Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

161 results about "Ultramarine (pigment)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetic ultramarine pigment. Ultramarine is a deep blue color and a pigment which was originally made by grinding lapis lazuli into a powder. The name comes from the Latin ultramarinus, literally "beyond the sea", because the pigment was imported into Europe from mines in Afghanistan by Italian traders during the 14th and 15th centuries.

Pigmented polymerizable compositions and optical articles prepared therefrom

Provided is a polymerizable composition including: (a) a polymerizable component; and (b) a pigment component the pigment component includes: (i) an ionic or amphoteric dispersant material; and (ii) pigment nanoparticles uniformly dispersed in the dispersant material (i). The nanoparticles have a particle size of up to 500 nanometers. Also provided is a polymerizable composition of: (a) a polymerizable component including: (i) diethylene glycol bis(allyl carbonate); and (ii) a radical initiator; and (b) a pigment component which includes: (i) an ionic or amphoteric dispersant material derived from polycaprolactone; and (ii) pigment nanoparticles of ultramarine blue having an average particle size of up to 500 nanometers, uniformly dispersed in the dispersant material.

Owner:PPG IND OHIO INC

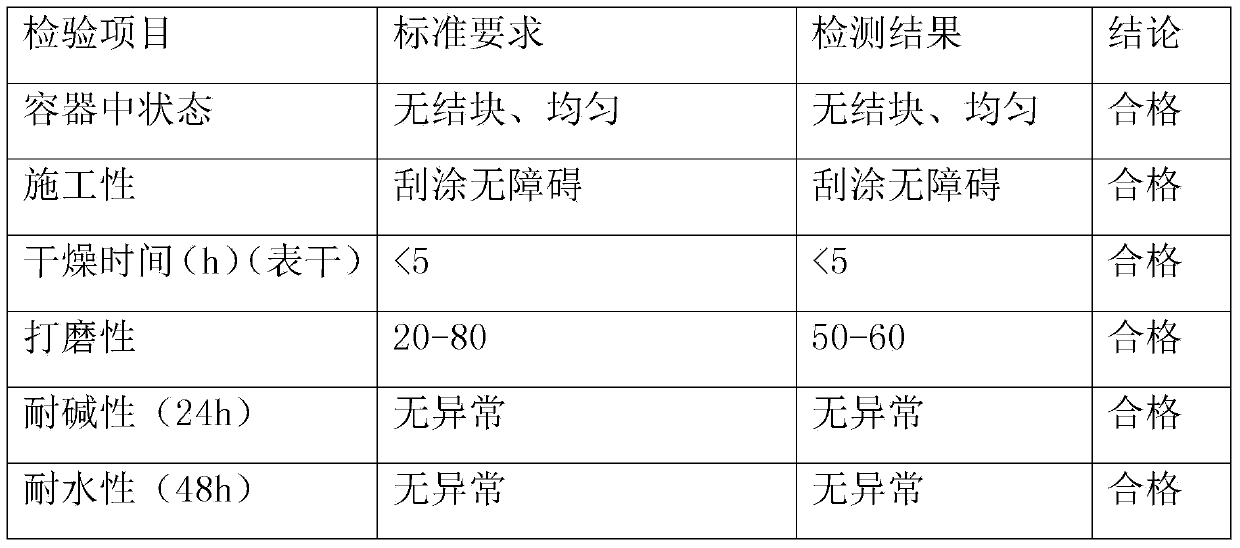

Interior wall putty powder

InactiveCN103725075AImprove general performanceLow costFilling pastesAdditive ingredientHigh intensity

The invention discloses interior wall putty powder. The interior wall putty powder mainly comprises the following ingredients by weight: 750-850 parts of heavy calcium carbonate powder, 120-180 parts of sierozem powder, 40-60 parts of white cement, 3.5-5.5 parts of HPMC, and 0.6-0.9 part of ultramarine. The interior wall putty powder has the advantages of strong universality, low cost, high intensity, good water resistance, high whiteness, and the like; when mixed with a proper amount of other functional components, the interior wall putty powder can still hold the original intensity and quality requirement. The invention further provides interior wall putty powder with a health care function; the interior wall putty powder contains the traditional Chinese medicine component of radix curcumae; the radix curcumae contains volatile components which can cure insomnia; the radix curcumae containing interior wall putty powder can emit the scent of radix curcumae, and has the health care effect of preventing insomnia and soothing the mind, thereby being suitable for decoration of a bedroom interior wall.

Owner:CHONGQING TAIRUI NEW BUILDING MATERIALS

Special dual-component road bench mark coating material for cement pavement and producing method thereof

The invention relates to a cement road special dual-group road mark dope, and relative production, for making the cement road with high adhesive force. The invention comprises A and B components, wherein the A component comprises 70-90 deals of epoxy resin, 10-20 deals of solvent, 20-30 deals of titanium dioxide, 1-5 deals of elasticizer, 0.1-0.3 deals of ultramarine, 0.1-0.3 deals of ultraviolet absorber, and the total deals are 140, and the B component comprises 35-45 deals of modified aliphatic amine, 5-8 deals of phosphate ester, 15-20 deals of fly powder, 5-10 deals of titanium dioxide, 1-4 deals of elasticizer, 1-3 deals of 2, 4, 6-3 (dimethylin methyl) fenol (DMP-30), 0.1-0.3 deals of anti-oxidant, and the total deals are 70, while the A and B components are mixed at 1-5:1 ratio. And the invention prepares A and B components respectively to be mixed when in use.

Owner:山西长达交通设施有限公司

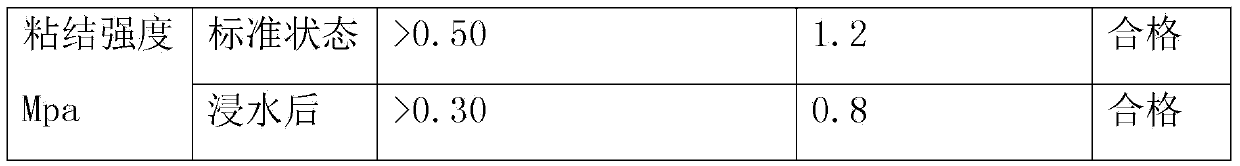

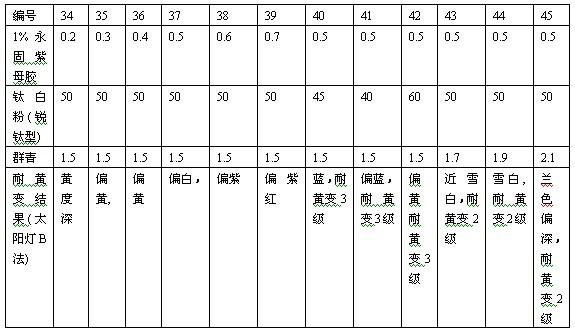

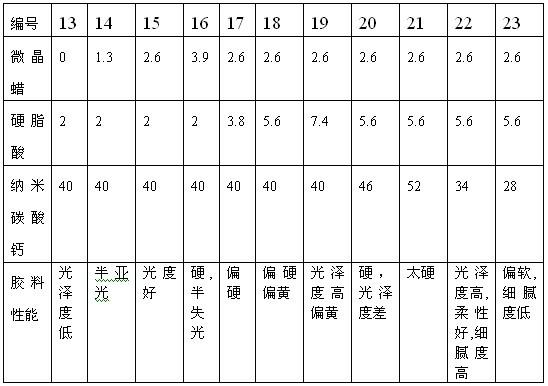

High-mutual viscosity lustered yellowing-resistance bleached sole rubber and preparation method thereof

The invention relates to high-mutual viscosity lustered yellowing-resistance bleached sole rubber and a preparation method thereof. The high-mutual viscosity lustered yellowing-resistance bleached sole rubber comprises 60 to 70 weight parts of No.1 standard rubber, 10 to 20 weight parts of 2000R solution polymerized butadiene-styrene rubber, 15 to 25 weight parts of cis-1,4-butadiene rubber, 1 to 3 weight parts of sulfur, 2.2 to 2.6 weight parts of promoter, 5 to 6 weight parts of stearic acid, 2 to 3 weight parts of nano zinc oxide, 4 to 5 weight parts of polyethylene glycol No.4000, 1 to 2 weight parts of anti-aging agent, 1.7 to 2.1 weight parts of ultramarine, 45 to 55 weight parts of titanium white, 40 to 50 weight parts of white carbon black, 20 to 30 weight parts of nano calcium carbonate, 0.4 to 0.6 weight part of 1-percent pigment permanent violet and 7 to 9 weight parts of white engine oil. In the invention, the formula and preparation method of the product are improved, and sole rubber, which has high rubber viscosity and luster and is yellowing-resistance and as white as snow, is obtained by screening.

