Method and device for moving molten metal

A technology of molten metal and electromagnetic poles, which is applied in the direction of circulating melting devices, stirring devices, electromechanical devices, etc., and can solve problems such as the depth of molten metal becoming shallower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

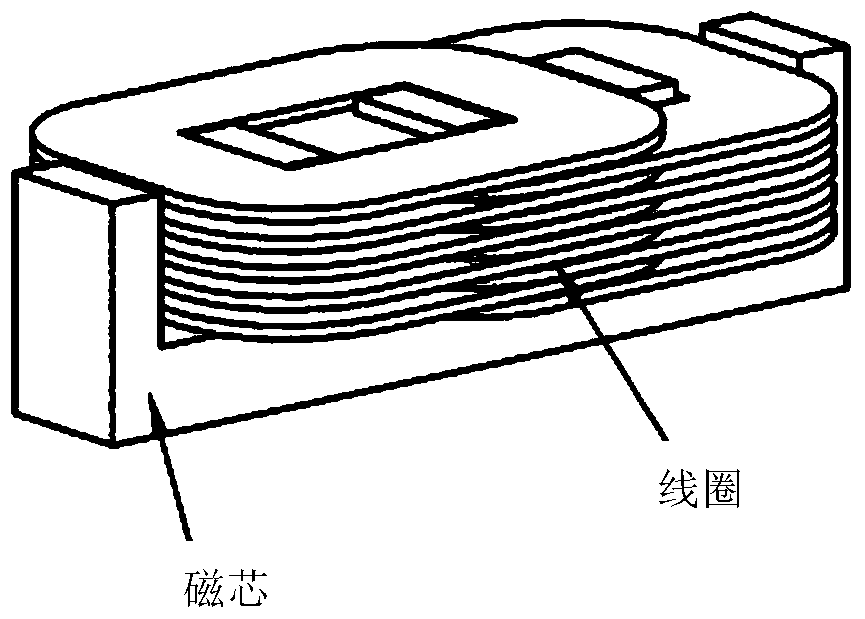

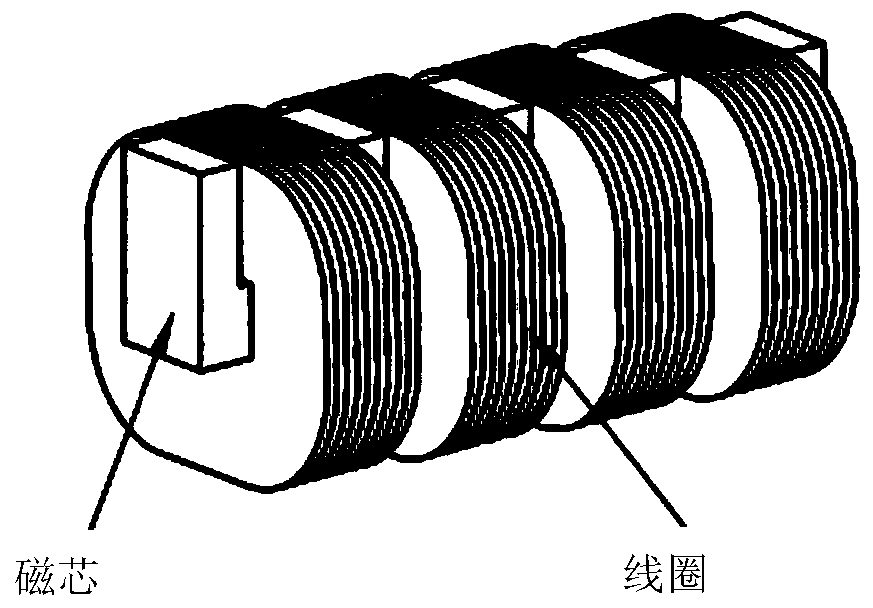

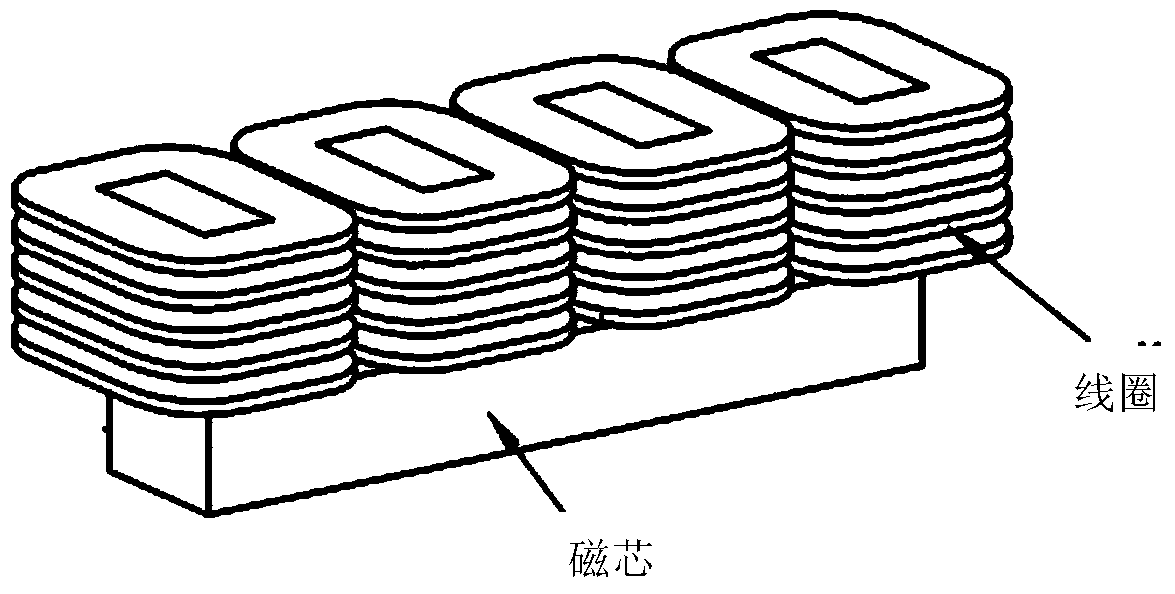

[0098] Currently, different magnetohydrodynamic (MHD) mixers are widely used in the aluminum industry in alloy preparation to improve temperature homogenization and melting rate. In fact MDH mixers have become a standard in efficient foundry equipment. Traditionally, an MHD mixer for metals in a furnace is a linear induction motor with two-phase or three-phase coils, and can be made according to different structural designs. Figures 1a to 1c An example of a typical coil configuration is shown in . Figure 1a The structure in has overlapping coils; Figure 1b The structure in has coils around the neck wrapping the steel core; and Figure 1c The structure in has a coil wrapped around a salient pole tooth.

[0099] Due to these shapes of the coils, the inductor can have a different number of phases and teeth depending on a two-pole, three-pole or multi-pole design. The inductor can be a salient pole or a non-salient pole asynchronous motor. However, a consistent feature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com