Building board manufacture method and products thereof

A technology for building boards and manufacturing methods, which is applied in the direction of layered products, etc., can solve hidden safety concerns and other problems, and achieve the effect of increasing gas content, delicate bubbles, and crisp appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

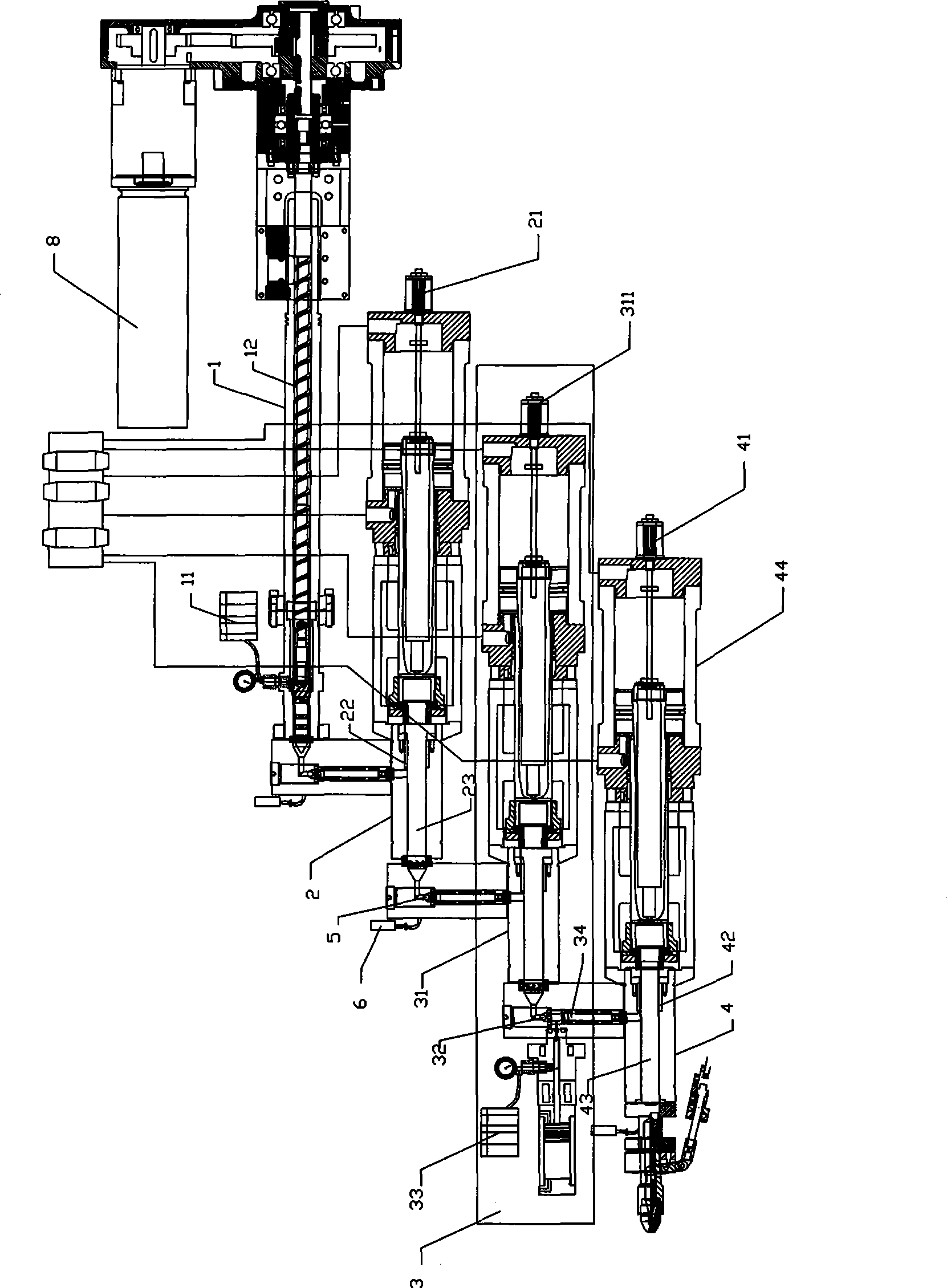

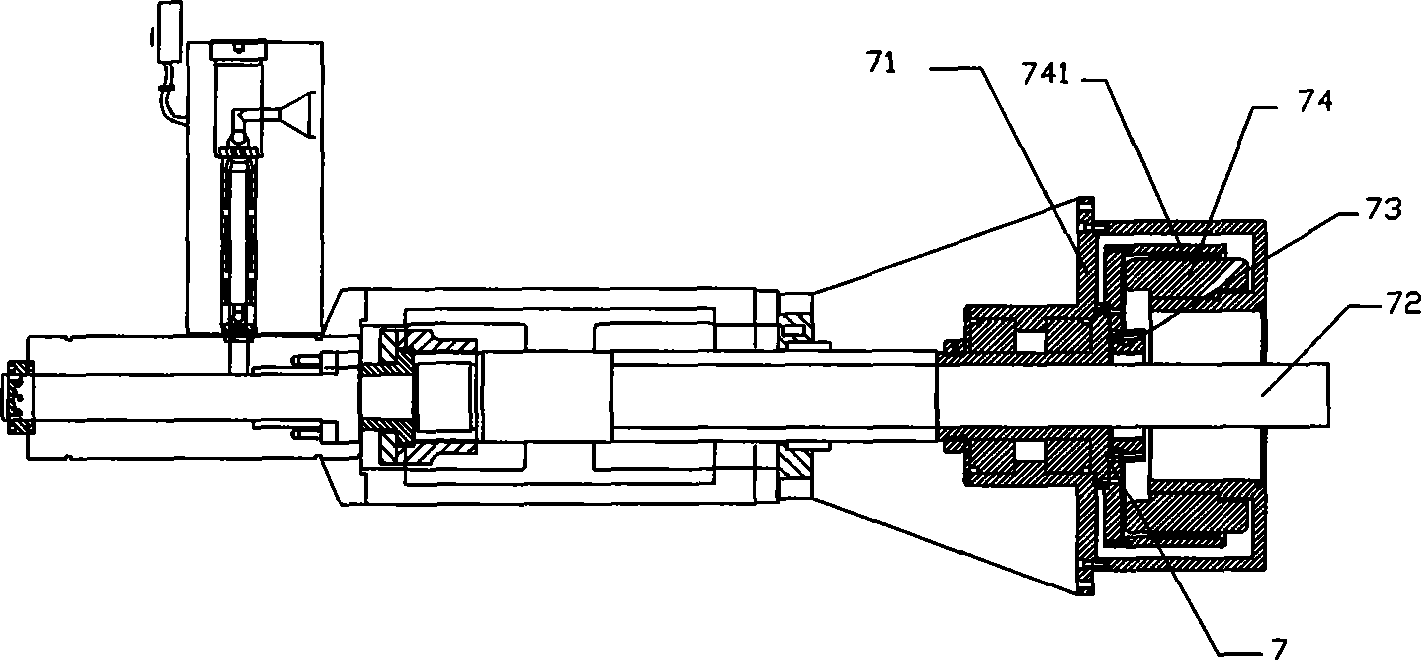

[0042] Refer to attached Figure 1-8 :

[0043]The manufacturing method of building board material of the present invention, comprises the steps:

[0044] 1. Making injection molds for plastic building panels;

[0045] 2. Inject plastic and gas into the feeding barrel 1, heat and stir with the screw 12 to melt the aforementioned plastic and mix with the aforementioned gas to form a mixed foamed plastic melt;

[0046] 3. Introduce the aforementioned mixed foamed plastic melt into the first storage barrel 2;

[0047] 4. Extrude the plastic melt with a capacity suitable for one shot out of the first accumulator barrel 2, and at the same time perform pressure control and compensation in the cavity of the first accumulator barrel 2 to maintain the first accumulator barrel 2. Stable pressure in the 2 cavities of the storage barrel;

[0048] 5. The plastic melt that is pressed out of the first storage barrel 2 is introduced into the second storage barrel 31 through the first one-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com