Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Crisp appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-stiffness lustered yellowing-resistance bleached shoe side rubber and preparation method thereof

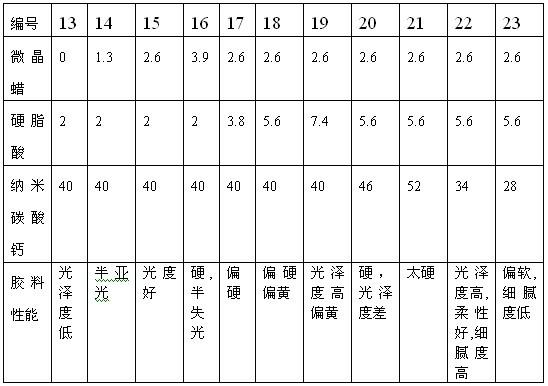

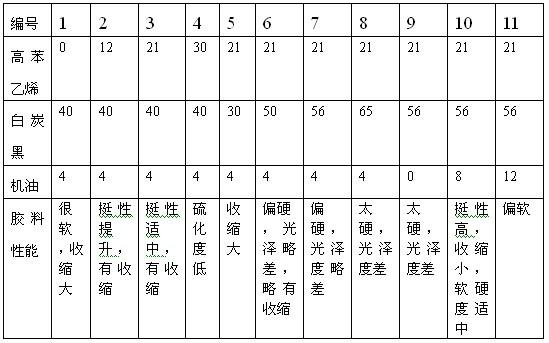

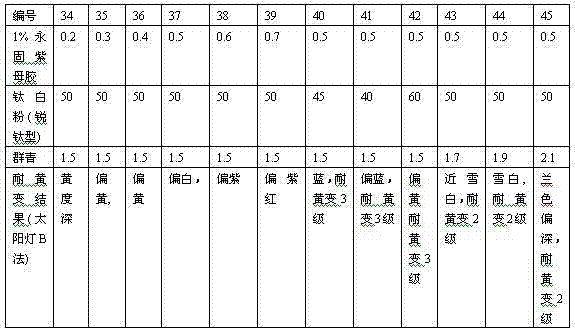

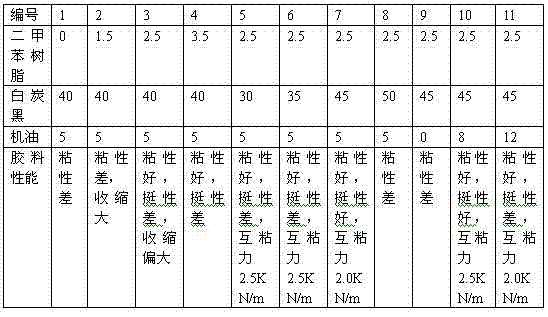

The invention discloses high-stiffness lustered yellowing-resistance bleached shoe side rubber, which comprises 80 to 90 weight parts of No.1 standard rubber, 10 to 20 weight parts of solution polymerized butadiene styrene rubber 2003, 18 to 25 weight parts of high styrene, 1 to 3 weight parts of sulfur, 2.4 to 2.8 weight parts of microcrystalline wax, 2.2 to 2.6 weight parts of promoter, 5 to 6 weight parts of stearic acid, 2.5 to 3.4 weight parts of nano zinc oxide, 4 to 5 parts of polyethylene glycol 4000, 1 to 2 weight parts of antiaging agent, 1.7 to 2.1 weight parts of ultramarine, 53 to 60 weight parts of titanium white, 50 to 60 weigh parts of white carbon black, 30 to 40 weight parts of nano calcium carbonate, 0.1 to 0.15 weight part of 4-percent pigment permanent violet and 7 to 9 weight parts of white engine oil. In the invention, the formula and preparation method of the product are improved, and shoe side rubber, which has high rubber stiffness and luster and is yellowing-resistance and as white as snow, can be obtained by screening.

