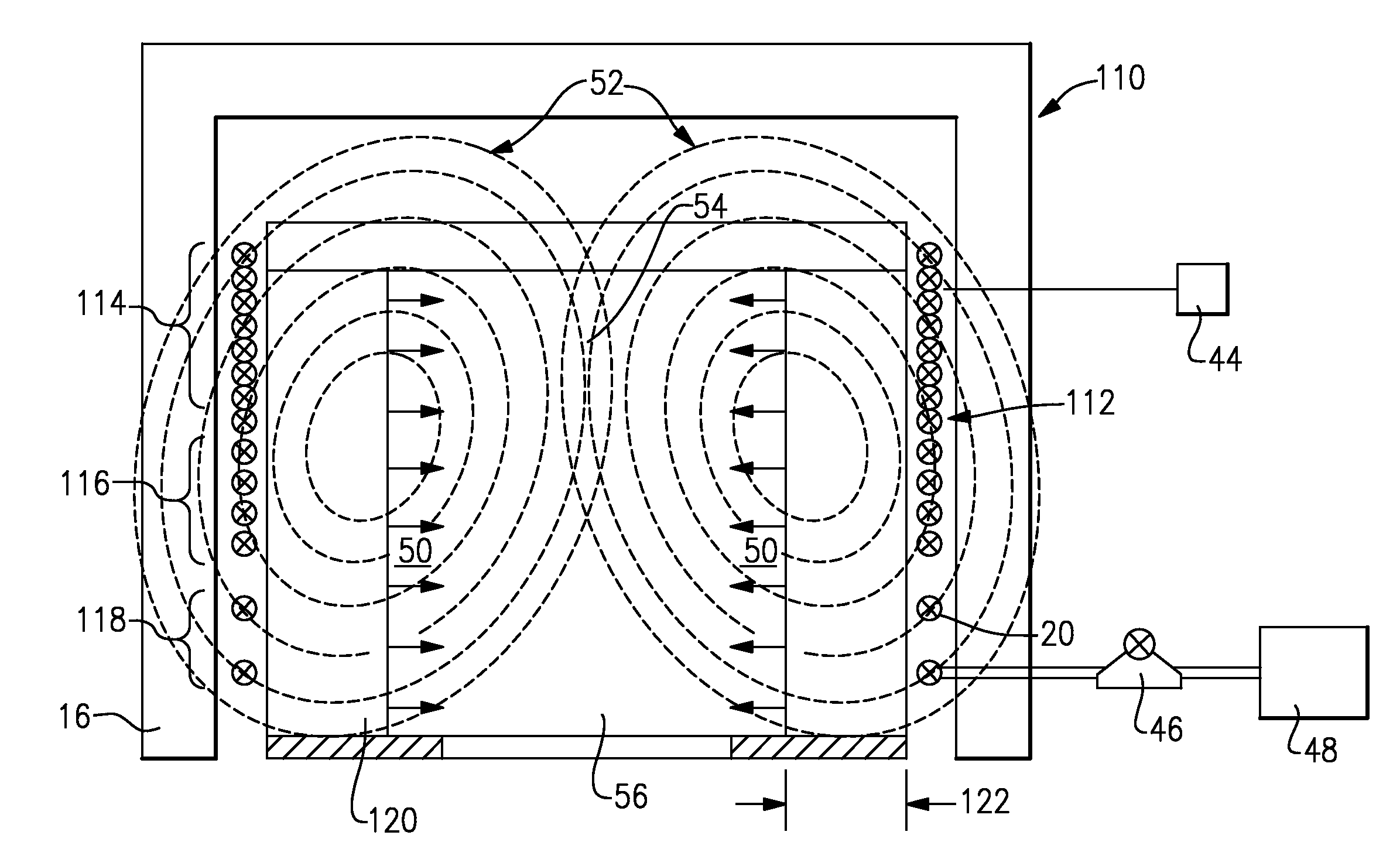

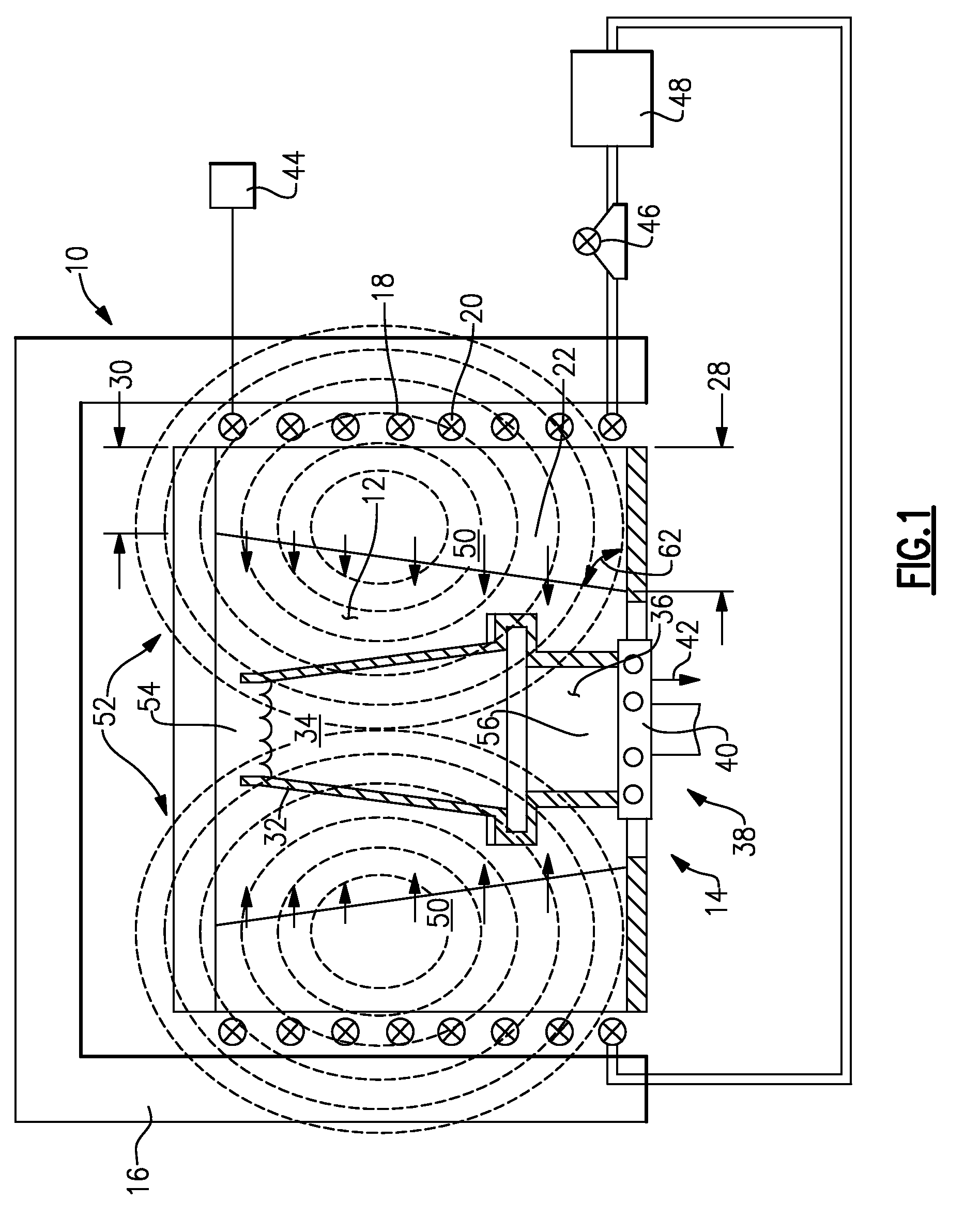

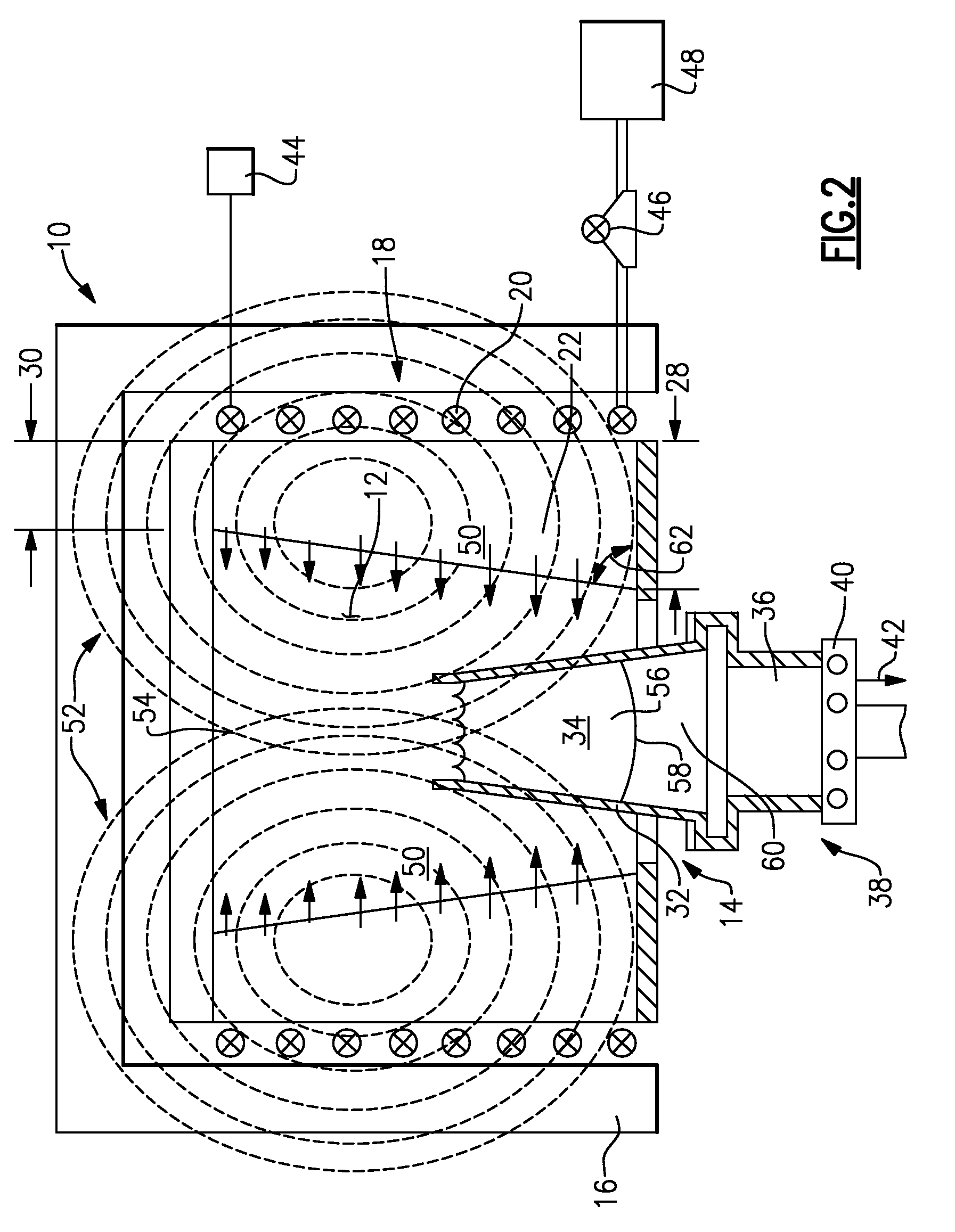

Apparatus and method are provided for electric induction heating and / or stirring of a molten electrically conductive composition in a containment vessel with the apparatus being removably insertable in the molten composition. An induction coil embedded in refractory or a coating is submerged in the composition and used to heat and / or stir the molten composition either externally or internally to the refractory or coating.

Owner:INDUCTOTHERM INDS

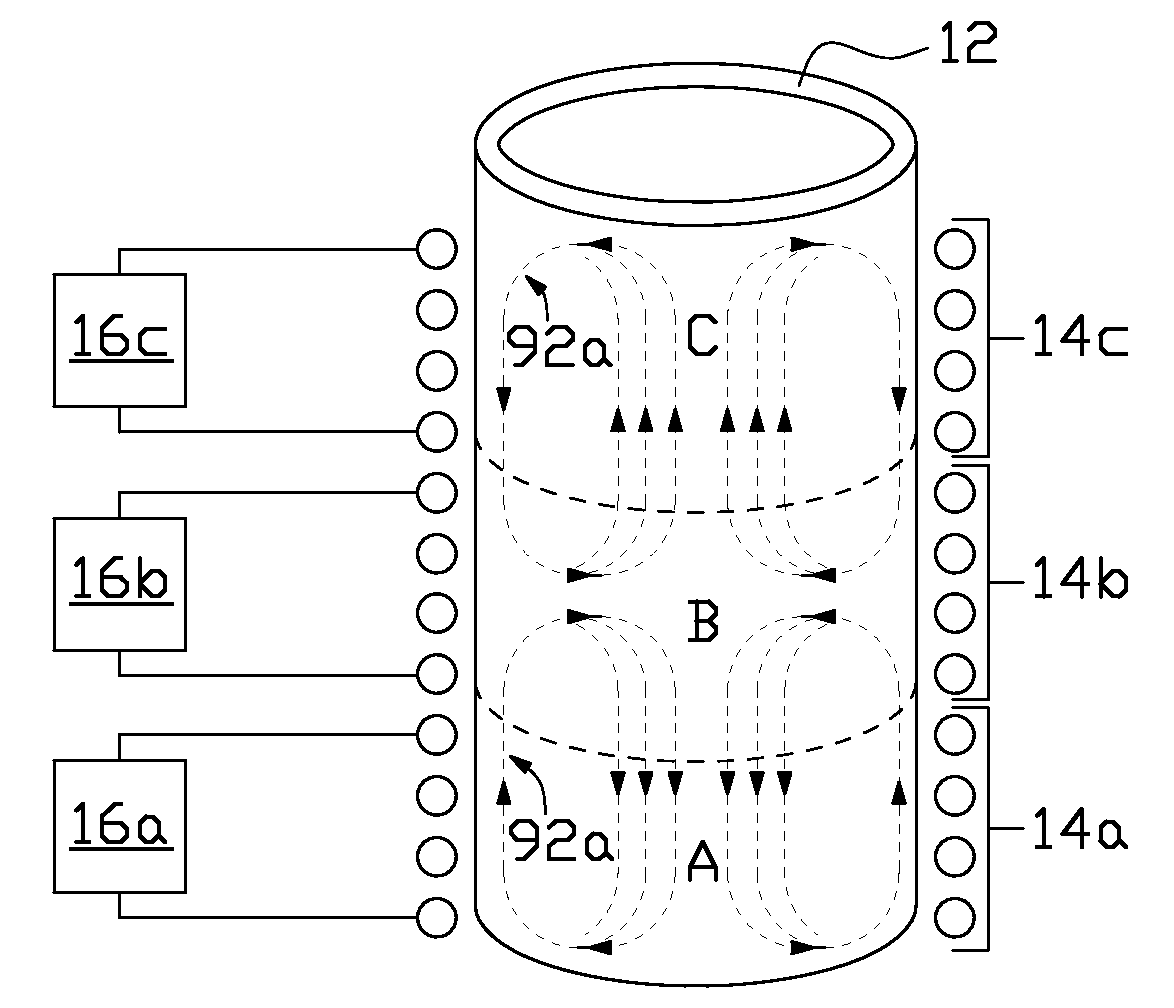

Melting and mixing of materials in a crucible by electric induction heel process

ActiveUS20090129429A1Reduce output frequencyFurnaces without endless coreMechanical apparatusCrucibleSemi solid

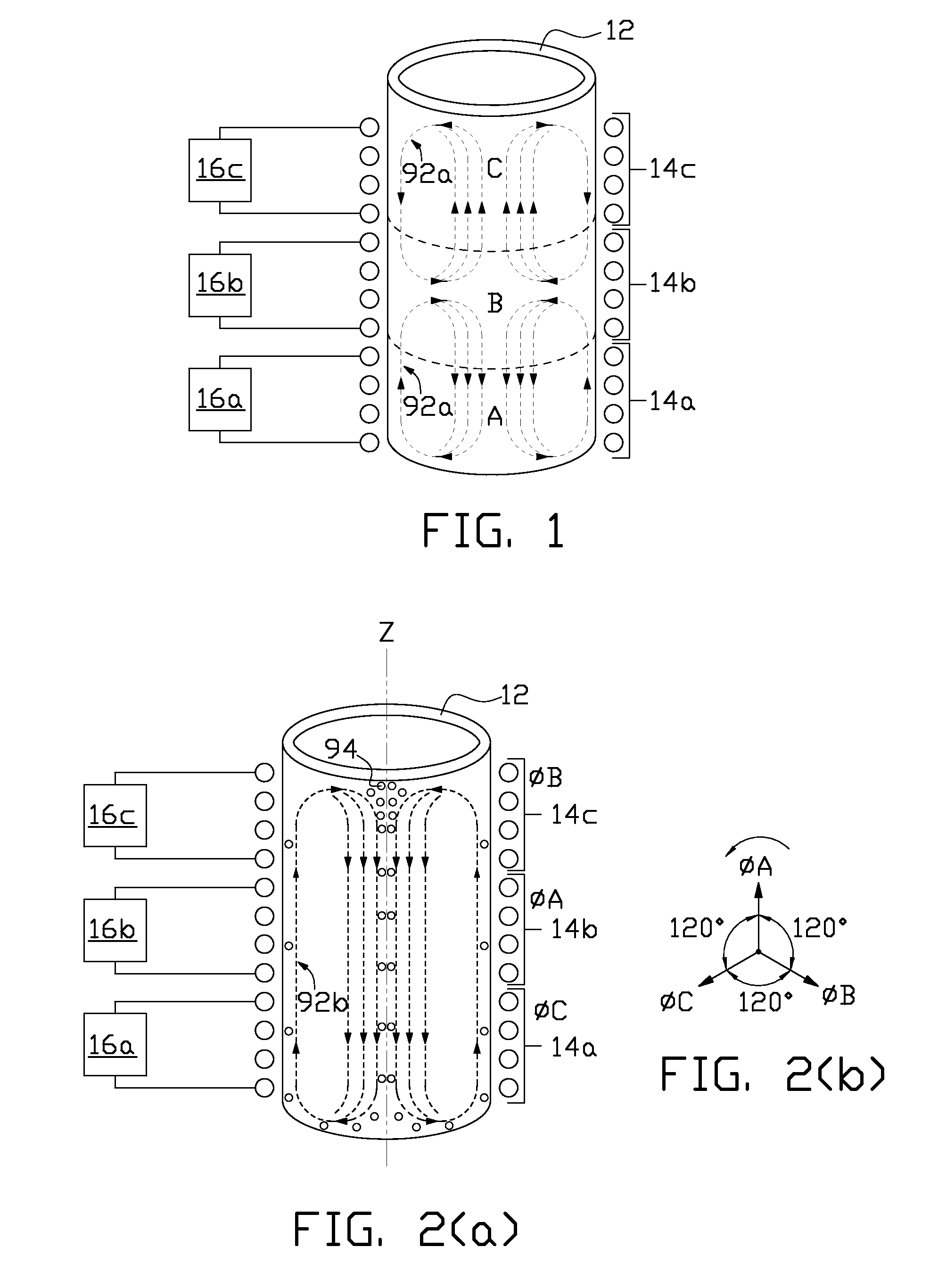

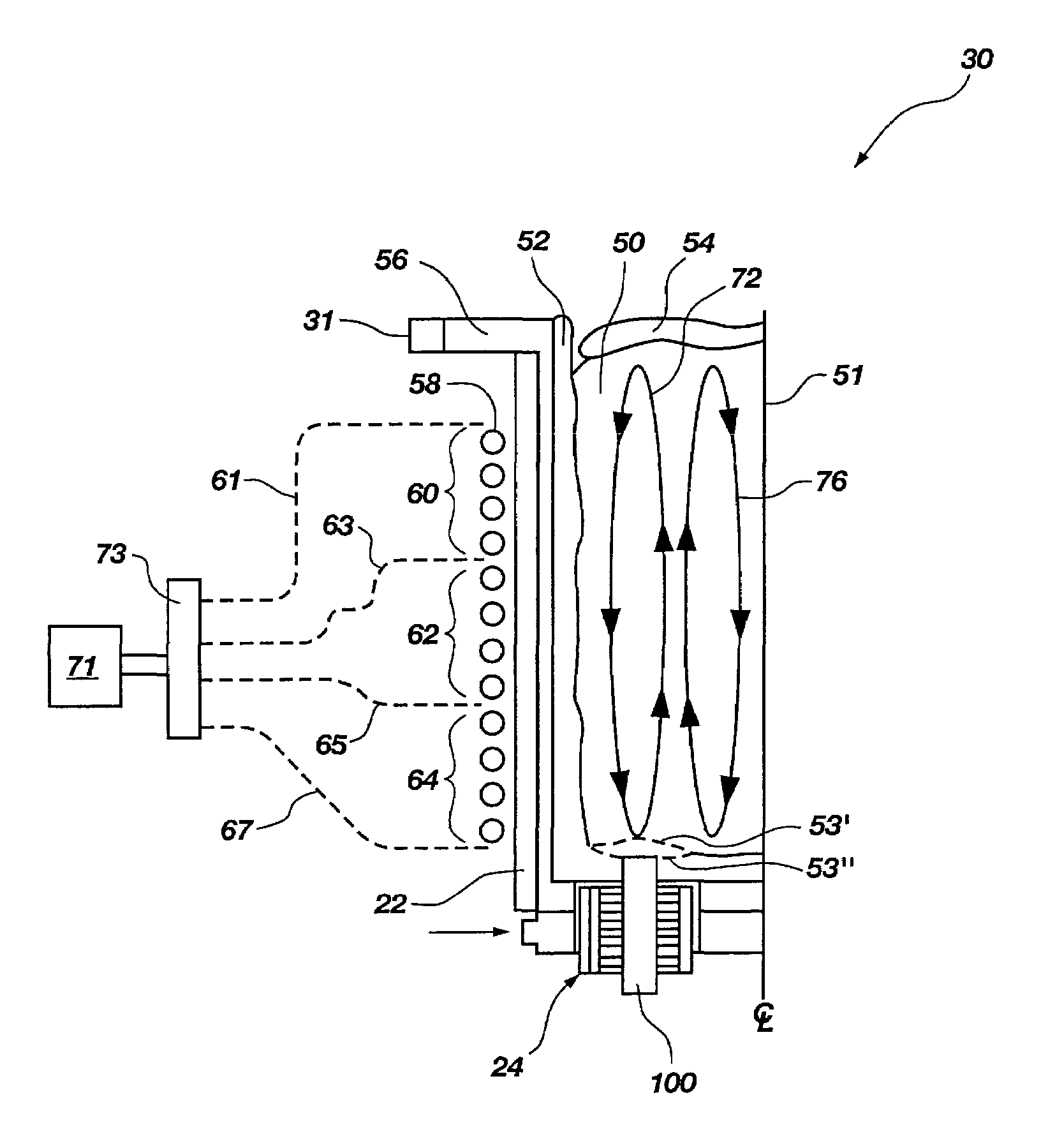

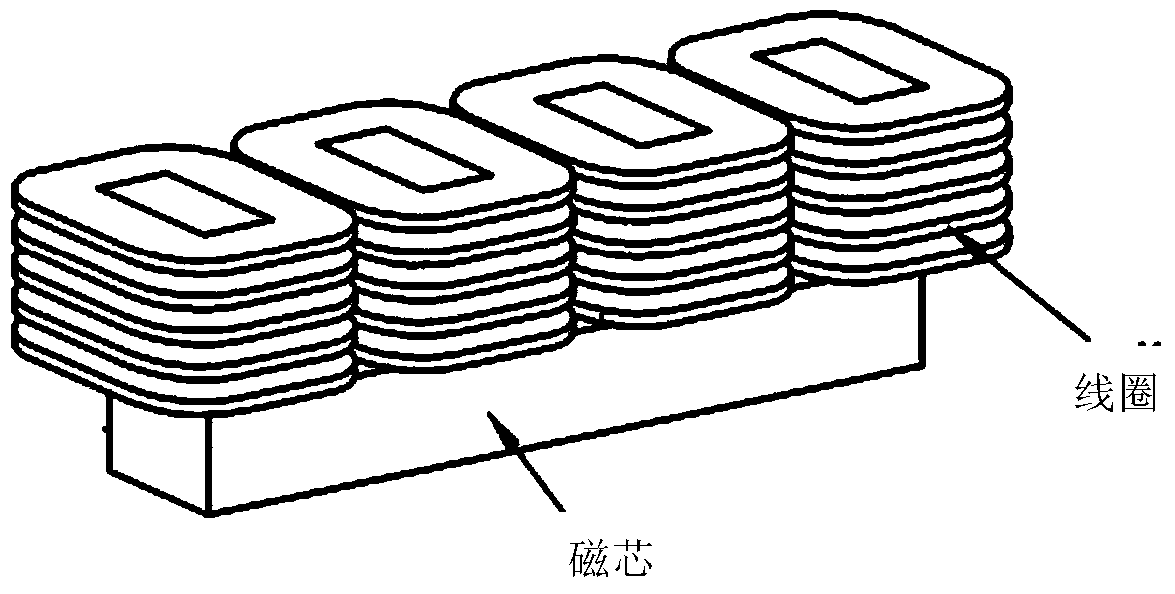

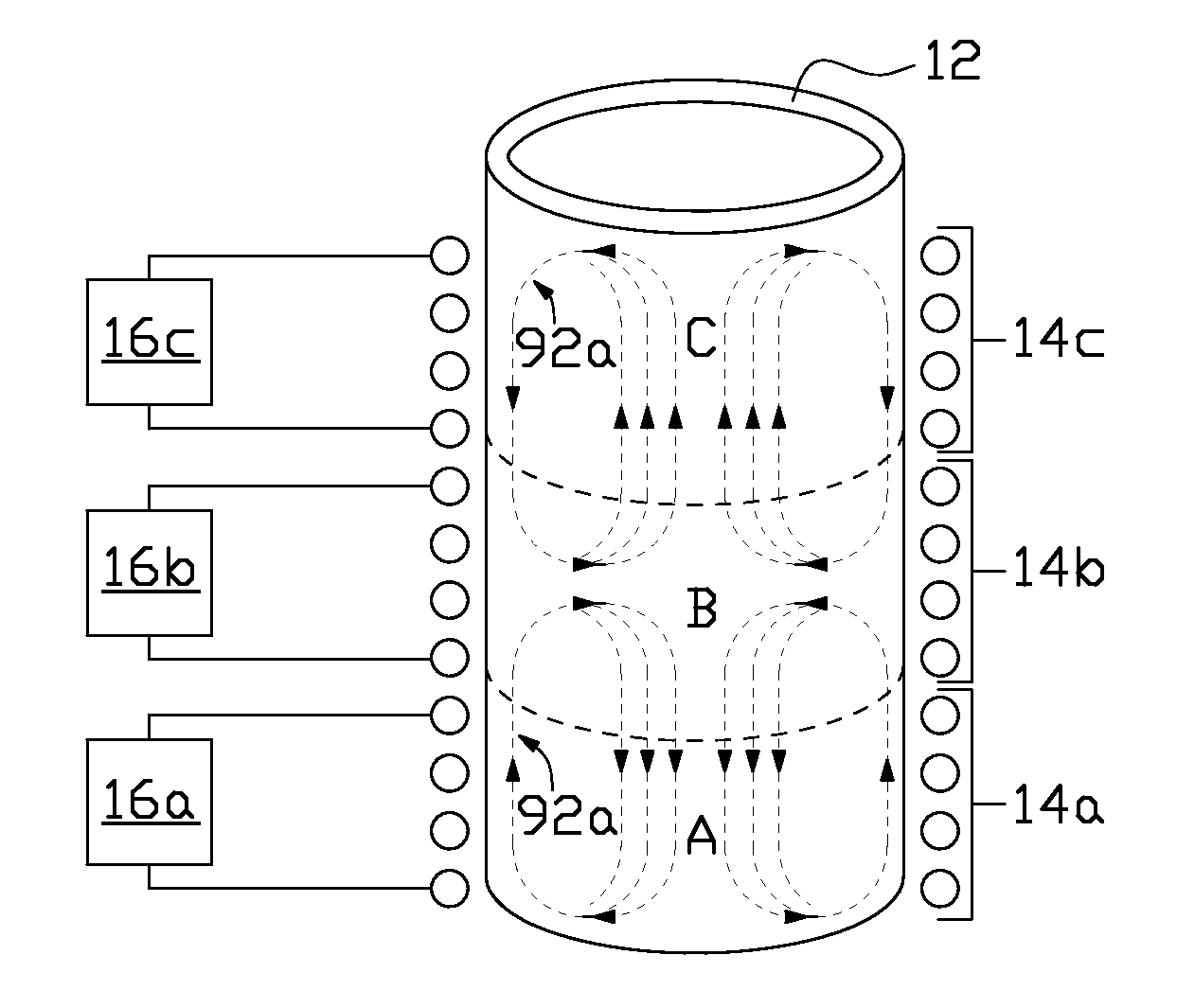

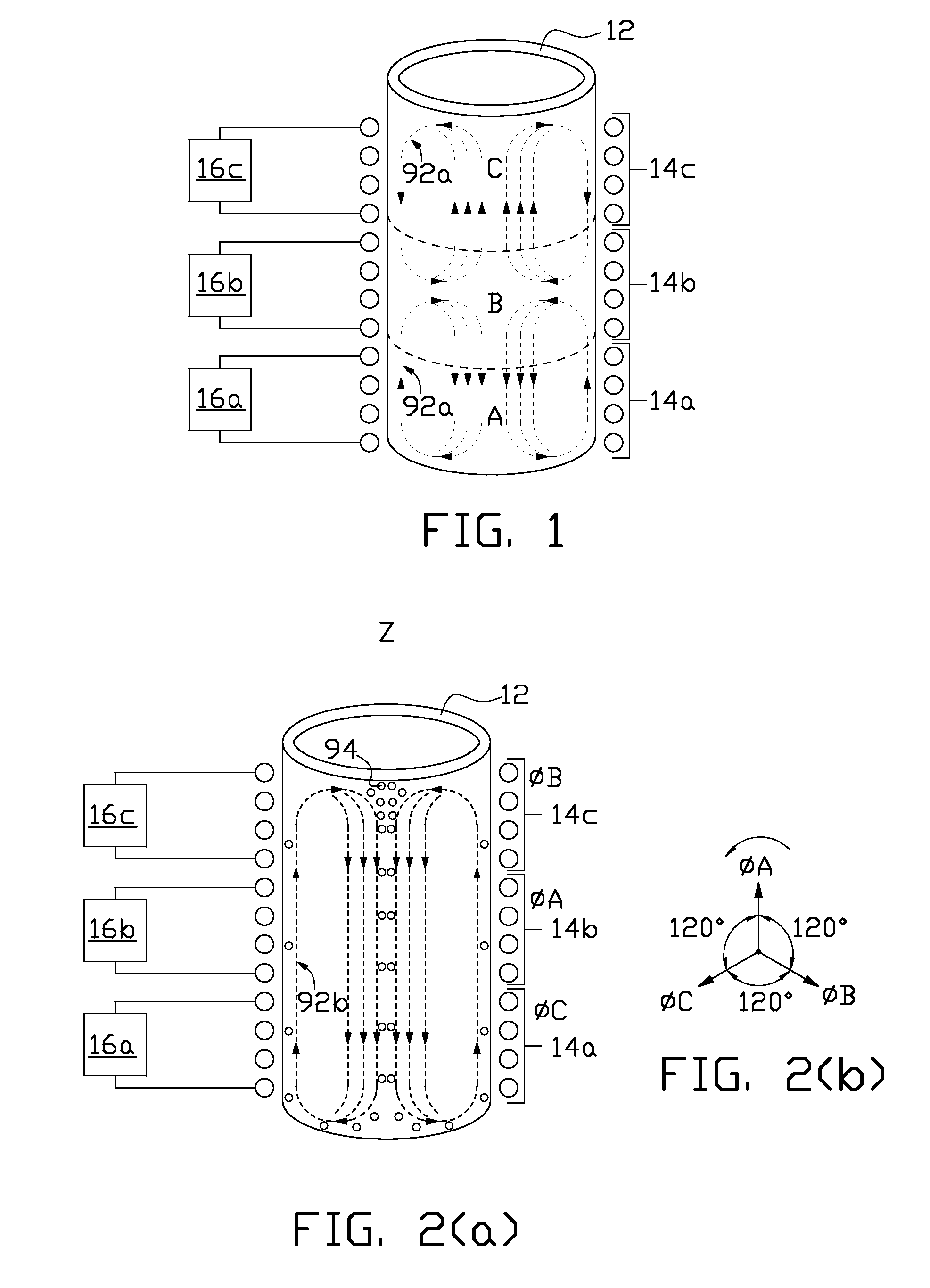

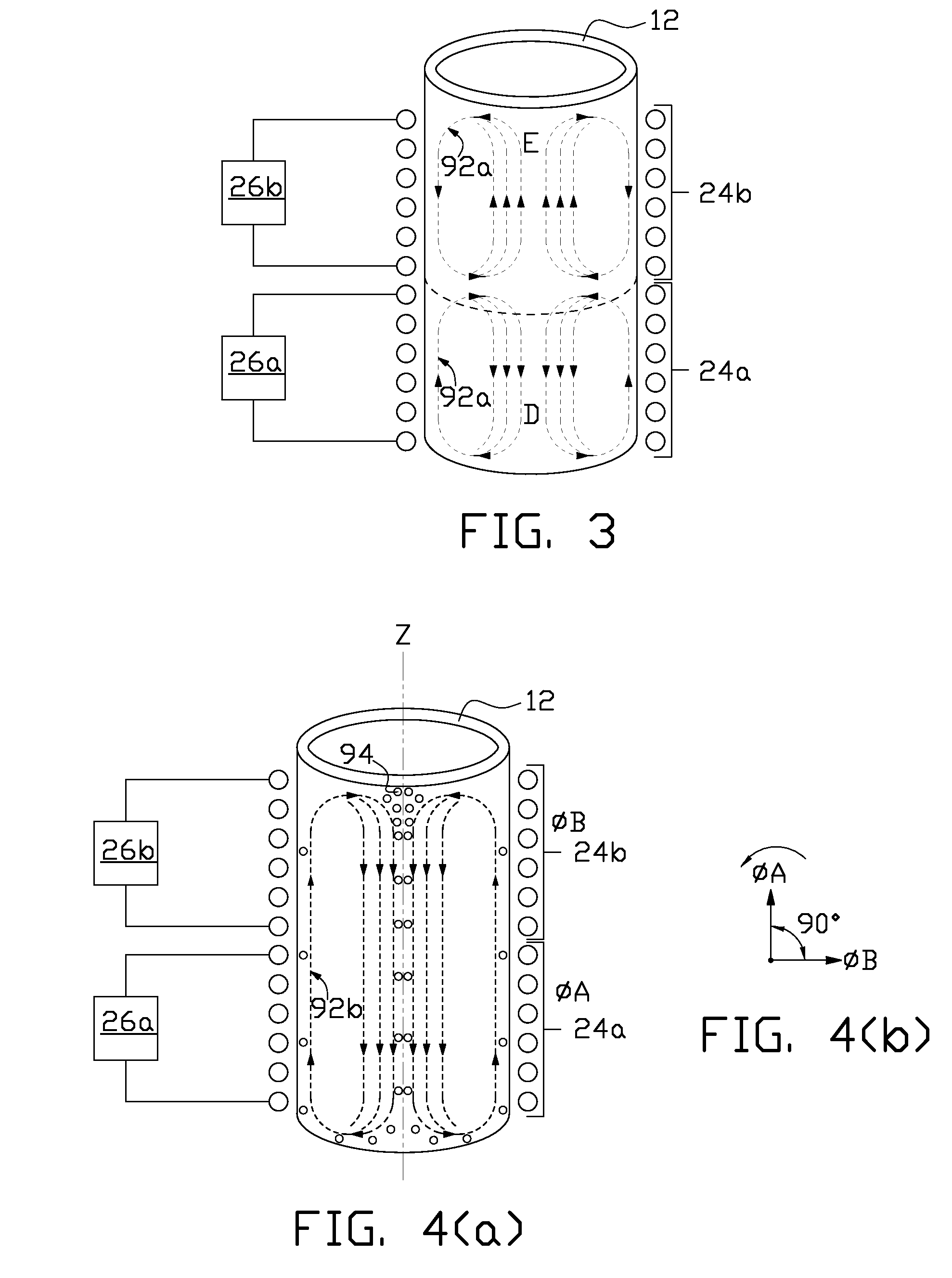

Apparatus and method are provided for electric induction heating and melting of a transition material that is non-electrically conductive in the solid state and electrically conductive in the non-solid state in an electric induction heating and melting process wherein solid or semi-solid charge is periodically added to a heel of molten transition material initially placed in a refractory crucible. Induction power is sequentially supplied to a plurality of coils surrounding the exterior height of the crucible at high power level and high frequency with in-phase voltage until a crucible batch of transition material is in the crucible when the induction power is reduced in power level and frequency with voltage phase shifting to the induction coils along the height of the crucible to induce a unidirectional electromagnetic stir of the crucible batch of material.

