LED lampshade injection blow grade light scattering PC and preparation method

A technology of LED lampshade and light diffusing agent, which is applied in the field of chemical materials, can solve the problems of difficult control of lampshade thickness uniformity, unstable flame retardancy, and difficulty in molding, etc., and achieve the effect of uniform thickness of lampshade, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

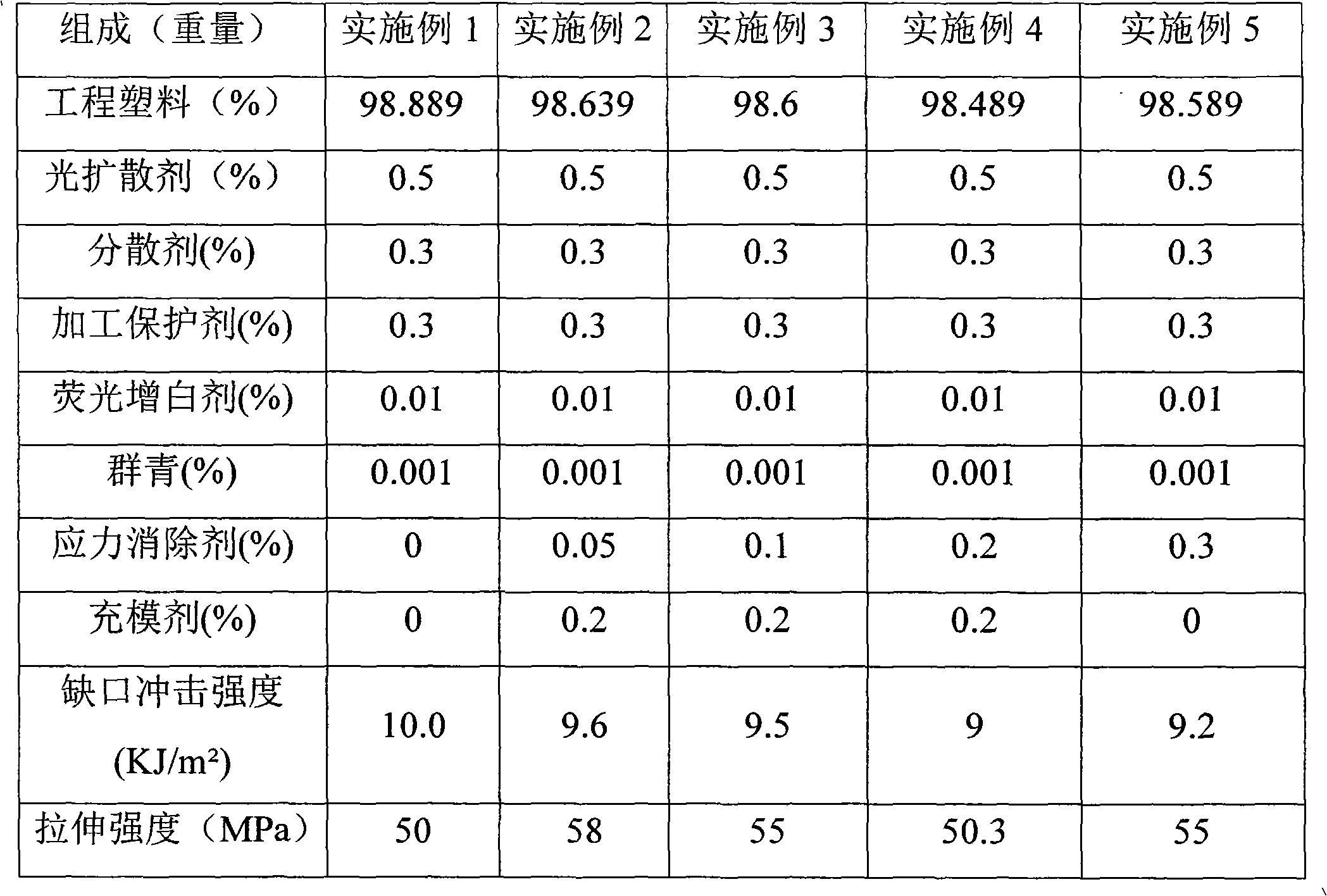

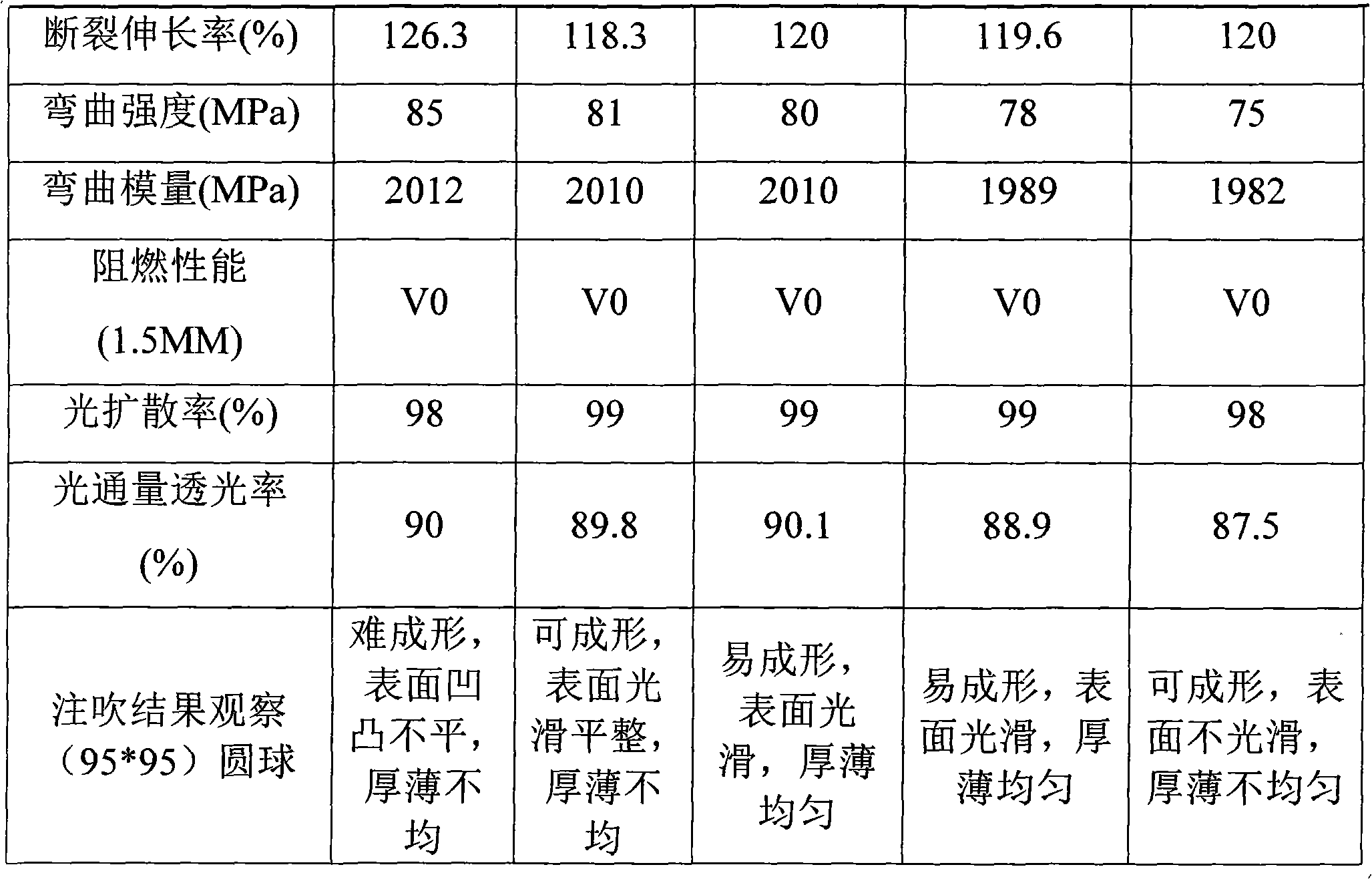

Examples

Embodiment 1

[0028] (1) engineering plastics with a weight ratio of 98.889%;

[0029] (2) Take by weight 0.5% light diffusing agent and 0.3% processing protection agent, and mix evenly;

[0030] (3) Weigh the weight ratio and weigh 0.01% fluorescent whitening agent and 0.001% ultramarine blue, and put them into the mixer together with the engineering plastics in (1) and the mixed light diffusing agent and processing protection agent in (2) Continue mixing until homogeneous;

[0031] (4) Put the mixed raw materials in (3) into the feeding hopper of the twin-screw extruder, wait for melt extrusion, and granulate. The processing technology is as follows: the temperature of the first zone of the twin-screw extruder is 170-190°C, the temperature of the second zone is 240-255°C, the temperature of the third zone is 245-260°C, the temperature of the fourth zone is 250-260°C, the temperature of the fifth zone is 250-260°C, The temperature of the sixth zone is 260-270°C, the temperature of the se...

Embodiment 2

[0033] (1) Take by weight 98.639% engineering plastics and 0.2% mold filling agent, mix evenly;

[0034] (2) Weigh 0.5% light diffusing agent, 0.3% processing protection agent and 0.05% stress reliever in weight ratio, and mix evenly;

