A kind of men's Zhongshan suit standing lapel and production method

A tunic and lapel technology, applied in clothing, apparel, applications, etc., can solve the problems of easily reversed collar corners, unsightly wearing, rigid lapels, etc., to achieve the effect of a crisp appearance, enhanced three-dimensional sense, and a smooth outer collar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

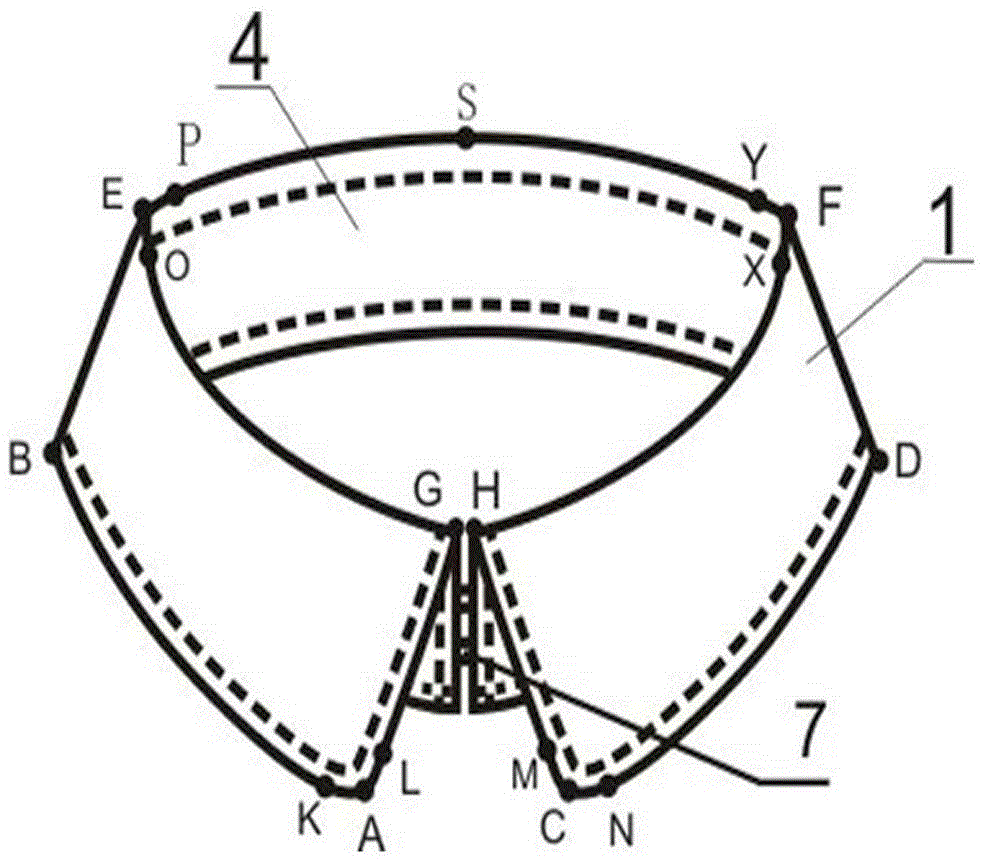

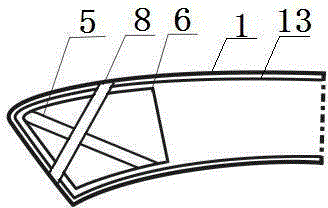

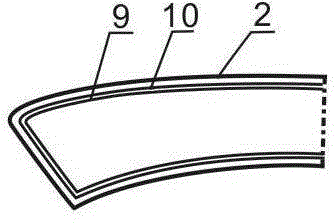

[0028] as attached figure 1 , 4 As shown, the present invention includes a seat collar and a lapel arranged on the seat collar, the seat collar includes a seat collar surface 3 and a seat collar inner 4, and the reverse side of the seat collar surface 3 is bonded with cotton knitting Collar hard liner A 12, the full cotton knitted adhesive collar hard liner A 12 is the same size as the net sample of the collar surface 3, and the net sample is the net sample without seams. Lining layer A 12 is glued on the cotton knitted adhesive collar soft lining A 11, and the cotton knitted adhesive collar soft lining A 11 is indented 0.2cm-0.3cm from each side of the collar surface 3 net samples, That is, the distance between the soft lining A 11 of the all-cotton knitted adhesive collar and the corresponding sides of the 3 clean samples of the collar is 0.2cm-0.3cm, which increases the flatness of the outer and inner openings of the lapel and makes the outer collar thinner. The two front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com