Owner:际华制鞋工业有限公司

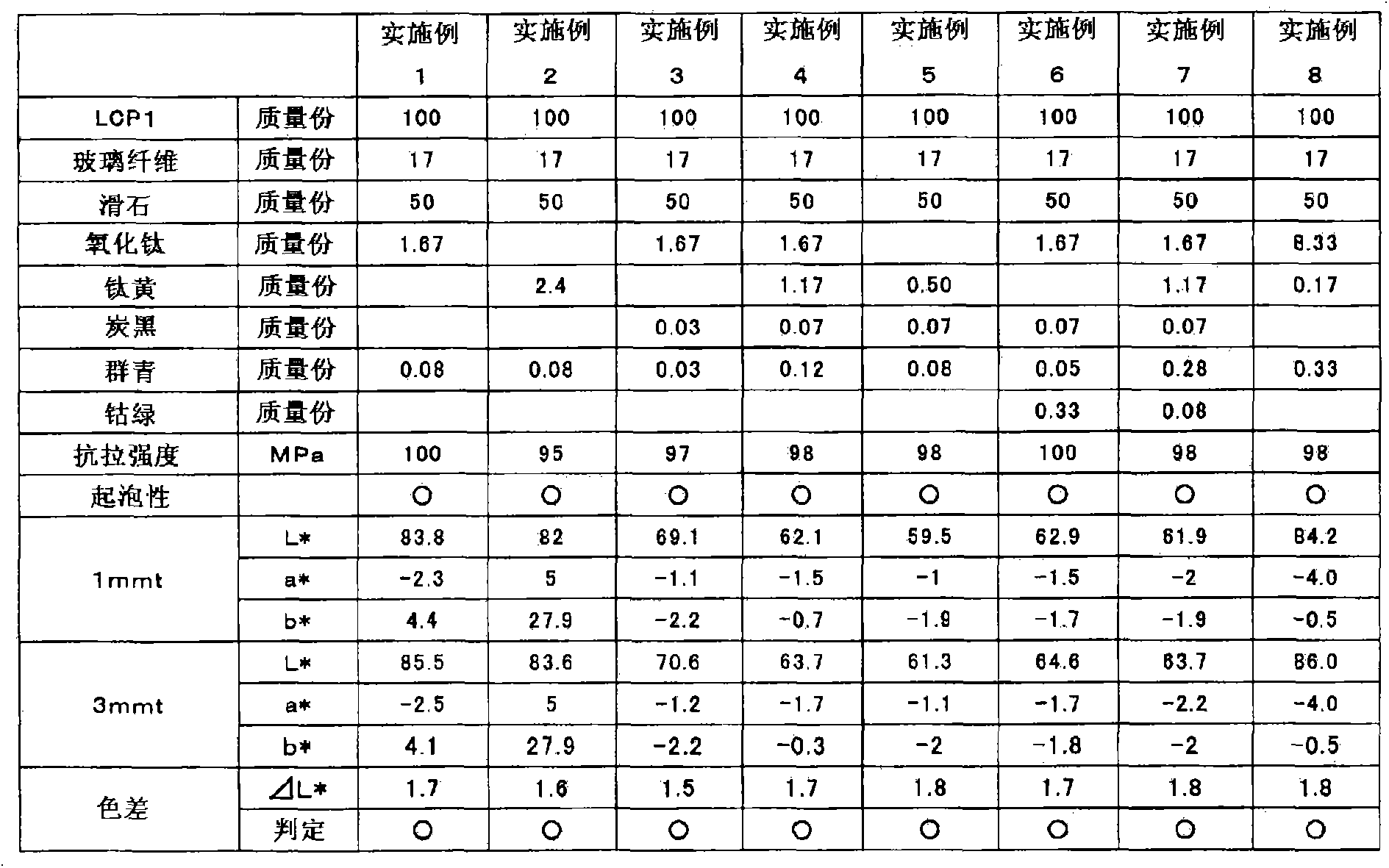

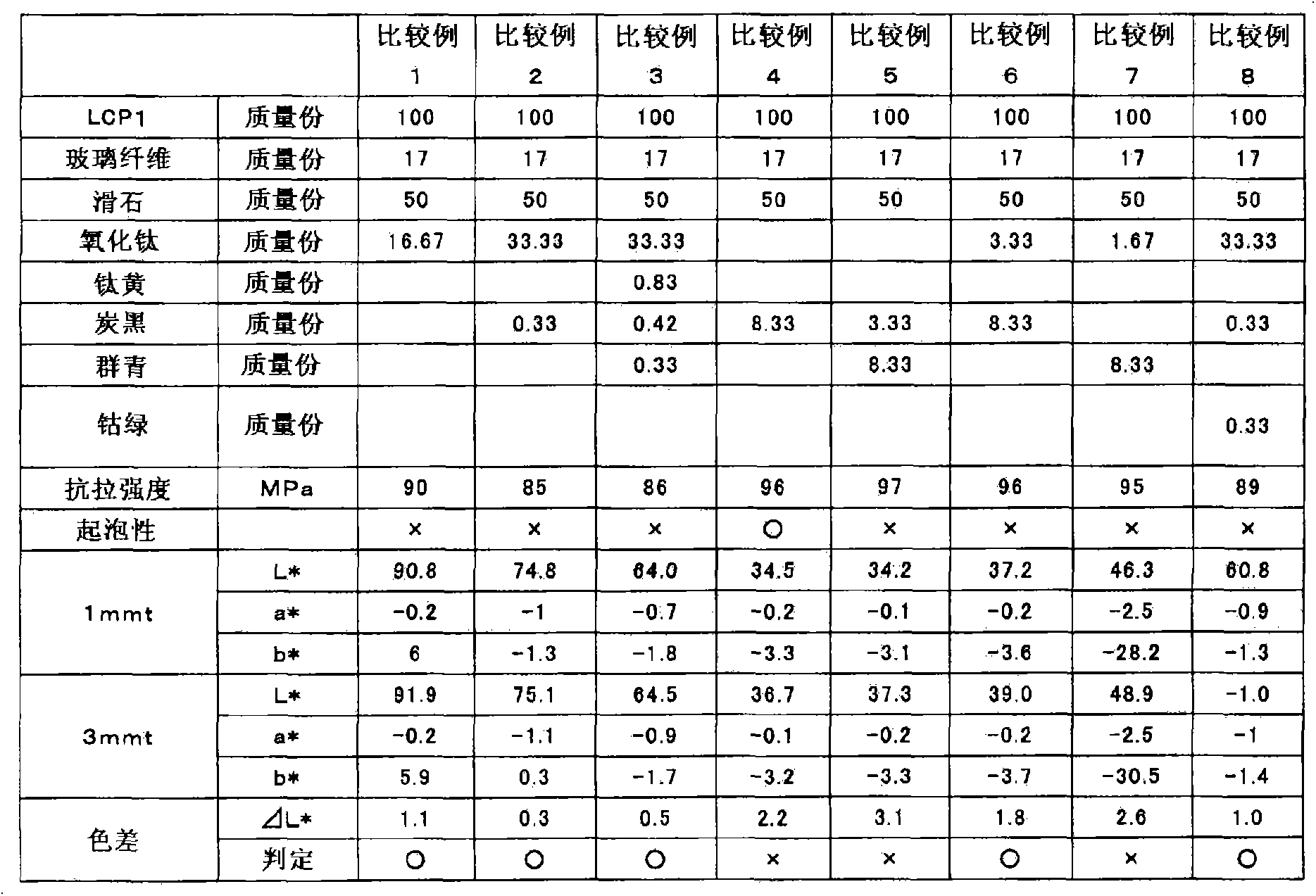

A liquid crystal polyester composition and a molded body formed by the same

ActiveCN103360730AGuaranteed mechanical strengthHigh resistance to foamingCouplings bases/casesPolyesterTitanium oxide

The invention provides a liquid crystal polyester composition and a molded body formed by the same. The molded body has reduced color variation caused by thickness difference of positions, maintained mechanical strength, and high foaming resistant characteristic. The liquid crystal polyester comprises, by weight, 100 parts of liquid crystal polyester, from 0.01 to 5 parts of titanium oxide and / or mixed metal oxides, and from 0.01 to 3 parts of ultramarine. The mixed metal oxides include titanium oxide used as a main component and a compound which is used as an auxiliary component and which contains one or more than two metallic elements selected from a group including antimony, nickel, chromium, iron, zinc, molybdenum, and tungsten.