Owner:INDUCTOTHERM INDS

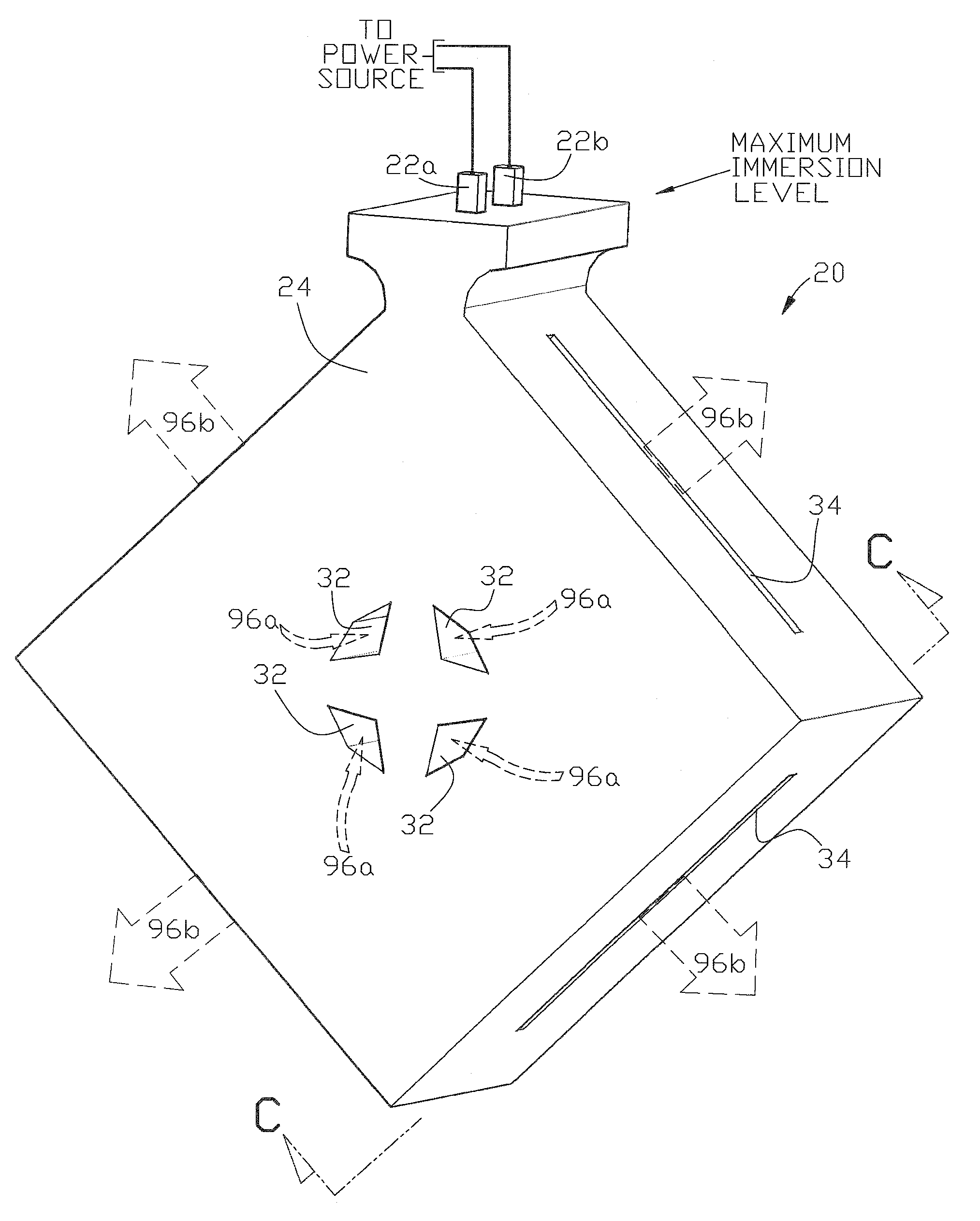

Induction coil configurations, bottom drain assemblies, and high-temperature head assemblies for induction melter apparatus and methods of control and design therefor

InactiveUS20050111518A1Improve temperature uniformityReduce external temperatureFurnaces without endless coreMechanical apparatusElectrical resistance and conductanceVitrification

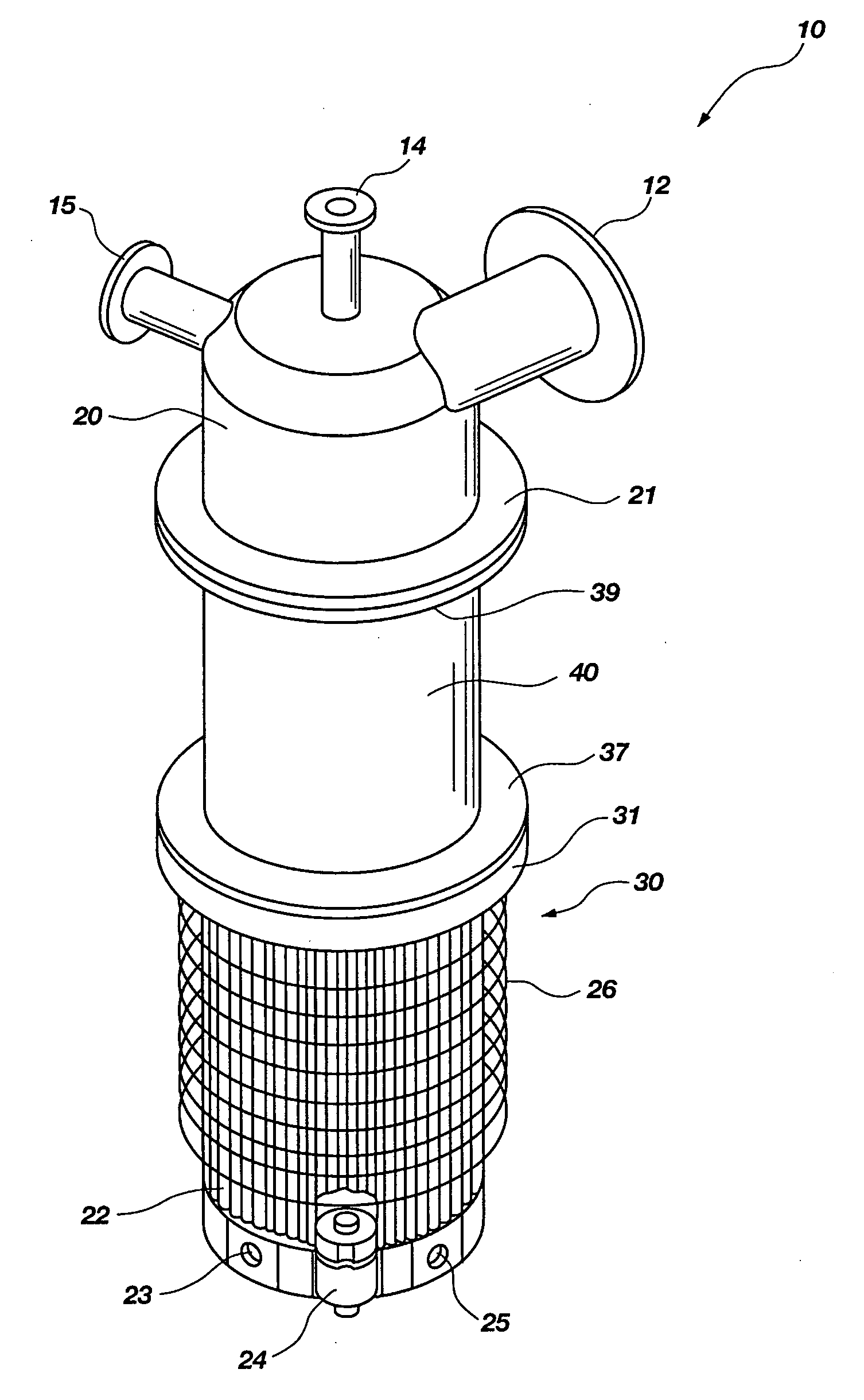

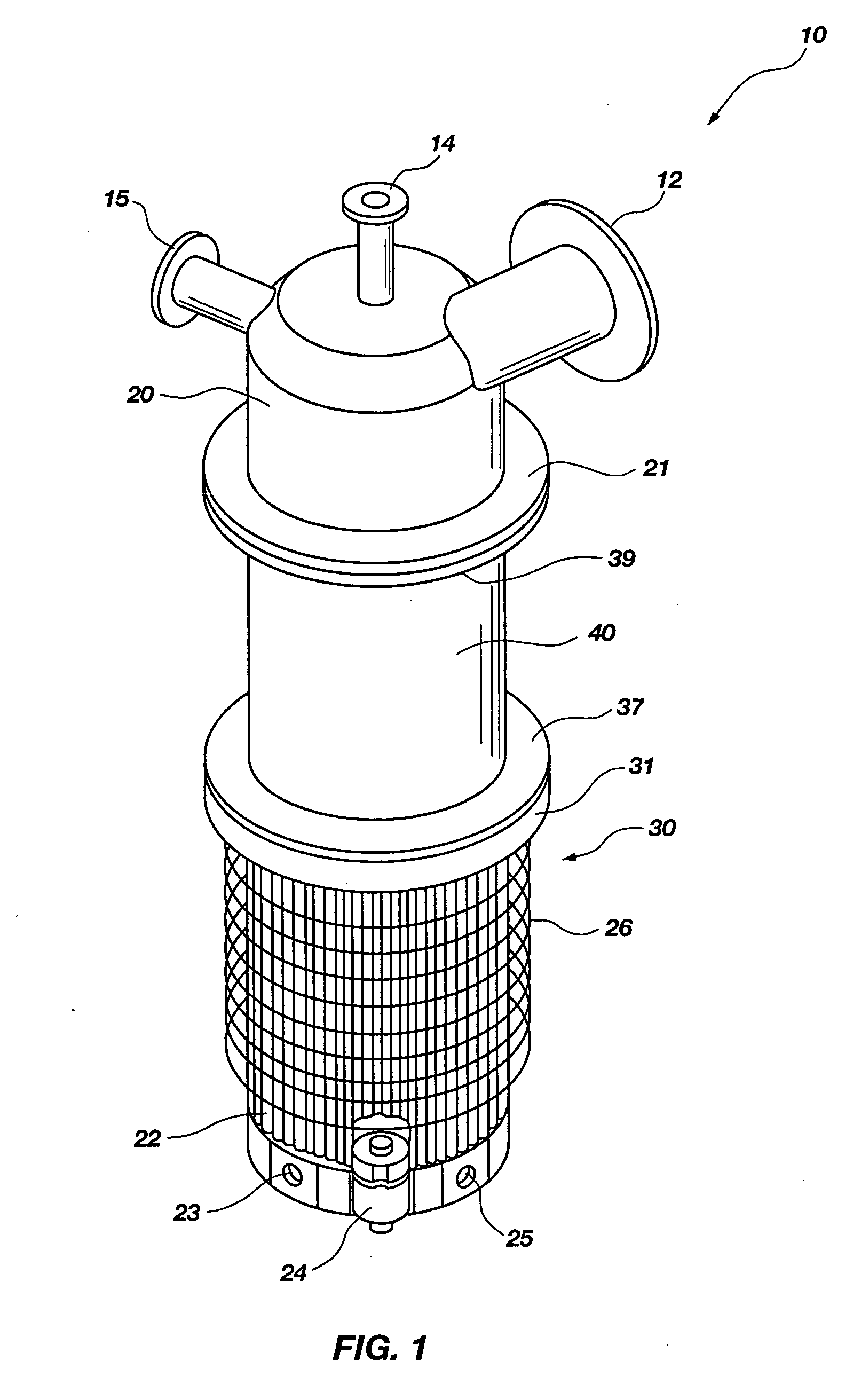

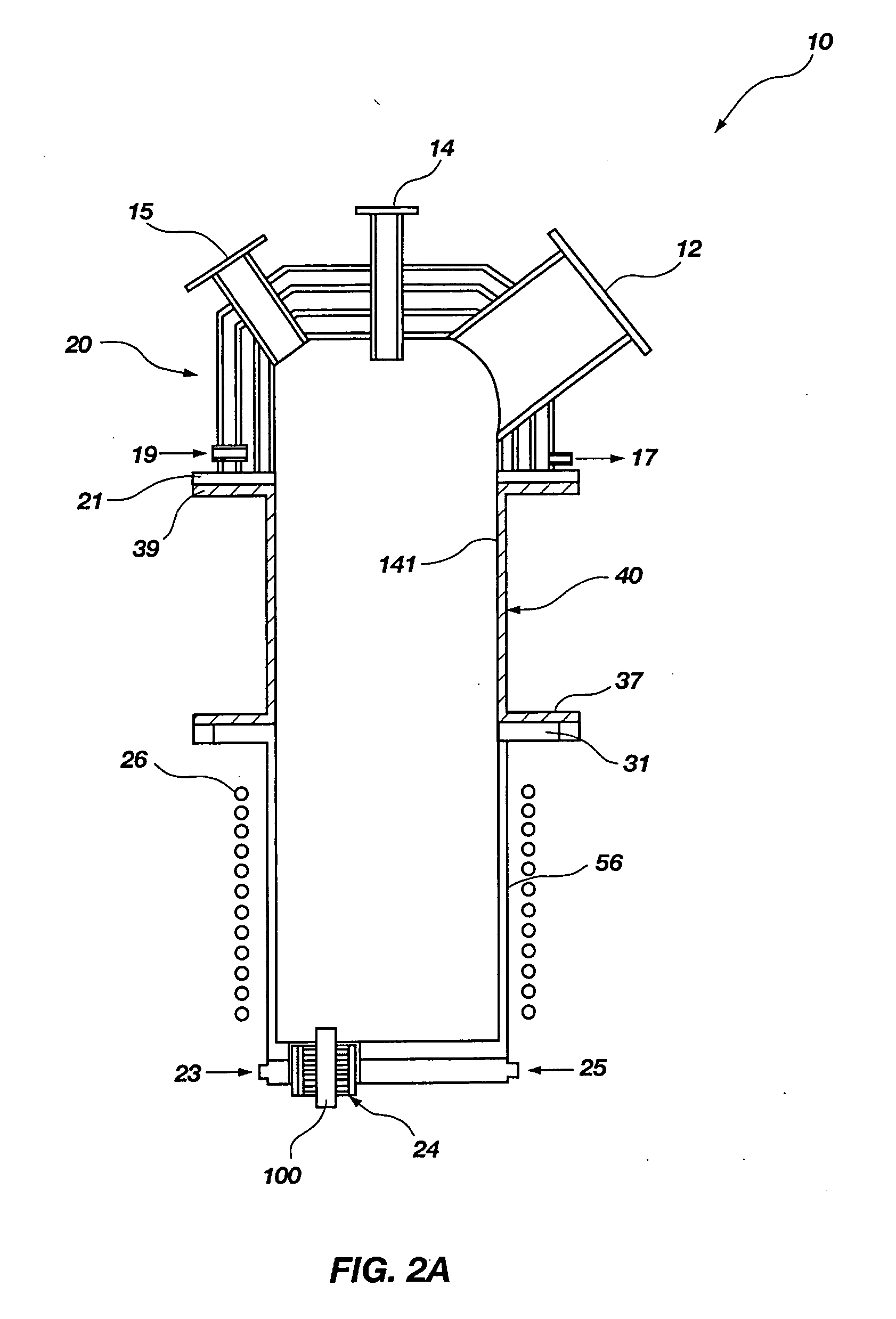

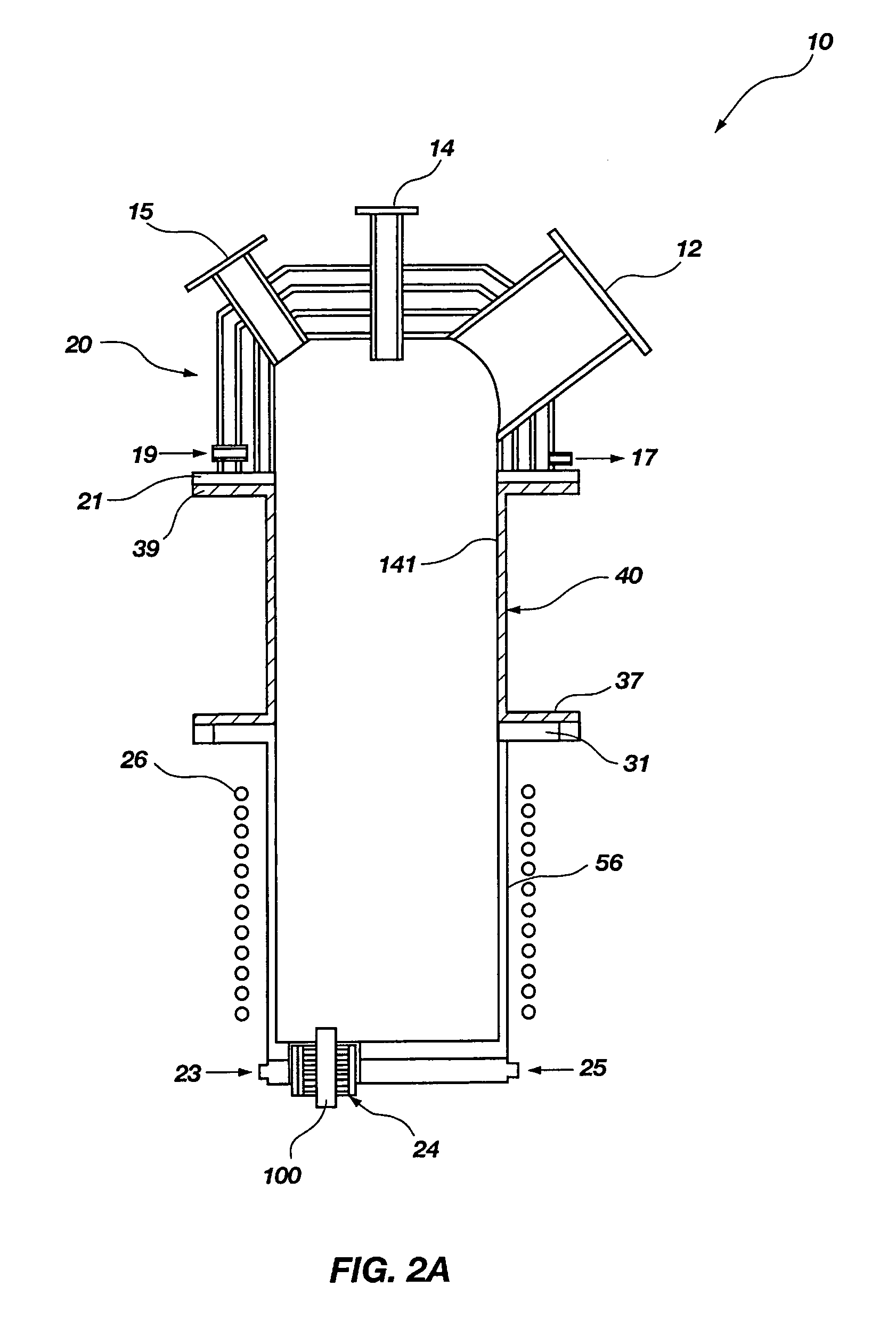

Apparatus and methods of operation are provided for a cold-crucible-induction melter for vitrifying waste wherein a single induction power supply may be used to effect a selected thermal distribution by independently energizing at least two inductors. Also, a bottom drain assembly may be heated by an inductor and may include an electrically resistive heater. The bottom drain assembly may be cooled to solidify molten material passing therethrough to prevent discharge of molten material therefrom. Configurations are provided wherein the induction flux skin depth substantially corresponds with the central longitudinal axis of the crucible. Further, the drain tube may be positioned within the induction flux skin depth in relation to material within the crucible or may be substantially aligned with a direction of flow of molten material within the crucible. An improved head design including four shells forming thermal radiation shields and at least two gas-cooled plenums is also disclosed.

Owner:BATTELLE ENERGY ALLIANCE LLC

Operating an induction melter apparatus

InactiveUS6993061B2Improved control and maintenanceEasy to controlFurnaces without endless coreMechanical apparatusVitrificationElectrical resistance and conductance