Owner:JIHUA 3537 SHOE MAKING

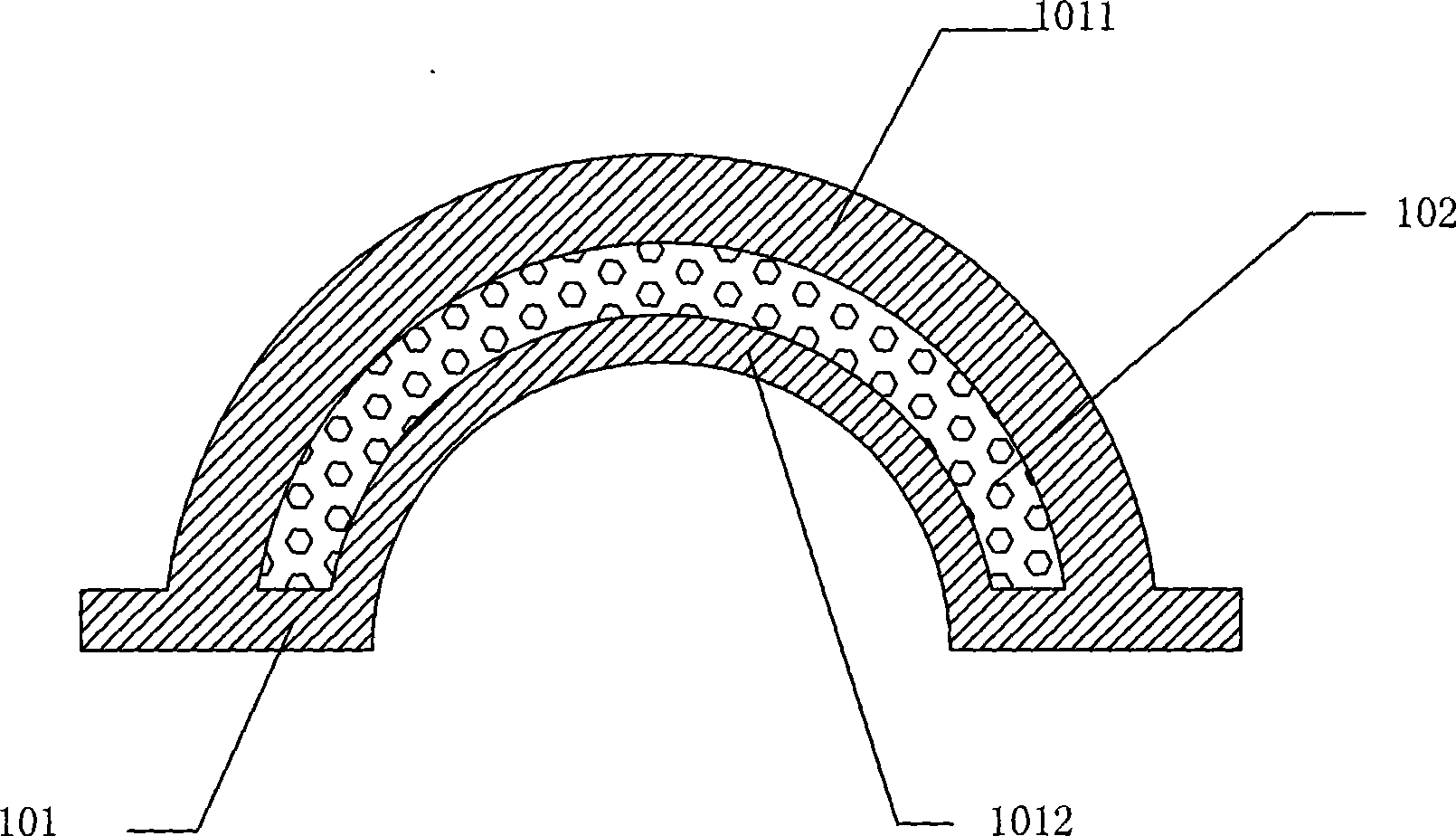

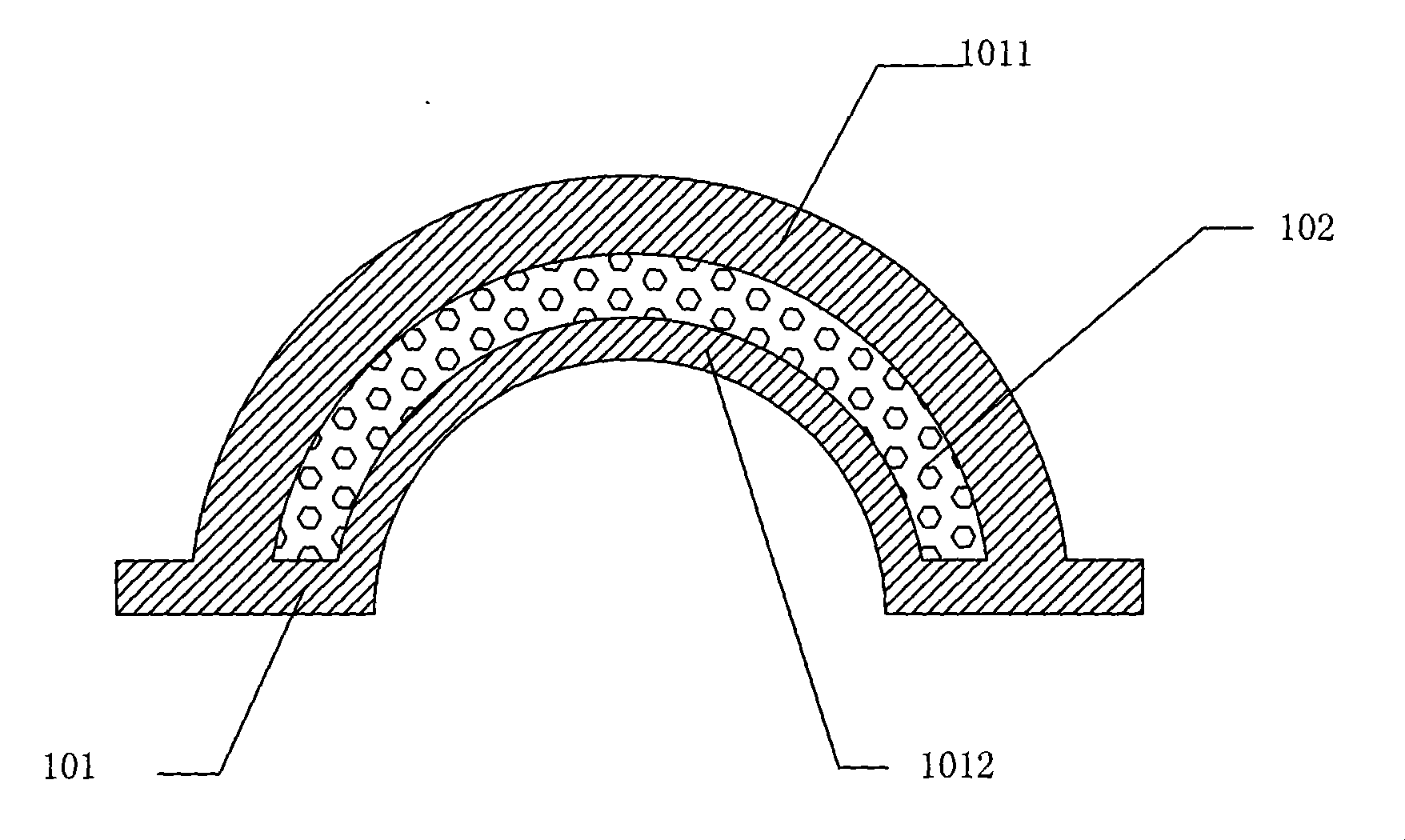

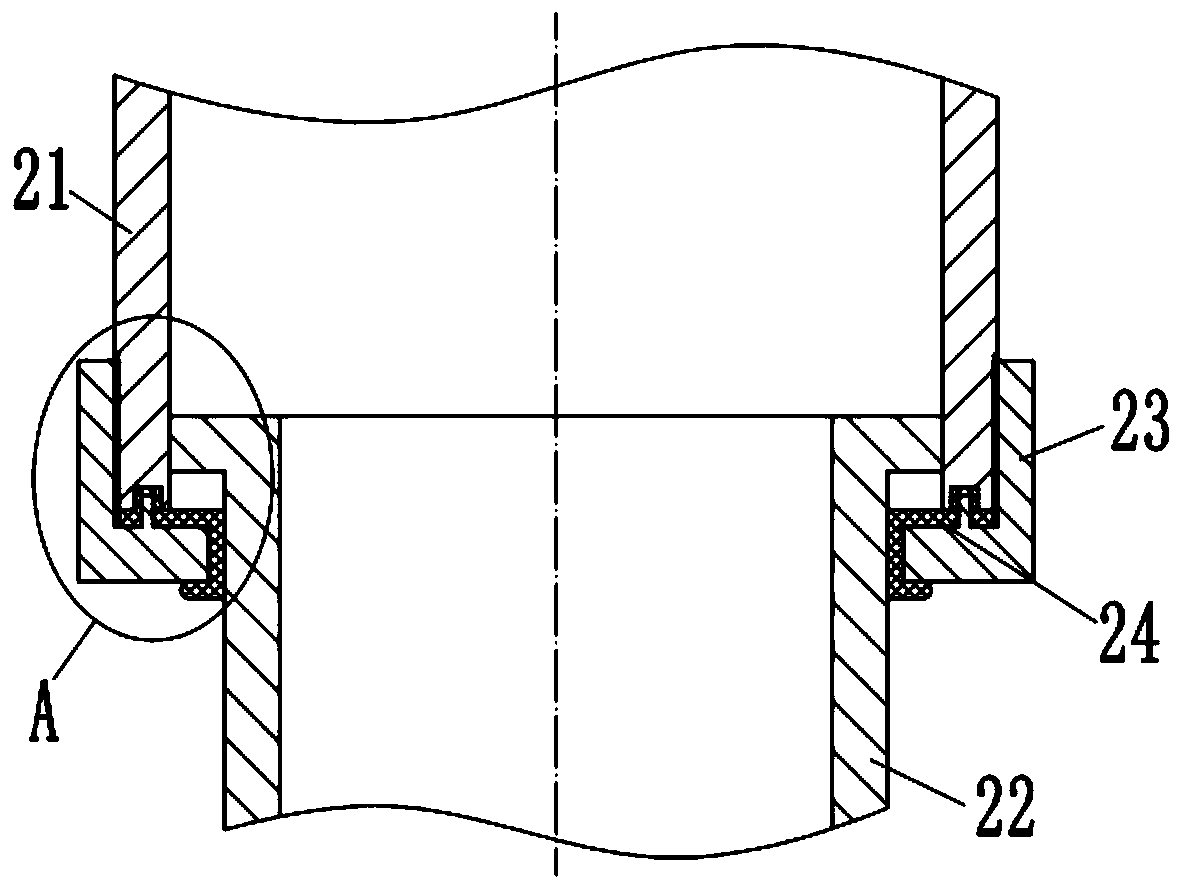

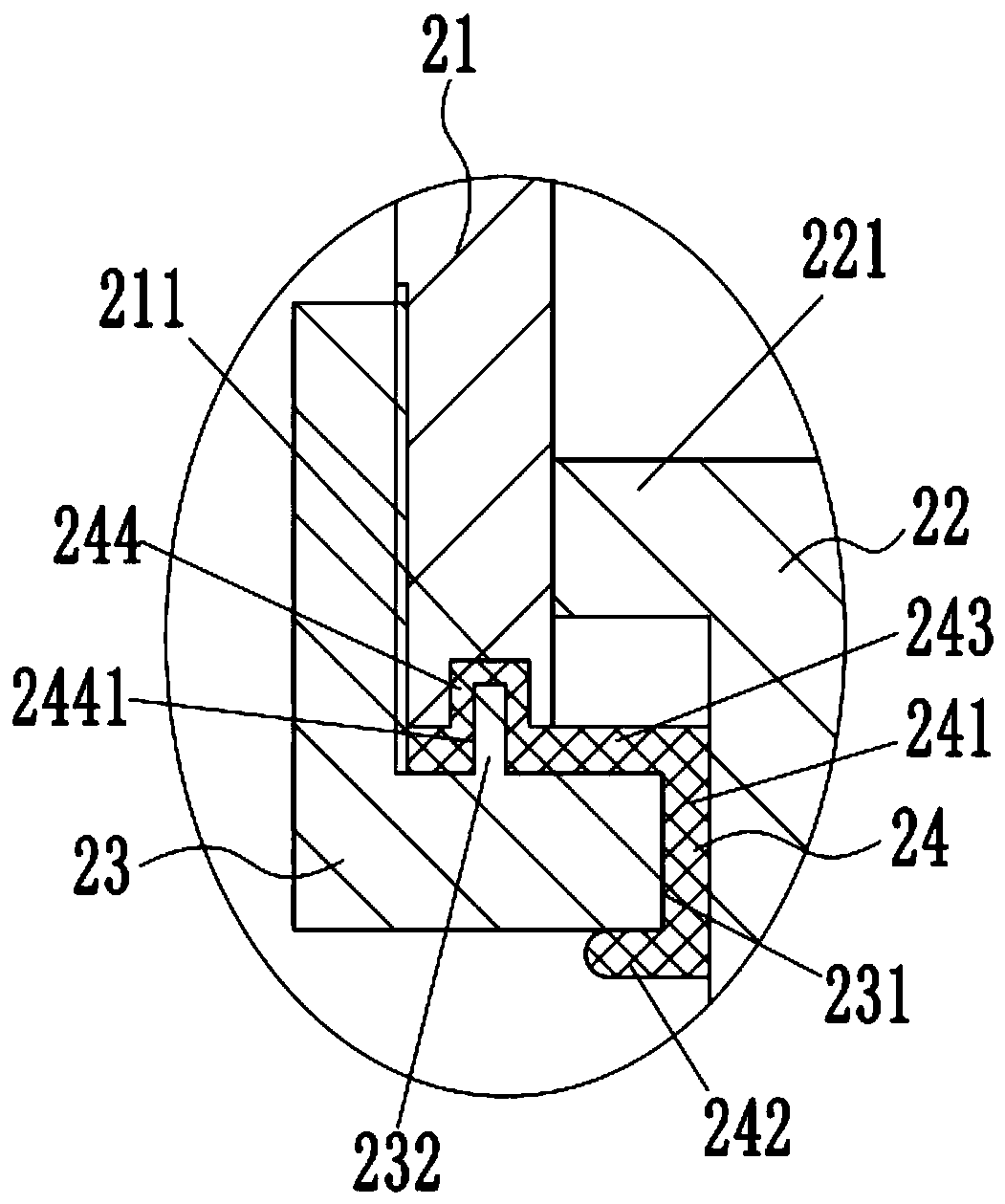

Helmet manufacture method and products thereof

InactiveCN101417489AAppearance crispImprove waterproof performanceLayered productsHelmetsCheck valveGas bubble

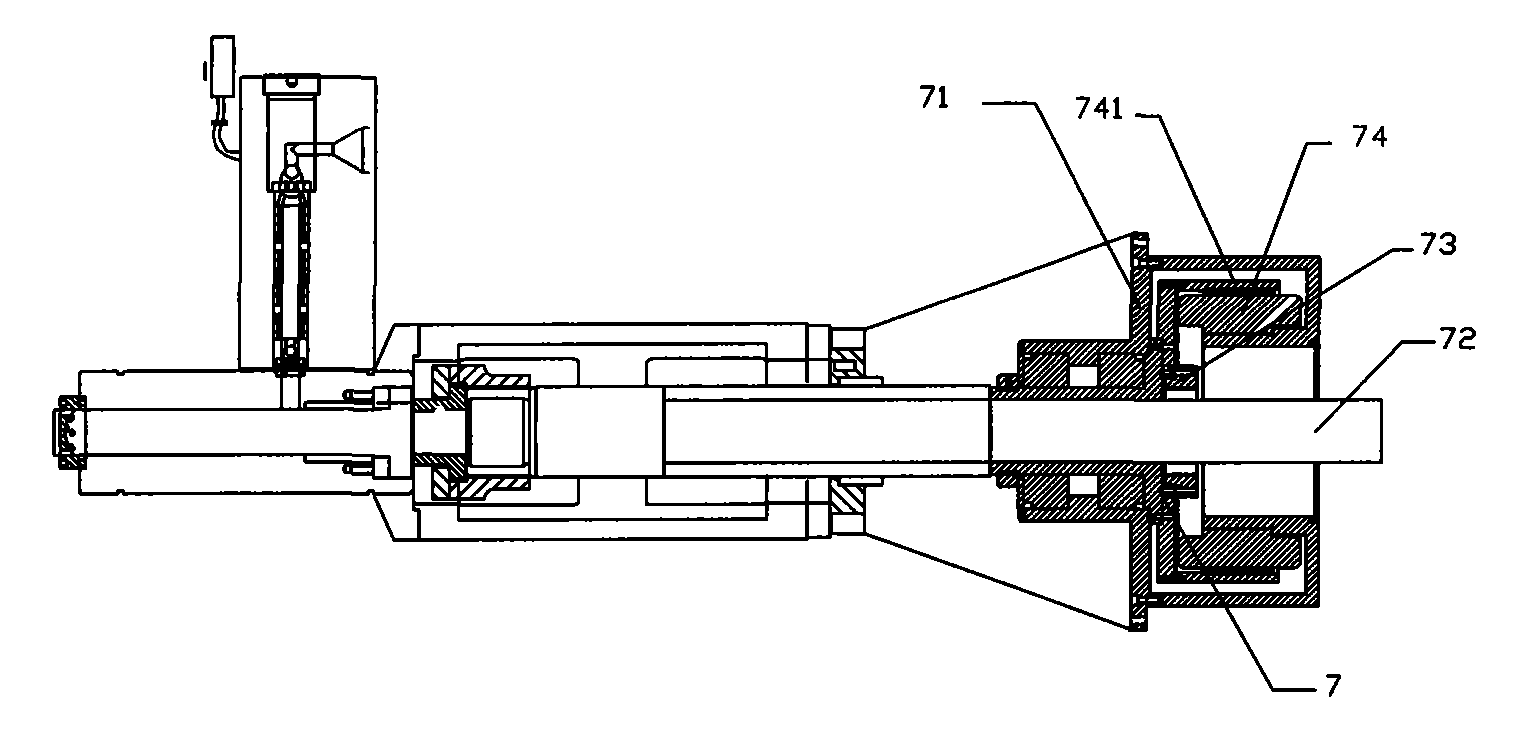

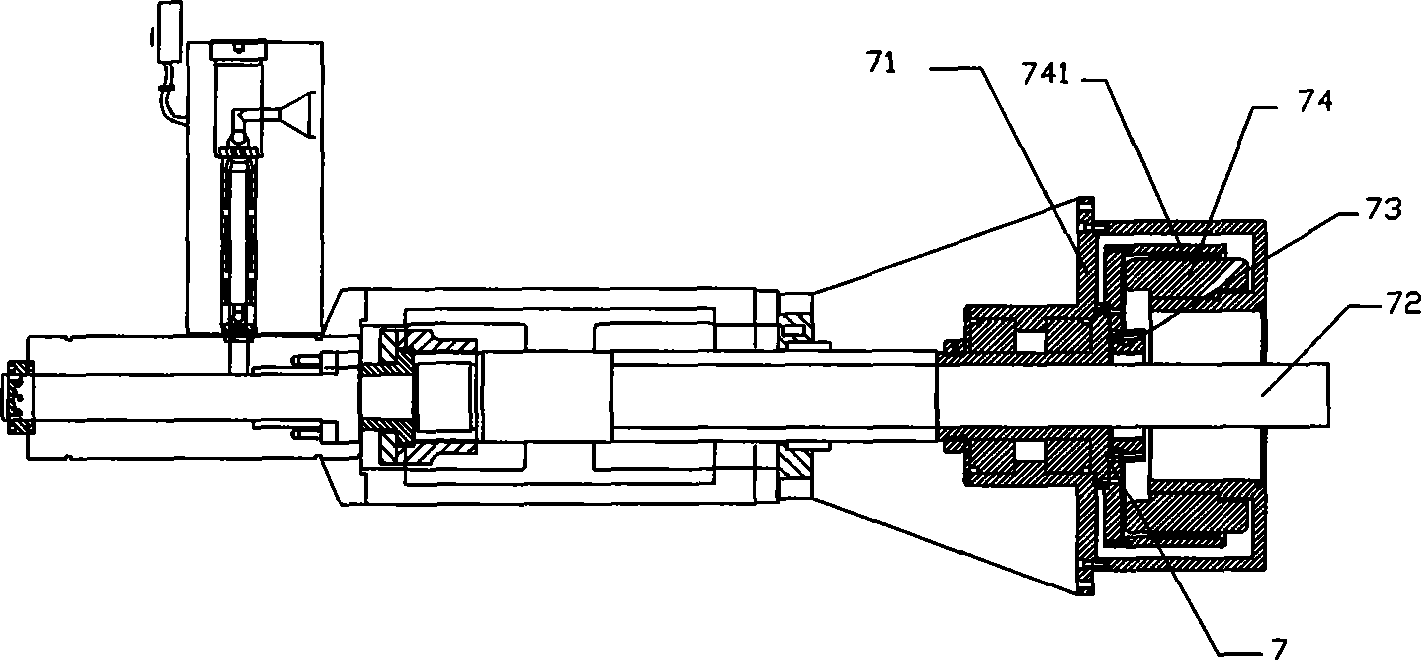

The invention relates to a manufacturing method of a helmet, comprising the following steps: manufacturing an injection mold of a plastic helmet; manufacturing mixed foamed plastic liquid, leading the liquid into a first storage machine barrel, extruding the liquid out of the first storage machine barrel, then leading the liquid into an injection machine barrel by a first check valve, simultaneously feeding materials into the first storage machine barrel by a feeding machine barrel, pressurizing the injection machine barrel, carrying injection until the mold is molded, firstly cooling the surface of the plastic liquid, measuring the current amount of injection of the injection machine barrel and the current output speed of the feeding machine barrel, adjusting the output speed of the feeding machine barrel, adjusting the rotating speed of a screw of the feeding machine barrel so as to control the feeding speed of the plastics and simultaneously adjusting the admission speed so as to match the feeding speed of the plastics. The product obtained according to the method comprises a lining which is coated by an outer layer; the helmet product obtained according to the method comprises the outer layer which does not contain bubbles or contains few bubbles and an inner core containing bubbles; and the inner core is coated by the outer layer.