Owner:SUMITOMO CHEM CO LTD

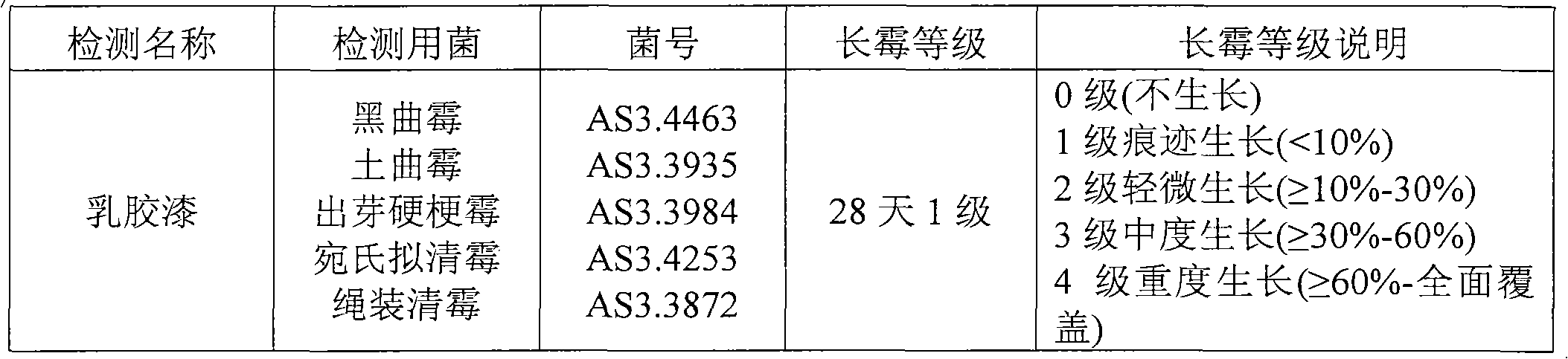

Emulsion paint capable of absorbing and burying carbon dioxide in air

ActiveCN102010635AReduce pollutionHarm reductionEmulsion paintsDefoaming AgentsTriple superphosphate

The invention discloses an emulsion paint capable of absorbing and burying the carbon dioxide in the air. The emulsion paint is prepared from the following raw materials in parts by weight: 213 to 328 parts of water, 2 to 3.5 parts of hydroxyethylcellulose, 8 to 12 parts of propylene glycol, 3 to 7 parts of dispersing agent, 1 to 3.5 parts of wetting agent, 2 to 6 parts of defoaming agent, 0.5 to 1 part of ammonia water, 0.01 to 0.1 part of ultramarine, 0.5 to 1 part of bactericide, 80 to 160 parts of titanium white, 80 to 150 parts of 800-meshed triple superphosphate, 50 to 120 parts of 600-mesh calcium hydroxide, 60 to 80 parts of calcined kaolin, 20 to 40 parts of 700-mesh kieselguhr, 5 to 10 parts of dodecyl acetate, 0.5 to 0.8 part of antiseptic, 200 to 380 parts of acrylate emulsion or pure acrylic emulsion, and 3 to 5.5 parts of thickening agent. The wall surface emulsion paint prepared according to the invention has the advantages of absorbing and burying the carbon dioxide in the air, sterilizing, disinfecting, cleaning the air, and having ultra-strong water resistance after the drying and the solidifying.

Owner:青岛润东新型建筑材料科技有限公司

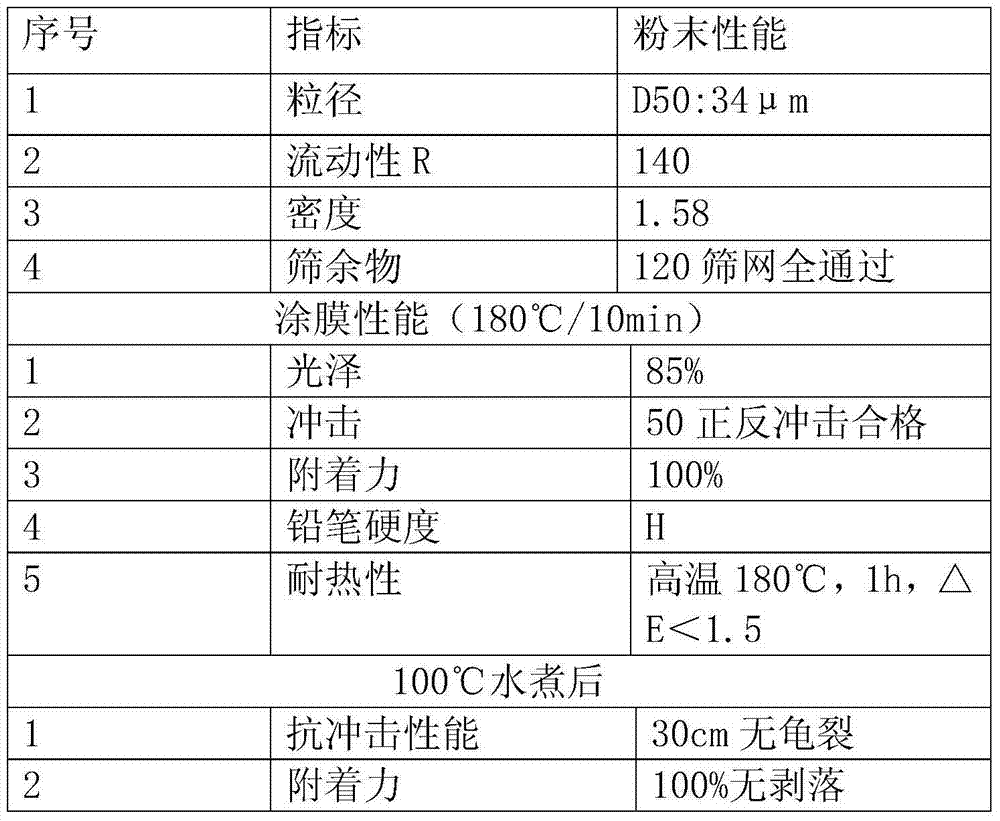

Ultra-level highlight powder coating formula and preparation method thereof

InactiveCN104745042AImprove the level ofDecorativePowdery paintsEpoxy resin coatingsEpoxyAntioxidant

The invention relates to the technical field of preparation for powder coatings with special performances, and particularly relates to an ultra-level highlight powder coating formula and a preparation method thereof. The powder coating has the following formula components in parts by mass: 28-34 parts of epoxy resin, 28-34 parts of polyester resin, 1.5-3.5 parts of a levelling agent, 22-25 parts of titanium dioxide, 2.5-4.8 parts of barium sulphate, 0.1-0.6 part of benzoin, 0.2-0.6 part of an antioxidant, 0.02-0.28 part of ultramarine, 0.002-0.004 part of carbon black and 0.2-0.35 part of silicon dioxide. The coating film of the powder coating obtained by the technical scheme disclosed by the invention has a good levelling performance, the interface cured by the powder coating has good decoration performance, and the powder coating can be applied to surface protection on automobiles, household appliances, furniture and the like, as well as is low in use cost and suitable for popularization and application.

