A system and a method for determining temperature of a metal melt in an electric arc furnace

A metal melt and electric arc furnace technology, which is applied in chemical instruments and methods, electric furnaces, metal processing, etc., can solve the problems of delaying processing time, increasing the cost of consumable probes, and cumbersome problems, so as to improve the working environment and reliable release time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

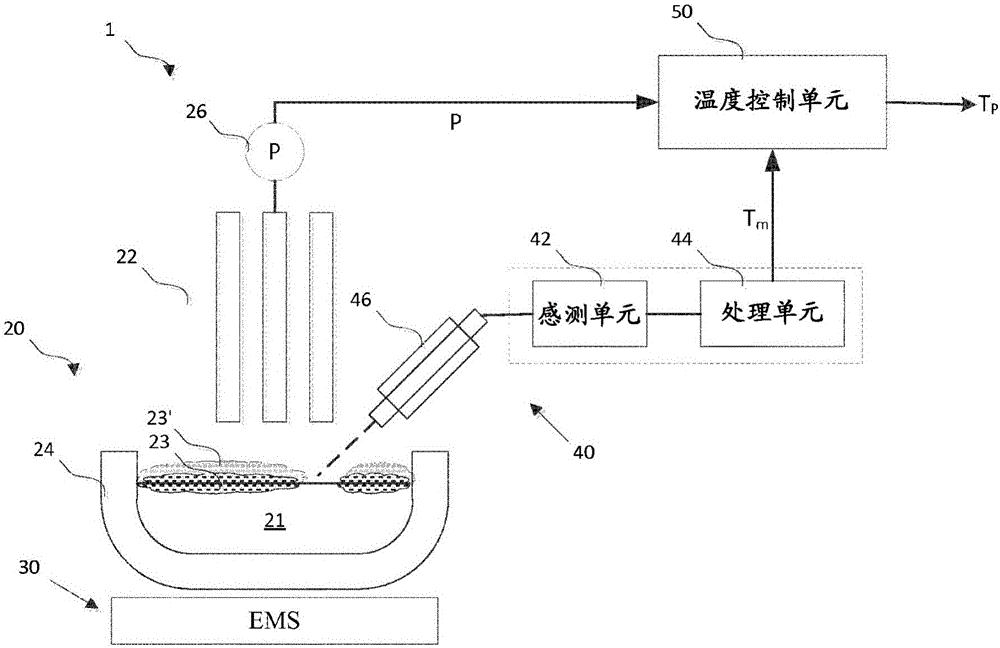

[0027] figure 2 Shown is a system 1 for determining / predicting the tap time of a metal melt in an electric arc furnace (EAF) 20, comprising an electromagnetic stirring system (EMS) 30 with an electromagnetic stirrer provided for stirring the metal melt, for A temperature measurement device 40 providing temperature measurement of the metal melt, and a temperature control unit 50 for estimating / predicting the temperature of the metal melt.

[0028] The EAF 20 is arranged for melting metallic material, such as metal or metal alloys. EAF can be DC EAF or ACEAF.

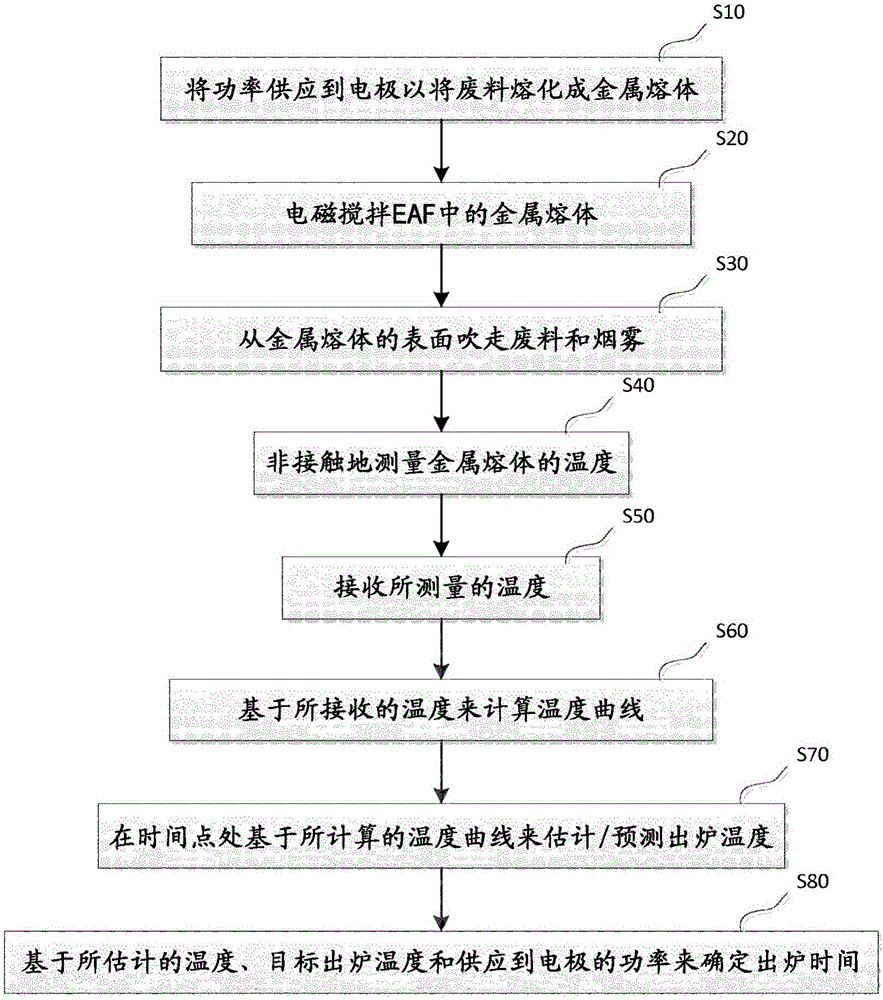

[0029] The EAF 20 also includes one or more electrodes 22 (this example shows three electrodes equipped with an EAF); covered with a retractable top ( figure 2 (not shown in ) container 24 through which the electrode enters the furnace; and a power supply system 26 operatively connected to the electrode 22 for supplying power to the electrode to melt the scrap into a metal melt, with reference to step S10 of FIG. 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com