Owner:UNION PLASTIC HANGZHOU MACHINERY

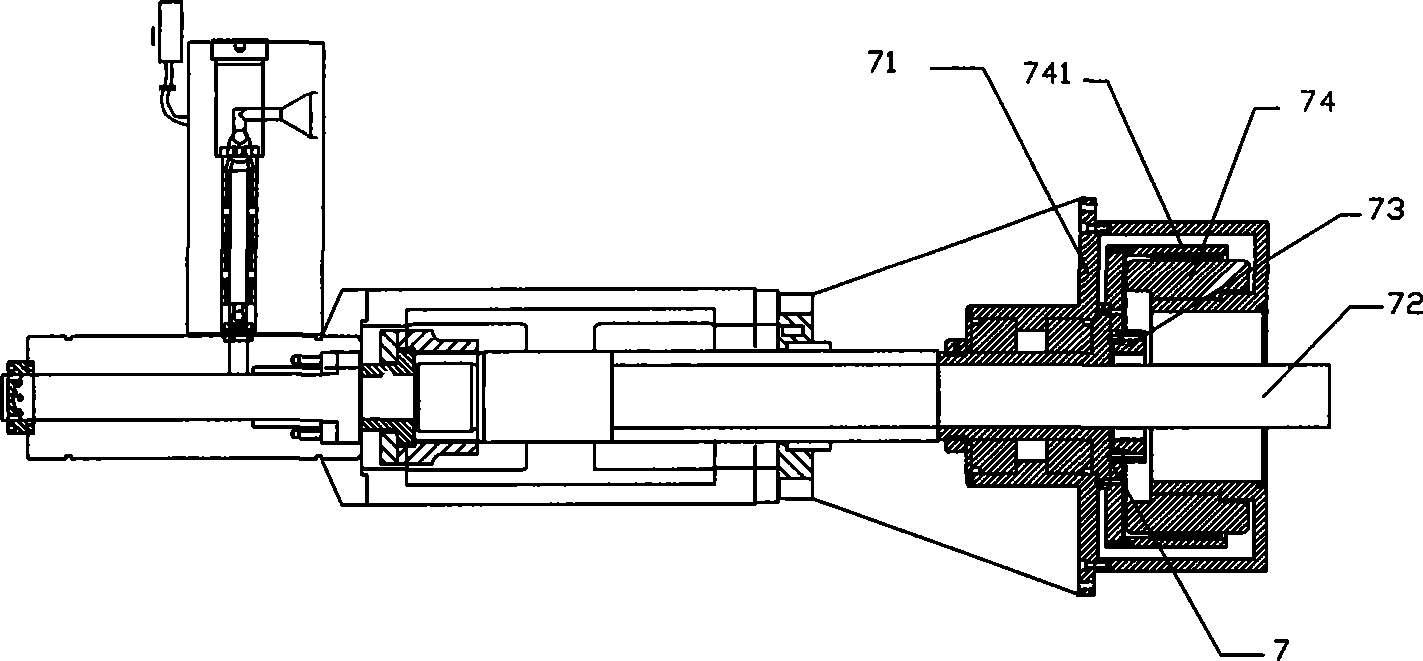

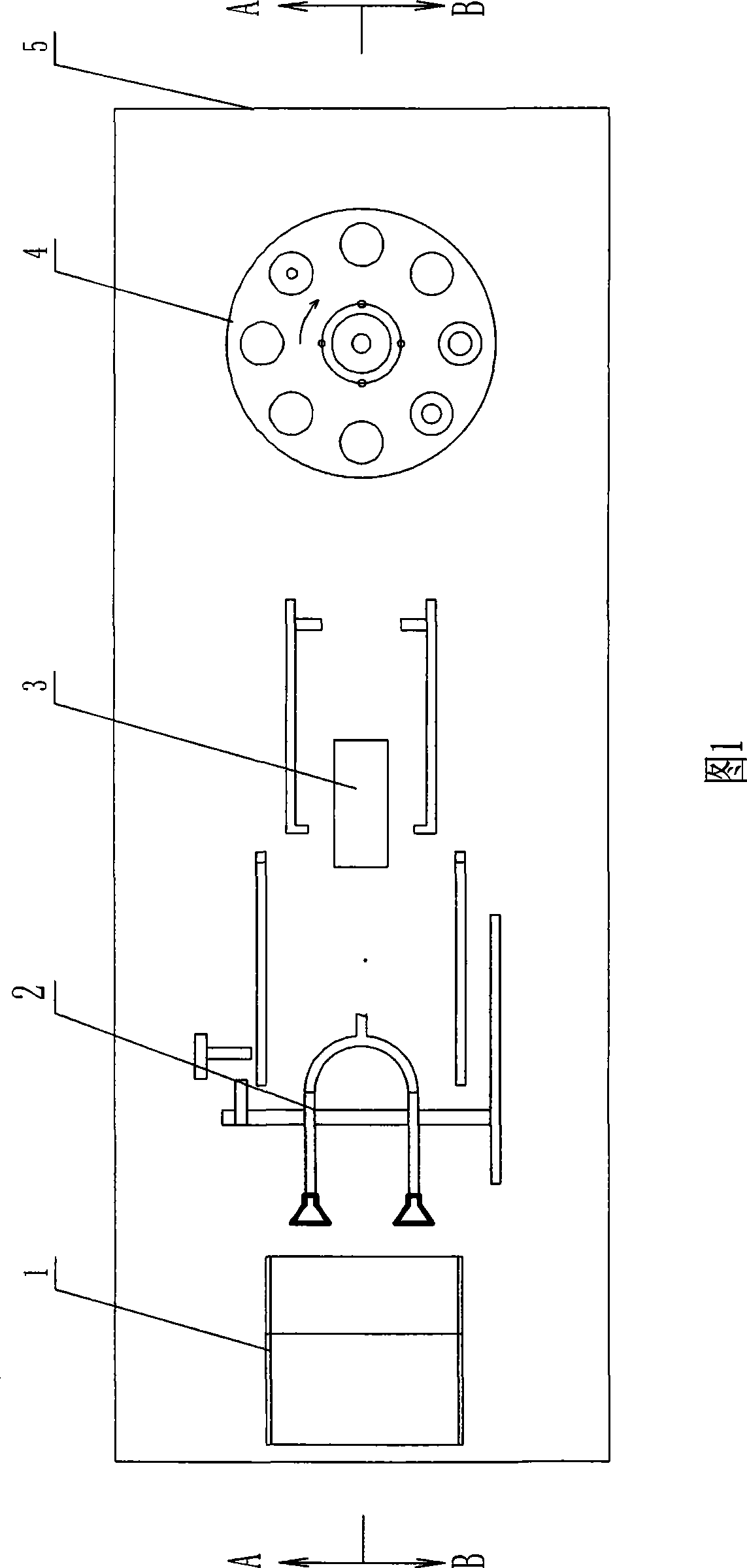

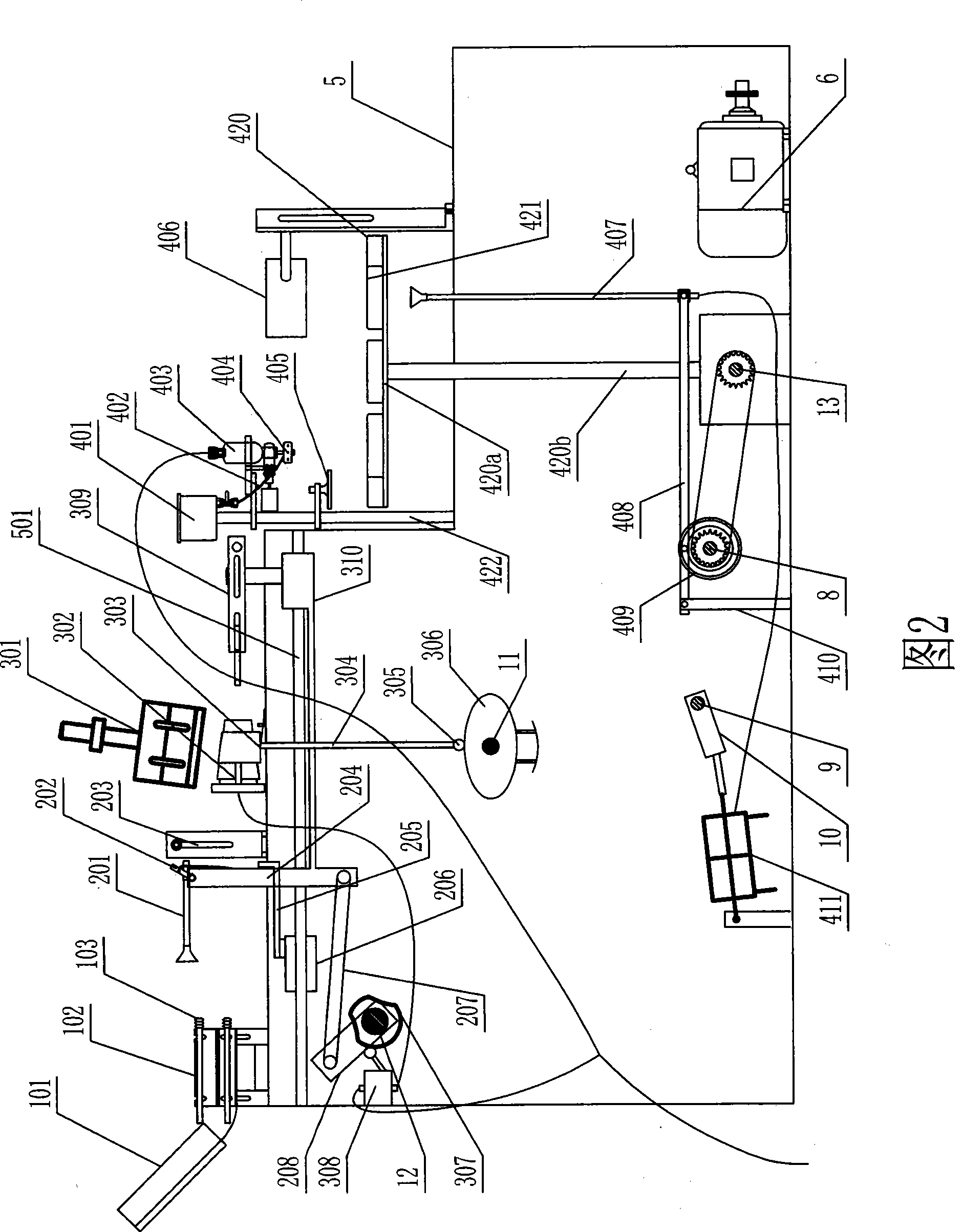

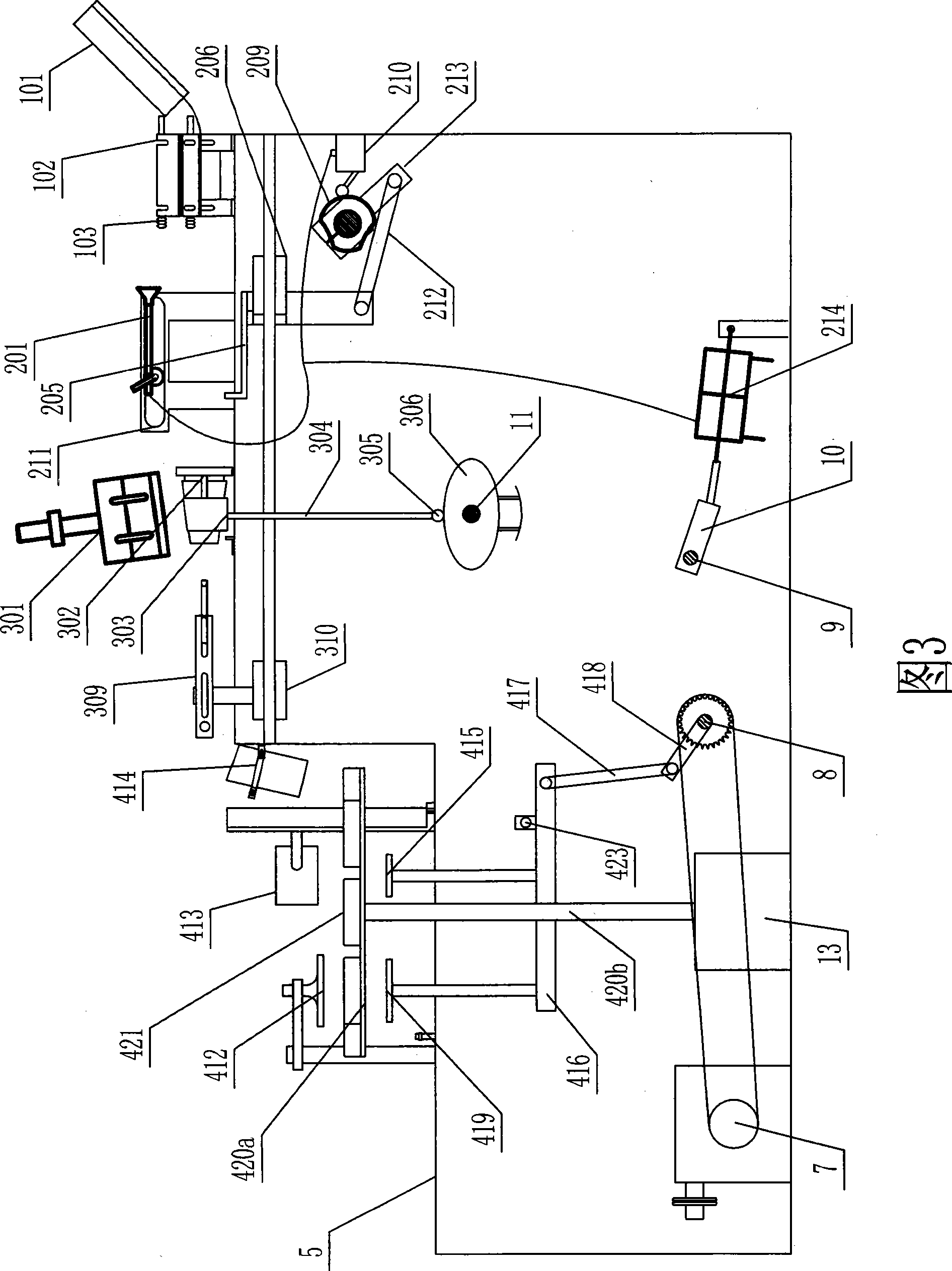

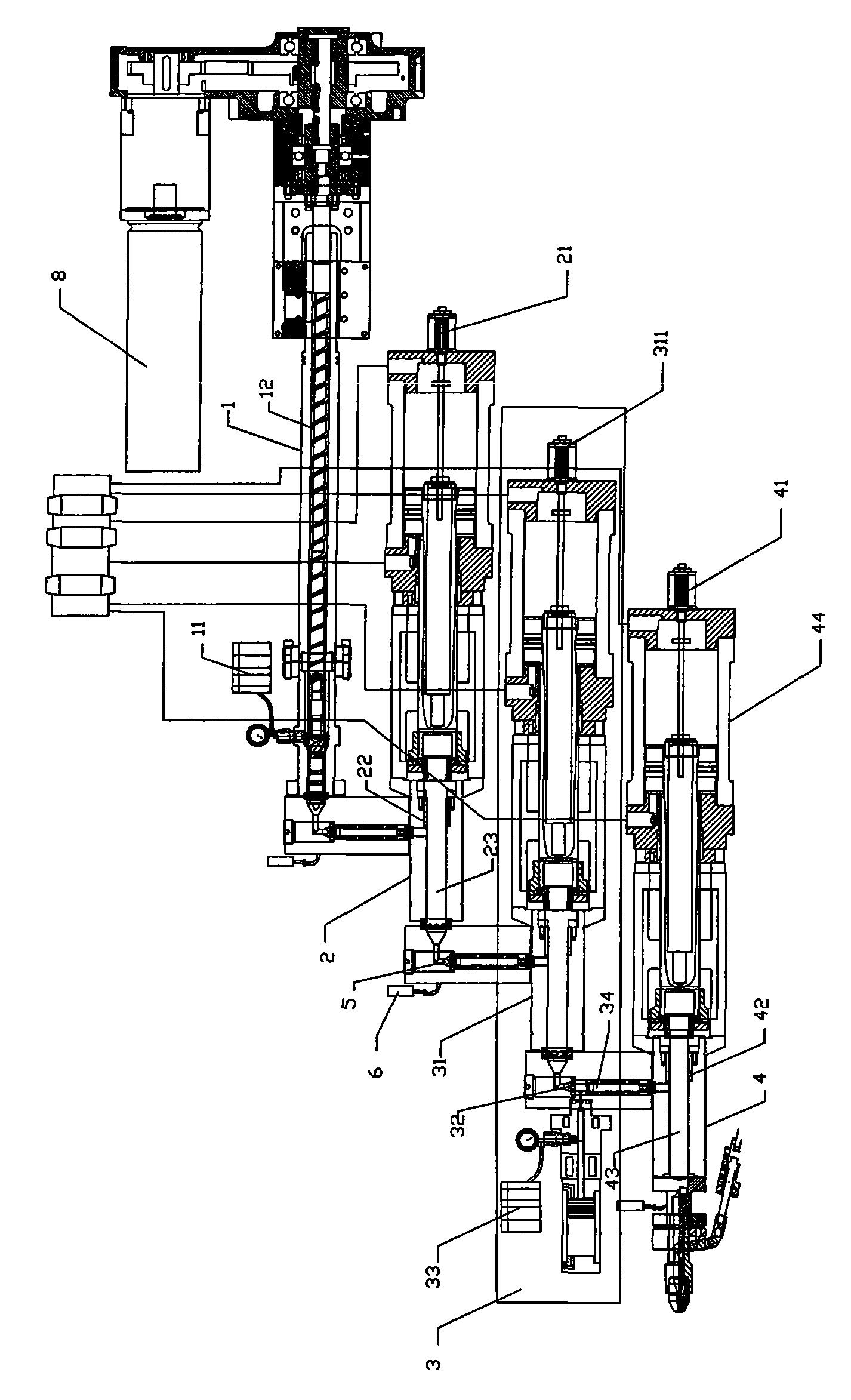

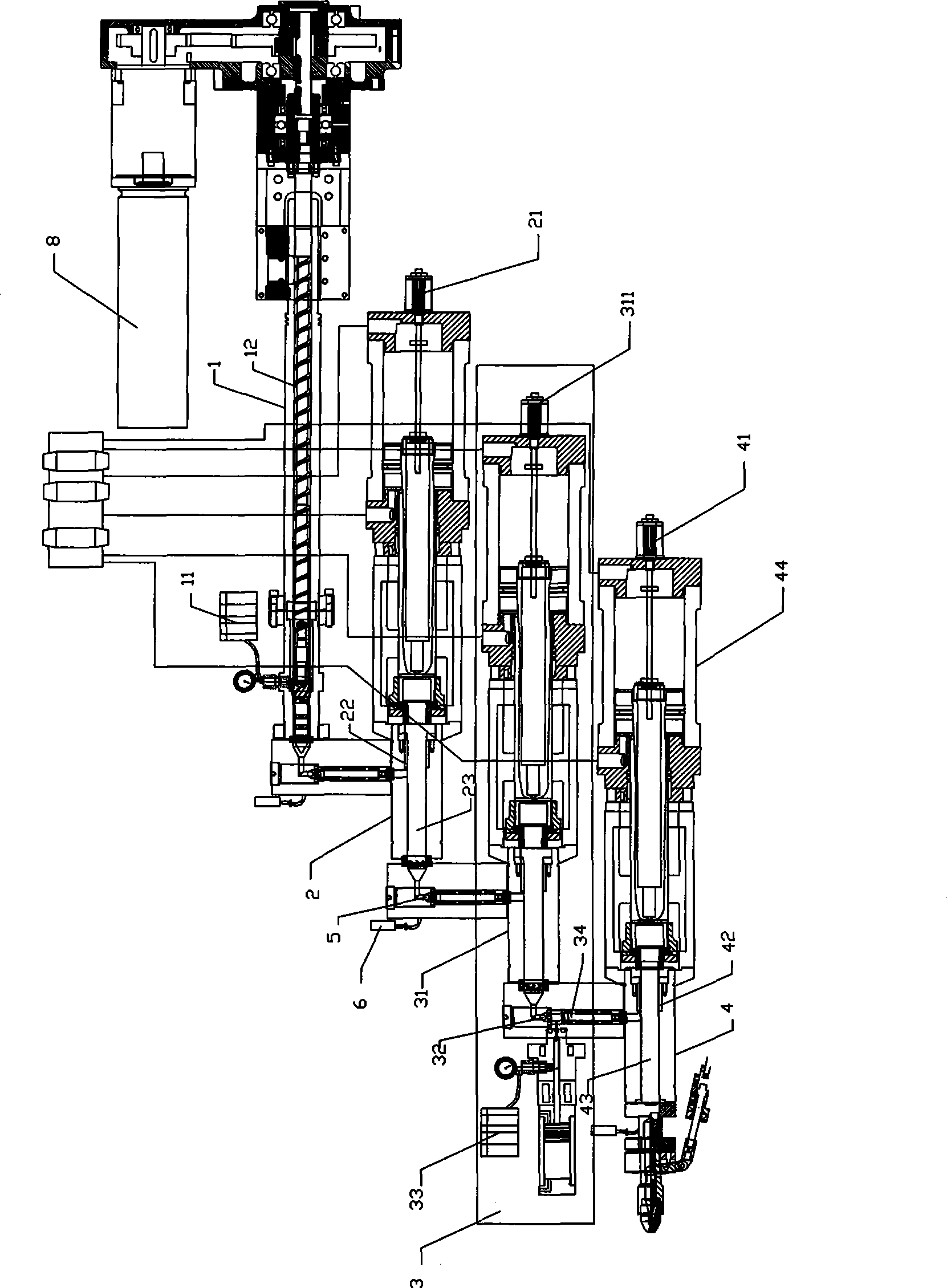

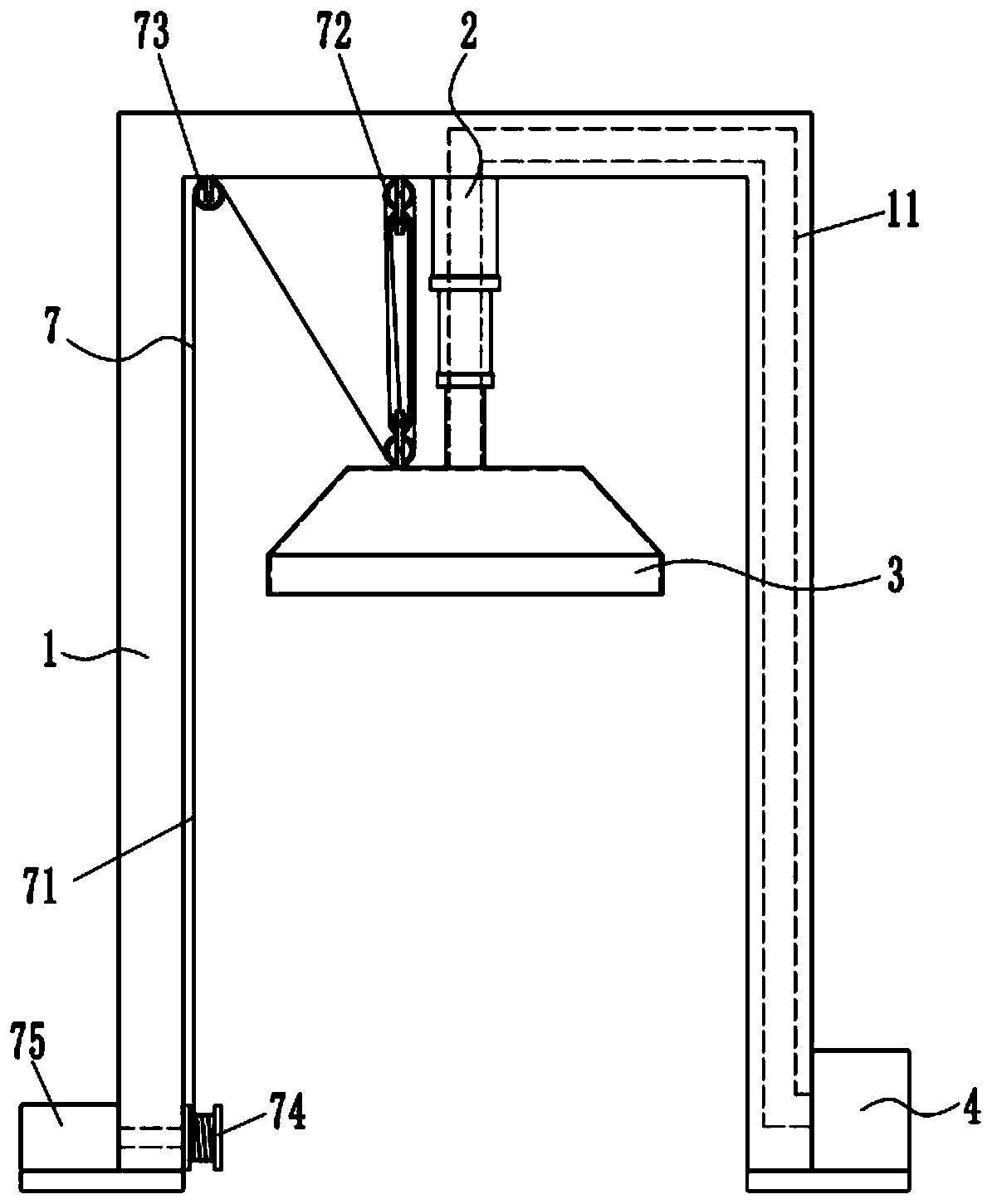

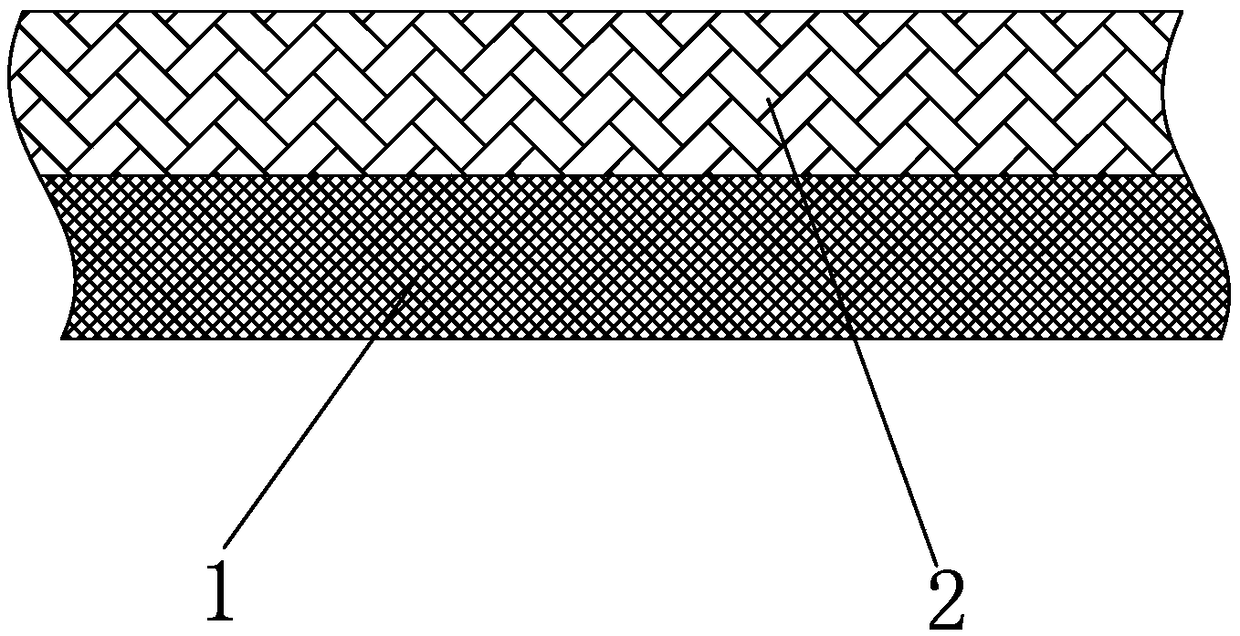

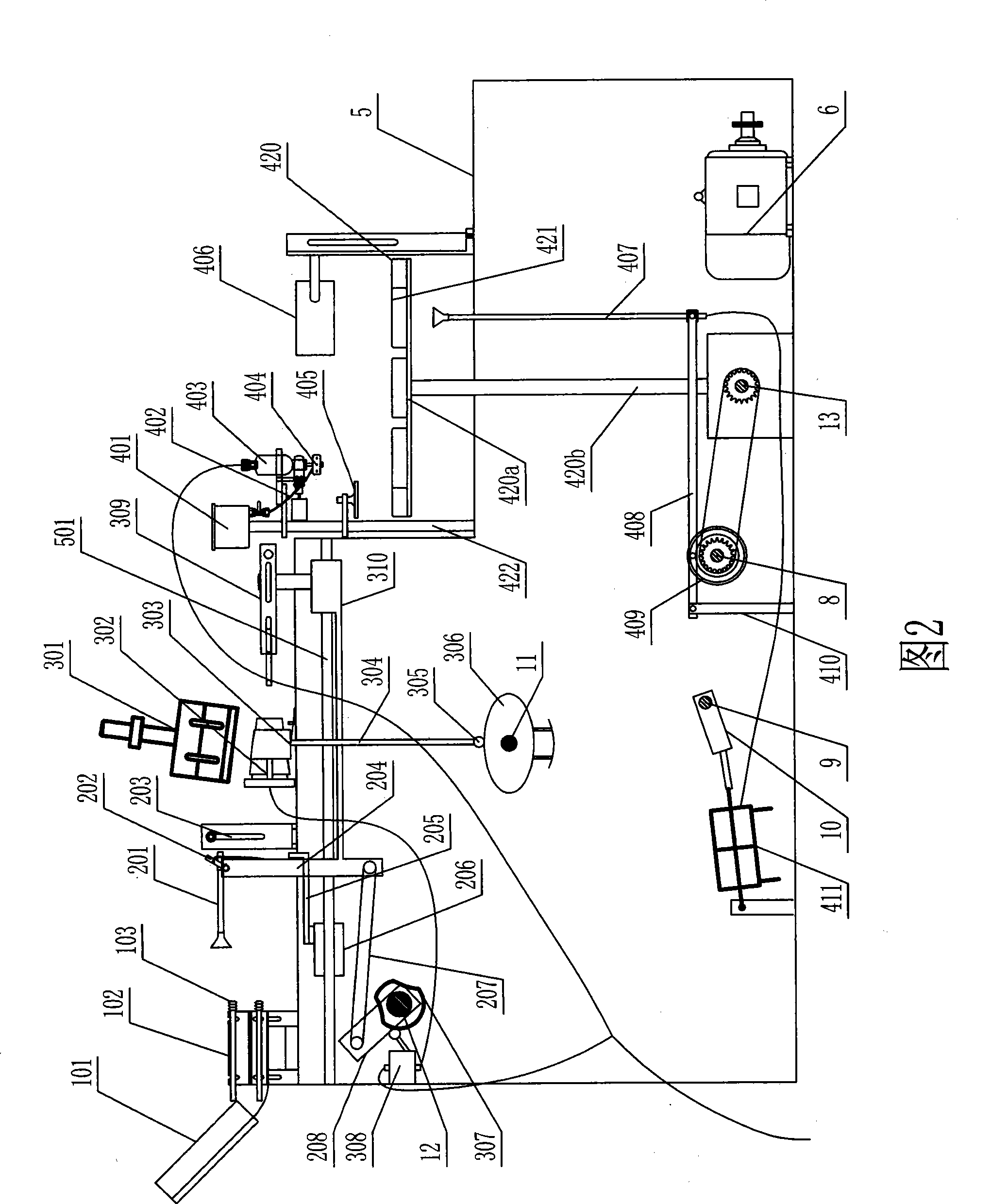

Composite paper-cup forming machine with corrugated coat

The invention provides a corrugated sleeve composite paper cup forming machine, belonging to the technical field of disposable paper cup production equipment. The paper cup forming machine is characterized in that two sides of a frame are respectively provided with a paper storage mechanism and a sleeve composite mechanism; the right side of the paper storage mechanism is sequentially matched with a paper feeding mechanism and an ultrasonic cup sleeve forming mechanism; a frame is internally matched with a composite driving shaft, an ejector package set driving shaft, a cylinder driving shaft and a paper feeding driving shaft which are matched with an output shaft of the motor in a transmission way; the paper feeding mechanism is connected with the paper suction cylinder passage and connected with the paper feeding driving shaft in a transmission way; the ultrasonic cup set forming machine is connected with the air passage of a compressed air storage tank, and matched with the ejector package set driving shaft in a transmission way; the sleeve composite mechanism is connected with the air passage of a suction internal cup cylinder and matched with the composite driving shaft in a transmission way; and the paper suction cylinder and the suction internal cup cylinder are respectively connected with the cylinder driving shaft in a transmission way. The proposal of the paper cup forming machine can completely replace the traditional manual forming mode of the corrugated sleeve composite paper cup, leads the appearance to be stiff and beautiful, improves the production efficiency, reduces the preparation cost, and is applicable for production in batch and in scale.

Owner:张鹏伟 +1

Method for coating surface cover of automobile seat

InactiveCN102452210ACrisp appearanceFull shapeLamination ancillary operationsLaminationMan-hourCar seat