Owner:JIANGSU HUAGUANG NEW MATERIAL TECH CO LTD

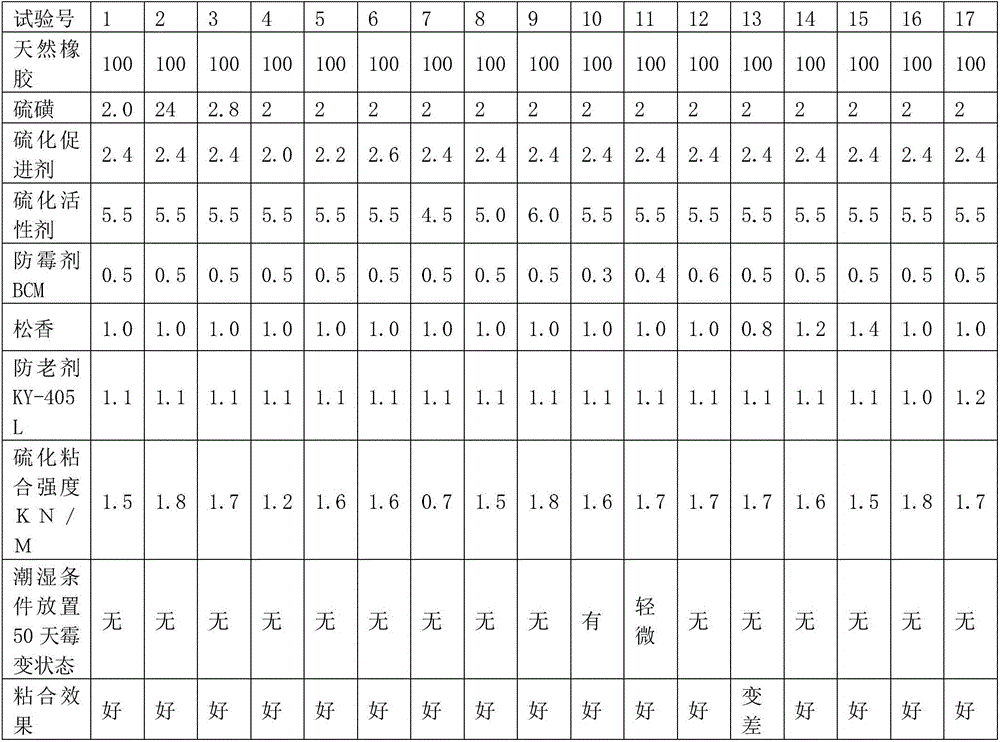

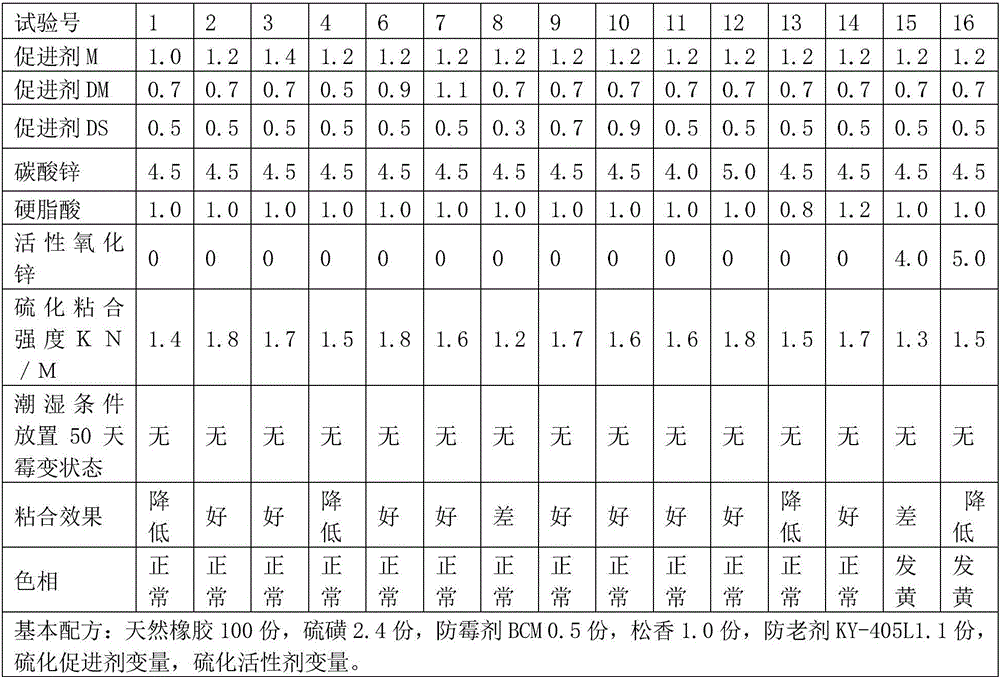

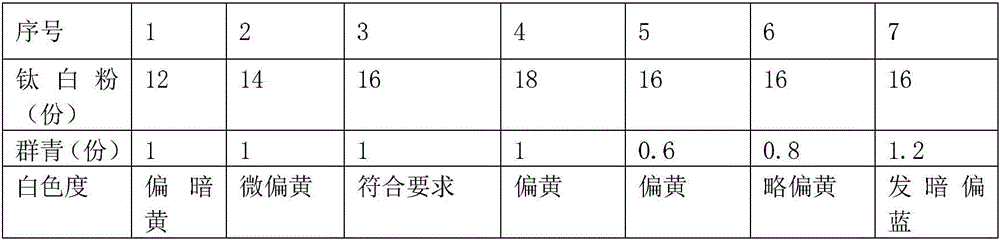

Head covering cloth adhesive for white upper and preparation method and application of head covering cloth adhesive

InactiveCN106189925AEliminate unbeautifulEliminate friction during wearingNatural rubber adhesivesNon-macromolecular adhesive additivesVulcanizationAgricultural engineering

The invention discloses a head covering cloth adhesive for a white upper and a preparation method and application of the head covering cloth adhesive. The head covering cloth adhesive is prepared from natural rubber, a vulcanization agent, an accelerant M, an accelerant DS, an accelerant DM, a vulcanizing activator, rosin, composite resin DS-B, titanium dioxide, ultramarine and 120# gasoline. The reasonable adhesive formula and preparation method are screened out, the adhesive has good adhesion strength and is used for bonding head covering cloth and the upper, the product quality is guaranteed, meanwhile, the problems that a sewing process is not attractive in appearance, friction is large in the wearing process, and consequently toes are injured can be solved, and the appearance quality and wear comfort degree of the product are improved. The production efficiency is not reduced, and the industrialization degree is good. The head covering cloth adhesive is simple and easy to apply, low in cost and good in use effect.

Owner:JIHUA 3537 SHOE MAKING

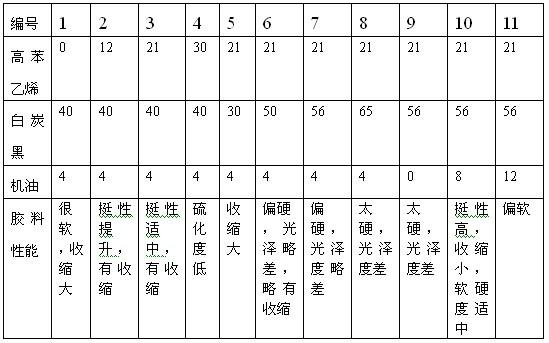

PVC (Polyvinyl Chloride) diaphragm and manufacturing method thereof

The invention discloses a PVC (Polyvinyl Chloride) diaphragm and a manufacturing method thereof. The PVC diaphragm is manufactured by using the raw materials: 100 parts of PVC resin, 1.0-1.2 parts of 719 type oxidized polyethylene wax, 0.015-0.017 part of auxiliary stabilizer, 3.5-4.0 parts of MBS (Methacrylate-Butadiene-Styrene) resin, 0.9-1.1 parts of ACR (Acrylate), 0.45-0.55 part of internal lubricant, 0.1-0.2 part of external lubricant, 0.3-0.4 part of PX1000, 0.011-0.013 part of ultramarine and 0.004-0.005 part of disperse purple, wherein the auxiliary stabilizer is composed of monomethyltin and antimony mercaptide which are in the weight ratio of 1:4. The manufacturing method of the PVC diaphragm comprises the steps: firstly, adding all the raw materials into a kneading pot to knead, and discharging when the temperature is up to 80-90 DEG C; entering a cooling pot, and discharging when the temperature is up to 60-70 DEG C; next, squeezing out the raw materials at the temperature of 120-160 DEG C; then, calendering the raw materials at the temperature of 180-200 DEG C to form a sheet; after stripping, cooling and shaping, cropping and winding. The PVC diaphragm is good in stability, high in strength and low in manufacturing cost.

Owner:江苏晨洁家化制造有限公司

Hot melt type vibration gage mark coating

The invention discloses a melt vibrating bench mark paint, which is characterized by the following: the paint is composed by following mass percent raw material: 15-12% C5 resin, 5-2% titanium white, 1.3-1.0% EVA, 35-32% quartz sand, 35-32% heavy calcium carbonate, 12-10% glass bead, 1.0-0.8% vegetable oil, 1.3-1.0% polyethylene wax and 0.04-0.02% ultramarine; the product is a new type road safety gage mark material; the method chooses single-purpose glass micro bead with refractive index table bigger than 1.5. This material possesses bloomy look and reflecting characteristics, which can be used to urban road, suburb road, airport and highway widely.

Owner:周鹏

High weather resistance PVC profile for doors and windows and production technology

The invention discloses a high weather resistance PVC profile for doors and windows. The PVC profile is prepared from, by weight, 420 parts of PVC resin, 13-14 parts of ACR processing aids, 25 parts of stabilizer, 50-55 parts of chlorinated polyethylene, 32 parts of CaCO3, 20 parts of superfine CaCO3, 36-38 parts of titanium dioxide, 2-2.5 parts of antioxidants, 1.4-2 parts of ultraviolet light absorbents and 2.5-3 parts of ultramarine. The stabilizer is one or more of calaium strarate, calcium ricinoleate, zinc stearate and zinc diricinoleate. The invention further discloses a production technology of the PVC profile. According to the high weather resistance PVC profile for the doors and the windows and the production technology of the PVC profile, the PVC profile has higher rigidity, wind load resistance and low temperature enhancement by means of optimizing of profile raw materials and the preparation technology.

