Tapping device and method using induction heat for melt

A technology of induction heating and discharge device, which is applied in the direction of induction heating, circulation melting device, electric furnace heating, etc. It can solve the problems that the molten material storage container cannot be accurately filled, it is not suitable for discharging viscous molten material, and it cannot be carried out smoothly, etc. , to achieve the effect of eliminating close-distance operations, improving operational safety, and preventing easy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be described in detail with reference to the drawings.

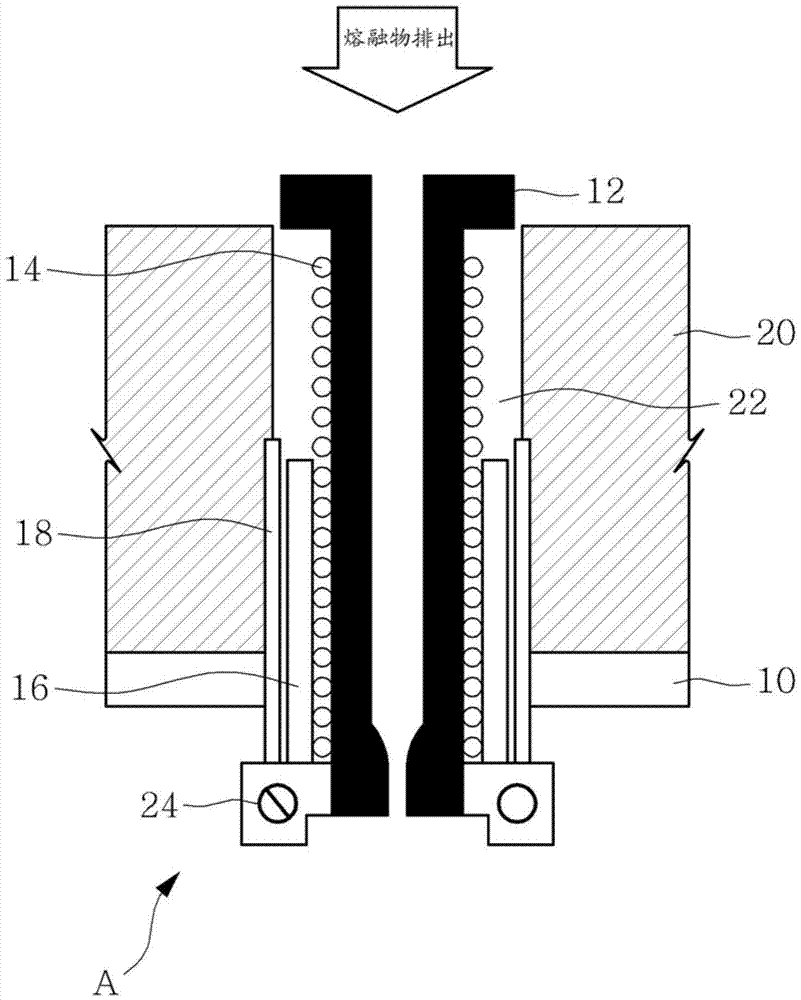

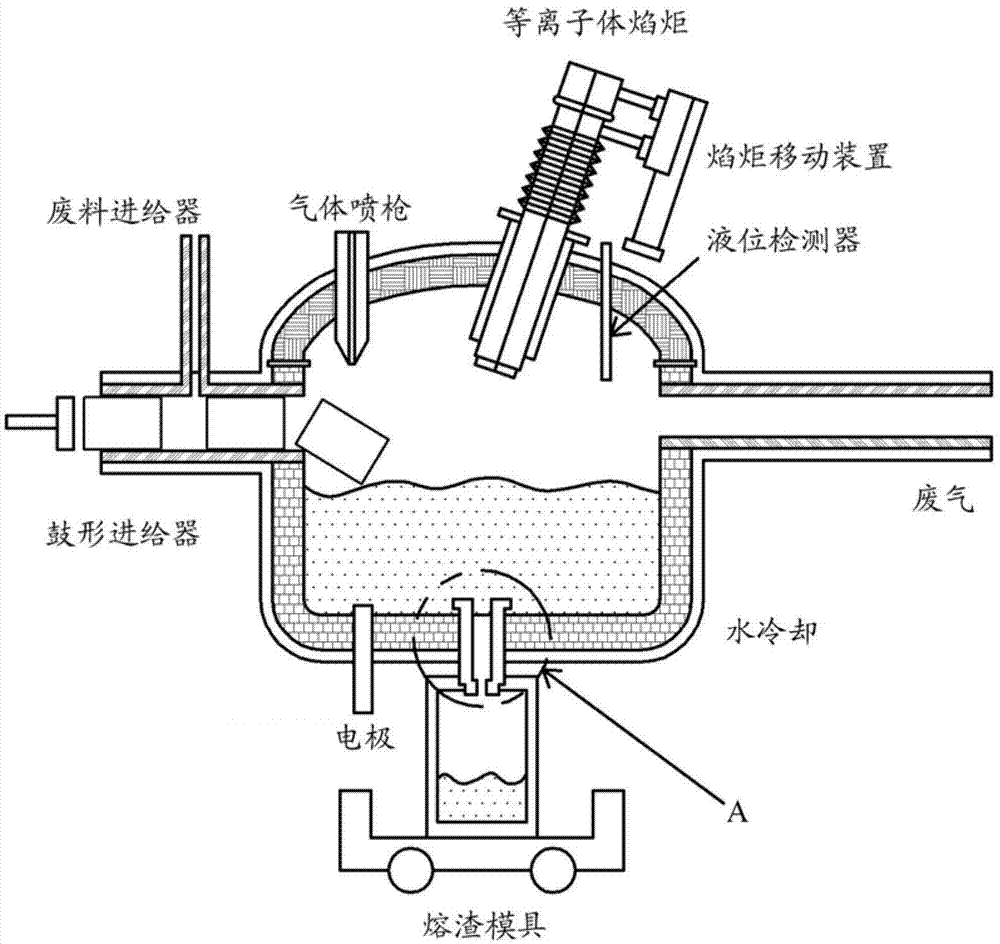

[0022] figure 1 is a schematic diagram showing an induction heating type discharge device of melt according to the present invention, figure 2 It is a conceptual diagram showing the state in which the induction heating discharge apparatus of the molten material according to this invention is installed in a melting furnace.

[0023] As shown in the figure, the induction heating discharge device of the melt according to the present invention includes: a melting furnace 10 made of steel material; a heating element 12 arranged on the upper part of the melting furnace 10 , and made of graphite material; induction coil 14, the induction coil 14 is wound on the outside of the heating element 12; insulator 16, the insulator 16 is arranged on the part in contact with the side of the melting furnace 10; bracket 18 , the support 18 is arranged outside the insulator 16 ; and a refrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com