The invention provides a method for coating a surface cover of an automobile seat, which comprises the steps of: spraying a hot melt adhesive by a spraying gun on the surface of polyurethane foam pad of the seat, and curing for 30-60s at normal temperature; coating the surface cover on the polyurethane foam pad with a cured adhesive layer and reshaping; melting the cured adhesive layer again by high temperature steam; and cooling and forming. The method provided by the invention is simple to operate, and saves the man hour. The surface cover is stiff and smooth in shape and full without drapes and is more suitable for production of seat which has complicated appearance, thereby greatly enhancing the decorative effect of the seat.

Owner:BAODING YANFENG JOHNSON CONTROLS SEATING

White edge strip and production method thereof

The invention provides a white edge strip comprising the following raw materials in parts by weight: 90-110 parts of 1# glue, 3-5 parts of zinc oxide, 1.1-1.9 parts of stearic acid, 2.5-3.5 parts of diethylene glycol, 2-3 parts of a yellowing-resistant accelerant, 1.1-1.8 parts of an anti-aging agent RDZ, 1.7-2.3 parts of a thermal antioxidant, 2.6-3.4 parts of a brightener, 1.7-2.3 parts of sulphur, 78-88 parts of superfine calcium carbonate, 35-45 parts of titanium dioxide, 0.35-0.48 part of ultramarine blue, 0.45-0.58 part of permanent violet masterbatch and 28-38 parts of white carbon black. The white edge strip has the advantage of good yellowing resistance. The invention also provides a production method of the white edge strip.

Owner:河南荣光鞋业有限公司

Novel formaldehyde-free crease-resist finishing agent and finishing process thereof

InactiveCN105484027AImprove wrinkle resistanceImprove wash resistanceFibre treatmentIsooctyl acrylateResist

The invention discloses a novel formaldehyde-free crease-resist finishing agent. The novel formaldehyde-free crease-resist finishing agent is prepared from acryloyl succinic acid monomers, iso-octyl acrylate, styrene, methyl methacrylate, high-density polyethylene wax emulsion, dimethyl silicone oil, a non-phosphorus catalyst, N-beta-aminoethyl-gamma-aminopropyl methyl dimethoxy silane, etherified dihydroxyl ethylene urea, chitosan, polyethylene glycol and itaconic acid. The invention provides a formaldehyde-free phosphorus-free