Owner:LIAONING CHENGWEI PLASTIC PROFILE

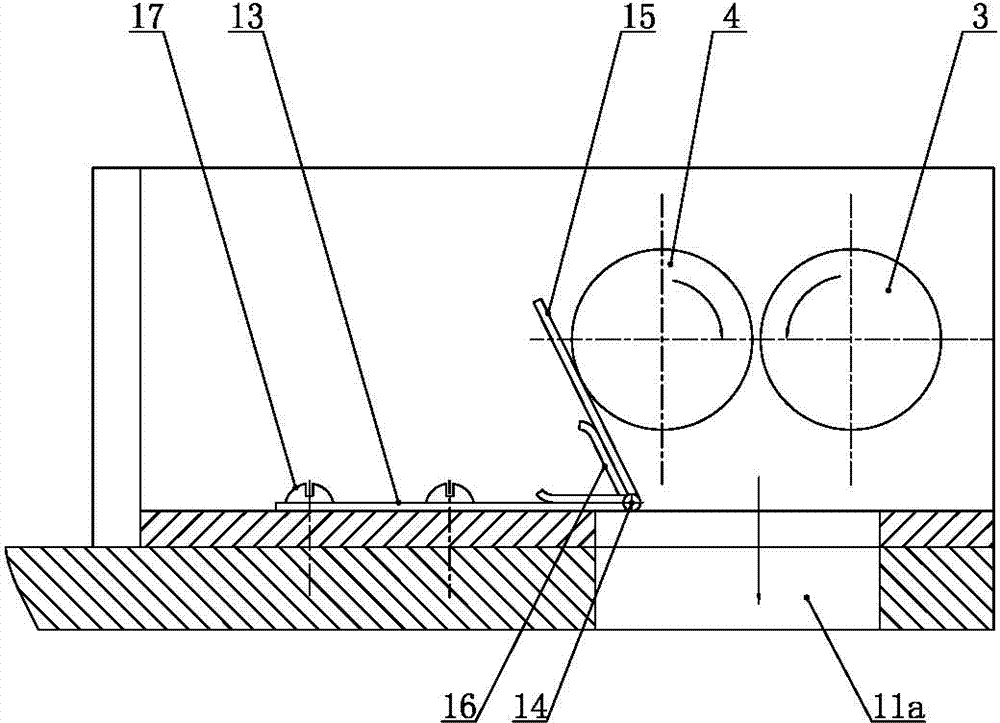

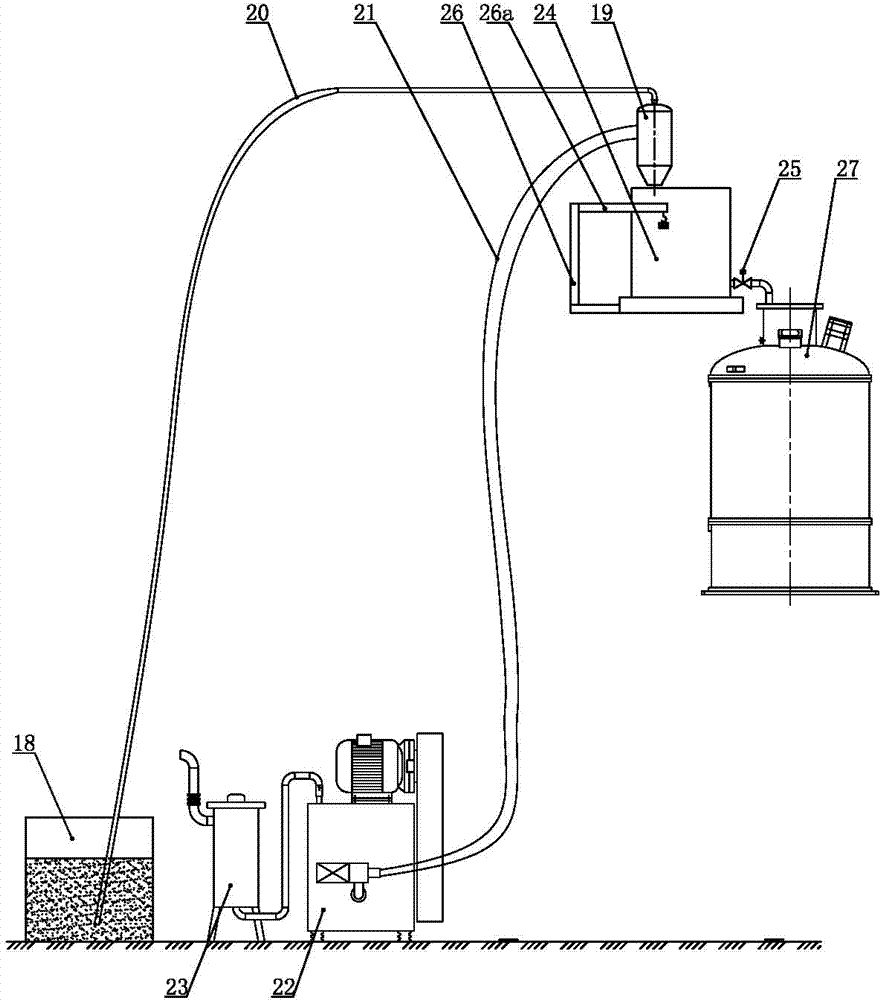

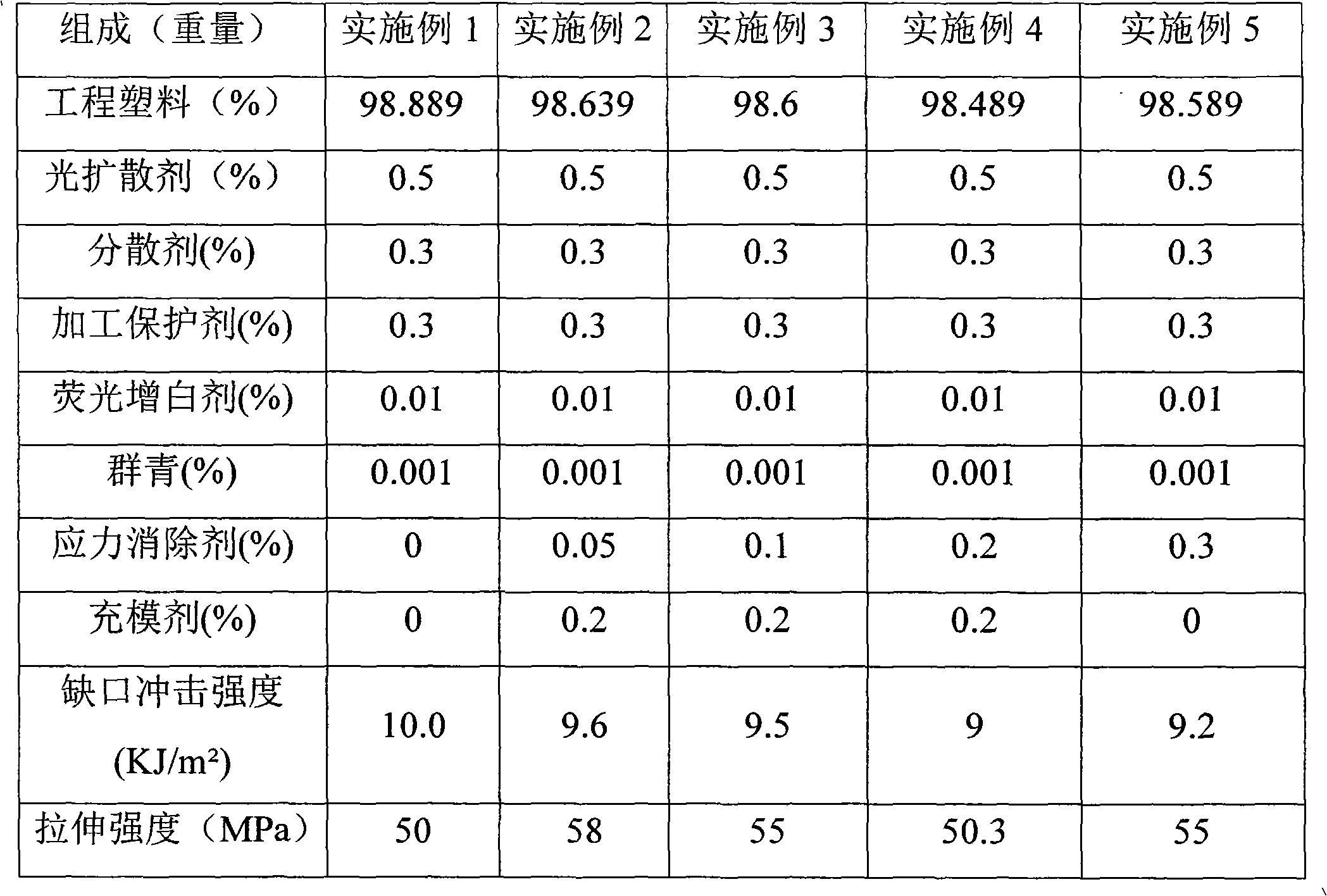

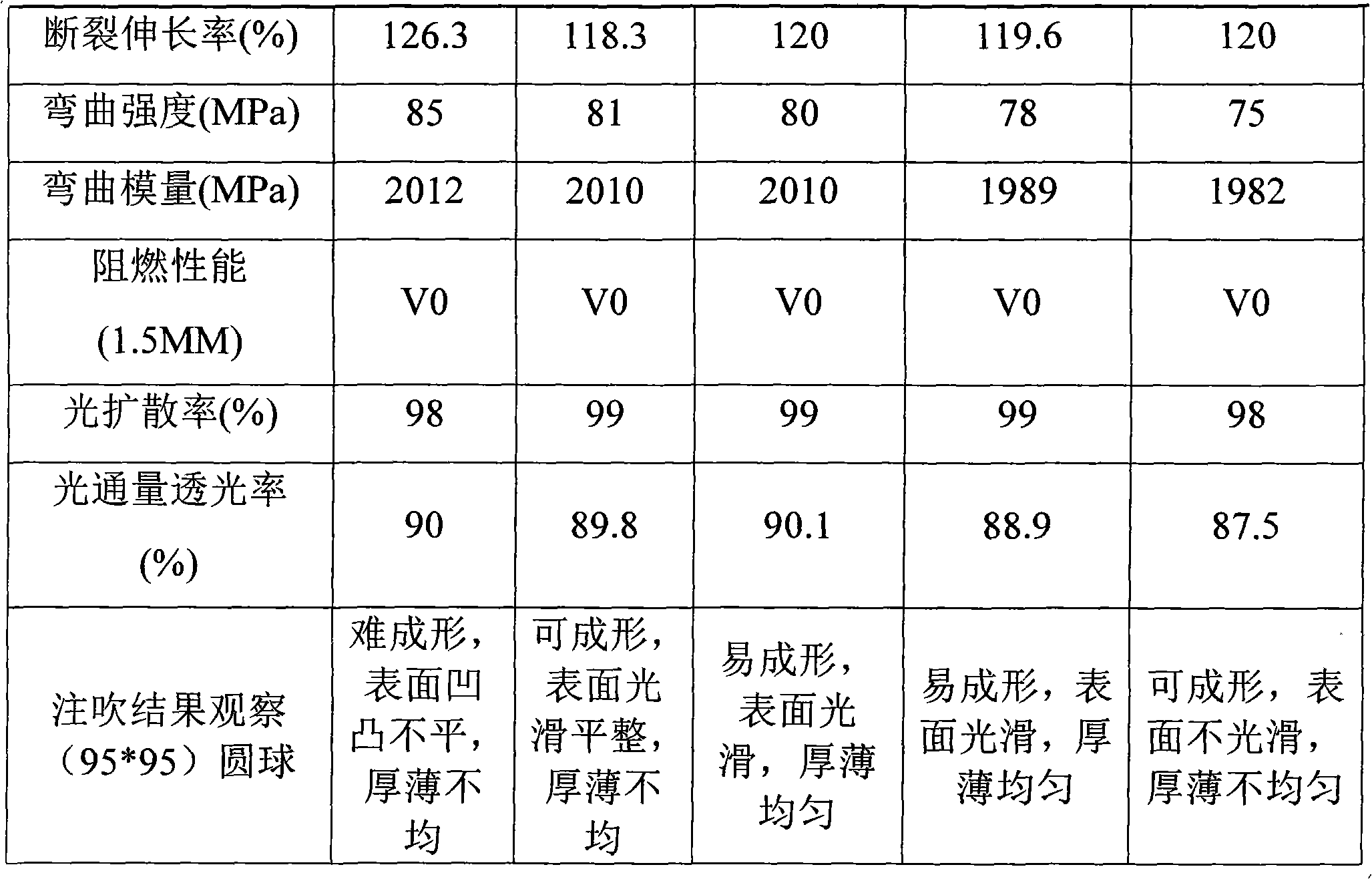

LED lampshade injection blow grade light scattering PC and preparation method

InactiveCN103724960AUniform thicknessImprove yieldPoint-like light sourceGlobesMold fillingFluorescence

The invention discloses a LED lampshade injection blow grade light scattering PC and a preparation method. The LED lampshade injection blow grade light scattering PC comprises the following components by weight: 97-99% of engineering plastics, 0-1 parts of light scattering agent, 0.3-0.7% of dispersant, 0.2-0.6% of processing protective agent, 0.01-0.1% of stress remover, 0-0.2% of mold filling agent and 0.1-0.2% of other auxiliary agents. The preparation method comprises the following steps: weighting the engineering plastic, the mold filling agent, the light scattering agent, the processing protective agent, the stress remover, a fluorescent brightening agent and ultramarine by weight, uniformly mixing, then putting into a loading hopper of a double screw extruder, extruding after melting, and granulating. The yield of the LED lampshade injection blow grade light scattering PC injection molding can be increased, the internal stress generation of the injection molding can be reduced at maximum degree, the lampshade thickness is uniform, the luminous flux transmittance is high, the flame retardation grade is increased from UL94V2 to V0, and the preparation method has the advantages of simple technology, convenient operation and low cost.

Owner:厦门市宏盛坤工贸有限公司

Hot-melt vibrating graticule coating

The invention relates to a chemical preparation, in particular hot-melt vibrating scale mark coating. The coating is composed of the following materials: C5 resin, titanium white powder, EVA, quartz sand, large calcium carbonate, glass bead, vegetable oil, polyethylene wax, ultramarine. The coating is a new type road safety scale mark material, and having fast construction, fast drying, wear-resisting, bright look and night reflection. Its product is suitable for urban road, suburb highway, airport and express highway.

Owner:周鹏

Chemical method silicone heat resistance paint and preparation method thereof

InactiveCN109423202AOil resistantMoisture-proofFireproof paintsAnti-corrosive paintsMoisture resistanceSilicon dioxide

The invention discloses chemical method silicone heat resistance paint which belongs to the technical field of heat resistance paint. The paint includes, by weight, the following raw materials: 10-40parts of a silicone resin liquid, 25-55 parts of anatase type titanium dioxide, 10-20 parts of ultramarine, 2-3 parts of chromium oxide, and 1-3 parts of kaolin. The chemical method silicone heat resistance paint utilizes the silicone resin liquid as a film-forming material and utilizes a vitreous silica material, a special ceramic material, zinc phosphate, and a fiber material as fillers to prepare heat preservation and insulation anticorrosion heat resistance paint. After curing, the heat resistance paint has the characteristics of heat resistance, oil resistance, moisture resistance, insulation, strong adhesion, good mechanical properties, and the like, and has good a heat insulation effect; and another purpose of the invention is to provide a preparation method of the chemical method silicone heat resistance paint.

Owner:陈兴月

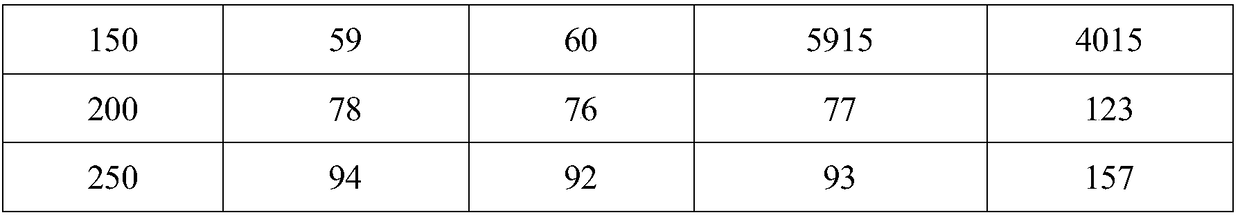

High-stiffness lustered yellowing-resistance bleached shoe side rubber and preparation method thereof