Owner:BATTELLE ENERGY ALLIANCE LLC

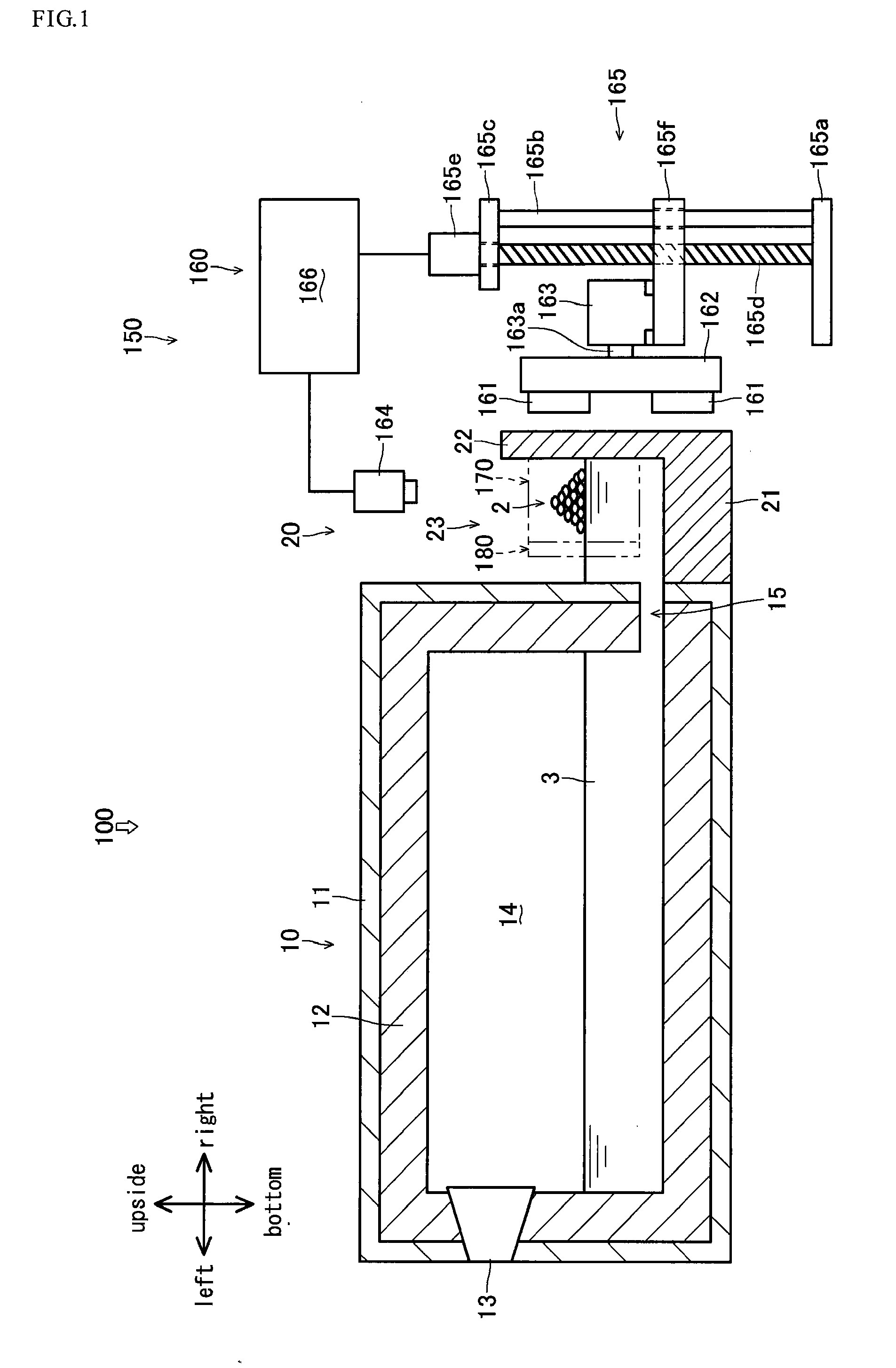

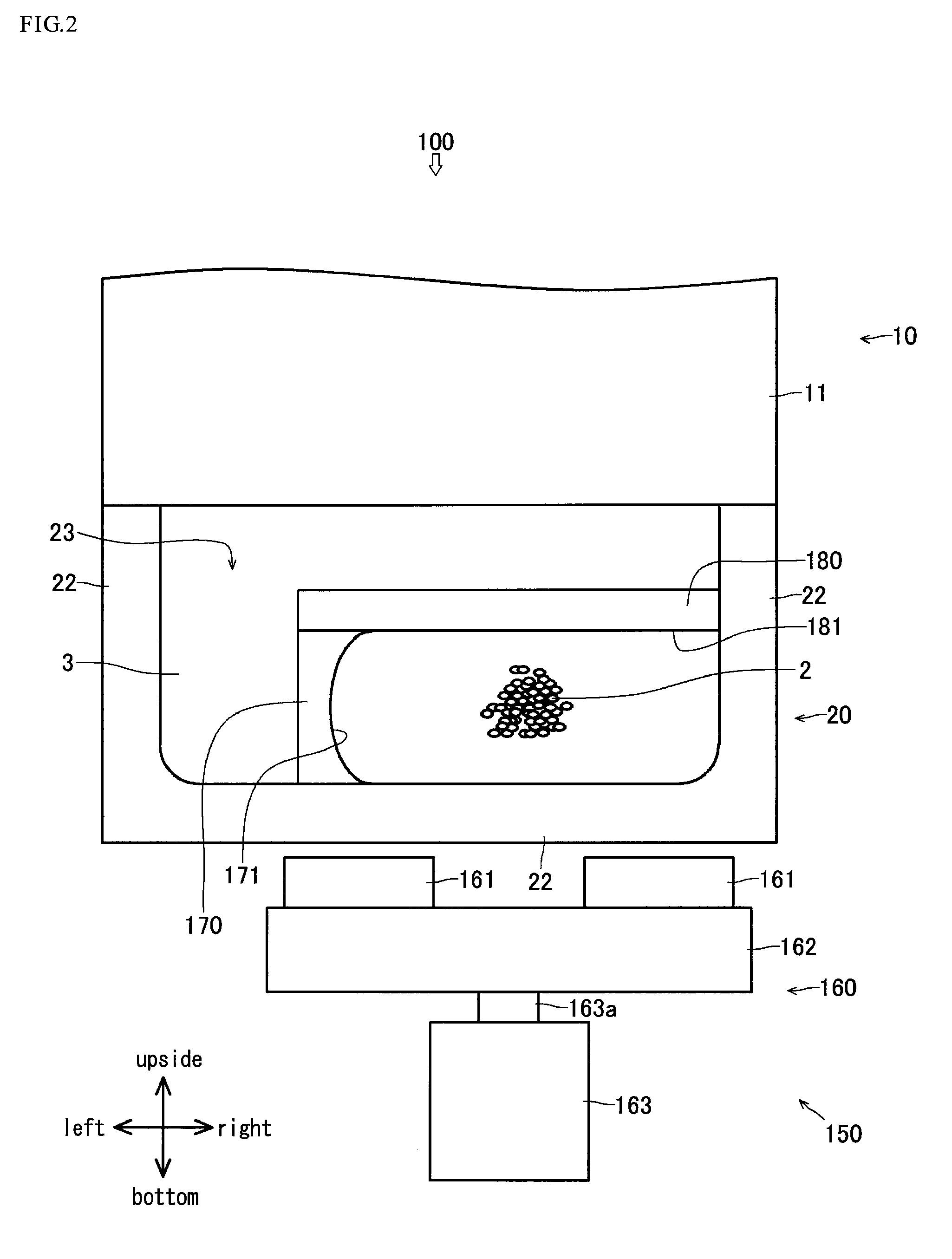

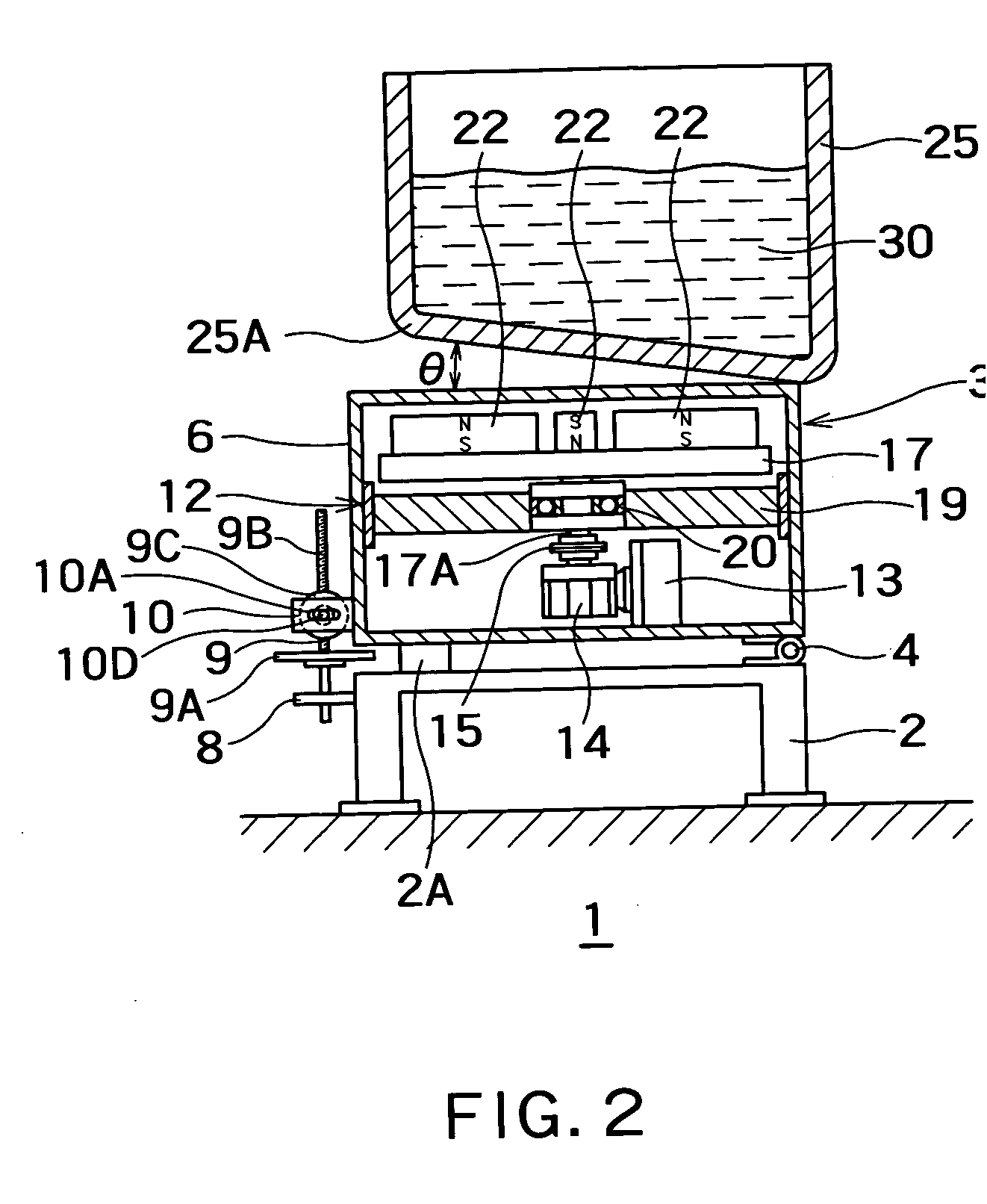

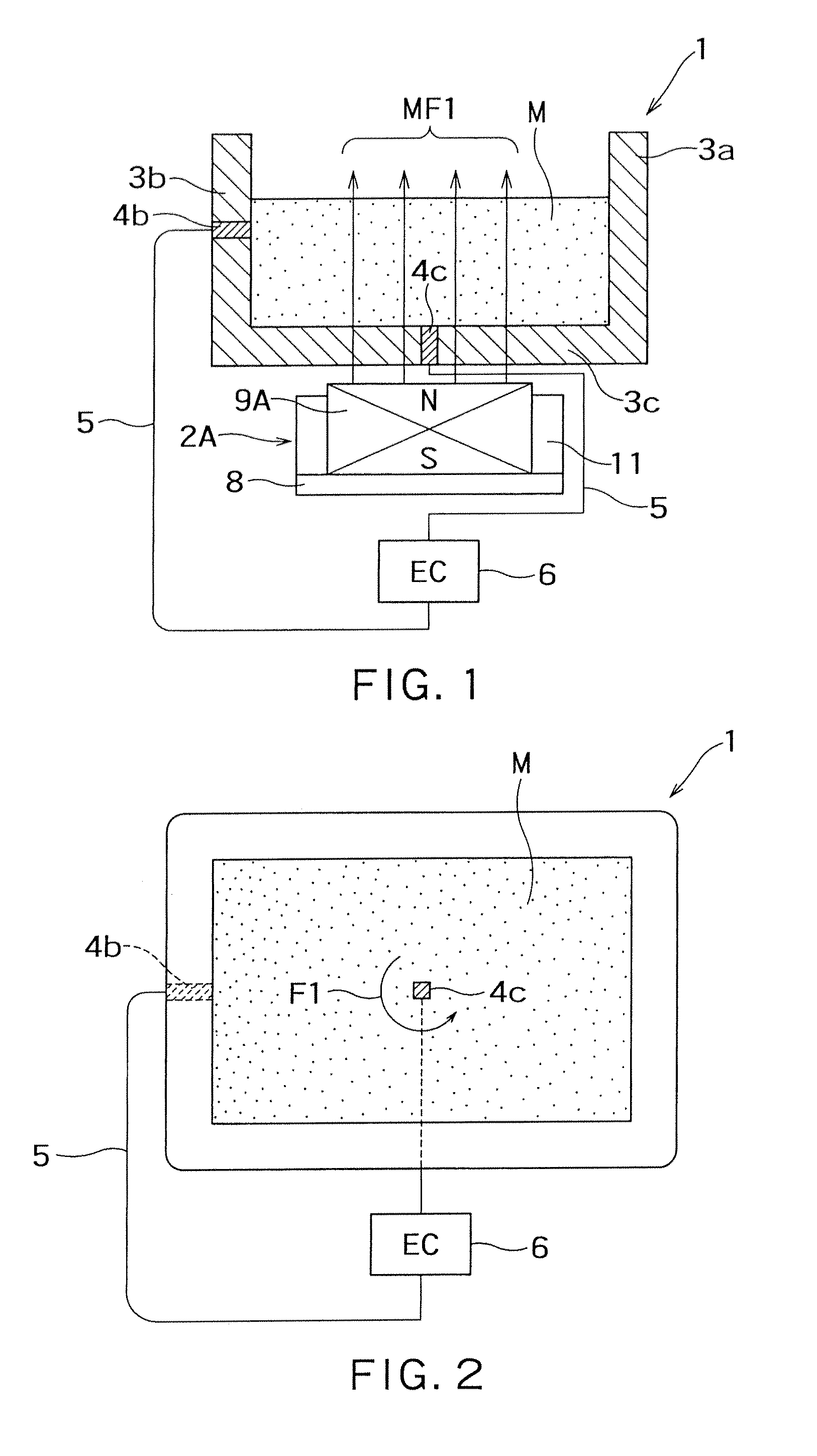

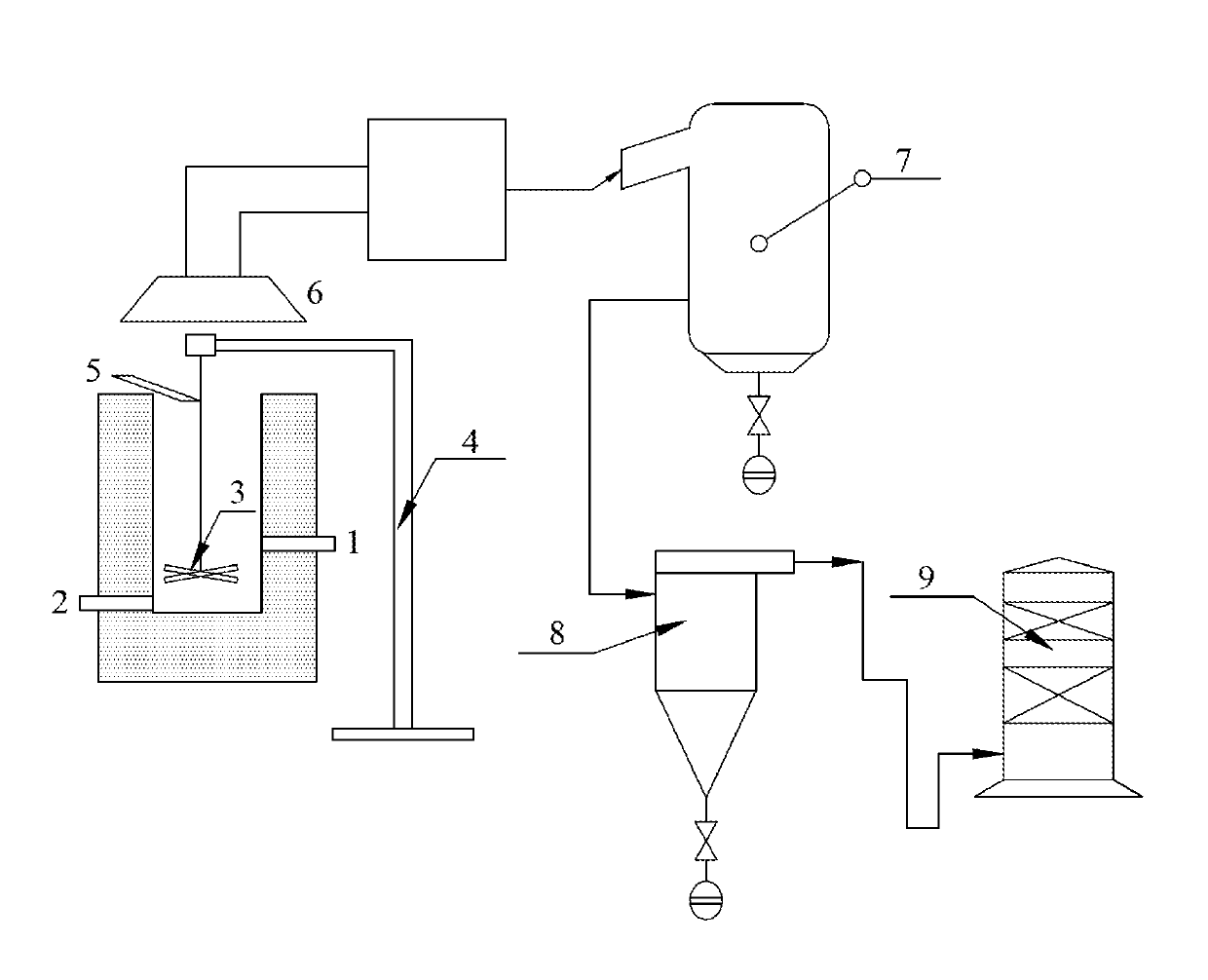

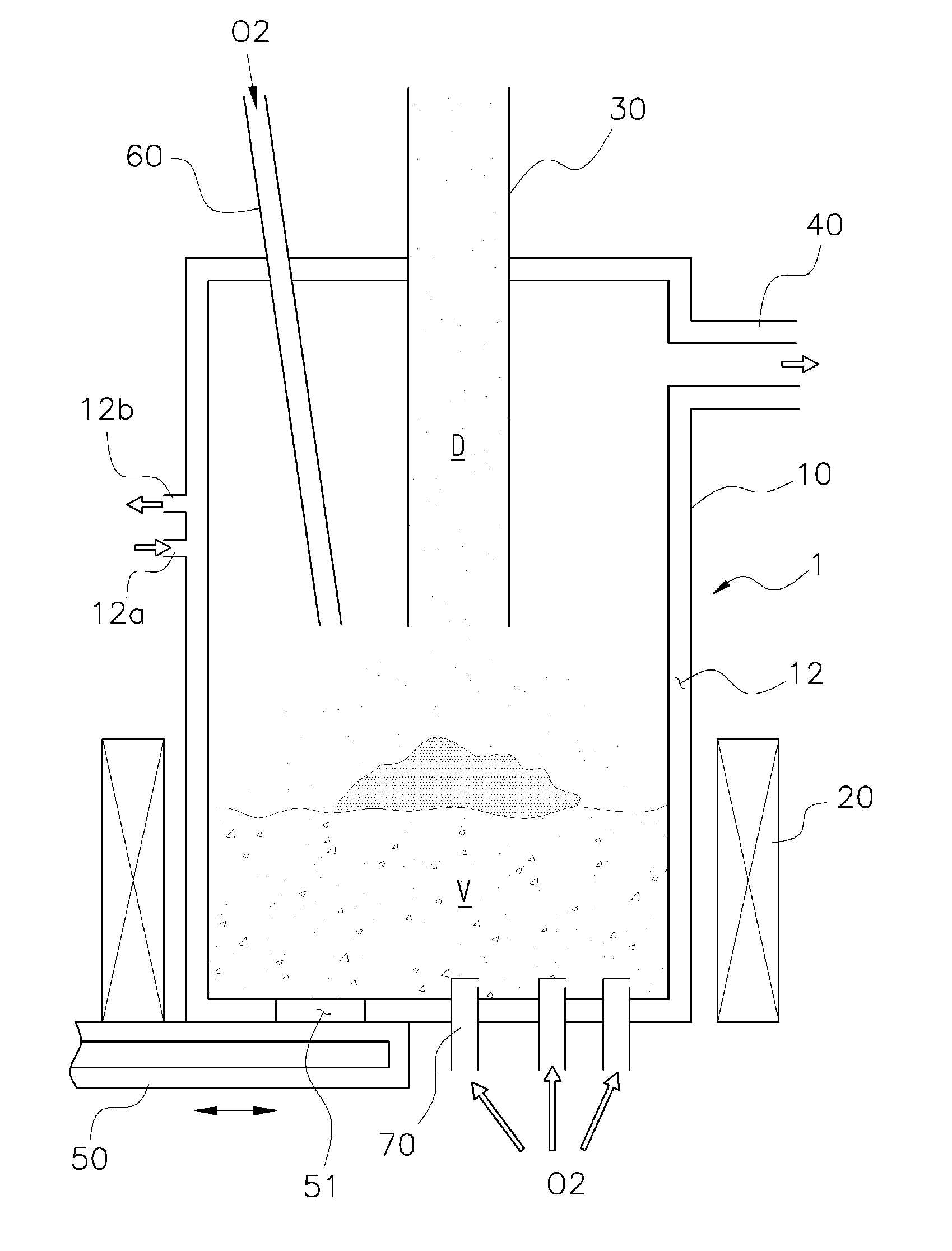

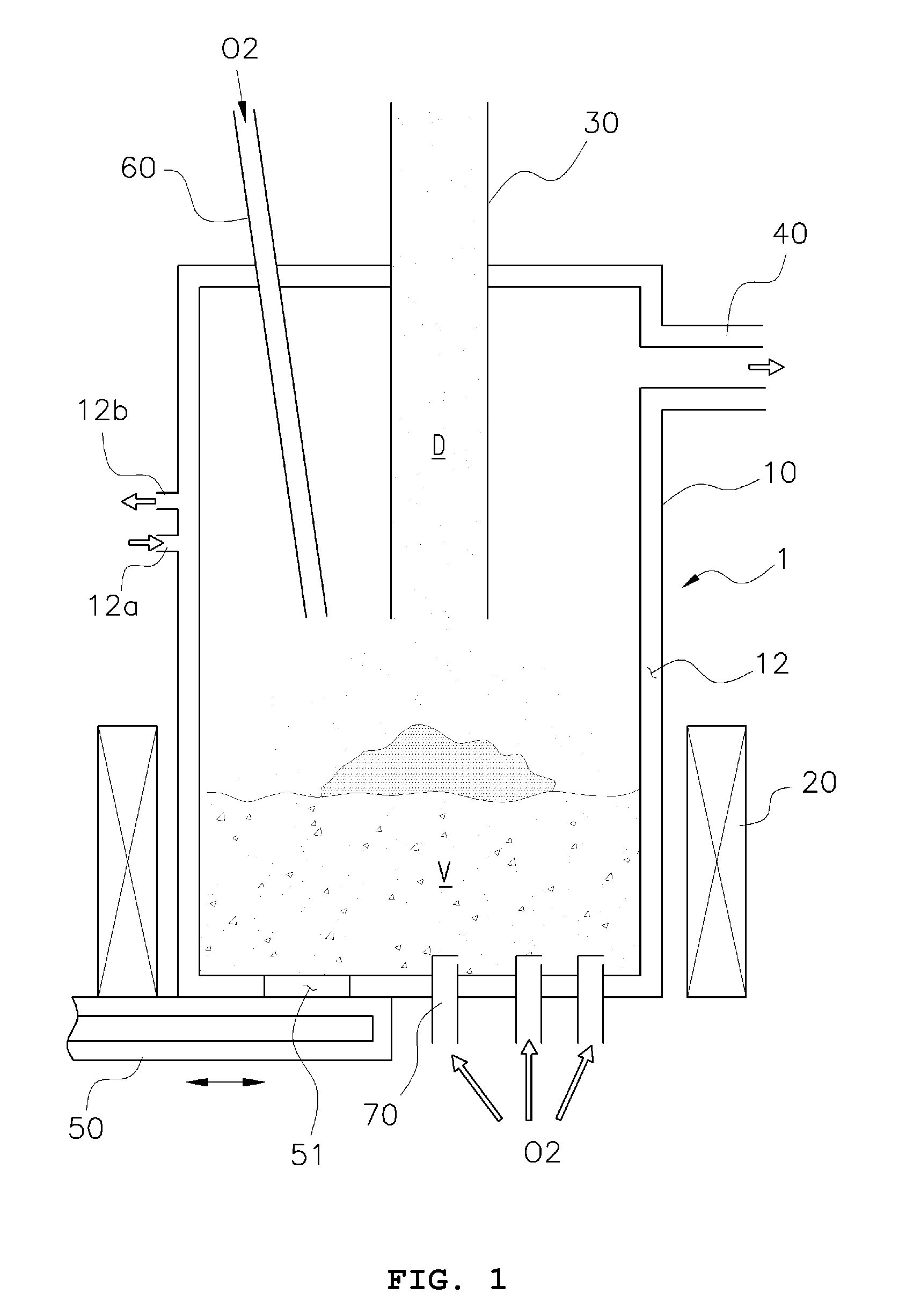

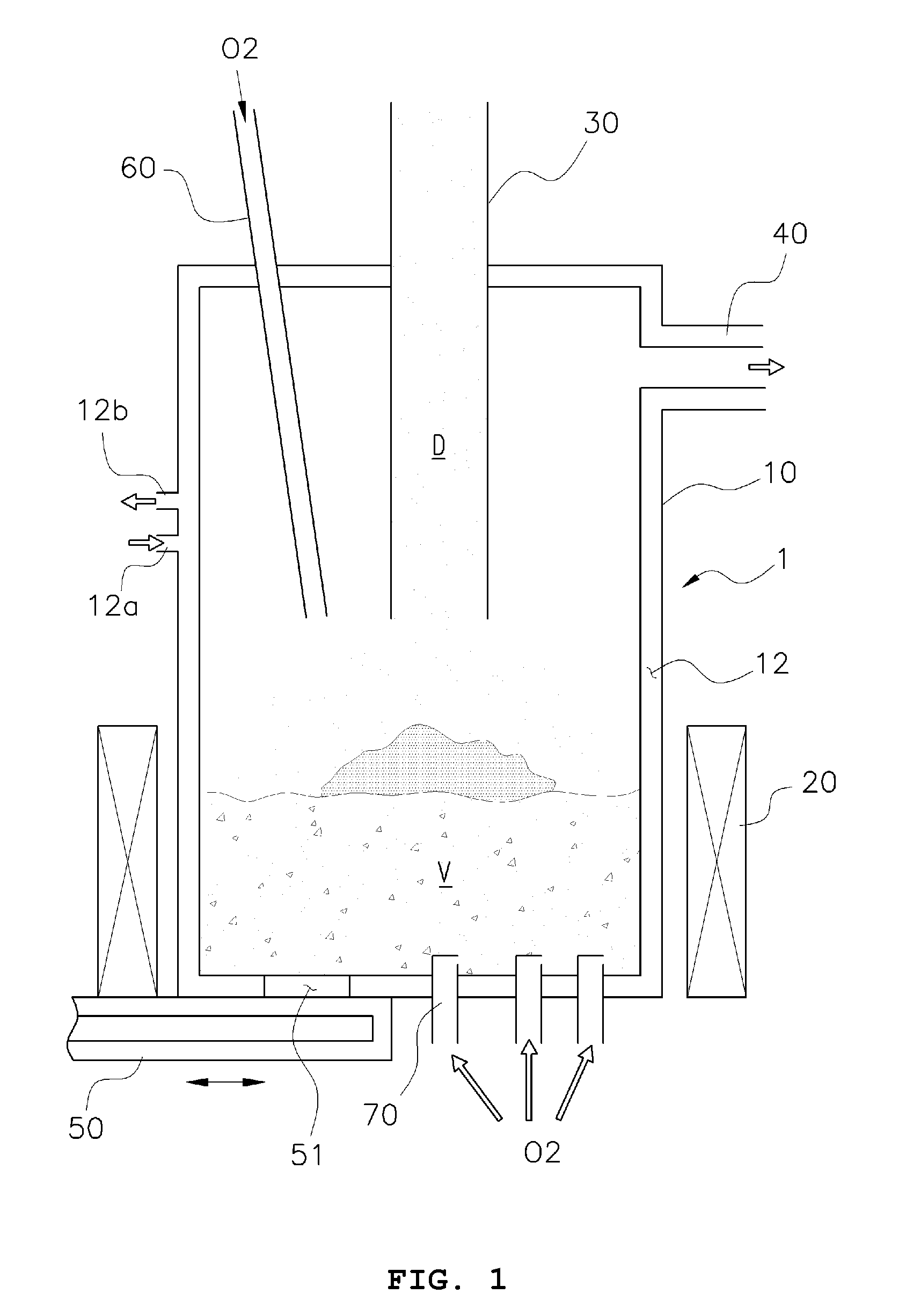

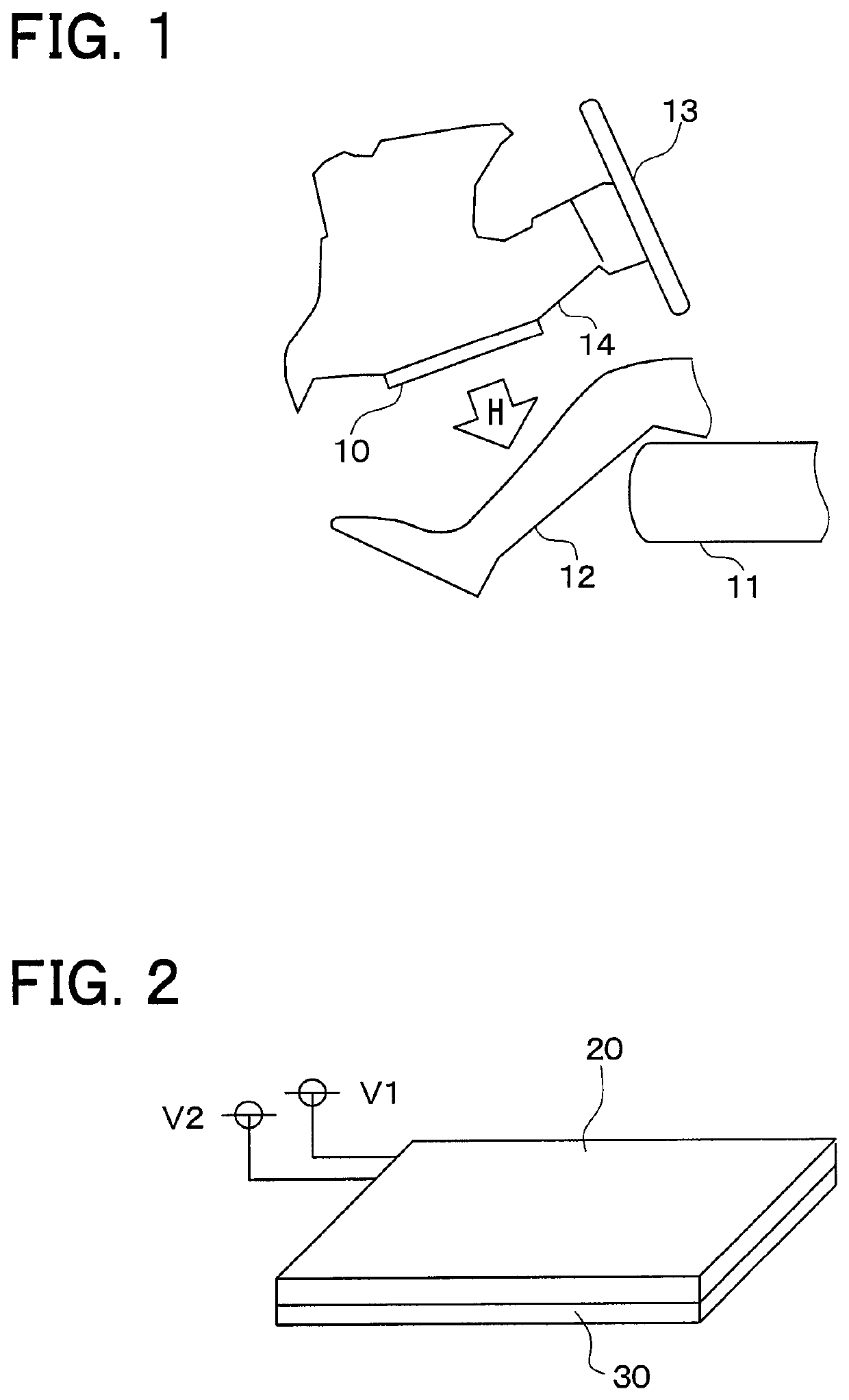

Agitation device, melting apparatus and melting method

ActiveUS20110197709A1Improve melting efficiencyImprove efficiencyMelt circulation arrangementsStirring devicesMolten metalMagnetic field

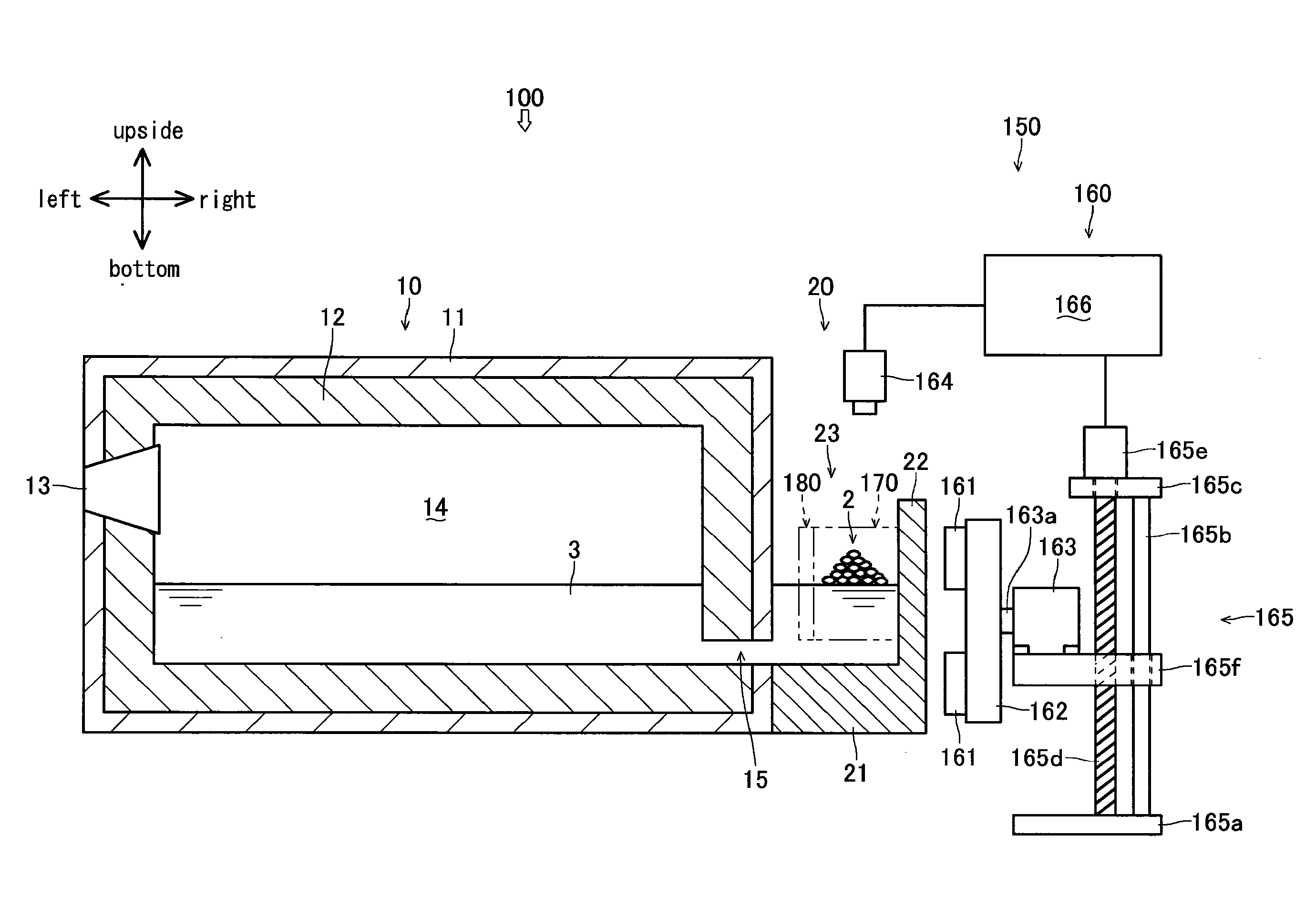

Provided are an agitation device, a melting apparatus, and a melting method which achieve good melting efficiency without contaminating molten metal. The agitation device is provided with a traveling magnetic field generating unit which is disposed outside a charging tank for storing molten metal and generates, inside the charging tank, a magnetic field that travels downward along the rear sidewall of the charging tank, whereby a flow of the molten metal that rotates longitudinally about an axis approximately parallel to the surface of the molten metal is produced in the molten metal. By charging aluminum cutting chips into the molten metal in which the flow is produced, the aluminum cutting chips move with the flow of the molten metal, get into the molten metal roughly in the position where a downward flow of the molten metal is produced, and are immersed in the molten metal, and thus the melting of the aluminum cutting chips is accelerated.