crease-resist finishing agent for a cotton fabric and a finishing method of the finishing agent. The problems that a traditional unsaturated carboxylic acid finishing agent is prone to yellowing, low in power, poor in polymerization effect and the like are solved, damage of phosphorus-containing wastewater to the environment can further be reduced, environment protection and industrial production are facilitated, and after crease-resist and durable pressing finishing is conducted, a treated fabric has good crease resistance, shape memorizing property and washing fastness.

Owner:湖州市千金丝织厂(普通合伙)

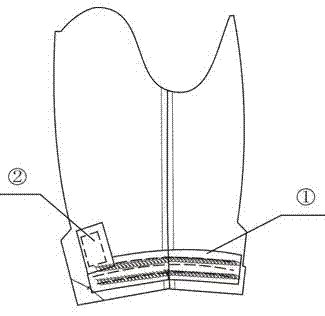

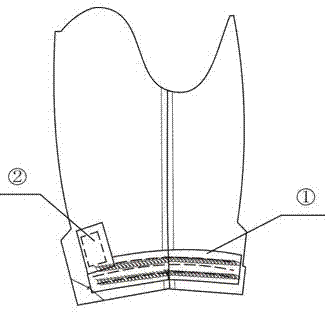

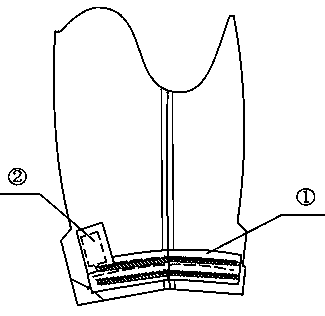

Processing method of suit cuff

The invention discloses a processing method of a suit cuff, which comprises the following steps: (1) tailoring a cuff lining and a mock button hole lining according to the garment size design and adopting a positive bias hair interlining strip with the width of 5-7cm; (2) setting the cuff lining to be 1-2cm from the cuff, 0.2-0.3cm from a sleeve under facing and 0.3-0.4cm from a beveling point of a sleeve facing and cutting an opening of 1.5-2.5cm at an inseam of a sleeve; designing the mock button hole lining to be 1cm from the upper end of a sleeve facing and be level to the front end of the cuff lining and overlap with the cuff lining for about 1-2cm; (3) spreading out the cuff lining and fixing the cuff lining by uniformly basting three circles of thread adjacent to the inseam; spreading out the mock button hole and fixing the mock button hole by basting a circle at 1cm away from a mat; (4) uniformly pry-seaming two circles of thread to fix the cuff lining and folding and ironing 4-5cm of a folding edge of the cuff; (5) joining the sleeve facing, joining external seams of the cuff and respectively ironing seam heads outside the cuff; and (6) spreading out the cuff, basting to fix the folding edge of the cuff and pry-seaming to fix the folding edge of the cuff at 0.7-1.5cm to a deckle edge. According to the processing method provided by the invention, a non-woven lining is replaced by the hair interlining strip, so that the finished cuff of the suit has a stiff, smooth and even appearance, soft hand feel, and the product level is improved.