The invention discloses high-stiffness lustered yellowing-resistance bleached shoe side rubber, which comprises 80 to 90 weight parts of No.1 standard rubber, 10 to 20 weight parts of solution polymerized butadiene styrene rubber 2003, 18 to 25 weight parts of high styrene, 1 to 3 weight parts of sulfur, 2.4 to 2.8 weight parts of microcrystalline wax, 2.2 to 2.6 weight parts of promoter, 5 to 6 weight parts of stearic acid, 2.5 to 3.4 weight parts of nano zinc oxide, 4 to 5 parts of polyethylene glycol 4000, 1 to 2 weight parts of antiaging agent, 1.7 to 2.1 weight parts of ultramarine, 53 to 60 weight parts of titanium white, 50 to 60 weigh parts of white carbon black, 30 to 40 weight parts of nano calcium carbonate, 0.1 to 0.15 weight part of 4-percent pigment permanent violet and 7 to 9 weight parts of white engine oil. In the invention, the formula and preparation method of the product are improved, and shoe side rubber, which has high rubber stiffness and luster and is yellowing-resistance and as white as snow, can be obtained by screening.

Owner:JIHUA 3537 SHOE MAKING

Method for preparing colorant used in mass coloration of acrylic fibre spinning

The preparation method of colouring material for mass coloration process in spinning of acrylic fibre includes the following steps: mixing pigment, dispersing agent and NaSCN aqueous solution and grinding by means of ball-grinding machine. In the colouring material the pigment content is 5-25 wt%, the weight ratio of pigment and dispersing agent is 100:3-30, and the grinding time is 0.5-5.0 hr., then the colouring material can be obtained. The above-mentioned dispersing agent is one compound selected from alkyl-polyoxyethylene ether, alkylphenol ethoxylates, trimethyl stearamide chloride or hexadecyltrimethylamine bromide or their mixture, and the pigment is cabron, black, phthalocyanine blue, iron oxide or ultramarine generally.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Environment-friendly plastic profile and its production method

The invention discloses an environment-friendly plastic profile and its production method. The production method includes: adding a filler calcium carbonate, a toughening agent chlorinated polyethylene, and an ACR aid into polyvinyl chloride resin according to proportion, then adding a lubricant stearic acid and PE wax, and then adding a whitening agent, titanium dioxide and ultramarine, finally adding lead-free calcium zinc heat stabilizer, putting the materials into a high speed mixing machine together, conducting high temperature mixing at 130-140DEG C for 8-12min, then placing the mixture into a low-speed mixing machine to cool it to 35-45DEG C, subjecting the mixture to extrusion molding, and carrying out cutting so as to obtain a finished product. The environment-friendly plastic profile solves the exceeding heavy metal problem in the prior art, does not contain chlorine, bromine or other halogens, and has high flame retardance, thus meeting the EU ROHS and the relevant IEE standards.

Owner:安徽深泰新型建材有限公司

Powdery eye shadow block

InactiveCN101804020ANon-irritatingNo other side effectsCosmetic preparationsMake-upSide effectIrritation

The invention discloses a powdery eye shadow block comprising the following materials in parts by weight: 50-60 parts of kaolin, 10-20 parts of ultramarine, 3-5 parts of titanium dioxide, 15-25 parts of bismuth hydroxide, 2-5 parts of beeswax, 4-8 parts of isopropyl palmitate, 0.5-1 part of glycerin monostearate and 0.3-0.6 part of essence. Compared with the prior art, the invention has good gloss and easy inunction without irritation on skin and eyes and any other side effect, can not be afraid of being soaked by rainwater, tears and sweats and has proper drying property.

