High-salt-spray-corrosion-resistant powder paint

A powder coating and salt spray resistance technology, applied in powder coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of coating aging failure, surface appearance deterioration, shortening the effective life time of the coating, etc., to achieve good resistance to boiling The effect of improving the resistance to salt spray corrosion and good resistance to cathodic disbonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

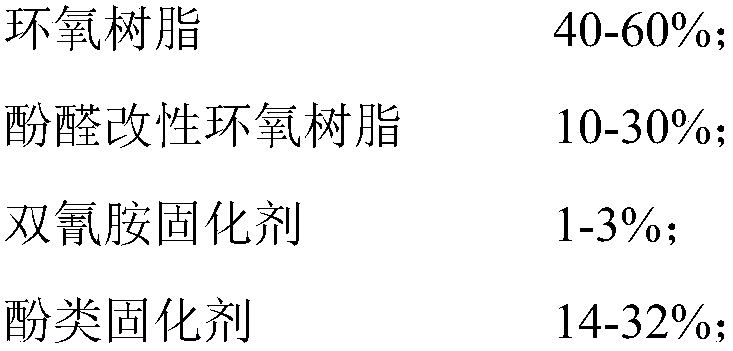

[0026] The powder coating with high resistance to salt spray corrosion includes main materials and auxiliary materials, wherein the main materials are made of the following raw materials in weight percentage:

[0027]

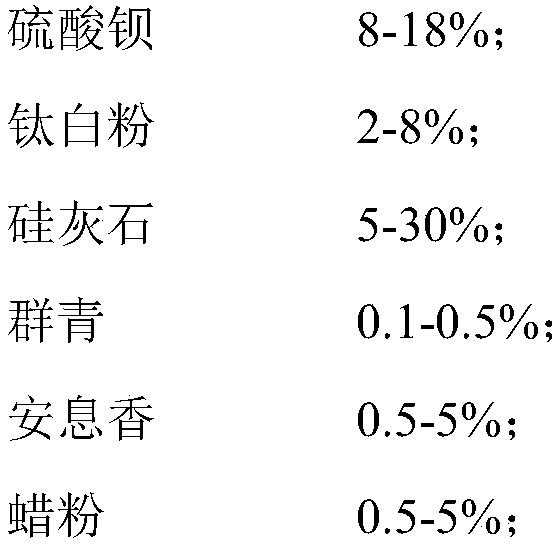

[0028] The auxiliary materials include barium sulfate, titanium dioxide, wollastonite, ultramarine blue, benzoin, wax powder, 2-methylimidazole and boron oxide, and the mass percentages of the main ingredients are as follows:

[0029]

[0030] The fineness of the auxiliary material is 200 mesh.

Embodiment 2

[0034] The powder coating with high resistance to salt spray corrosion includes main materials and auxiliary materials, wherein the main materials are made of the following raw materials in weight percentage:

[0035]

[0036] The auxiliary materials include barium sulfate, titanium dioxide, wollastonite, ultramarine blue, benzoin, wax powder, 2-ethylimidazole and boron oxide, and the mass percentages of the main ingredients are as follows:

[0037]

[0038] The fineness of the auxiliary material is 200 mesh.

Embodiment 3

[0042] The powder coating with high resistance to salt spray corrosion includes main materials and auxiliary materials, wherein the main materials are made of the following raw materials in weight percentage:

[0043]

[0044] The auxiliary materials include barium sulfate, titanium dioxide, wollastonite, ultramarine blue, benzoin, wax powder, 2-methylimidazole and boron oxide, and the mass percentages of the main ingredients are as follows:

[0045]

[0046] The fineness of the auxiliary material is 200 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com