Owner:SHANDONG NANSHAN TEXTILE GARMENT

Coloured lining cloth capable of transmitting anions

The invention discloses a color padding cloth capable of emitting negative ions, which adopts a coated fabric with the function of emitting negative ions. The coated fabric comprises mixed colloid through optimized combination, and is able to ensure that the emission density of the negative ions can meet the demands of the color padding cloth. The fabric uses the super fine denier color filaments, so as to ensure the bright color and obviate the need for dyeing treatment. The color padding cloth capable of emitting negative ions has the advantages that: a jacket or other coats lined with the healthy lining, when worn by a consumer, can not only play a role in invigorating and refreshing the wearer, but also can help to absorb a great amount of toxic substances in the public places with dirty air. Moreover, the clothes made of the padding cloth can easily restore to the original shape after washing, and thus substantially doing good to the healthcare of the wearer.

Owner:SHENGHONG GRP CO LTD

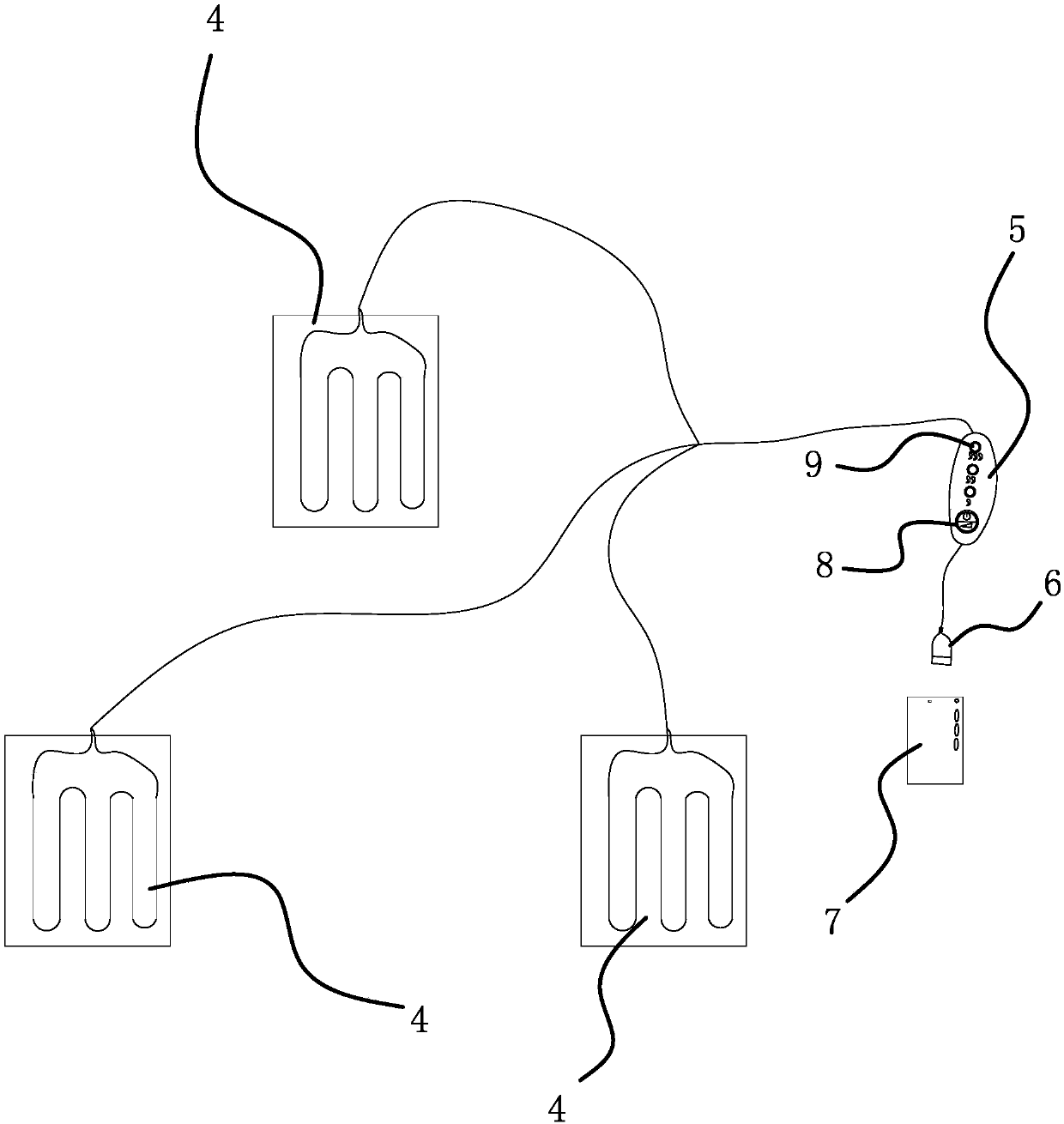

Preparing method of compact comfortable stiff and smooth type knitting fabric

ActiveCN107287746AIncrease elasticityImprove wearing comfortWeft knittingSingeingPolyesterMechanical engineering

The invention provides a preparing method of a compact comfortable stiff and smooth type knitting fabric and relates to the knitting fabric. The method comprises the steps that step A, polyester cotton, regenerated cellulose fiber and spandex are selected and interwoven through a knitting machine, so that a fabric grey cloth is formed, the spandex is located on the front surface of the fabric grey cloth, wherein an odd number needle is formed into a loop through nine weaving structures which are floating threads, floating threads, loop formation, floating threads, loop formation, floating threads, loop formation, floating threads and floating threads, and an even number needle is formed into a loop through nine weaving structures which are loop formation, loop formation, loop formation, loop formation, loop formation, loop formation, loop formation, loop formation and loop formation; step B, the fabric grey cloth is subjected to pre-shaping; step C, the fabric grey cloth is dyed; step D, the fabric grey cloth is subjected to shaping again, and after shaping is completed, the compact comfortable stiff and smooth type knitting fabric is obtained. The compact comfortable stiff and smooth type knitting fabric has the double advantages of good elasticity and good wearing comfort of the knitting fabric and stiff and smooth appearance and good ductility of the woven fabric.

Owner:NINGBO DAQIAN TEXTILE

Multi-fiber composite wear-resistant anti-microbial woven fabric and manufacturing method for same

InactiveCN105155092AImprove spinnabilityImprove spinning qualityConjugated cellulose/protein artificial filamentsWoven fabricsFiberWear resistant

The invention discloses a multi-fiber composite wear-resistant anti-microbial woven fabric. The multi-fiber composite wear-resistant anti-microbial woven fabric is composed of warp yarns and weft yarns which are woven by an air-jet loom. The raw materials of the warp yarns and the weft yarns are made from the following components, by weight, 30 to 33 parts of polypropylene, 20 to 25 parts of down feather, 23 to 26 parts of terylene, 24 to 28 parts of chicken feather, 16 to 19 parts of shengma fiber, 13 to 17 parts of acetate rayon, 2 to 4 parts of bentonite, 0.3 to 0.5 part of zinc oxide, 0.7 to 0.9 part of nanometer zirconia powder, 3 to 6 parts of mercaptoacetic acid, 7 to 10 parts of n-Propyl acrylate, 6 to 9 parts of dipropylene glycol dibenzoate, 3 to 5 parts of ginger, 2 to 4 parts of burdock, 85 to 95 parts of 1-butyl-3-methylimidazolium acetate, 90 to 110 parts of 1- allyl-3-methylimidazolium bromide, a proper amount of water, and 5 to 8 parts of auxiliary agent. The multi-fiber composite wear-resistant anti-microbial woven fabric can be used for automotive trims, and is stiff and smooth in appearance and fashionable.

Owner:安徽省中日农业环保科技有限公司

Antistatic woven fabric and preparation method thereof

InactiveCN105113092ACrisp appearanceImprove thermal stabilityDyeing processWoven fabricsPolyesterYarn

The invention discloses antistatic woven fabric and a preparation method thereof. The antistatic woven fabric comprises 50-60 parts of polyester fiber polyester yarn, 10-15 parts of wool, 10-15 parts of cashmere, 5-8 parts of cotton, 3-5 parts of mucilage glue and 0.5-1.5 parts of antistatic agents. The preparation method comprises the steps of loose wool dyeing, wool combining, carding, twisting, sheet weaving, after-finishing and the like. The woven fabric prepared through the blends of different proportions has the advantages of being stiff in appearance, good in heat stability, soft, free of pilling, free of static and the like, and compared with conventional multifunctional finished fabric, the production and aftertreatment process is greatly simplified, and production efficiency is improved.

Owner:SUZHOU SHUNTANG CHEM FIBER

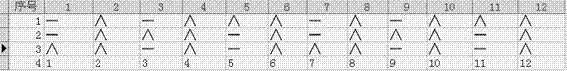

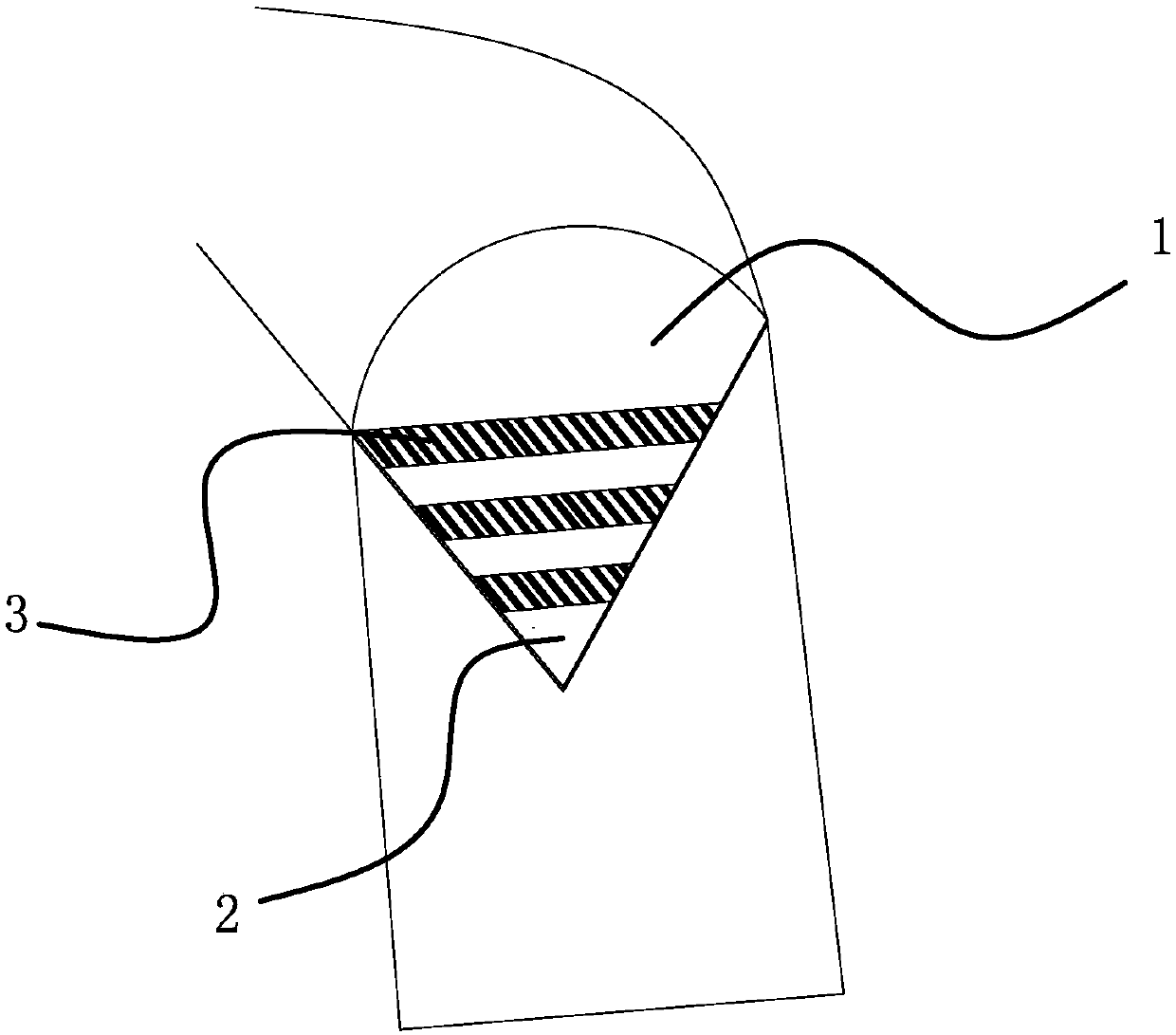

Carbon fiber heating fur clothes

InactiveCN107647496AImprove plasticityAppearance straightGarment special featuresProtective garmentFiberUSB

The invention provides carbon fiber heating fur clothes. The carbon fiber heating fur clothes comprise a fur clothes body, a fur clothes pocket and a fur clothes shoulder, the fur clothes shoulder isprovided with three pieces of fur material and three pieces of carbon fiber composite cloth, carbon fiber fabric is located on the inner side of the fur clothes, a triangular hole is formed in the outer part of the fur clothes shoulder, the carbon fiber composite cloth is rectangular, the two ends of the carbon fiber composite cloth are in sewing connection with the edges of the triangular hole, the fur clothes body is composed of inner layer fabric and outer layer leather, three carbon fiber heating sheets are arranged between the inner layer fabric and the outer layer leather, correspond tothe back of the human body and the waists at the two sides respectively, and are connected to a USB plug through a wire, a controller is arranged on the wire, a charge pal is placed inside the fur pocket, and the USB plug is plugged onto the charge pal. The fur clothes body has a heating function, and the carbon fiber composite cloth is arranged at the two ends of the shoulder, so that the fur clothes looks much straighter and stiffer.