Owner:任芳芳

Polyvinyl chloride profile and preparing method thereof

The invention discloses a polyvinyl chloride profile. The polyvinyl chloride profile is prepared from, by weight, 80-120 parts of polyvinyl chloride, 10-30 parts of active calcium, 3-5 parts of a composite rare earth stabilizer, 5-15 parts of a processing agent, 4-7 parts of titanium dioxide, 0.1-0.5 part of calcium stearate, 0.1-0.5 part of PE wax and 0.001-0.002 part of ultramarine. Polyvinyl chloride is selected as a base material, auxiliary materials such as active calcium, the composite rare earth stabilizer and the suitable processing agent are combined, the prepared polyvinyl chloride profile is more excellent in tensile strength, impact strength, bending strength and the like, and the number of times of recycle is increased.

Owner:重庆海塑建材有限公司

Moisture-proof putty powder

The invention relates to a putty powder, specifically relates to an indoor moisture-proof putty powder, and belongs to the technical field of building materials. The moisture-proof putty powder is prepared from the following raw materials in parts by weight: 15 to 25 parts of white cement, 6 to 14 parts of palygorskite clay, 3 to 8 parts of bagasse fiber, 0.5 to 1 part of hydroxypropyl methyl cellulose, 4 to 8 parts of super absorbent resin, 2 to 4 parts of bentonite, 2 to 4 parts of sodium alginate, 0.5 to 1 part of sodium chloride, and 0.6 to 0.9 part of ultramarine. The provided moisture-proof putty powder has the advantages of strong versatility, low cost, high strength, good waterproof property, and high whiteness.

Owner:徐勤凤

Method of producing environment protection type heat insulating waterproof coating material for building

PendingCN101153153AWith imitation porcelain effectGood heat insulationFireproof paintsAntifouling/underwater paintsCelluloseAlcohol

The present invention discloses a preparation method of environment-protective heat-insulation and waterproof dope used in construction; the component contains: 1kg of sodium hexametahposphate solution with the concentration of 10 percent, 0.02kg of stain-proofing agent, 0.02kg of brightening agent, 0.01kg of ultramarine, 28kg of polyethylene alcohol synthesized tackiness agent, 0.15kg of tributyl phosphate, 10kg of light calcium, 27kg of hydroxyethyl cellulose solution with the concentration of 2 percent, 20kg of active calcium carbonate, 10kg of benzene latex, and the other of water; firstly, the polyethylene alcohol synthesized tackiness agent is added into a jar for mixing, at the same time, the cellulose solution is added; after mixing for 15 minutes, the stain-proofing agent is also added to be mixed for 5 minutes; the active calcium carbonate and the light calcium are added together to be mixed for 30 minutes. The ultramarine and the brightening agent are added to be mixed for 15 minutes; the tributyl phosphate is added to be mixed for 10 minutes; finally, the benzene latex is added to be evenly mixed. The present invention has the advantages of much better heat-insulating effect as well as much better waterproof performance. The present invention is innocuous, flavourless and non-pollution. In addition, the present invention has the effect of imitating porcelain.

Owner:ZHONGHONG (TIANJIN) IND CO LTD

Plastic material capable of releasing anions and preparation method of plastic material

The invention discloses a plastic material capable of releasing anions and a preparation method of the plastic material. The plastic material is prepared from the following raw materials in parts by weight: 80-100 parts of polyvinyl chloride resin, 1-10 parts of an anion additive, 20-30 parts of calcium carbonate powder, 5-15 parts of sepiolite powder, 1-2 parts of an ACR assistant, 2.5-4.2 titanium dioxide, 0.05-0.1 part of stearic acid, 3-4 parts of a lead-free calcium-zinc heat stabilizer, 0.3-0.4 part of polyethylene wax, 0.1-0.15 part of an ultraviolet light absorber and 0.01-0.03 part of ultramarine. The plastic material produced by the method has good heat dissipation performance and good tensile property; meanwhile, the molecular structures of the materials such as lead, cadmium and mercury are changed; the activity of harmful molecules is lowered; the content of partial harmful molecules in products is neutralized; and meanwhile, the plastic material also contains an anion releasing agent, so that the plastic material has antibacterial, anti-toxicity and smell-removing efficacies.

Owner:安徽深泰新型建材有限公司

Formula and preparation method of novel environment-friendly sectional materials

The invention discloses a formula and a preparation method of novel environment-friendly sectional materials. The formula consists of the following raw materials in parts by weight: 65-85 parts of polyvinyl chloride resin, 70-80 parts of polyvinyl chloride reclaimed materials, 20-30 parts of calcium carbonate powder, 5-15 parts of chlorinated polyethylene, 1-2 parts of ACR auxiliaries, 2.5-4.2 parts of titanium white, 0.05-0.1 part of stearic acid, 3-4 parts of lead-free calcium-zinc thermal stabilizer, 0.3-0.4 part of polyethylene wax, 0.1-0.15 part of ultraviolet absorbent and 0.01-0.03 part of ultramarine. Plastic sectional materials prepared by the preparation method have good heat dissipating performance and good tensile property; meanwhile, molecular structures of materials containing lead, cadmium, mercury and the like are changed, the activity of harmful molecules is lowered, and the content of part of harmful molecules in products is neutralized, so that the products reach ROHS and related IEE standards of European Union.