Owner:TOYOTA JIDOSHA KK

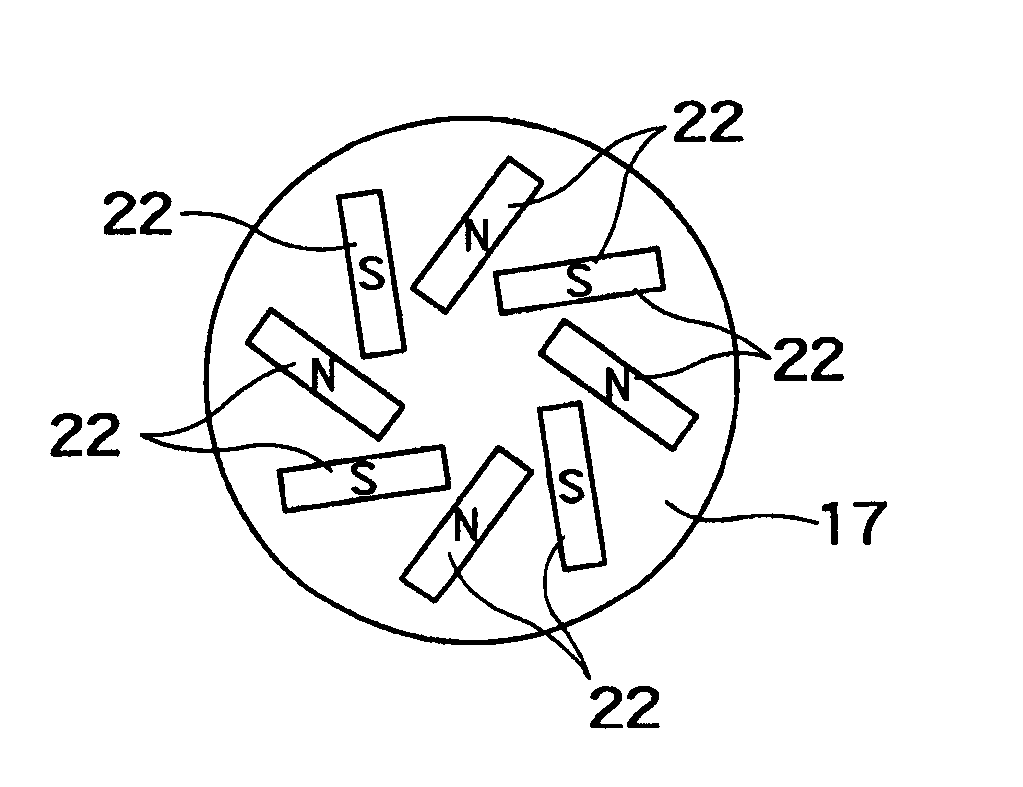

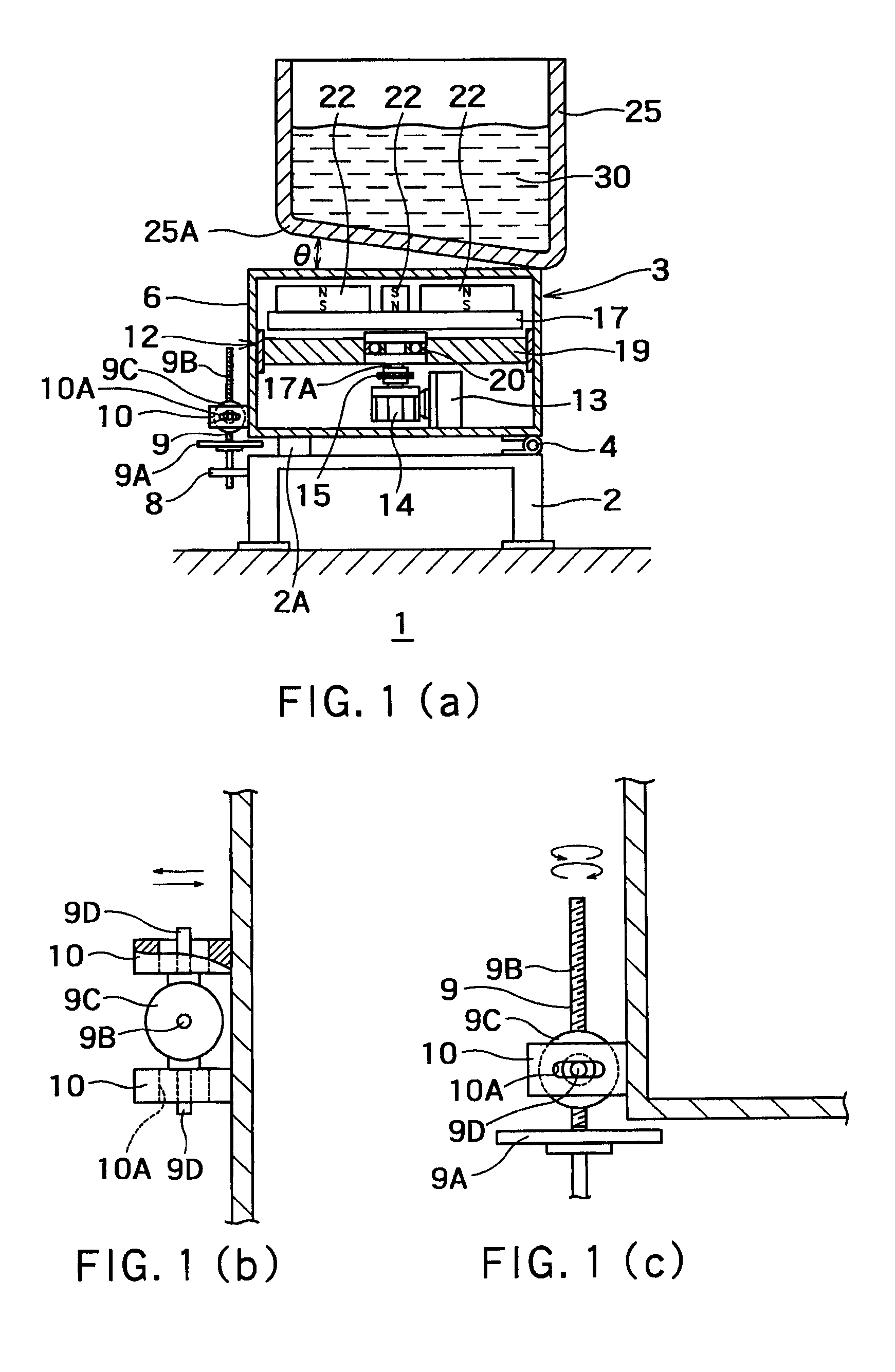

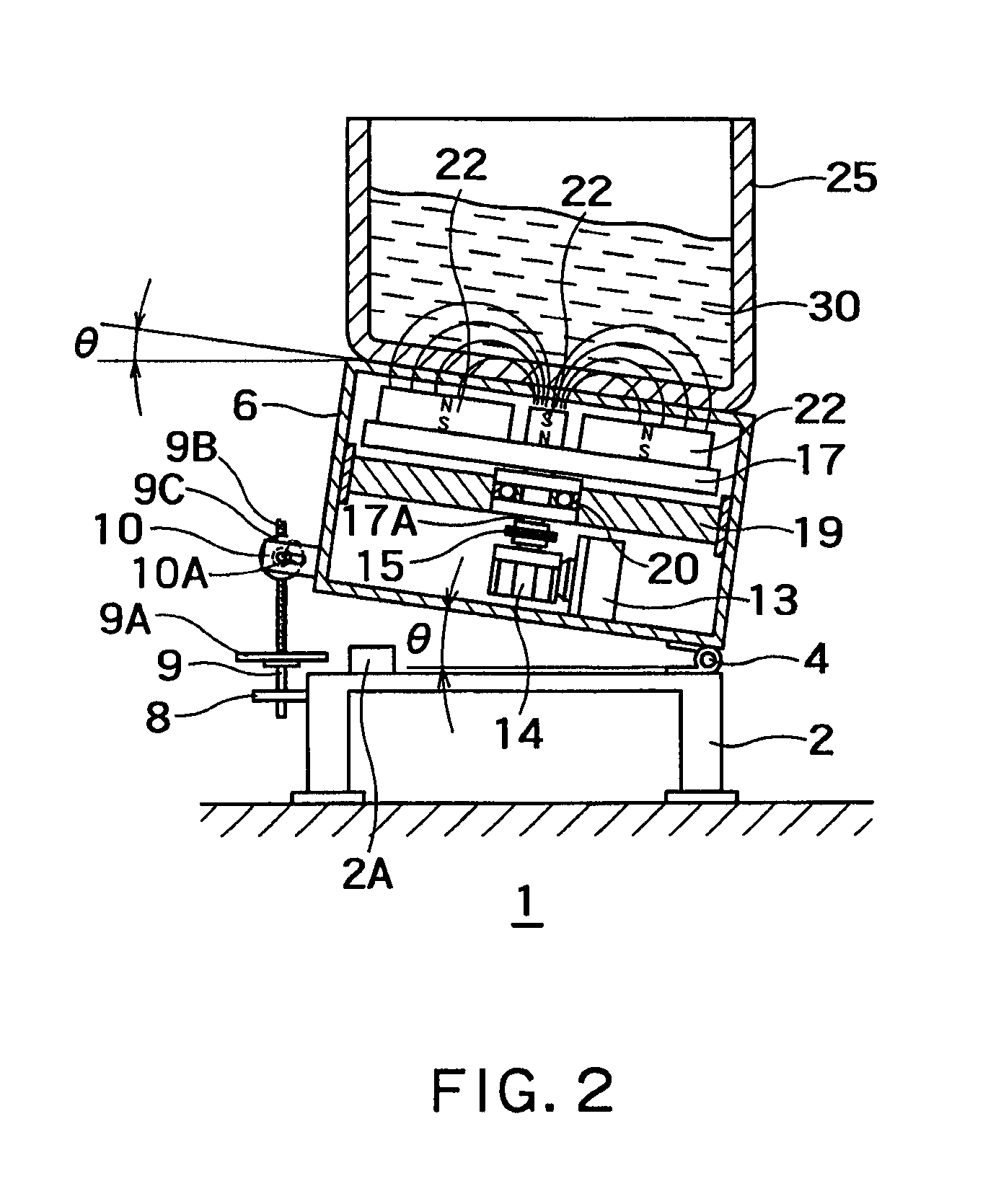

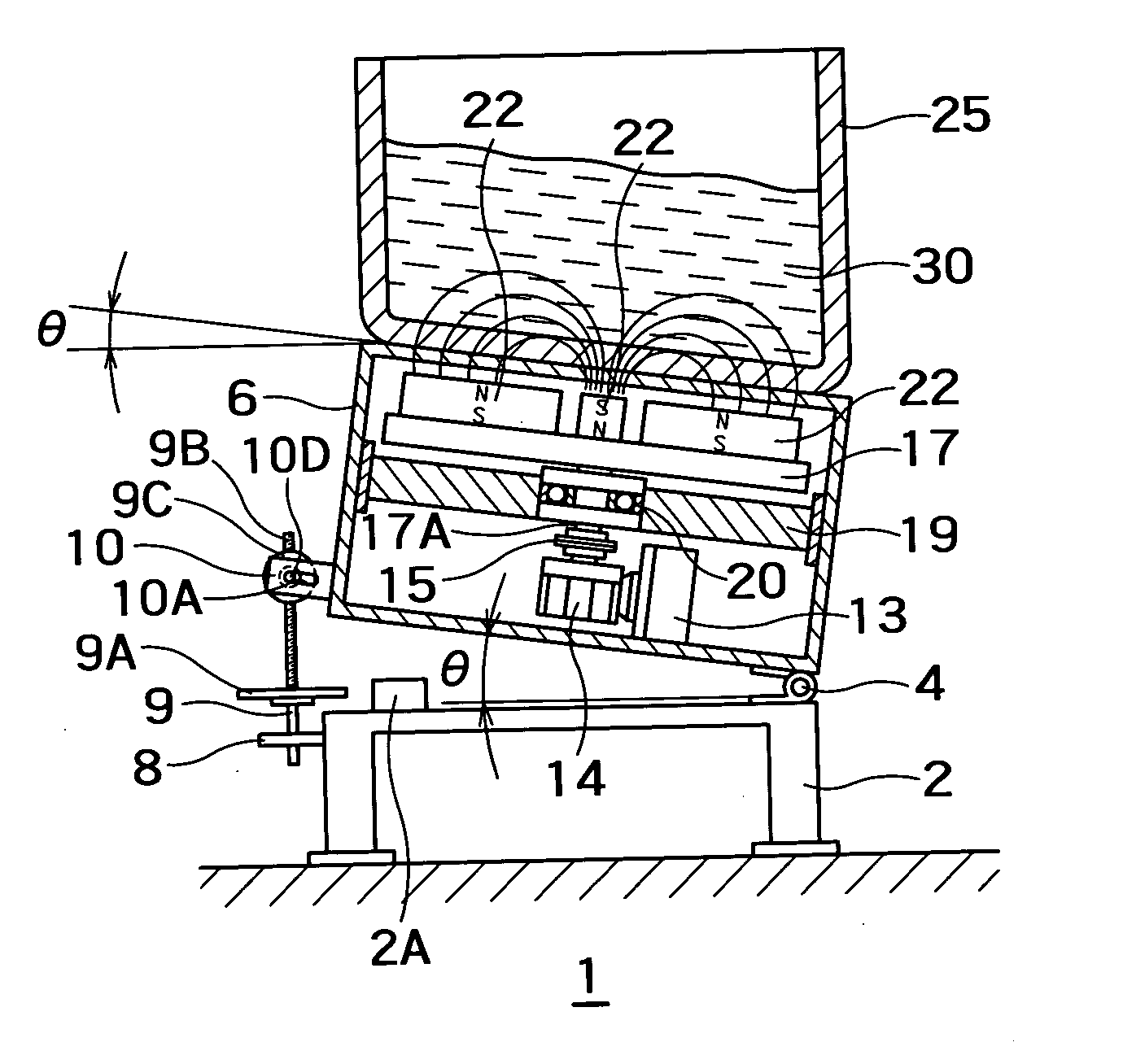

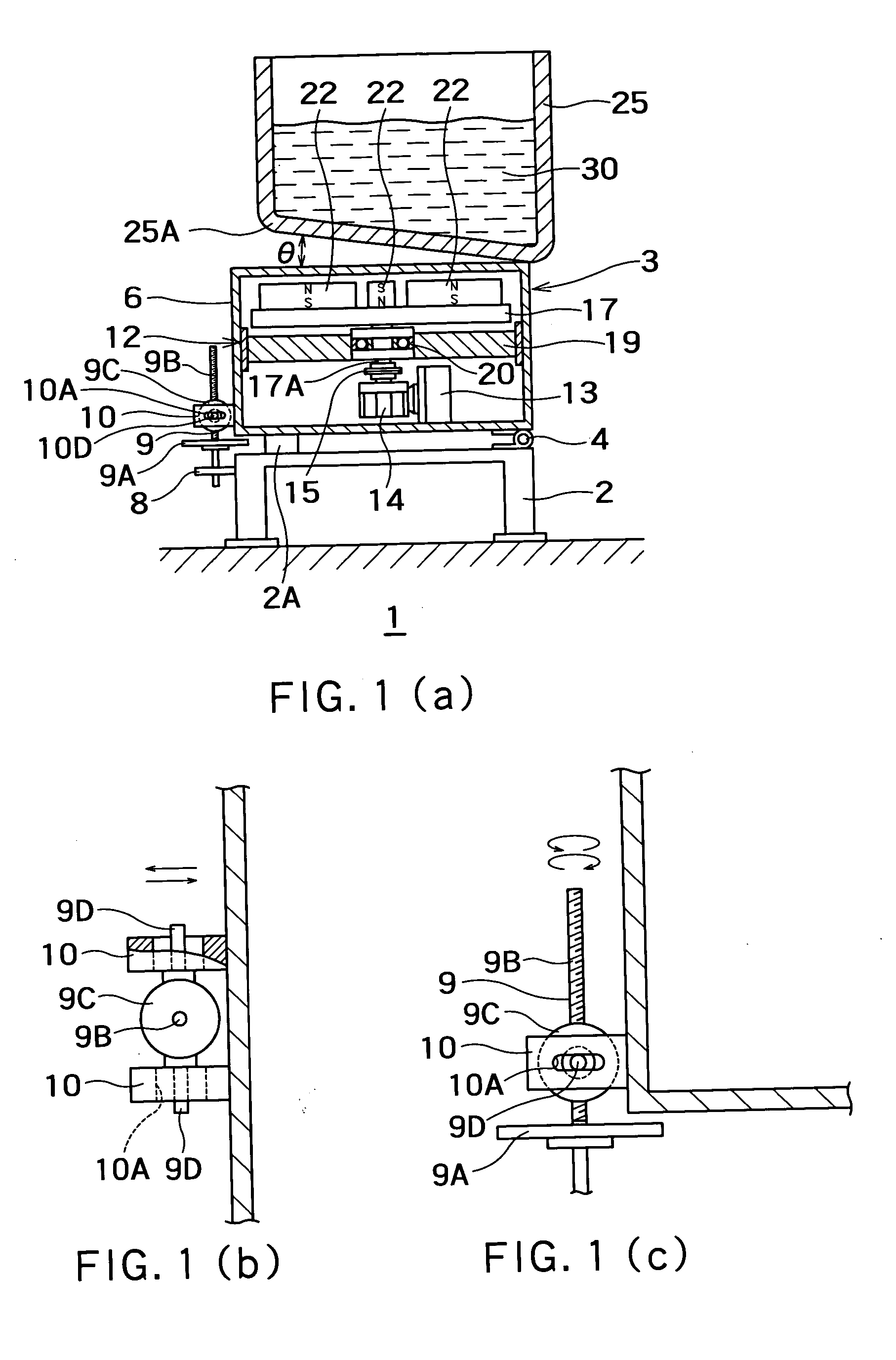

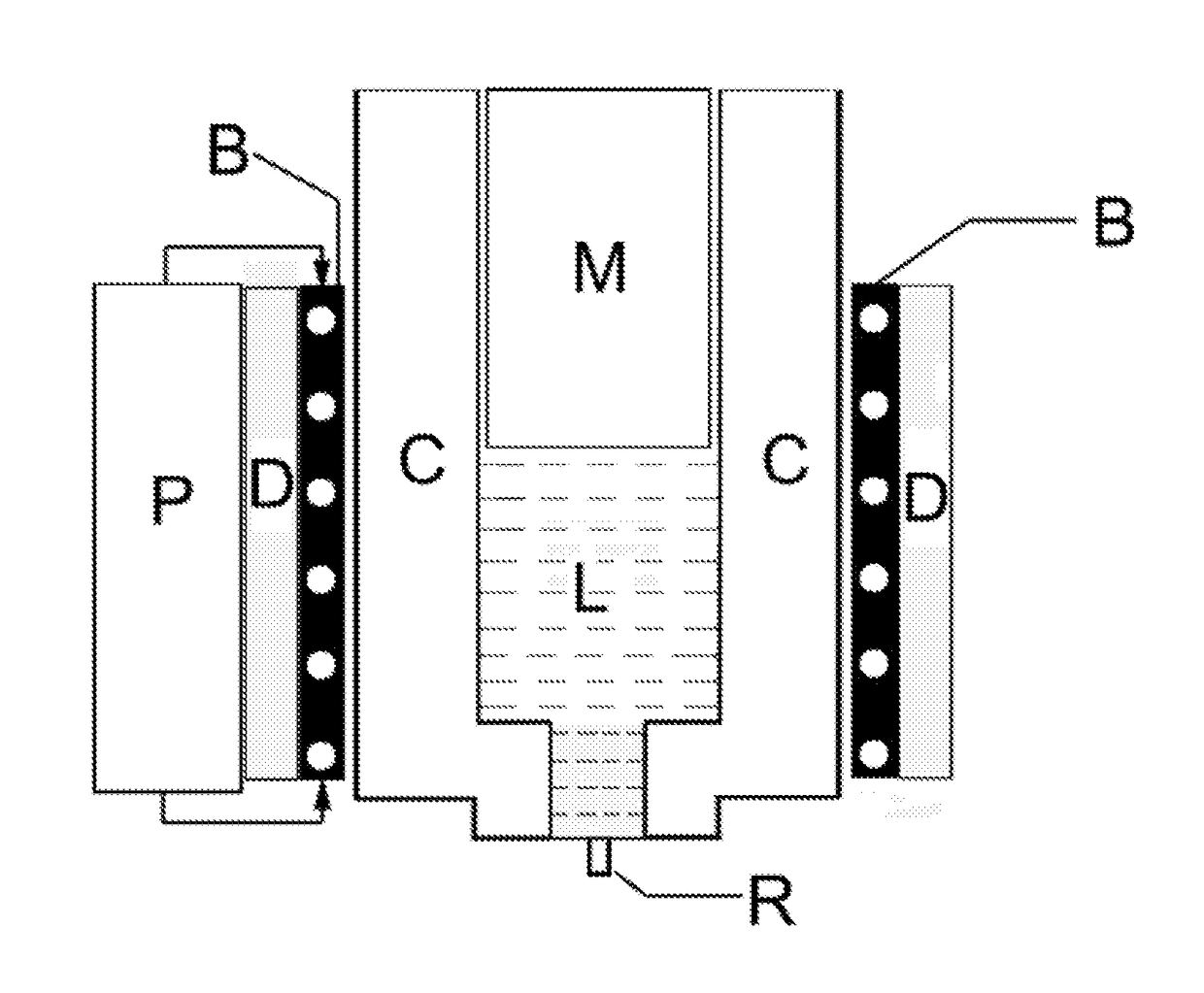

Agitator and melting furnace with agitator

ActiveUS7815846B2Easy to operateLow running costMelt circulation arrangementsElectric discharge heatingMaterials scienceMagnetic line

An agitator for applying an alternating field to a melting furnace main body in order to melt a row material to form a melt includes a plurality of magnets, which are arranged so that magnetic lines of force emitted from one of the magnets pass through the melt in the melting furnace main body and return to another magnet, the magnets being fixed to an inclined surface which is inclined by an angle with respect to a horizontal surface, and being rotatable around an axis substantially perpendicular to the inclined surface.

Owner:TAKAHASHI KENZO

Method of producing a fine grain casting

InactiveUS20100238967A1Furnaces without endless coreMelt circulation arrangementsHeating furnaceGrain structure

An induction heated furnace assembly for producing a directionally solidified casting includes a susceptor that tailors strength of the magnetic field within the chamber to provide a desired grain structure in a completed cast part. The susceptor proportionally blocks portions of the magnetic field to provide different levels of magnetic stirring within the molten material at different locations within the furnace assembly stirring induced by the magnetic field is controlled and varied throughout the furnace assembly to create the desired grain structures in the completed cast article.

Owner:UNITED TECH CORP

Agitator and melting furnace with agitator

ActiveUS20060001200A1Easy to operateLow running costMelt circulation arrangementsElectric discharge heatingMaterials scienceMagnetic line

An agitator for applying an alternating field to a melting furnace main body in order to melt a row material to form a melt includes a plurality of magnets, which are arranged so that magnetic lines of force emitted from one of the magnets pass through the melt in the melting furnace main body and return to another magnet, the magnets being fixed to an inclined surface which is inclined by an angle with respect to a horizontal surface, and being rotatable around an axis substantially perpendicular to the inclined surface.

Owner:TAKAHASHI KENZO

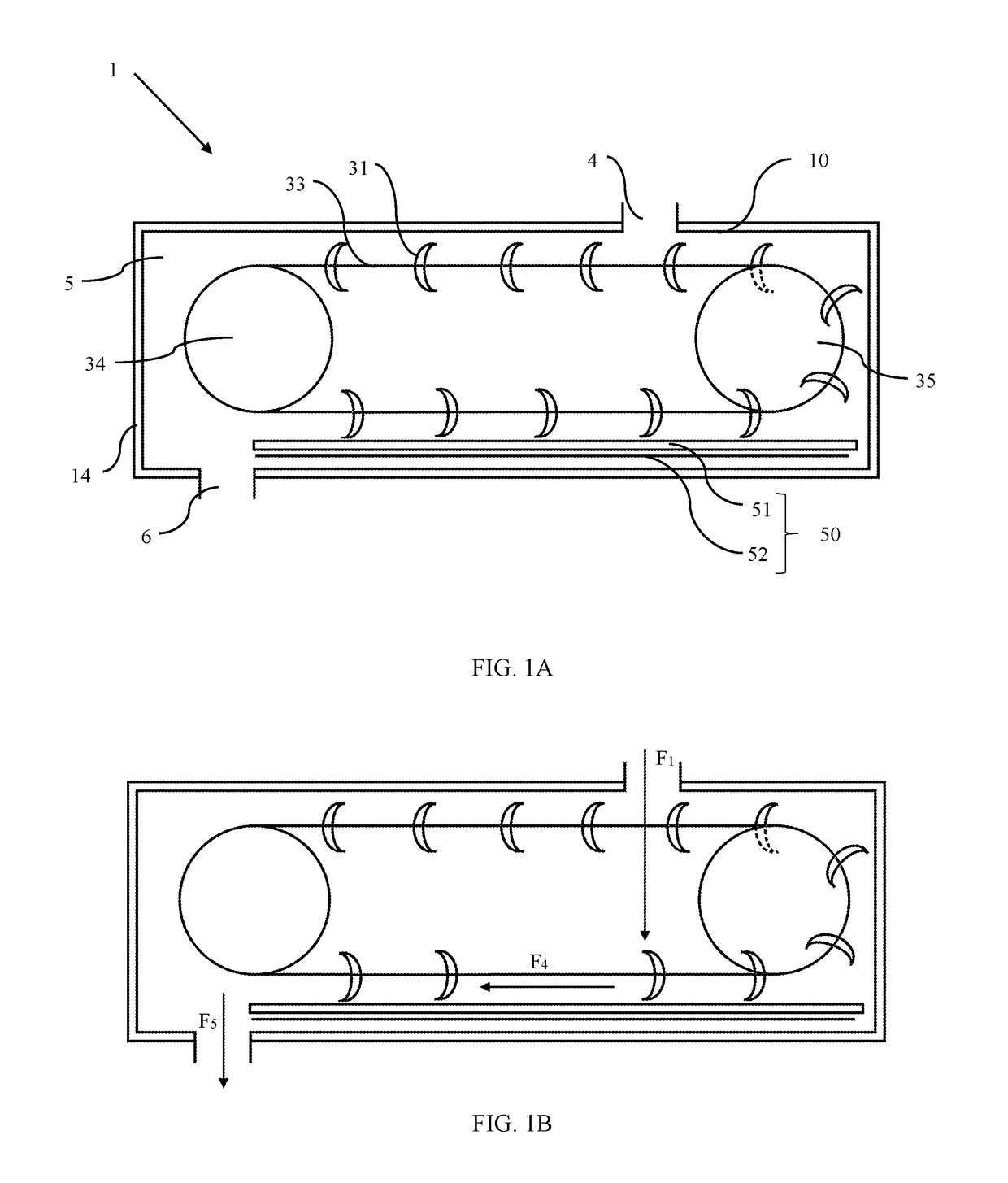

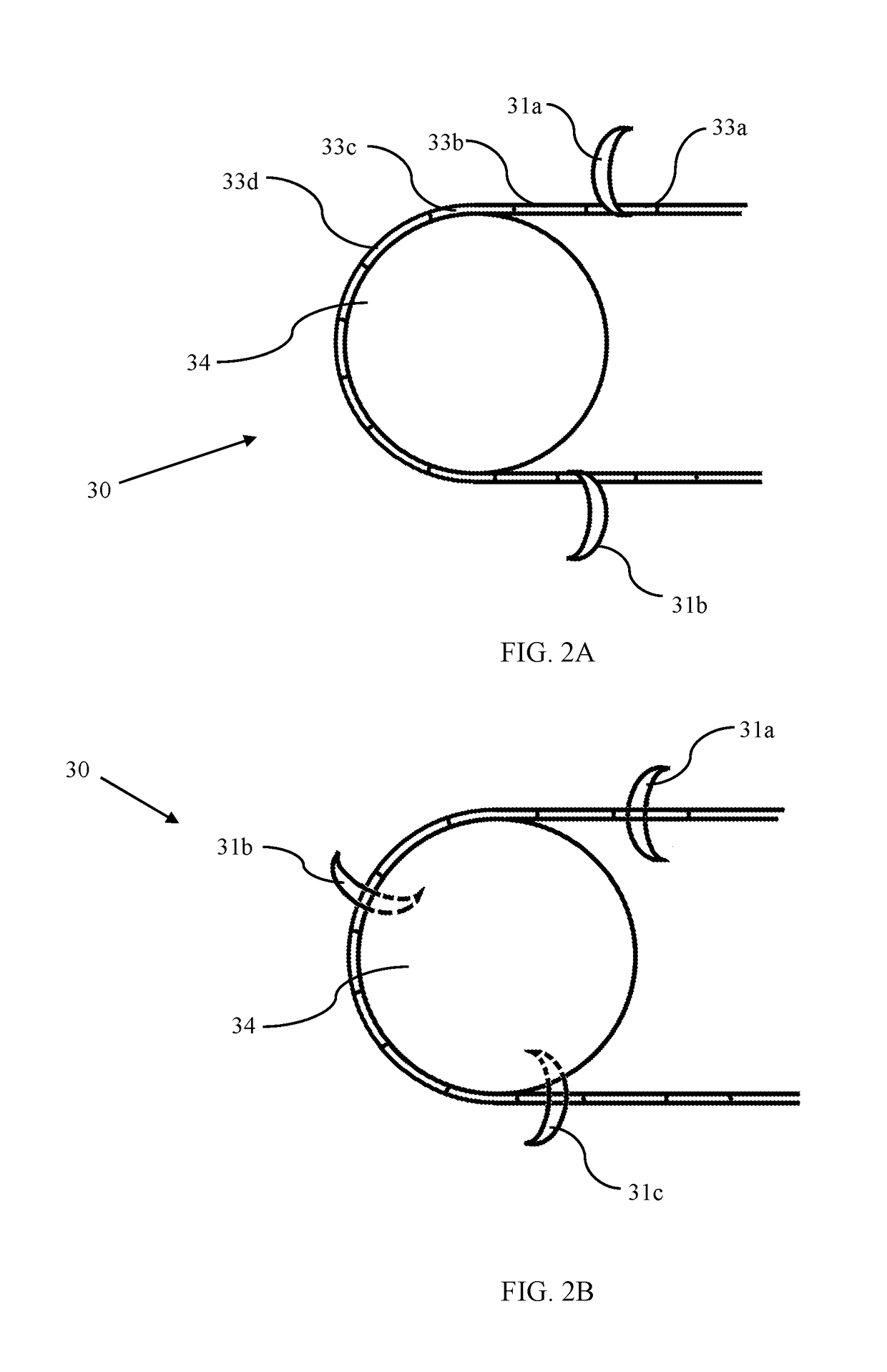

System and method for recycling asphalt using induction heating

ActiveUS20170305800A1Easy to transportMelt circulation arrangementsClimate change adaptationSystems designTransfer system

An asphalt processing system is formed from a heating chamber, a transfer system and an induction heating system. A plurality of paddles, conveyor flights, or conveyor belts having a U-shaped blade move the asphalt through the system while concurrently mixing the material to ensure consistent temperatures through the asphalt cement. The asphalt is heating using one or more induction heating systems to quickly heat the asphalt to between 300° F. and 350° F. The system can include a convection system designed to collect air from the heating chamber, further heat it, and recirculate the air to enhance the asphalt heating. A water condenser can be employed to remove moisture during air recirculation, reducing moisture content in the asphalt cement. The asphalt cement is optionally then modified by addition of one or more rejuvenation oils. This system is particularly useful for recycled asphalt pavement, but can be used for all asphalt products.

Owner:CRUPI FRANCESCO A +1

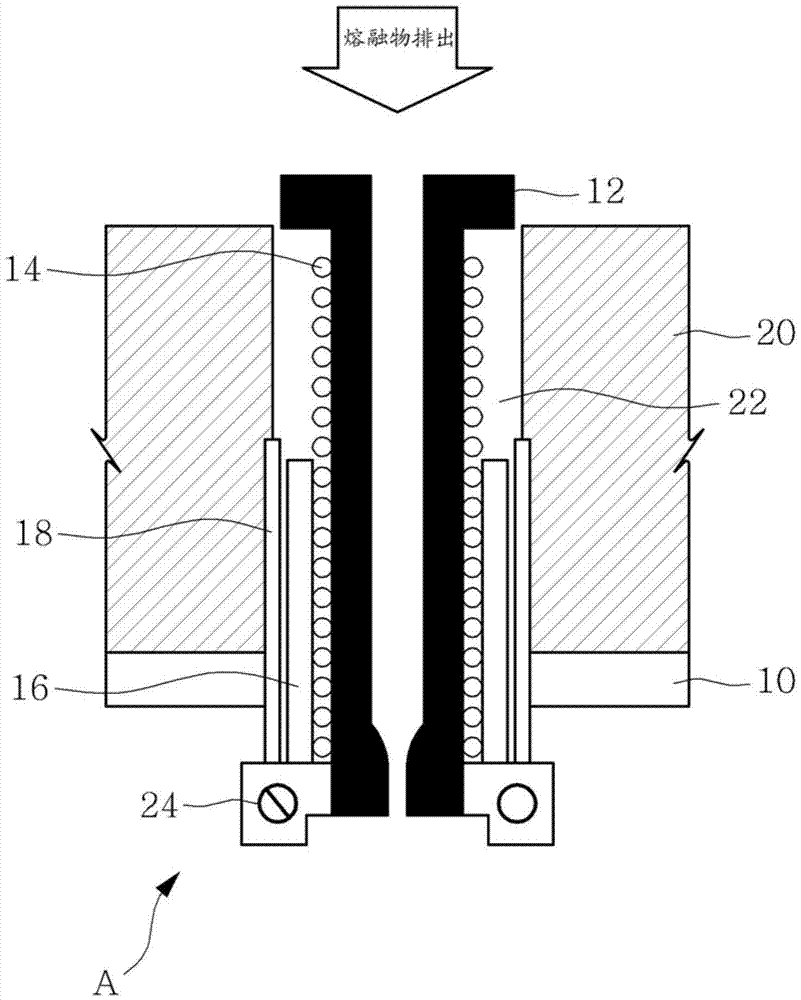

Tapping device and method using induction heat for melt

ActiveCN104515398AAvoid dischargePrevent easy consumptionFurnaces without endless coreMelt circulation arrangementsGraphiteThermal efficiency

A tapping device and method using induction heat for melt comprises melting furnace made of steel; heating unit disposed in the upper part in the melting furnace and made of graphite material; induction coil wound around the heating unit; insulator disposed adjacent to the bottom surface of the lower part of the melting furnace; supporter disposed outside the insulator; and firebricks disposed on the bottom surface of melting furnace and outside the supporter.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