Owner:HAINING ANJIE COMPOSITE MATERIAL

Preparation method for coral velvet fabric

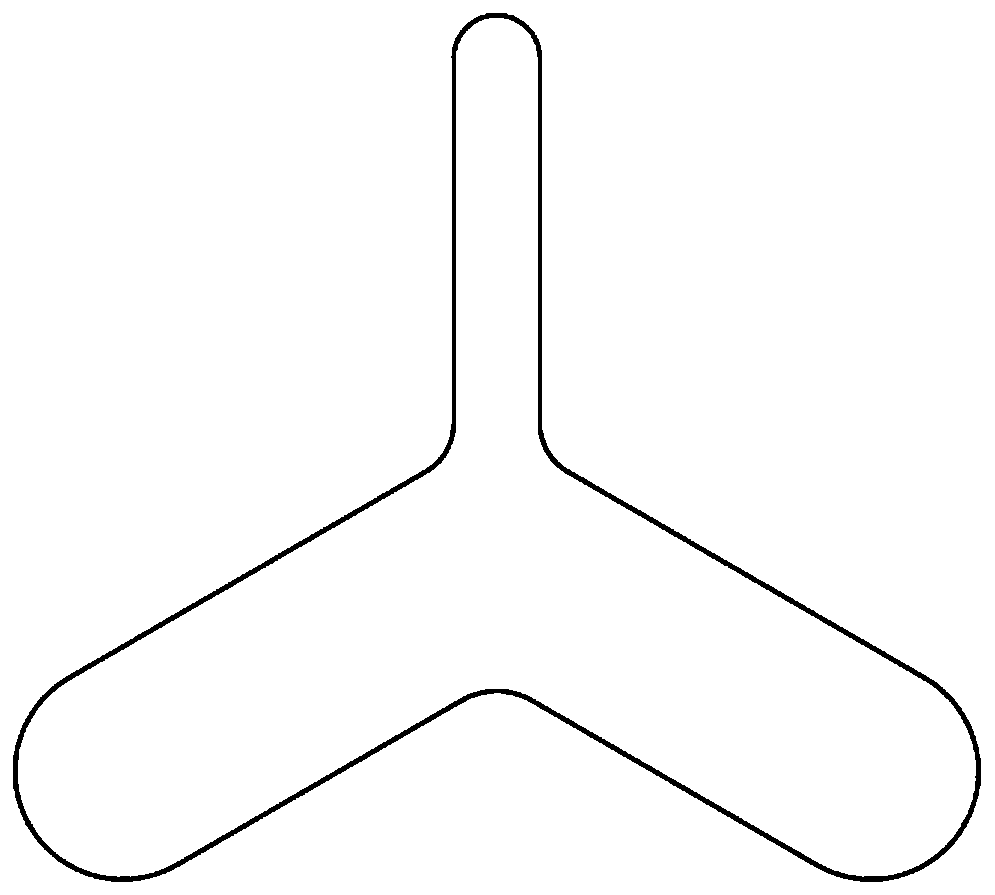

ActiveCN111118626AImprove stiffnessGood hygroscopicityFilament/thread formingHeating/cooling textile fabricsPolyesterPolymer science

The invention relates to a preparation method of a coral velvet fabric. According to the preparation method, plush grey cloth is manufactured by weaving special-shaped semi-dull polyester drawn yarn as a raw material of wool yarn and polyester FDY yarn as a raw material of ground yarn, and then the coral velvet fabric is obtained through presetting, soft finish, fluff opening, napping, after-finish and resetting, wherein the wool yarn obtained by carrying out heat treatment and twisting on the special-shaped semi-dull polyester drawn yarn; a preparation process for the special-shaped semi-dullpolyester drawn yarn comprises the following steps of cooling through ring blowing after a PET melt is extruded from trilobal spinneret holes in a spinneret plate, and preparing the special-shaped semi-dull polyester drawn yarn according to an FDY process, wherein three leaves of each trilobal spinneret hole have the same length and different widths, the trilobal spinneret holes are distributed in a concentric circle, the center line of the narrowest leaf passes through the center of the circle and the pointing is away from the center of the circle. The preparation method disclosed by the invention is easy to operate, fluff of the prepared coral velvet fabric is fluffy, full, soft in hand feeling and good in warmth retention property.

Owner:JIANGSU HENGLI CHEM FIBER

Production method of UV resistant fabric

The invention relates to a production method of a UV resistant fabric. The fabric comprises a composite yarn prepared by twisting tencel yarns and cotton yarns, wherein the weight ratio of tencel yarns to cotton yarns is 30-40:70-60. The wefts are prepared by spinning modal fiber yarns. The warps and wefts are intersected, overlapped, and woven along the longitudinal and latitudinal directions so as to form the textile fabric. A ciba dye is added into a saline solution to prepare a dye solvent. The fabric and the dye solvent are added into a dye jar to carry out dyeing. The fabric, which has been subjected to a finishing treatment, is dried at a temperature of 90 to 110 DEG C for 30 minutes so as to obtain a semi-finished fabric. A wear resistant layer is painted on the external surface of the semi-finished fabric at first, then a UV resistant coating is painted on the external surface of the wear resistant layer, and the inner surface of the fabric body is provided with a thermal insulation coating. The softness and water absorbing performance of the fabric are both improved; the soft touch feeling is enhanced; the wear resistant performance is enhanced, the UV resistant effect becomes better and lasts for a longer time, and moreover, the thermal insulation performance is strengthened.

Owner:福建金苑服饰有限公司

Preparation method of non-ironing garment material fabric stiffening agent

ActiveCN106638002AImprove stabilityImprove washing resistanceBiochemical fibre treatmentGrip property fibresEscherichia coliGlycidyl ethers

The invention discloses a preparation method of a non-ironing garment material fabric stiffening agent and belongs to the technical field of printing and dyeing auxiliaries. The preparation method comprises the steps that firstly, escherichia coli suspension liquid is injected into hungering yellow mealworm larvae to produce a large amount of antibacterial components in the larvae, then body fluid of the larvae is collected and is subjected to centrifugal separation and purification to serve an antibacterial component of the stiffening agent, the dodecyl glycidyl ether is utilize to graft modified hydrophilic carboxymethyl chitosan and make the modified hydrophilic carboxymethyl chitosan have amphiphilicity, the modified hydrophilic carboxymethyl chitosan is coated with a yellow mealworm larva extract and then is mixed with polyvinyl alcohol and the like into an uniform emulsion, and the non-ironing garment material fabric stiffening agent is prepared. The prepared non-ironing garment material fabric stiffening agent utilizes the modified carboxymethyl chitosan to form a firm three-dimensional network structure in fabric pores in the using process and can make the coated antibacterial component slowly released, and the problem that a traditional fabric stiffening agent is poor in wash resistance property and does not mildew in the storage process.

Owner:石狮市新华宝纺织科技有限公司

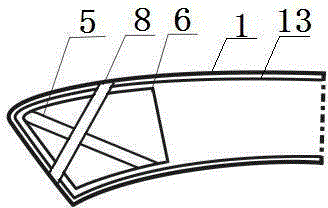

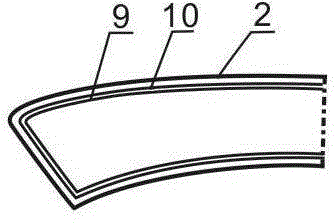

Shirt using polyester-cotton fuzzed cloth as collar lining

ActiveCN100423661CSmall warp and weft shrinkageAvoid deformationWoven fabricsShirtsPolyesterEngineering

The present invention relates to a shirt whose collar lining is made up by using polyester cotton raised lining cloth. The collar made from said polyester cotton raised lining cloth is not deformed, and its appearance is smooth and stiff. Said invention also provides the concrete characteristics and specification of said collar lining cloth.

Owner:HEILAN HOME

Helmet manufacture method and products thereof

InactiveCN101417489BCrisp appearanceImprove waterproof performanceLayered productsHelmetsCheck valveGas bubble

Owner:UNION PLASTIC HANGZHOU MACHINERY

Building board manufacture method and products thereof

The invention relates to a manufacturing method of a building board, and a product thereof. The method comprises the following steps: manufacturing an injection mold of the plastic building board, manufacturing mixed foamed plastic liquid, leading the liquid into a first storage machine barrel, extruding the liquid out of the first storage machine barrel, then leading the liquid into an injection machine barrel by a first check valve, simultaneously feeding materials into the first storage machine barrel by a feeding machine barrel, pressurizing the injection machine barrel, carrying injection until the mold is molded, firstly cooling the surface of the plastic liquid, measuring the current amount of injection of the injection machine barrel and the current output speed of the feeding machine barrel, adjusting the output speed of the feeding machine barrel, adjusting the rotating speed of a screw of the feeding machine barrel so as to control the feeding speed of the plastics and simultaneously adjusting the admission speed so as to match the feeding speed of the plastics. The building board obtained according to the method comprises an outer layer, and an inner core containing bubbles.

Owner:UNION PLASTIC HANGZHOU MACHINERY +1

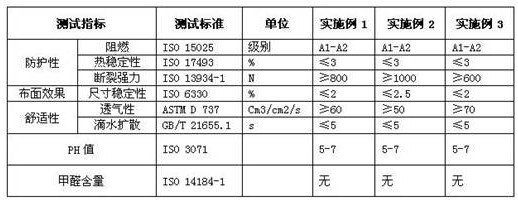

A kind of aramid fiber unidirectional moisture-wicking fabric and its preparation method

ActiveCN109267216BVariety of colorsHigh color fastnessHeating/cooling textile fabricsWoven fabricsYarnColour fastness

The invention discloses an aramid unidirectional moisture-wicking fabric and a preparation method thereof. Washing and drying, special moisture-conducting finishing (padding is scheduled, additives to control viscosity), one-way finishing (roller coating), drying and setting, etc., to obtain a light and thin aramid one-way moisture-conducting fabric. Through the above method, the product of the present invention has the characteristics of lightness and comfort, rich colors, high color fastness, etc., and has multi-functional protective properties such as high-efficiency flame retardant and heat insulation, antibacterial, moisture absorption and perspiration. The application field of nylon fabrics has greatly improved the comfort of light and thin fabrics; the process is easy to operate, cost-effective, and convenient for later industrialized scale-up production; it ensures the stability of PH value and excellent color fastness degree, the process is energy-saving and environmentally friendly.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

Antistatic knitted fabric and preparation method thereof

InactiveCN105256451ACrisp appearanceImprove thermal stabilityWeft knittingFibre typesPolyesterPolymer science

The invention discloses an antistatic knitted fabric and a preparation method thereof; the antistatic knitted fabric comprises the following components by mass percentage: 50-60 parts of polyester fiber proliferation nylon filament; 10-15 parts of wool; 5-10 parts of flax; 5-8 parts of ramie; 3-5 parts of viscose glue; 0.5-1.5 parts of antistatic agent. The preparation method comprises fading, twisting, coloring, compositing and making sheet so as to obtain the knitted fabric. The knitted fabric made by the raw materials and preparation method is stiff in appearance, good in heat stability, soft, no pilling, is antistatic, and production technology is simplified, thus improving production efficiency.

Owner:SUZHOU SHUNTANG CHEM FIBER

Comfortable linen-like knitted fabric and preparation process thereof

The invention discloses a comfortable linen-like knitted fabric and a preparation process thereof. The comfortable linen-like knitted fabric is formed by blending and weaving acrylic staple fibers, viscose fibers, cotton fibers and slub cotton, wherein the comfortable linen-like knitted fabric comprises, in percent by mass, 15%-25% of the acrylic staple fibers, 25%-35% of the viscose fibers, 10%-20% of the slub cotton and the balance being the cotton fibers. According to the prepared comfortable linen-like knitted fabric, the acrylic staple fibers, the viscose fibers, the cotton fibers and theslub cotton are selected, the yarn forming property of the viscose fibers with the acrylic staple fibers is enhanced through surface modification on the viscose fibers, first yarn and second yarn have better stability and compatibility, therefore, the surface flatness and hand feeling of the linen-like knitted fabric are improved, the appearance is stiff, and the quality is excellent.

