High-stiffness lustered yellowing-resistance bleached shoe side rubber and preparation method thereof

A technology of resistance to yellowing and bleaching, applied in footwear, applications, clothing, etc., can solve the problems of poor pattern retention, exposed sole traces, poor flexion resistance, etc., and achieve stable molding dimensions and product appearance. Crisp, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

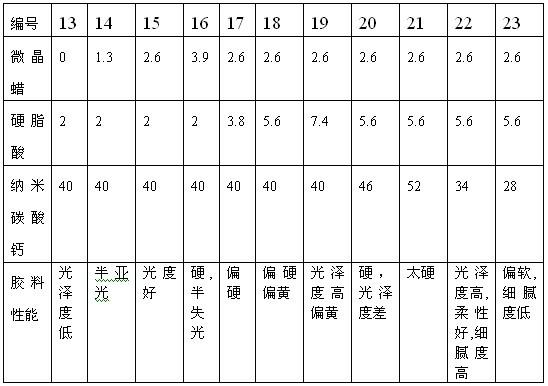

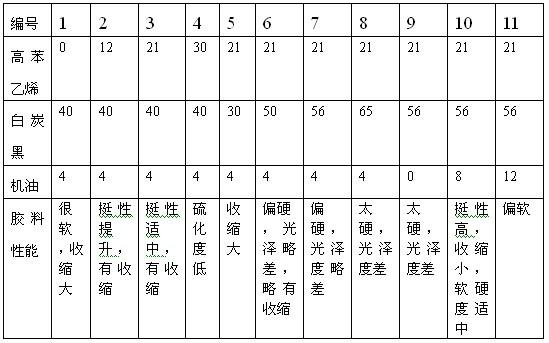

[0042]Embodiment 1 of the present invention: high stiffness gloss type anti-yellowing bleaching white shoe edge rubber, calculated in parts by weight, it includes 85 parts of 1# standard glue, 15 parts of solution polystyrene butadiene rubber 2003, 21 parts of high styrene , 2 parts of sulfur, 2.6 parts of microcrystalline wax, 2.4 parts of accelerator (accelerator consists of 0.5 parts of accelerator M and 1.9 parts of accelerator DM), 5.6 parts of tertiary stearic acid, 2.9 parts of nano-zinc oxide, 4.3 parts of poly Ethylene glycol 4000, 1.7 parts of anti-aging agent KY-405L, 1.9 parts of ultramarine blue, 56 parts of titanium dioxide, 56 parts of white carbon black, 34.6 parts of nano calcium carbonate, 0.13 parts of permanent purple masterbatch (mass percentage The mass percentage of 4% permanent violet masterbatch is calculated based on 4 parts of permanent violet mixed with 100 parts of 1# standard glue) and 8 parts of 5# white machine oil.

[0043] The preparation meth...

Embodiment 2

[0044] Embodiment 2 of the present invention: high stiffness gloss type anti-yellowing bleaching white shoe edge rubber, calculated in parts by weight, it includes 80 parts of 1# standard glue, 20 parts of solution polystyrene butadiene rubber T2003, 18 parts of high styrene , 1 part of sulfur, 2.8 parts of microcrystalline wax, 2.2 parts of accelerator (the accelerator consists of 0.4 parts of accelerator M and 1.8 parts of accelerator DM), 5 parts of tertiary stearic acid, 2.5 parts of nano-zinc oxide, 4 parts of poly Ethylene glycol 4000#, 1 part of anti-aging agent KY-405L, 1.7 parts of ultramarine blue, 53 parts of anatase titanium dioxide, 50 parts of white carbon black, 30 parts of nano-calcium carbonate, 0.1 part of permanent violet mother of 4% by mass Glue and 8 parts of 5# white machine oil.

[0045] The preparation method of high-strength gloss type anti-yellowing bleaching white shoe edge rubber is first plasticized, and the 1# standard rubber is pressed in an int...

Embodiment 3

[0046] Embodiment 3 of the present invention: high stiffness gloss type anti-yellowing bleaching white shoe edge rubber, calculated in parts by weight, it includes 90 parts of 1# standard glue, 10 parts of solution polystyrene butadiene rubber 2003, 25 parts of high styrene , 3 parts of sulfur, 2.4 parts of microcrystalline wax, 2.6 parts of accelerator (accelerator consists of 0.6 parts of accelerator M and 2.0 parts of accelerator DM), 6 parts of tertiary stearic acid, 3.4 parts of nano-zinc oxide, 5 parts of poly Ethylene glycol 4000, 2 parts of anti-aging agent KY-405L, 2.1 parts of ultramarine blue, 60 parts of anatase titanium dioxide, 60 parts of white carbon black, 40 parts of nano-calcium carbonate, 0.15 parts of 4% permanent purple masterbatch by mass And 9 parts of 5# white machine oil.

[0047] The preparation method of high-strength gloss type anti-yellowing bleaching white shoe edge rubber is first plasticized, and the 1# standard rubber is pressed in an internal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com