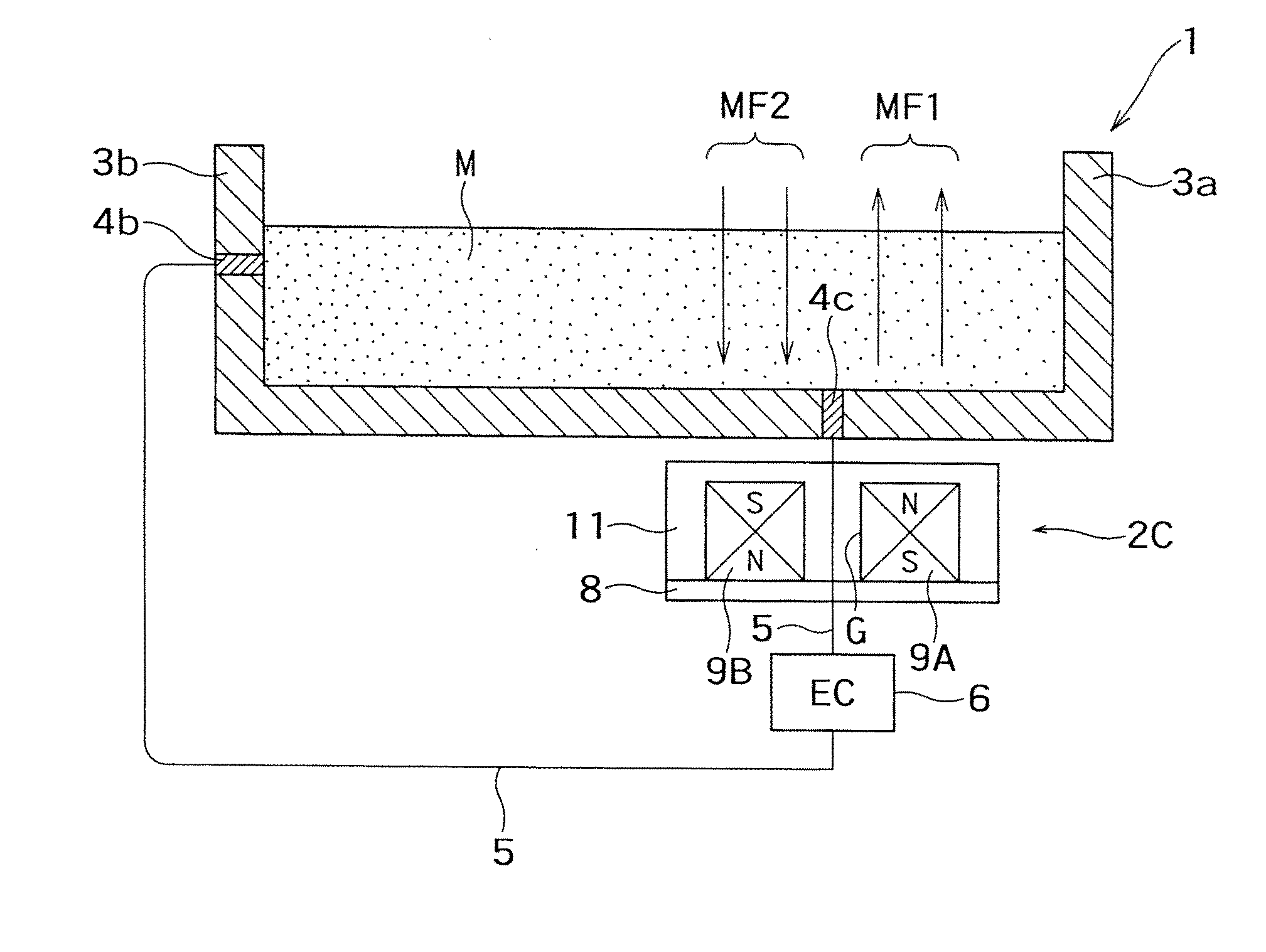

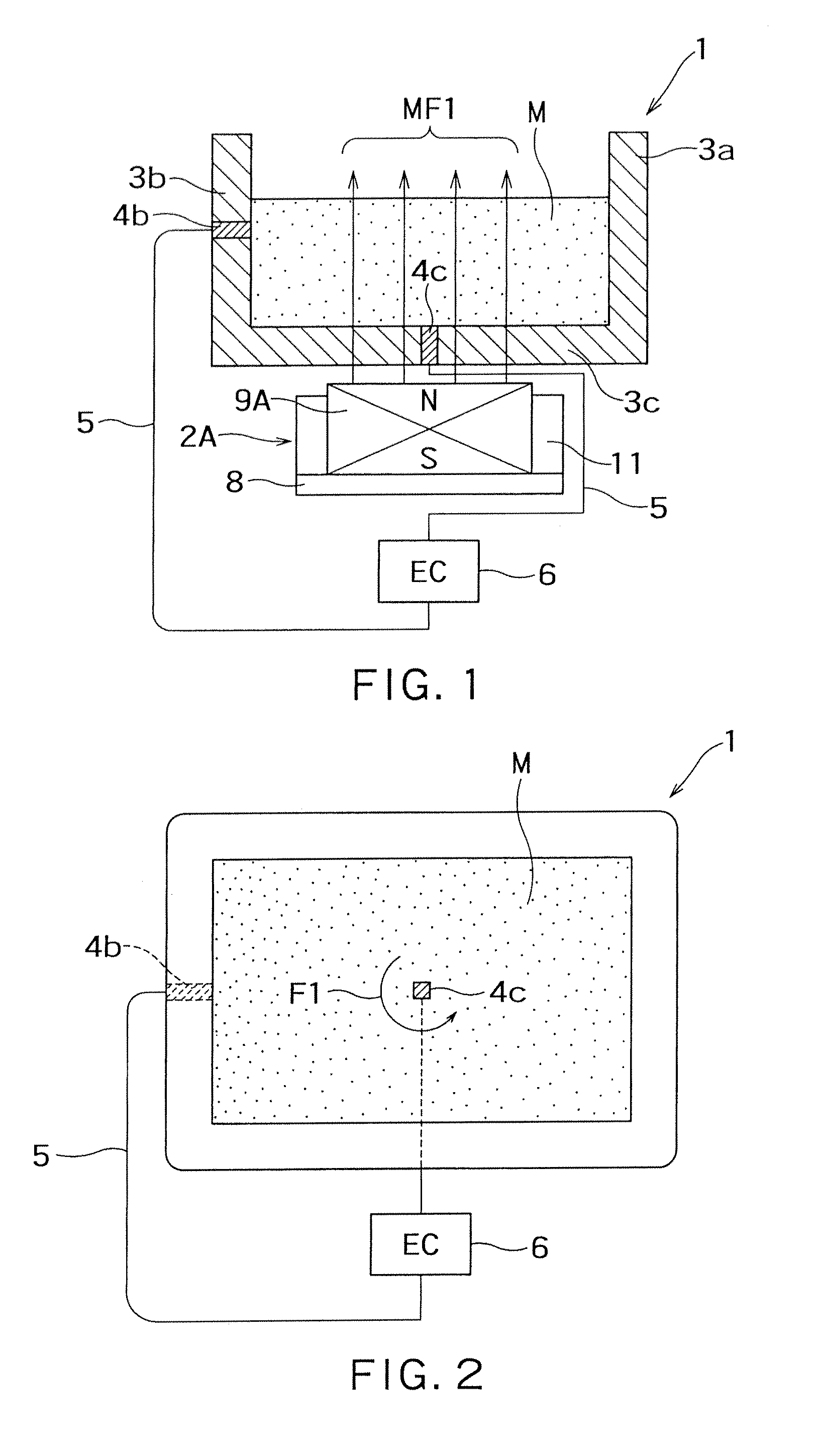

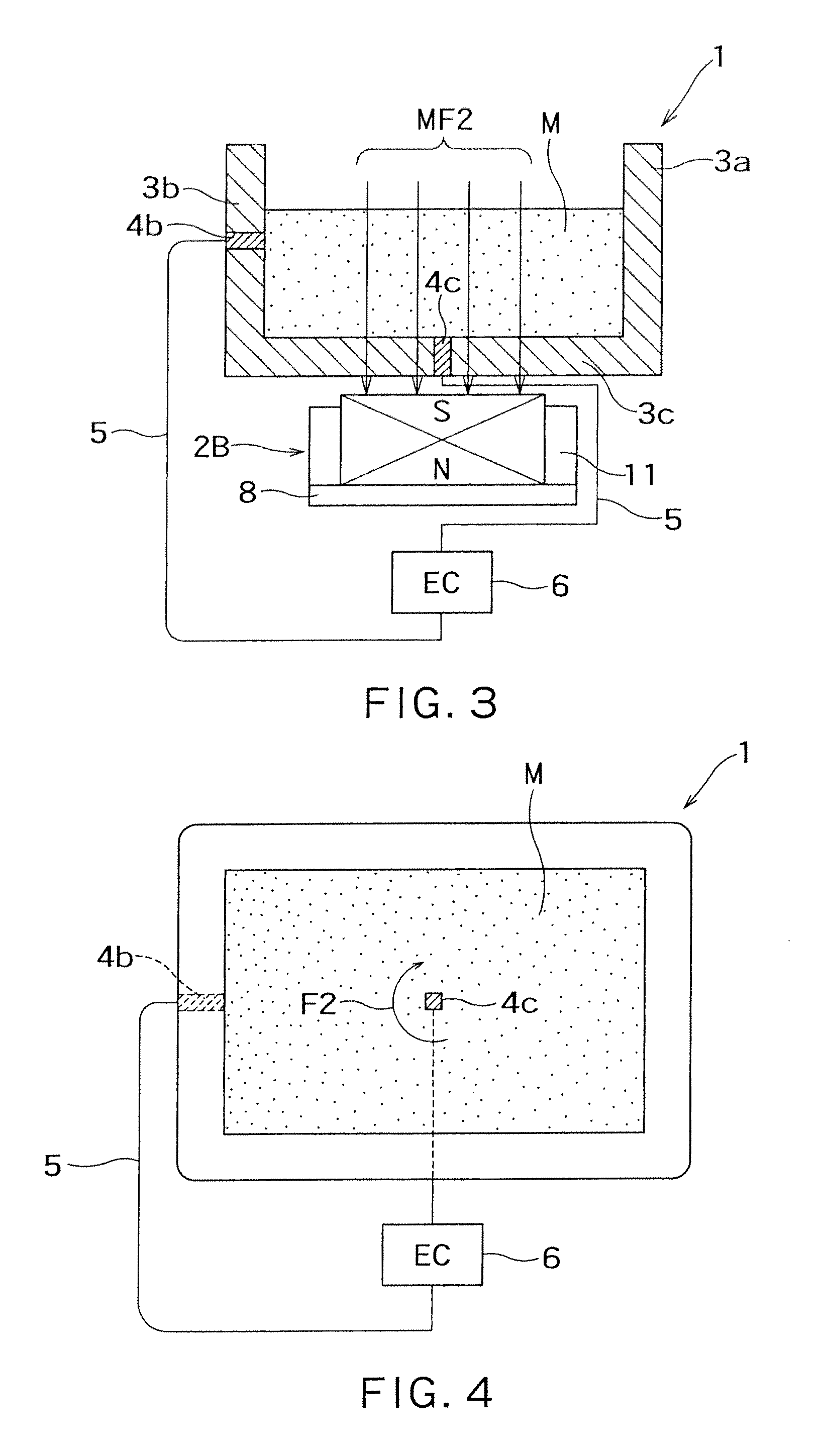

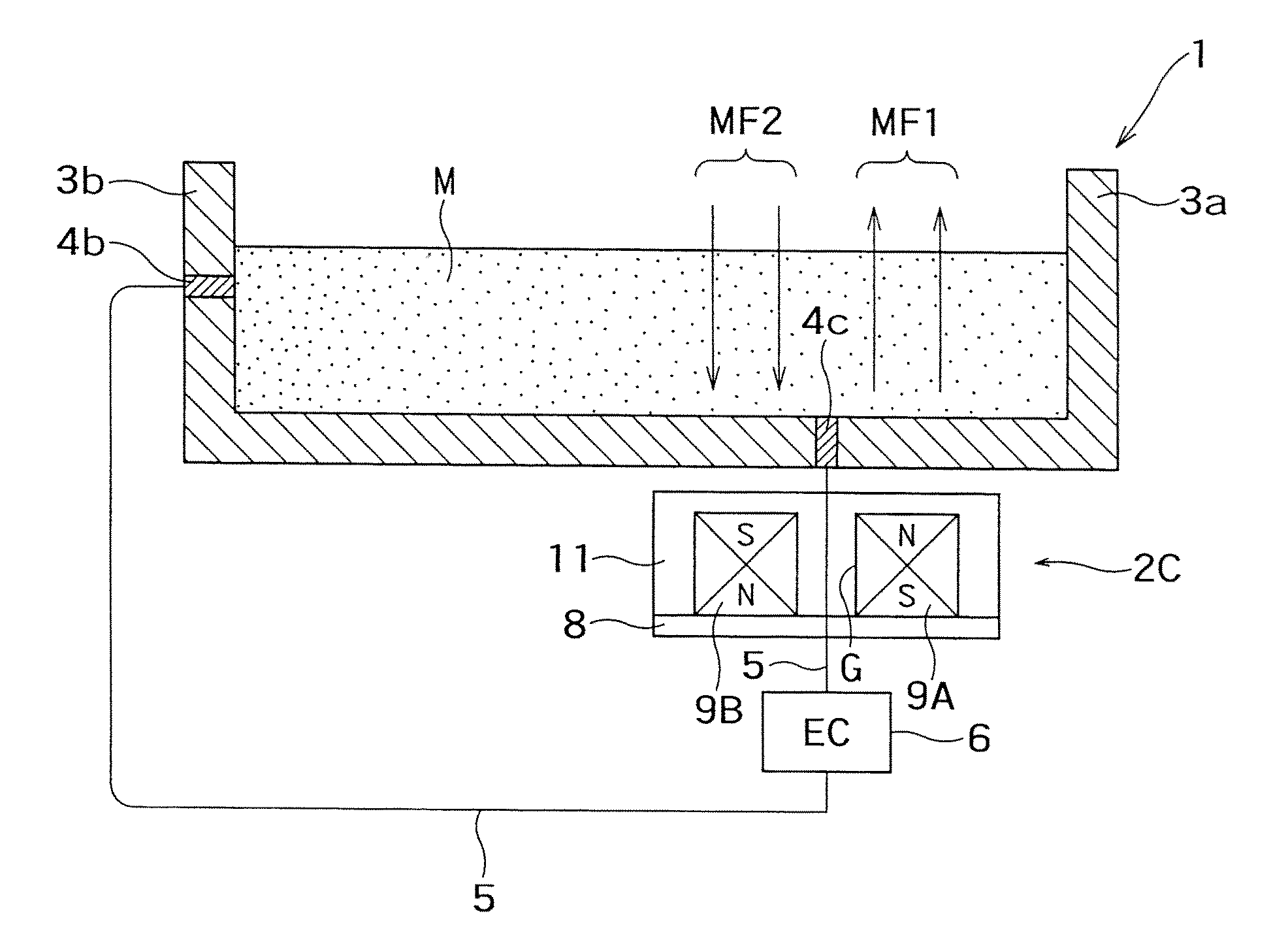

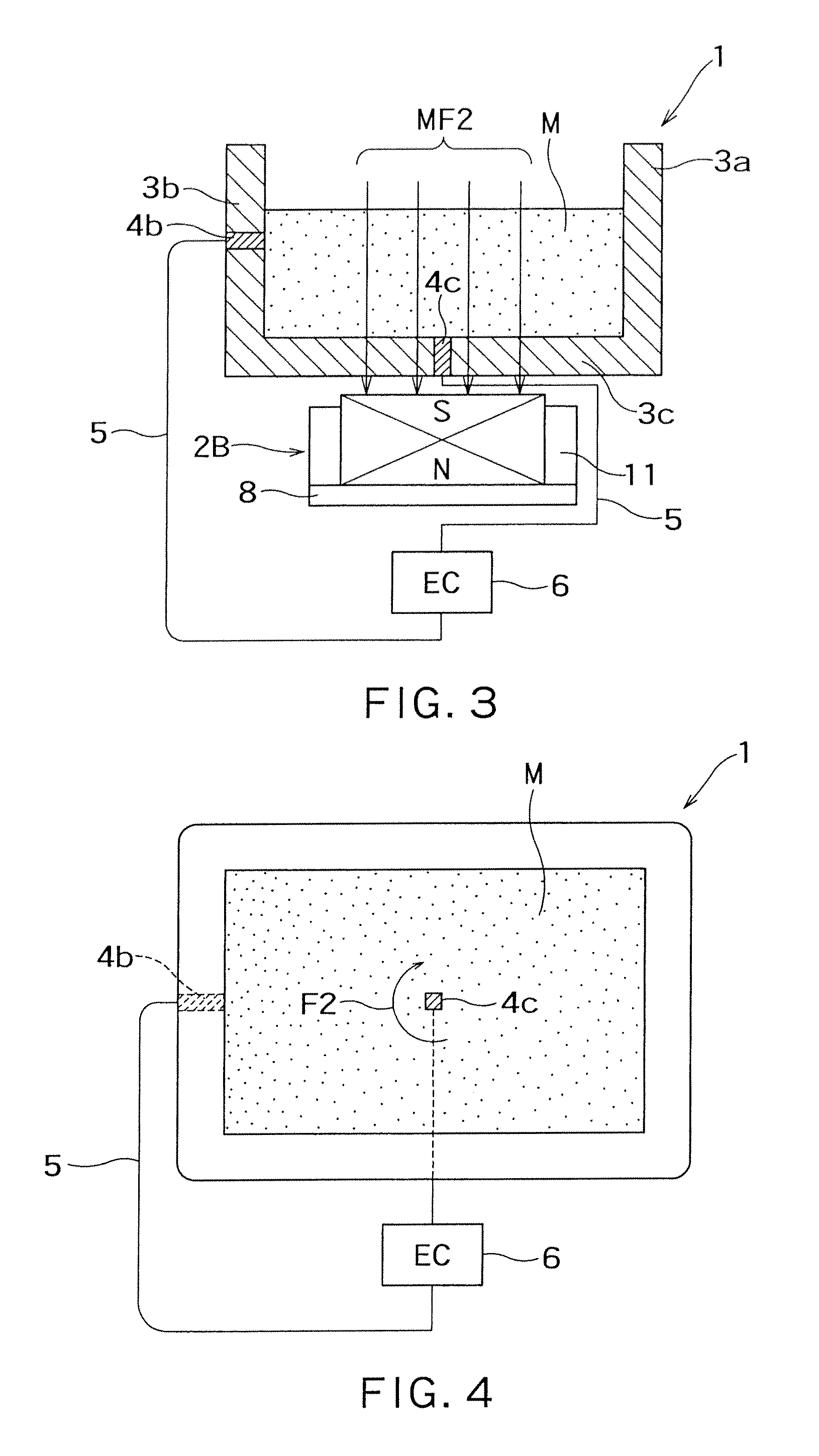

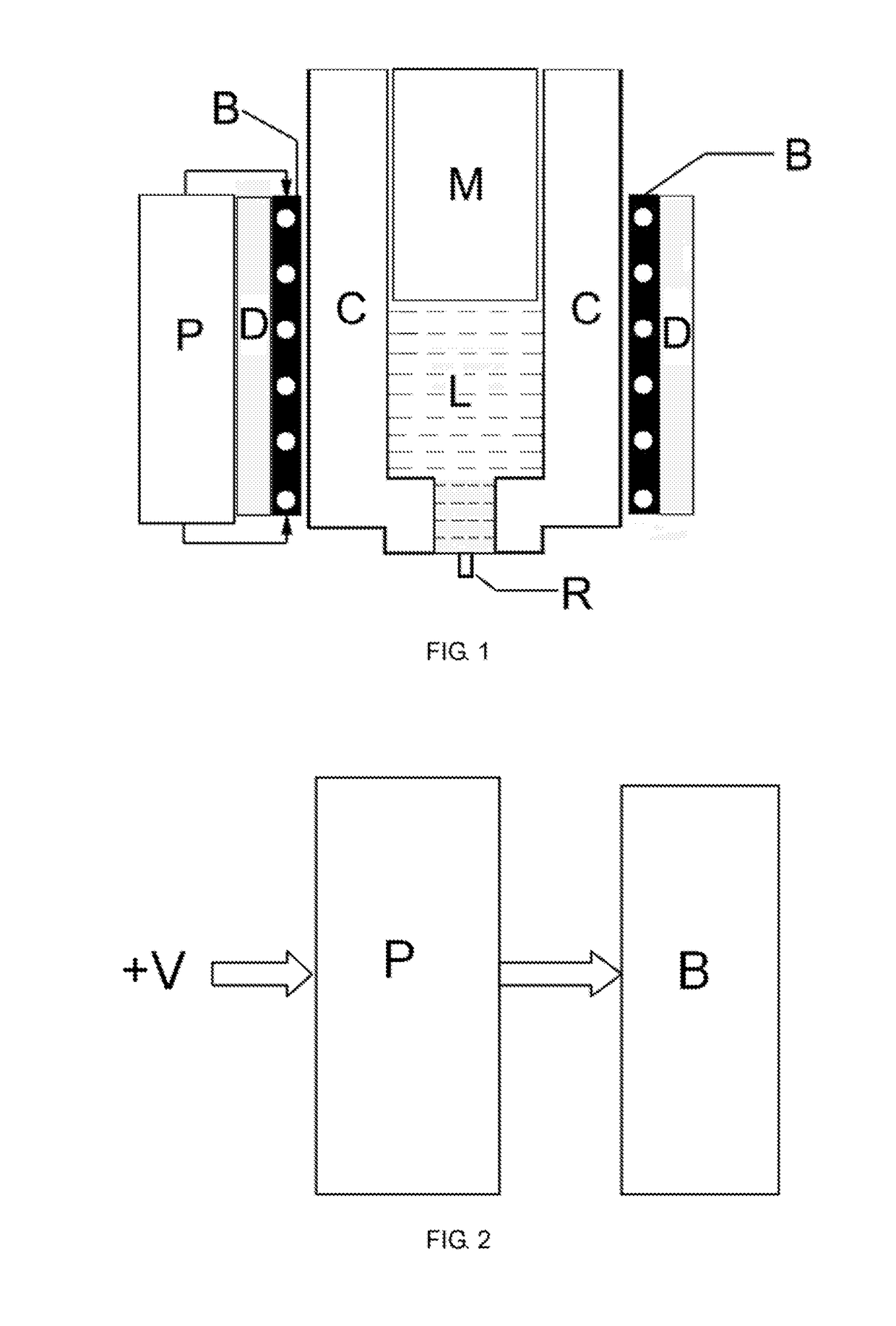

Melting furnace with agitator

ActiveUS20090322000A1Easy to handleSimple structureMechanical apparatusMelt circulation arrangementsMagnetic fieldMelting furnace

There is provided a melting furnace with an agitator. The melting furnace with an agitator includes a melting furnace that contains melt, and an agitator that agitates the melt by an electromagnetic force. The agitator includes a first electrode that is provided at an arbitrary position of the melting furnace so as to come in contact with the melt contained in the melting furnace, a second electrode that is provided near a bottom wall of the melting furnace so as to come in contact with the melt, a first magnetic field device that is provided outside the melting furnace so as to face the bottom wall of the melting furnace and makes a north pole face the bottom wall, and a second magnetic field device that is provided outside the melting furnace so as to face the bottom wall of the melting furnace and makes a south pole face the bottom wall. The first and second magnetic field devices are disposed with a gap in a certain direction.

Owner:TAKAHASHI KENZO

Melting furnace with agitator

ActiveUS7736586B2Easy to handleSimple structureMelt circulation arrangementsTransportation and packagingMagnetic fieldMelting furnace

There is provided a melting furnace with an agitator. The melting furnace with an agitator includes a melting furnace that contains melt, and an agitator that agitates the melt by an electromagnetic force. The agitator includes a first electrode that is provided at an arbitrary position of the melting furnace so as to come in contact with the melt contained in the melting furnace, a second electrode that is provided near a bottom wall of the melting furnace so as to come in contact with the melt, a first magnetic field device that is provided outside the melting furnace so as to face the bottom wall of the melting furnace and makes a north pole face the bottom wall, and a second magnetic field device that is provided outside the melting furnace so as to face the bottom wall of the melting furnace and makes a south pole face the bottom wall. The first and second magnetic field devices are disposed with a gap in a certain direction.

Owner:TAKAHASHI KENZO

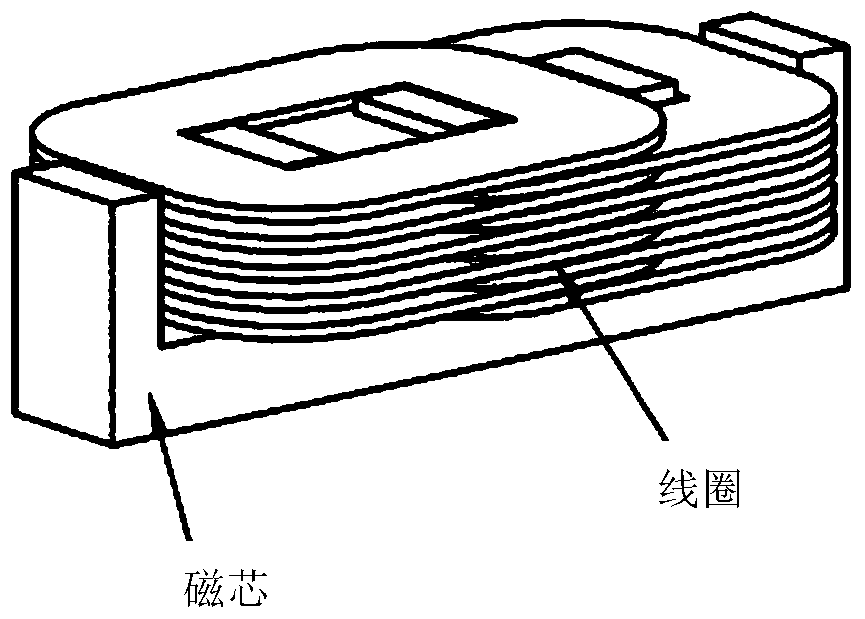

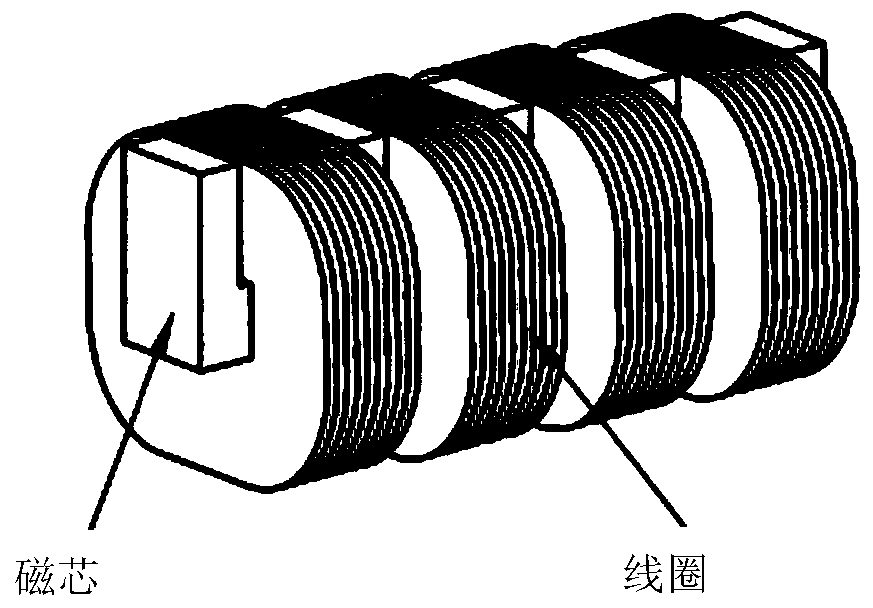

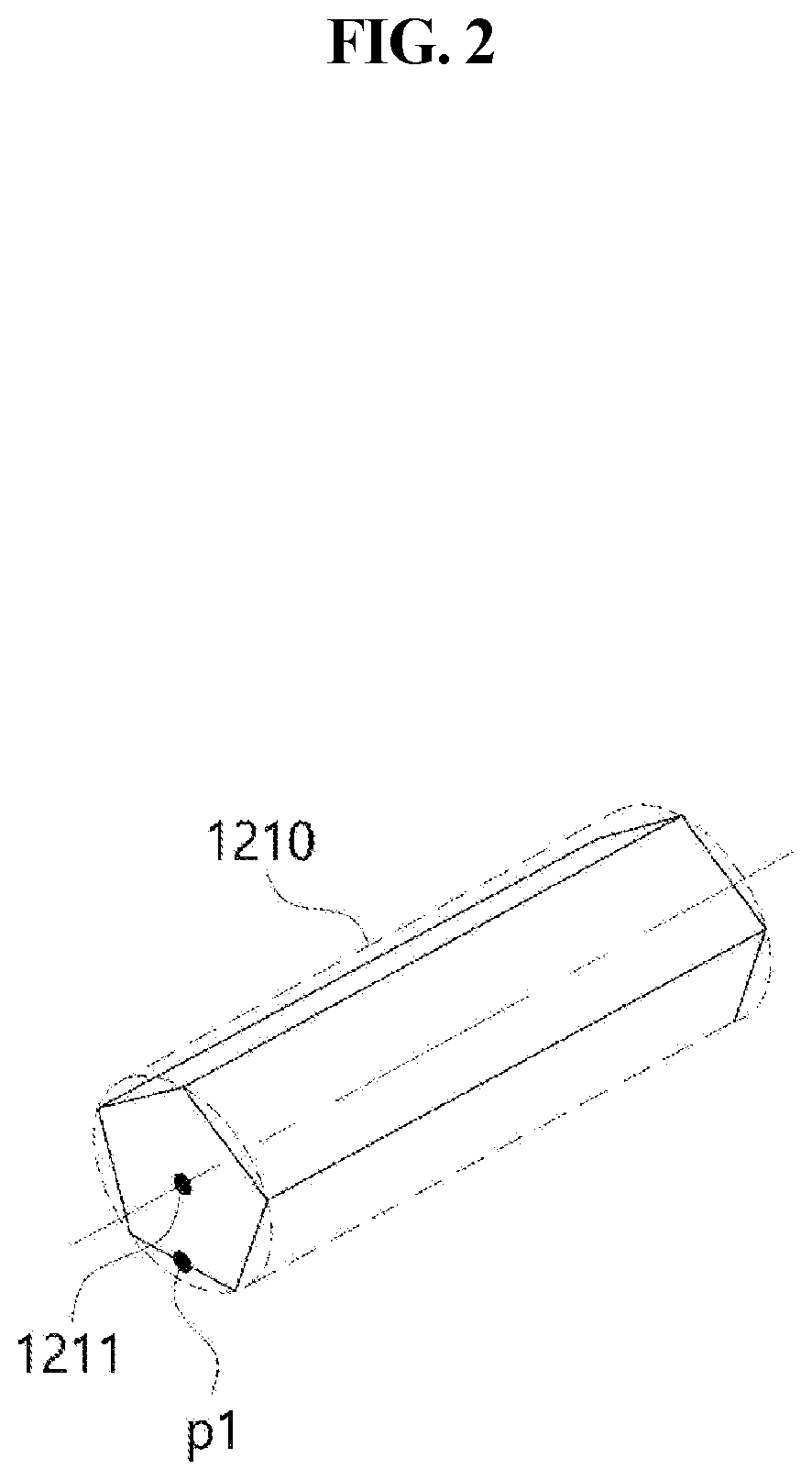

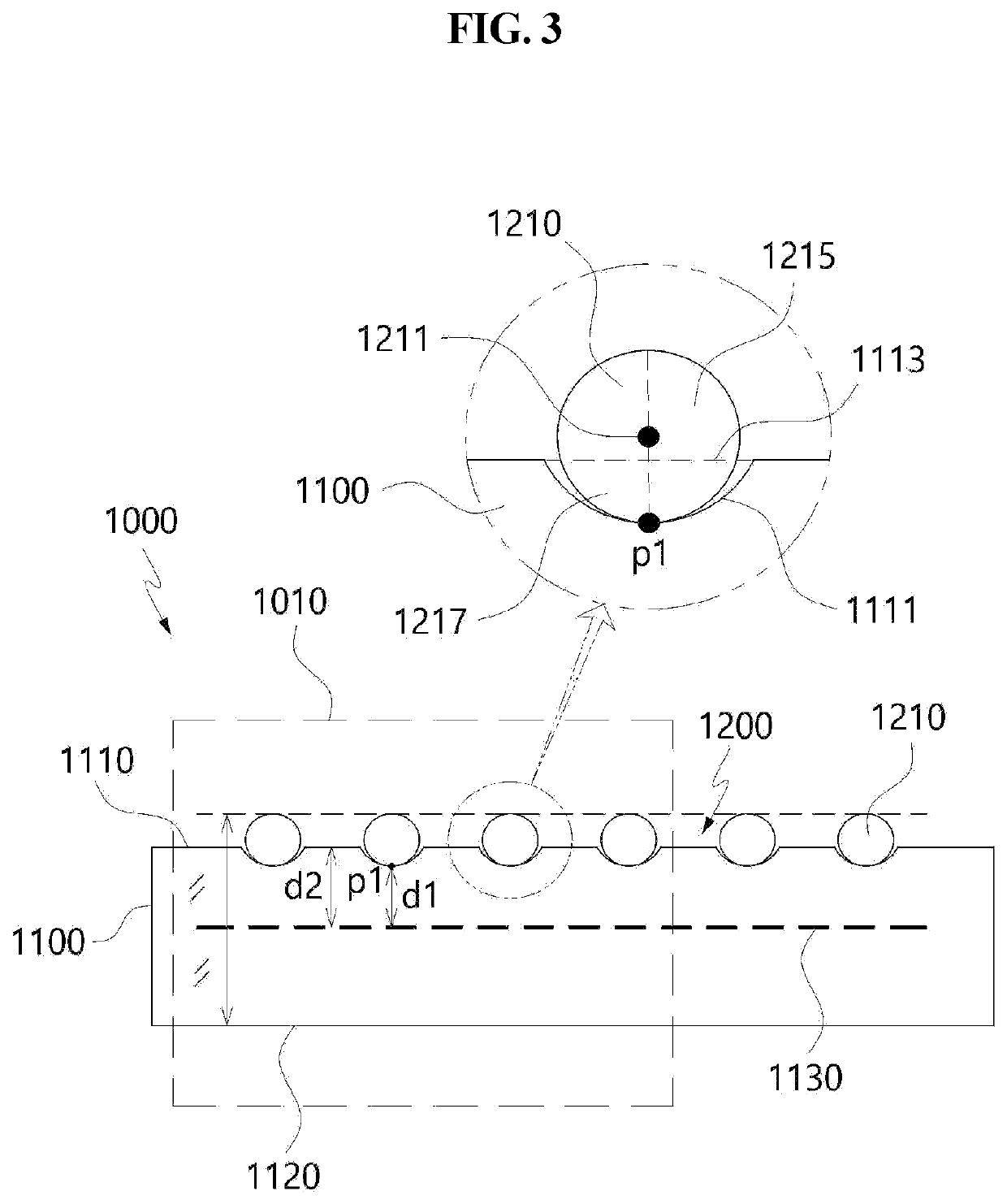

Method of Rapidly Melting Metal for 3D Metal Printers by Electromagnetic Induction

InactiveUS20180324903A1Improve energy conversion efficiencyFast printAdditive manufacturing apparatusMelt circulation arrangementsHigh energyDirect heating

This invention relates to the field of 3D metal printing, and more particularly to a method of rapidly melting metal for 3D metal printers by electromagnetic induction. This is a new cost-effective 3D metal printing method that enables direct heating and rapid melting of metals, higher energy conversion efficiency, higher deposition rates, smaller oxide, higher safety and controllability, faster printing, and larger-size metal components manufacturing.

Owner:ZENG RICHARD +1

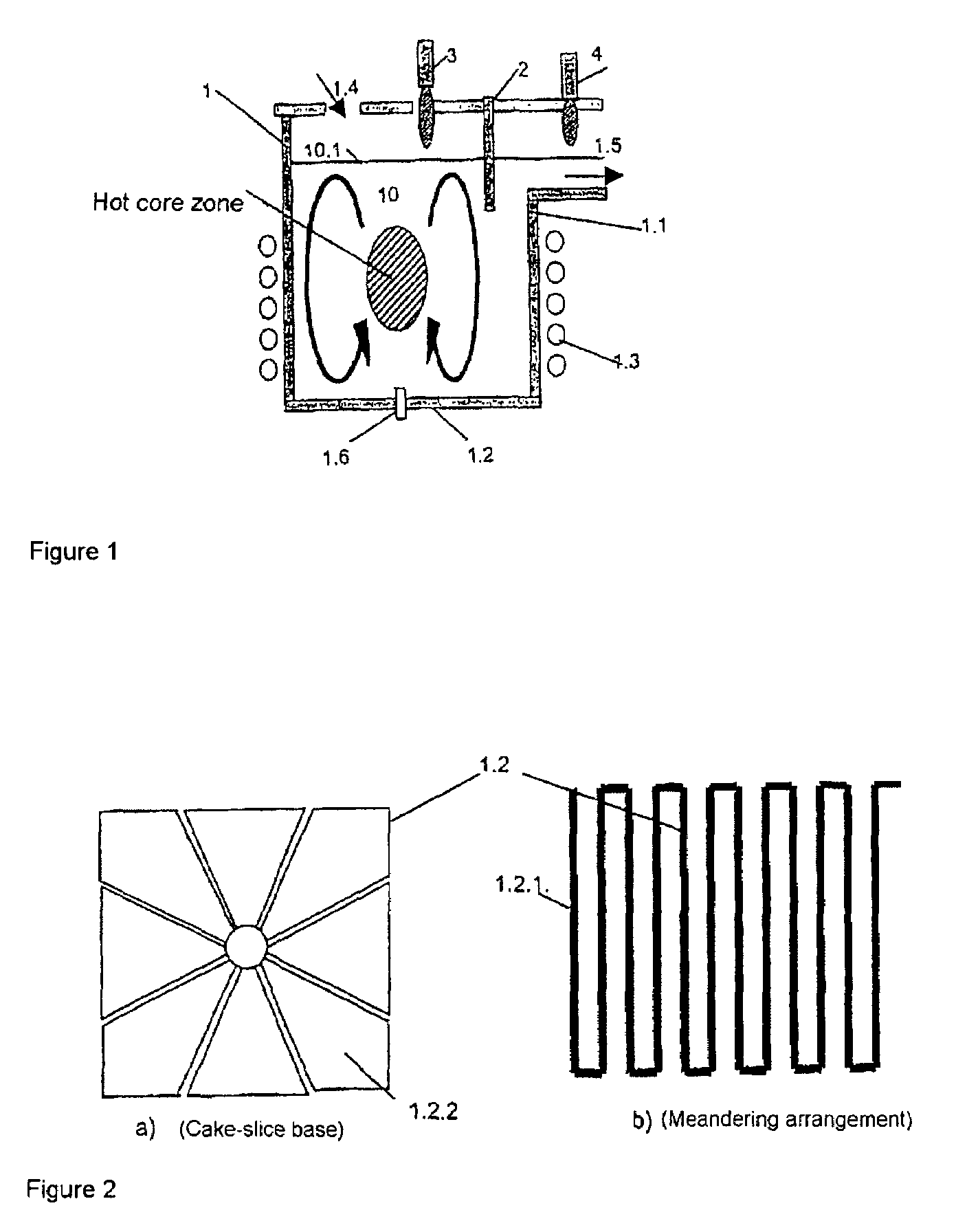

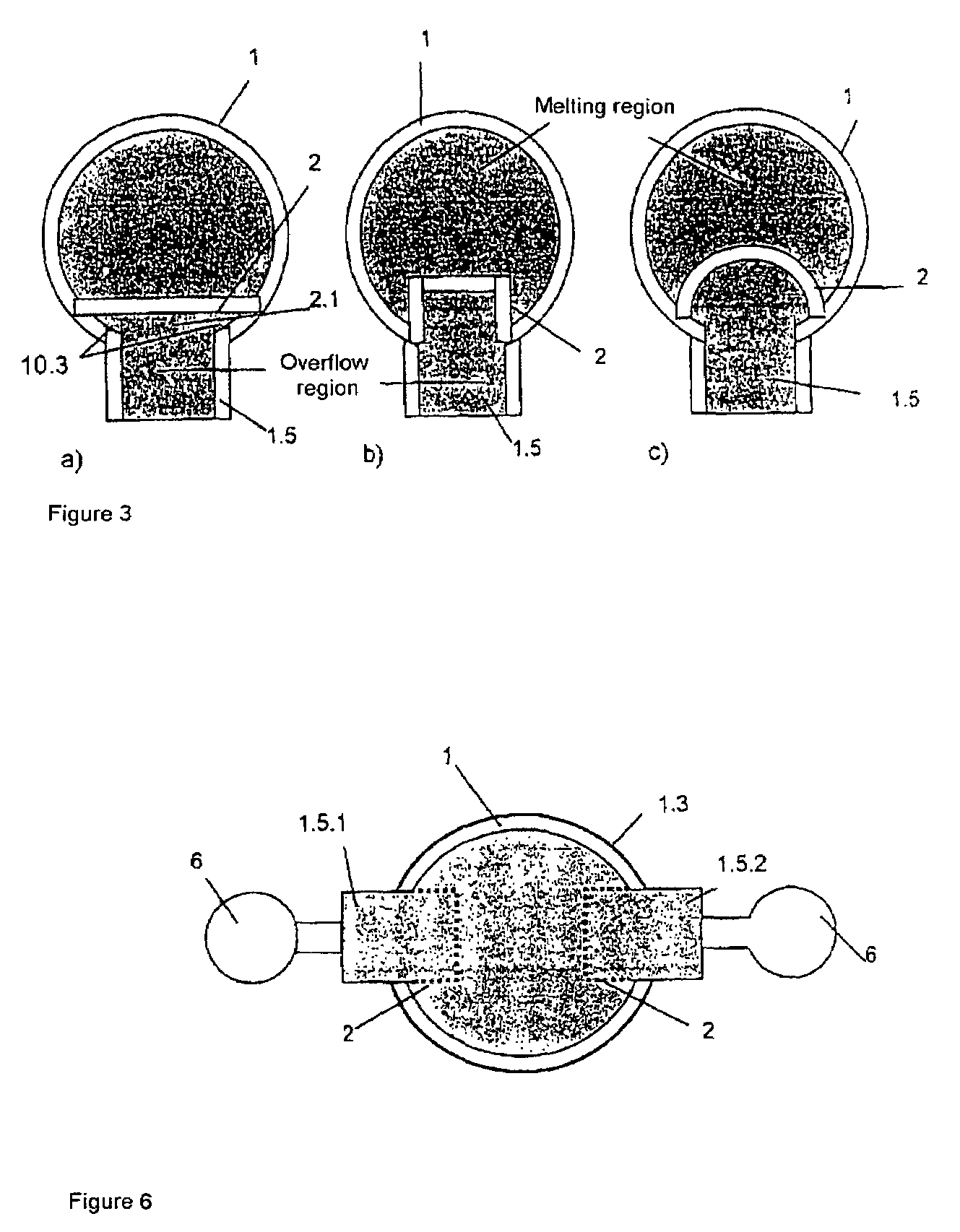

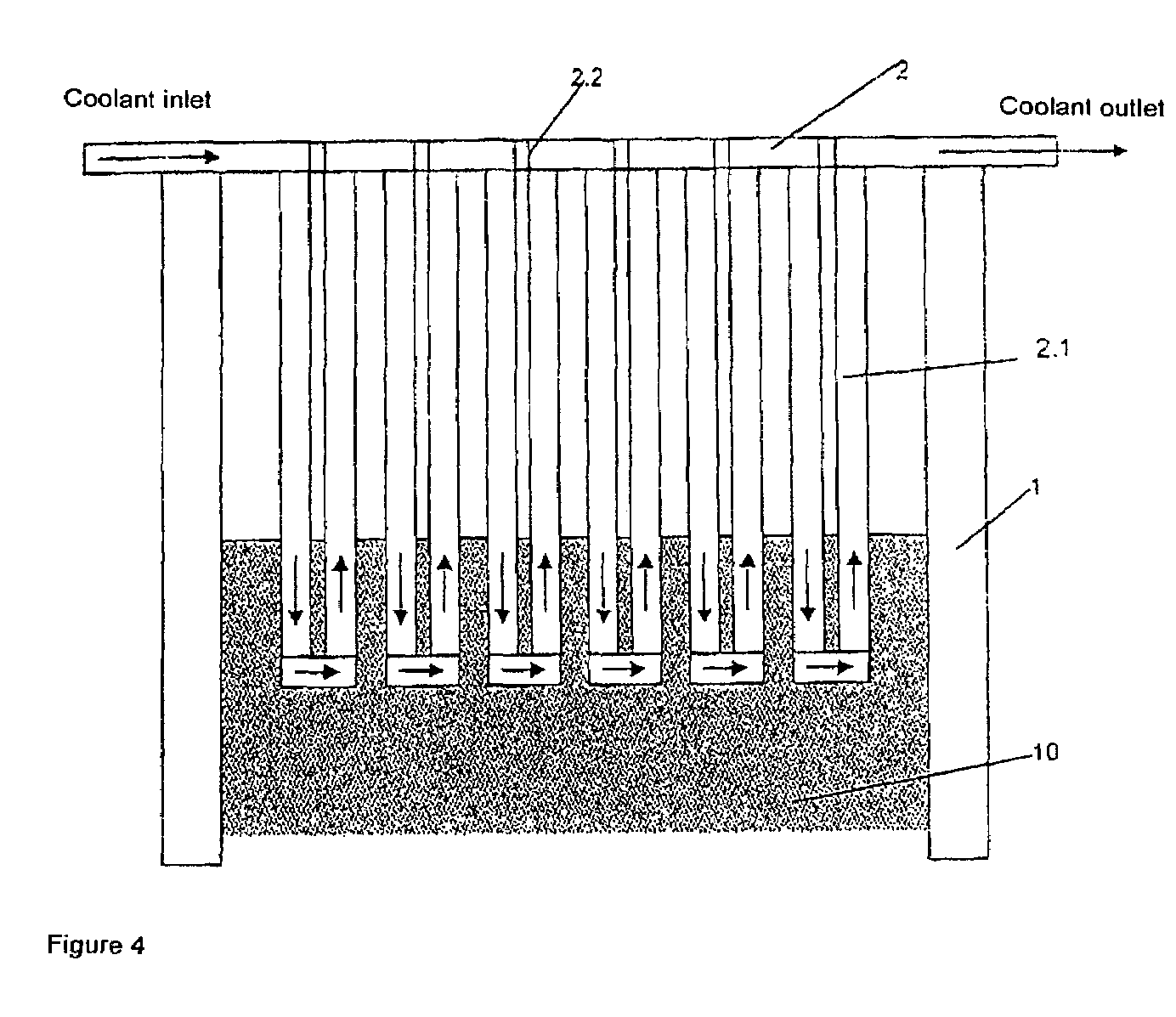

Method and device for melting glass using an induction-heated crucible with cooled crust

InactiveUS7444837B2Quality improvementSimple and inexpensive to connectFurnaces without endless coreMelt circulation arrangementsMolten glassHigh frequency

A method and an apparatus for the rapid melting of glasses in a skull crucible is provided. The method and apparatus introduce high-frequency energy into the contents of the crucible by means of a coil arrangement surrounding the skull crucible, in order to heat the melt, and the batch is laid and the molten glass discharged in the upper region of the crucible, and undissolved constituents of the batch are retained by means of a cooled bridge which is immersed in the melt. The glass is taken off above the coil arrangement and is fed for further processing without flowing through the coil region.