Owner:安徽深泰新型建材有限公司

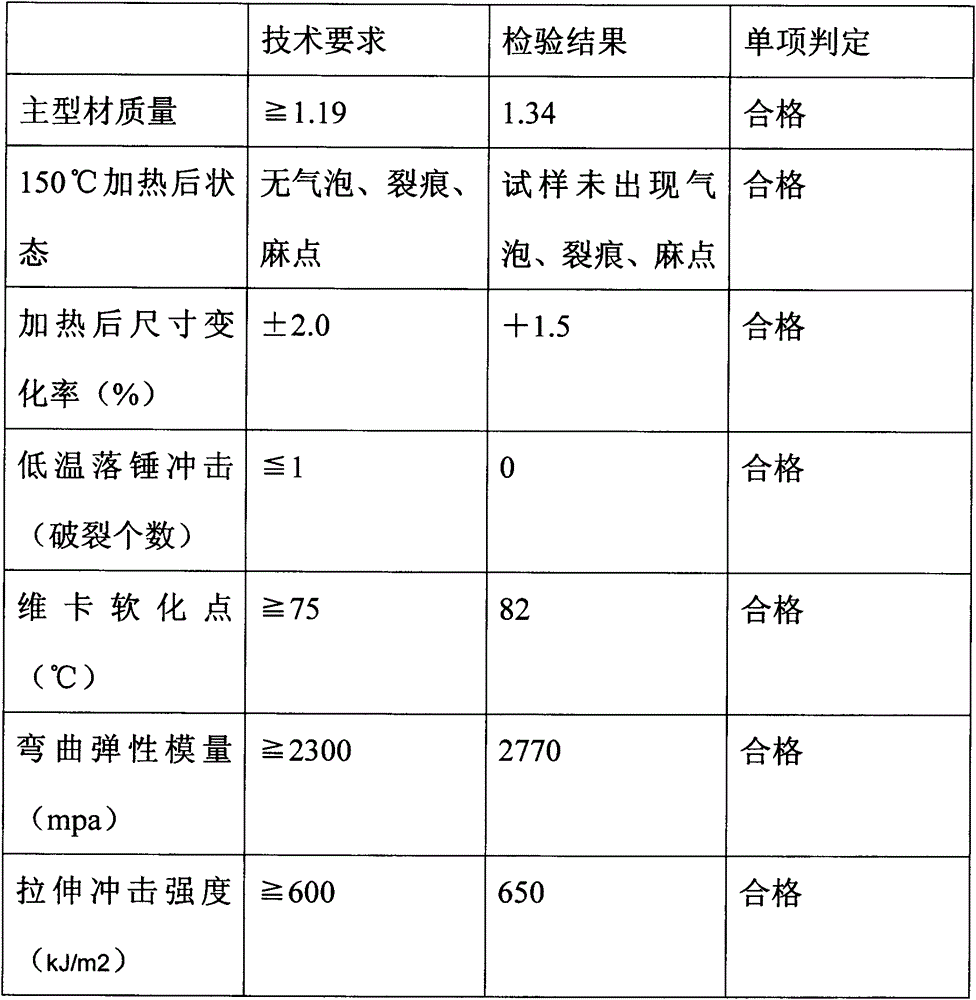

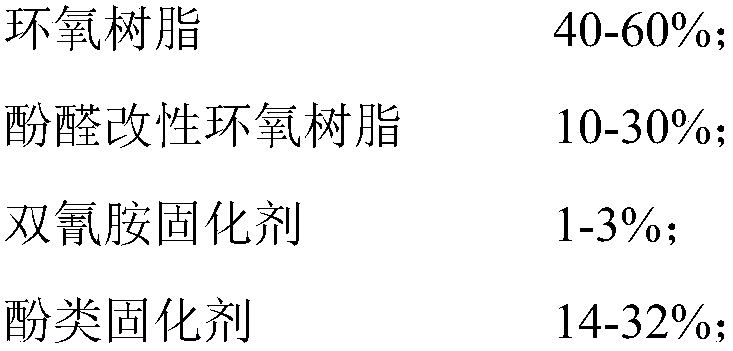

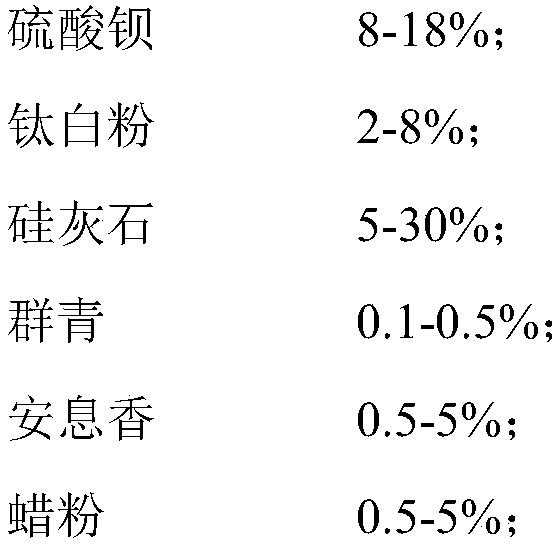

High-salt-spray-corrosion-resistant powder paint

InactiveCN108441084AImprove enduranceReduce the rate of decomposition and degradationAnti-corrosive paintsPowdery paintsEpoxyWax

The invention belongs to the field of powder coating, and particularly relates to a high-salt-spray-corrosion-resistant powder paint which comprises a main material and auxiliary materials. The main material is prepared from, by weight, 40-60% of epoxy resin, 10-30% of phenolic modified epoxy resin, 1-3% of dicyanodiamide curing agent and 14-325 of phenolic curing agent, and the auxiliary materials include, by mass accounting for the main material, 8-18% of barium sulfate, 2-8% of titanium dioxide, 5-30% of wollastonite, 0.1-0.5% of ultramarine, 0.5-5% of benzoin, 0.5-5% of wax powder, 0.5-5%of imidazole and 0.5-5% of boron oxide. A coating formed by the powder paint has excellent resistance to salt spray and water boiling, and cathode striping resistance can be improved.

Owner:山东兰生环保科技有限公司

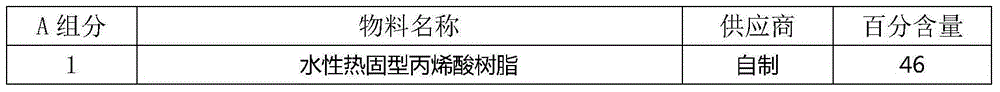

Water-based glass high-temperature baking varnish and preparation method thereof

The invention discloses a water-based glass high-temperature baking varnish and a preparation method thereof. The water-based glass high-temperature baking varnish comprises a component A, a component B and deionized water in a weight ratio of 100:2:(30-40). The component A comprises the following raw materials in percentage by weight: 40-50 parts of water-based thermosetting acrylic resin, 10-15 parts of amino resin, 0.10-0.50 part of water-based defoaming agent, 0.20-1.00 part of water-based dispersing agent, 0.05-0.20 part of vapor-phase silicon dioxide, 3.3 parts of phthalocyanine blue BGS pigment, 2.86 parts of blue ultramarine pigment, 0.10-0.50 part of substrate wetting agent, 10-20 parts of ethanol, 5-10 parts of propylene glycol monomethyl ether and 1-10 parts of deionized water. Compared with the prior art, by performing the raw material selection and proportioning and the reasonable matching control on parameters in the preparation method, the prepared water-based glass high-temperature baking varnish has the advantages of favorable adhesive force, favorable leveling property, high water resistance and high alcohol resistance.

Owner:WUHU CHUNFENG NEW MATERIAL

Novel emulsion paint

The invention relates to a novel emulsion paint which comprises the following components in percentage by weight: 8.5% of ultramarine, 0.2% of cellulose, 0.07% of humidizer, 0.6% of dispersing agent, 4.2% of titanium white, 17.7% of silicon dioxide superfine powder, 5.7% of kaolin, 7.1% of calcium carbonate light, 7.1% of sierozem, 2.8% of talcum powder, 14.2% of poval, 14.2% of high polymer emulsion and 17.63% of water. The novel emulsion paint has the advantages of ageing resistance, high strength, wet rub resistance, flat and smooth surface and the like, and has less possibility of shedding; after the novel emulsion paint is used for a long term, no splitting phenomenon occurs; and due to high density, the novel emulsion paint has better stain resistance.

Owner:王永华

Novel interior wall paint

The invention relates to a novel interior wall paint. The interior wall paint comprises, by weight, 3.3% of corn starch, 1.4% of caustic soda, 17.1% of light calcium carbonate, 9.5% of talc powder, 0.2% of borax, 0.15% of ultramarine, 0.02% of brightener, 4.8% of polyvinyl alcohol adhesive, and the balance water supplementing 100% . The paint has the advantages of anti-aging, high strength, wet-rub resistance and flat and smooth surface.

Owner:王永华

White rubber oil-resistant footwear material

InactiveCN103613795AImprove insulation performanceImprove corrosion resistanceRubber materialWear resistant

The invention discloses a white rubber oil-resistant footwear material. The material comprises following components: 100 parts of raw rubber, 1-4 parts of insoluble sulphur, 0-1 part of a promoter TS / TMTM, 0-1 part of a promoter D, 0-1.5 parts of a promoter M, 0.5-3 parts of a promoter DM, 3-7 parts of zinc oxide, 0.1-3 parts of stearic acid, 0-1.5 parts of an anti-aging agent 2246, 0.5-3 parts of an anti-aging agent SP-C, 10-30 parts of titanium dioxide, 5-50 parts of white carbon black, 0.1-4 parts of polyethylene glycol / diglycol, 0-100 parts of calcium carbonate, 0-100 parts of active calcium, 0-6 parts of a C5 / 80 resin, 1-15 parts of dioctyl phthalate, 0.1-3 parts of ultramarine and 0-0.5 part of 8818 color master batch. The material is oil-resistant, acid-resistant, alkali-resistant, cold-resistant and wear-resistant, and has good electrical insulating properties and strong corrosion resistance. The material is manufactured by using environmental-friendly rubber materials as the main raw materials. The white color of the material is simple and decent. The material is suitable for requirements of various occupation characteristics.

Owner:CHANGZHOU MEIJIA INT TRADE

9-18mm-thick polyvinyl chloride curst foamed furniture board

ActiveCN104893157AThe ratio is scientific and reasonableGuaranteed DensityPolyvinyl chlorideAzodicarbonamide

The invention discloses a 9-18mm-thick polyvinyl chloride crust foamed furniture board, belonging to the technical field of polyvinyl chloride boards. The 9-18mm-thick polyvinyl chloride crust foamed furniture board solves the problems of high production cost, low yield and poor quality in the prior art. The 9-18mm-thick polyvinyl chloride crust foamed furniture board is composed of the following raw materials in parts by weight: 60-80 parts of polyvinyl chloride SG8 resin, 50 parts of heavy calcium carbonate, 40 parts of furniture moldboard reclaimed material, 7-8 parts of foaming regulator 903, 2-3 parts of foaming regulator 902, 2.8-3.2 parts of lead salt composite stabilizer, 0.6-0.7 part of internal lubricant ZB-60, 0.35-0.4 part of polyethylene wax, 0.2-0.3 part of AP, 0.5-0.6 part of plasticizer OA3, 0.3-0.4 part of heat-release AC (azodicarbonamide) foaming agent, 1.4-1.6 parts of heat-absorption Zhongkai c-2 foaming agent, 0.07 part of blue light whitener, 0.01 part of blue ultramarine and 1 part of titanium white. The product has smoother surface than the wood board, and can be directly used or used for processing modification.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

Method for preparing ultramarine blue with coal gangue calcination

InactiveCN101318661ATake advantage ofProtect environmentPigmenting treatmentSilicon compoundsSodium BentoniteInternational market

The invention relates to a method for producing an ultramarine, in particular to a method for producing an ultramarine by calcining gangue. The method comprises the steps as follows: materials are selected and mixed, the materials comprise gangue powder, quartz powder, soda, sulfur, anhydrous sodium sulphate, charcoal, bentonite, and are ground, filled into a boiler and a furnace, calcined, taken out from the furnace, selected, preliminarily washed, ground, filtered pressing, dried, and crushed, the product obtained is measured, packed and warehoused. The method for producing the ultramarine has the beneficial effect of 1 making full use of waste gangue and protecting environment, 2 meeting the domestic market demand and participating in the international market competition, and earning foreign exchange by export, 3 facilitating industrial restructuring and upgrading and updating of products, 4 relieving local employment pressure and promoting the development of local economy.

Owner:大同市晟威矸石有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com