Preparing method of compact comfortable stiff and smooth type knitting fabric

A knitted fabric, a stiff technology, used in knitting, weft knitting, fabric surface trimming, etc., can solve the pursuit of consumers' dual quality of aesthetics and comfort, the splicing can not be eliminated, and the colors of different fabrics are not mixed. Pure seamability and other problems, to achieve the effect of tight structure, solving splicing problems, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

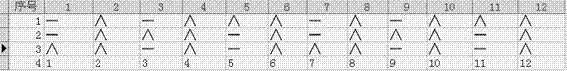

[0016] Example 1, such as figure 1 As shown, a method for preparing a compact, comfortable and crisp knitted fabric includes the following steps. Step A: In terms of weight percentage, 70% to 80% of polyester cotton, 10% to 20% of regenerated cellulose fiber and 5%~20% of spandex is used as raw material to interweave fabric gray fabric through fine needle knitting machine. The spandex is located on the front side of the gray fabric, wherein the odd-numbered needles are composed of 9 weaving structures of floating thread, floating thread, looping, floating thread, looping, floating thread, looping, floating thread, floating thread, and the even-numbered needles The cycle is composed of 9 weaving structures of looping, looping, looping, looping, looping, looping, looping, looping, and looping in turn. In the triangular structure of 12 routes, routes 1, 3, 5, 7, 9 and 11 are air-spun cotton yarns, routes 2, 6 and 10 are polyester, modal, viscose blended siro compact spinning yar...

Embodiment 2

[0020] Example 2, such as figure 2 As shown, a method for preparing a compact, comfortable and crisp knitted fabric includes the following steps. Step A: In terms of weight percentage, 50% to 65% of polyester cotton, 30% to 35% of regenerated cellulose fiber and 5%~10% of spandex is used as raw material to interweave fabric gray fabric through fine needle knitting machine. The spandex is located on the front side of the gray fabric, wherein the odd-numbered needles are composed of 9 weaving structures of floating thread, floating thread, looping, floating thread, looping, floating thread, looping, floating thread, floating thread, and the even-numbered needles The cycle is composed of 9 weaving structures of looping, looping, looping, looping, looping, looping, looping, looping, and looping in turn. In the triangular structure of 12 routes, routes 1, 3, 5, 7, 9 and 11 are air-spun pure cotton indigo yarns, routes 2, 4, 6, 8, 10 and 12 are polyester, modal and viscose blended...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com