Owner:SCHOTT AG

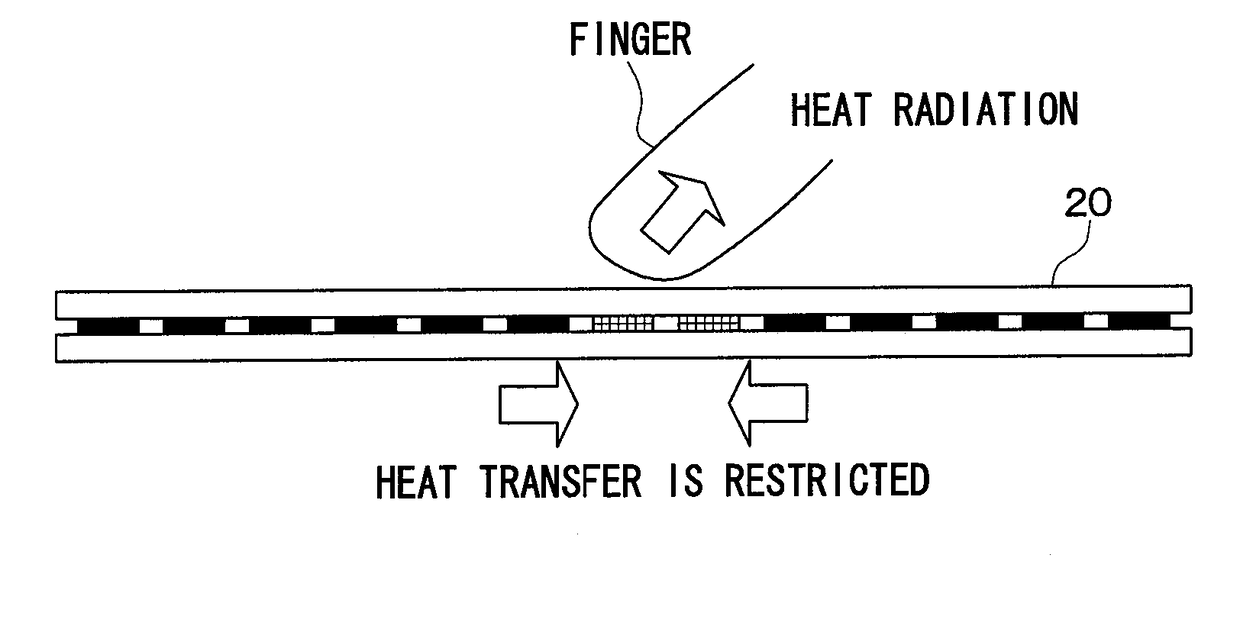

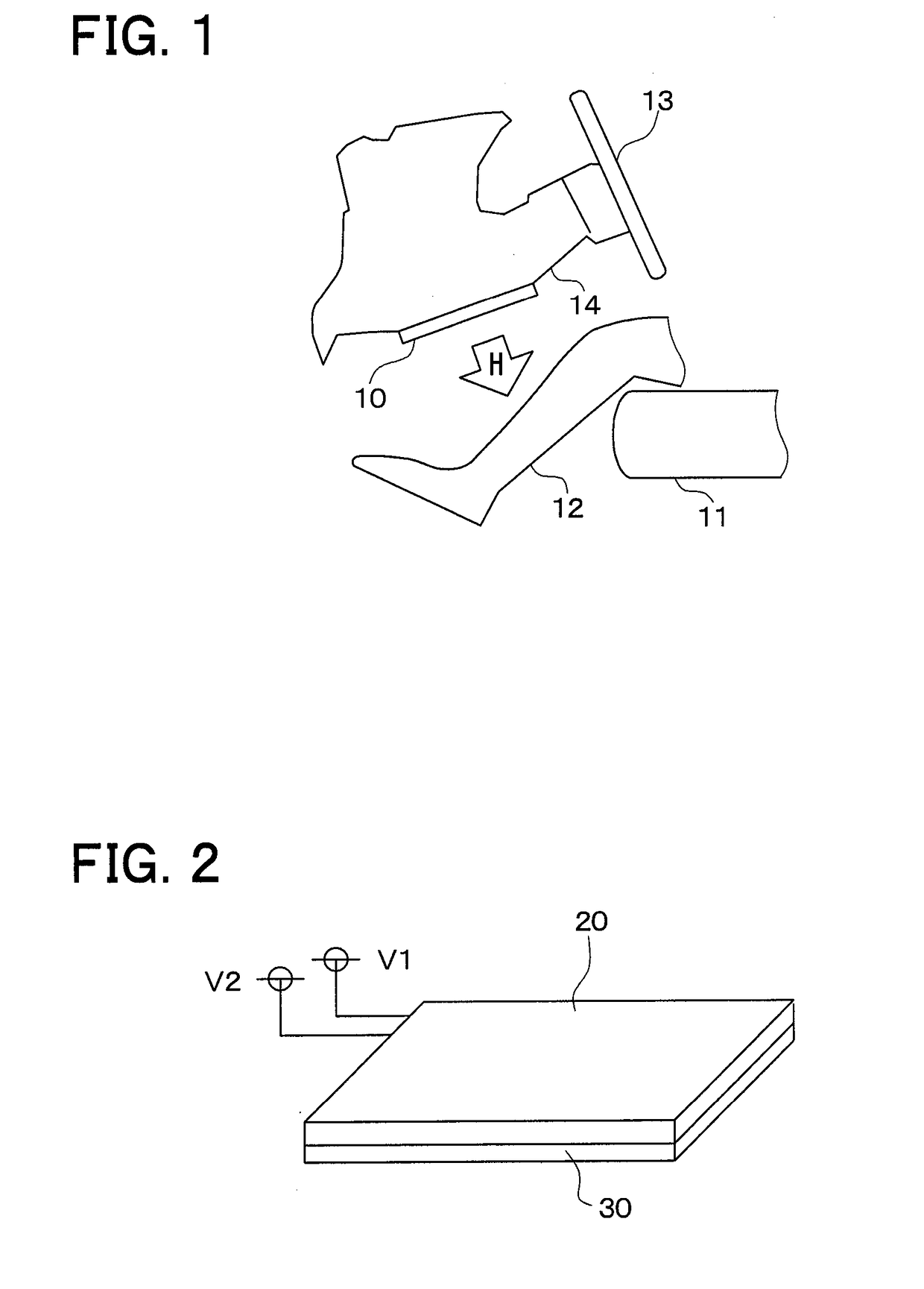

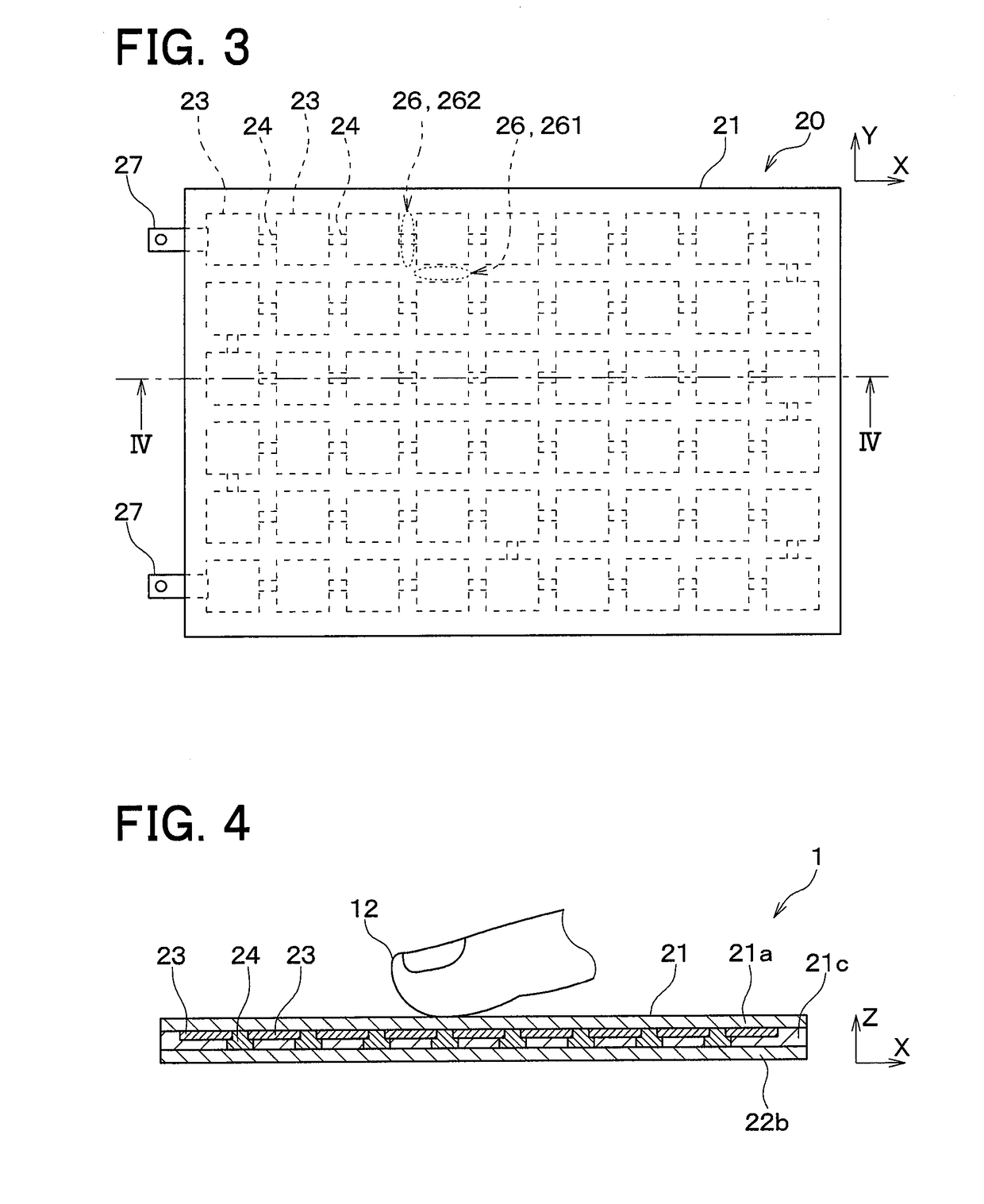

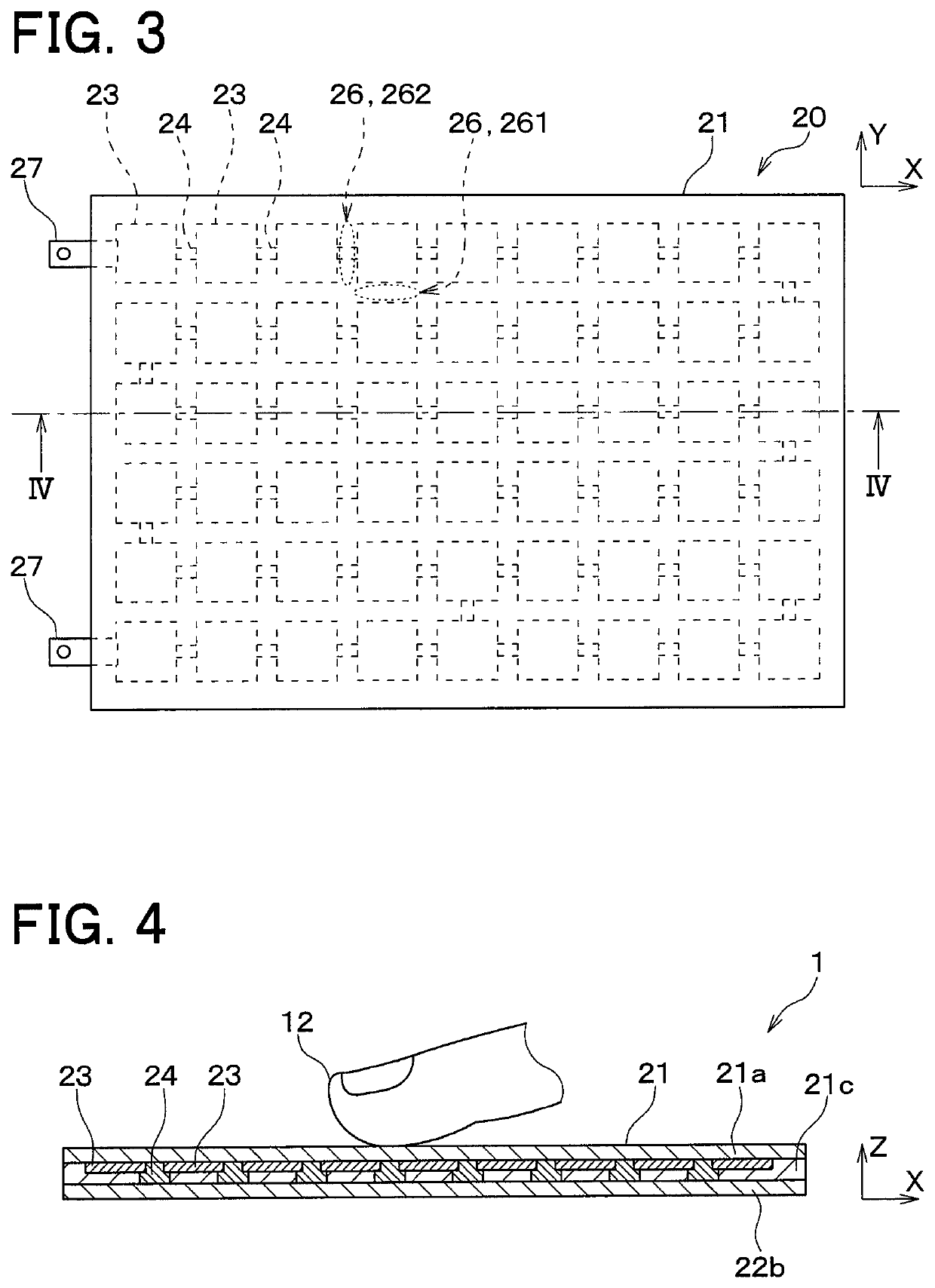

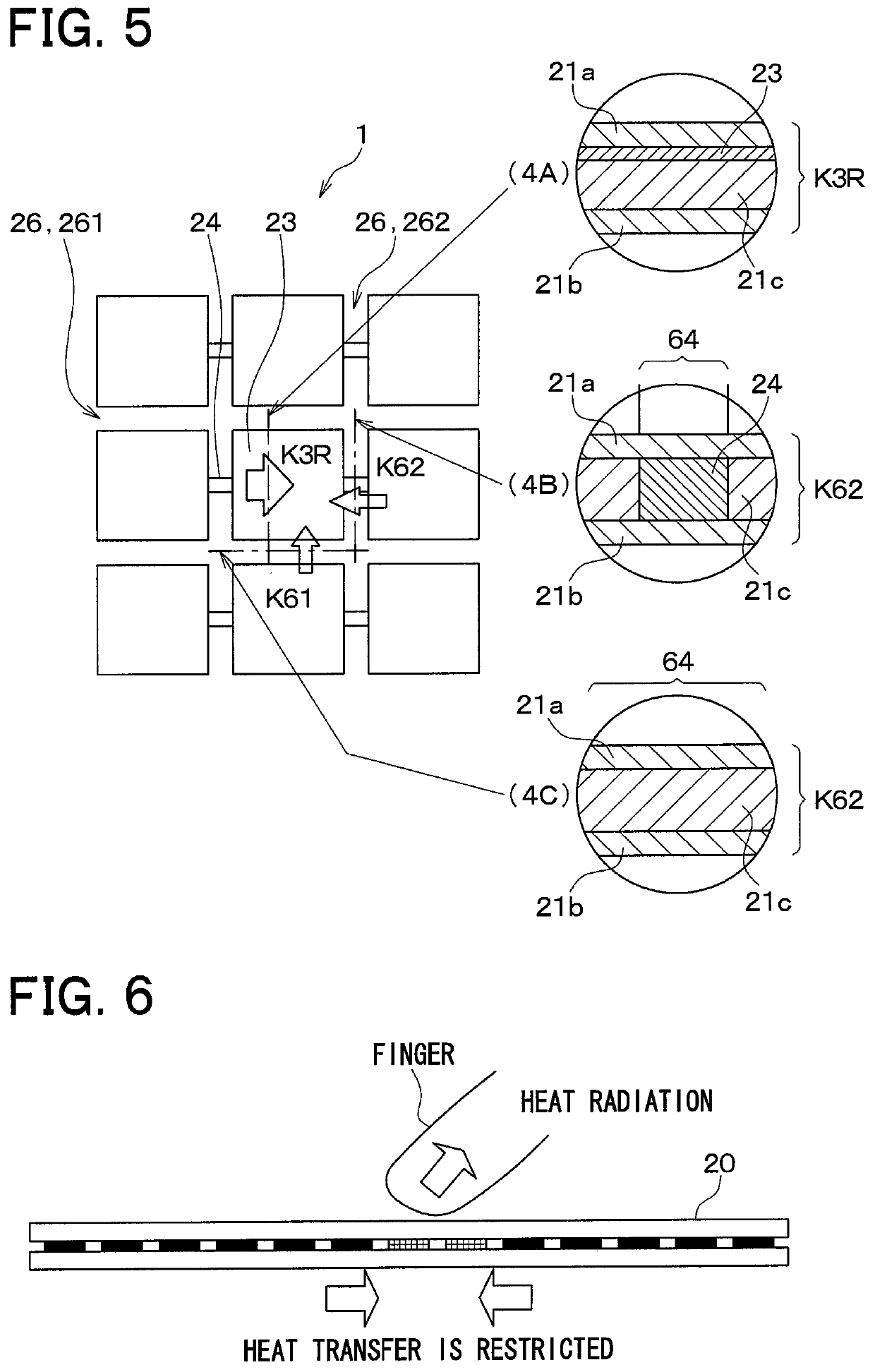

Radiation heating device

ActiveUS20170321902A1Avoid heat transferIncrease temperatureAir-treating devicesDomestic stoves or rangesEngineeringThermal radiation

A radiation heating device includes: a planar heat generation layer; a heat generation portion that is provided in the heat generation layer and that generates heat by energization; a plurality of heat radiation portions that are disposed in the heat generation layer and that radiate heat transferred from the heat generation portion; a low heat conduction portion that is provided around each of the heat radiation portions and that has a lower heat conductivity than the heat radiation portions; and a contact detection unit that detects contact of an object with the heat generation layer. The radiation heating device further includes an energization amount decrease unit that decreases an energization amount of the heat generation portion when the contact detection unit detects the contact of the object with the heat generation layer.

Owner:DENSO CORP

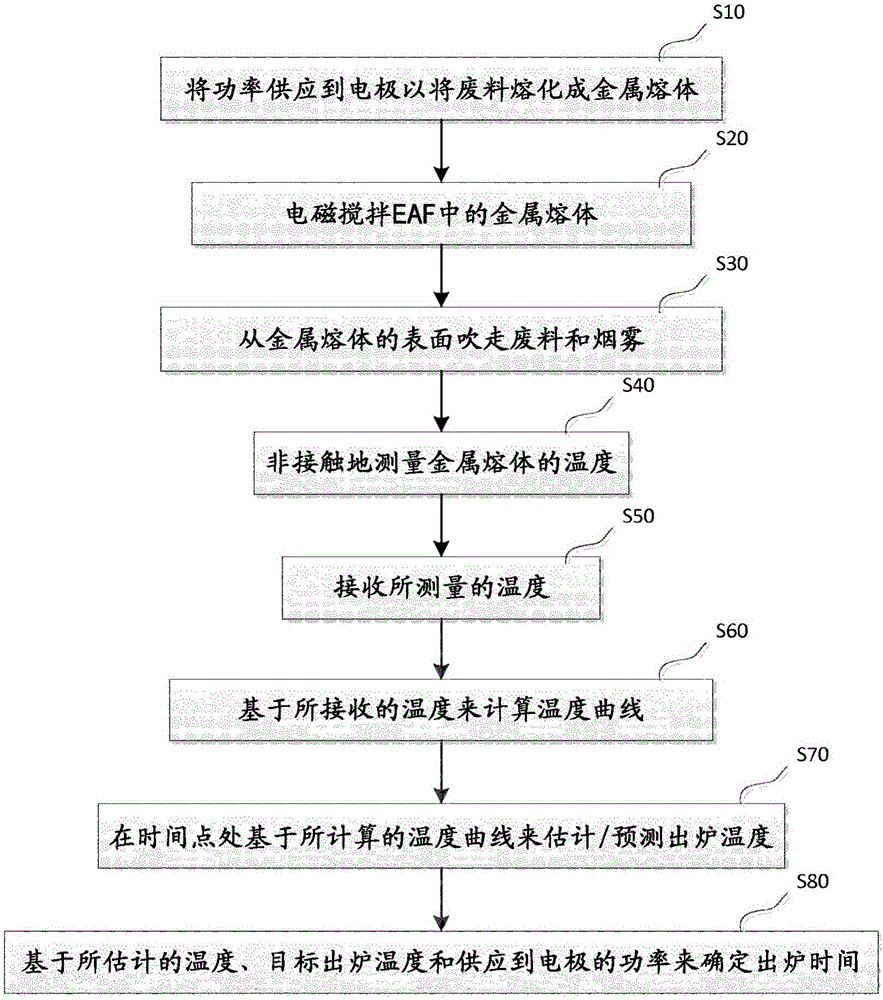

A system and a method for determining temperature of a metal melt in an electric arc furnace

ActiveCN106662404AUniform temperatureAccurate calculationMelt circulation arrangementsElectric discharge heatingElectric arc furnaceSlag

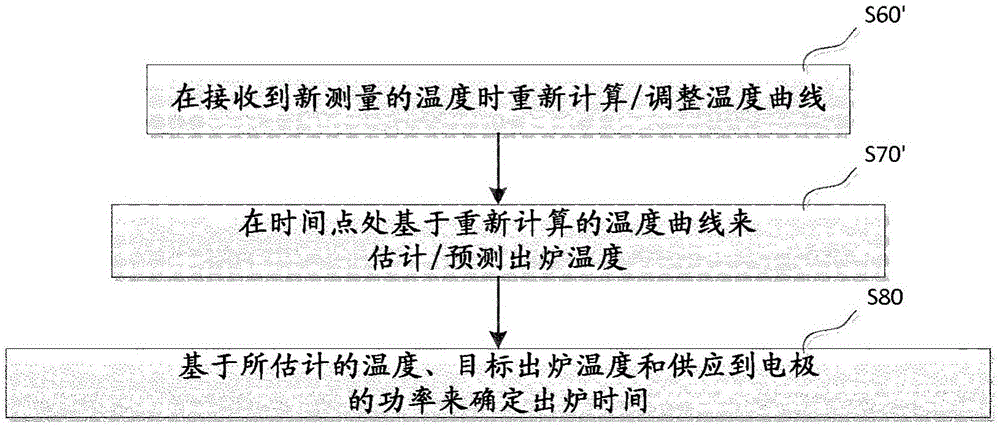

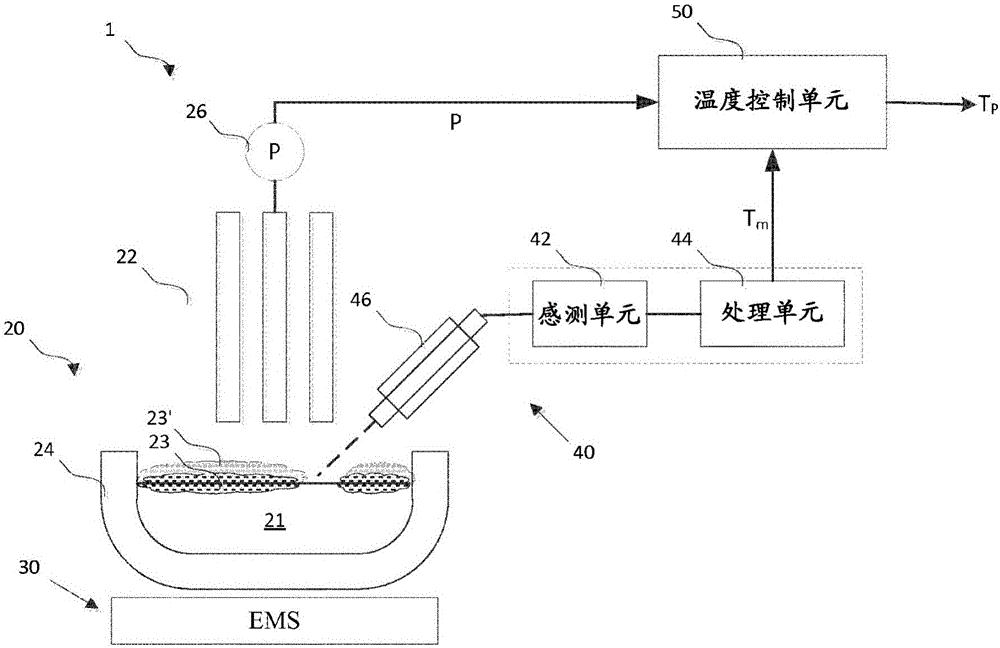

The present invention relates to a system and a method for determining / predicting a tapping time for a metal melt in an electric arc furnace (EAF), wherein at least one electrode is provided for melting the metal melt until it reach a target tapping temperature, wherein the EAF further comprises a slag and smoke layer on the surface of the metal melt, wherein an electromagnetic stirrer is provided for stirring the metal melt. The method comprises supplying a power to the electrode in order to melt a scrap to a metal melt (S10), electromagnetic stirring the metal melt in the EAF (S20), blowing away the slag and smoke from the surface of the metal melt (S30), non- contactingly measuring a temperature of the metal melt (S40), receiving the measured temperature (S50), calculating a temperature profile based on the received temperature (S60), estimating / predicting a tapping temperature at a time point based on the calculated temperature profile (S70), and determining a tapping time based on the estimated temperature, the target tapping temperature and the power supplied to the electrode (S80).

Owner:ABB (SCHWEIZ) AG

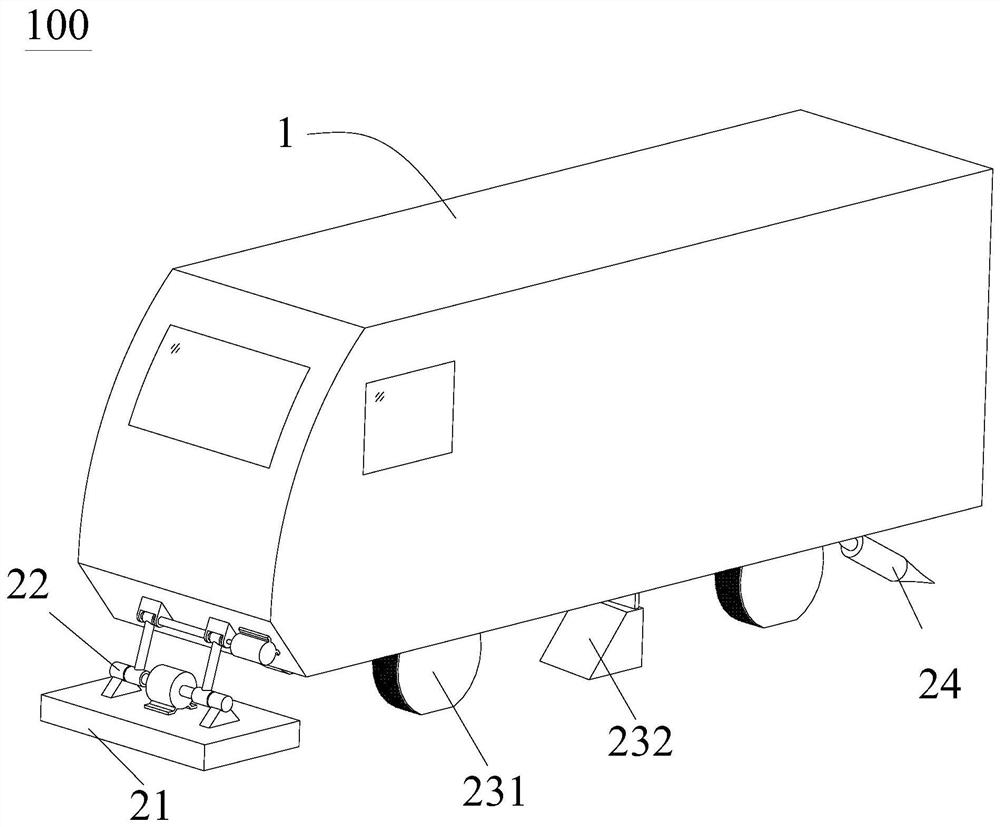

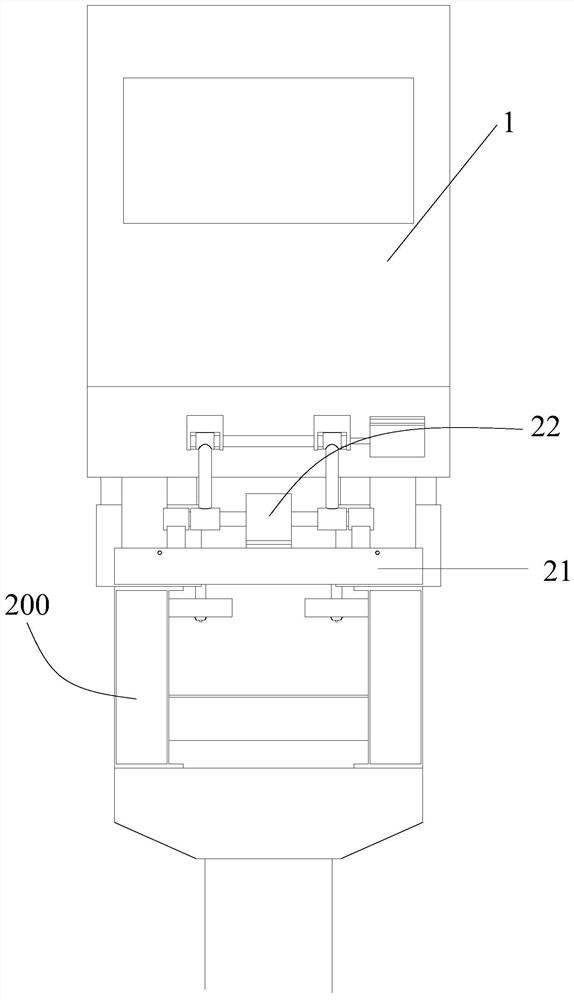

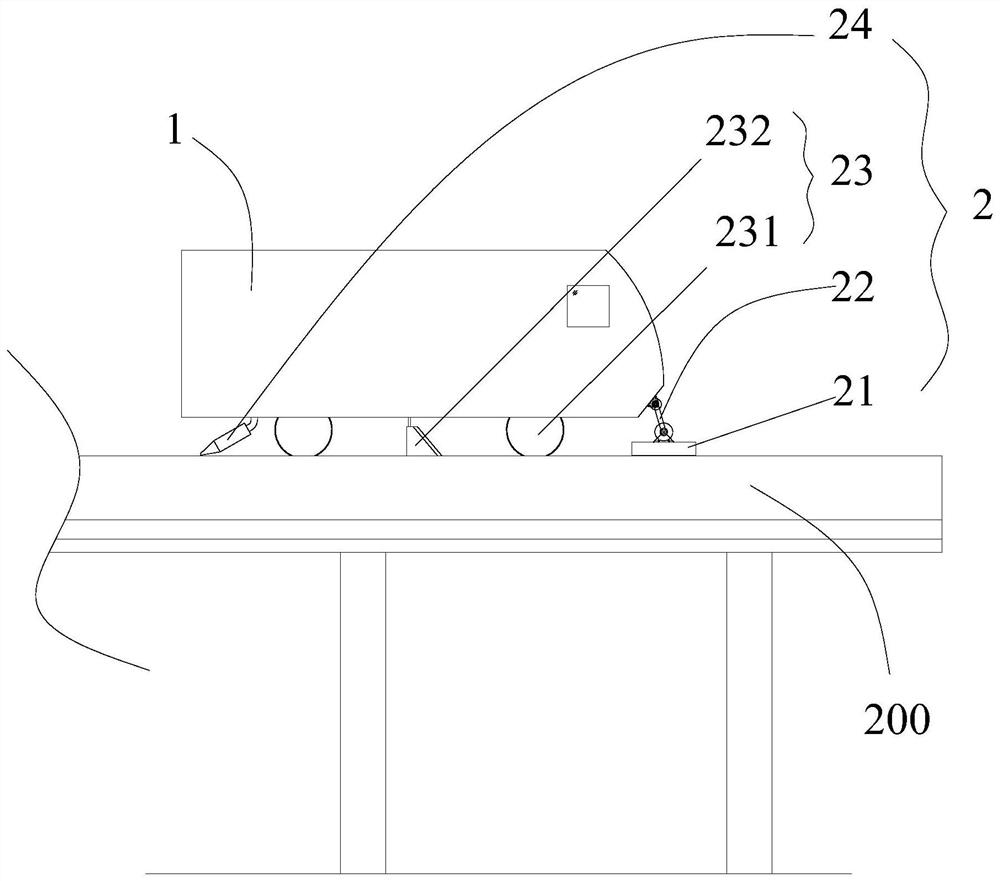

Track deicing vehicle

PendingCN113756250ANo mechanical shockMelt circulation arrangementsRailway cleaningThermodynamicsTrackway

The invention discloses a track deicing vehicle which is suitable for being erected on a metal track. The track deicing vehicle comprises a vehicle body and a deicing mechanism arranged on the vehicle body, wherein the deicing mechanism comprises an electromagnetic heating ice melting device which is used for heating the track through electromagnetic heating so as to melt ice; a mechanical ice crushing device which is used for crushing the ice layer heated by the electromagnetic heating ice melting device; and a drying device which is used for drying accumulated water on the surface of the track; the electromagnetic heating ice melting device, the mechanical ice crushing device and the drying device are sequentially arranged in the advancing direction of the track deicing vehicle and located below the vehicle body. According to the track deicing vehicle, the electromagnetic heating ice melting device utilizes the electromagnetic heating principle to heat the track, the bottom of an ice layer in contact with the track surface is melted, a water film is formed at the contact position of the bottom of the ice layer and the track surface, the binding force of the ice layer and the track surface is damaged, and the ice layer is separated from the track surface; and the mechanical ice crushing device is used for rolling to crush the ice layer, so mechanical impact on the track surface is avoided, and the track is not damaged.