[0035] (3) Weigh the weight ratio and take 0.01% fluorescent whitening agent and 0.001% ultramarine blue, mix with the engineering plastics in (1), mold filling agent and (2) in the light diffusing agent, processing protection agent and stress Put the powder such as eliminating agent into the mixer together and continue mixing until uniform;

[0036] (4) Put the mixed raw materials in (3) into the feeding hopper of the twin-screw extruder, wait for melt extrusion, and granulate. The processing technology is as follows: the temperature of the first zone of the twin-screw extruder is 170-190°C, the temperature of the second zone is 240-255°C, the temperature of the third zone is 245-260°C, the temperature of the fourth zone is 250-260°C, the tem...

Embodiment 3

[0038] (1) Take by weight 98.6% engineering plastics and 0.2% mold filling agent, mix evenly;

[0039] (2) Weigh 0.5% light diffusing agent, 0.3% processing protection agent and 0.1% stress reliever in weight ratio, and mix evenly;

[0040] (3) Weigh the weight ratio and take 0.01% fluorescent whitening agent and 0.001% ultramarine blue, mix with the engineering plastics in (1), mold filling agent and (2) in the light diffusing agent, processing protection agent and stress Put the powder such as eliminating agent into the mixer and continue mixing until uniform;

[0041] (4) Put the mixed raw materials in (3) into the feeding hopper of the twin-screw extruder, wait for melt extrusion, and granulate. The processing technology is as follows: the temperature of the first zone of the twin-screw extruder is 170-190°C, the temperature of the second zone is 240-255°C, the temperature of the third zone is 245-260°C, the temperature of the fourth zone is 250-260°C, the temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com