Inserted intermediate frequency fused salt heater

A heater and plug-in technology, applied in the field of molten salt energy storage, can solve the problems of low heating efficiency and complex structure, and achieve the effects of high heating efficiency, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

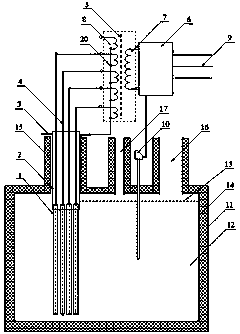

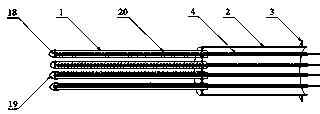

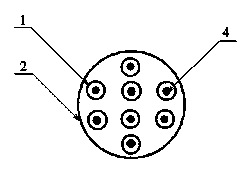

[0013] This patent includes in the drawings: several heating tubes 1 are welded and fixed under the heating tube fixing seat 2, the heating tube fixing seat 2 is a tubular structure, the upper part is welded to the fixing seat flange 3, and each heating tube 1 has a fixed lead wire 4 inside, The lead wire 4 is tightly welded to the bottom of the heating tube 1 to form a welding point 18. The lead wire 4 is connected to the secondary coil 8 of the intermediate frequency transformer 5, and the primary coil 7 of the intermediate frequency transformer 5 is connected to the intermediate frequency power supply 6.

[0014] The heating tube 1 of this patent, the heating tube fixing seat 2, the fixing seat flange 3, and the protective cap 19 are made of stainless steel, the lead wire 4 is an insulating layer wire with an oxygen-free copper jacket that can withstand high temperature and high pressure, and the intermediate frequency transformer 5 is made of amorphous ferrite The magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com