Owner:BYD CO LTD

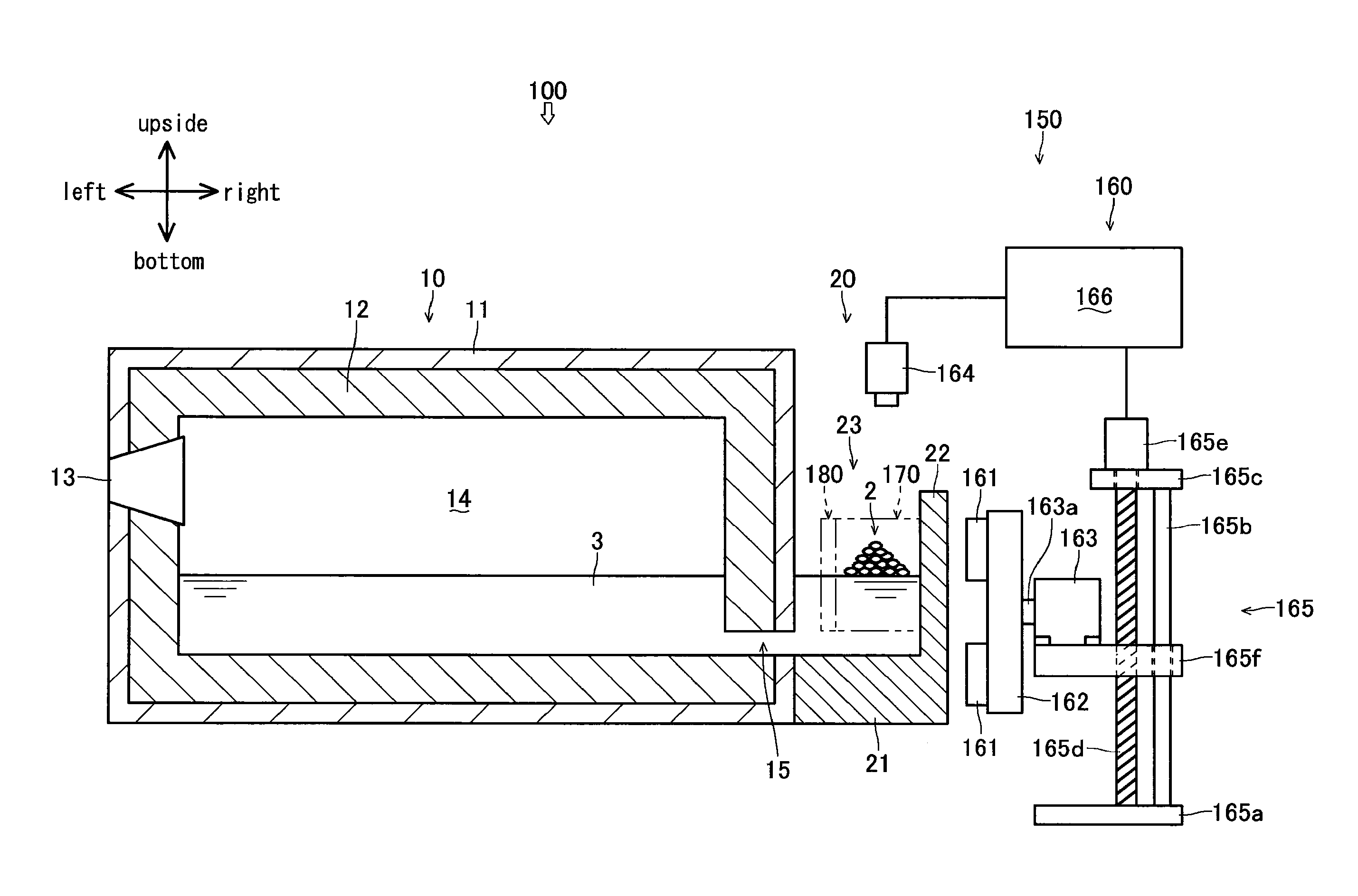

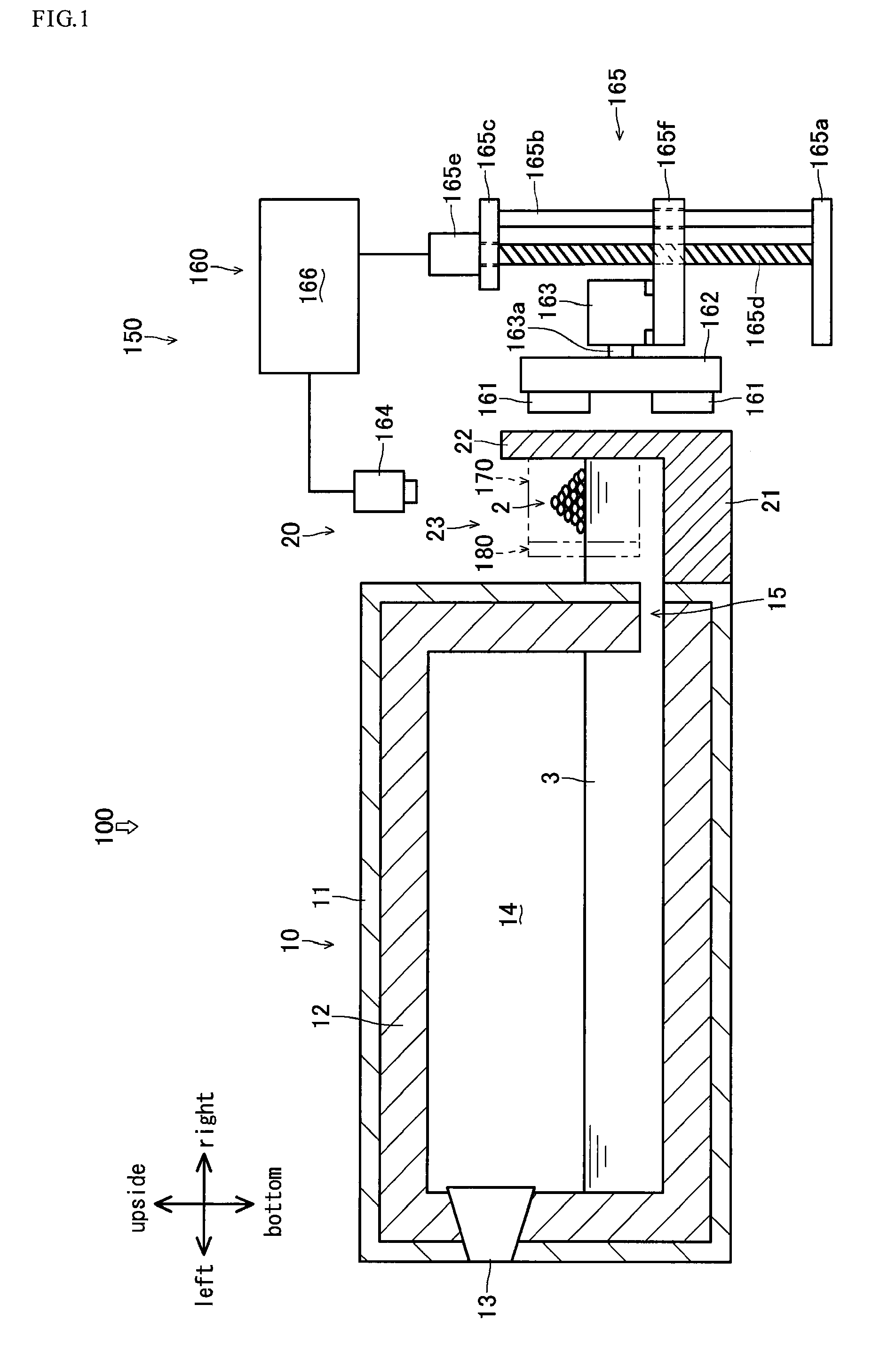

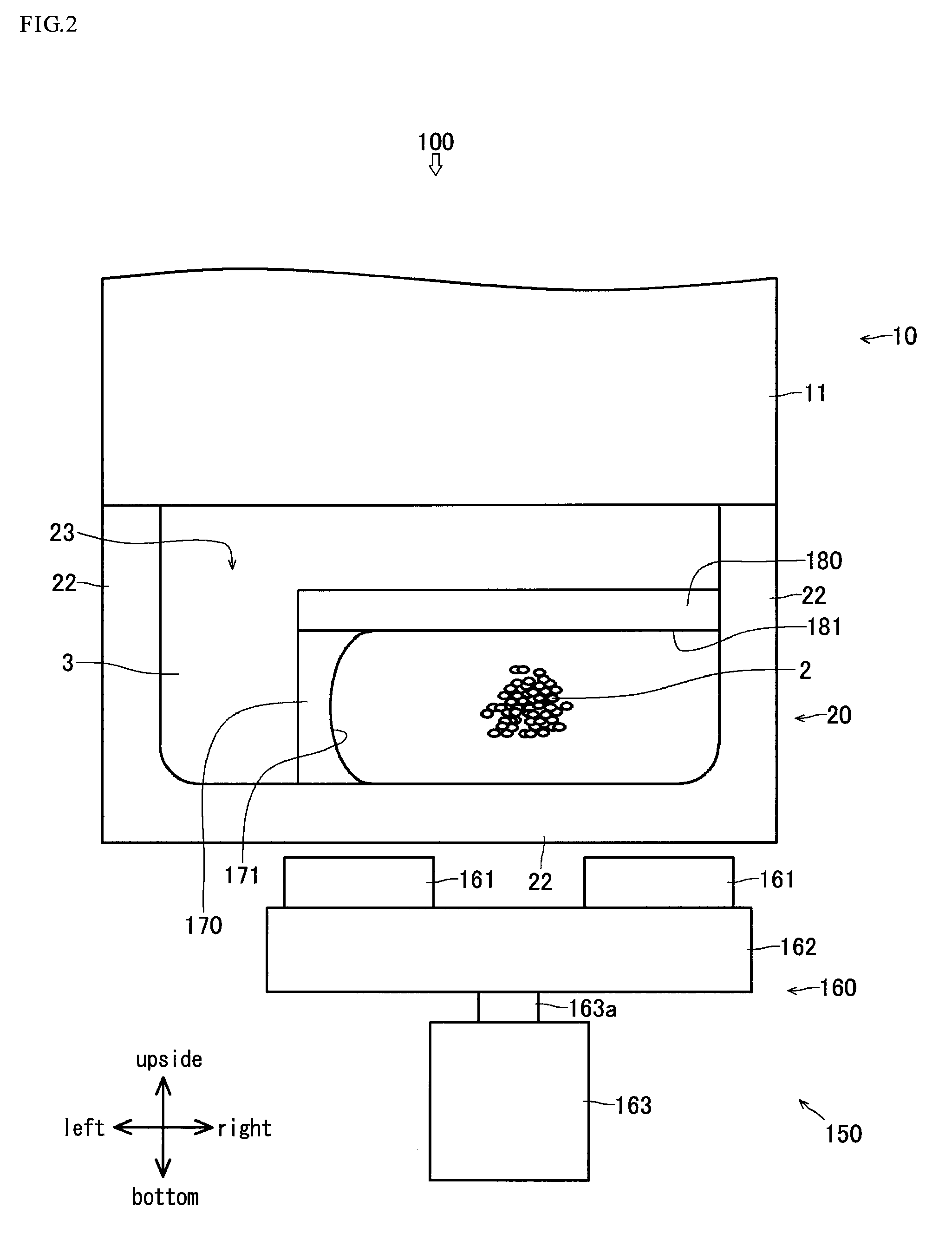

Agitation device, melting apparatus and melting method

ActiveUS8599899B2Improve efficiencyMelt circulation arrangementsStirring devicesMolten metalGenerating unit

An agitation device, a melting apparatus, and a melting method for improving melting efficiency of molten metal without contaminating the same. The agitation device is provided with a traveling magnetic field generating unit which is disposed outside a charging tank for storing molten metal and generates, inside the charging tank, a magnetic field that travels downward along the rear sidewall of the charging tank. A flow of the molten metal that rotates longitudinally about an axis approximately parallel to the surface of the molten metal is produced in the molten metal. By charging aluminum cutting chips into the molten metal in which the flow is produced, the aluminum cutting chips move with a downward flow of the molten metal, and are immersed in the molten metal. As a result, melting of the aluminum cutting chips can be accelerated.

Owner:TOYOTA JIDOSHA KK

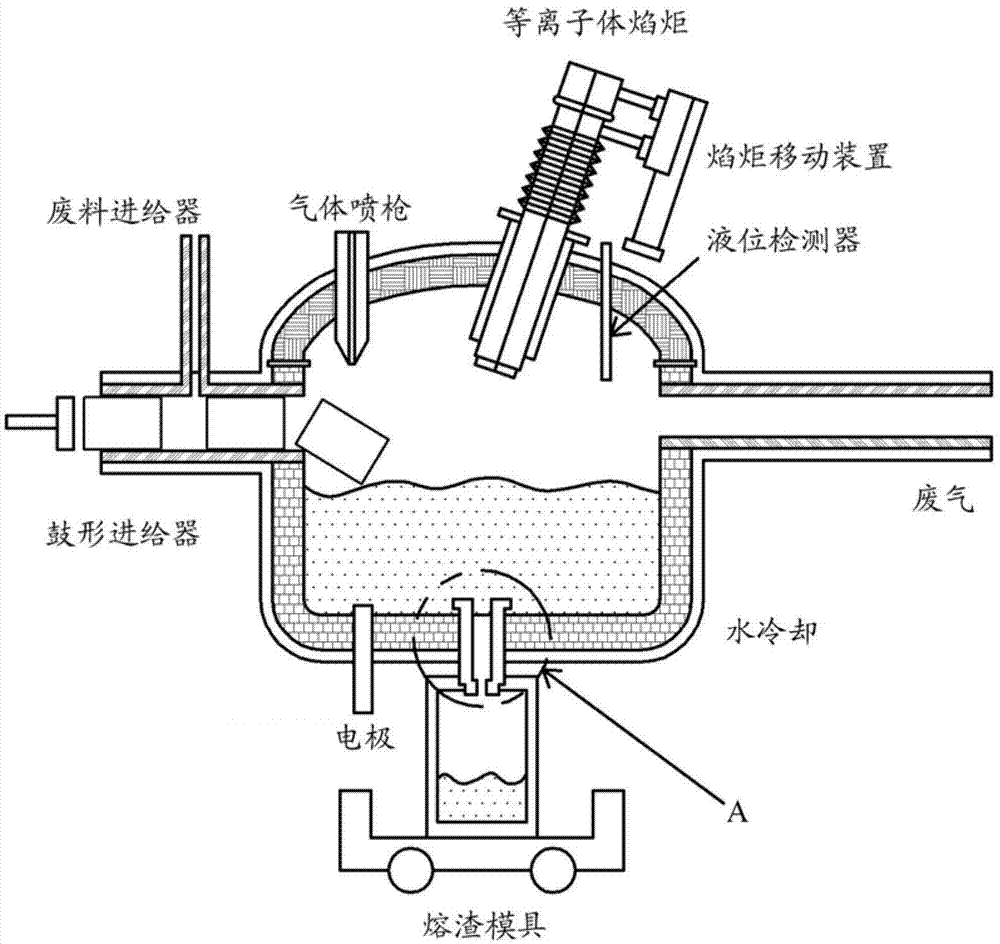

Method for ironmaking by smelting reduction in stir-generated vortex

ActiveUS20190230746A1Low utilization rateIron-containing oxides are rapidly reducedMelt circulation arrangementsCoil arrangementsMolten statePowder mixture

A method for ironmaking by smelting reduction in a stir-generated vortex includes: (1) placing a pig iron in an induction furnace, and then heating the pig iron to a molten state to form a molten iron, and maintaining the molten iron to be greater than or equal to 1450° C.; (2) stirring a center of the molten iron to form a vortex with a height-to-diameter ratio of 0.5-2.5, and continuously performing stirring; (3) mixing and grinding on an iron-containing mineral, a reducing agent and a slag-forming agent in a mass ratio of 1:(0.1-0.15):(0.25-0.4) to obtain a powder mixture, spraying and blowing the powder mixture to a center of the vortex, performing a reduction reaction, and stopping the stirring after the molten iron and molten slags are obtained, wherein a waste gas is produced; and (4) discharging the molten iron and the molten slags respectively, and exhausting a treated waste gas.

Owner:NORTHEASTERN UNIV

Wireless amagnetic heating module

ActiveUS20200137840A1Big advantageSecurity is importantMelt circulation arrangementsInduction heating apparatusMagnetic heatingMetal alloy

A non-magnetic wireless heating module is described. The module consists of a, preferably embossed, surface or plane and a dielectric surface or plane. The surface or plane is made of an inductive non-magnetic metal alloy that contains a first amagnetic metal or a first non-magnetic mixture of metals in a percentage between 85% and 99.99% by weight to the total weight and contains a second ferromagnetic or ferrimagnetic metal or a second ferromagnetic or ferrimagnetic mixture of metals in a percentage between 0.01% and 15% by weight to the total weight. The wireless amagnetic heating module is inserted into a chamber (for example a pipe or a portion of a pipe, a cubic container, a cistern . . . ) for the passage or storage of fluids, liquids, gases or solids; when the wireless amagnetic heating module is subjected to a variable electromagnetic field, it heats up, allowing heating, drying, passage of phase, . . . of the material in contact with it and contained in the chamber.

Owner:E WENCO SRL

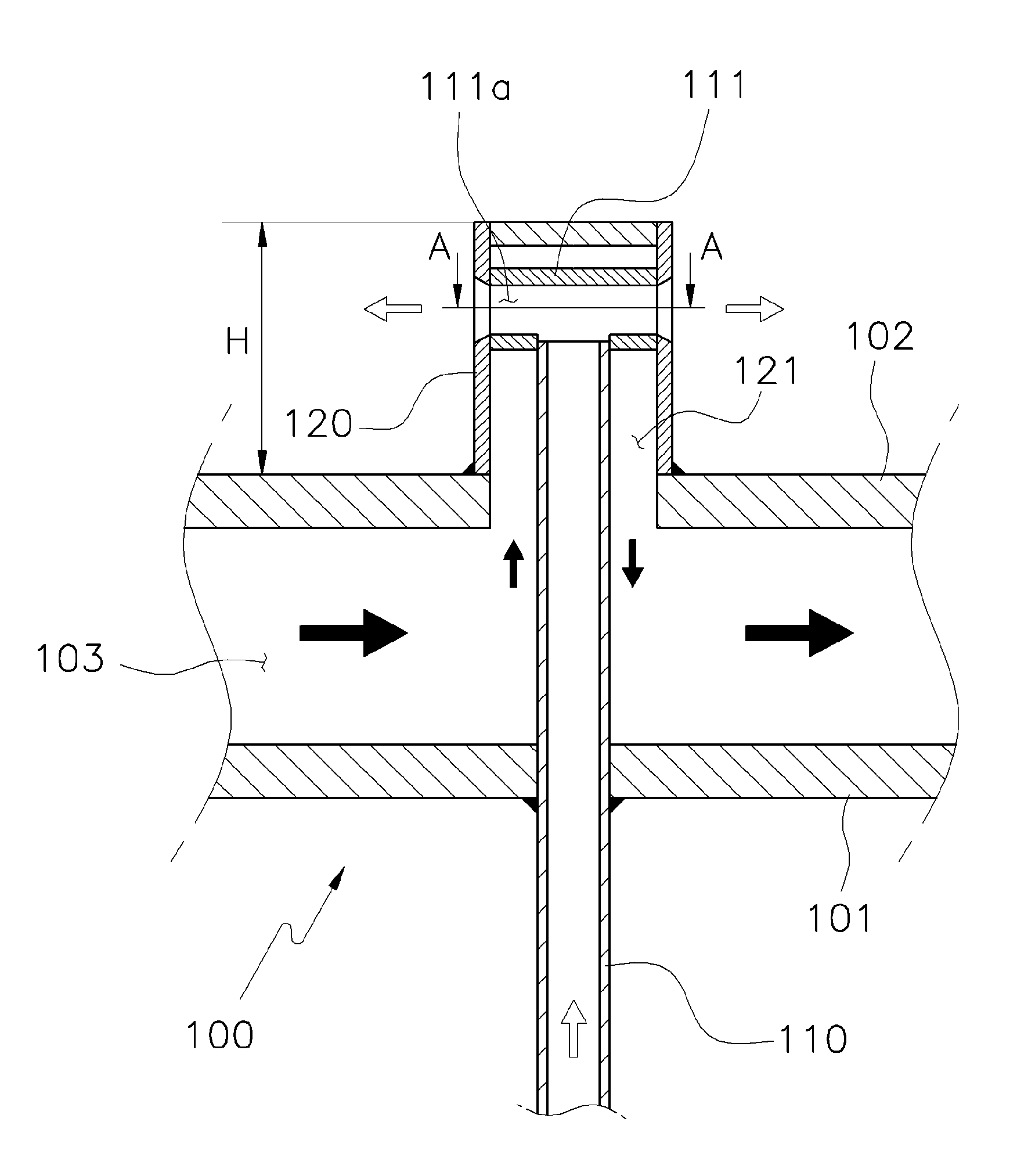

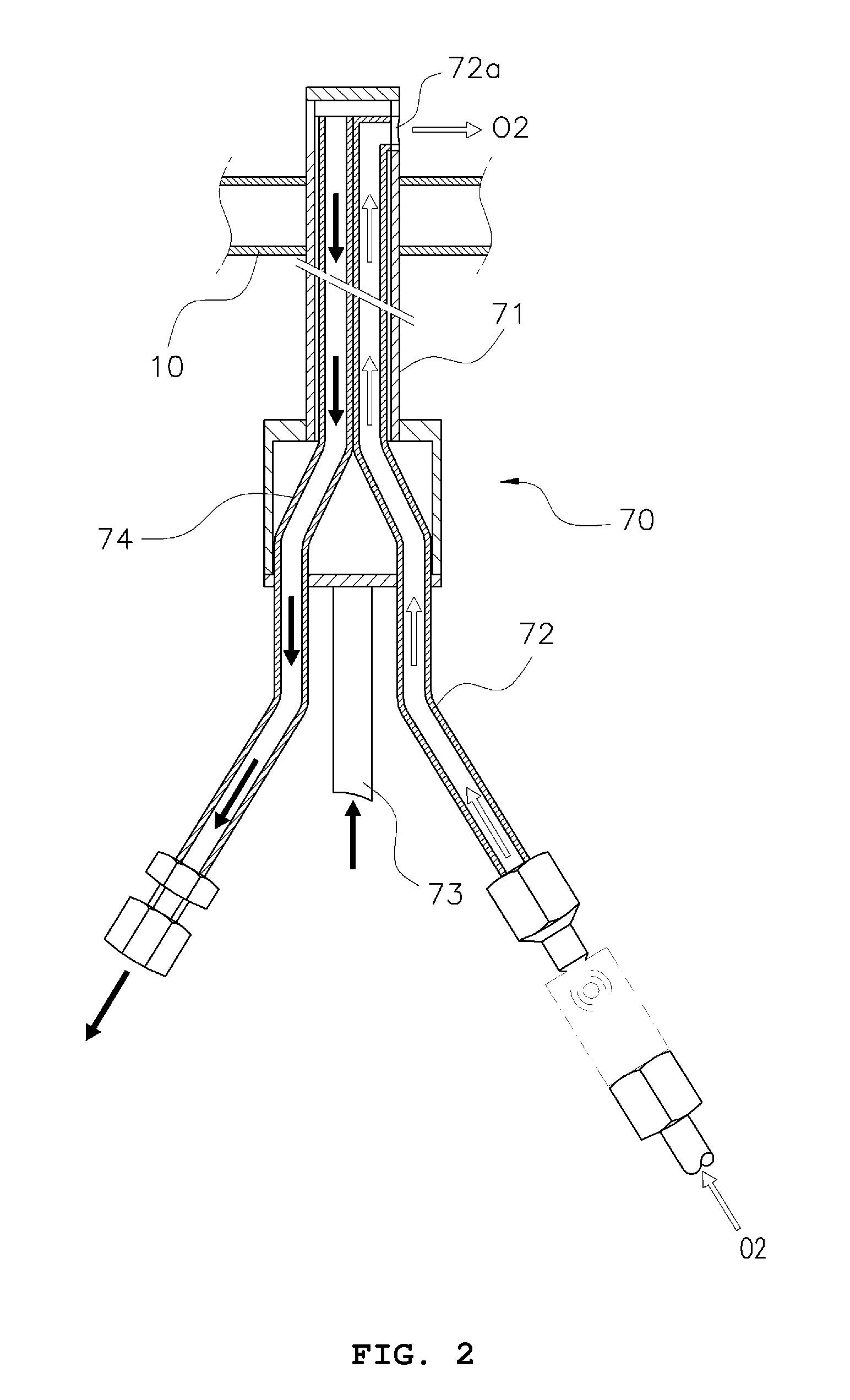

Melting furnace having a gas supplying apparatus

ActiveUS20130070803A1Increased durabilitySimple structureFurnaces without endless coreMelt circulation arrangementsGas supplyCooling channel

A melting furnace includes a gas supplying unit configured to protrude inwardly of the melting furnace to supply a gas to the melting furnace, the gas supplying unit including a gas supplying pipe configured to penetrate the melting furnace to protrude inwardly of the melting furnace and configured to have a nozzle hole formed at a front end thereof; and a cooling passage pipe provided outside the gas supplying pipe to include a second cooling passage through which a cooling liquid flows, the second cooling passage being directly connected to a first cooling passage through which the cooling liquid is circulated along a wall of the melting furnace.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

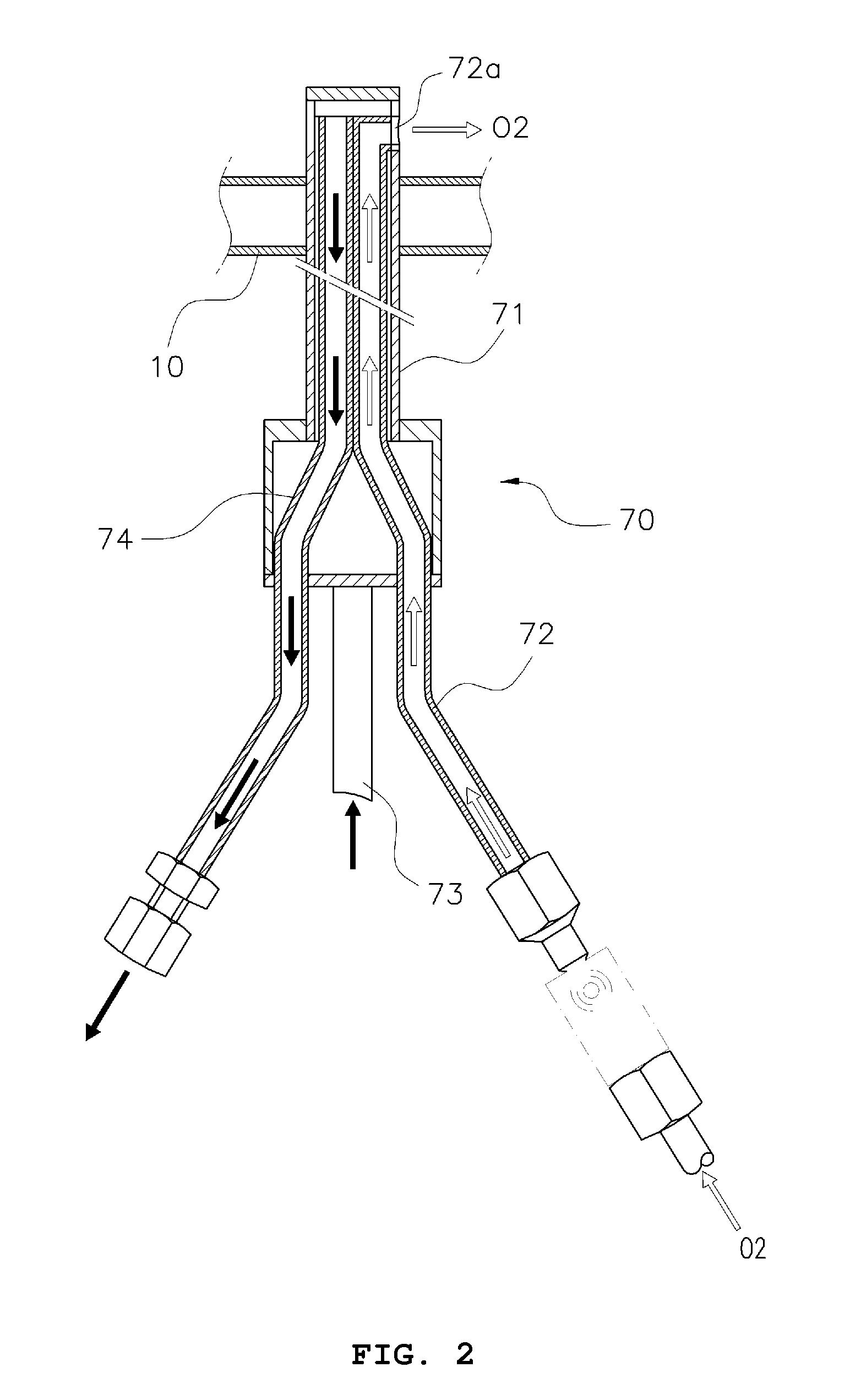

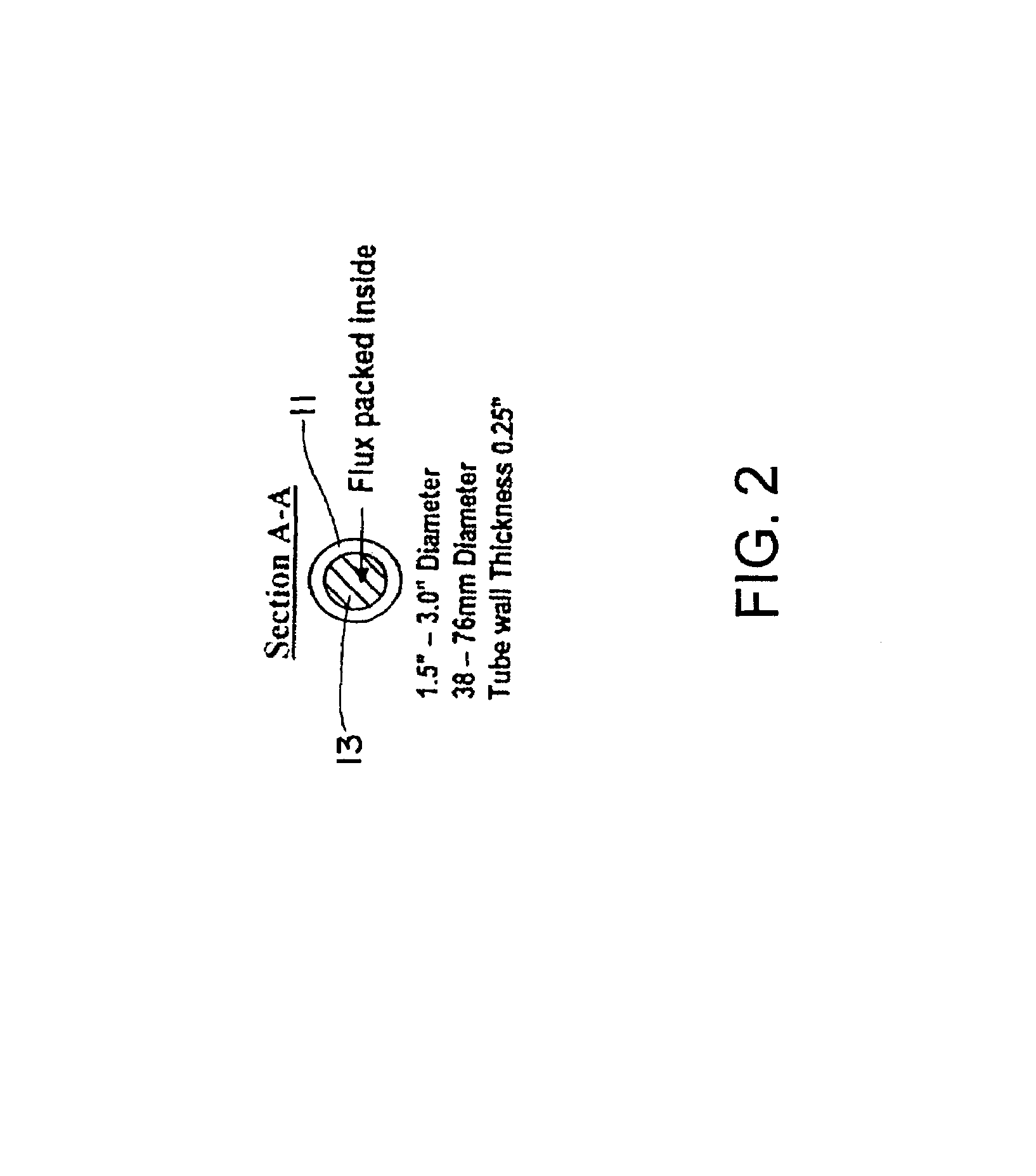

Method for improving operational efficiency in clogged induction melting and pouring furnaces

ActiveUS7618473B1Soften fastRevive and restore electrical property of channelMelt circulation arrangementsStirring devicesSilicon dioxideCarbonate

A method of restoring the electrical efficiency of channel and pressure pour furnaces includes plunging a fluxing material with a specially designed plunging lance. The plunging lance chamber containing the fluxing material is 24 to 32 inches in length, 3 inches in diameter and has a capacity to hold 5 to 7.5 pounds of flux briquettes. The plunging chamber has holes drilled along the length of the body. The fluxing material contains by weight from 8.0 to 28.7% CaCO3 (calcium carbonate or limestone), from 0 to 18.5% MgCO3 (magnesium carbonate), from 3.6 to 18.0% Al2O3 (alumina) from 1.4 to 7.1% SiO2 (silica), in the form of a complex aluminosilicate, and from 19.4 to 46.4% Na2O (sodium oxide), in the form of soda ash (sodium carbonate). The total level of sodium ranges from 23 to 26% and up to 10% sodium fluoride or sodium chloride may be substituted for soda ash.