Owner:石狮耀翔织造有限公司

Processing method of suit cuff

The invention discloses a processing method of a suit cuff, which comprises the following steps: (1) tailoring a cuff lining and a mock button hole lining according to the garment size design and adopting a positive bias hair interlining strip with the width of 5-7cm; (2) setting the cuff lining to be 1-2cm from the cuff, 0.2-0.3cm from a sleeve under facing and 0.3-0.4cm from a beveling point of a sleeve facing and cutting an opening of 1.5-2.5cm at an inseam of a sleeve; designing the mock button hole lining to be 1cm from the upper end of a sleeve facing and be level to the front end of the cuff lining and overlap with the cuff lining for about 1-2cm; (3) spreading out the cuff lining and fixing the cuff lining by uniformly basting three circles of thread adjacent to the inseam; spreading out the mock button hole and fixing the mock button hole by basting a circle at 1cm away from a mat; (4) uniformly pry-seaming two circles of thread to fix the cuff lining and folding and ironing 4-5cm of a folding edge of the cuff; (5) joining the sleeve facing, joining external seams of the cuff and respectively ironing seam heads outside the cuff; and (6) spreading out the cuff, basting to fix the folding edge of the cuff and pry-seaming to fix the folding edge of the cuff at 0.7-1.5cm to a deckle edge. According to the processing method provided by the invention, a non-woven lining is replaced by the hair interlining strip, so that the finished cuff of the suit has a stiff, smooth and even appearance, soft hand feel, and the product level is improved.

Owner:SHANDONG NANSHAN TEXTILE GARMENT

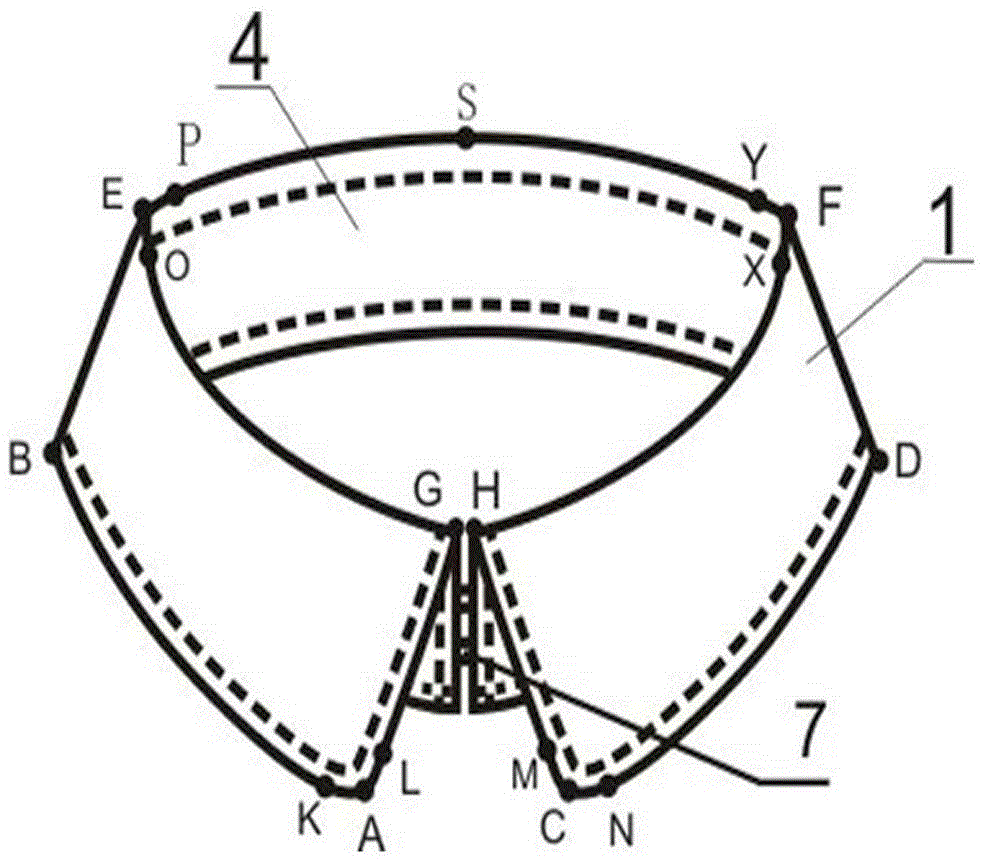

A kind of men's Zhongshan suit standing lapel and production method

Owner:JIHUA 3502 PROFESSIONAL GARMENT

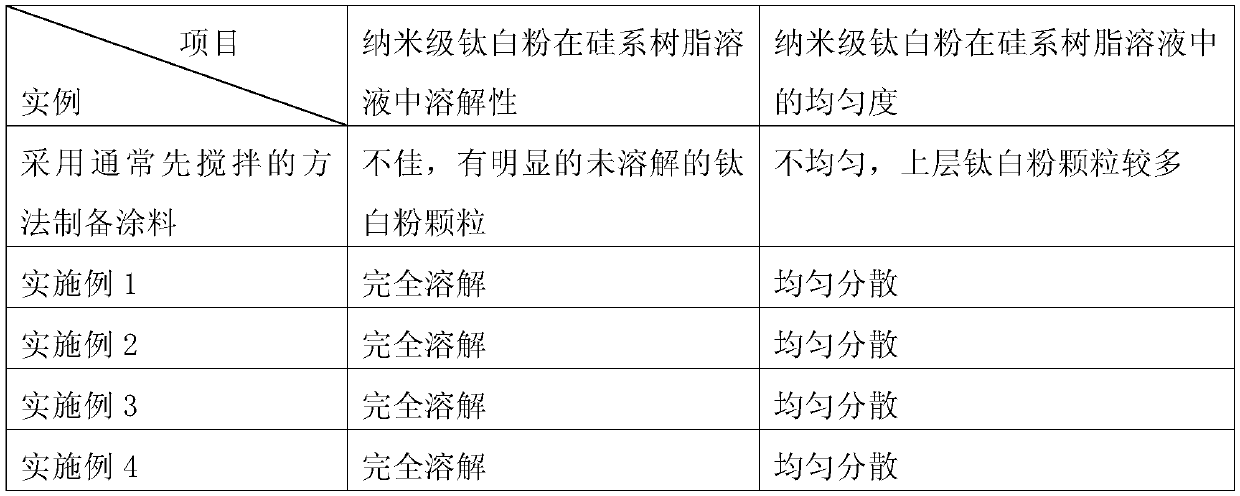

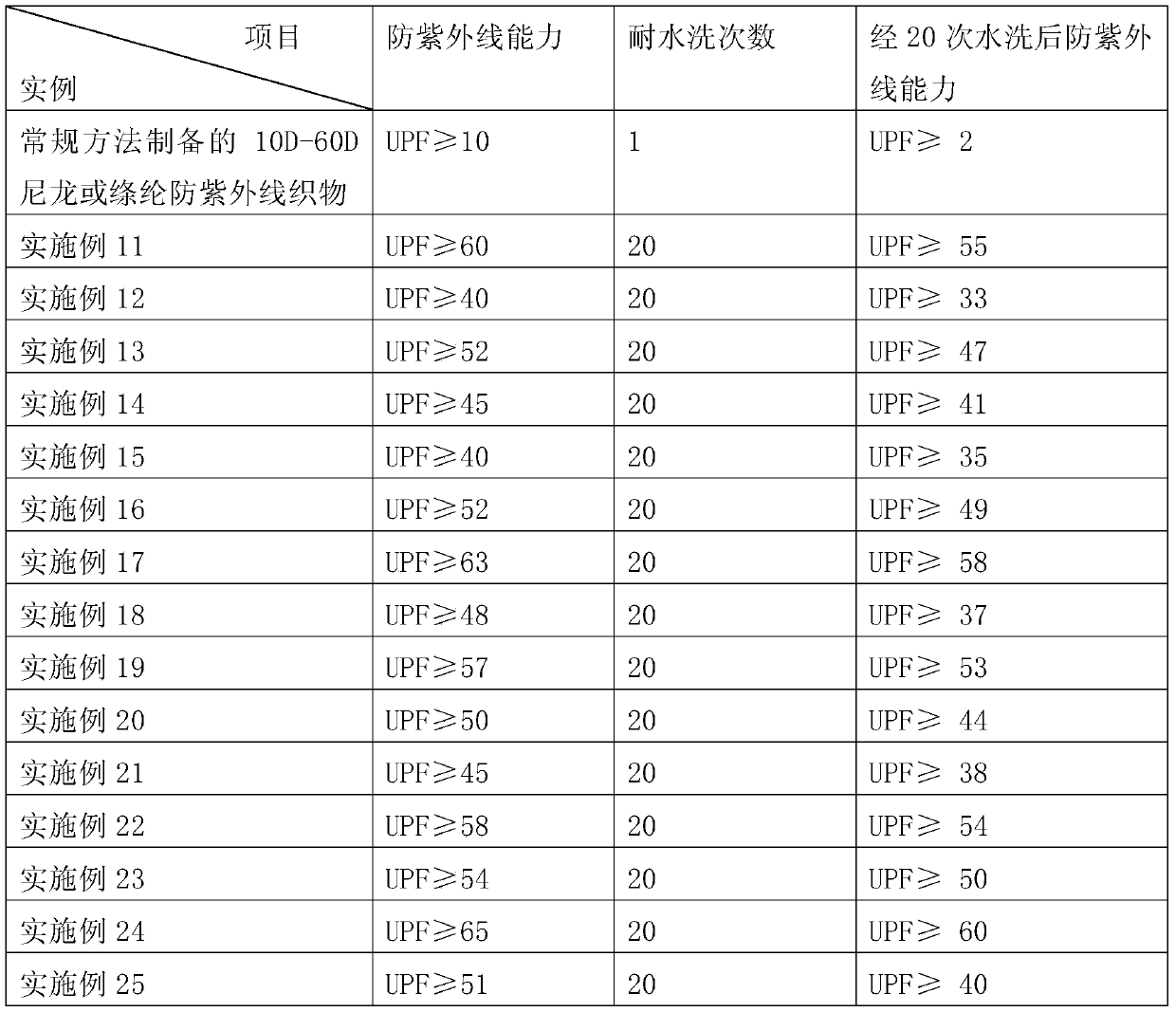

Anti-ultraviolet fabric and its preparation method, anti-ultraviolet coating and its preparation method

ActiveCN103451949BImprove UV protection effectGood UV protection durabilityFibre treatmentUltraviolet protectionUV coating

Owner:ZHEJIANG TAIHUA NEW MATERIAL

Mothproof fabric

PendingCN109330069AGood skin affinityGood moisture absorption and air permeabilitySynthetic resin layered productsWoven fabricsEngineeringFabric structure

The invention discloses a mothproof fabric. The mothproof fabric comprises a fabric body of a double-layer fabric structure, the fabric body comprises an inner-layer fabric body and an outer-layer fabric body, the inner-layer fabric body and the outer-layer fabric body are separated woven, and polyurethane fiber yarn of a tucking structure is woven in series. A 2 / 1 twill weave structure is adopted, and milk protein yarn as warp yarn and bamboo charcoal fiber yarn as weft yarn are woven to form the inner-layer fabric body; a plain weave structure is adopted, and polypropylene fiber yarn as warpyarn and kawo kawo fiber yarn as weft yarn are woven to form the outer-layer fabric body. The warp density of the inner-layer fabric body is 180-210 pieces / 10 centimeters; the weft density of inner-layer fabric body is 160-180 pieces / 10 centimeters; the warp density of the outer-layer fabric body is 140-160 pieces / 10 centimeters; the weft density of outer-layer fabric body is 130-160 pieces / 10centimeters. The mothproof fabric wears comfortable, is high in heat retention property and wrinkle resistance and easy to store and has the mothproof function.

Owner:苏州高研纺织科技有限公司

A kind of preparation method of non-ironing garment fabric fabric stiffening agent

ActiveCN106638002BImprove stabilityImprove washing resistanceBiochemical fibre treatmentGrip property fibresEscherichia coliEmulsion

Owner:石狮市新华宝纺织科技有限公司

Composite paper-cup forming machine with corrugated coat

InactiveCN101391494BCrisp appearanceNice appearancePaper/cardboard articlesManufacturing cost reductionDrive shaft

Owner:张鹏伟 +1

A preparation method of compact, comfortable and crisp knitted fabric

ActiveCN107287746BIncrease elasticityImprove wearing comfortWeft knittingSingeingPolyesterEngineering

Owner:NINGBO DAQIAN TEXTILE

High-mutual viscosity lustered yellowing-resistance bleached sole rubber and preparation method thereof

Owner:JIHUA 3537 SHOE MAKING

Preparation method of elastic woven fabric

The invention discloses a preparation method of an elastic woven fabric. According to the preparation method, 70-count mercerized wool, polyester and chinlon serve as raw materials and woven into an elastic fabric by the steps: a) spinning; b) dyeing; c) weaving; d) finishing. The blending ratios of the raw materials are 40% of mercerized wool, 35% of polyester and 25% of chinlon. The breadth of the elastic fabric prepared by the method is 160cm, and the gram density of the elastic fabric is 180g / m<2>. The preparation method of the elastic woven fabric is simple and convenient in process and easy to implement. By reasonable selection of the raw materials and scientific matching design, the prepared fabric has the advantages of comfort, softness, high resilience, wear resistance, warmth retention property and the like, and is rich in stiff and smooth appearance, fashionable and popular.

Owner:RUGAO LANTU KNITTING CLOTHING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com