Owner:NARO RODNEY L

Melting furnace having a gas supplying apparatus

ActiveUS8498320B2Increased durabilitySimple structureFurnaces without endless coreMelt circulation arrangementsGas supplyCooling fluid

A melting furnace includes a gas supplying unit configured to protrude inwardly of the melting furnace to supply a gas to the melting furnace, the gas supplying unit including a gas supplying pipe configured to penetrate the melting furnace to protrude inwardly of the melting furnace and configured to have a nozzle hole formed at a front end thereof; and a cooling passage pipe provided outside the gas supplying pipe to include a second cooling passage through which a cooling liquid flows, the second cooling passage being directly connected to a first cooling passage through which the cooling liquid is circulated along a wall of the melting furnace.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

Radiation heating device

ActiveUS10563870B2Reducing thermal discomfort feltAvoid heat transferAir-treating devicesMelt circulation arrangementsEngineeringRadiative heating

A radiation heating device includes: a planar heat generation layer; a heat generation portion that is provided in the heat generation layer and that generates heat by energization; a plurality of heat radiation portions that are disposed in the heat generation layer and that radiate heat transferred from the heat generation portion; a low heat conduction portion that is provided around each of the heat radiation portions and that has a lower heat conductivity than the heat radiation portions; and a contact detection unit that detects contact of an object with the heat generation layer. The radiation heating device further includes an energization amount decrease unit that decreases an energization amount of the heat generation portion when the contact detection unit detects the contact of the object with the heat generation layer.

Owner:DENSO CORP

Electric induction heating and stirring of an electrically conductive material in a containment vessel

ActiveUS8735783B2Furnaces without endless coreFrom normal temperature solutionsRefractoryMaterials science

Apparatus and method are provided for electric induction heating and / or stirring of a molten electrically conductive composition in a containment vessel with the apparatus being removably insertable in the molten composition. An induction coil embedded in refractory or a coating is submerged in the composition and used to heat and / or stir the molten composition either externally or internally to the refractory or coating.

Owner:INDUCTOTHERM INDS

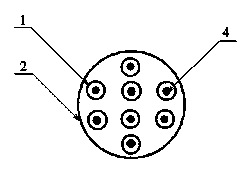

Method and device for moving molten metal

InactiveCN105263652BElectromagnets without armaturesMelt circulation arrangementsInductorEddy current

A method and device for moving molten metal are provided, wherein the electromagnetic inductor includes at least two electromagnetic pole pairs, and a first electromagnetic pole is generated between one electromagnetic pole of the first electromagnetic pole pair and the second electromagnetic pole of a different electromagnetic pole pair. A magnetic field component, and a second magnetic field component is generated between two electromagnetic poles of one or more electromagnetic pole pairs, which second magnetic field component thus generates one or more eddy currents within the molten metal. These eddies are generally parallel to the surface of the molten metal and therefore have greater amplitude and extent than eddies perpendicular to the surface. Especially when the depth of the molten metal is small, such eddies provide additional movement to the molten metal, for example for stirring purposes.

Owner:叶夫盖尼·帕夫洛夫

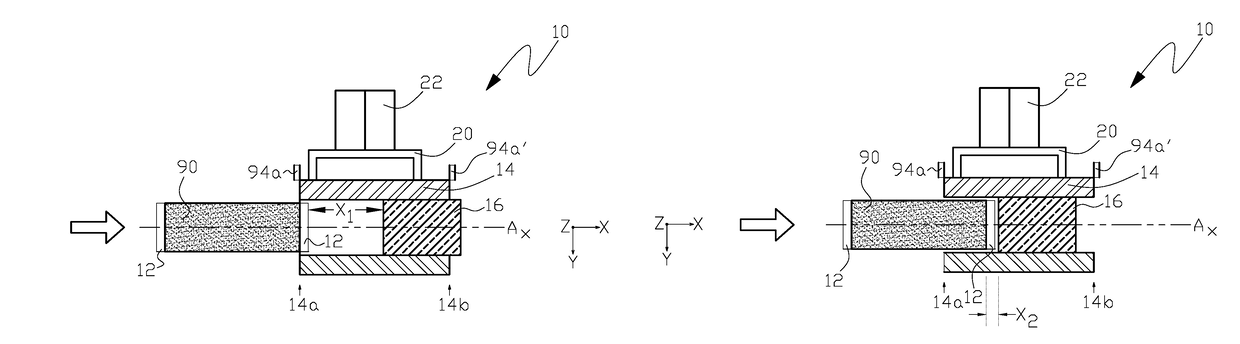

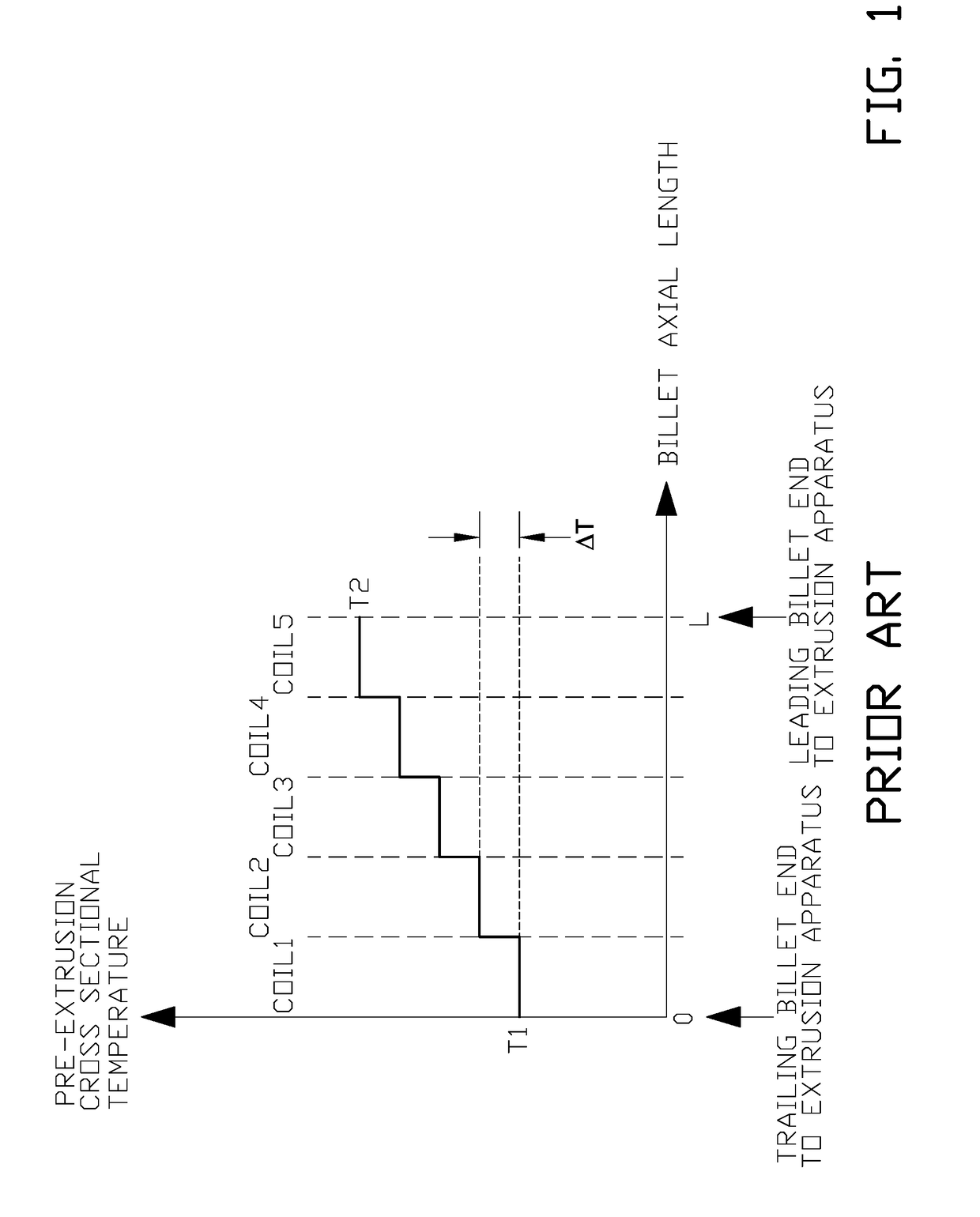

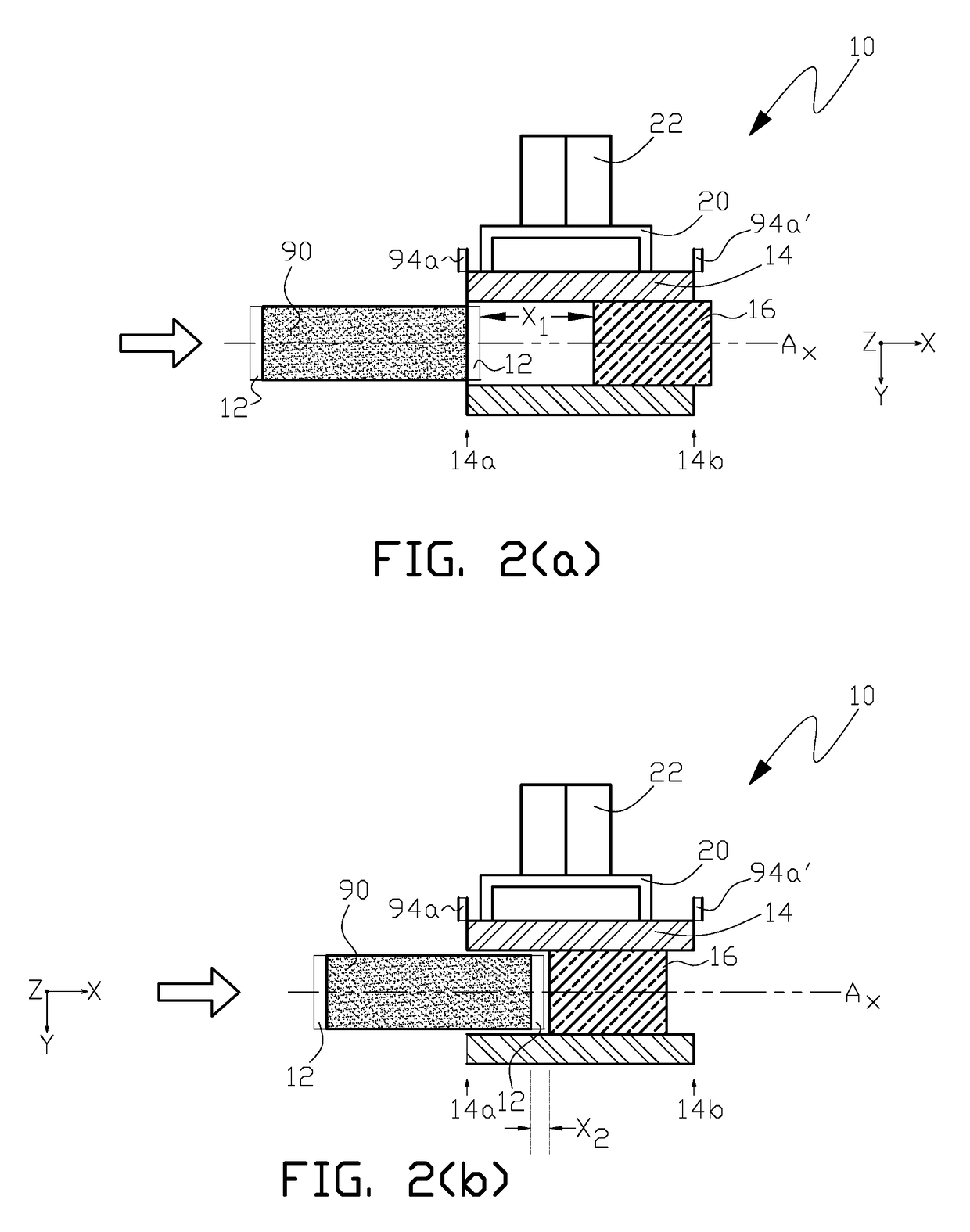

Large billet electric induction pre-heating for a hot working process

A process for electric induction heating of large billets to a tapered cross sectional heating profile by inductively scan heating the axial circumference of the large billet with a single induction coil prior to hot working the large billet in an extrusion or forging process is provided.

Owner:RADYNE CORP

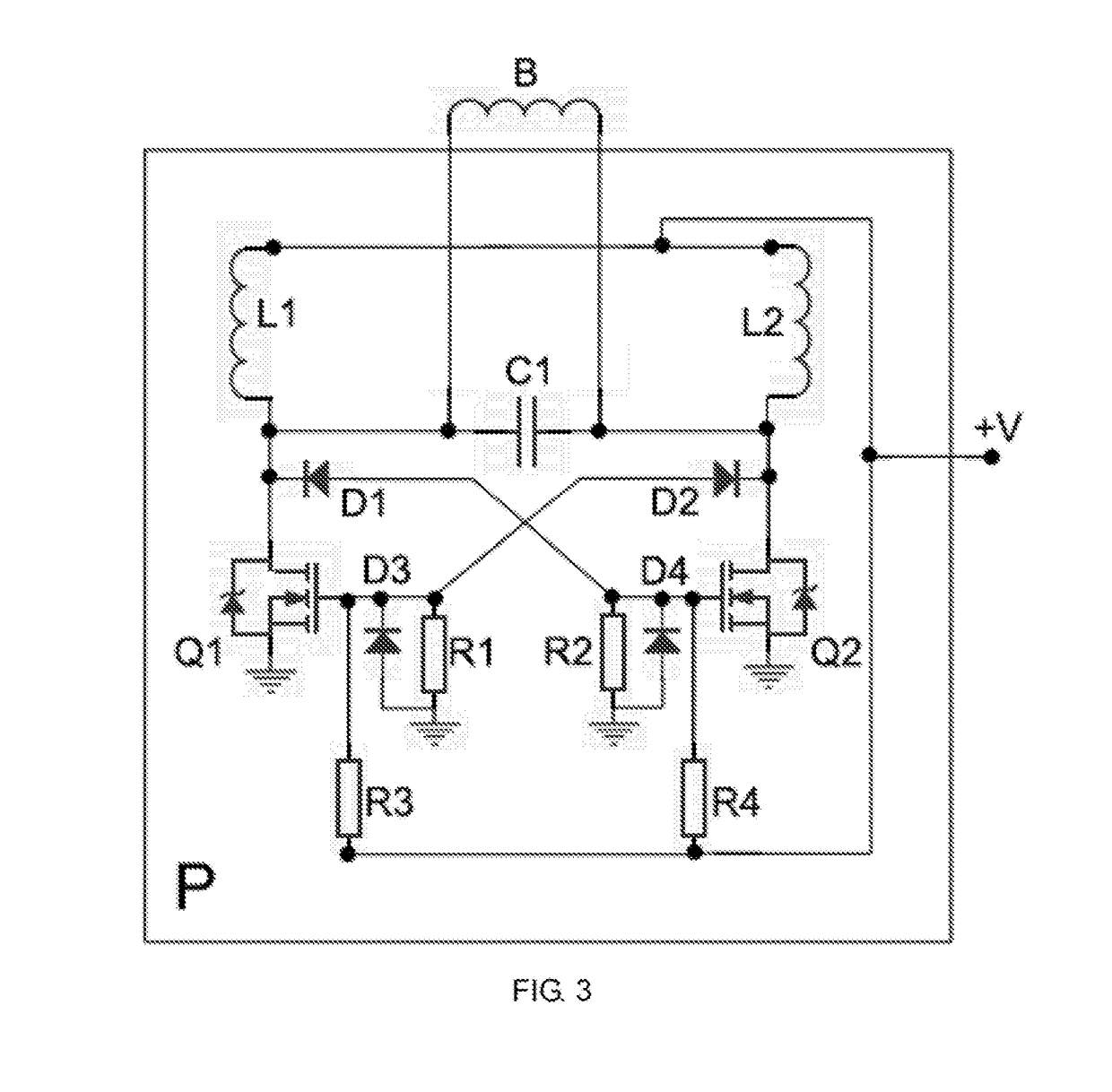

Melting and mixing of materials in a crucible by electric induction heel process

Apparatus and method are provided for electric induction heating and melting of a transition material that is non-electrically conductive in the solid state and electrically conductive in the non-solid state in an electric induction heating and melting process wherein solid or semi-solid charge is periodically added to a heel of molten transition material initially placed in a refractory crucible. Induction power is sequentially supplied to a plurality of coils surrounding the exterior height of the crucible at high power level and high frequency with in-phase voltage until a crucible batch of transition material is in the crucible when the induction power is reduced in power level and frequency with voltage phase shifting to the induction coils along the height of the crucible to induce a unidirectional electromagnetic stir of the crucible batch of material.

Owner:INDUCTOTHERM INDS

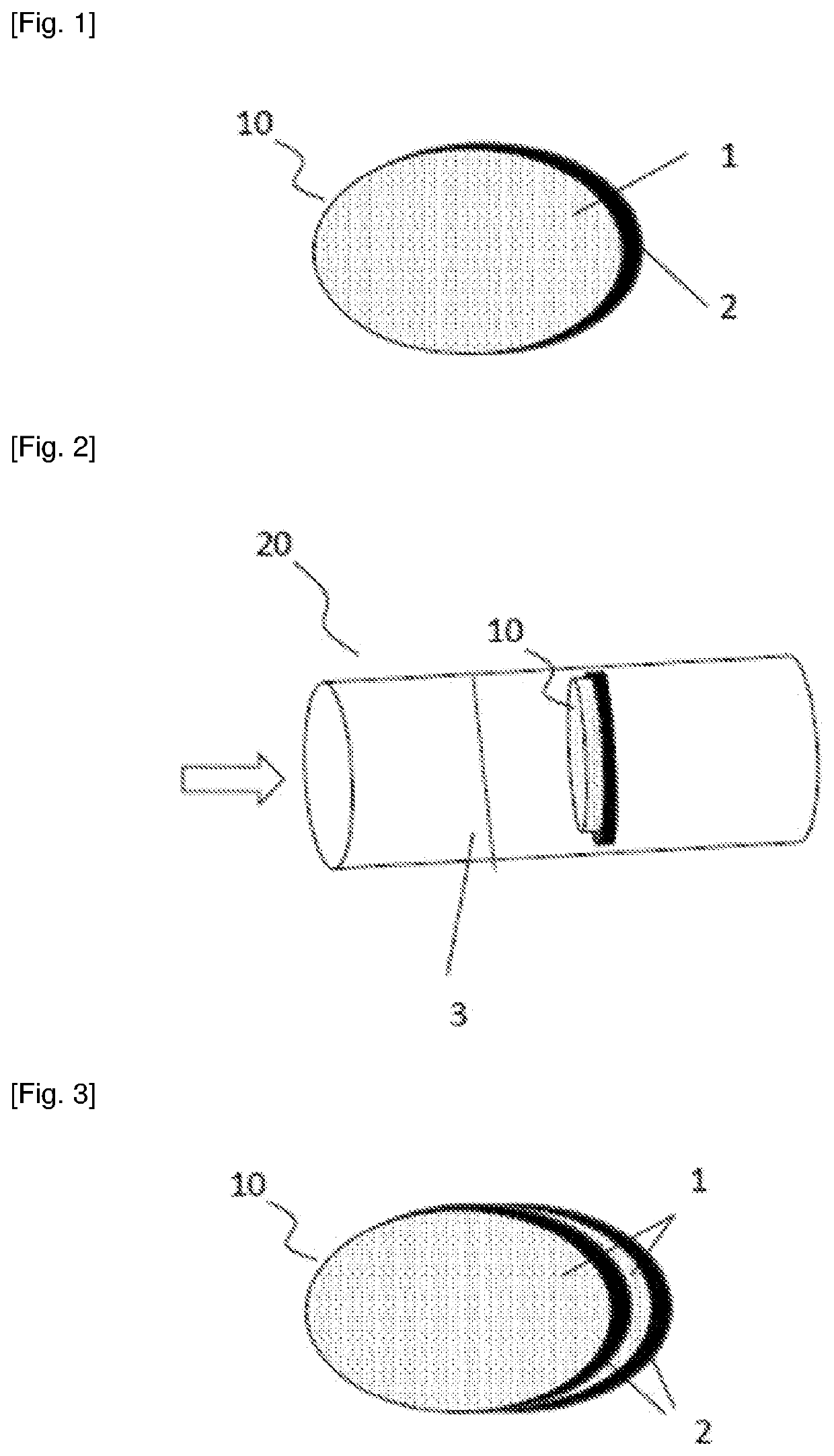

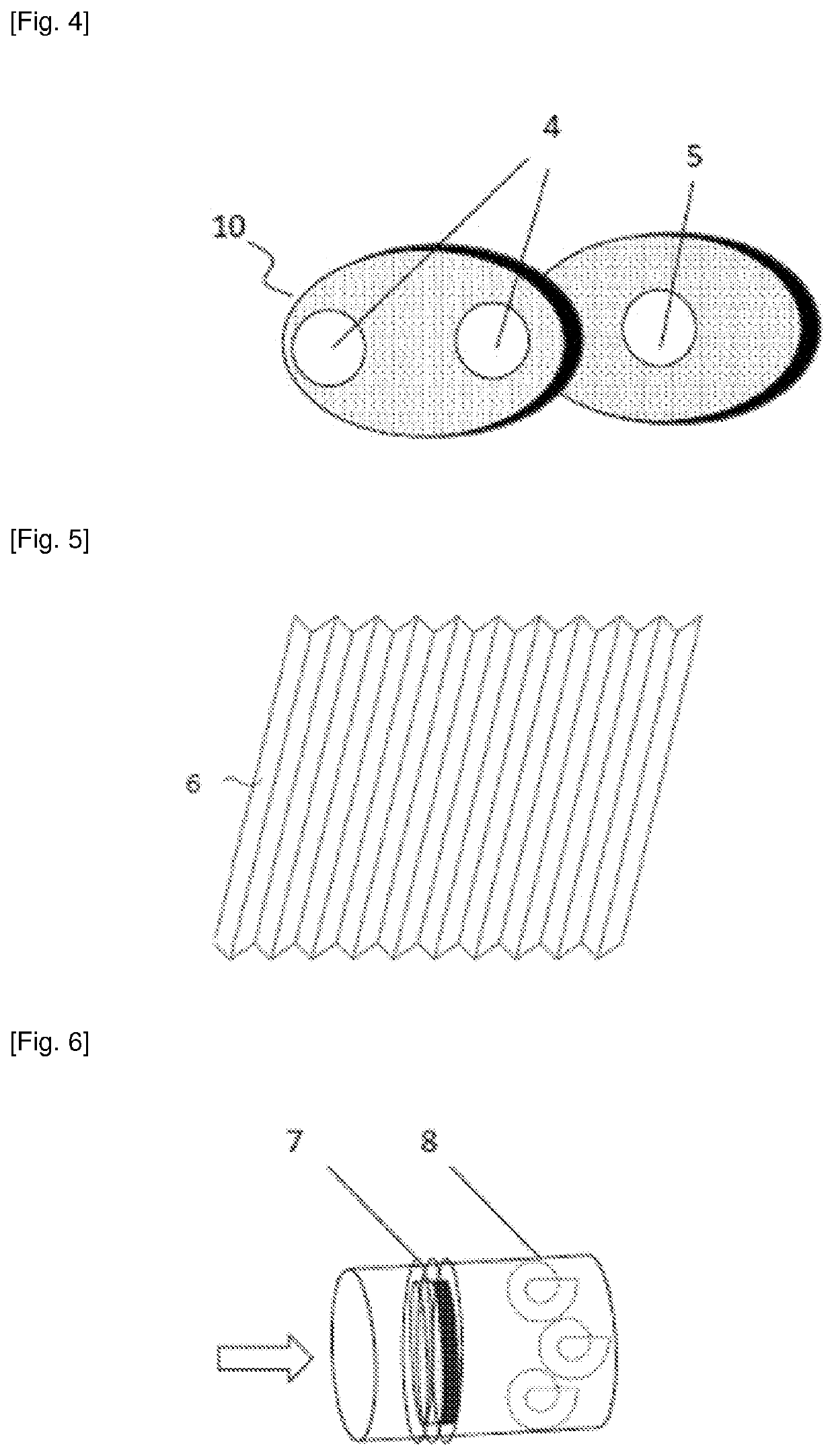

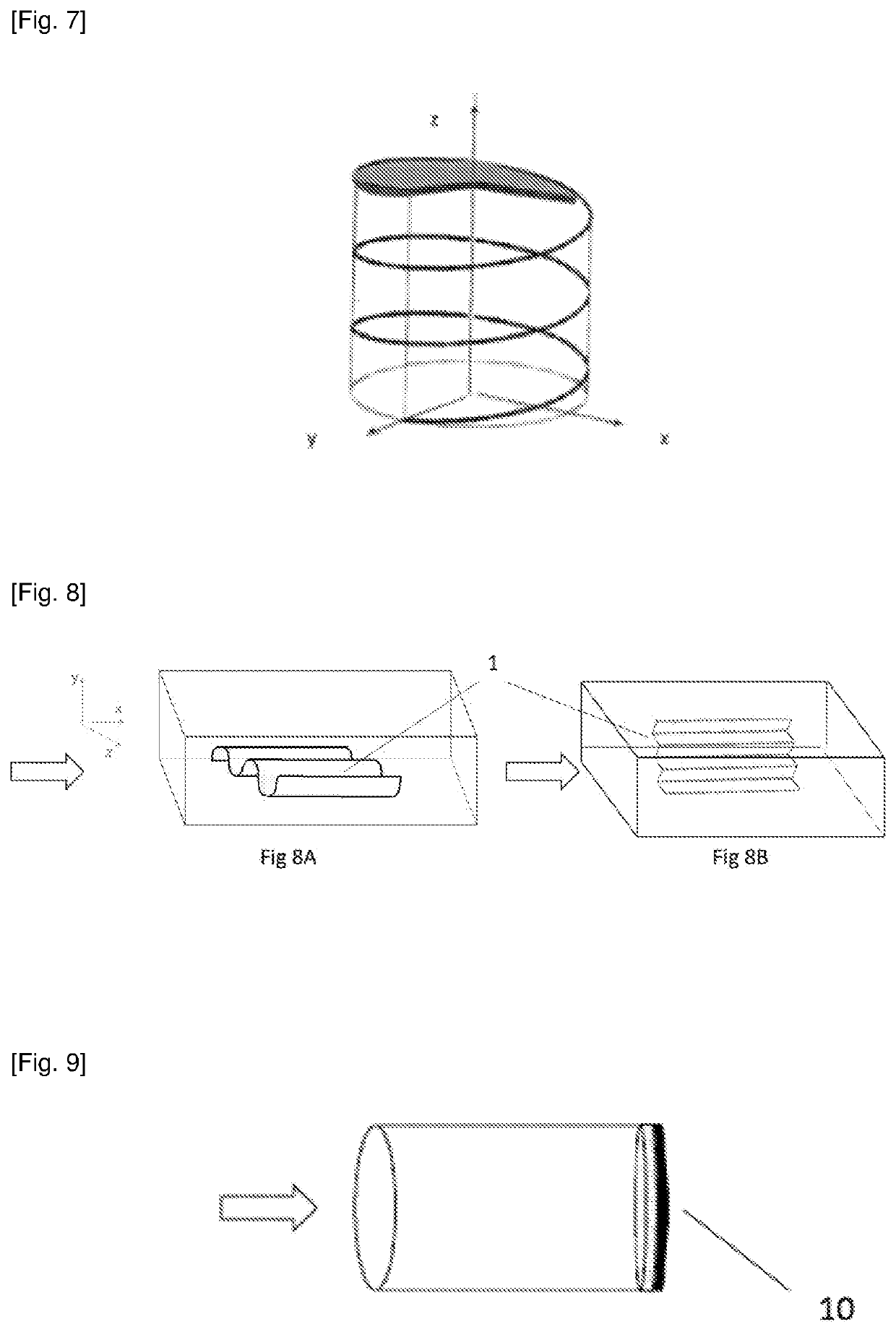

Transparent heating film

PendingUS20220272798A1Easy to installImprove conductivityMelt circulation arrangementsAntenna supports/mountingsShortest distanceEngineering physics

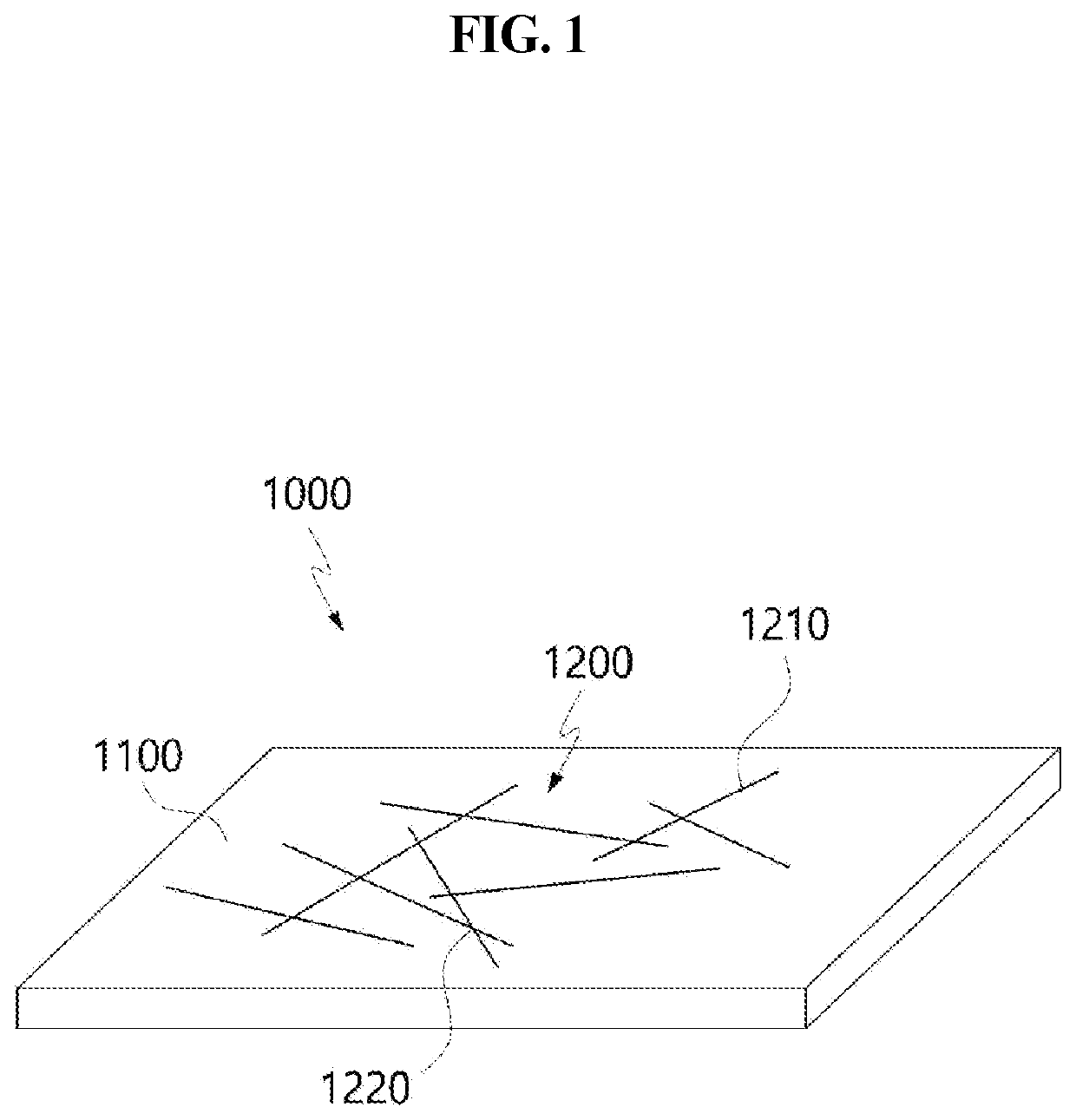

A transparent heating film according to an embodiment includes: a transparent substrate including a top surface in which a plurality of grooves are formed and a flat bottom surface; and a plurality of metal nanostructures located on the top surface of the transparent substrate. The metal nanostructures have a first distance from a middle plane of the transparent heating film, and an imaginary line extending from the top surface of the transparent substrate has a second distance from the middle plane of the transparent heating film. The transparent heating film includes a first region in which the first distance is shorter than the second distance, and the first distance is a shortest distance between a first point at which each of the metal nanostructure and the transparent substrate are in contact with each other and the middle plane, the first point being located in each of the grooves. A radius of curvature of the metal nanostructures in a region adjacent to the first points may be equal to or smaller than a radius of curvature of the groove in the region adjacent to the first point.

Owner:ITED INC

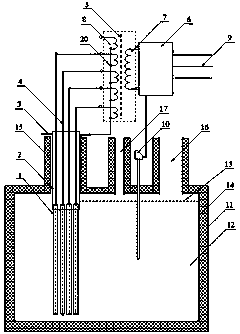

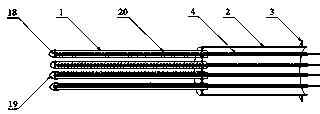

Inserted intermediate frequency fused salt heater

InactiveCN109309975AImprove heating efficiencyNo safety hazardMelt circulation arrangementsHeat storage plantsIntermediate frequencyLow voltage

An inserted intermediate frequency fused salt heater comprises a tubular heating tube fixed seat, a plurality of heating tubes welded and fixed at the lower portion of the tubular heating tube fixed seat, a fixed seat flange welded at the upper portion of the tubular heating tube fixed seat, leads arranged in heating tubes, a medium frequency transformer and a medium-frequency power supply, wherein the leads are tightly welded with the bottom ends of the heating tubes, the leads are connected with secondary coils of the medium frequency transformer, the primary coil of the medium frequency transformer is connected with the medium-frequency power supply, and the secondary coil of the medium frequency transformer inducts a frequency high current in a low voltage; the leads, the heating tubes, the heating tube fixed seat and the secondary common end of the medium frequency transformer are connected to form a loop, each lead is connected with the secondary coil end, eddy is formed on the tube bodies of the heating tubes to perform rapid heating, and the intermediate frequency intermediate frequency is employed to allow the heating tube to directly heat in the fused salt liquid. The inserted intermediate frequency fused salt heater is high in heating efficiency, has no potential safety hazards of damaging people caused by electric leakage, and is long in service life, simple in structure, low in cost, convenient to maintain and very safe and reliable in usage.

Owner:何树香

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com